Glucose-modified polyimide fiber and preparation method thereof

A polyimide fiber, glucose technology, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve the problem of polyimide fiber damage, high cost, inability to meet polyimide fiber processability and Adhesion and other issues to achieve the effect of improving processability and adhesion and expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Dissolve 0.3g of sodium dodecylbenzenesulfonate in 1L of deionized water, add 0.3g of polyimide fiber, stir at 60°C for 1 hour, wash with deionized water for 5 times, and in 105°C Dry 12h in the blast drying oven to obtain clean polyimide fibers;

[0040] Step 2, mixing 0.2 g of the polyimide fiber obtained in step (1) with a glucose solution with a concentration of 0.15 mol / L, the volume of the glucose solution is 60 mL, and stirring for 15 min to obtain a reaction system;

[0041] Step 3, the reaction system obtained by stirring in step 2 is placed in a 100mL polytetrafluoroethylene lining, and after a hydrothermal reaction in a blast drying oven at 180°C for 12 hours, the modified polyimide fiber is obtained;

[0042]In step 4, the polyimide fiber obtained in step 3 was washed with deionized water for 7 times, and then dried in a blast drying oven at 105° C. for 12 hours, and glucose-modified polyimide fiber was successfully prepared.

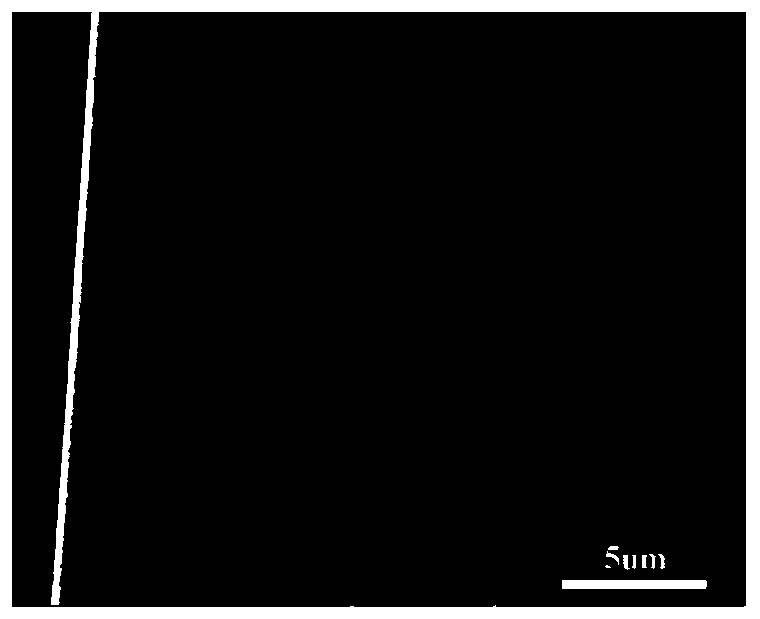

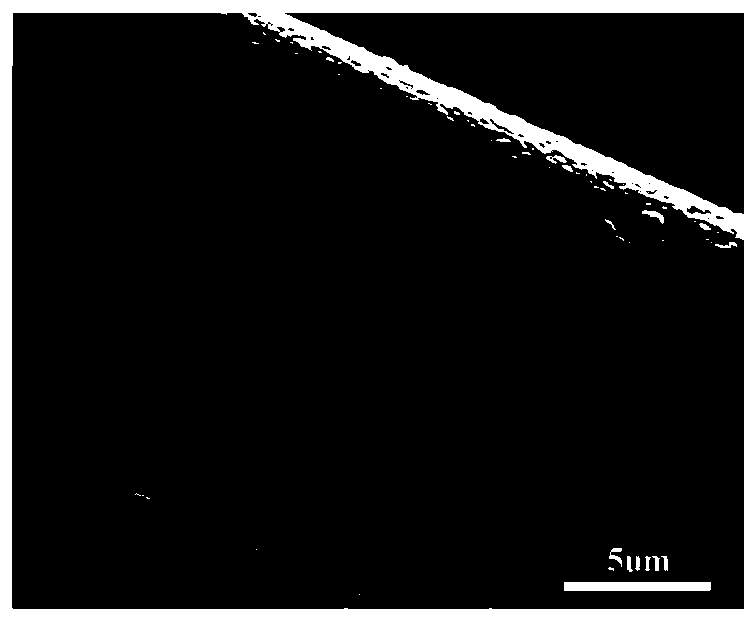

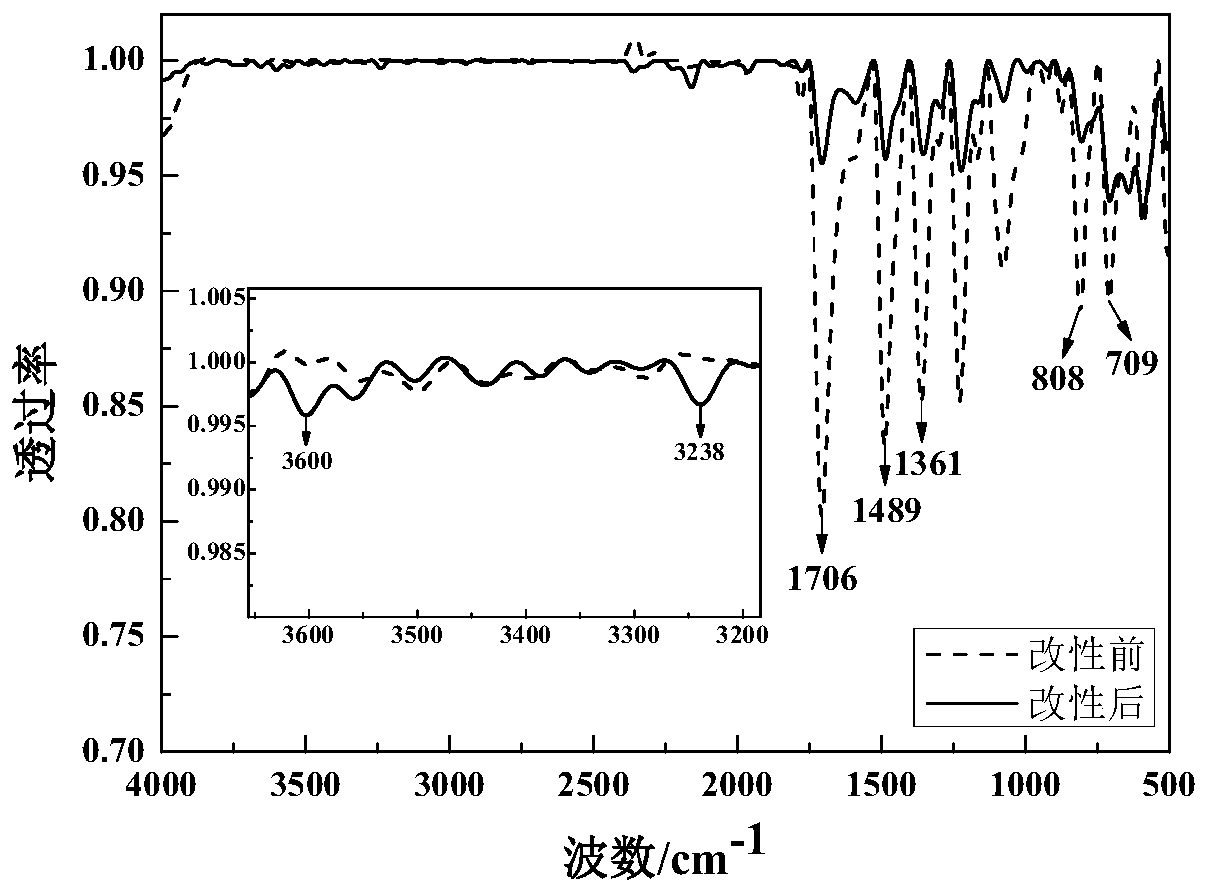

[0043] see figure 1 ...

Embodiment 2

[0045] Step 1, dissolve 0.2g sodium dodecylbenzenesulfonate in 1.2L deionized water, add 0.3g polyimide fiber, stir at 40°C for 0.5h, wash with deionized water 10 times, and Dry in a blast drying oven at ℃ for 24 hours to obtain clean polyimide fibers;

