Patents

Literature

108results about How to "Fully clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

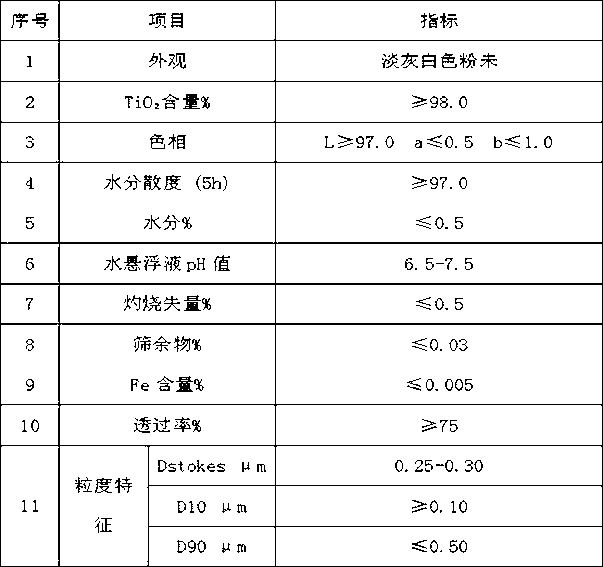

Method for preparing titanium dioxide for delustering chemical fibers

The invention belongs to the field of fine chemical engineering, and particularly relates to a method for preparing titanium dioxide for delustering chemical fibers. The method comprises the following technological flows: slurry making, iron-removal filtering, wet grinding, diluting, iron-removal filtering, grading, surface treatment, washing settling, atomized drying, grinding and packaging. The method provided by the invention has the advantageous effects as follows: 1, the prepared products have controllable particle sizes and stable dispersity; 2, the impurity removal effect is good; 3, the removal effect of soluble slats is good; and 4, the product quality is guaranteed.

Owner:JIAXING GAOSHENG NEW MATERIAL TECH

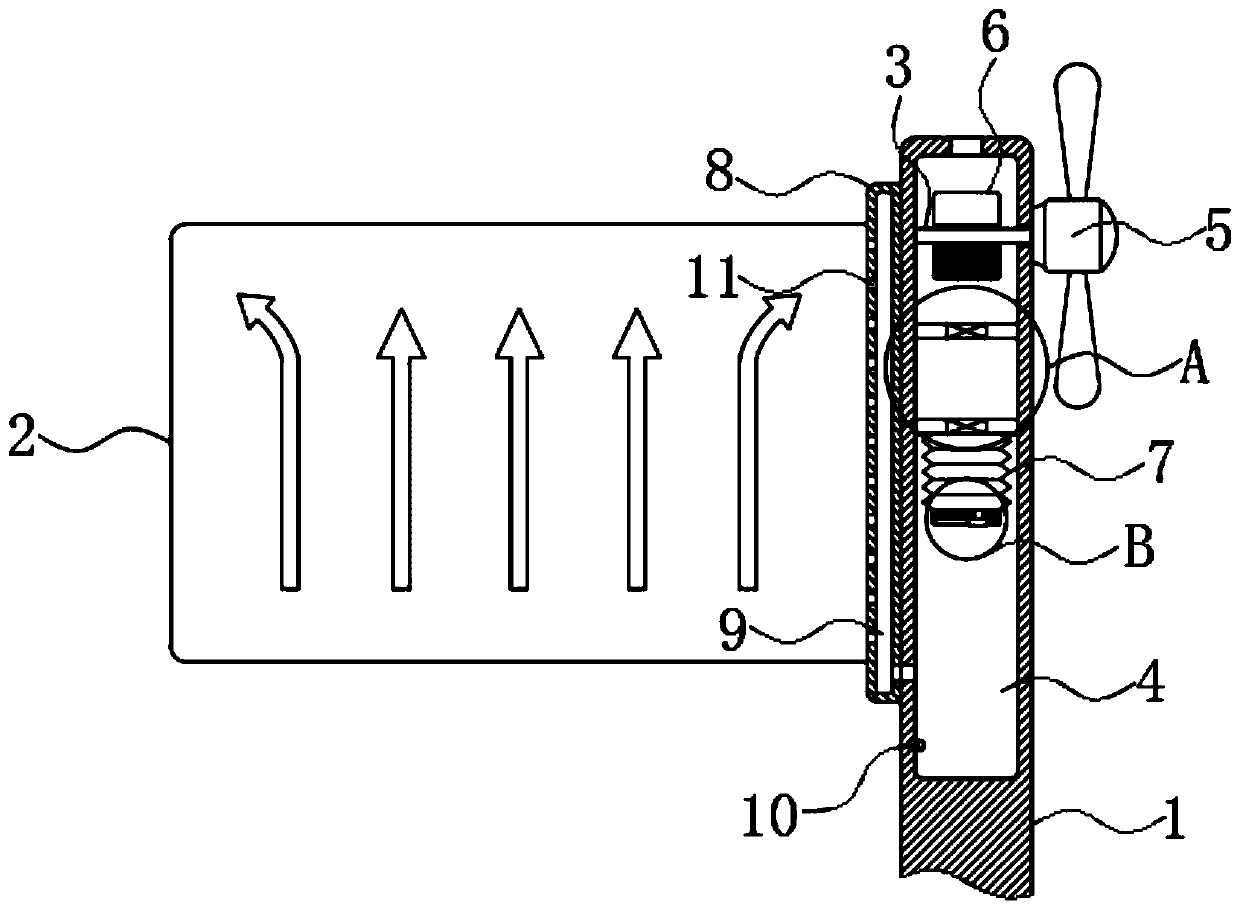

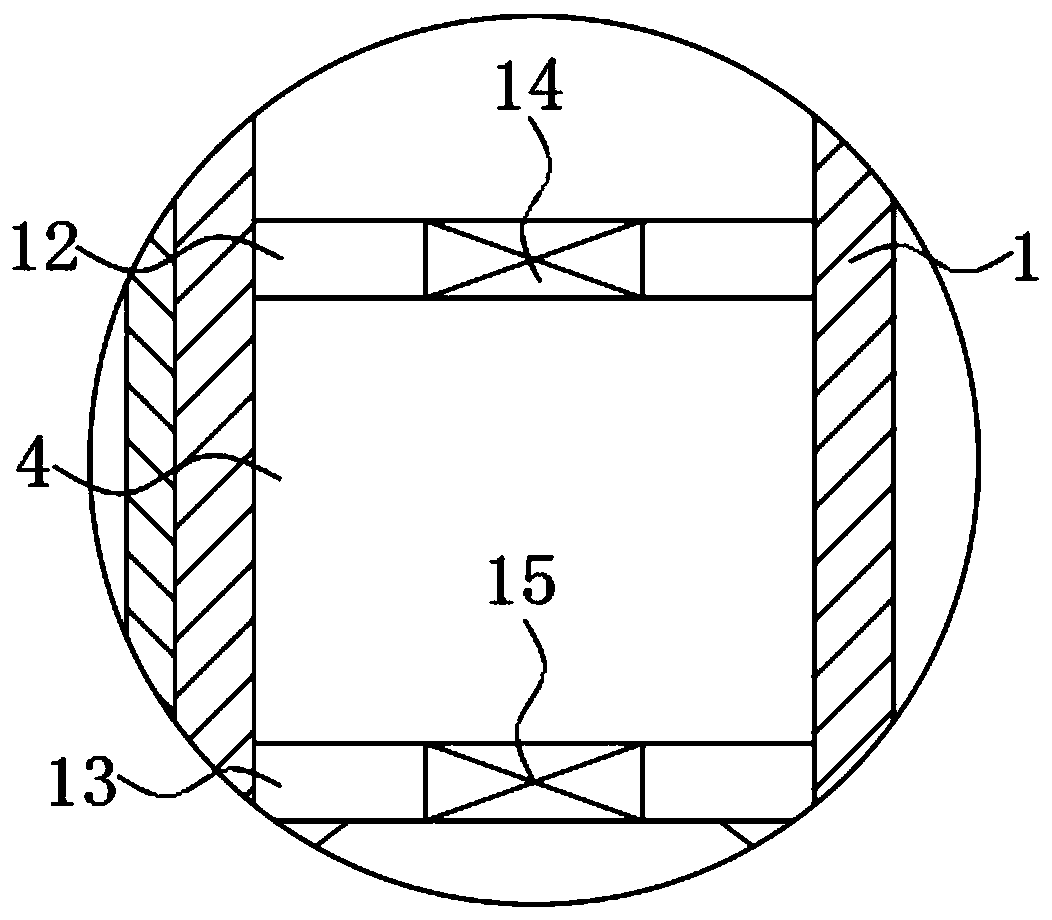

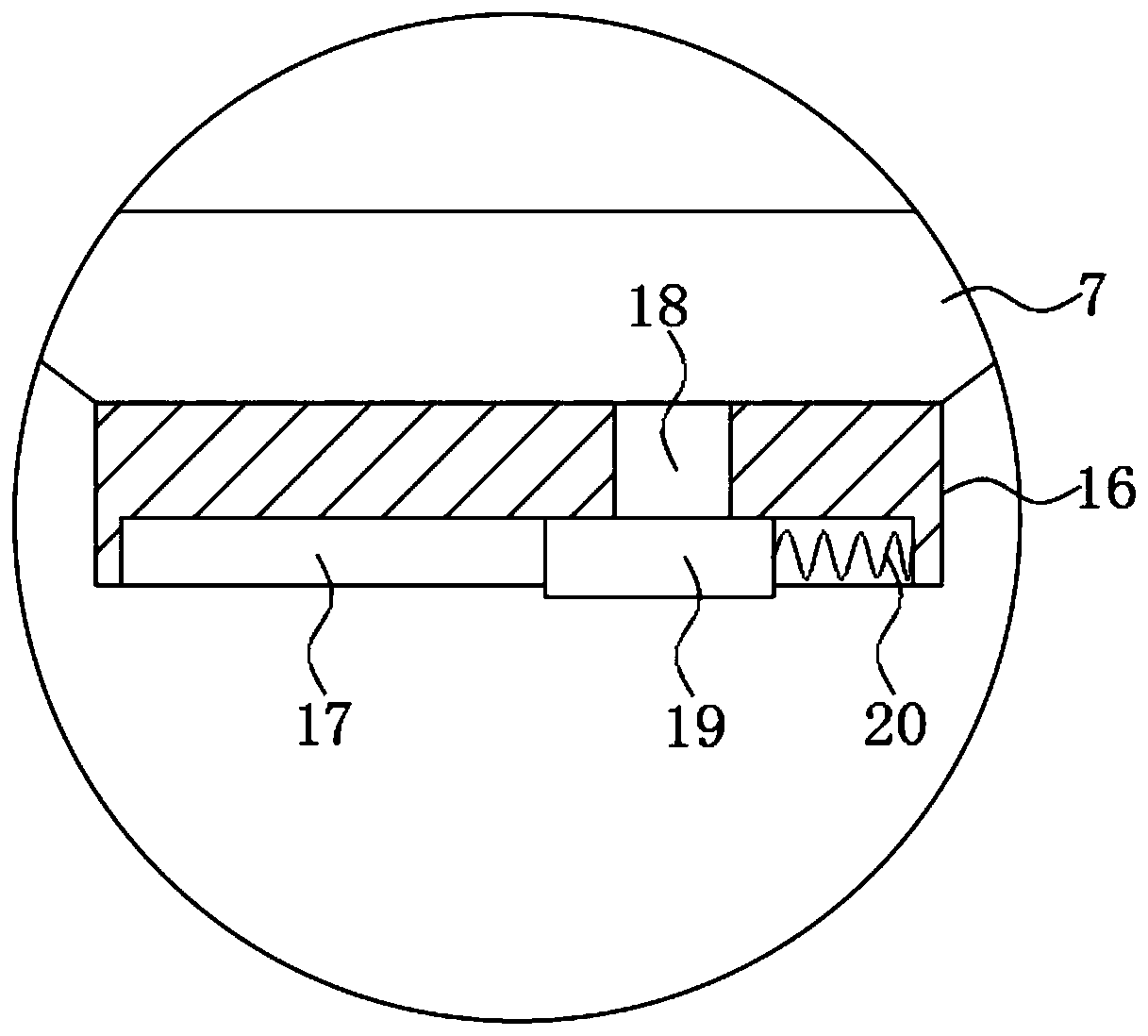

Self-cleaning type road sign for building site

ActiveCN110777689AAvoid occlusionDifficult to obtain road conditionsTraffic signalsCleaning using gasesArchitectural engineeringDust control

The invention discloses a self-cleaning type road sign for a building site. The self-cleaning type road sign for the building site comprises an upright post and a sign body fixedly connected to the side wall of the upright post through a fixing plate, wherein a device cavity is formed in the side wall of the upright post, an impeller is rotatably connected to the side wall of the upper end of theupright post through a rotating shaft, and the rotating shaft penetrates into the device cavity and is fixedly connected with a permanent magnet. According to the self-cleaning type road sign for thebuilding site, the impeller, the permanent magnet, a stretchable air bag, an air outlet mechanism, a spiral coil and indicator lamp strips are arranged, so that the automatic cleaning and dust removalof the surface of the sign can be realized, and a driver can know the road conditions clearly. Meanwhile, the potential safety hazard of manual cleaning is avoided, the cleaning efficiency is improved, and the labor intensity is reduced. The indicator lamp strips can emit light to enhance the warning effect of the road sign, and the driver can be better helped to know the instruction content andcan also be attracted to actively watch the sign to know the road conditions.

