Patents

Literature

59results about How to "Avoid lamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

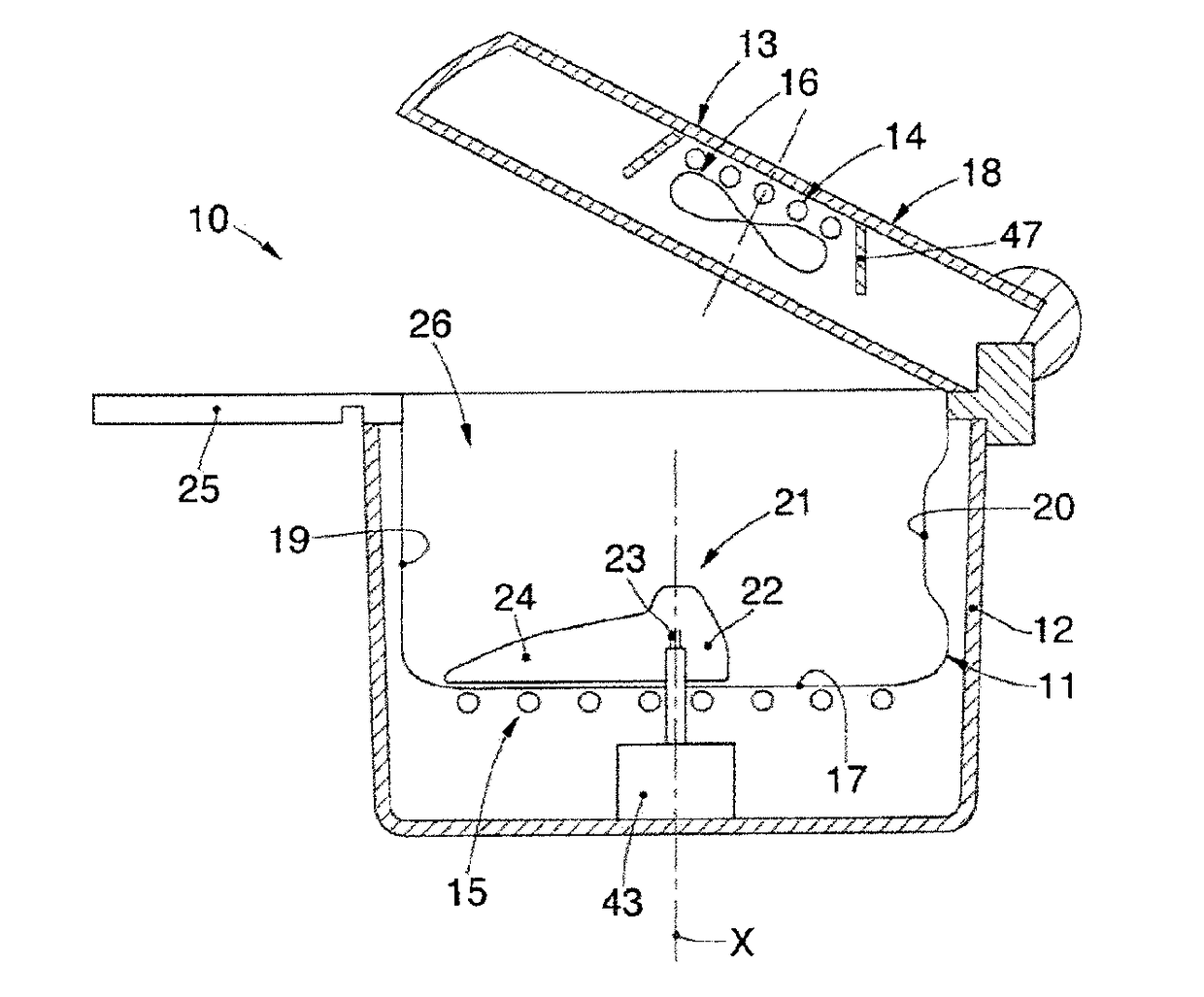

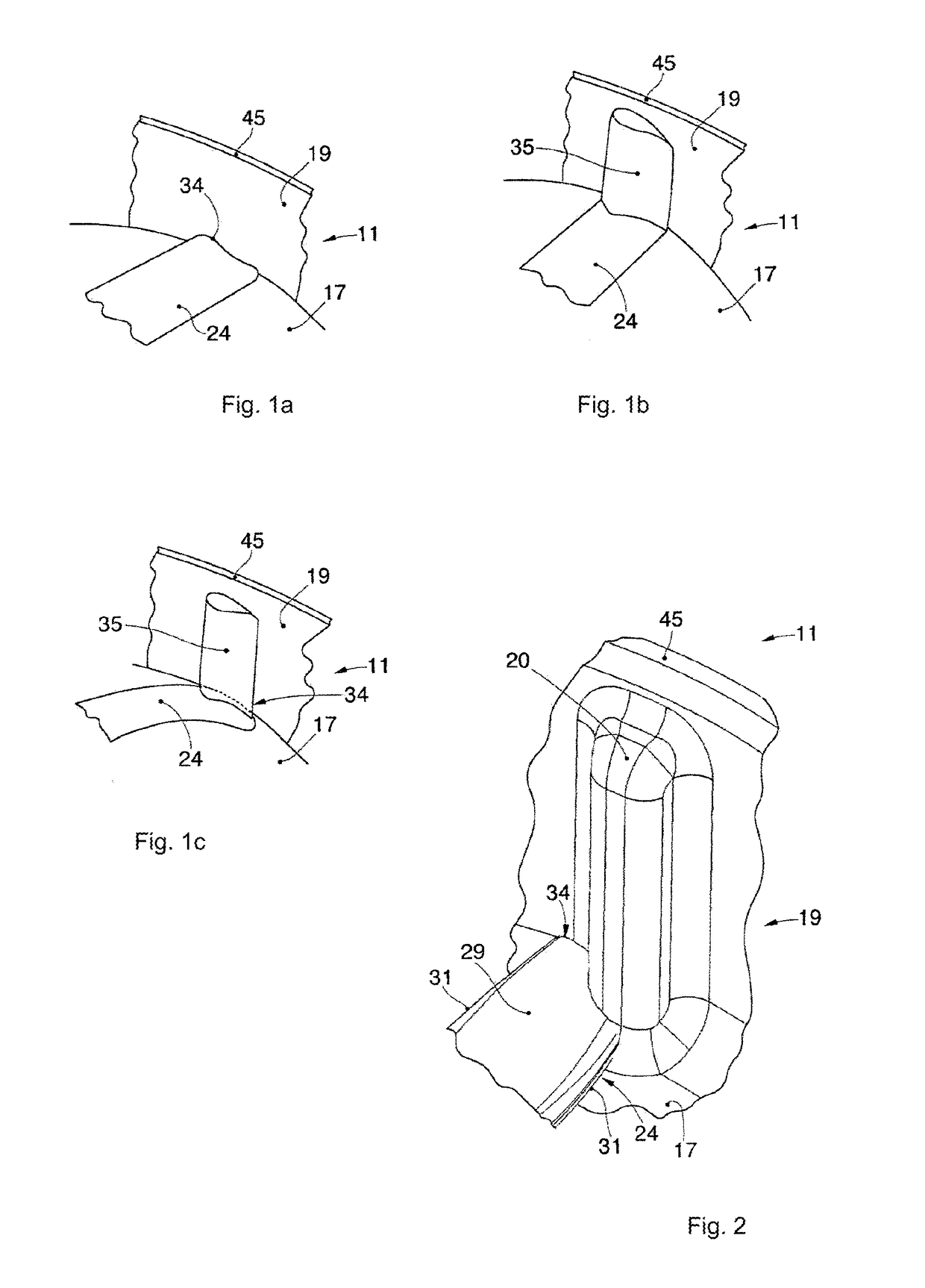

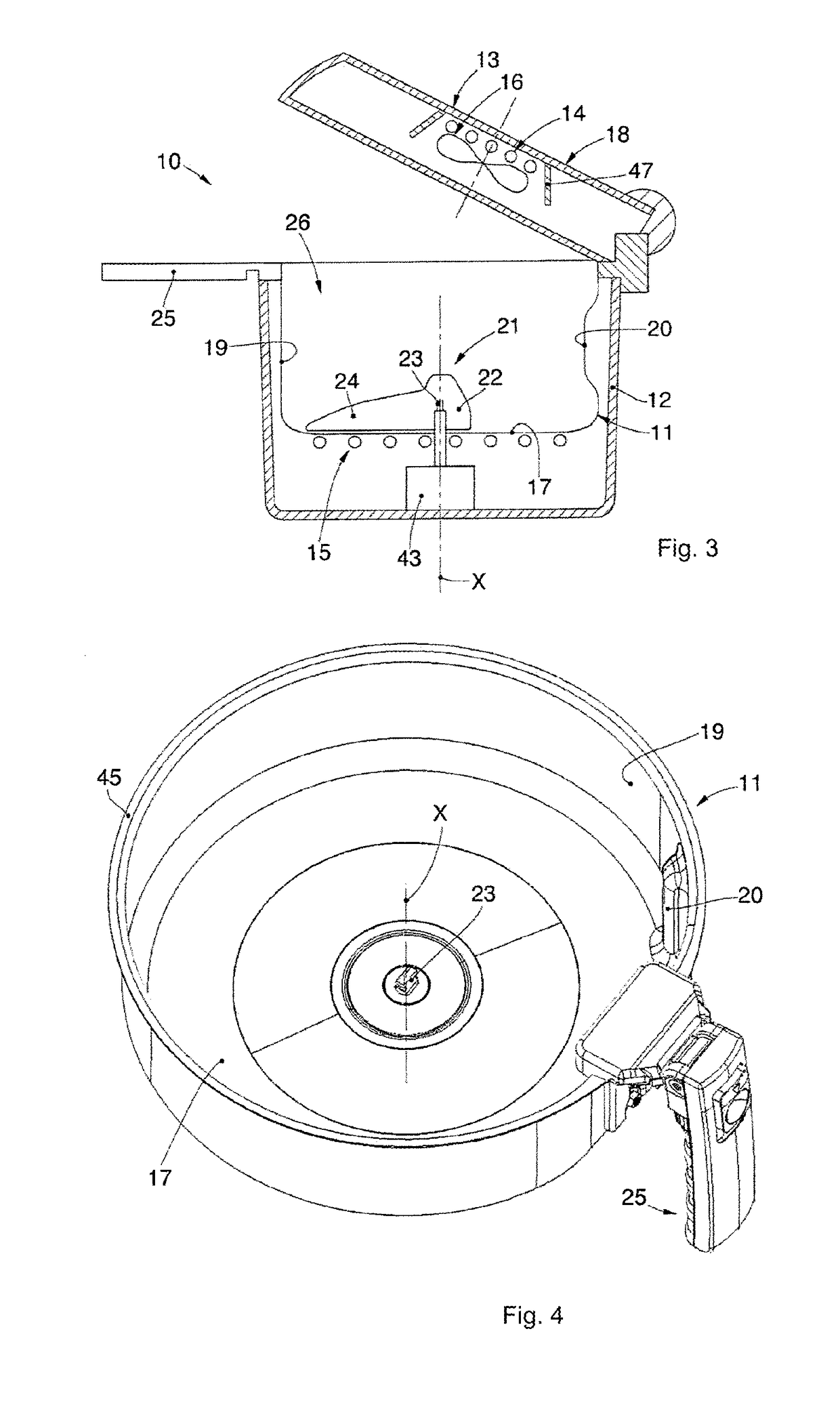

Apparatus for Cooking Foods

ActiveUS20180184848A1Avoid laminationRisk of breakdownRotary stirring mixersTransportation and packagingEngineeringIngested food