[0046] Step 2, mixing 0.1 g of the polyimide fiber obtained in step (1) with a glucose solution with a concentration of 0.28 mol / L, the volume of the glucose solution is 40 mL, and stirring for 10 min to obtain a reaction system;

[0047] Step 3, the reaction system obtained by stirring in step 2 is placed in a 100mL polytetrafluoroethylene lining, and after a hydrothermal reaction in a blast drying oven at 160°C for 24 hours, the modified polyimide fiber is obtained;

[0048] In step 4, the polyimide fiber obtained in step 3 was washed 5 times with deionized water, and then dried in an air-blast drying oven at 80° C. for 24 hours, and glucose-modified polyimide fiber was successfully prepared.

Embodiment 3

[0050] Step 1: Dissolve 0.4g of sodium dodecylbenzenesulfonate in 1.5L of deionized water, add 0.5g of polyimide fiber, stir at 80°C for 1.5h, wash with deionized water for 7 times, and Dry in a blast drying oven at ℃ for 20 hours to obtain clean polyimide fibers;

[0051] Step 2, mixing 0.3 g of the polyimide fiber obtained in step (1) with a glucose solution with a concentration of 0.07 mol / L, the volume of the glucose solution is 80 mL, and stirring for 20 minutes to obtain a reaction system;

[0052] Step 3, the reaction system obtained by stirring in step 2 is placed in a 100mL polytetrafluoroethylene lining, and after a hydrothermal reaction in a blast drying oven at 200°C for 20 hours, the modified polyimide fiber is obtained;

[0053] In step 4, the polyimide fibers obtained in step 3 were washed with deionized water for 10 times, and then dried in a blast drying oven at 90° C. for 20 hours, and glucose-modified polyimide fibers were successfully prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com