Owner:湖州力卓机械设备技术开发有限公司

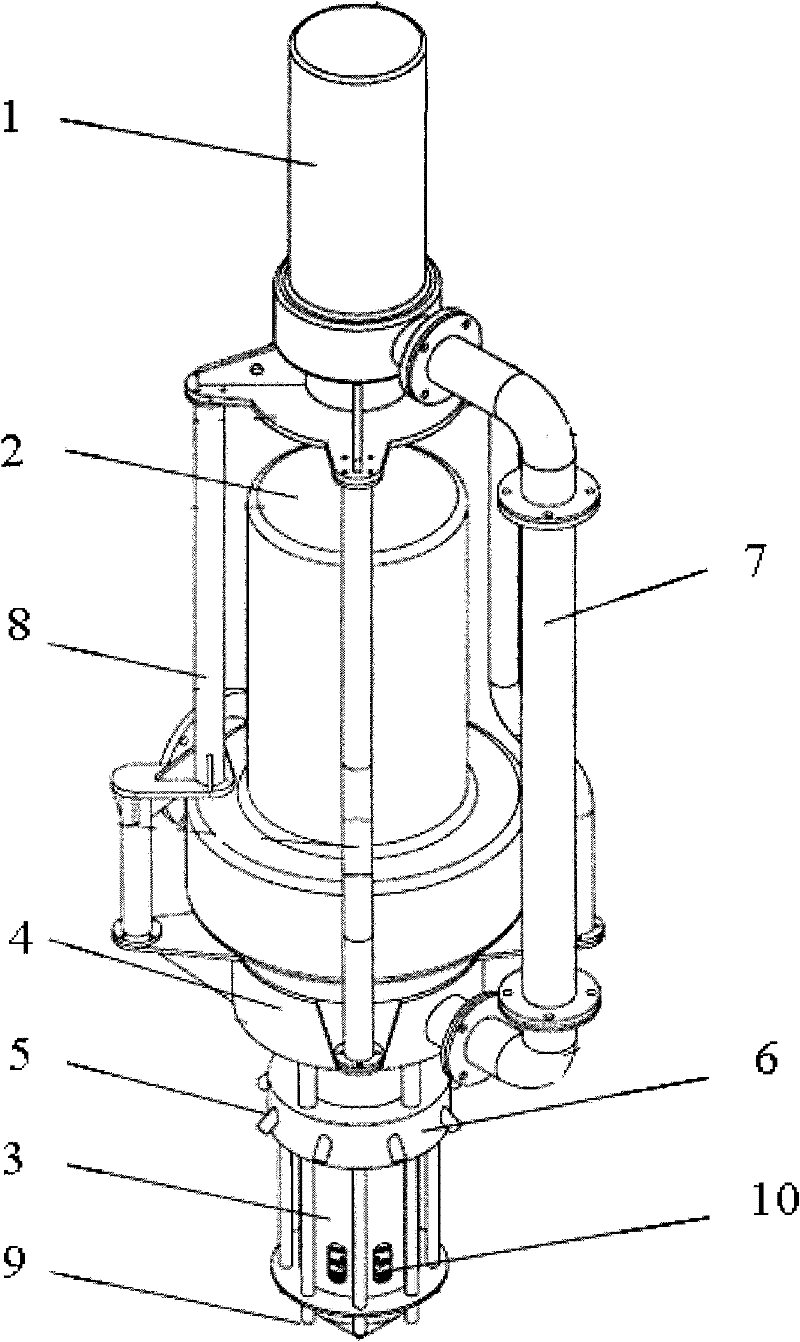

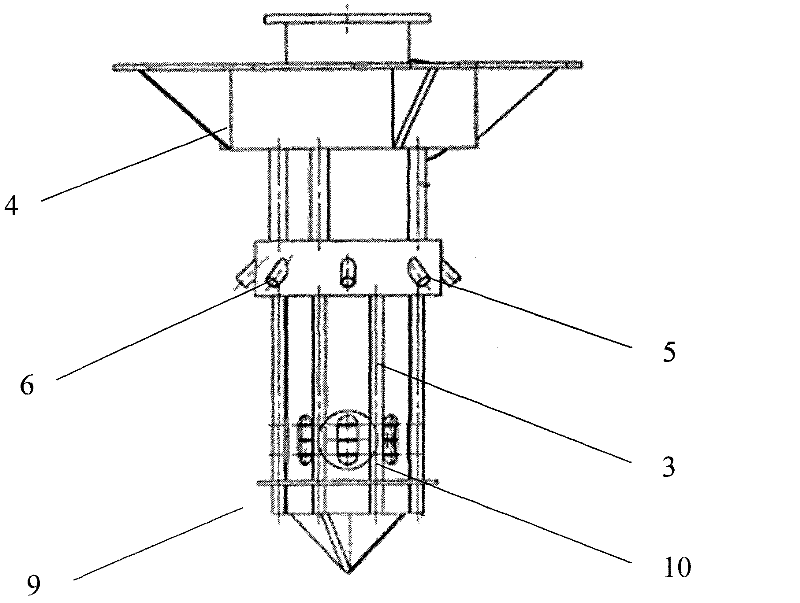

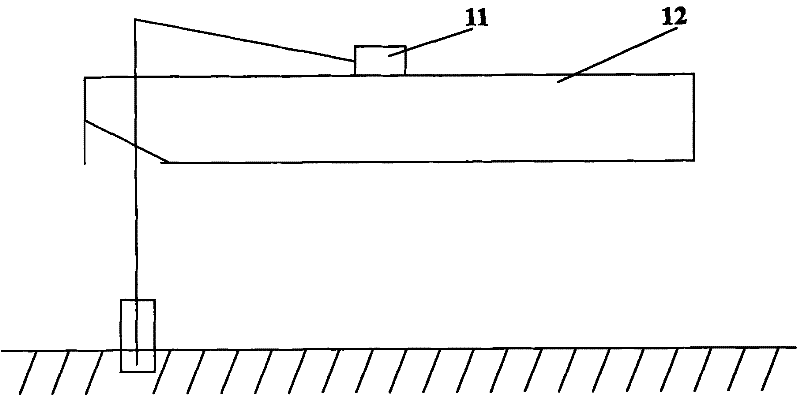

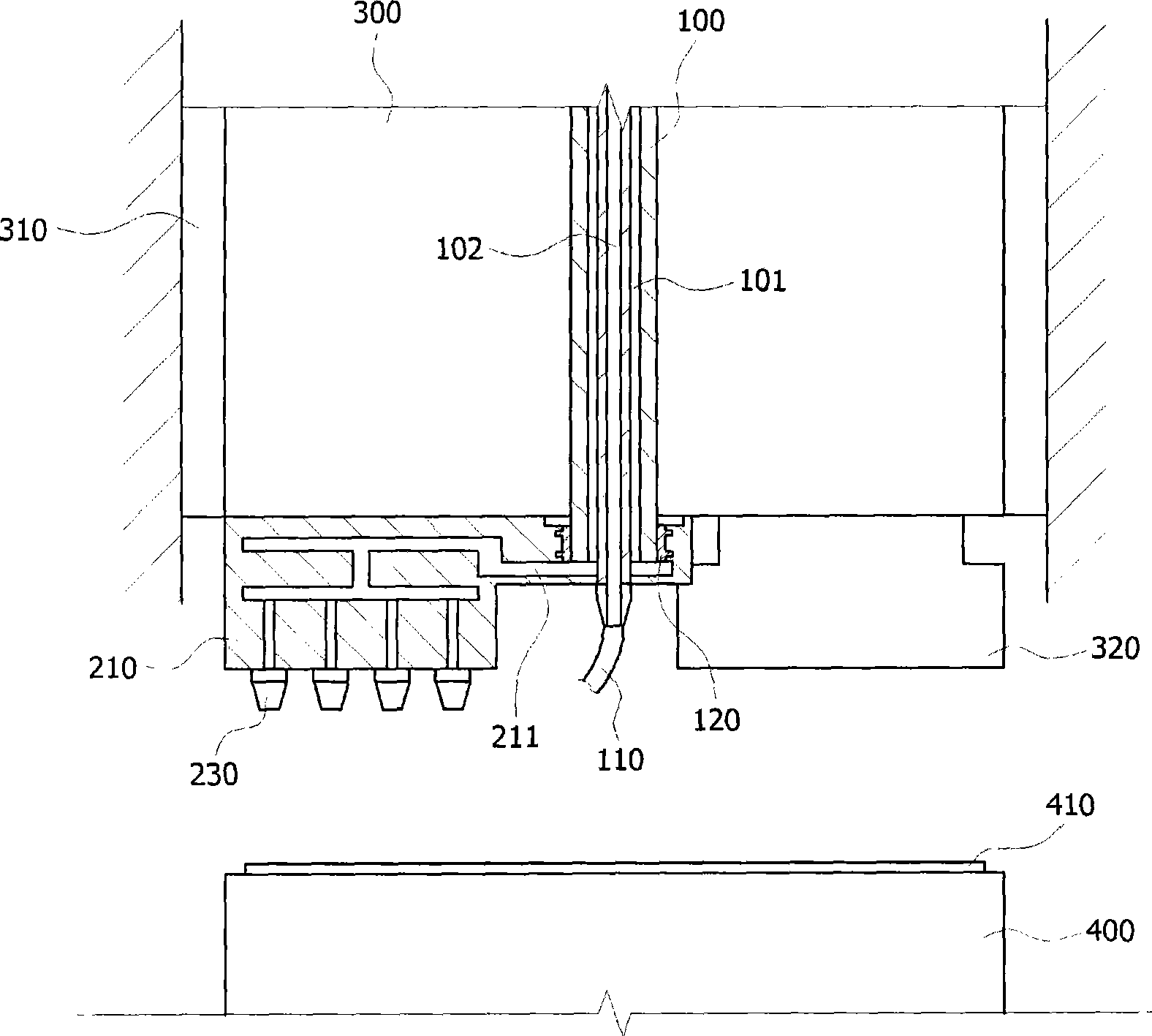

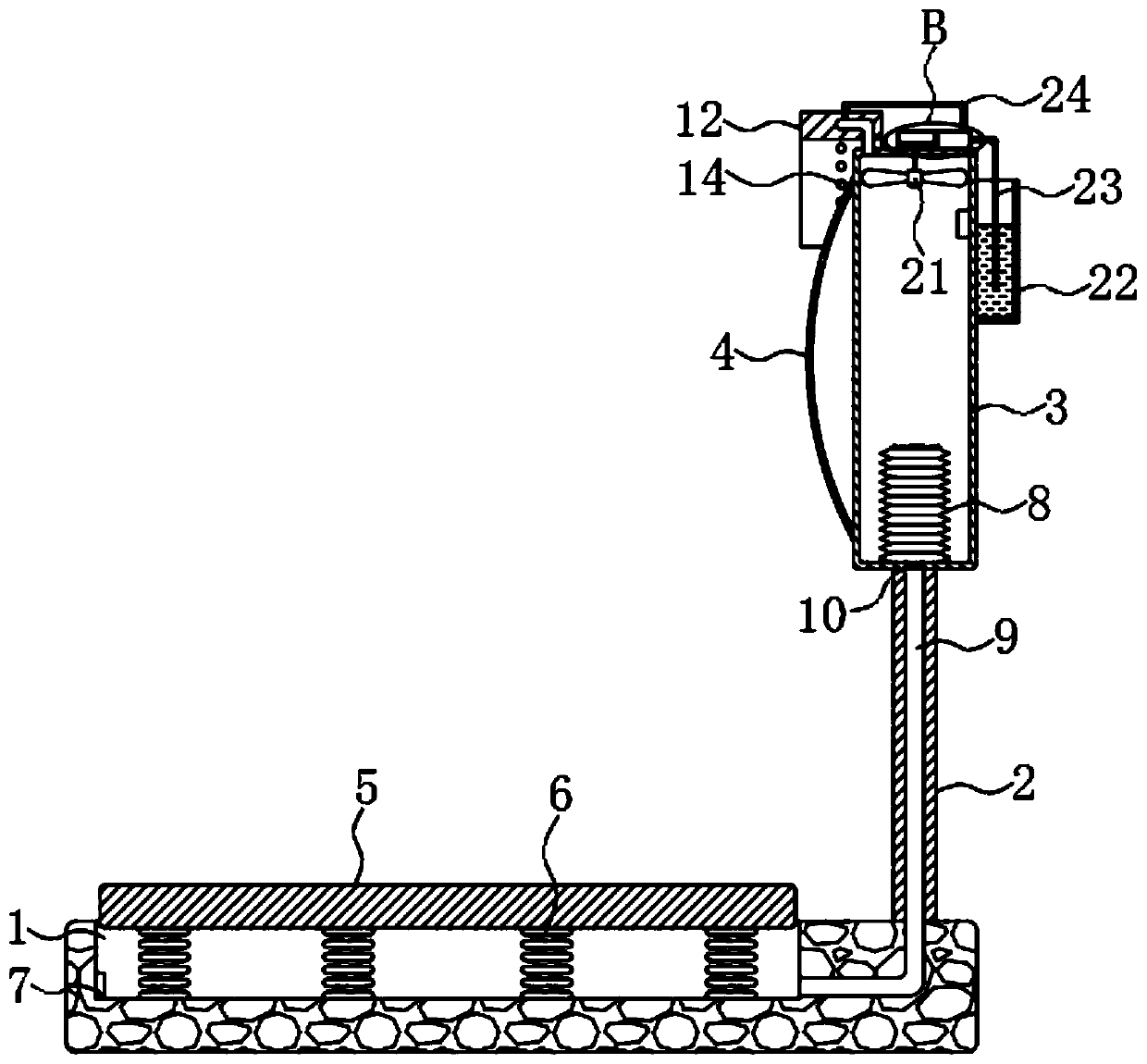

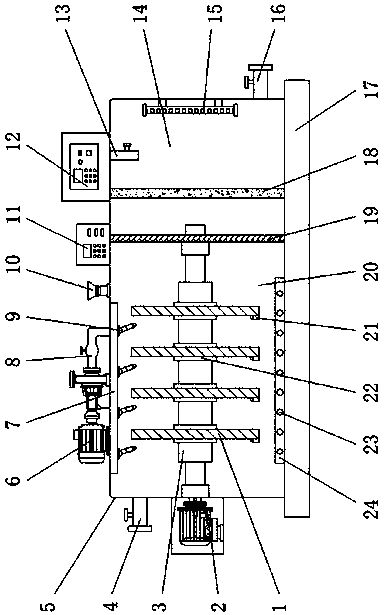

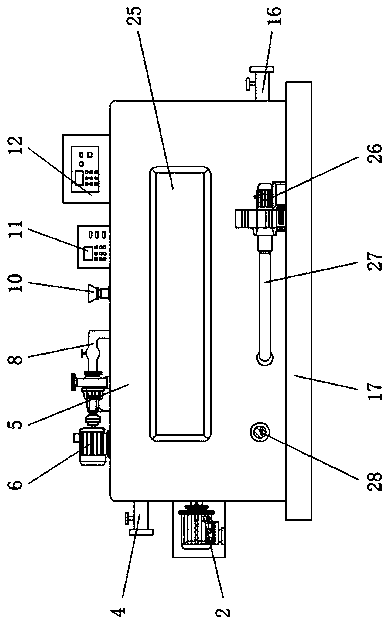

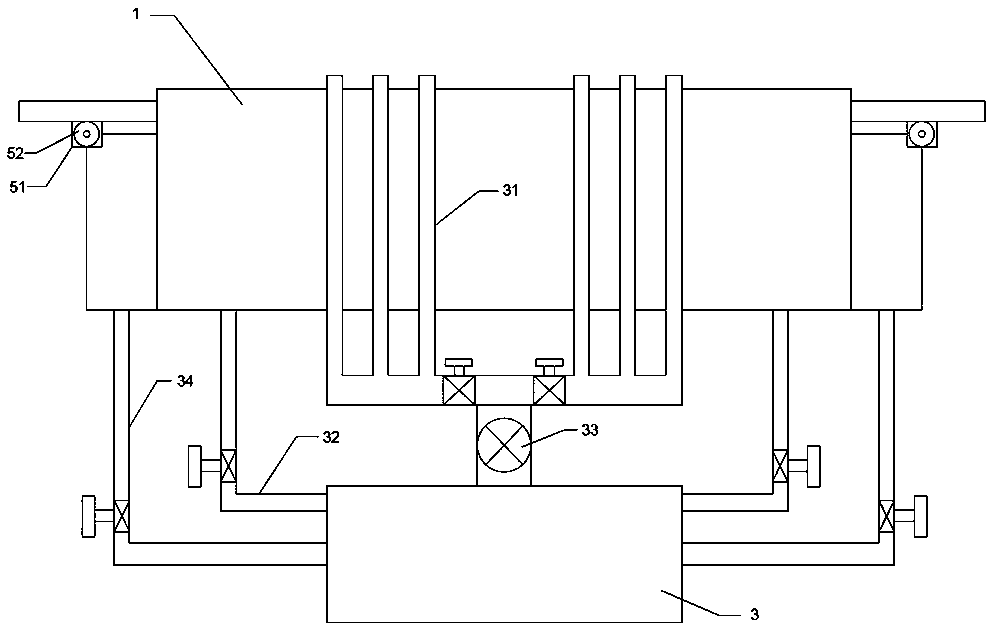

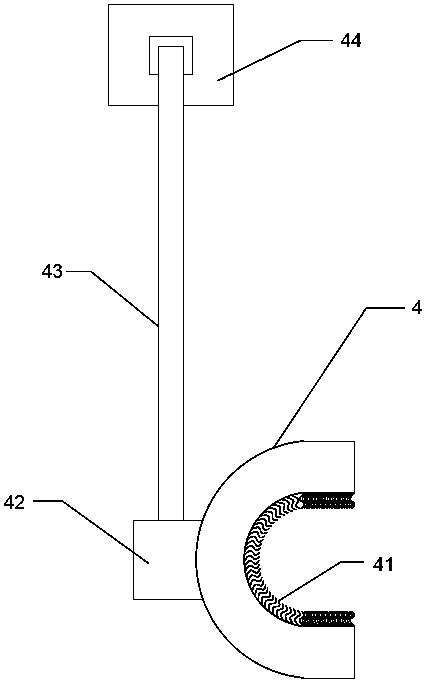

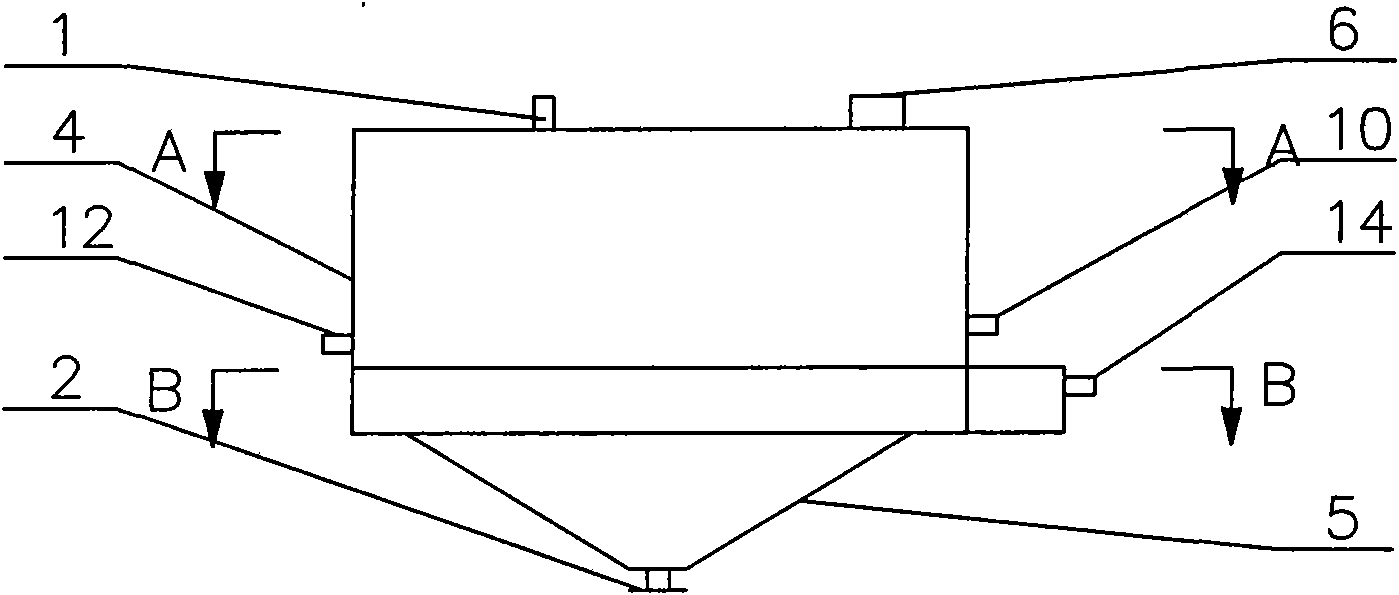

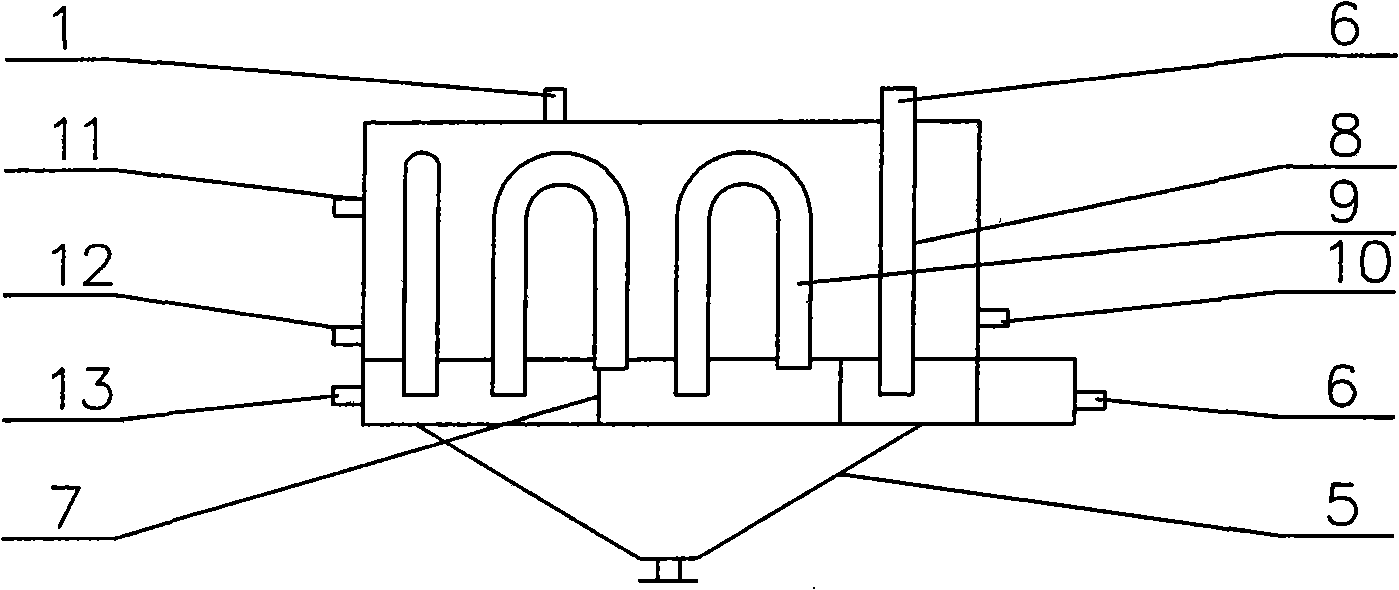

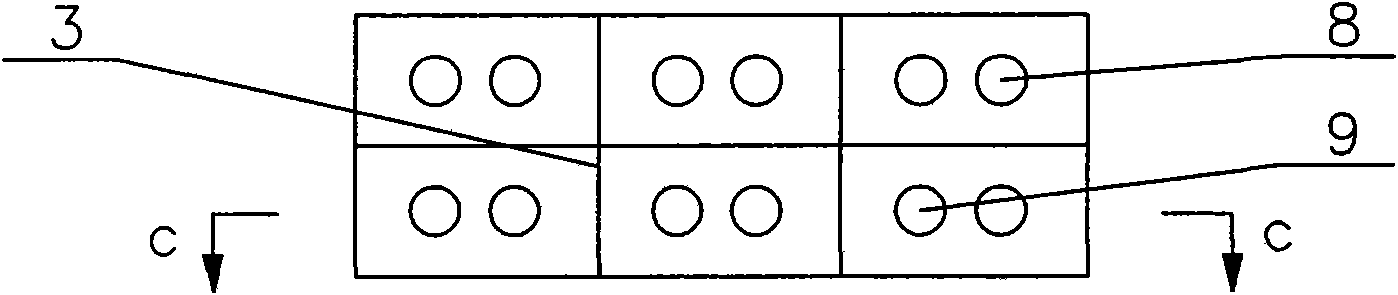

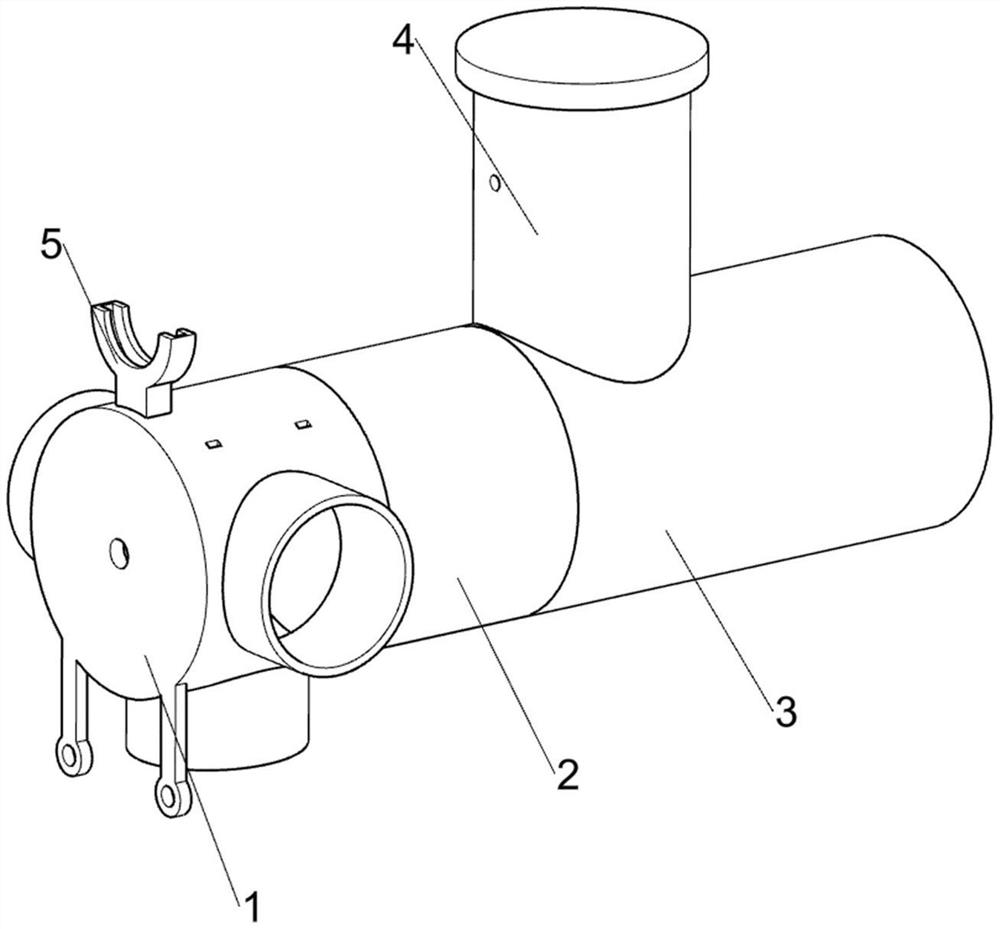

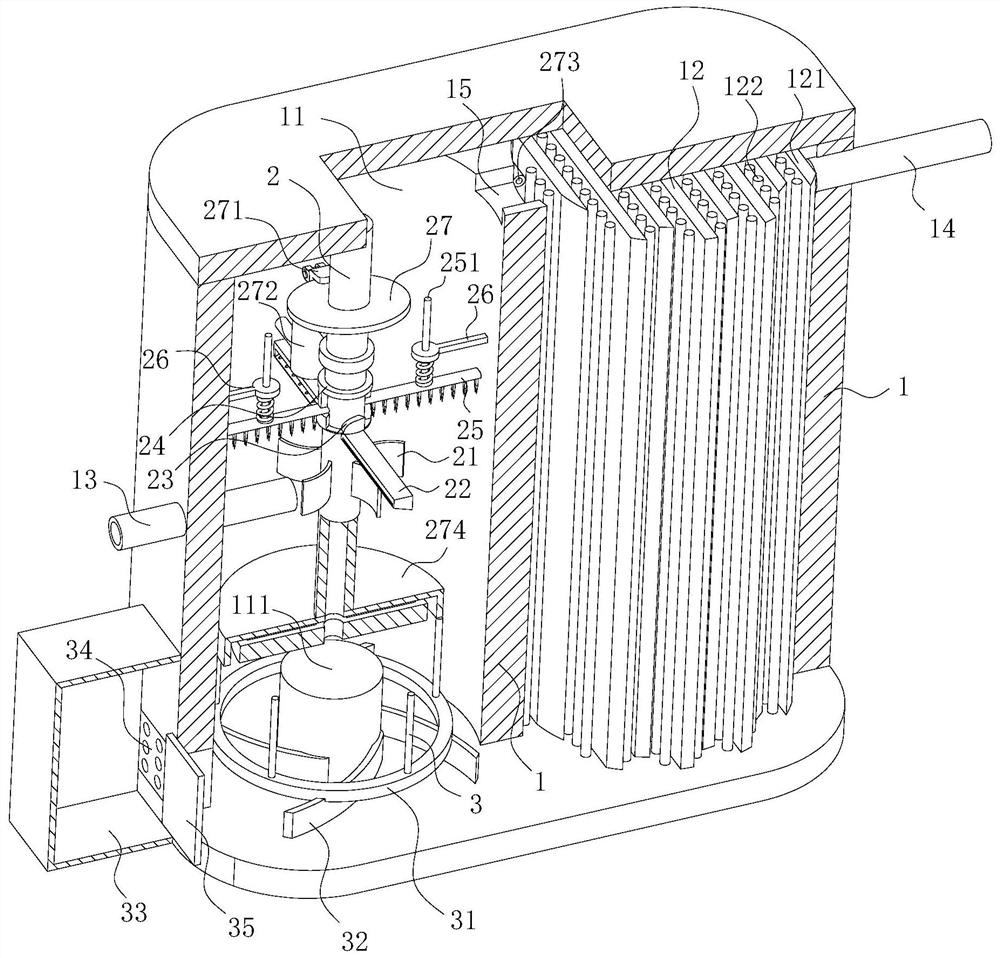

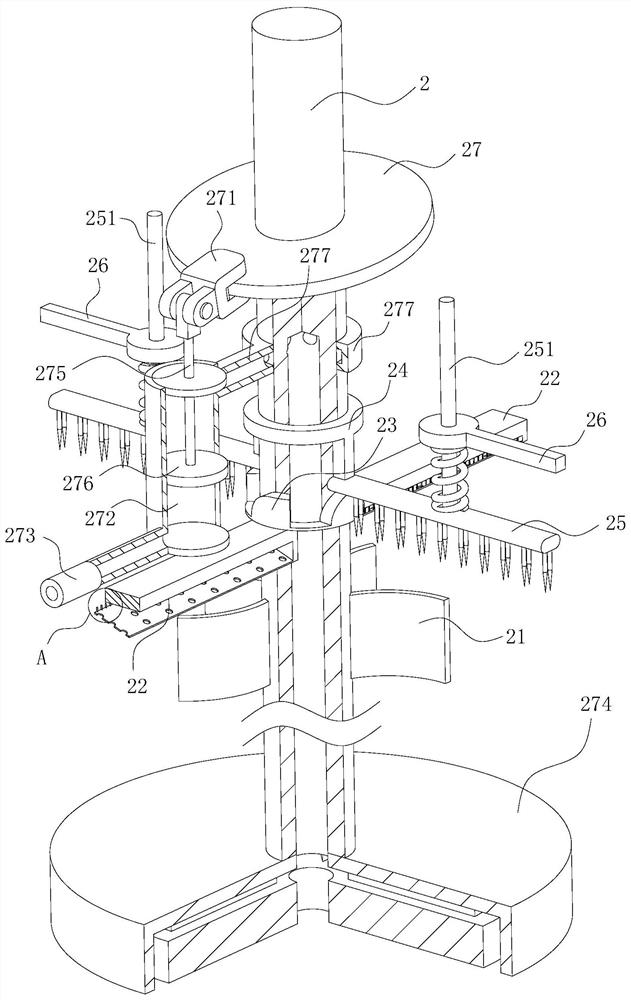

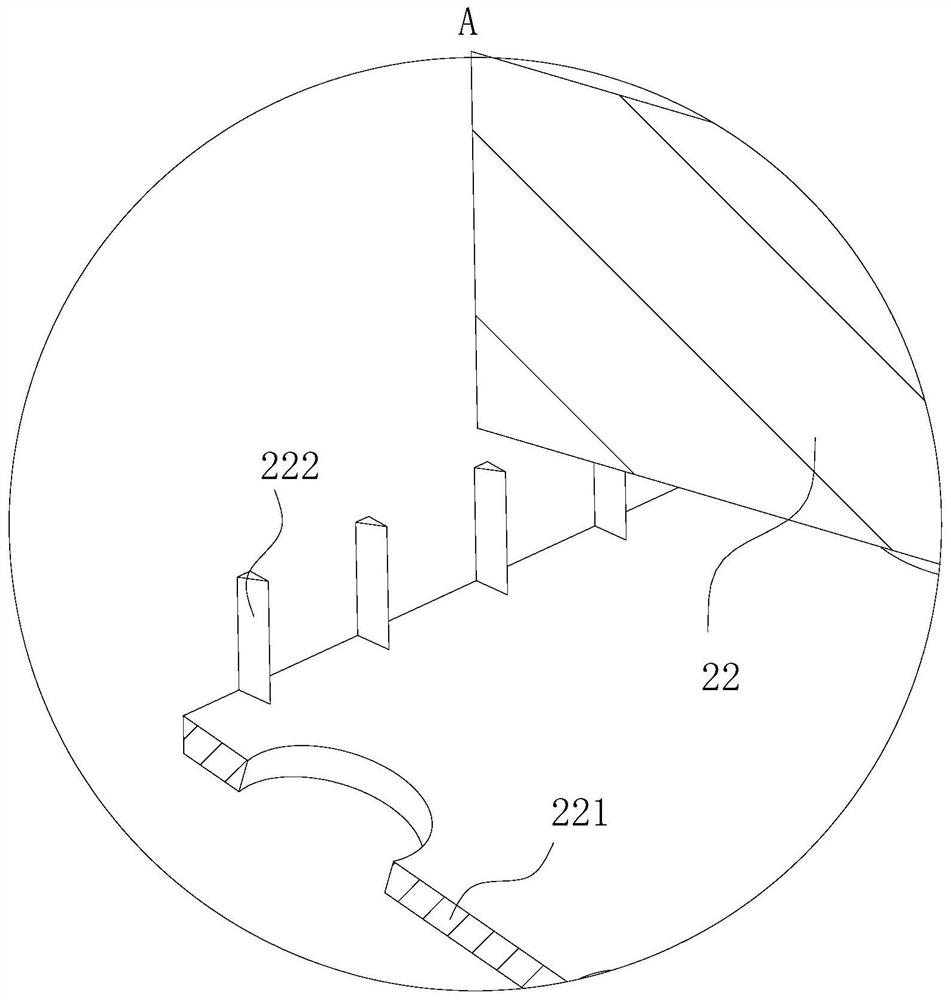

Dredging machine under wharf and dredging method thereof

ActiveCN102454178AImprove adaptabilityFully clearMechanical machines/dredgersAgricultural engineeringHigh pressure water

The invention discloses a dredging machine under a wharf and a dredging method thereof, and relates to dredging equipment and a construction method thereof. The dredging machine comprises a high-pressure water pump, a submersible mud pump, a dredging head and a nozzle, and is characterized in that: the high-pressure water pump is mounted above the submersible mud pump; the lower end of the submersible mud pump is connected with the dredging head; a sucking port is arranged at the bottom of the dredging head; a transition water tank is arranged at the upper part of the dredging head; a water outlet of the high-pressure water pump is connected with a water inlet of the transition water tank through a connection pipe; the transition water tank is connected with a high-pressure flushing watertank arranged at the middle part of the dredging head through a connection pipe; the nozzle is arranged at the lower end of a water pipe of the high-pressure flushing water tank vertically going to the bottom of the dredging head; high-pressure flushing nozzles forming an angle of 45 degrees with the horizontal plane are uniformly distributed along the edge of the high-pressure flushing water tank; after the dredging machine is placed on the soil surface by a dredging platform with hoisting equipment, the high-pressure water pump is started to perform vertical and horizontal high-pressure flushing to break soil; and then the submersible mud pump sucks mud, and the mud is sucked in through the dredging head and discharged to a mud boat through a mud pipe of the submersible mud pump.