Owner:DELONGHI APPLIANCES S R L CON UNICO SOCIO

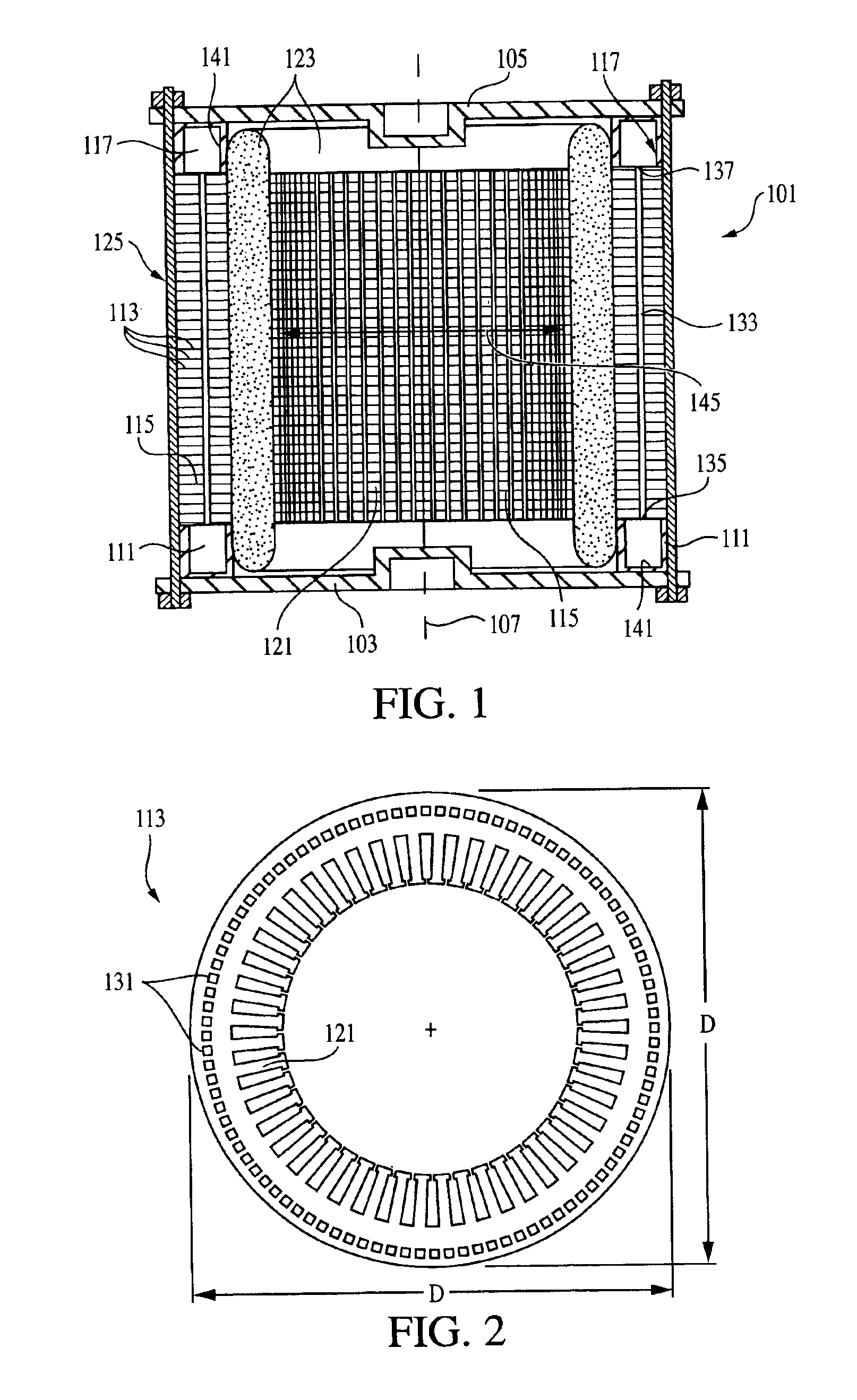

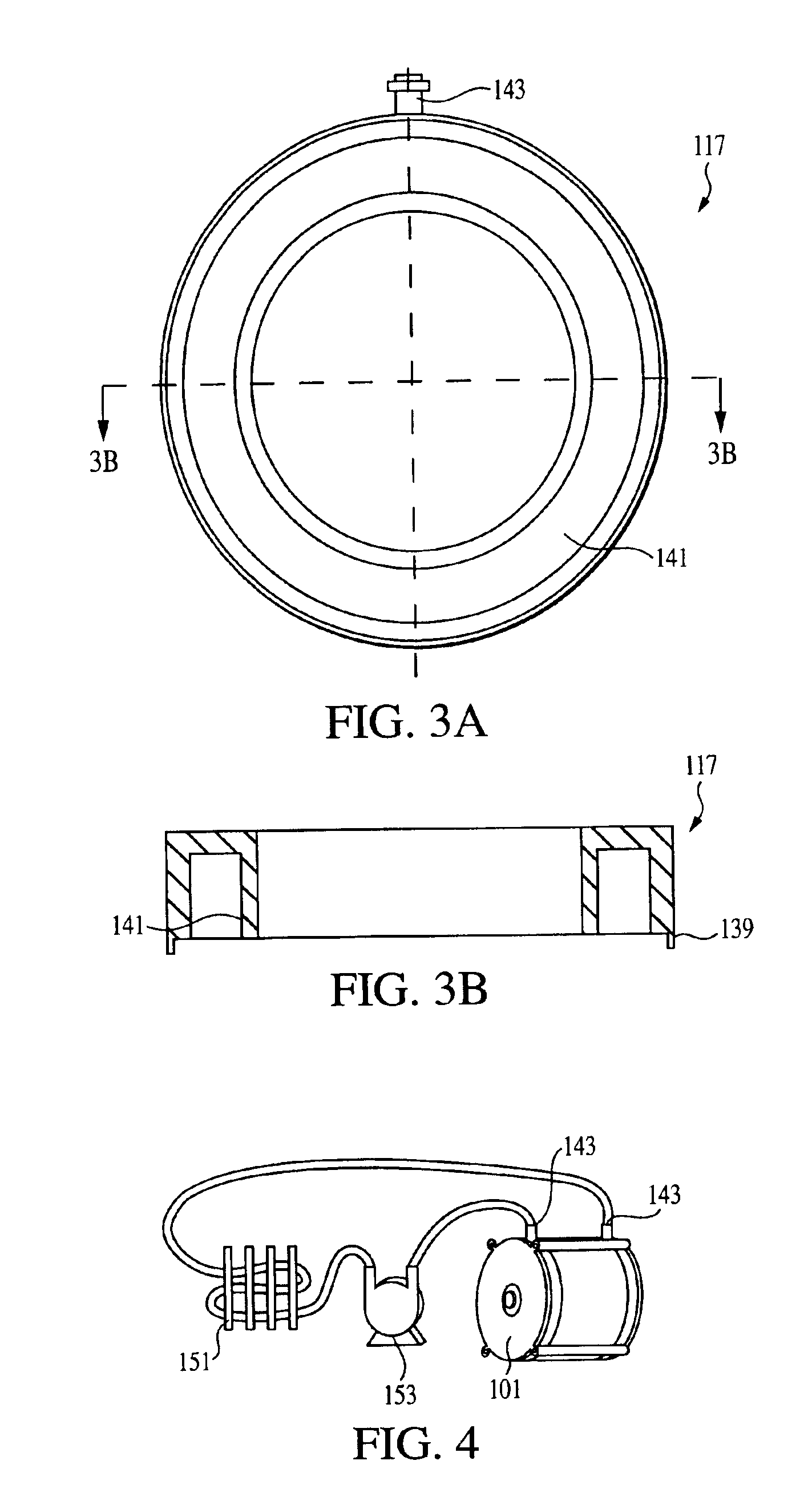

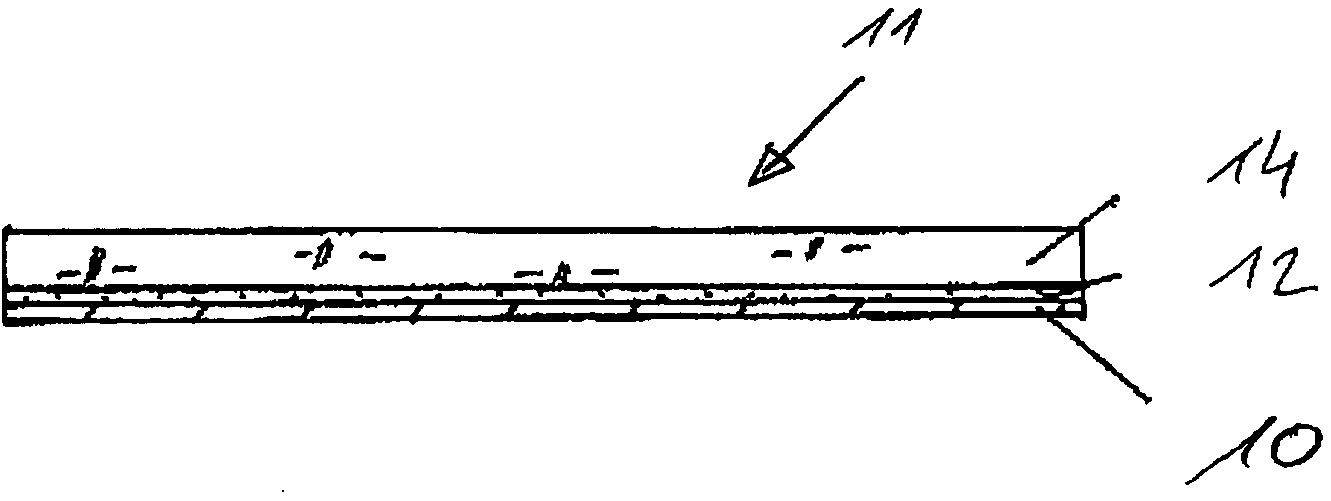

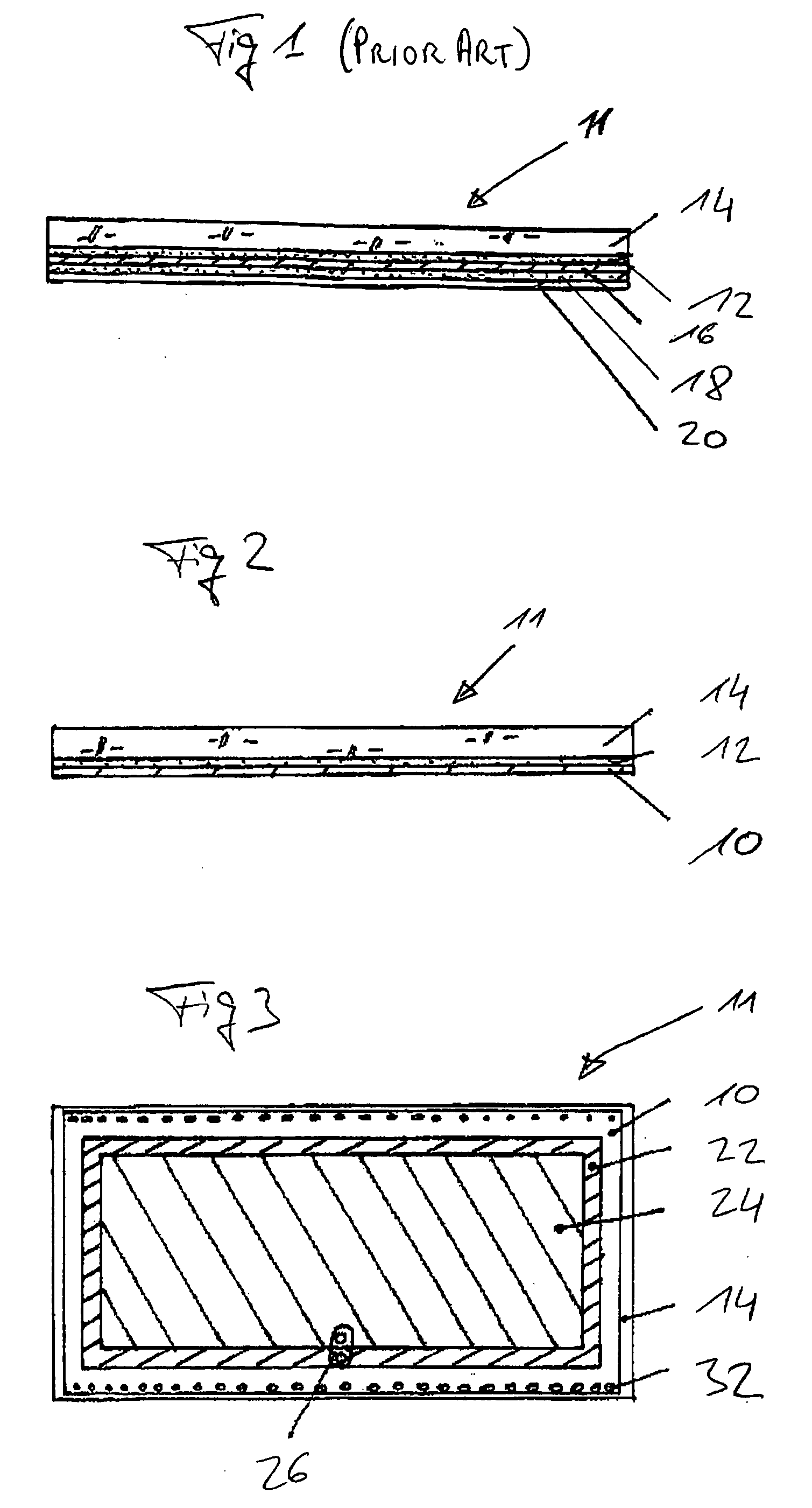

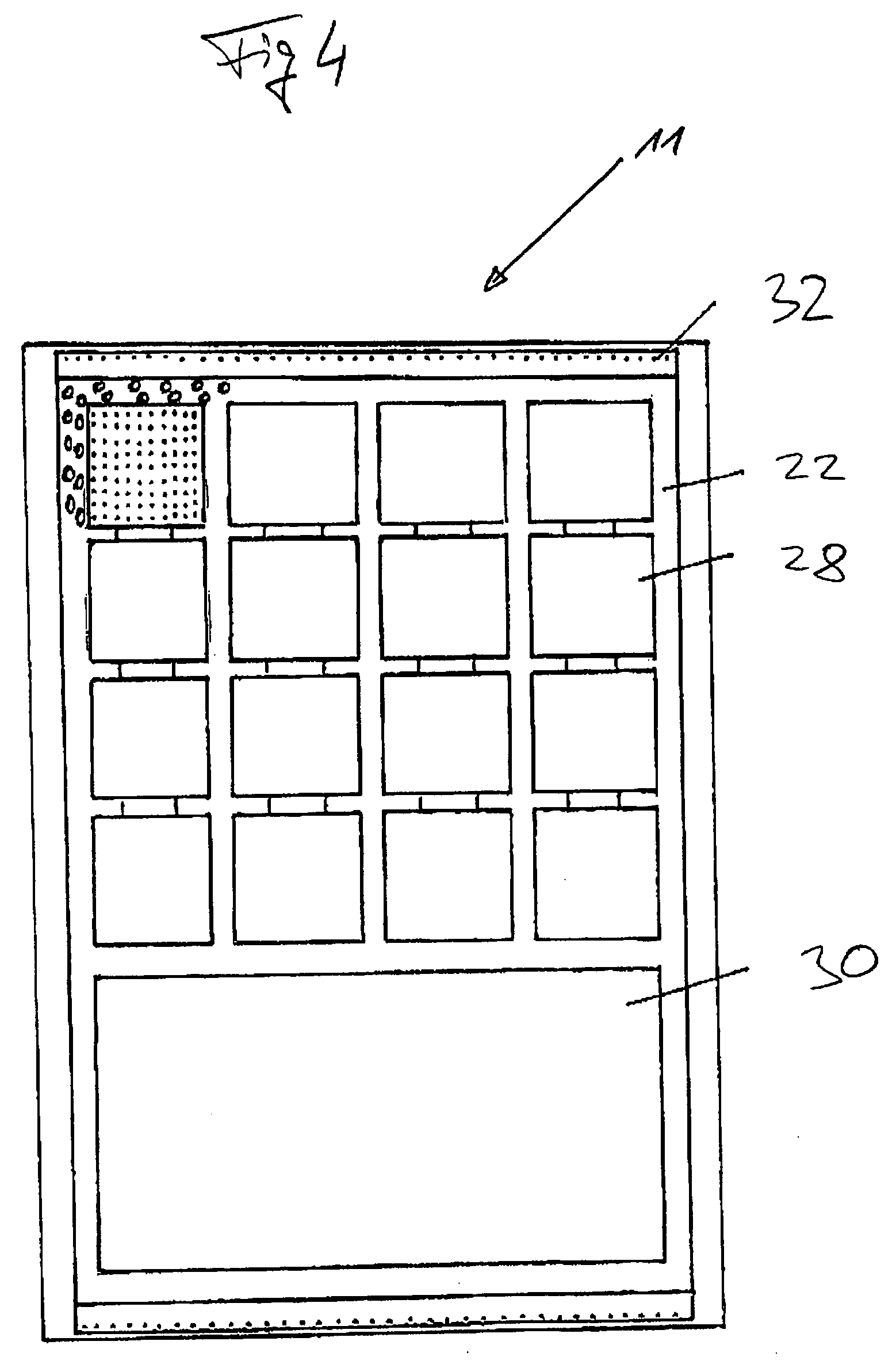

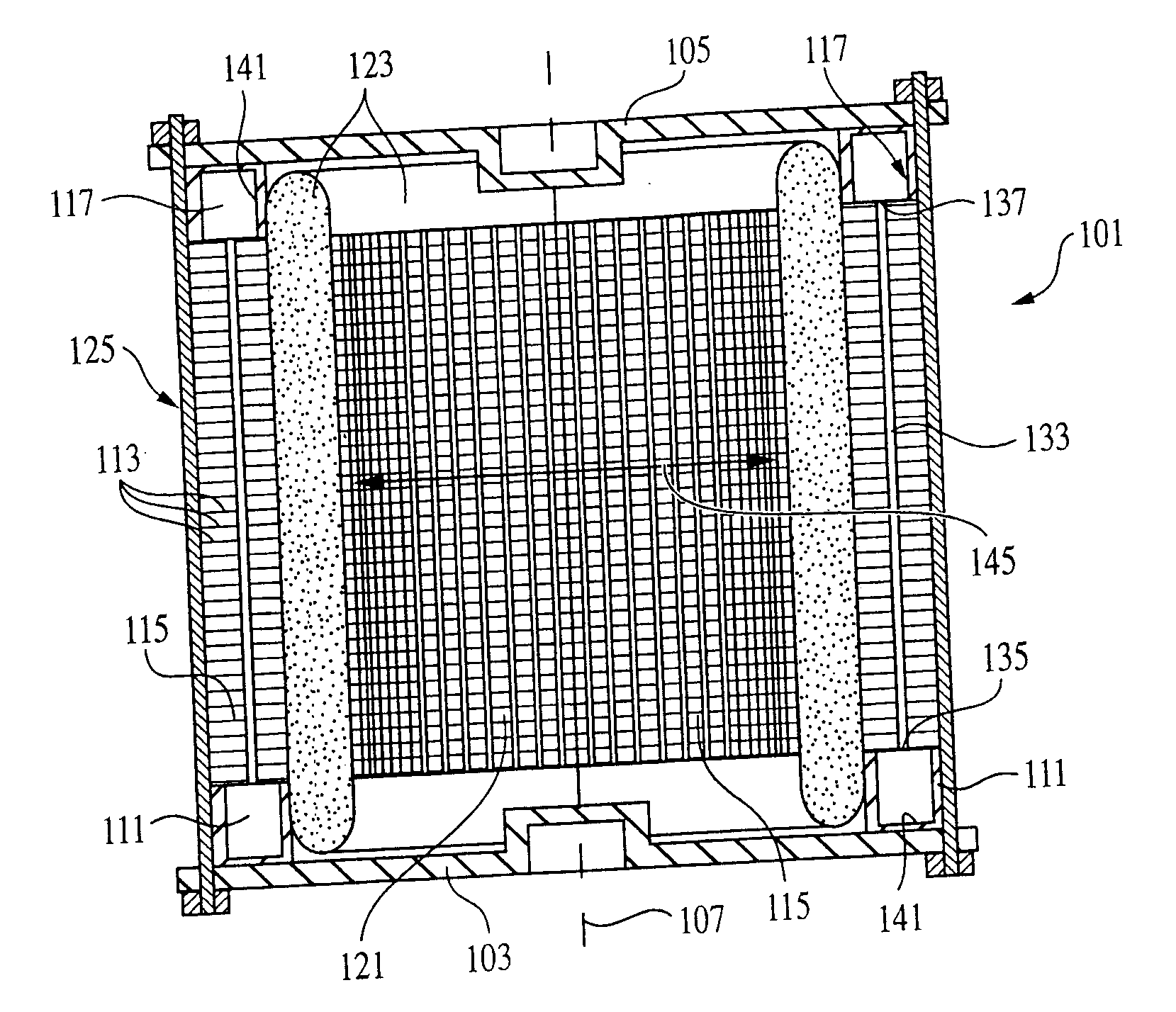

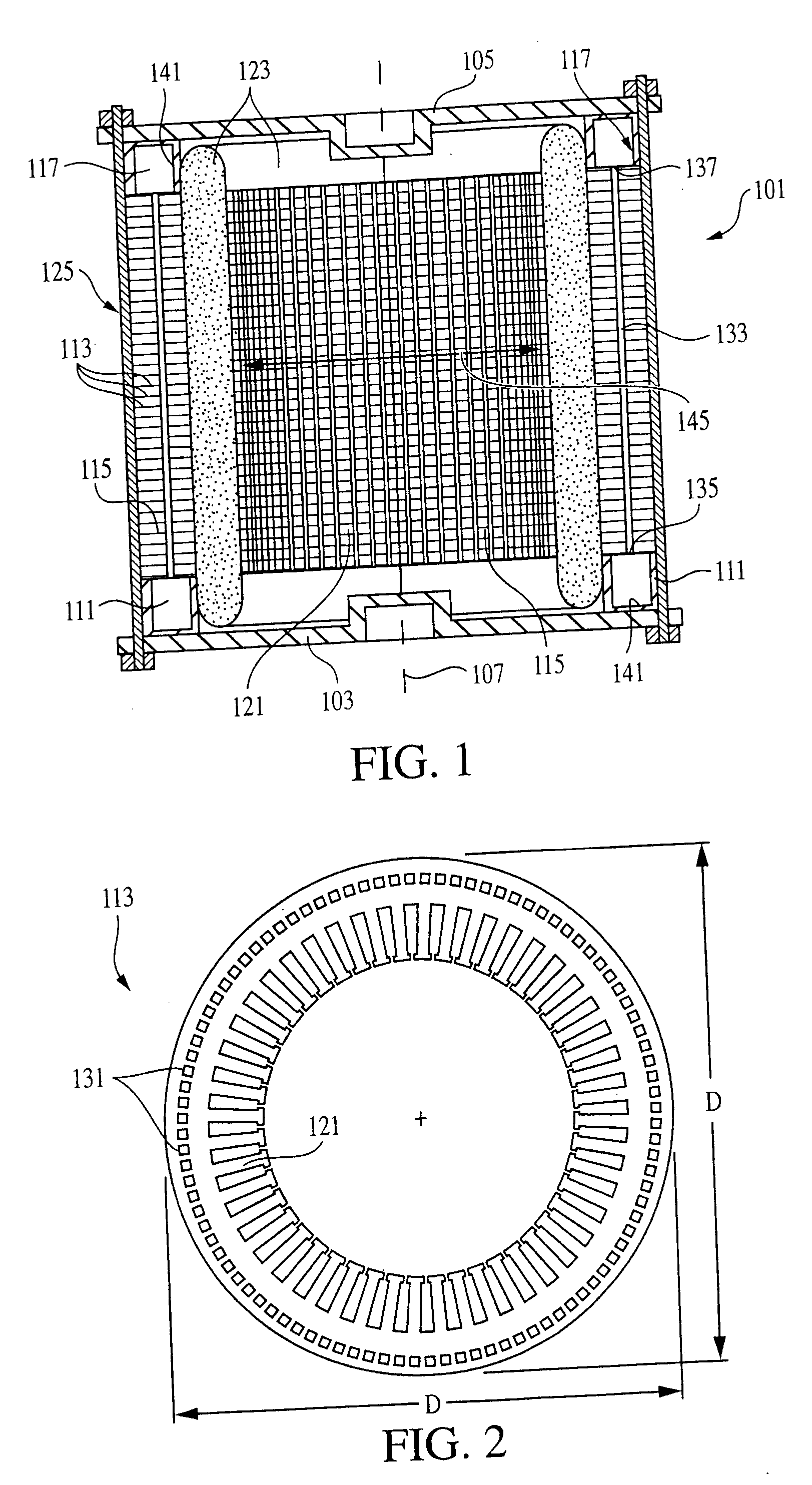

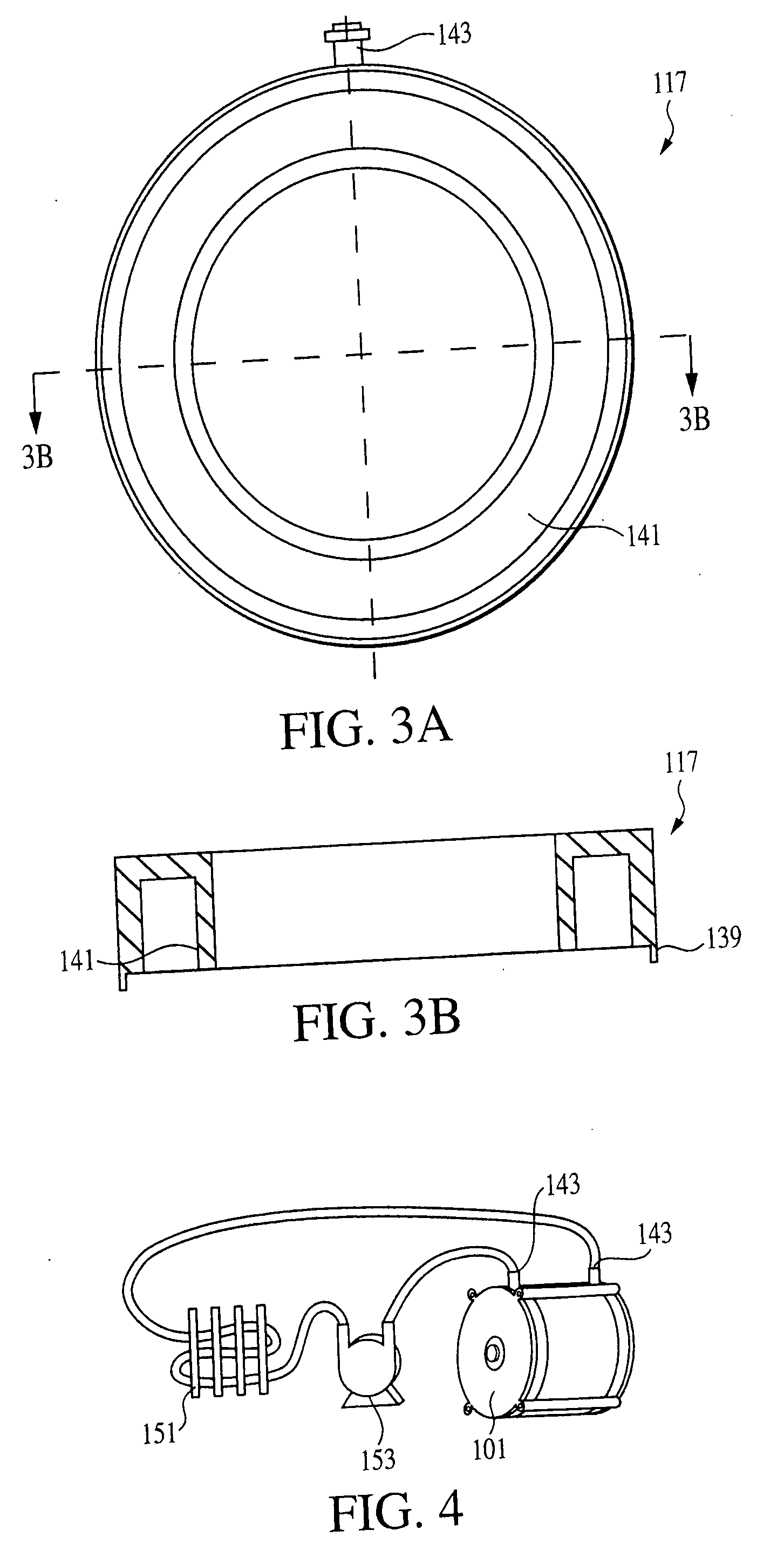

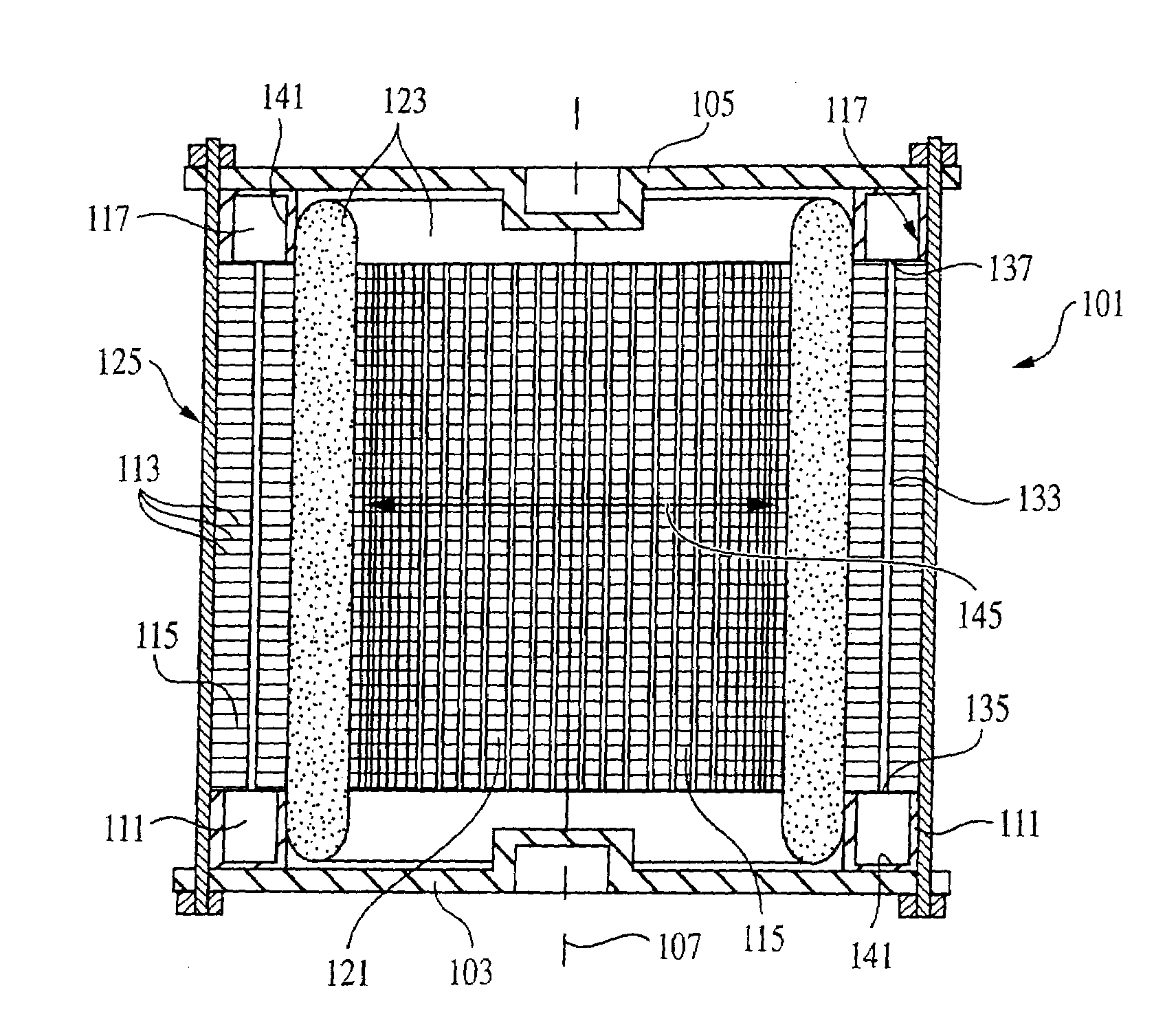

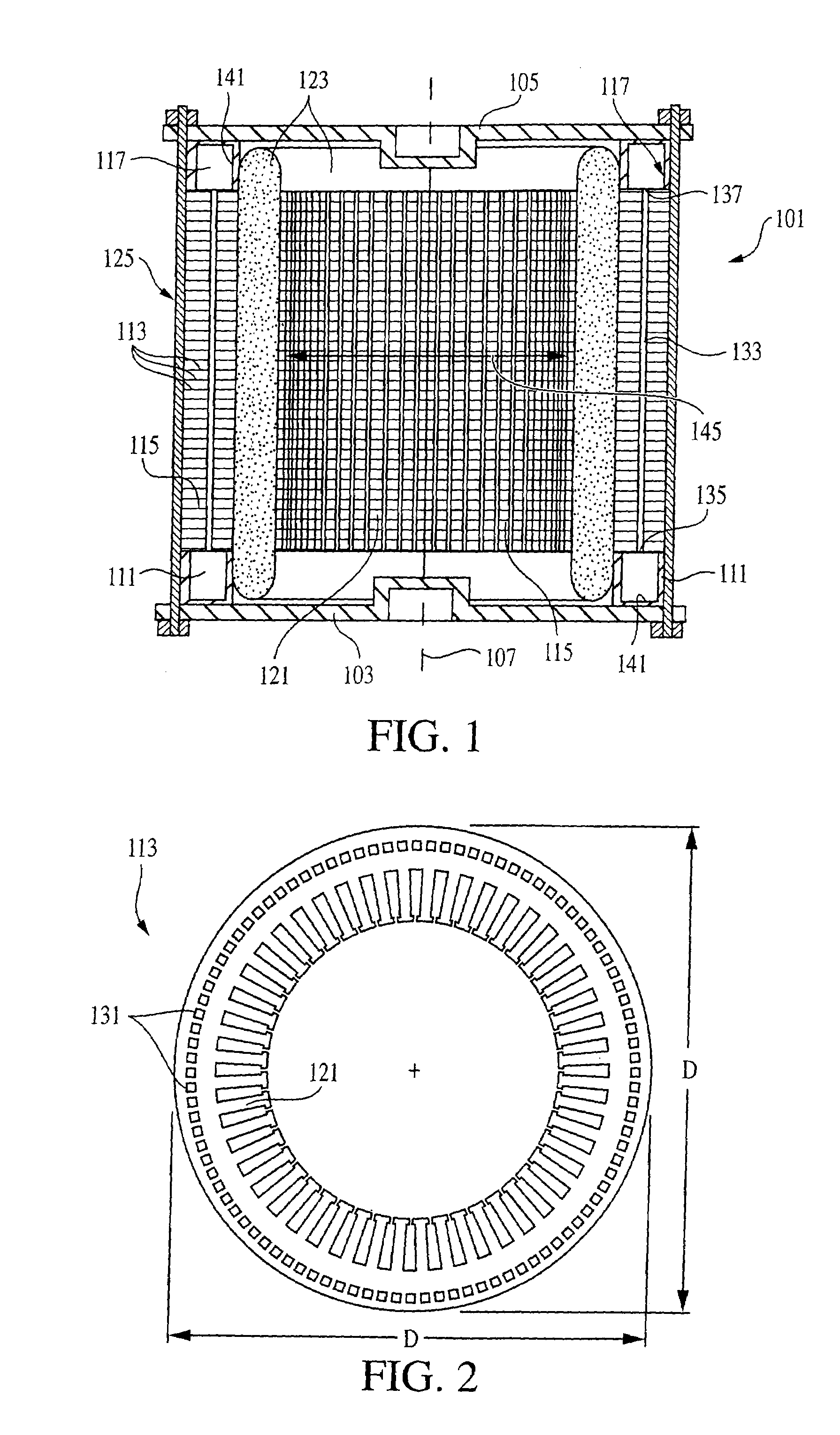

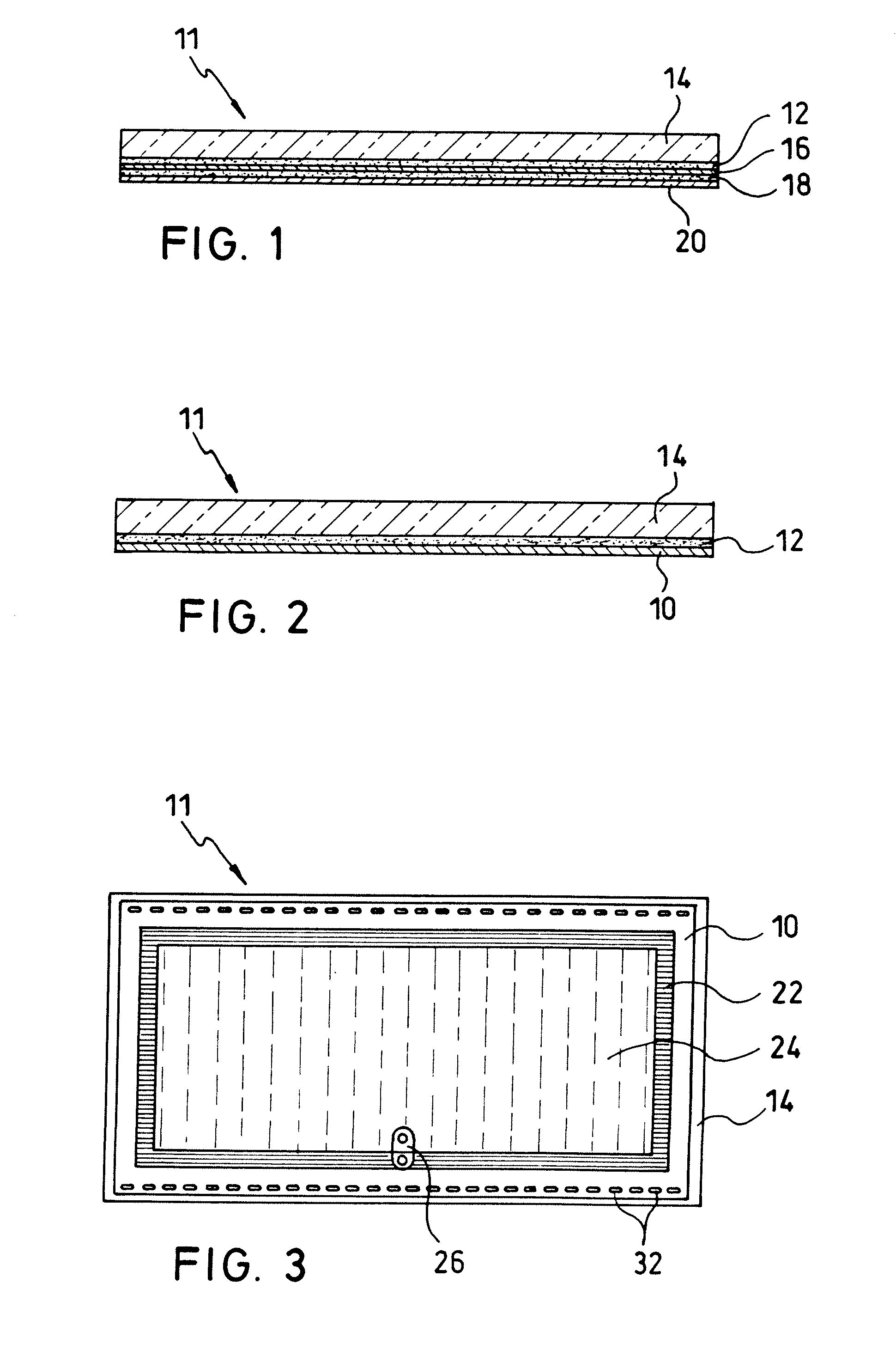

