Device and method for cleaning wool in karst areas

A cleaning device and karst technology, which is applied in the direction of animal wool fiber washing/scouring, can solve the problems of low efficiency, time-consuming and laborious, poor cleaning effect, etc., and achieve the effect of improved efficiency, wide application range and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

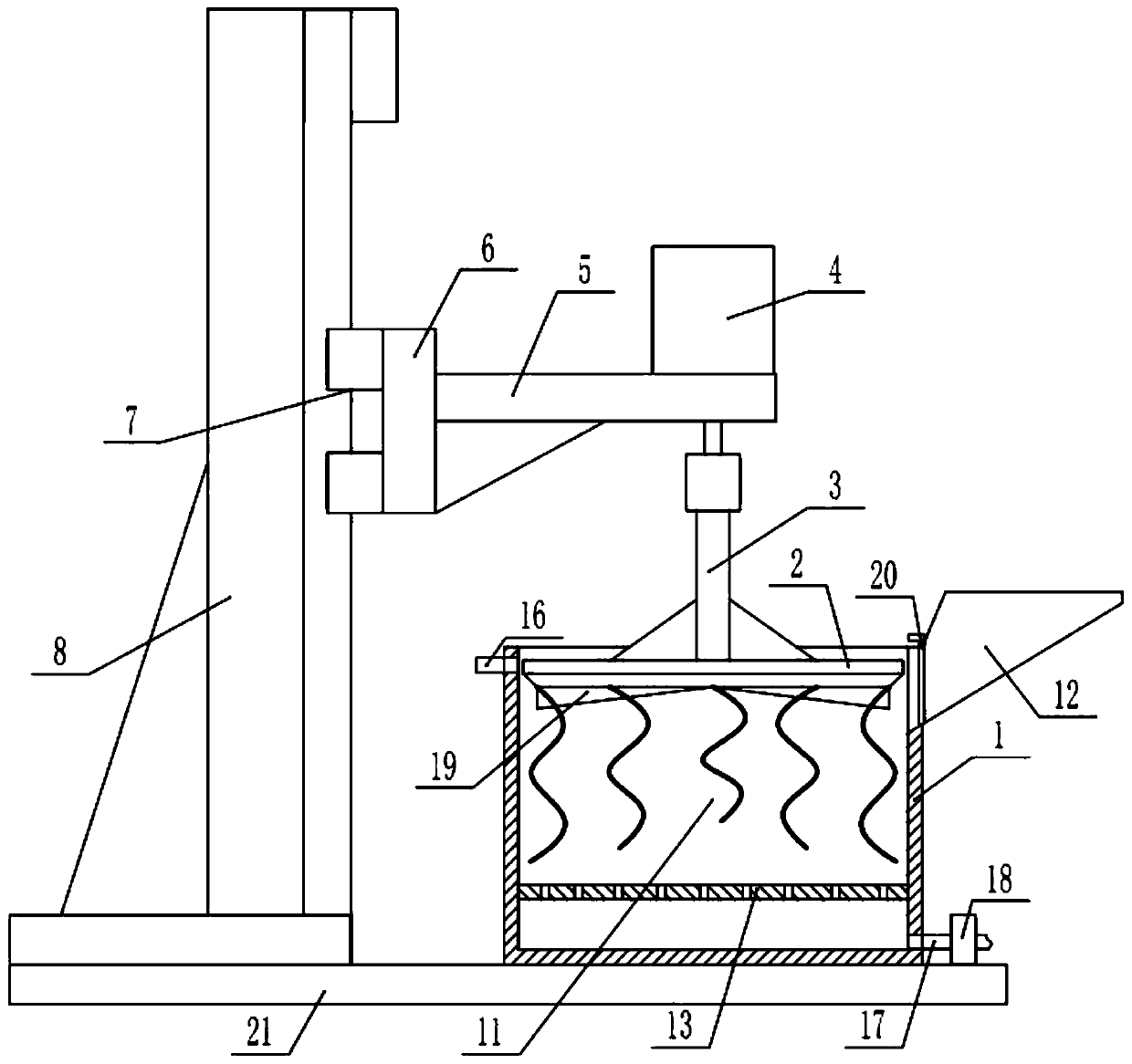

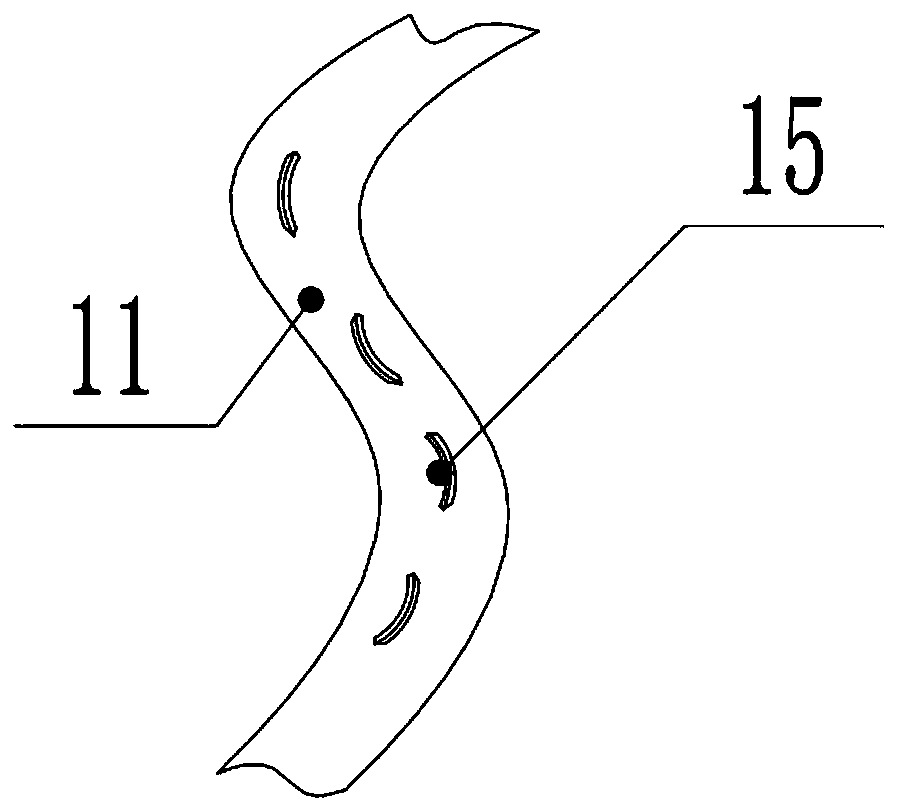

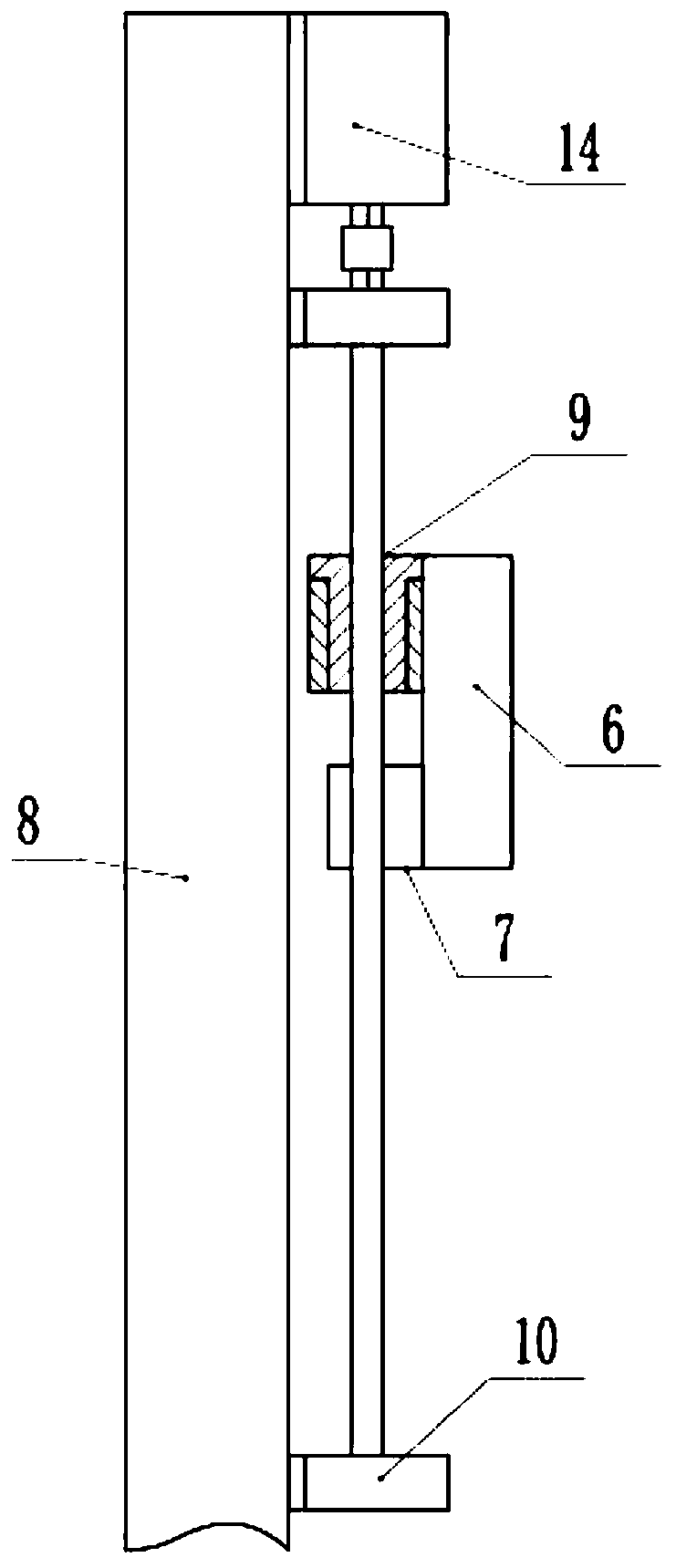

[0019] Example: such as Figure 1-Figure 4 As shown, a wool cleaning device in karst areas includes a storage bucket 1, an extrusion mesh plate 2, a screw rod 11 and a stirring motor 4, a hopper 12 is arranged on the upper side of the storage bucket 1, and a drainage pipe 17 is arranged on the side of the bottom. A filter screen plate 13 is