Owner:SHANGHAI WATERWAY ENG DESIGN & CONSULTING CO LTD

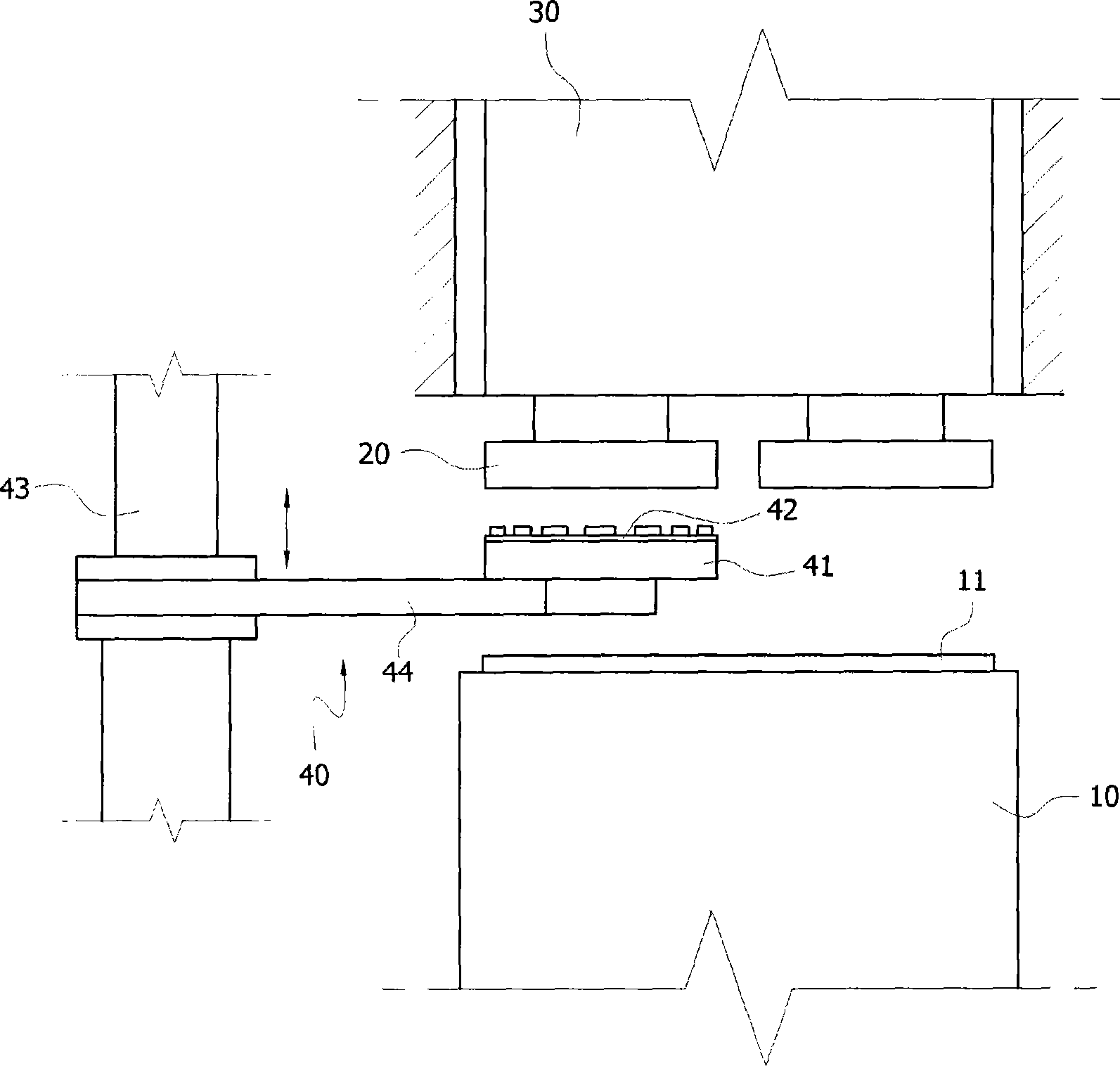

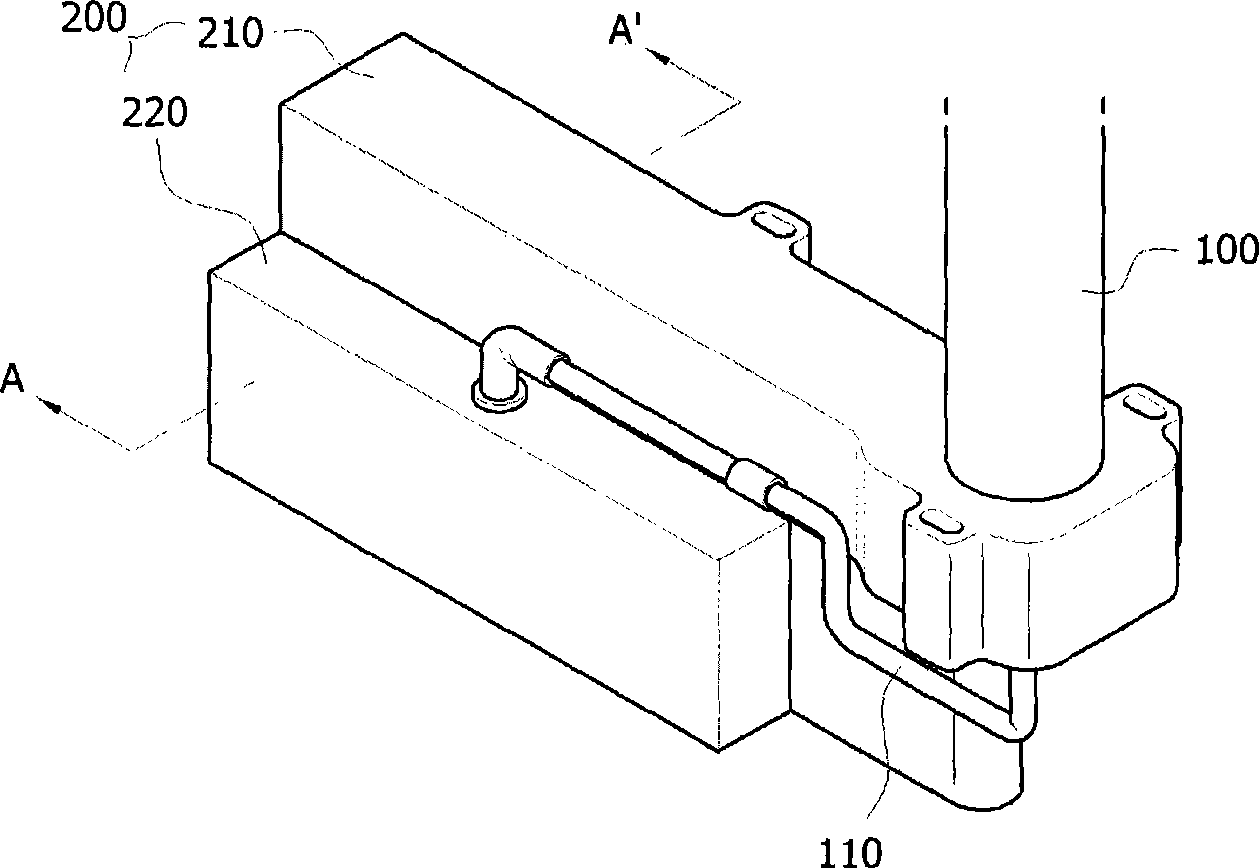

Cleaning device for chemical mechanical polishing device

ActiveCN101386149AFully clearPolishing machinesSemiconductor/solid-state device manufacturingMechanical equipmentImpurity

The invention discloses a cleaning device used in chemical mechanical equipment. The cleaning device comprises a non-rotatable central axis which is connected with a rotary main axis in a non-rotatable manner and a nozzle block; the non-rotatable central axis comprises a first channel and a second channel which are formed in the interior of the non-rotatable central axis; cleaning liquid flows into the first channel; a compressed gas flows into the second channel; the nozzle block is connected with the main axis so as to rotate around the non-rotatable central axis on a polishing pad; the nozzle block mixes the cleaning liquid provided by the first channel and the compressed gas provided by the second channel, thus forming two fluids; the mixed two fluids are sprayed on the polishing pad by pressure. Therefore, the cleaning liquid is pressurized and can be fast sprayed on the polishing pad, thereby being capable of completely removing mud particles and impurities from the polishing pad. Besides, the cleaning device can prevent a wafer from scratching and can also prolong the service life of the polishing pad.

Owner:K C TECH

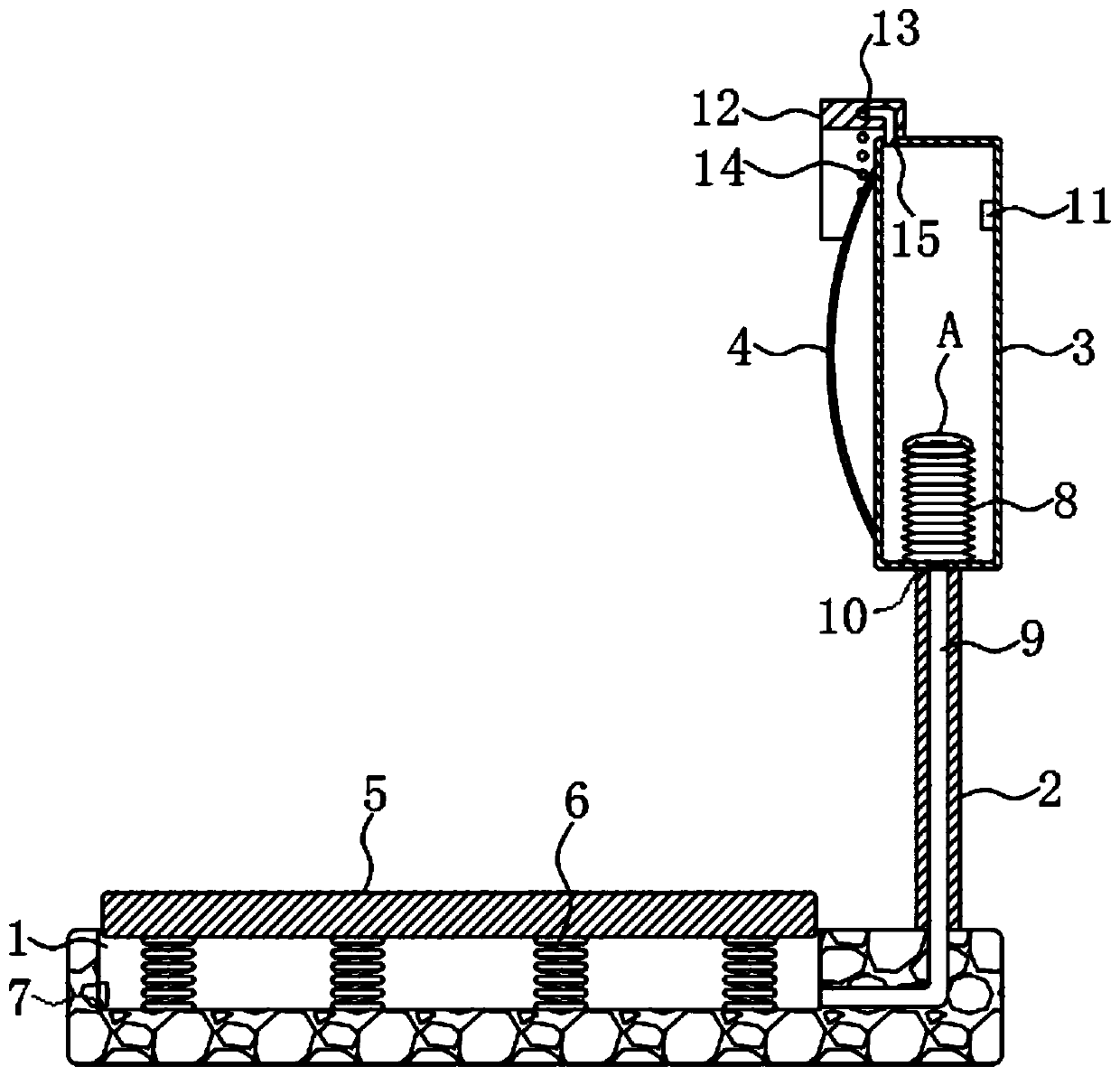

Self-dedusting road reflector

The invention discloses a self-dedusting road reflector. The reflector comprises a chute arranged on the ground and a shell fixedly connected to the ground through a supporting rod. A deceleration strip is connected into the chute in a sealed and sliding mode, a mirror surface and an arc-shaped flashing board are fixedly installed on the side wall and the upper end of the shell respectively, the deceleration strip is elastically connected to the inner bottom of the chute through a plurality of sets of first springs, an air inlet is formed in the inner wall of the chute, and a telescopic air bag is fixedly connected into the shell. An exhaust mechanism, an telescopic air bag, an impeller, a driving mechanism and a cleaning mechanism are arranged, air can be pumped into the telescopic air bag, air is stored, the stored air is used for removing dust on the mirror surface, the impeller can be driven to rotate through the sprayed air, then the cleaning mechanism pumps water to clean the mirror surface, dust on the mirror surface is thoroughly removed, manual cleaning is not needed, the mirror surface is not damaged, the structure is simple, electronic components needing to be maintainedare not needed, and the cost is low.