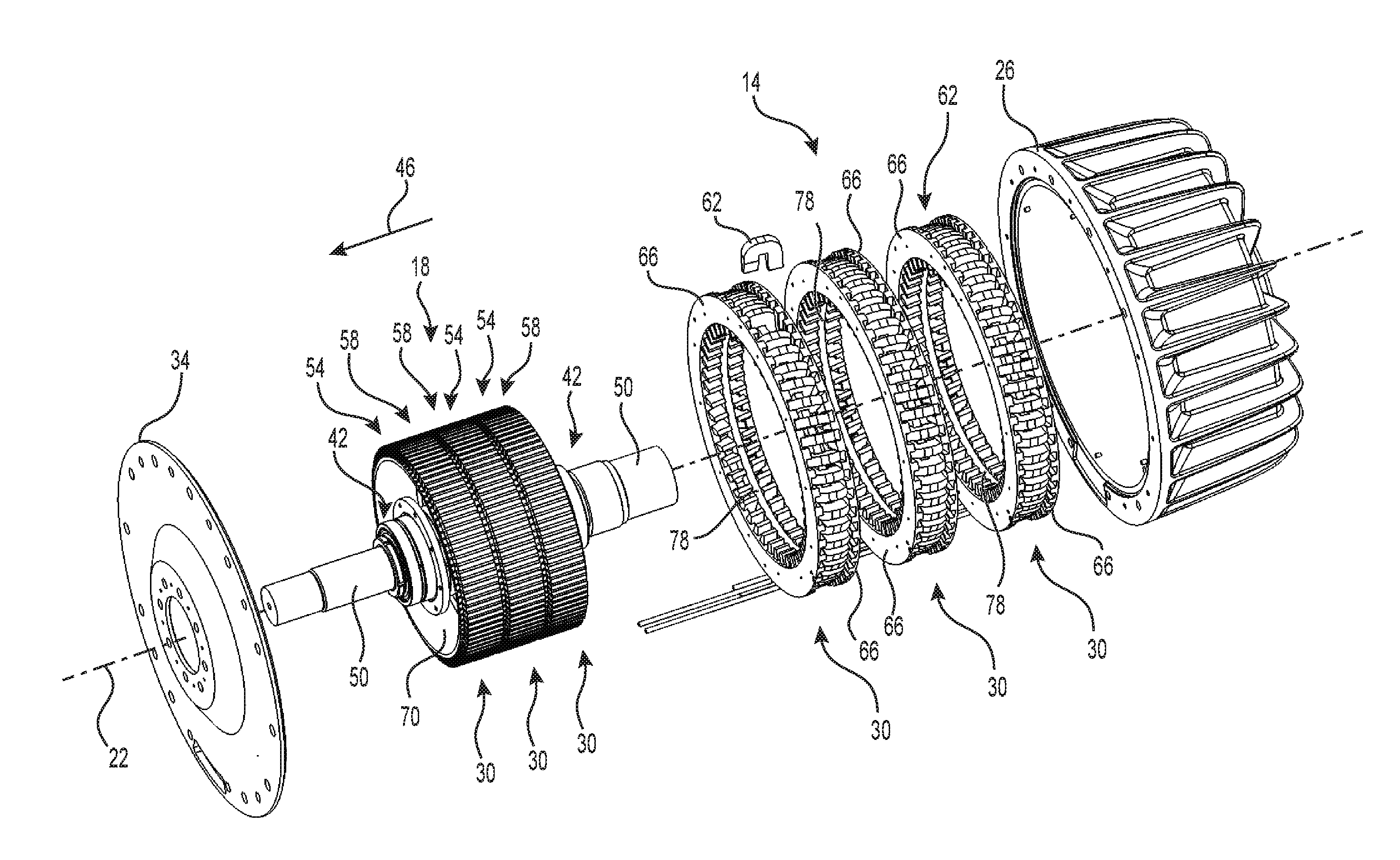

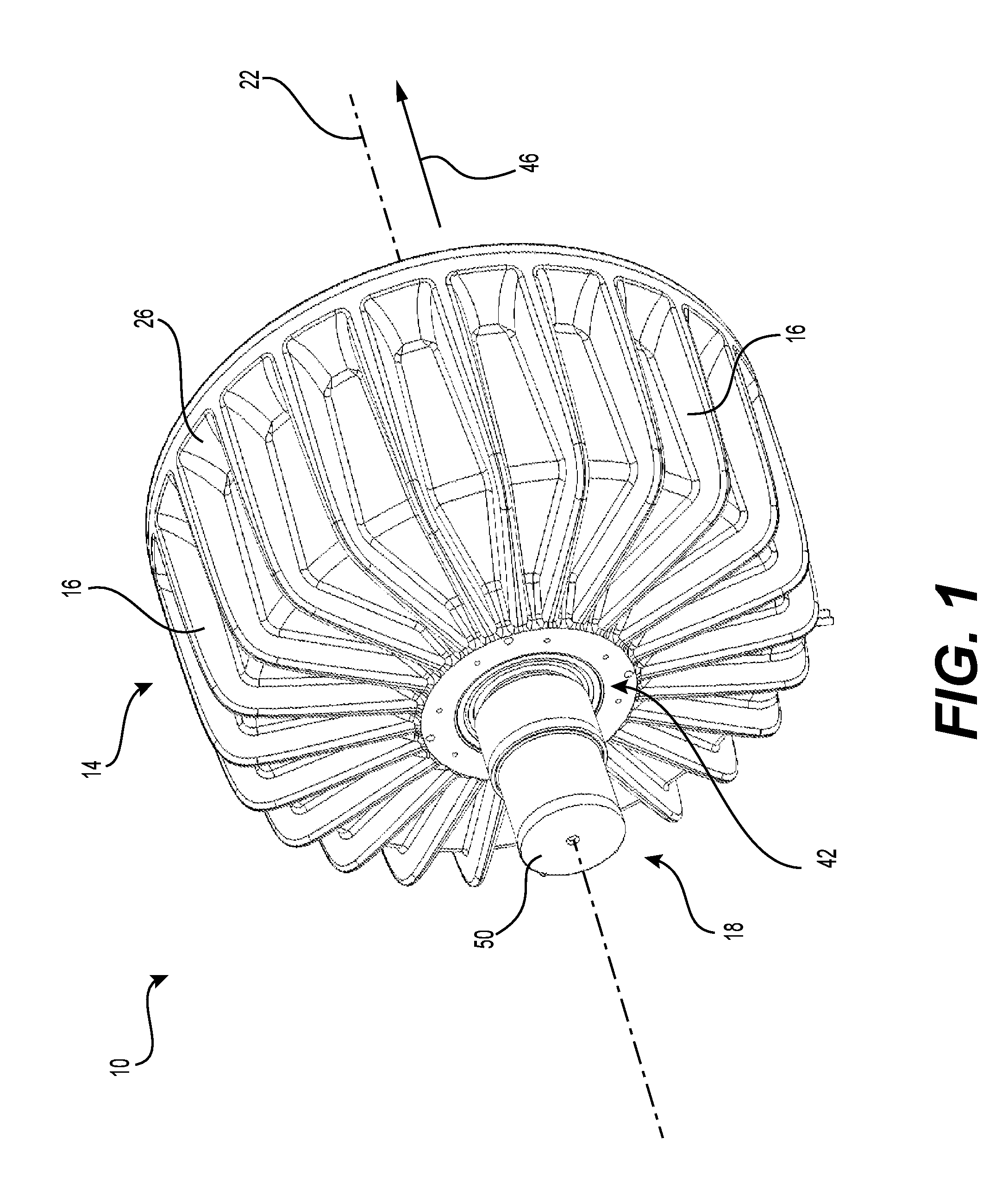

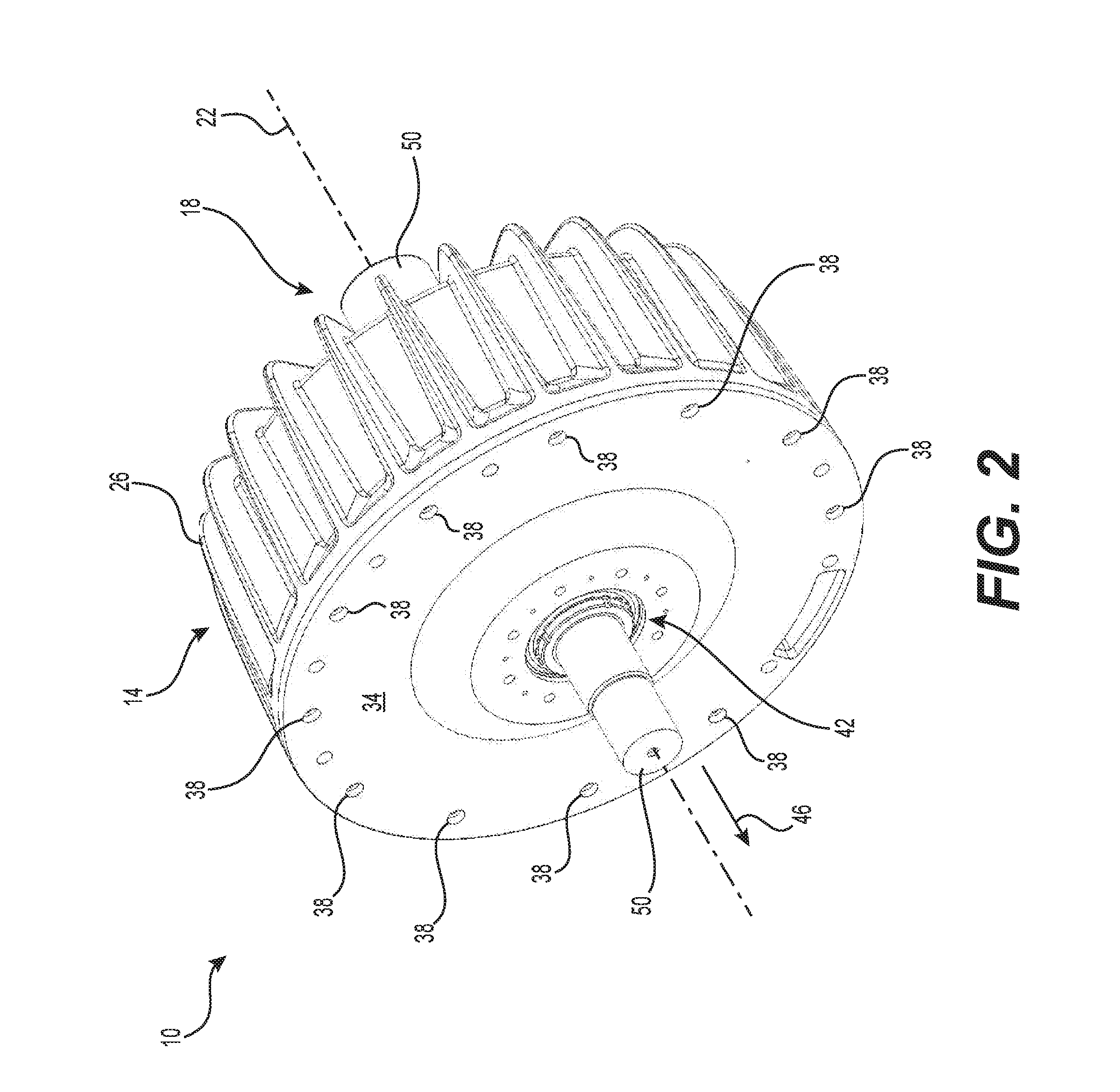

Lamination cooling system

InactiveUS6954010B2Improve heat transfer efficiencyReduce device sizeMagnetic circuit rotating partsMagnetic circuit stationary partsTransformerInductor

An electric motor, transformer or inductor having a lamination cooling system including a stack of laminations, each defining a plurality of apertures at least partially coincident with apertures of adjacent laminations. The apertures define a plurality of cooling-fluid passageways through the lamination stack, and gaps between the adjacent laminations are sealed to prevent a liquid cooling fluid in the passageways from escaping between the laminations. The gaps are sealed by injecting a heat-cured sealant into the passageways, expelling excess sealant, and heat-curing the lamination stack. The apertures of each lamination can be coincident with the same-sized apertures of adjacent laminations to form straight passageways, or they can vary in size, shape and / or position to form non-axial passageways, angled passageways, bidirectional passageways, and manifold sections of passageways that connect a plurality of different passageway sections. Manifold members adjoin opposite ends of the lamination stack, and each is configured with one or more cavities to act as a manifold to adjacent passageway ends. Complex manifold arrangements can create bidirectional flow in a variety of patterns.