provided on the inner side near the bottom, a gate valve 20 is provided at the outlet of the hopper 12, an agitator shaft 3 is connected to the upper end of the extrusion mesh plate 2 and can be placed in the storage barrel 1, and the lower end of the extrusion mesh plate 2 is provided with Multiple rows of radially arranged screw rods 11, the upper end of the stirring shaft 3 is connected to the stirring motor 4, the stirring motor 4 is fixedly connected to the cantilever beam 5, the cantilever beam 5 is vertically fixedly connected to the slide plate 6, and the slide plate 6 is connected to the lifting device. Both the lifting device and ...

Embodiment 2

[0027] Embodiment 2: A cleaning method for a wool cleaning device in a karst area, the method is as follows: send the wool into the storage bucket through the hopper, close the gate valve of the hopper, send water into the storage bucket, and move the extrusion mesh plate downward through the lifting device Press the wool until the wool is immersed in the water, soak for half an hour, start the stirring motor to rotate, choose 40 minutes and then drain the water through the drain pipe, close the valve after the water is drained, lift the extrusion mesh plate through the lifting device, add water again, add water to When setting the amount, stop, start the stirring motor to rotate, and repeat the process of water discharge-add water-stir several times until the wool is clean.

[0028] Preferably, during the stirring process of the above-mentioned stirring motor, the lifting device drives the extrusion mesh plate to move up and down, which can further improve the cleaning effect....

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com