Owner:杨程聆

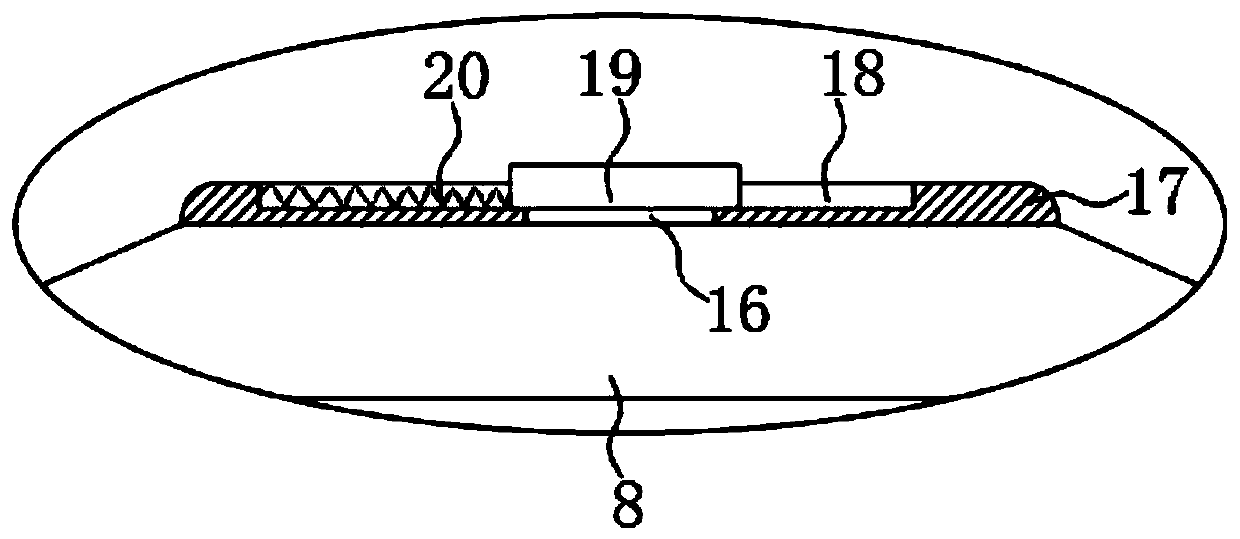

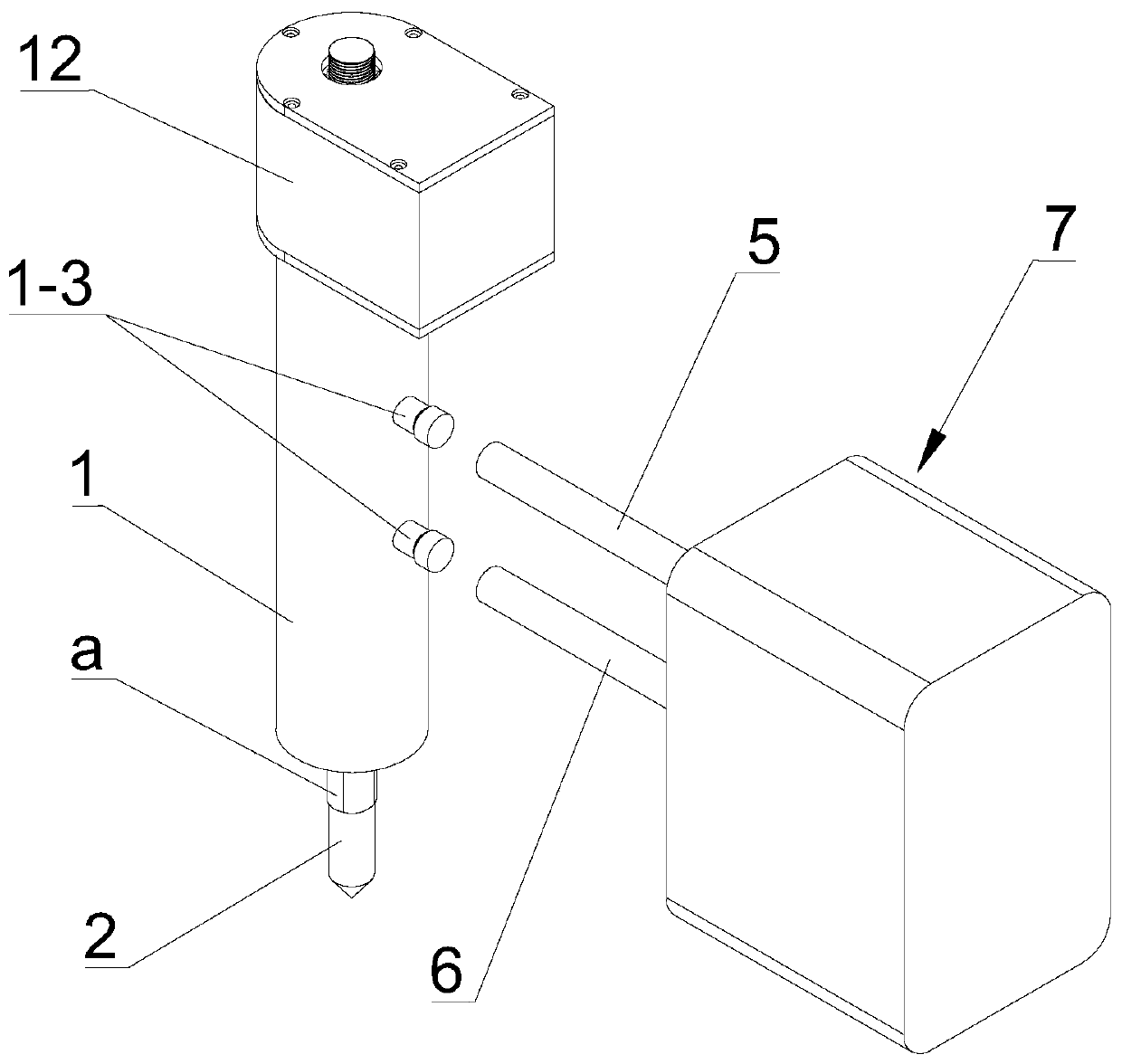

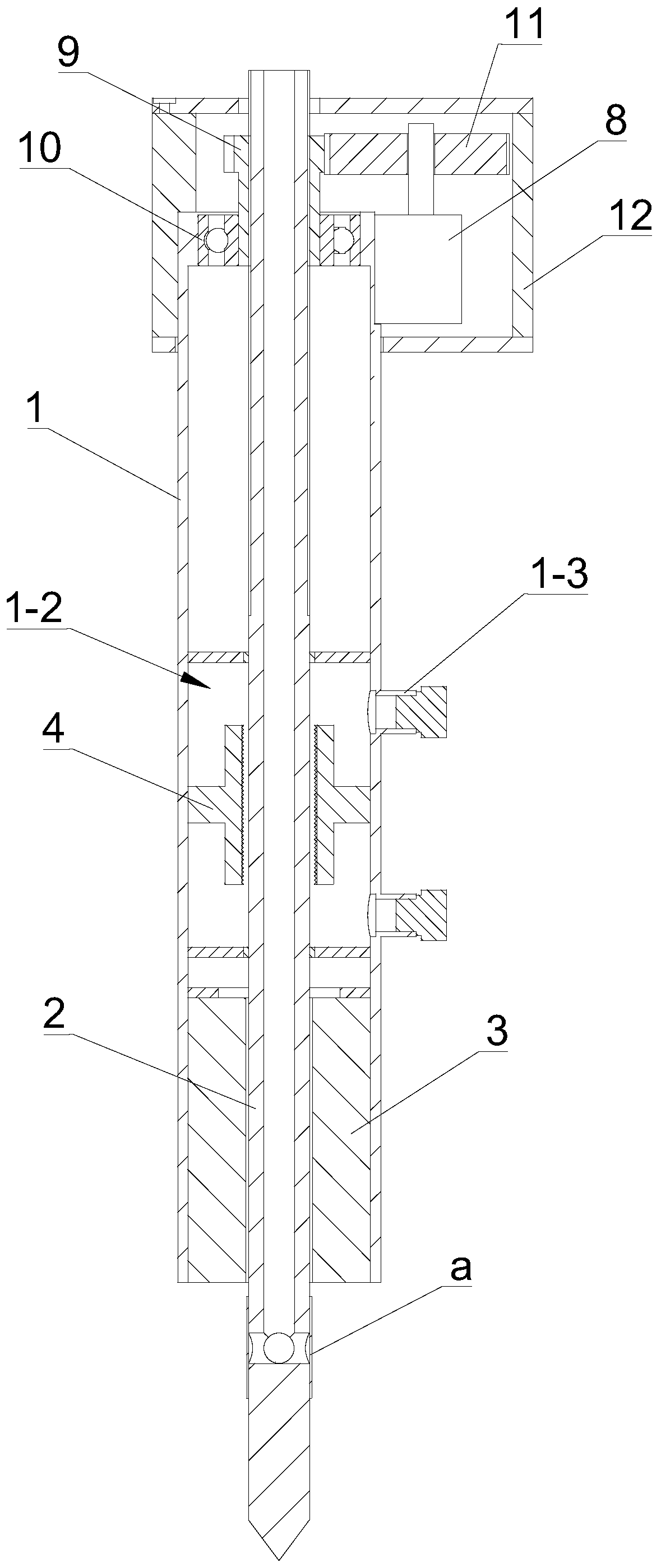

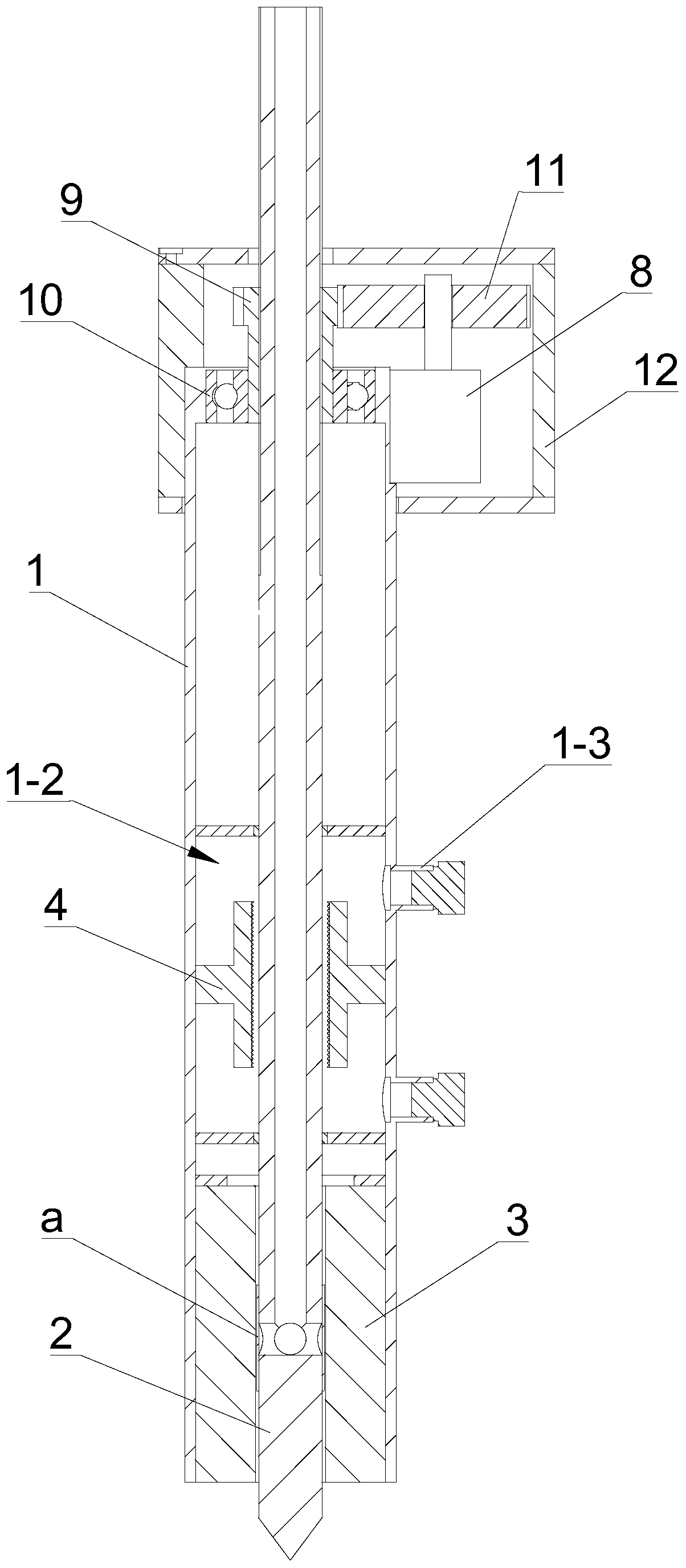

Soil detection probe with cleaning function

ActiveCN111044703AMaintain sensitivity and accuracyExtended service lifeEarth material testingCleaning using toolsEnvironmental chemistryStrain gauge

The invention discloses a soil detection probe with a cleaning function. The soil detection probe comprises a mounting shell, a probe and a cleaning mechanism. The probe passes through an inner cavityof the mounting shell. The cleaning mechanism comprises a first cleaning brush for primarily cleaning the probe, a second cleaning brush for sufficiently cleaning the probe again, and a cleaning driving mechanism for driving the probe to move back and forth relative to the first cleaning brush and the second cleaning brush for cleaning; the first cleaning brush and the second cleaning brush are arranged in an inner cavity of the mounting shell and are attached to and surround one end, located in the mounting shell, of the probe; the first cleaning brush is arranged at the end, close to the soil, of the mounting shell, and the second cleaning brush has a smaller cleaning gap relative to the first cleaning brush. The soil detection probe can automatically clean oxide, rust, corrosives and the like on the metal strain gauge of the probe, the sensitivity and accuracy of the metal strain gauge are kept; meanwhile, the service life is prolonged.

Owner:GUANGZHOU UNIVERSITY

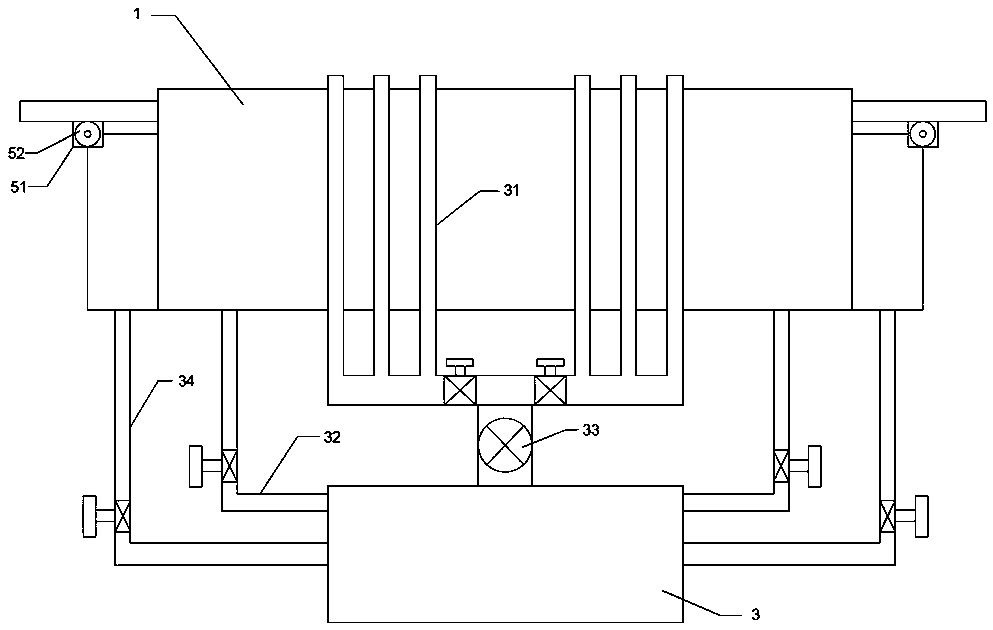

Rotating wheel type sewage treatment device

InactiveCN109748429AStir wellImprove processing efficiencyMultistage water/sewage treatmentOzone generatorFlocculation

The invention discloses a rotating wheel type sewage treatment device, which comprises fiber rotating plates, a tank, an ozone generator and a base. A water pump is mounted at the top end of the tankbody which is mounted at the top end of the base, a water guide pipe is mounted at a water outlet of the water pump, and the top end of the tank on one side, away from the water pump, of the water guide pipe is provided with an agent adding port. A controller is mounted at the top end of the tank on one side, away from the water pump, of the agent adding port. The ozone generator is mounted at thetop end of the tank on one side, away from the agent adding port, of the controller. By mounting of a hollow water outlet shaft, the fiber rotating plates are uniformly mounted on the hollow water outlet shaft and driven to rotate by a driving motor to make it convenient to stir sewage, so that the sewage and agent mixing speed is increased to realize complete mixing, and convenience in flocculation, sedimentation and filtration of pollutants in sewage is achieved; in addition, sewage filtered through the fiber rotating plates enters the hollow water outlet shaft, and sewage treatment efficiency is improved.

Owner:江苏弘汉生物科技有限公司

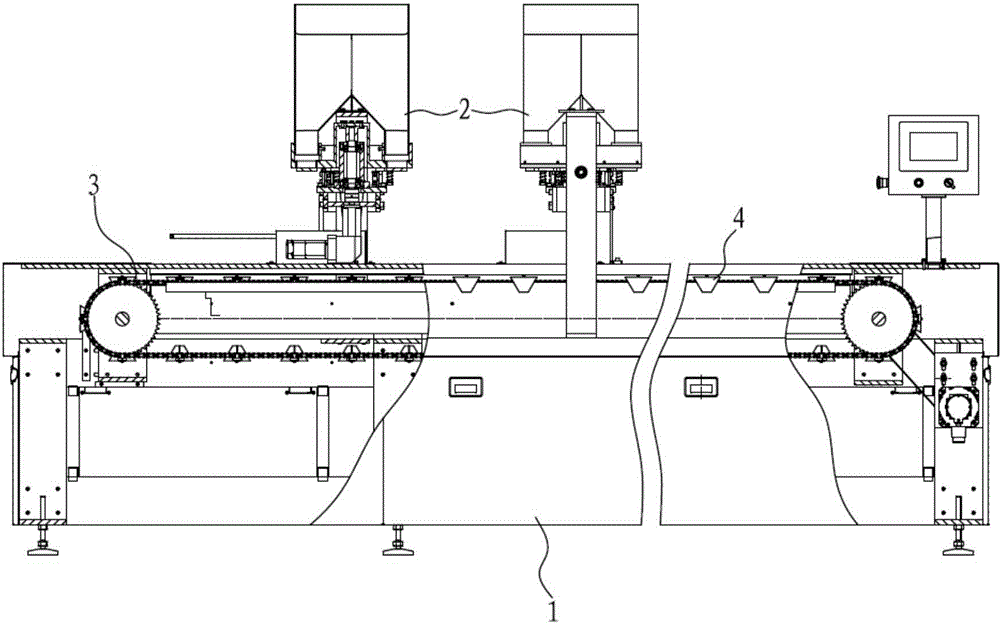

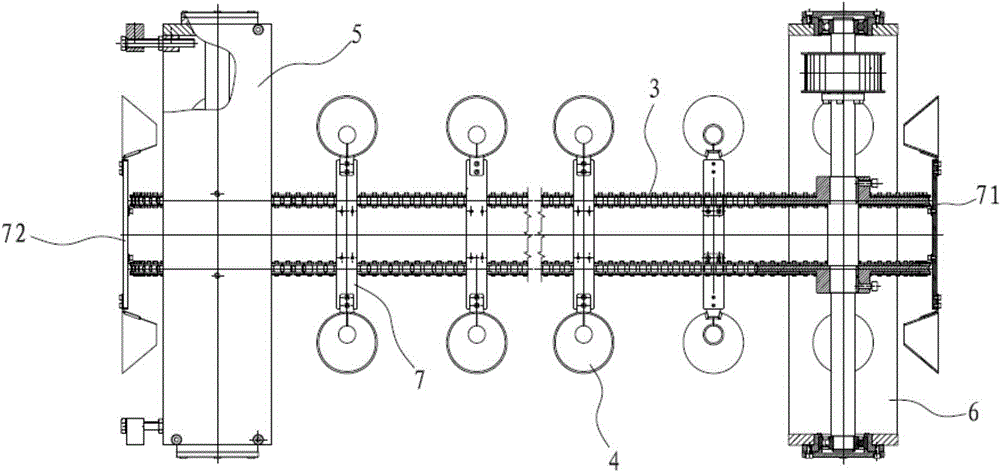

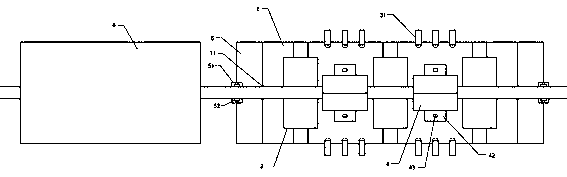

Semiautomatic rice dumping-wrapping machine

InactiveCN104803022ADoes not affect bendingInhibit sheddingWrappingSuccessive articlesDischargerEngineering

The invention discloses a semiautomatic rice dumping-wrapping machine, which comprises a rack, a conveying chain and rice dumpling leaf molds conveyed by the conveying chain are mounted in the rack, moreover, the conveying chain passes through the upper working area of the rack, and the working area is divided into a rice dumpling leaf-placing station, a primary rice-filling station, a stuffing-filling station, a secondary rice-filling station and a discharge and bundling station sequentially along the running direction of the conveying chain; quantitative rice dischargers are mounted in both the primary rice-filling station and the secondary rice-filling station, and each quantitative rice discharger comprises a hopper, a turntable, a plurality of measuring cylinders, valves and driving mechanisms; the hopper is fixedly mounted on the rack, and the bottom of the hopper is provided with a discharge outlet; the turntable is arranged under the hopper; the measuring cylinders run through the turntable and are evenly arranged around the axis of the turntable; each valve is movably mounted at the opening of the lower end of one measuring cylinder; the valves are driven by the driving mechanisms to close and open. The semiautomatic rice dumping-wrapping machine adopts an operating mode combining manual rice filling and automatic rice filling, thus solving the problem of low efficiency existing in manual production and also overcoming poor bundling quality caused by full-automatic production.

Owner:ZHEJIANG WUFANGZHAI INDAL

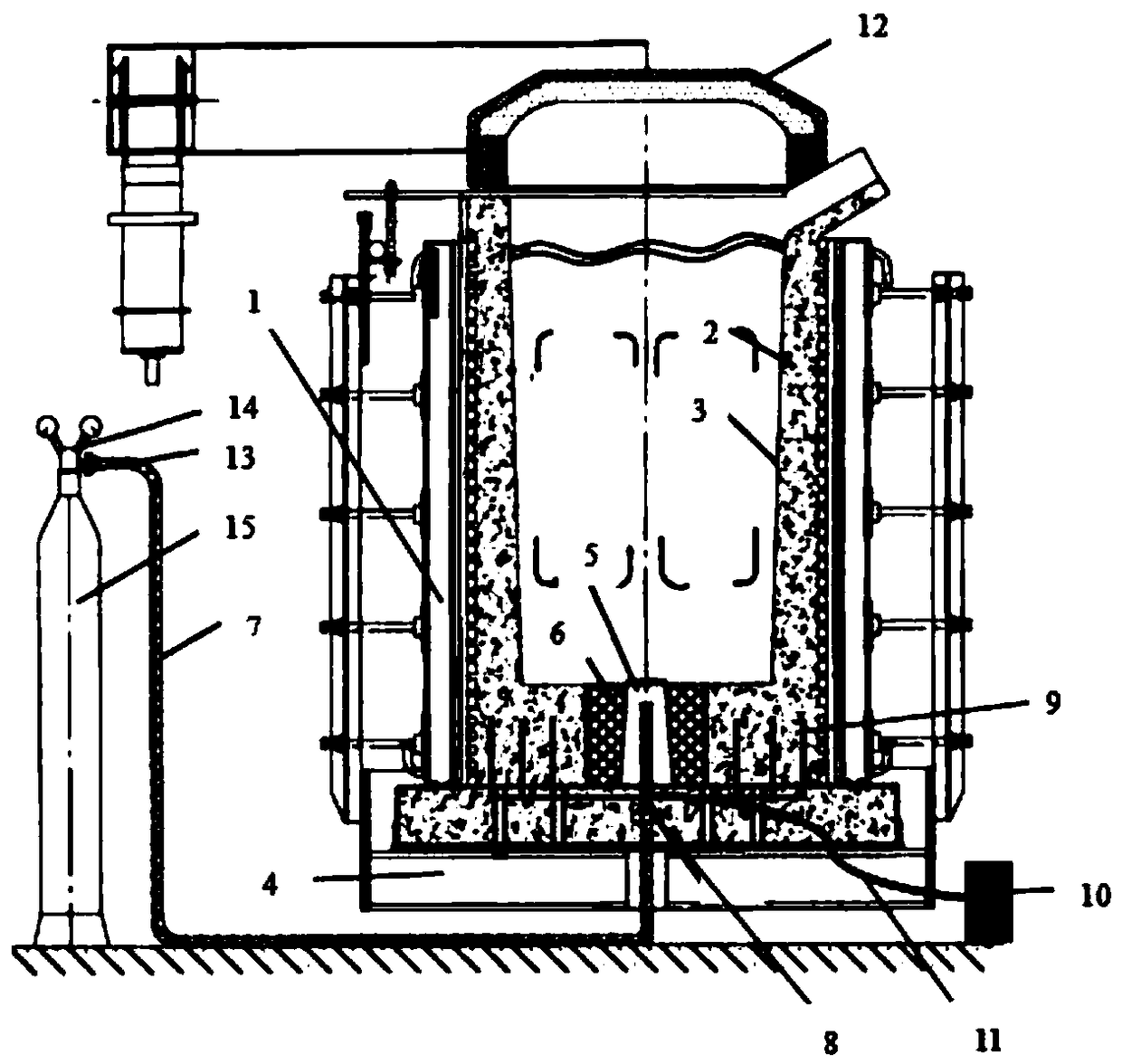

High-purity super-high manganese steel and preparation process thereof

ActiveCN109487178ALess investmentFine and fully evenly dispersedProcess efficiency improvementElectric furnaceHydrogenTrace element

The invention discloses high-purity super-high manganese steel which is prepared from the following components in percentage by mass: 0.75 to 1.76 percent of C, 22.0 to 30.0 percent of Mn, 0.1 to 0.8percent of Si, 0.021 to 0.043 percent of P, 0.016 to 0.035 percent of S, 0.07 to 2.5 percent of Cr, 0.52 to 2.3 percent of Mo, 0.01 to 1.34 percent of Ni, 0.03 to 1.5 percent of Cu, 0.01 to 0.2 percent of Nb, 0.032 to 0.083 percent of Al, 0.0006 to 0.0010 percent of O, 0.00014 to 0.00042 percent of H, less than or equal to 0.82 percent of other trace element, and the balance Fe. By adopting a preparation process of the high-purity super-high manganese steel provided by the invention, the contents of oxygen and hydrogen are effectively reduced, and a synthesized mechanical property of the highmanganese steel is improved.

Owner:广西长城机械股份有限公司

Method for recycling wastewater of electroplating industry

InactiveCN110040884ASufficient separationFully clearWater contaminantsTreatment involving filtrationFlocculationActivated carbon

The invention provides a method for recycling wastewater of electroplating industry. The method comprises the following steps: filtering electroplating wastewater by a grid and feeding a filtrate intoa flocculation basin; adding a flocculant into the flocculation basin, stably precipitating, and then adding a coagulant aid, fully stirring and mixing till the mixture is uniform, standing by and then filtering with a horizontal filter screen, and guiding clean liquor into an adsorption tank; adding a composite adsorbent into the adsorption tank, regulating PH value in the adsorption tank to 2-8, fully stirring till the mixture is uniform, standing by and then filtering with a horizontal filter screen, and guiding clean liquor into a settling tank, wherein the composite adsorbent comprises activated carbon, humic acid and active zeolite at a mass ratio of 1:(0.2-1.3): (2-3); regulating the PH value of solution in the settling tank to 6-7 and temperature at 50-70 DEG C, performing electric flocculation and then performing solid-liquid separation. The method provided by the invention has the beneficial effects that the treated water is ultralow in metal content, contains few soluble gases, is odorless and can be directly discharged.

