Full-automatic mobile phone curved screen engraving and milling machine and engraving and milling process thereof

A curved screen and engraving machine technology, applied in the direction of manufacturing tools, conveyor objects, grinding feed movement, etc., can solve the problems of resource consumption, reduce equipment efficiency, and low engraving efficiency, so as to improve work efficiency and reduce The effect of standby time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing:

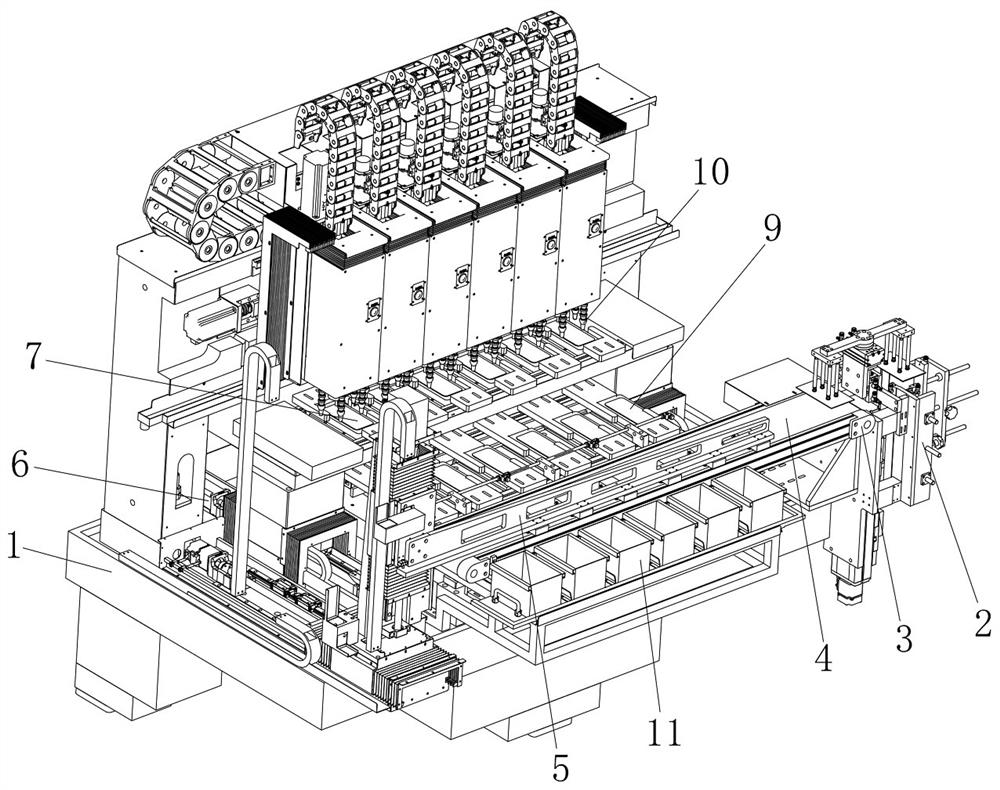

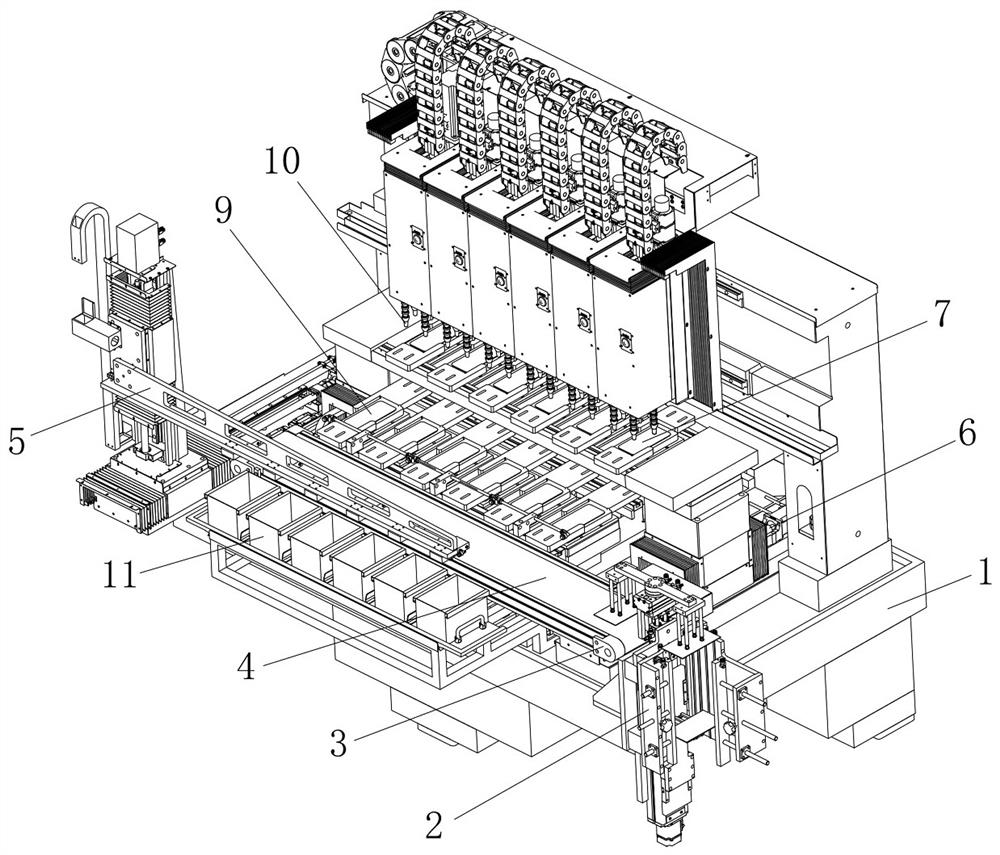

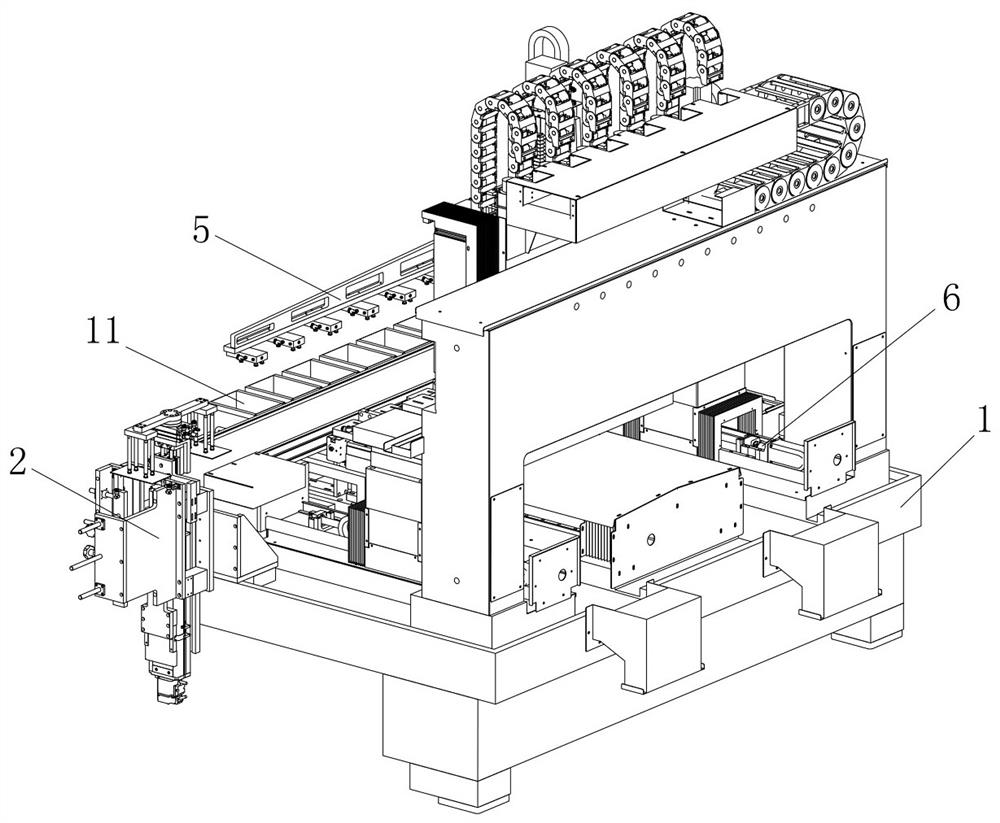

[0053] Such as Figure 1 to Figure 22 As shown, the technical scheme adopted by the present invention is as follows: a fully automatic curved screen engraving machine for mobile phones, including machine table, lifting feeding mechanism, transmission mechanism, manipulator 5, material platform, engraving head and discharge box; wherein, the above The lifting and feeding mechanism 2 is set at a corner of the machine platform 1, and the lifting and feeding mechanism includes a lifting component, a limit component and a feeding component; the above-mentioned transmission mechanism is set on the side of the lifting and feeding mechanism 2; the above-mentioned engraving head 10 is set at the rear of the transmission mechanism side; the above-mentioned material platform is set between the transmission mechanism and the engraving head 10; a carrier is arranged on the material plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com