Owner:WEBASTO CHARGING SYST INC

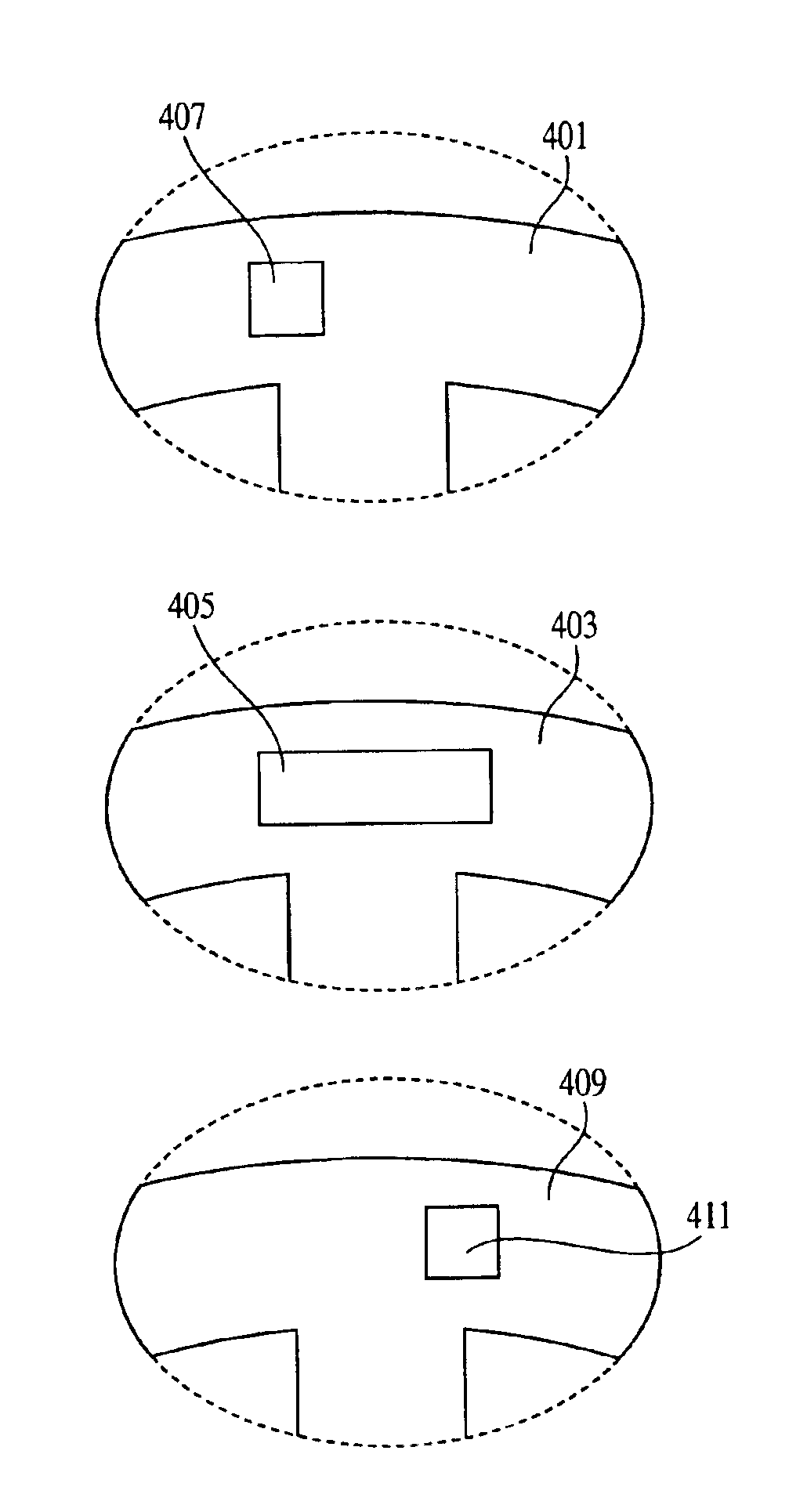

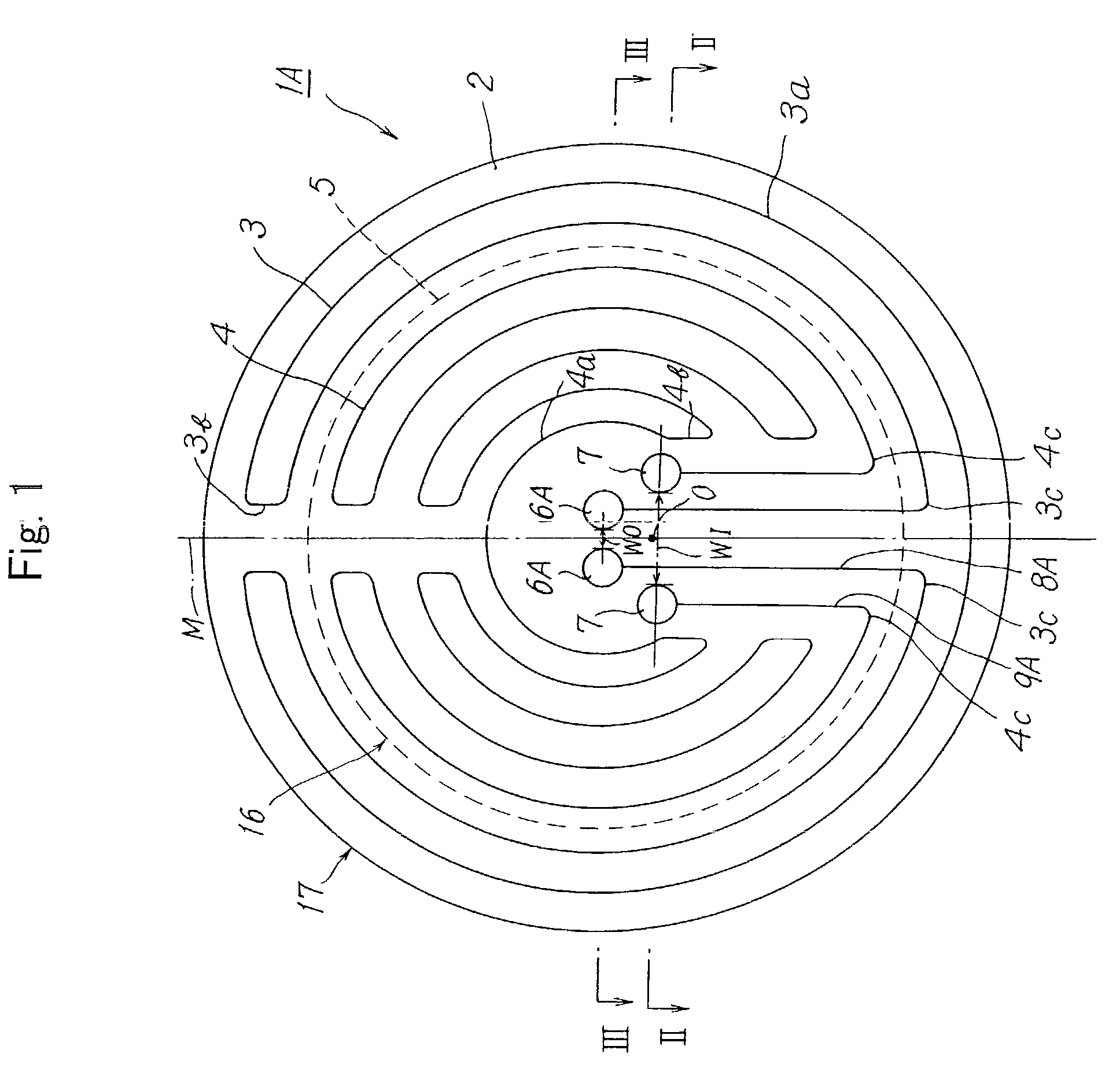

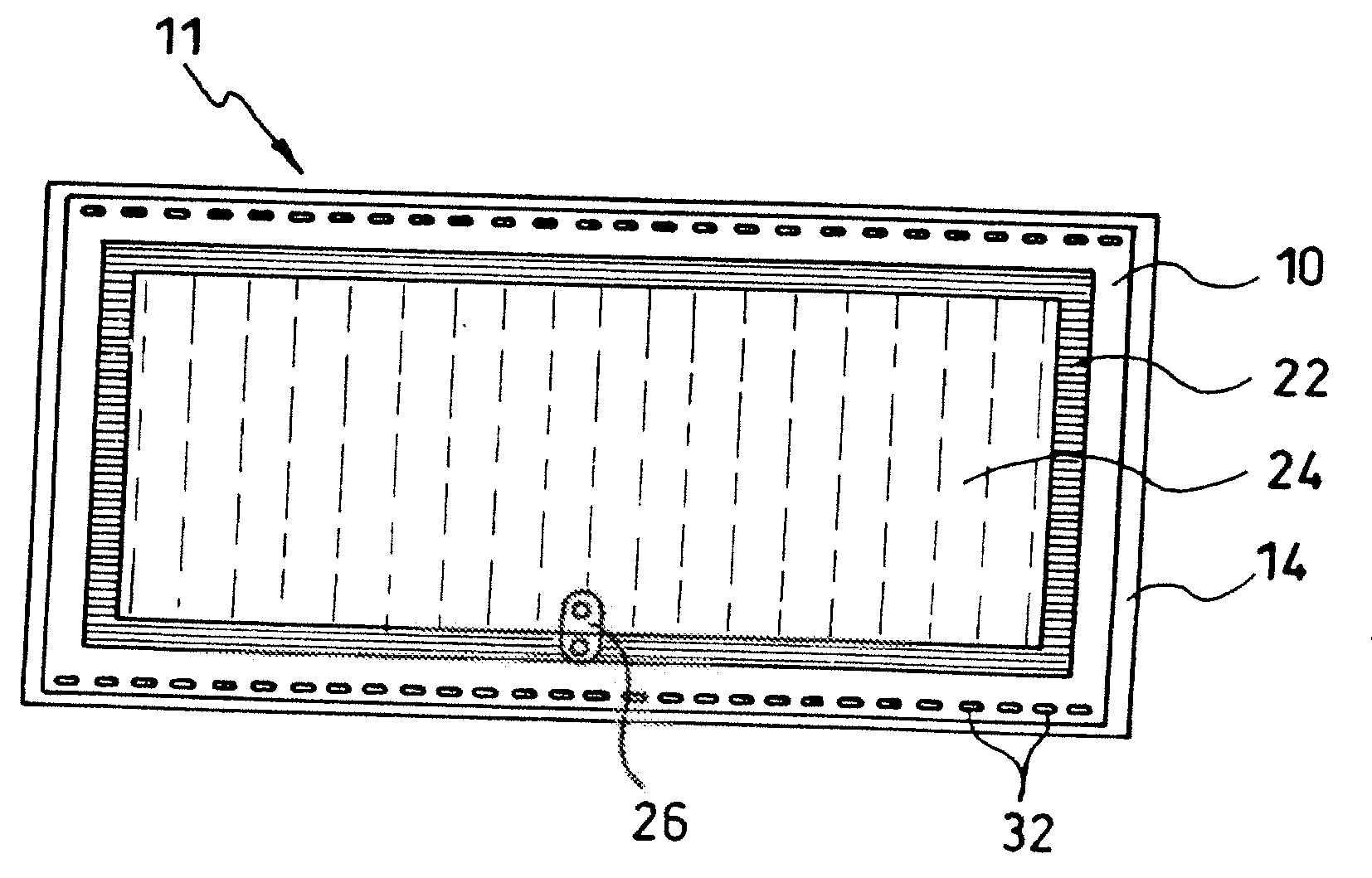

Heating apparatus

InactiveUS7279661B2Prevent increase in heat capacity of heatingEasy to fixOhmic-resistance electrodesHeater elementsEngineeringSemiconductor

A heating apparatus for a semiconductor producing system is provided, including a heater having a mounting face, an opposed back face, a first resistance heating element, a second resistance heating element provided along substantially the same plane as the first heating element, a first terminal connected with the first heating element and a second terminal connected with the second heating element. A supporting member is fixed to the back face of the heater. First and second power supply means are respectively connected with the first and second terminals and contained in an inner space of the supporting member. A conductive connector connects the first heating element and the first terminal but not the second heating element. The first heating element is provided in a first zone, the second heating element is provided in a second zone, and the conductive connector is provided in the plane and the second zone.