Owner:襄阳先创环保科技有限公司

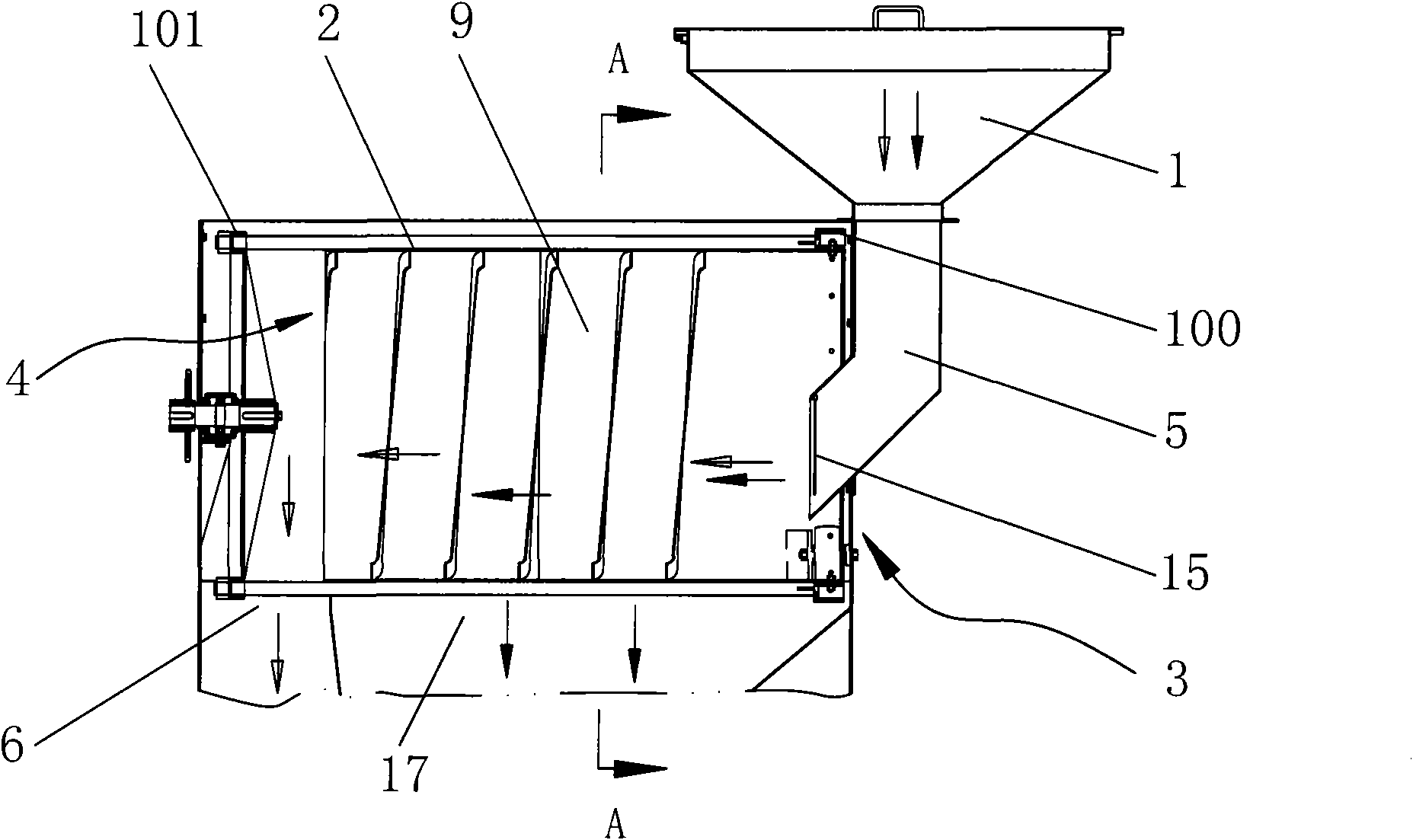

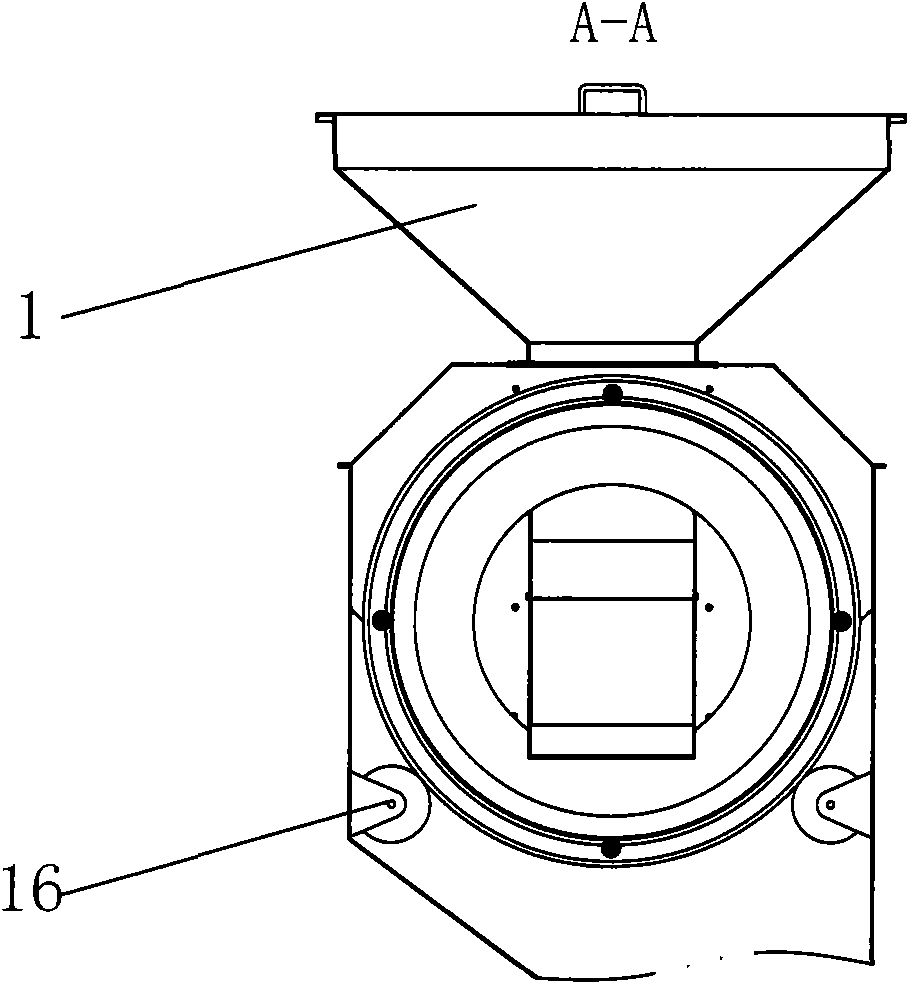

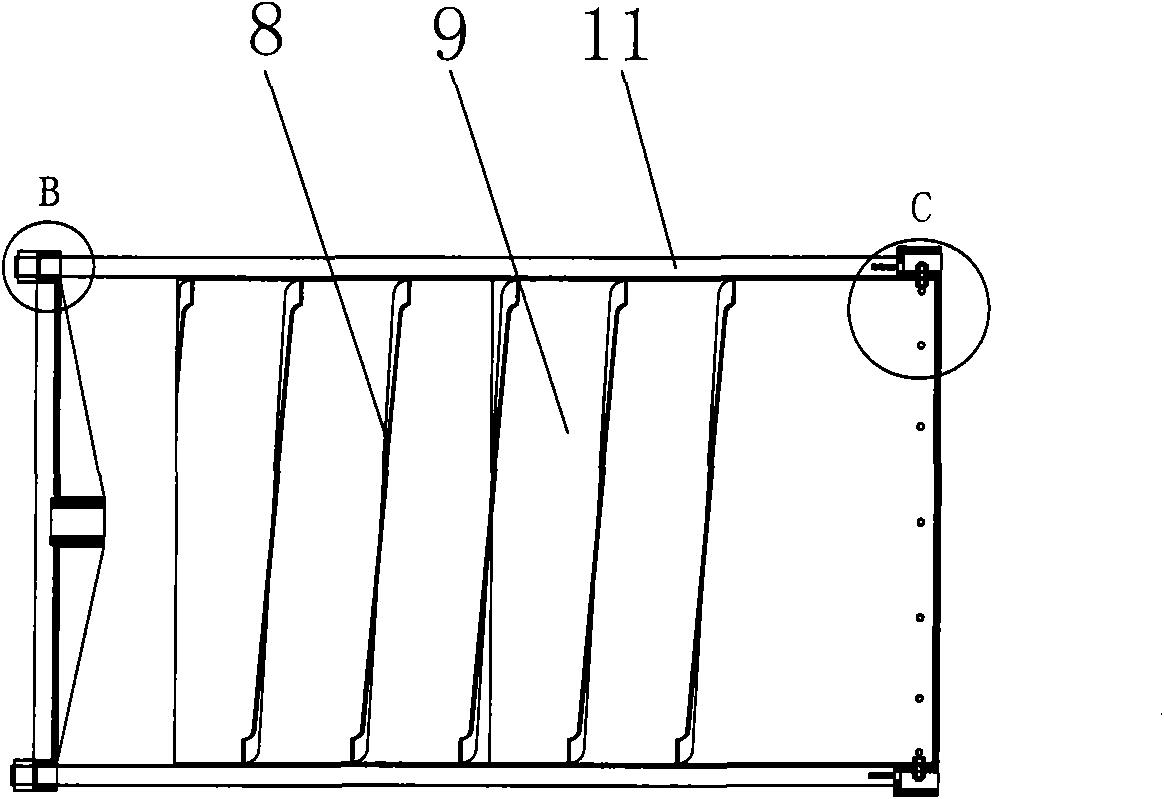

Cylindrical pre-cleaning screen

Owner:WUJIANG SHENGTIAN PACKING & CONVEYING MACHINERY

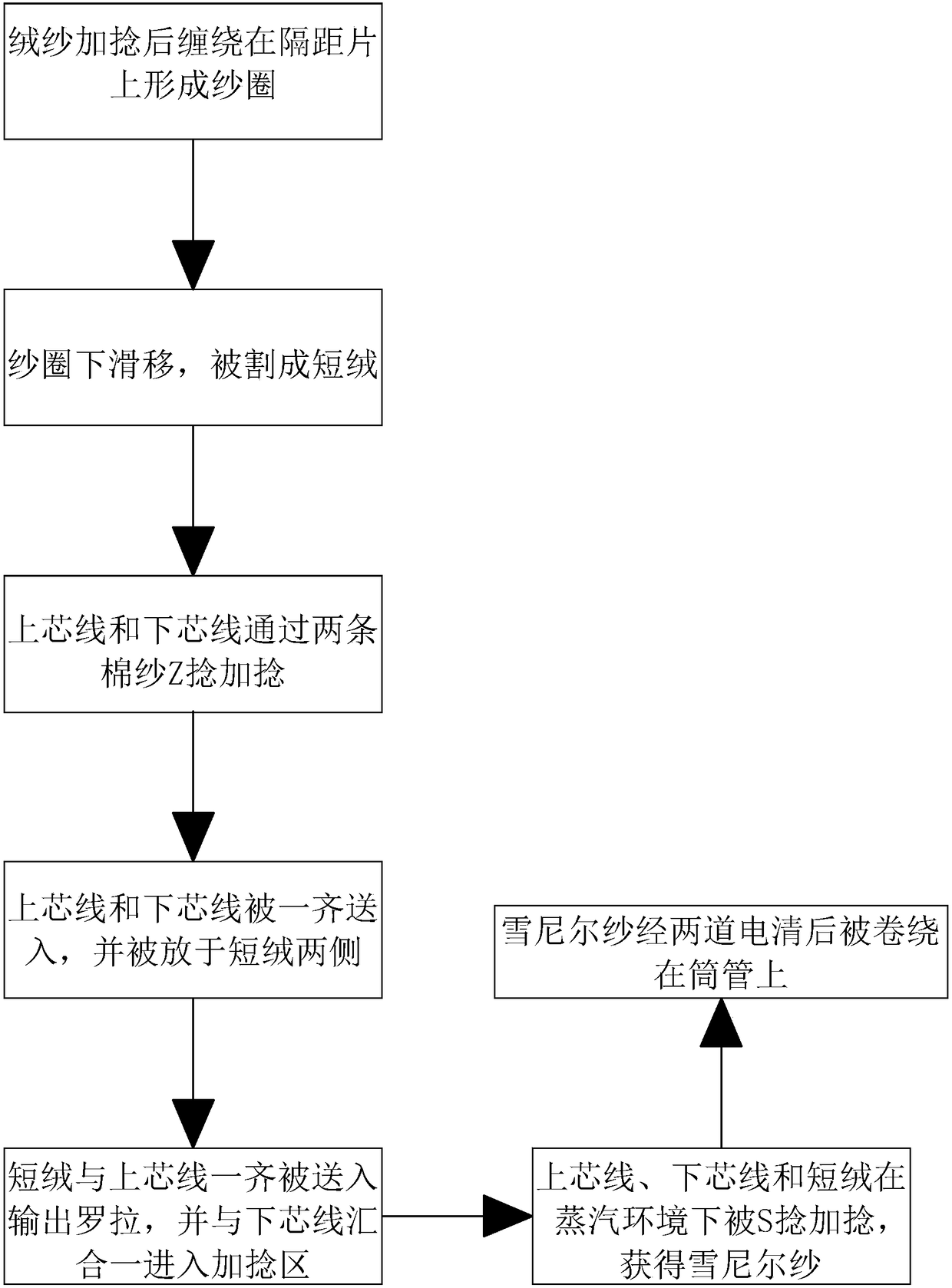

Spinning process for superfine chenille yarn

The invention relates to a spinning process for a superfine chenille yarn. The spinning process comprises the following steps: (S1) twisting two or three wool yarns along the rotation of a rotation head, and winding a 0.8mm spacing piece with the wool yarns, so as to form a yarn coil; (S2) moving the yarn coil downwards with the pressure of a nylon roller, and cutting the yarn coil into flocks byvirtue of a blade; (S3) unreeling an upper core wire and a lower core wire from a roll under the effect of a traction roller, simultaneously feeding the upper core wire and the lower core wire, putting the upper core wire and the lower core wire on two sides of the flocks under the effects of the nylon roller and the spacing piece, wherein the upper core wire and the lower core wire are simultaneously located in the middles of the flocks; (S4) simultaneously conveying the flocks and the upper core wire into an output roller to be combined with the lower core wire, clamping the flocks between the upper core wire and the lower core wire, and enable the flocks to enter a twisting region; and (S5) twisting the upper core wire, the lower core wire and the flocks at 1000r / m in an S twisting manner along the rotation of a spindle, so as to form the chenille yarn. The chenille yarn is formed by twisting the upper core wire, the lower core wire and the flocks, so that the chenille yarn is integrally relatively thin, and the hand feel of a textile produced from the chenille yarn is relatively comfortable in use.

Owner:ZHEJIANG LIDA MODERN TEXTILES

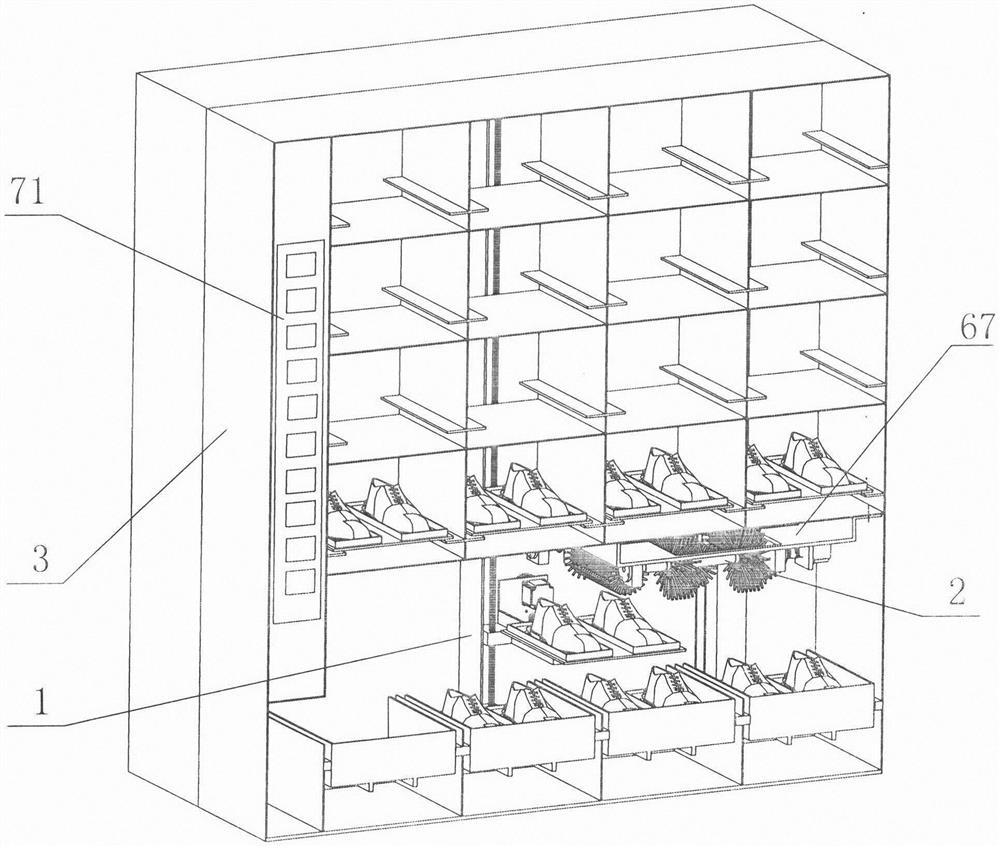

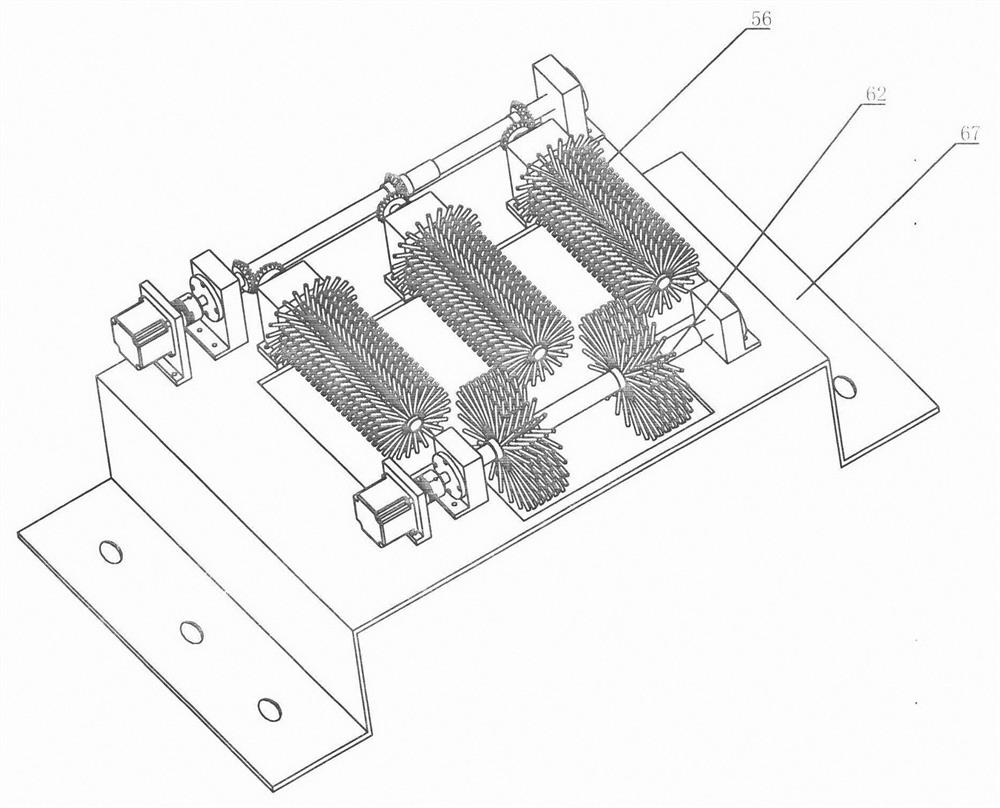

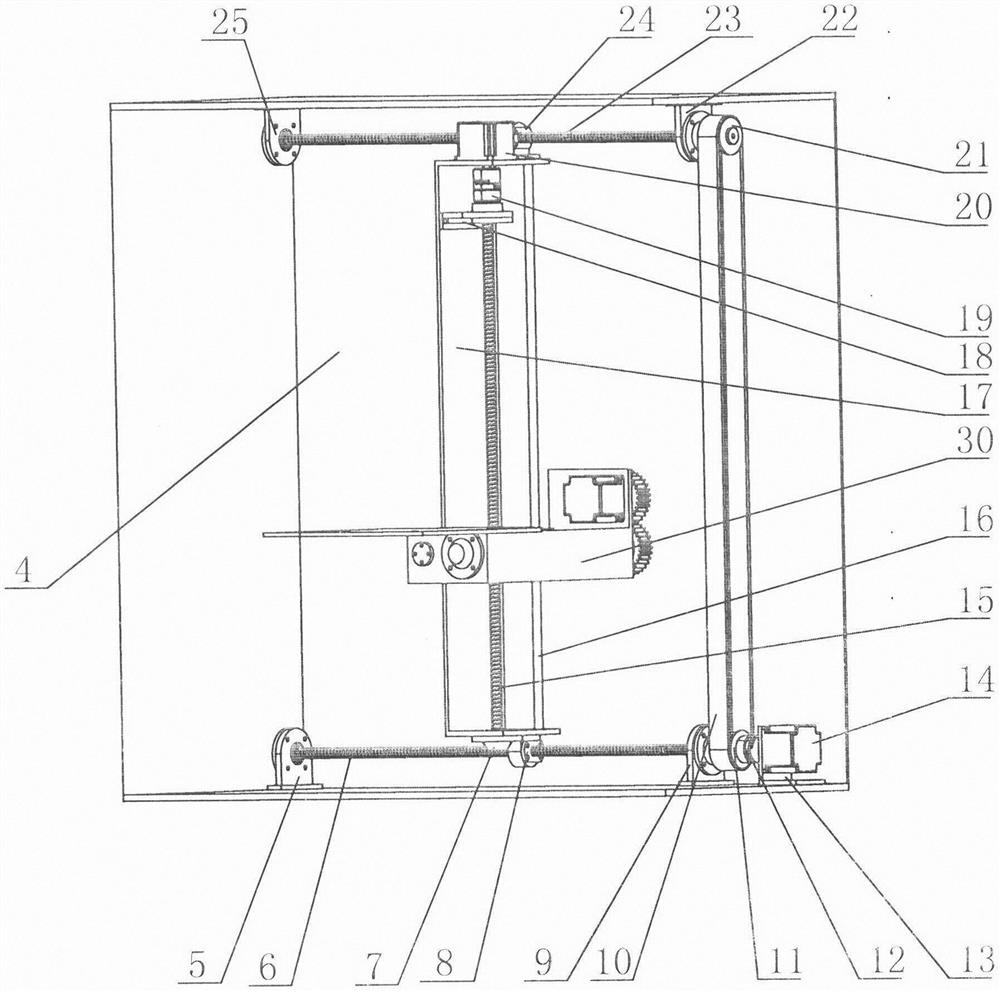

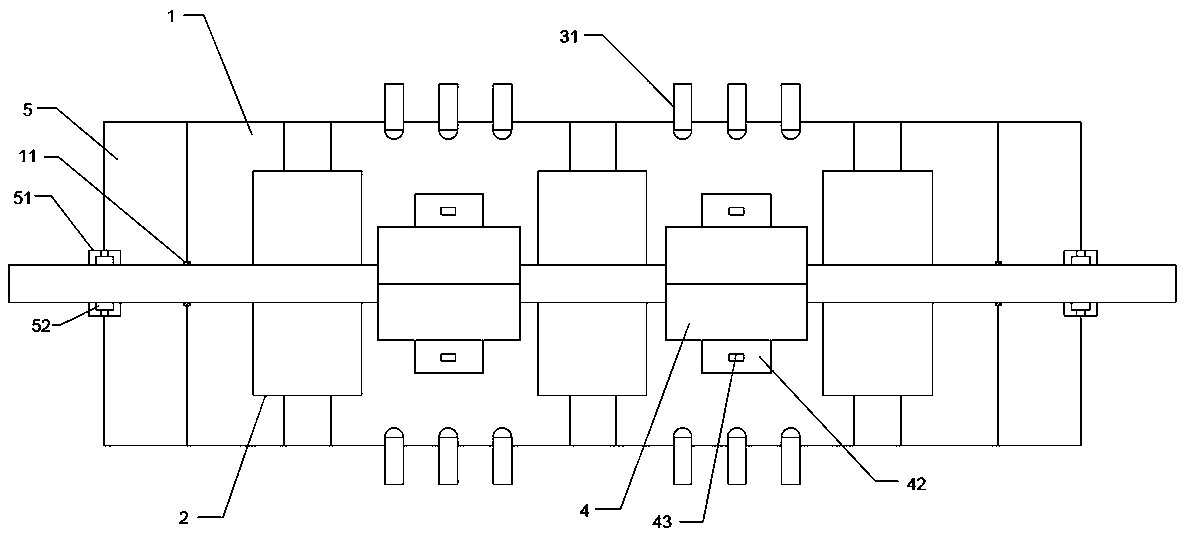

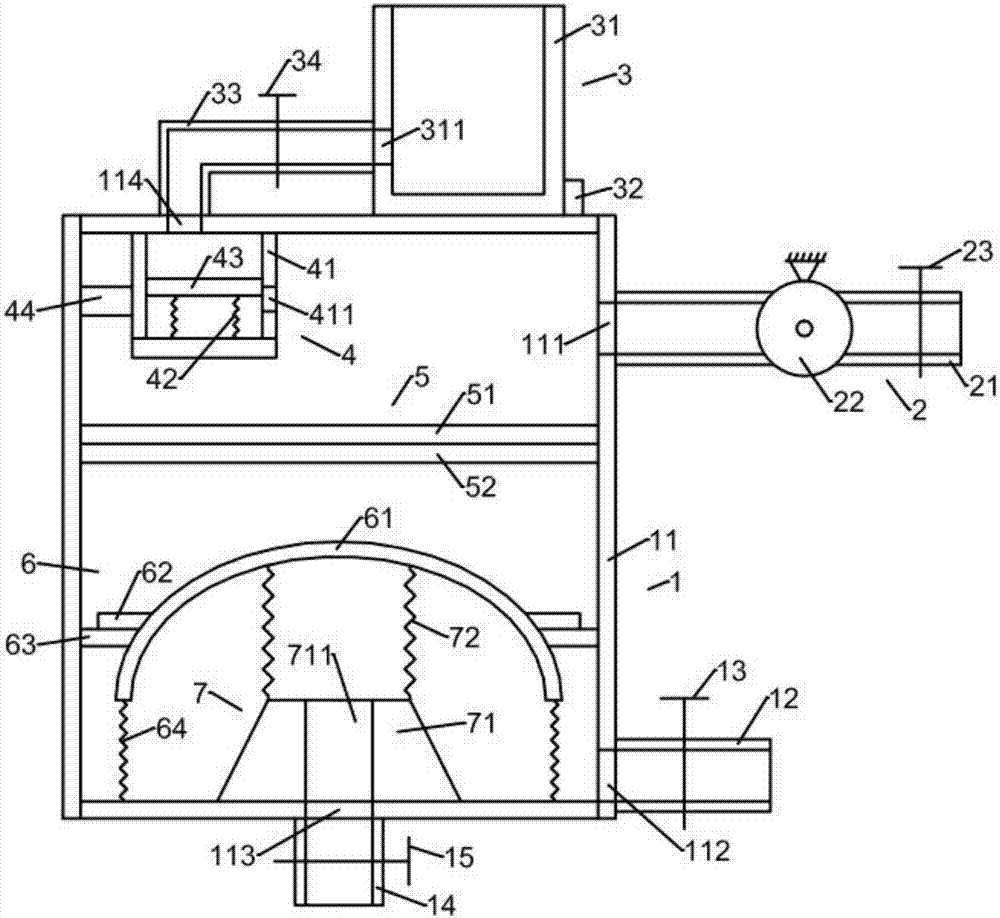

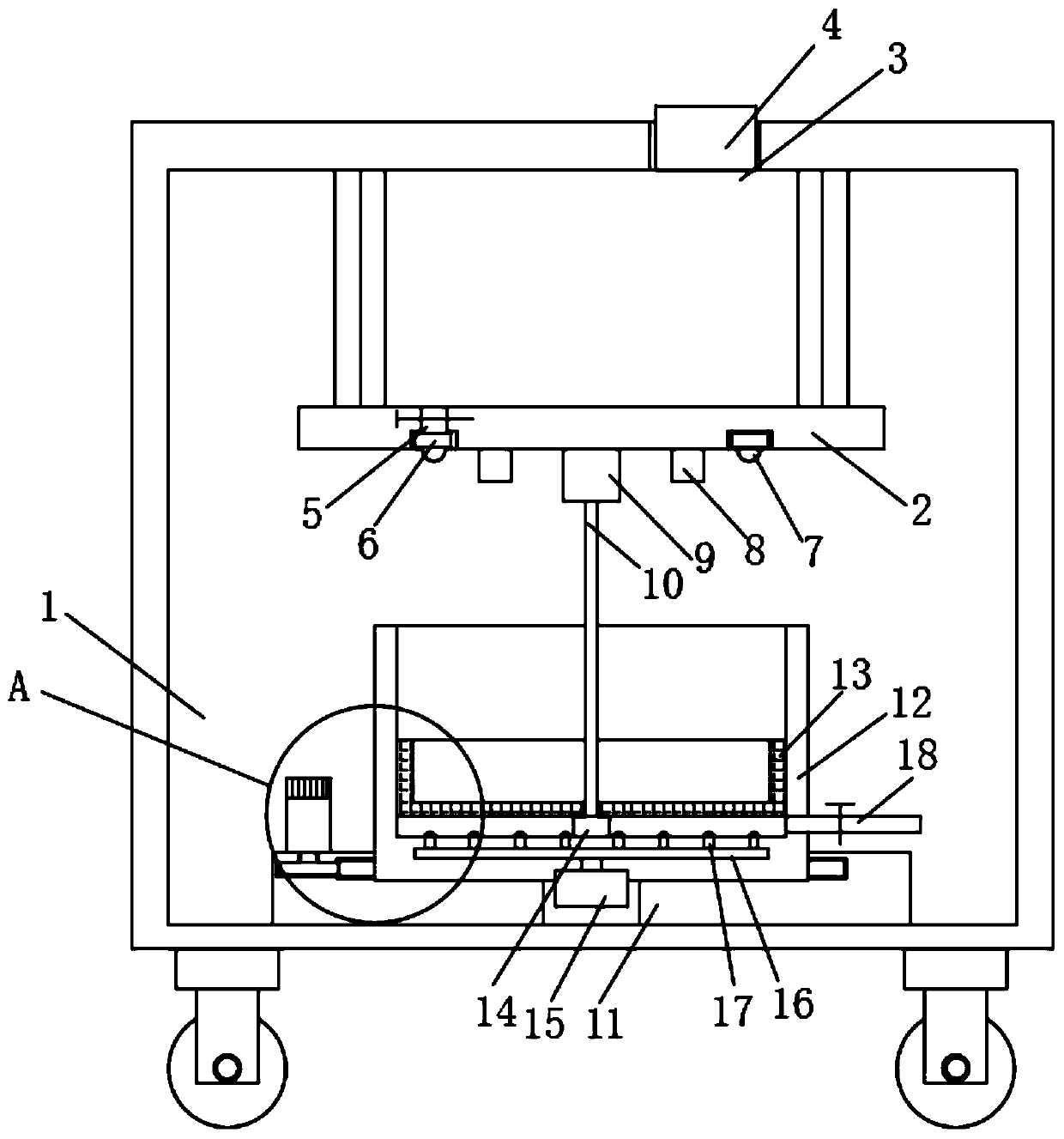

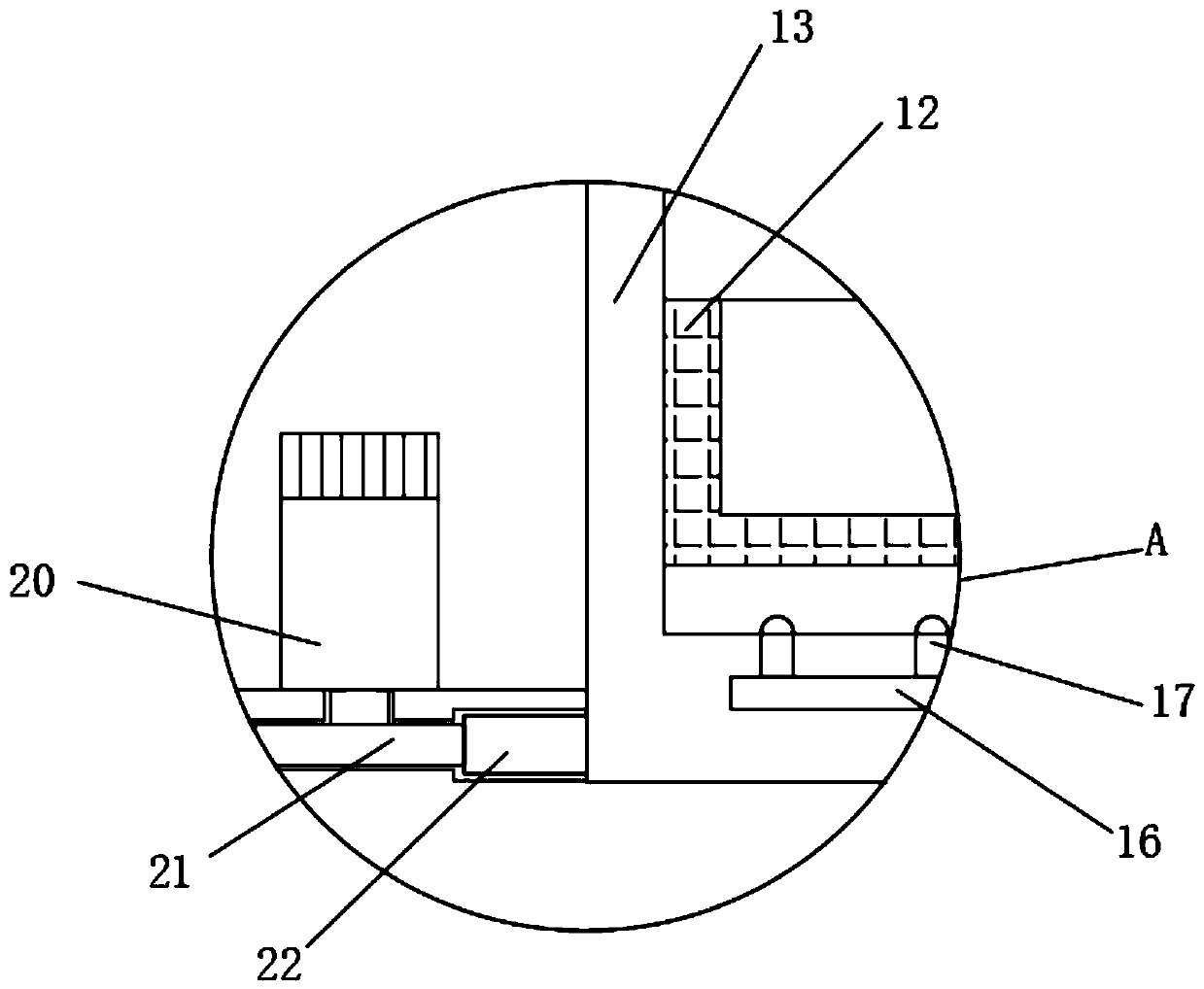

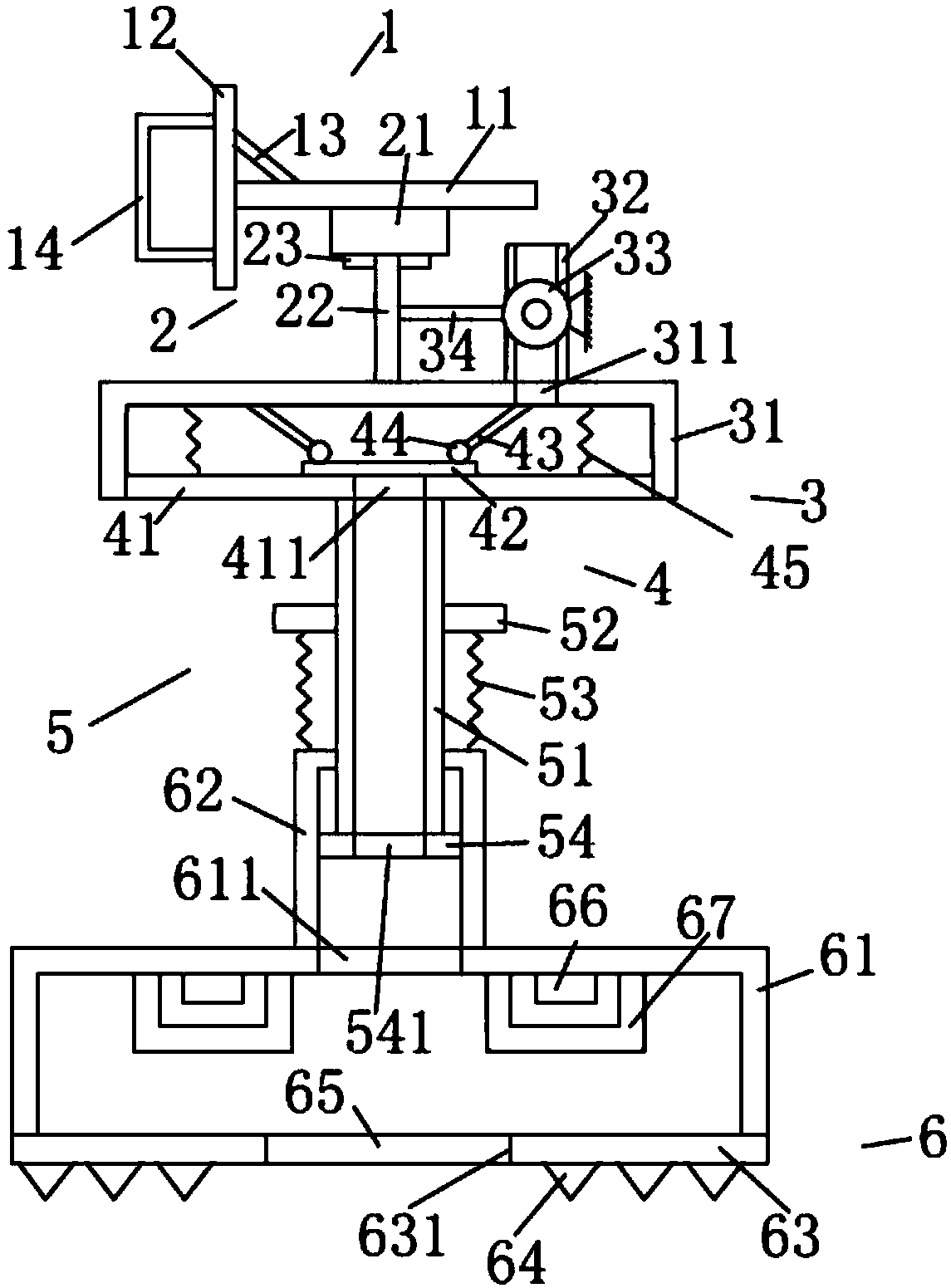

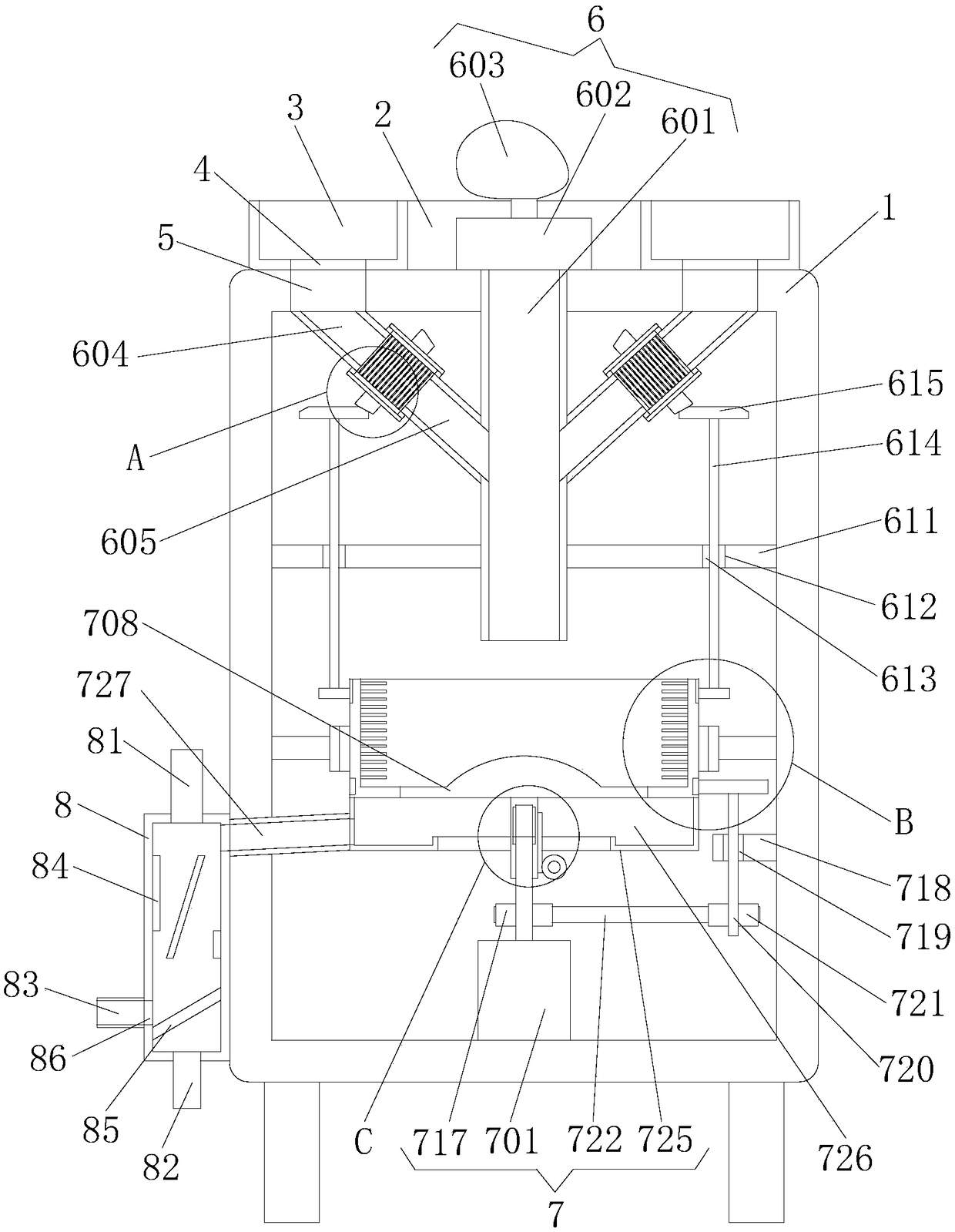

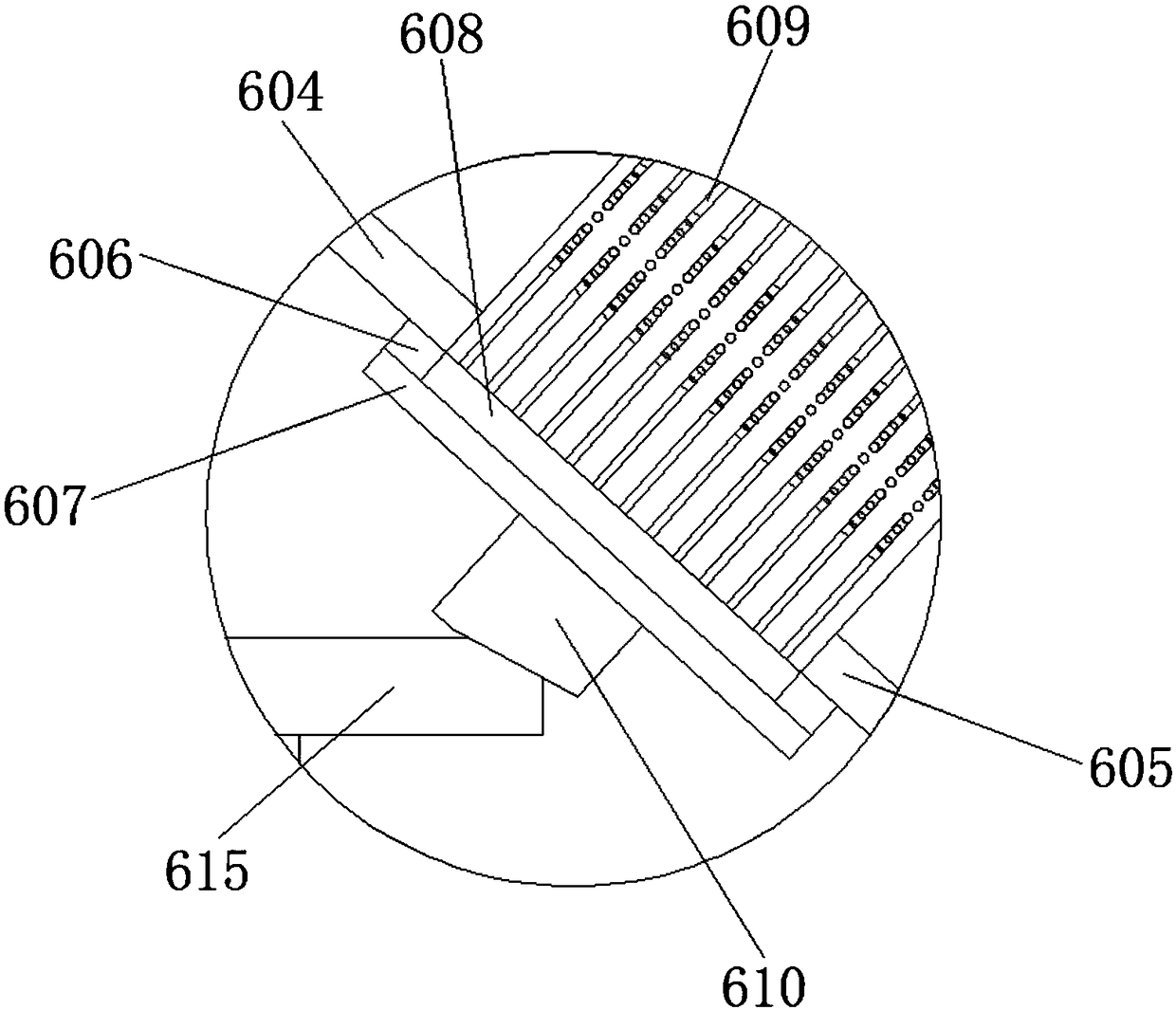

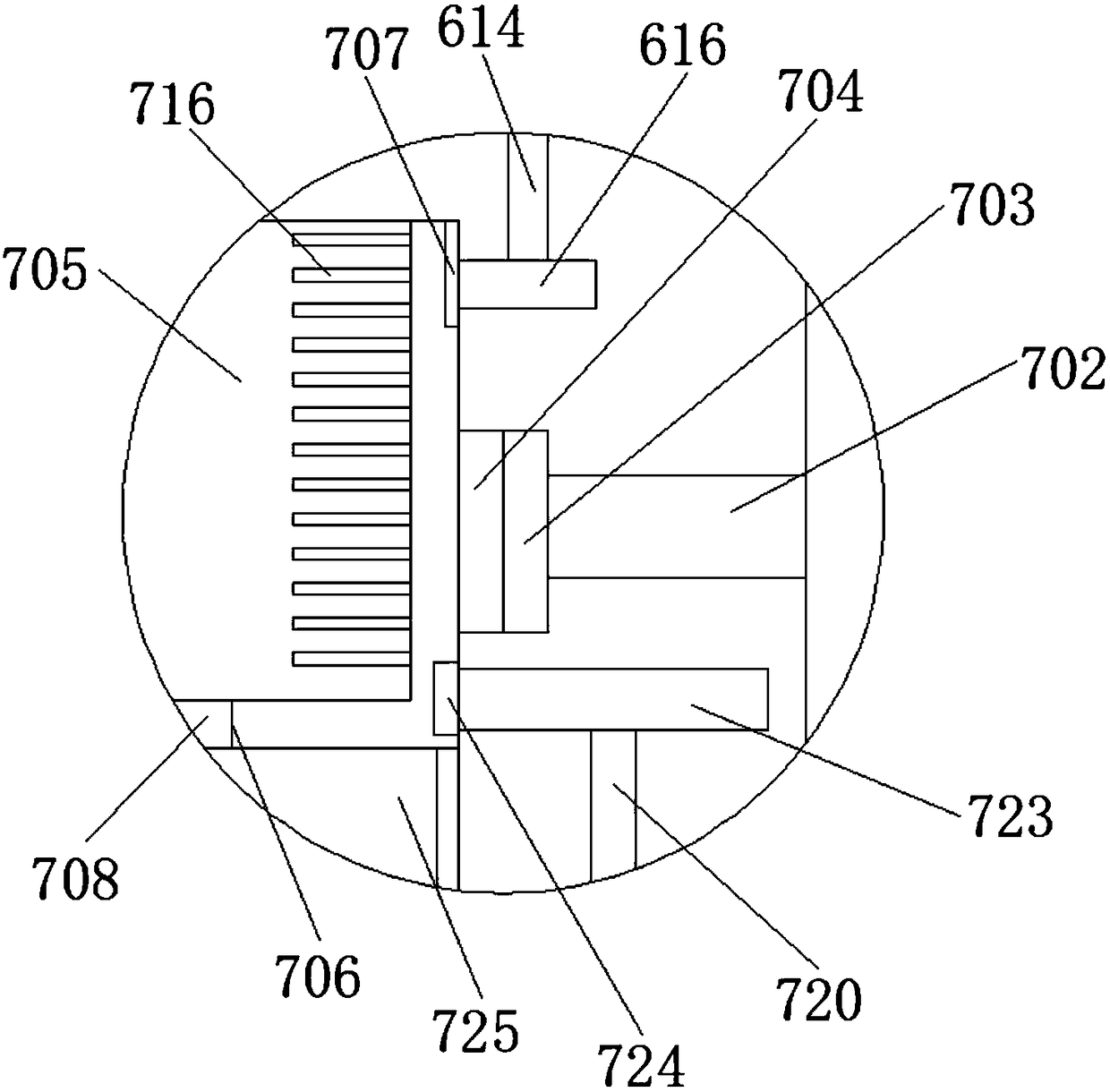

Intelligent shoe cabinet with shoe polishing mechanism

PendingCN112273880AFully intelligentRealize automatic shoe storageWardrobesStorage devicesShoe polishElectric machinery

The invention discloses an intelligent shoe cabinet with a shoe polishing mechanism, and belongs to the technical field of household electromechanical equipment. The intelligent shoe cabinet comprisesa shoe conveying mechanism, a shoe polishing mechanism and a shoe storage cabinet; the shoe conveying mechanism enables shoes to freely move in a three-dimensional space through spiral transmission,the functions of automatic shoe conveying, shoe storage and shoe taking are achieved, the shoe polishing mechanism drives three vertical brushes and three transverse brushes to rotate at the same timethrough two stepping motors, and the automatic shoe polishing function is achieved. The shoe storage cabinet is used for storing shoes, and a touch panel, a PLC module and a Bluetooth control moduleare further installed on the shoe storage cabinet, wherein the PLC module and the Bluetooth control module are used for achieving the intelligent control function. The intelligent shoe cabinet can fully clean vamps and remove dust and stains on the vamps, is very user-friendly, can store multiple pairs of shoes by reserving four shoe placing positions at the first storage layer of the shoe storagecabinet, can sequentially perform automatic dust wiping cleaning and shoe conveying into the shoe storage cabinet for treatment on the multiple pairs of shoes without waiting, and is stable in transmission, low in noise, convenient to manufacture and relatively low in cost.