Owner:NGK INSULATORS LTD

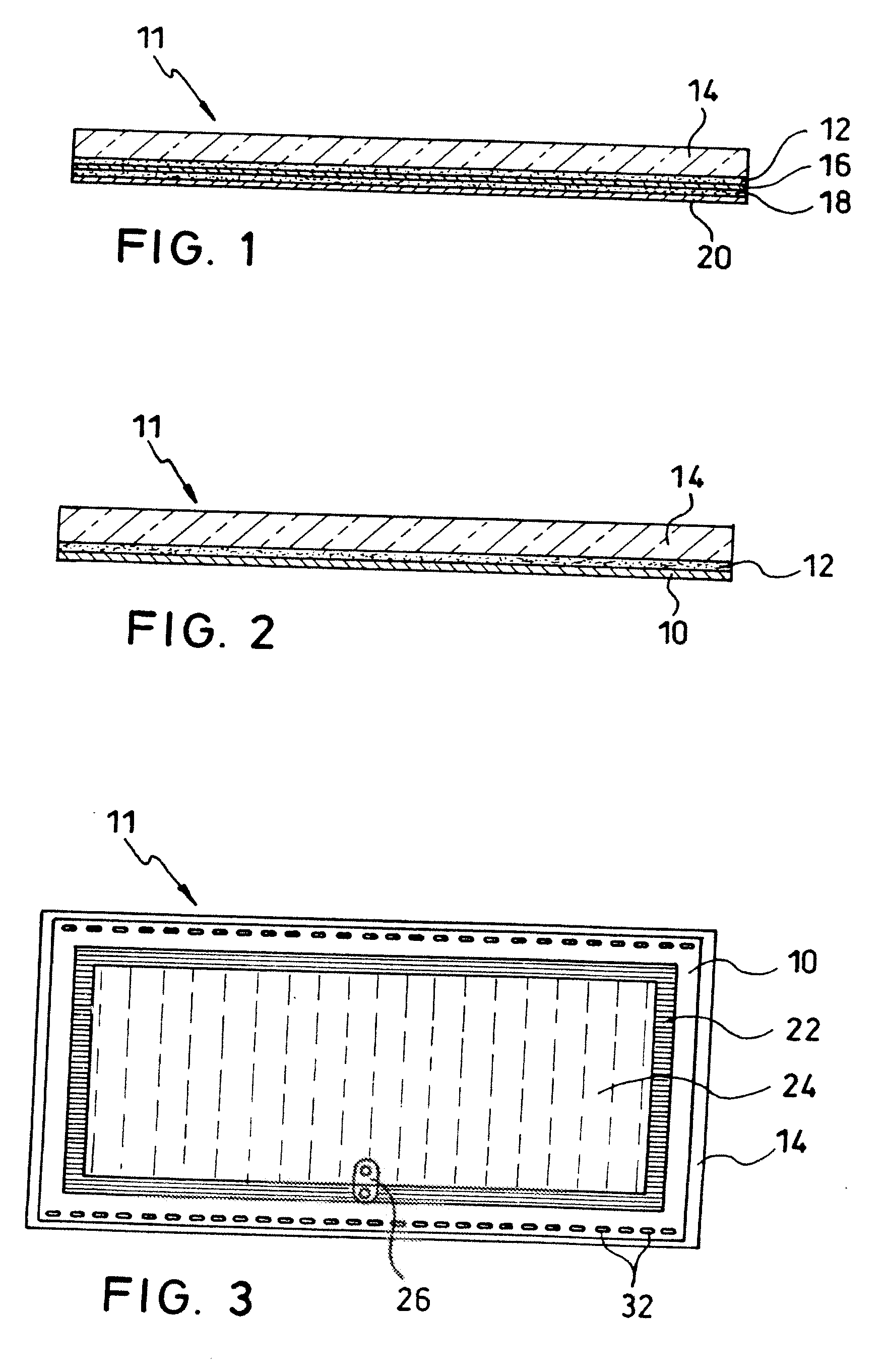

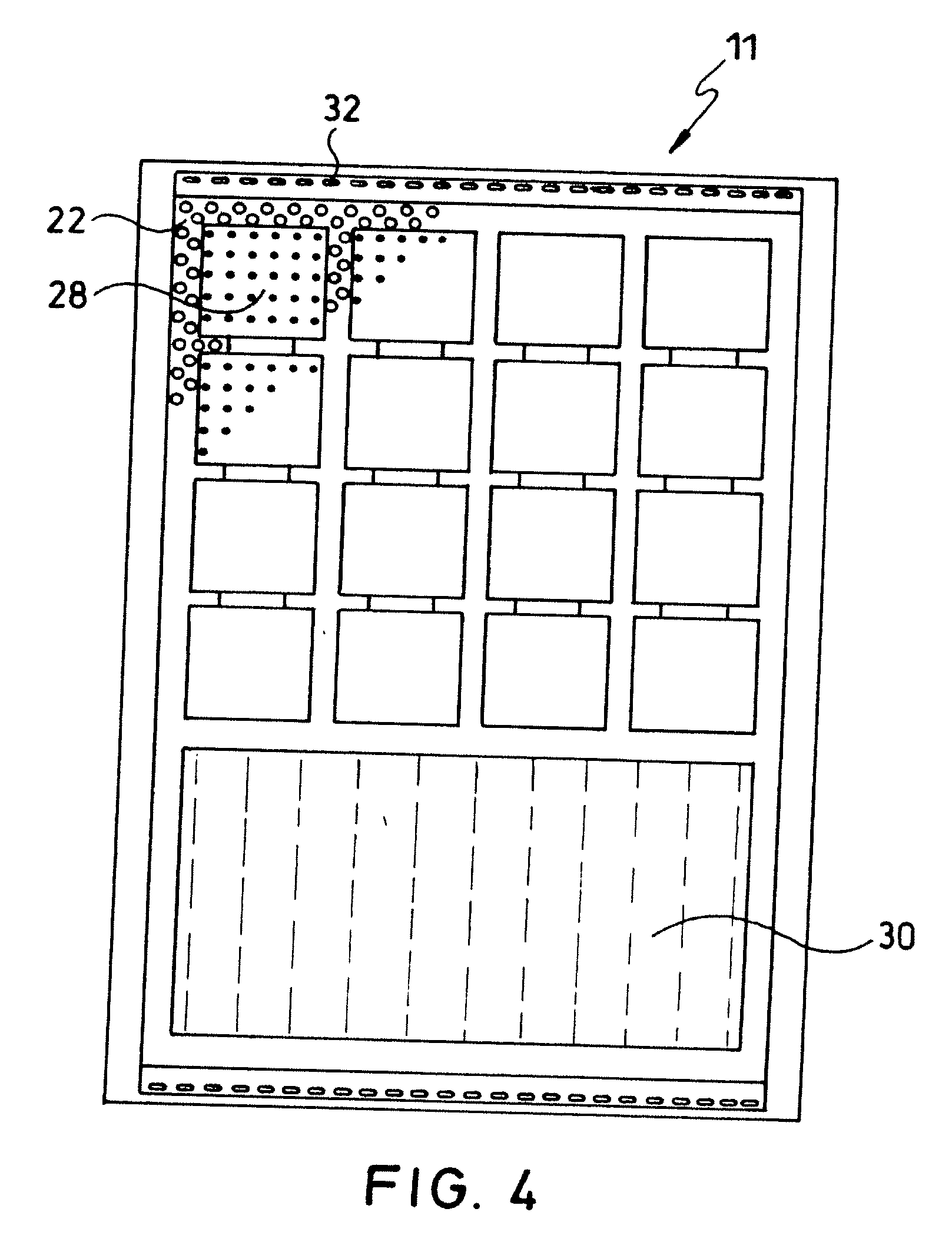

Process for producing a cover with a glass pane and electrical function elements

InactiveUS20050001456A1Simple and reliable processEasy to manufacturePV power plantsMetal-working apparatusMobile vehicleEngineering