Owner:NANJING FORESTRY UNIV

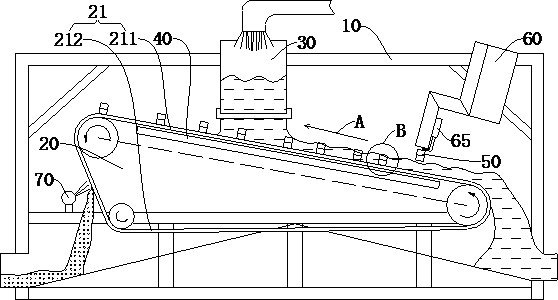

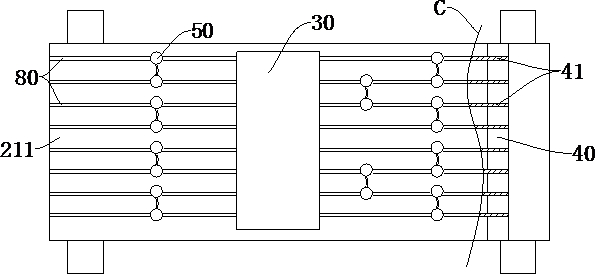

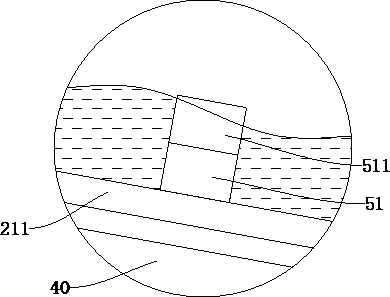

Cooling assembly for cable extrusion production line

PendingCN108454061ASimple structureEasy to useCleaning using toolsInsulating conductors/cablesProduction lineBristle

A cooling assembly for a cable extrusion production line comprises a cooling water tank, a circulating water mechanism and a bubble removing mechanism; a plurality of conveying carrier rollers are arranged in the cooling water tank at intervals in the cable conveying direction, cable through holes are formed in the two ends of the cooling water tank in the cable conveying direction, and the two ends are connected with guide conveying parts respectively; the circulating water mechanism comprises a water inlet pipe, a water outlet pipe, a water storage tank and a water pump; the bubble removingmechanism comprises base blocks and flexible bristles, the base blocks are located in the cooling water tank and between every two conveying carrier rollers, the flexible bristles are arranged on thebase blocks and used for horizontally rubbing with a cable back and forth, and the base blocks are connected with connecting blocks which are connected with connecting rods; each base block is connected with a horizontal reciprocating air cylinder through the corresponding connecting rod or at least two base blocks are connected with one horizontal reciprocating air cylinder through the corresponding connecting rods. The cooling assembly is simple in structure, convenient to use and good in overall cooling effect, the surface of an obtained product is smooth, and the quality is greatly improved.

Owner:FUJIAN TONGYU CABLES

Purifying device for haze particulate matters

The invention relates to a purifying device for haze particulate matters. The purifying device for haze particulate matters comprises a shell device, an air extracting device, a water tank device, a piston device, a filtering device, a purifying device and a lug boss device, wherein the air extracting device is located on the right side of the shell device; the water tank device is located above the shell device; the piston device is accommodated in the shell device; the filtering device is located under the piston device; the purifying device is located under the filtering device; the lug boss device is located under the purifying device. The purifying device for the haze particulate matters can completely purify the haze, has an obvious purifying effect, can completely remove the fine particles, such as, dust, in air, can guarantee the purifying quality of air and can avoid harm to human body.

Owner:GUANGZHOU ZHONGTAN AIR PURIFICATION TECH CO LTD

Paper pulp purification method for producing regenerated paper pulp by using waste paper

ActiveCN108842498AFully clearSolve the problem of reducing paper strengthPaper recyclingCellulose treatment using microorganisms/enzymesDeinkingHigh concentration

The invention discloses a paper pulp purification method for producing regenerated paper pulp by using waste paper. The method comprises the steps of repulpling, performing high-concentration residueremoval, performing coarse screening, performing low-concentration residue removal, performing fine screening, performing low-temperature deinking purification, and performing flotation and purification, wherein deinking purification enzyme is added, so that most of printing ink, lightweight sticking substances and light plastic in the waste paper raw pulp can be separated; due to via hole shear treatment and adoption of the deinking purification enzyme in a low-temperature deinking tank, various impurities in the waste paper pulp can be completely eliminated, the deinking treatment can be conducted under the environment that the temperature is 60 to 70 DEG C instead of the high-temperature environment being 220 DEG C or higher; energy conservation and environmental friendliness are achieved; various deinking preparations are not needed, so that the problem that the deinking preparation can reduce the intensity of paper is solved, clean production is realized and no pollution in the production process is generated.

Owner:DONGGUAN TAICHANG PAPER CO LTD

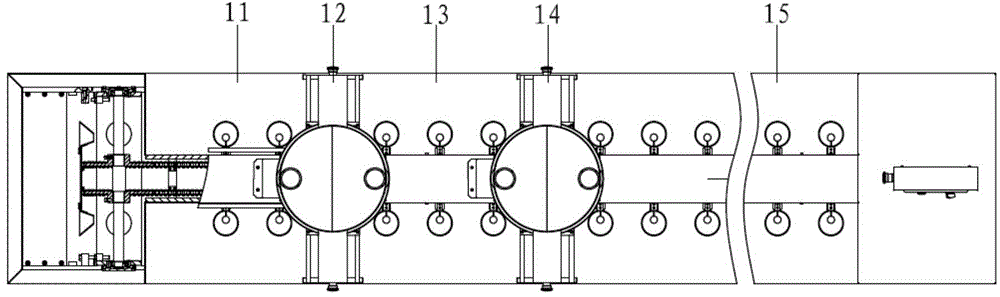

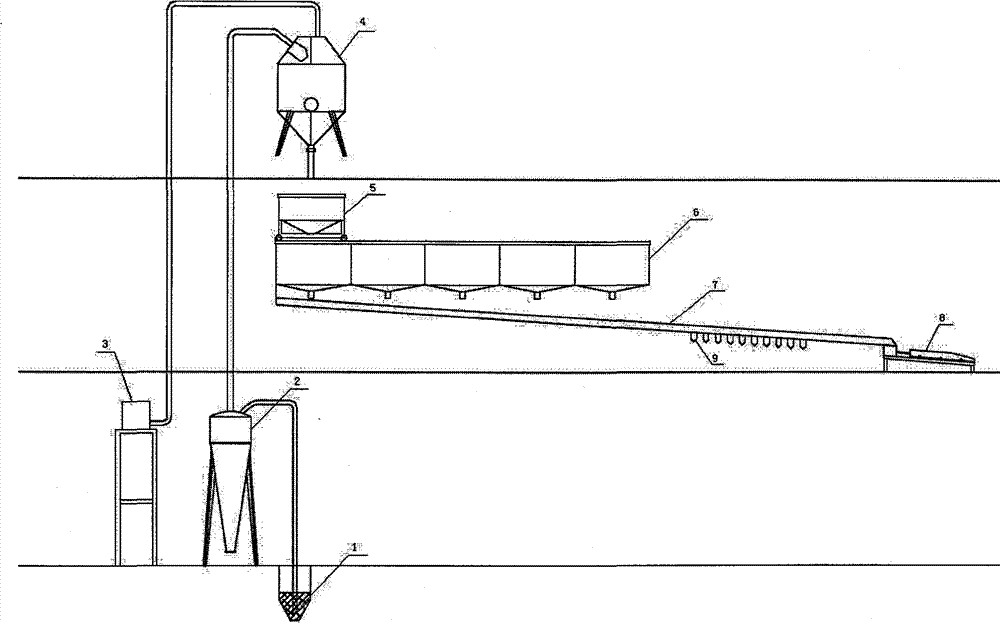

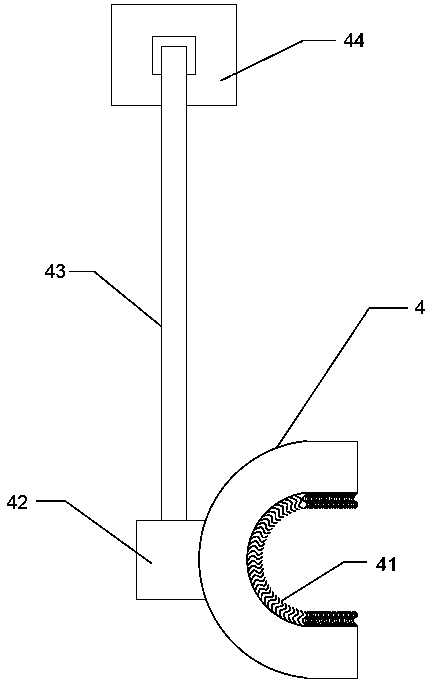

Bean product raw material impurity removing method and device for realizing same

InactiveCN104738796AReduce labor costsReduce pollutionFood treatmentWater resourcesCyclonic spray scrubber

The invention discloses a bean product raw material impurity removing method and a device for realizing the same. The method comprises the steps that vacuum lifting is conducted on raw materials, dry cleaning and impurity removal are conducted during lifting, then the raw materials enter a bean cylinder (4) and are poured into soaking cylinders (6) through a rail conveyer (5) to be soaked for impurity removal, and finally impurity removal is further conducted through a flowing groove (7) provided with a settling pond (9). The device comprises a bean groove (1), a cyclone dust collector (2), the bean cylinder (4), the rail conveyer (5), the soaking cylinders (6), the flowing groove (7) provided with the settling pond (9), and a vacuumizing device (3) used for maintaining vacuum degree, wherein the vacuumizing device (3) is directly connected with the bean cylinder (4), the bean cylinder (4) is directly connected with the cyclone dust collector (2), and a feed inlet of the cyclone dust collector (2) stretches into the bean groove (1). By the adoption of the impurity removing method, the defects of manual operation that bacterium breeding is caused easily and cleaning efficiency is low are overcome, impurity removing efficiency can be improved to 95%, and precious water resources are saved.

Owner:JINHUA FANGXIN VEGETABLE FOOD

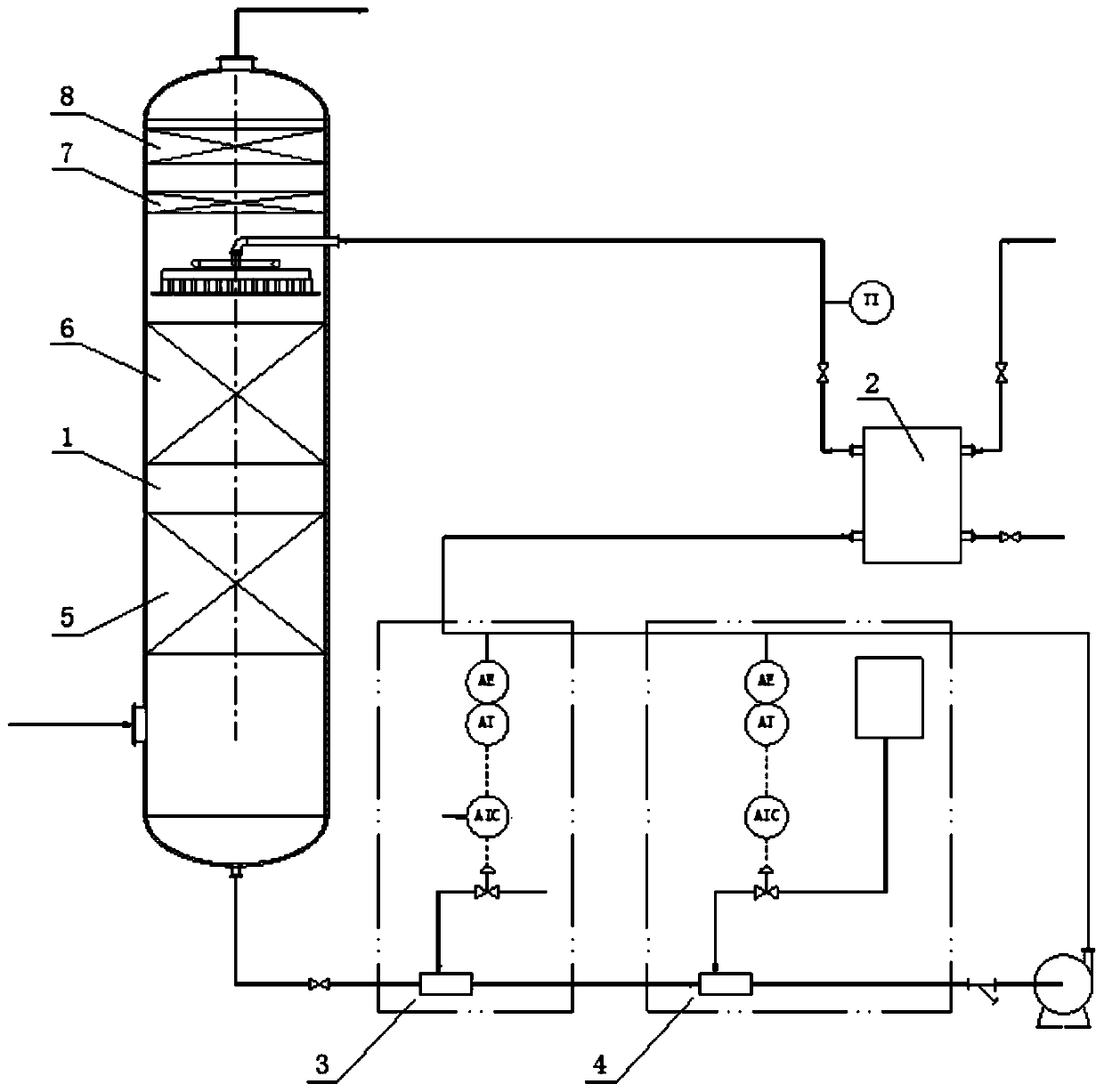

Circulating pretreatment system for carbon dioxide capture of coal-fired power plant

PendingCN109745850AImprove washing efficiencyReduce the content of acid pollutantsCombination devicesAir quality improvementAutomatic controlCarbon dioxide

The invention provides a circulating pretreatment system for carbon dioxide capture of a coal-fired power plant. The circulating pretreatment system comprises a water washing tower, a plurality of filler layer bodies disposed inside the water washing tower and distributed from bottom to top, a circulating water cooler, an automatic alkali adding device and a salinity adjustment device. In the pretreatment system, the combination of the filler layers is adopted to completely remove harmful substances such as dust and SO2 in flue gas, thereby improving the water washing efficiency and achievingthe purpose of reducing the temperature of the flue gas; the automatic alkali adding device and the salinity adjustment device are disposed outside the water washing tower, the alkaline adding amountcan be automatically adjusted according to the pH setting value of the circulating washing water so as to effectively remove the content of acidic substance in the soot, thereby guaranteeing the waterwashing effect of the flue gas; water can be automatically supplemented according to the salinity of the circulating washing water, and scaling due to excessive salinity is prevented. The circulatingpretreatment system for carbon dioxide capture of the coal-fired power plant is high in water washing efficiency and good in cooling effect, and automatic control of the pH value and salinity in circulating washing water is realized.

Owner:广东南方碳捕集与封存产业中心 +2

Cleaning and disinfecting device for inspection equipment

InactiveCN110935679ASave human effortSimplify the operation processDiagnosticsSurgeryWater pipeSewage

The invention discloses a cleaning and disinfecting device for inspection equipment. The cleaning and disinfecting device comprises a box body, wherein a mounting frame is fixedly mounted on the innerside of the top end of the box body; a water tank is placed on the mounting frame, the top end of the water tank is communicated with a water inlet pipe; the water inlet pipe penetrates through the top box wall of the box body; an annular groove is formed in the bottom end of the mounting frame; and an annular water pipe is fixedly mounted in the annular groove. According to the cleaning and disinfecting device, medical instruments are placed in a placing net capable of freely lifting, blood on the medical instruments is washed away through the spraying effect of a water spraying head, then sewage is discharged, the medical instruments in the placing net are soaked in a cleaning solution of a cleaning box, dirt on the medical instruments is fully removed through the spraying effect of thewater spraying head and the air spraying effect of an aeration spray head, then the cleaning solution in the cleaning box can be completely discharged, the medical instruments are dried through the air spraying effect of the aeration spray head, and the disinfection effect of an ultraviolet lamp is combined, so that the medical instruments are fully and sanitarily cleaned. The device is beneficial to saving manpower and simplifying the operation process.

Owner:许绘

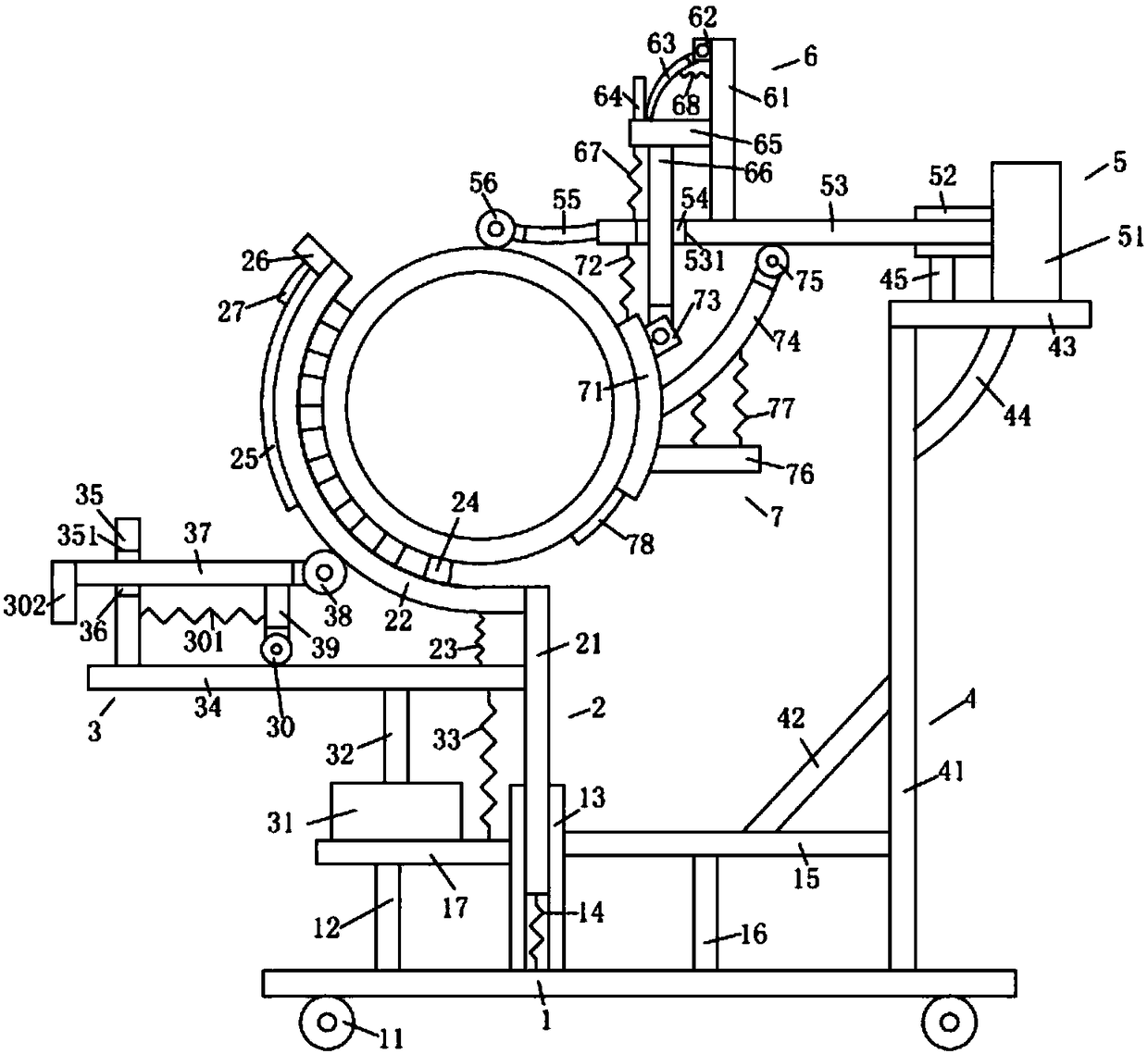

Novel efficient metal pipe outer wall polishing rust-removing device

ActiveCN108581659AFully clearIncrease pressureRevolution surface grinding machinesGrinding drivesMetalRust

The invention relates to a novel efficient metal pipe outer wall polishing rust-removing device which comprises a base plate, a first polishing device arranged on the base plate, a first electric cylinder device, a supporting device, a second electric cylinder device arranged on the supporting device, a connecting device arranged on the second electric cylinder device and a second polishing devicearranged on the connecting device. By means of the device, a metal pipe can be sufficiently polished, and the rust removing effect is good; an elastic plate and a polishing block are arranged, and therefore pressure across the polishing block and the pipe can be increased, it can be guaranteed that iron rust on the outer wall of the pipe can be effectively removed through the polishing block, thebent elastic plate and the polishing block are matched with a rotational polishing plate relatively to achieve clamping on the pipe, the pressure of the polishing block and the polishing plate on thepipe can be increased, iron rust on the pipe can be sufficiently removed, operation is simple, and the device is suitable for application and popularization.

Owner:张雪媚

Cleaning method of fresh tea

InactiveCN106798030AEnsure health and hygieneEnsure safetyPre-extraction tea treatmentSaline waterFiber

The invention provides a cleaning method of fresh tea, and relates to the technical field of tea processing. The method comprises the following steps: screening new tea, carrying out primary cleaning, disinfecting with light salt brine, removing scales with wheat flour, carrying out low-temperature precooling and degerming, refining and separating. The method thoroughly solves the problem of cleaning after the tea is picked, can sufficiently remove dust and pesticide residues left in the tea planting process, can not destroy the fiber textures of the tea in the cleaning process, and ensures the subsequently prepared tea to be healthy, clean and safe. The method is simple, and has obvious effects.

Owner:安徽省石台县日新茶叶实业有限公司

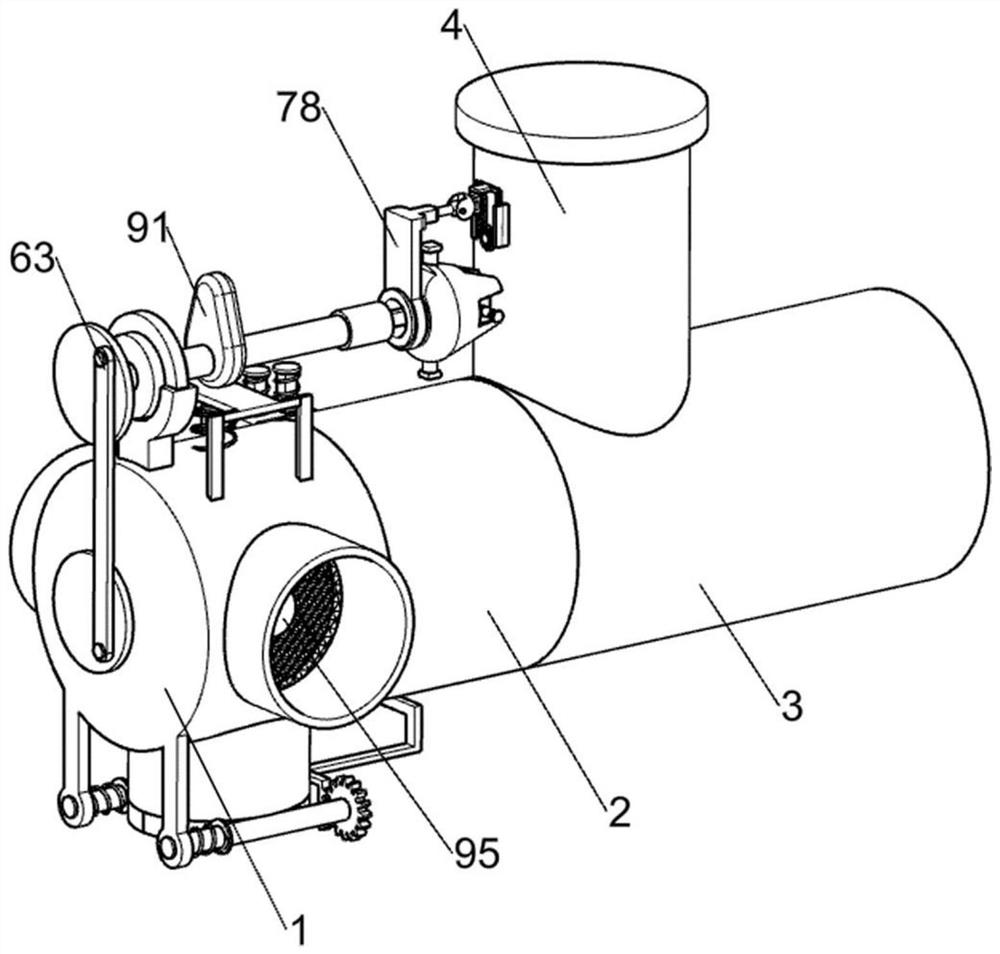

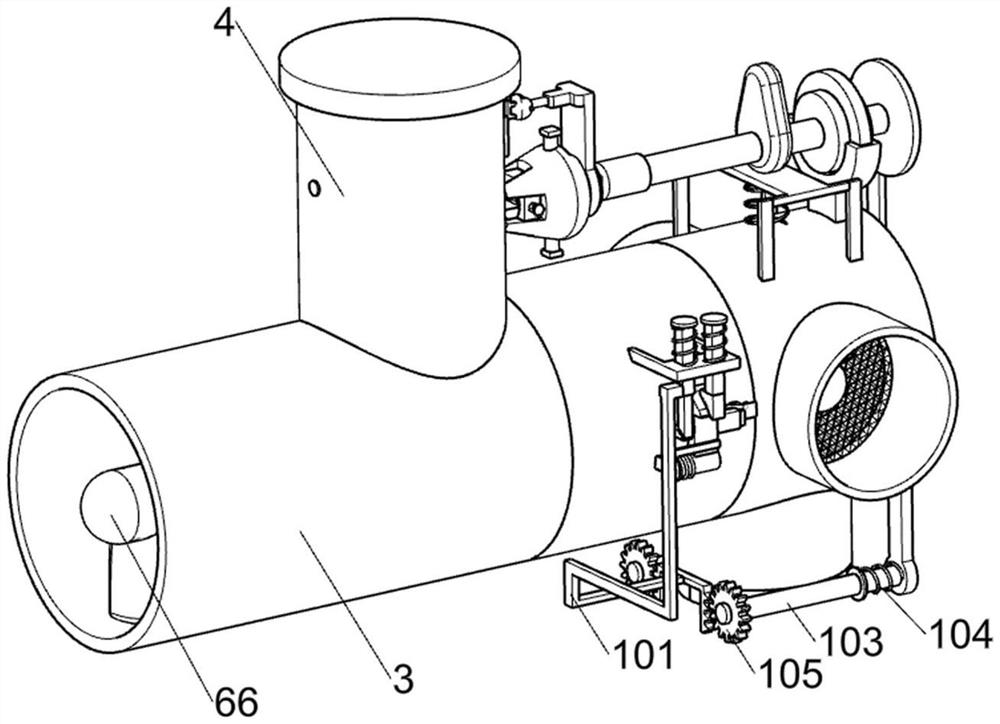

Comprehensive preparation equipment and method for weakly magnetic minerals

ActiveCN113843040AStrong magnetismLarge adsorption surface areaMagnetic separationCleaning using liquidsWater flowEngineering

The invention belongs to the technical field of mineral separation, and discloses comprehensive mineral separation equipment for weak magnetic minerals. The equipment comprises a rack, and a conveying device, a material uniformizing device, a magnetic plate, a distributing device and a spraying device which are mounted on the rack, and further comprises a magnetic conducting piece and a distributing device. The magnetic conducting piece comprises a fixing part, and the fixing part is provided with an extending structure extending upwards, and / or , the magnetic conducting part is provided with a flow guide part extending transversely, a strong magnetic part can attract the fixed part of the magnetic conducting part to the surface of an upper-layer belt, and the upper-layer belt can drive the strong magnetic part to move in the material guiding direction of an iron unloading belt. The distributing device and the material uniformizing device are sequentially installed on the rack in the material guiding direction of the iron unloading belt, the distributing device is provided with a discharging port facing the iron unloading belt, the distributing device is provided with a storage cavity for storing the magnetic conduction piece, the storage cavity communicates with the discharging port, and the magnetic conducting part can move to the surface of the upper-layer belt through the discharging port. Magnetic minerals carried up by water flow on the surface of the iron unloading belt can be effectively adsorbed and removed, so that weak magnetic minerals are screened more thoroughly.

Owner:WEIFANG BAITE MAGNET TECH CO LTD

Soot processing device

InactiveCN101607161AEasy to moveEasy to separateUsing liquid separation agentCombustion technology mitigationEngineeringThermal water

The invention relates to environment-friendly equipment, in particular to a device for processing soot of a boiler. The device is characterized by being provided with a clapboard which divides a water tank into an upper box body and a lower box body; the clapboard is provided with a plurality of through holes; the inside of the upper box body is provided with a smoke gas pipe; two ends of the smoke gas pipe after being bended are connected with the through holes of the clapboard respectively; the lower part of the clapboard is provided with an isolation plate for isolating two ports of the smoke gas pipe; a smoke gas inlet pipe and a smoke gas outlet pipe are connected with the through holes of the clapboard respectively; the device adopts a forced ventilation and multilevel processing mode to carry out heat exchange and cleaning on the soot; the exchanged hot water can be used for heating, bathing and the like; the processed soot is innocuous, colorless and tasteless, has the advantages of high heat exchange efficiency, energy saving, environmental protection, convenient operation, convenient mounting, safe operation and the like and is particularly suitable for processing the soot of a coal burning boiler.

Owner:奉日明

Snow plowing device for road engineering field

A snow plowing device for the road engineering field comprises a holding device, a motor device, a fan device, a filtering device, a connecting device and a scraping device, wherein the motor device is arranged on the holding device; the fan device is arranged on the motor device; the filtering device is arranged on the fan device; the connecting device is arranged on the filtering device; and thescraping device is arranged on the connecting device. According to the snow plowing device for the road engineering field, ices and snows on a road within a small area can be sufficiently cleared; the snow plowing effect is obvious; as the ices and snows are melted by being heated and then are scraped by using scraping teeth, the ices and snows on the road surface are completely cleared; the snowplowing is fast, the snow plowing efficiency is high; the snows do not need to be piled to one side; the labor intensity is low; the structure is simple; and the operation is convenient.

Owner:广州贤智科技有限公司

Kiwi fruit no-injury hair removing equipment

The invention belongs to the technical field of food processing mechanisms, and discloses kiwi fruit no-injury hair removing equipment. The kiwi fruit no-injury hair removing equipment comprises a machine housing, wherein the lower surface of a feeding ring is fixedly connected to the upper surface of the machine housing; an annular groove is formed in the upper surface of the feeding ring; inletsare respectively formed in the left side and the right side of the bottom wall of the annular groove; a material opening is formed in the position corresponding to each inlet, on the top wall of themachine housing; a fed material preprocessing mechanism is arranged on the upper side of the inner part of the machine housing; and a disk type brushing and removing mechanism is arranged on the lowerside of the inner part of the machine housing. According to the kiwi fruit no-injury hair removing equipment disclosed by the invention, the fed material preprocessing mechanism is arranged, so thatin the feeding process of kiwi fruits, preprocessing hair removing can be performed, quick hair removing is realized through the gravity and the rotation of a connecting ring, and the kiwi fruit no-injury hair removing equipment is simple in structure.

Owner:杨国宝

Combinational cooling apparatus of cable extrusion molding line

Disclosed is a combinational cooling apparatus of a cable extrusion molding line. The combinational cooling apparatus comprises a cooling water channel, a circulation water mechanism, a bubble removing mechanism and an air cooling mechanism; multiple conveying support rollers are arranged in the cooling water channel in the cable conveying direction at intervals; cable connecting ports are formedin the two ends, in the cable conveying direction, of the cooling water channel, and the two ends are also connected with guiding and conveying parts respectively; the circulation water mechanism comprises a water inlet pipe, a water outlet pipe, a water storage tank and a water pump; the bubble removing mechanism comprises base blocks positioned in the cooling water channel and between adjacent two conveying support rollers, and flexible brush bristles arranged on the base blocks and used for wiping cables horizontally in a reciprocating manner; the base blocks are connected with connecting blocks; the connecting blocks are connected with connecting rods; each base block is connected with a horizontal reciprocating air cylinder through the corresponding connecting rod, or at least two base blocks are jointly connected with one horizontal reciprocating air cylinder through the corresponding connecting rods; and the air cooling mechanism comprises a cylinder with a hollow body interiorand a fan. The combinational cooling apparatus is simple in structure, convenient to use and excellent in overall cooling effect, the obtained product is bright and clean in surface, and the quality is highly improved.

Owner:FUJIAN TONGYU CABLES

Impeller type water suction pump suitable for shallow rivers and easy to clean

The invention relates to an impeller type water suction pump, in particular to an impeller type water suction pump suitable for shallow rivers and easy to clean. The impeller type water suction pump comprises a multi-port water pump pipe, a water pump connecting pipe, a perforated water pump pipe, a perforated pipe with a cover, a motor supporting frame and the like, one end of the multi-port water pump pipe is fixedly connected with the water pump connecting pipe, one end of the water pump connecting pipe is fixedly connected with the perforated water pump pipe, the perforated water pump pipe is fixedly connected with the perforated pipe with the cover, and the top face of the multi-port water pump pipe is fixedly connected with the motor supporting frame. A cam is driven to continuously rotate through a filtering and brushing mechanism and a rotating shaft, so that a four-corner connecting plate and devices on the four-corner connecting plate do up-and-down reciprocating motion, a brush does up-and-down reciprocating motion to brush a second filter plate, and garbage and impurities on the second filter plate are fully removed.

Owner:吴福根

Treatment device for concentrated landfill leachate

ActiveCN112028349AFully clearAffect normal workSpecific water treatment objectivesWater/sewage treatment with mechanical oscillationsSewage treatmentElectrochemistry

The invention belongs to the technical field of sewage treatment equipment, and particularly relates to a treatment device for concentrated landfill leachate. The treatment device comprises a tank body, wherein the tank body is provided with an ultrasonic treatment tank and an electrochemical treatment tank; a liquid inlet pipe and a liquid outlet pipe are mounted on the tank body; an ultrasonic generator is mounted on the bottom surface of the ultrasonic treatment tank; a rotating shaft is mounted in the ultrasonic treatment tank; a pushing blade is mounted on the rotating shaft; the pushingblade is just over the outlet, in the ultrasonic treatment tank, of the liquid inlet pipe; a defoaming plate is mounted on the rotating shaft; polar plates are mounted in the electrochemical treatmenttank; and the polar plates are composed of a negative plate and a positive plate which are respectively communicated with the positive electrode and the negative electrode of a power supply. The device is simple in structure, convenient to use, good in treatment effect and high in treatment efficiency.

Owner:ANHUI QINGYANG WATER TREATMENT EQUIP TECH CO LTD

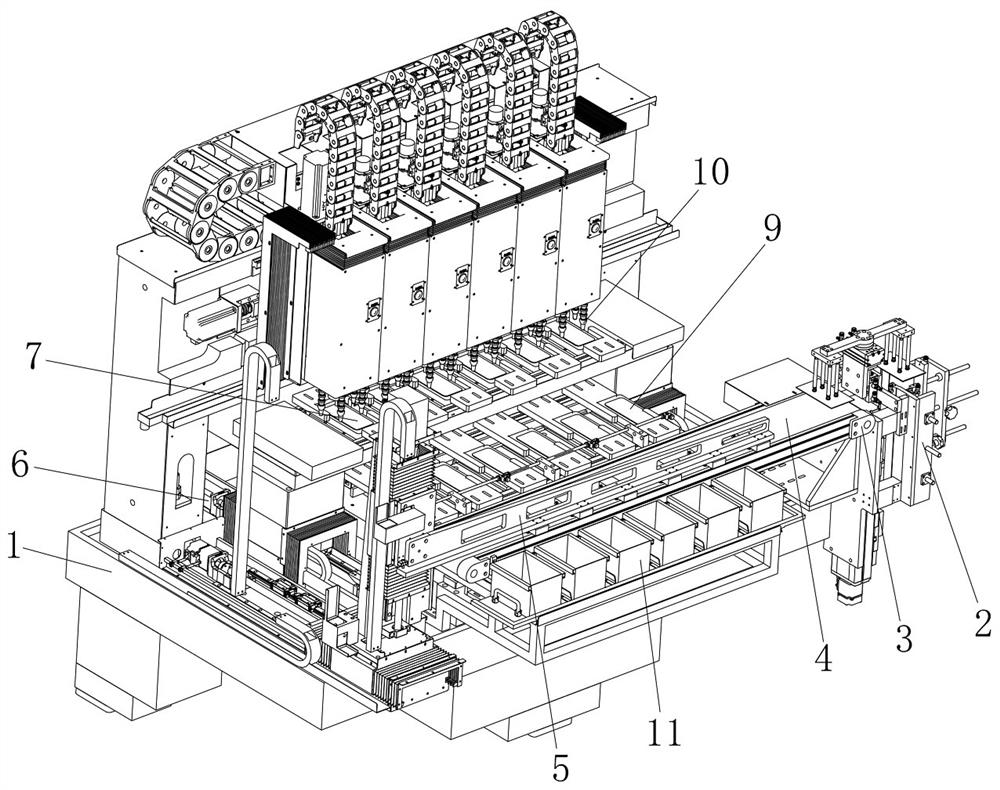

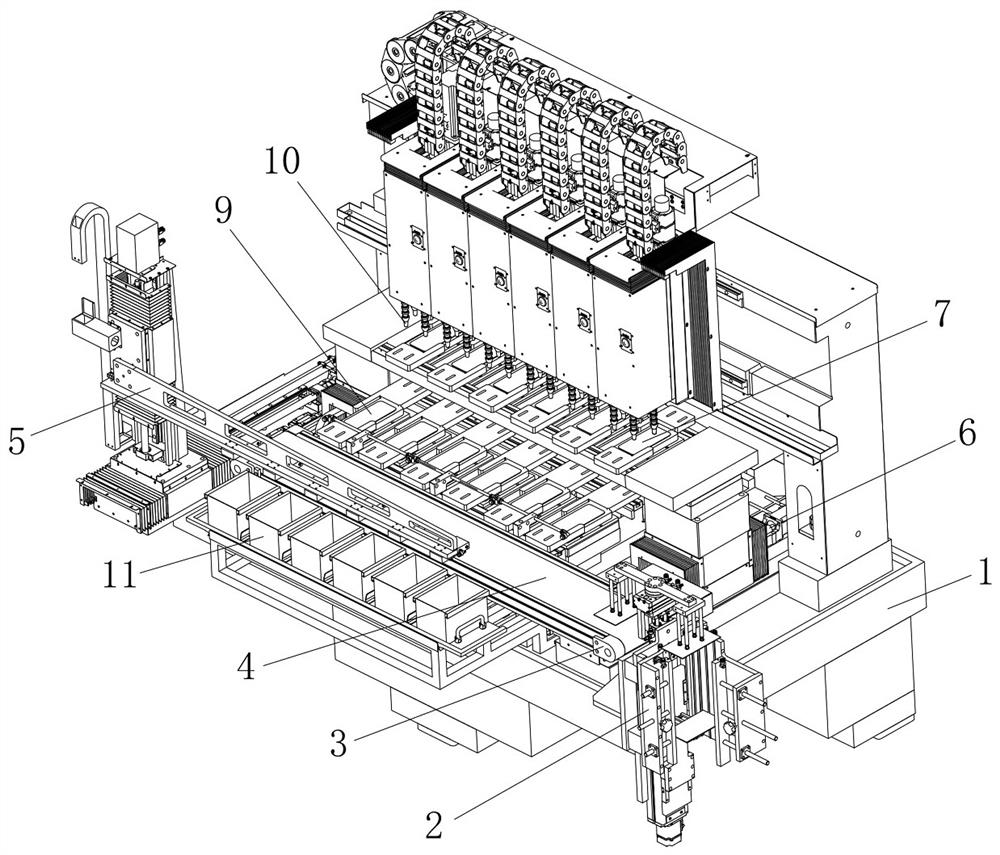

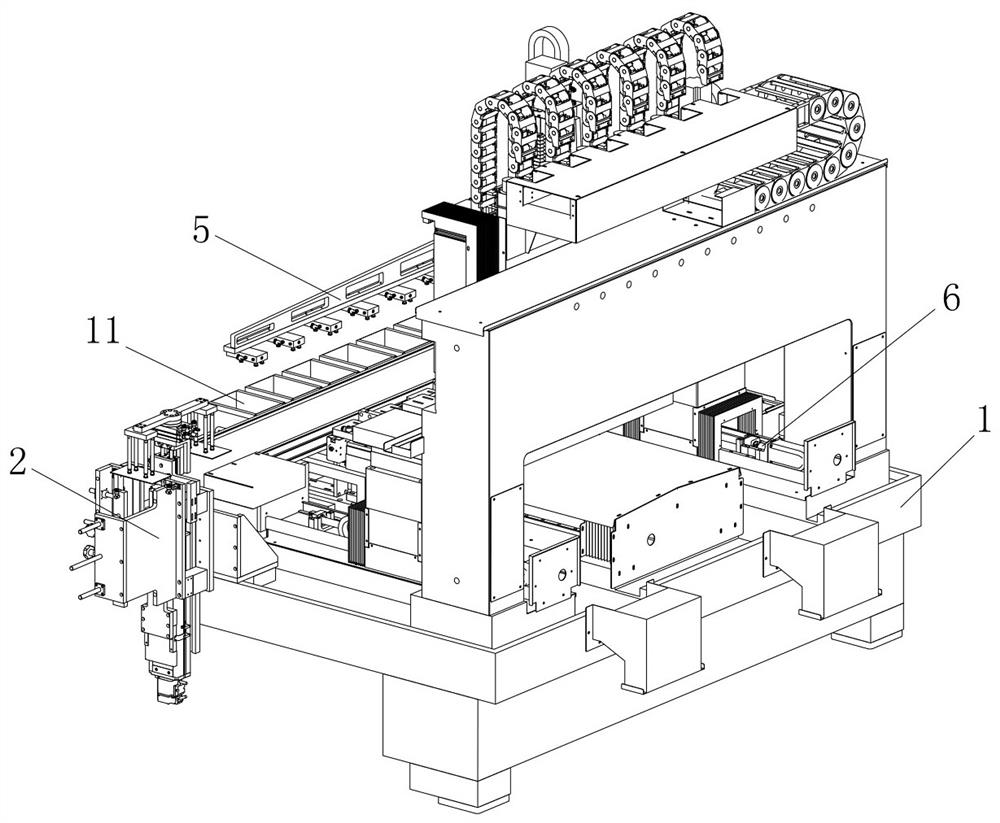

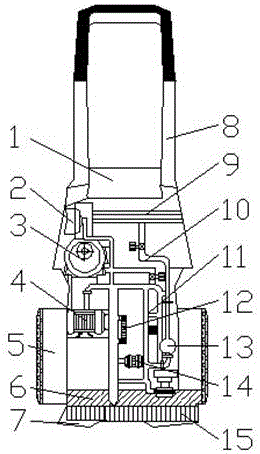

Full-automatic mobile phone curved screen engraving and milling machine and engraving and milling process thereof

PendingCN112388458AReduce standby timeImprove work efficiencyCharge manipulationGrinding machinesEngravingRobot hand

The invention discloses a full-automatic mobile phone curved screen engraving and milling machine and an engraving and milling process thereof. The full-automatic mobile phone curved screen engravingand milling machine comprises a machine table, a lifting feeding mechanism, a conveying mechanism, a mechanical arm, a material platform, an engraving and milling head and a discharging box; the lifting feeding mechanism is arranged at one corner of the machine table and comprises a lifting assembly, a limiting assembly and a feeding assembly; the conveying mechanism is arranged on the side portion of the lifting feeding mechanism; the engraving and milling head is arranged at the rear side of the conveying mechanism; the material platform is arranged between the conveying mechanism and the engraving and milling head; a carrier is arranged on the material platform; the material platform comprises an upper-layer material platform and a lower-layer material platform, and the upper-layer material platform and the lower-layer material platform alternately receive materials from the conveying mechanism and then feed the materials to the position below the engraving and milling head; the discharging box is arranged at the front side of the conveying mechanism; and the mechanical arm is arranged among the material platform, the conveying mechanism and the discharging box in a striding manner. By means of the full-automatic mobile phone curved screen engraving and milling machine, automatic circulating feeding is achieved, the materials of different specifications are limited, air is blown while the materials are lifted to prevent material lamination, and chippings generated after engraving and milling of the materials can be removed.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

Self walking type agricultural grass cutting machine

InactiveCN106258177AMaximize working timeImprove work efficiencyMowersAgricultural engineeringAlternating current

The invention discloses a self walking type agricultural grass cutting machine, which comprises a touch control screen, a heat radiation opening, a transmission device, a motor, a walking wheel, a regulator, a protection device, an armrest, a forage box, a connecting pipe, a motor, a lifting mechanism, a pressure meter, a voltage stabilizer and a cutting device, wherein the forage box is fixedly arranged under the touch control screen; the regulator is arranged under the motor; the regulator is arranged inside the walking wheel; the walking wheel is fixed above the protection device; the touch control screen is arranged under the armrest; the forage box is connected with the motor through the connecting pipe; the motor is fixed at the left end of the lifting mechanism; the pressure meter is connected with the pressure stabilizer through the connecting pipe; the regulator is arranged above the cutting device. The self walking type agricultural grass cutting machine is provided with an alternating current motor; the self walking type agricultural grass cutting machine can work by using an alternating current power supply; the maximum work time of the grass cutting machine can be ensured, so that the work efficiency of a user is improved; the requirements of people can be met.

Owner:滁州新源农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com