Owner:WEBASTO AG

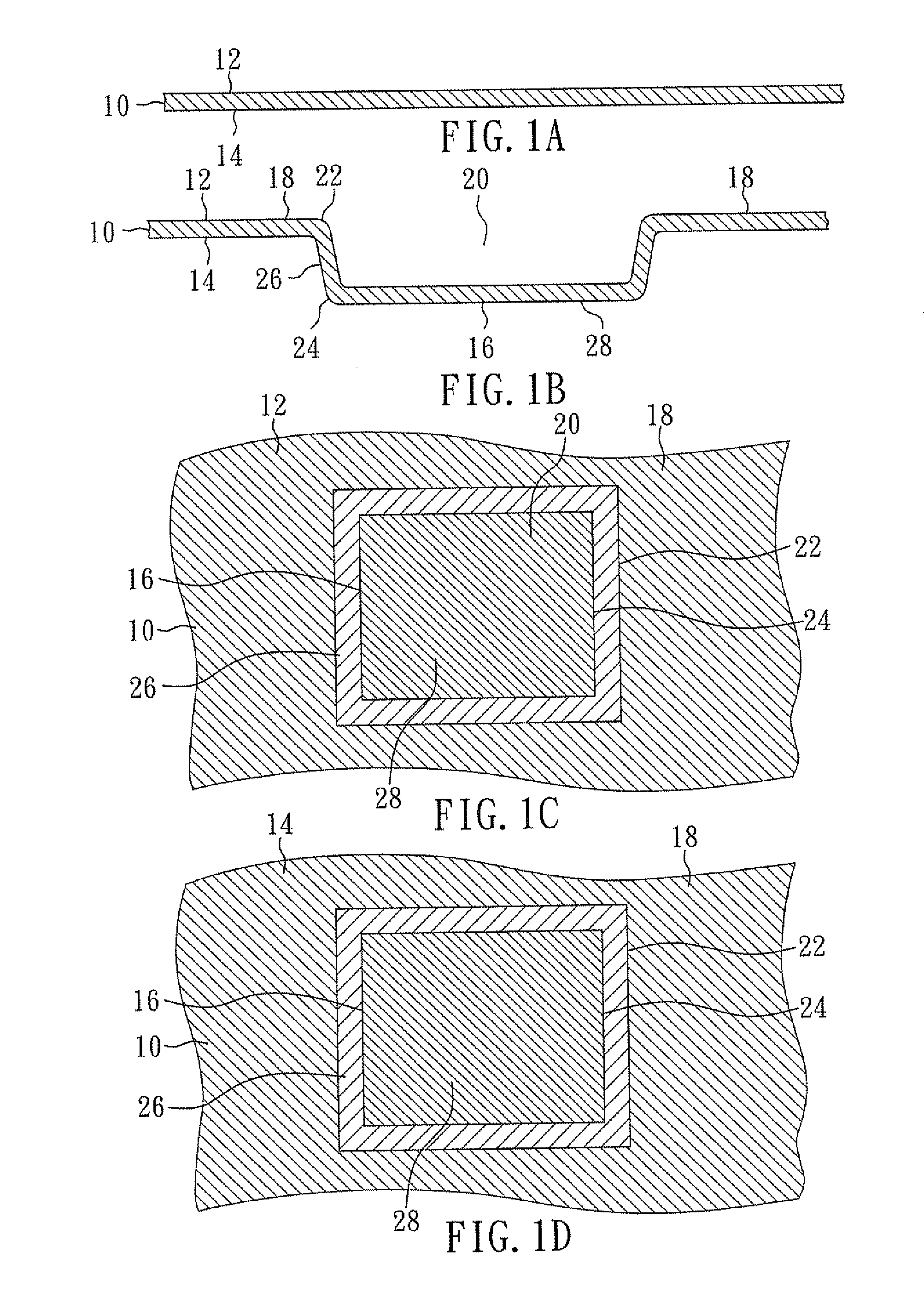

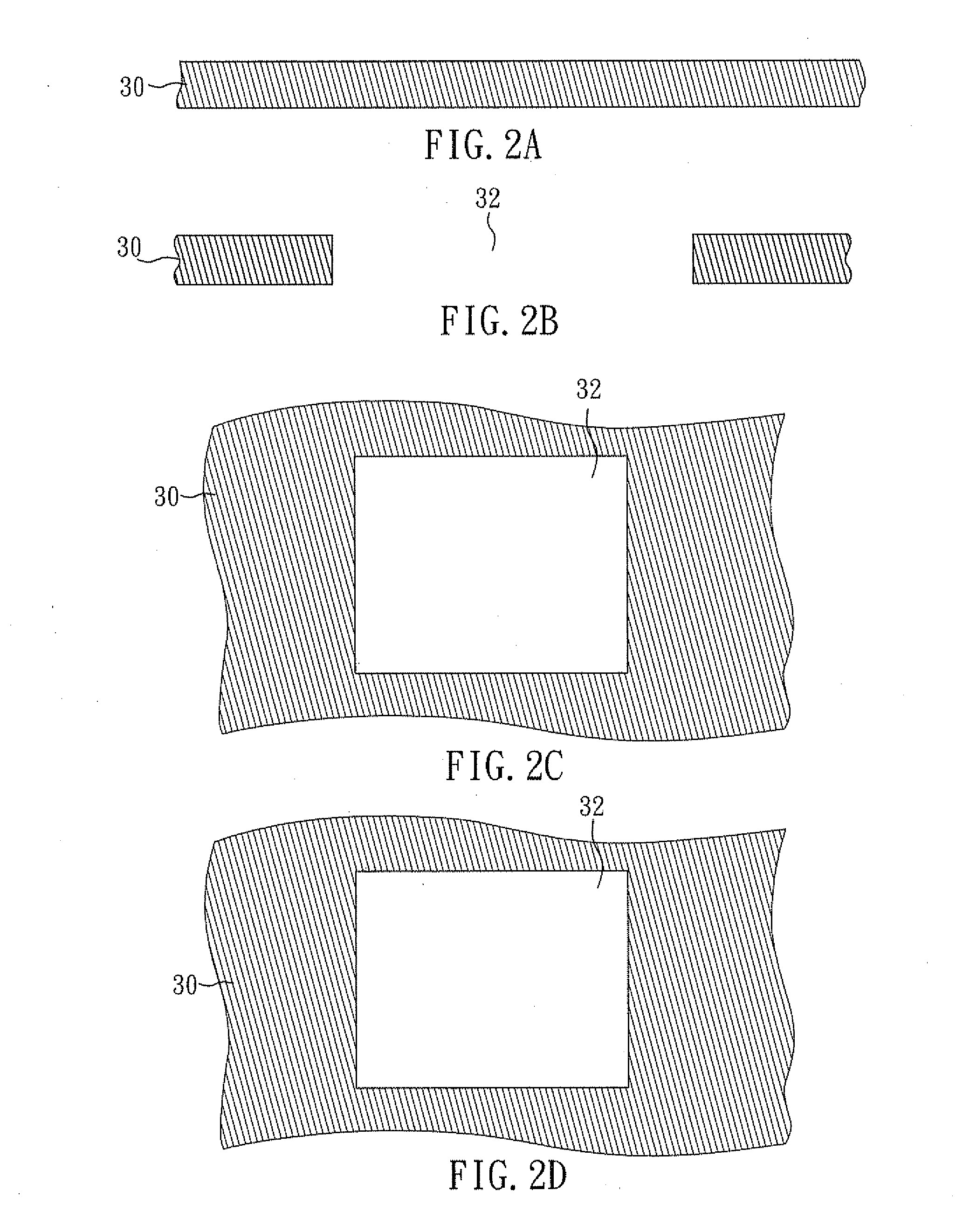

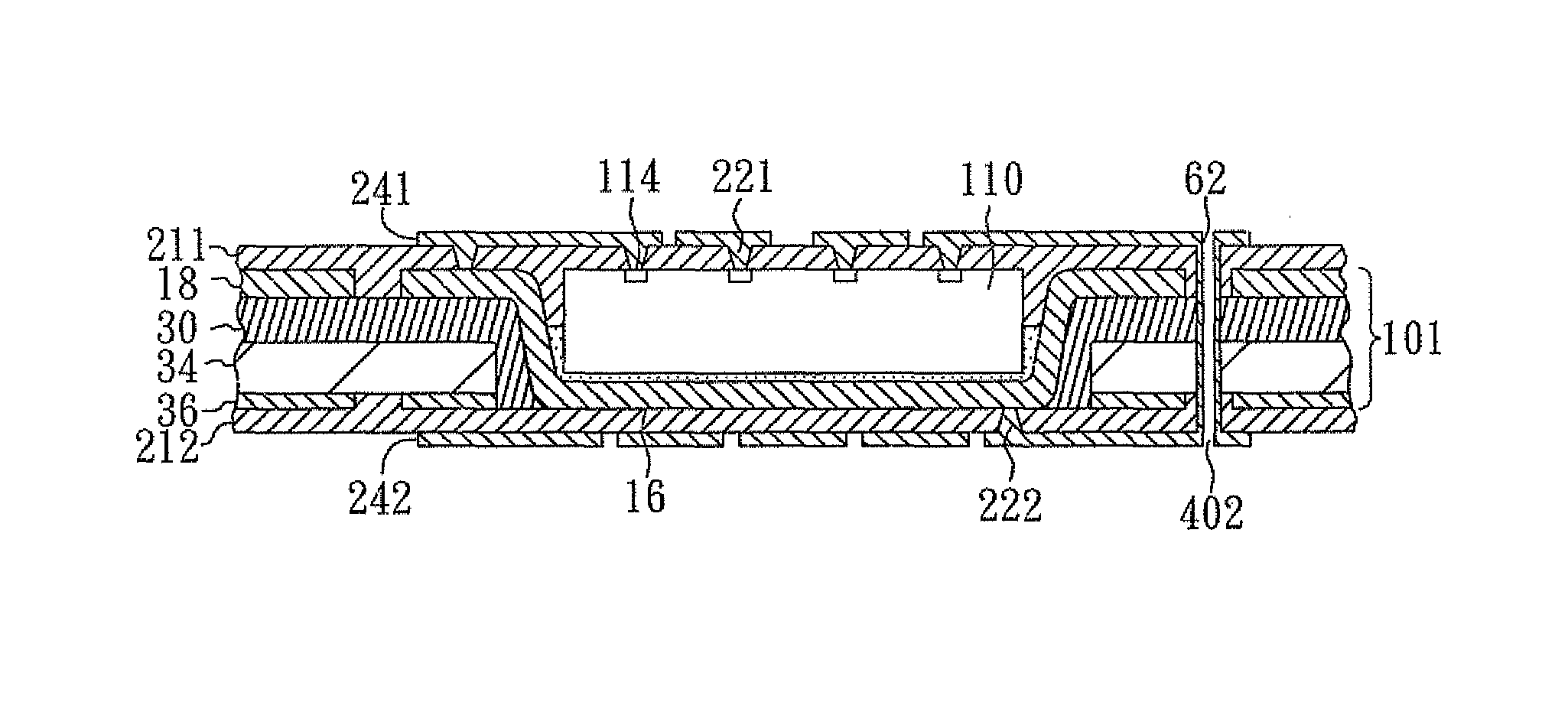

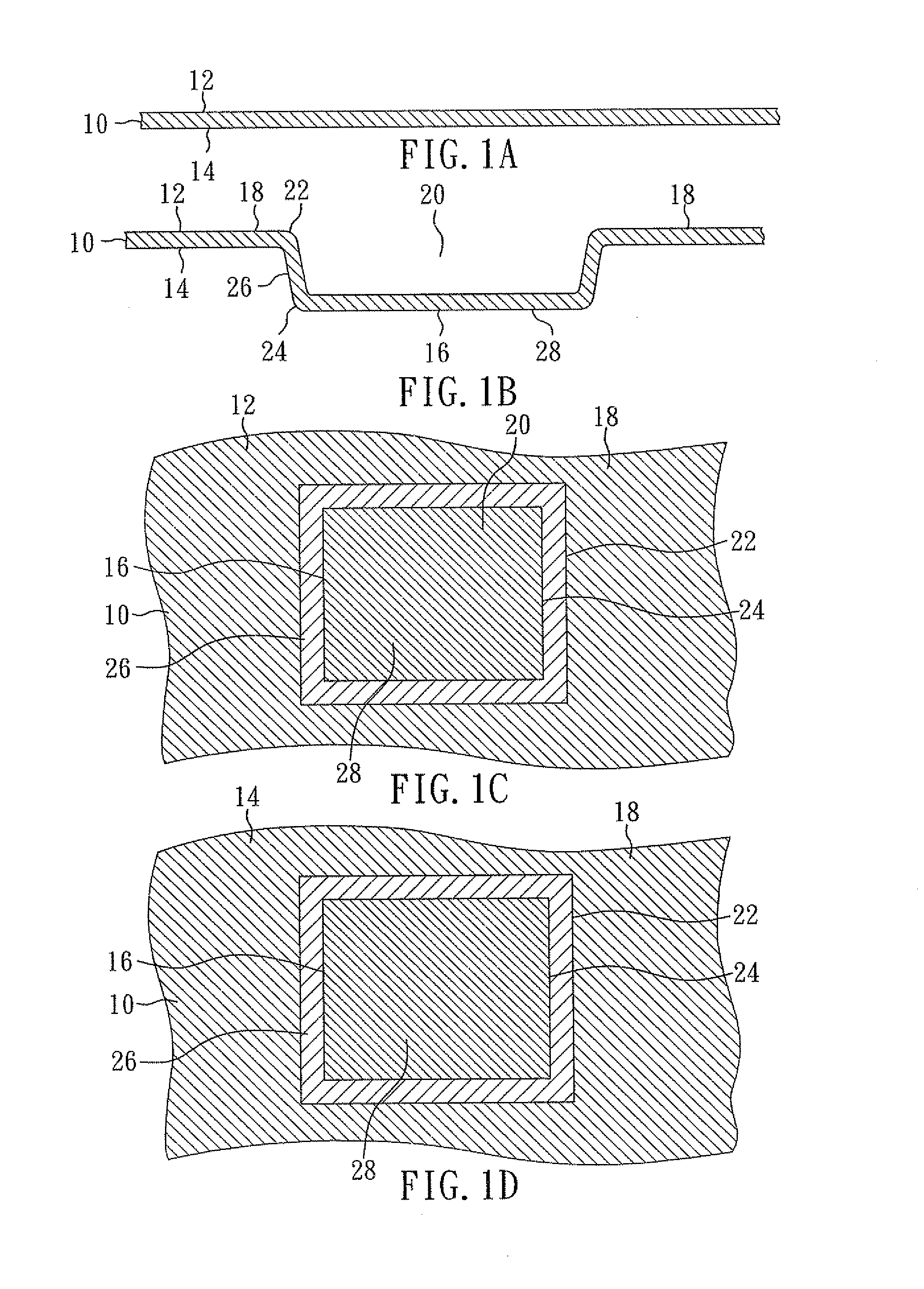

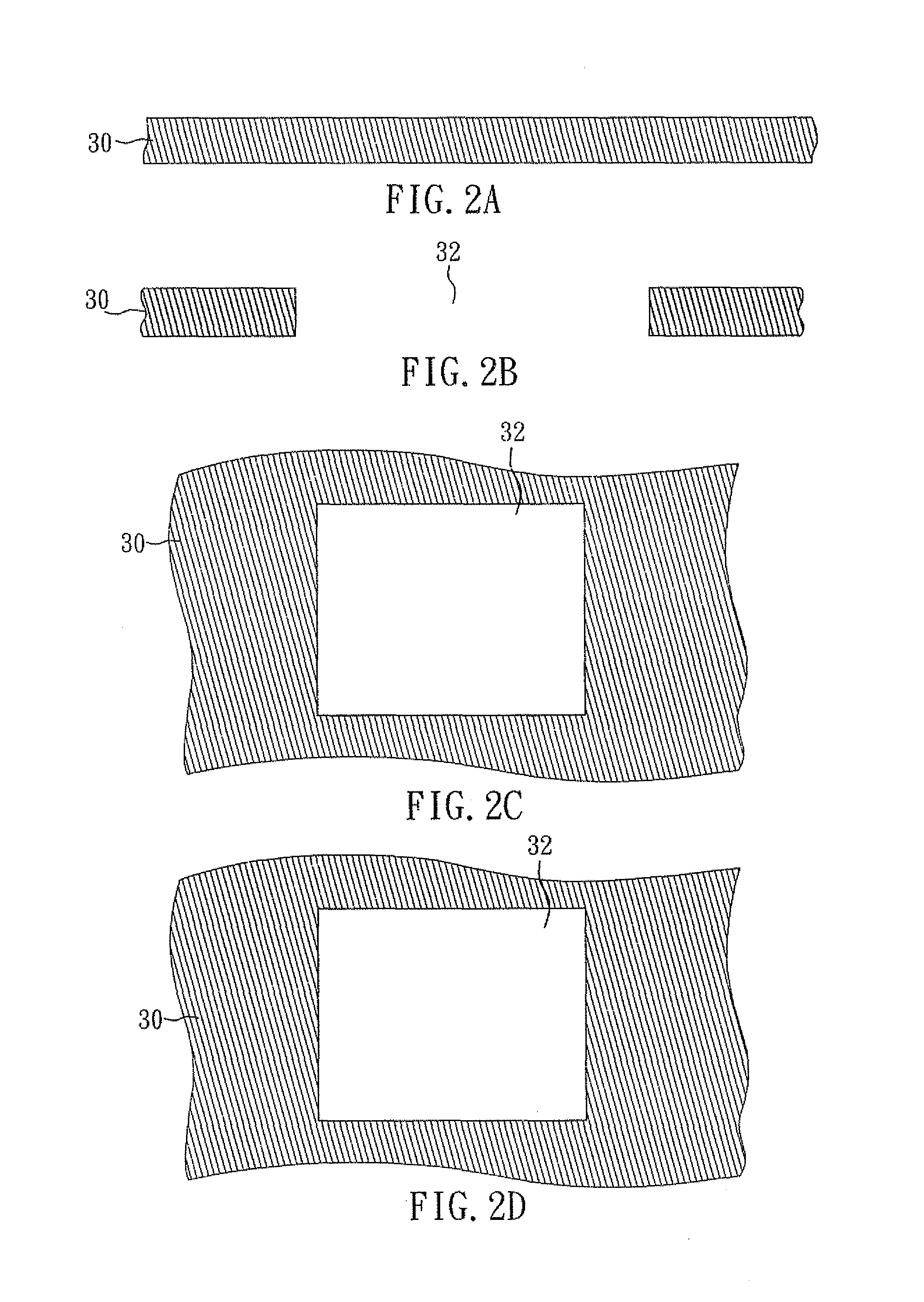

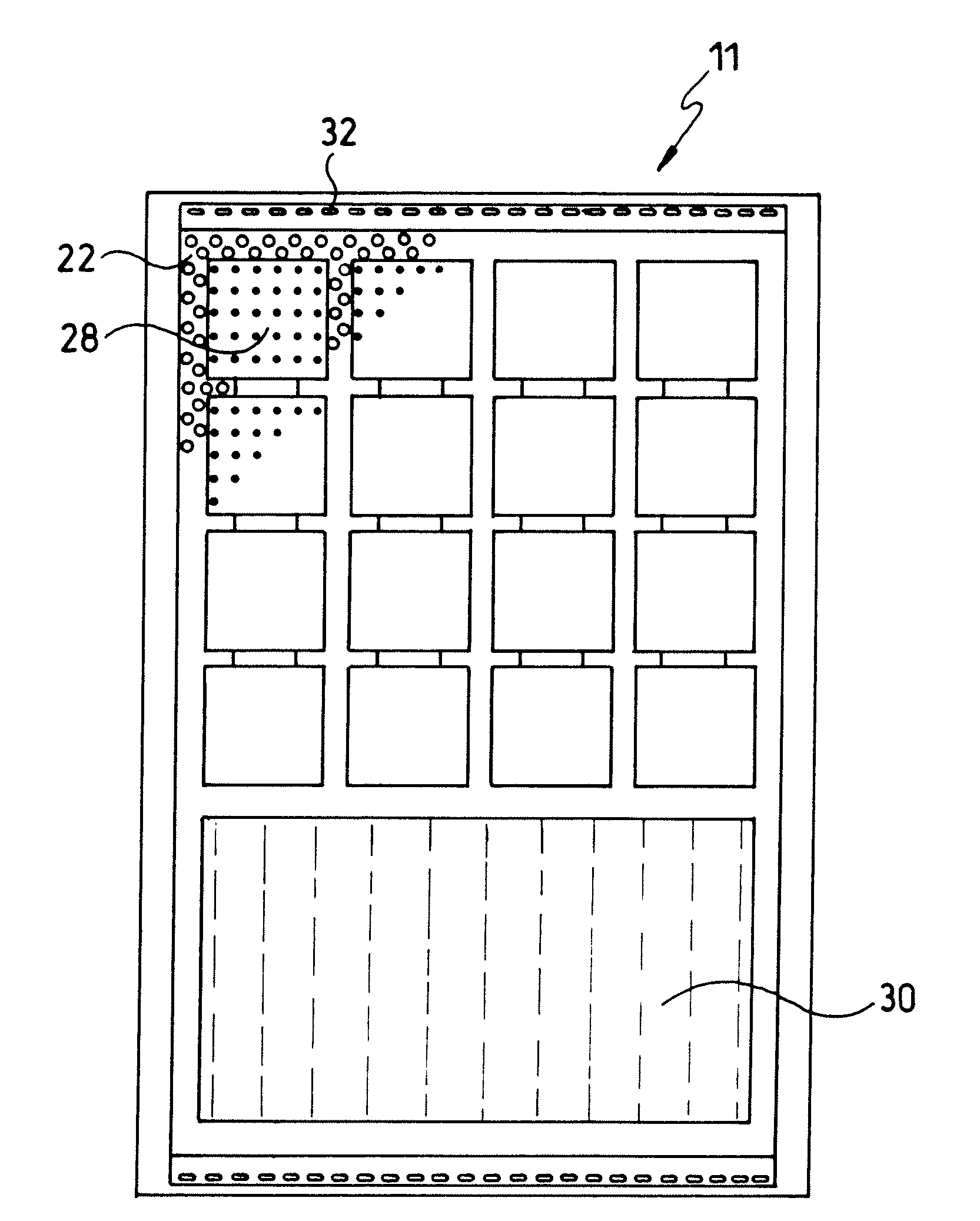

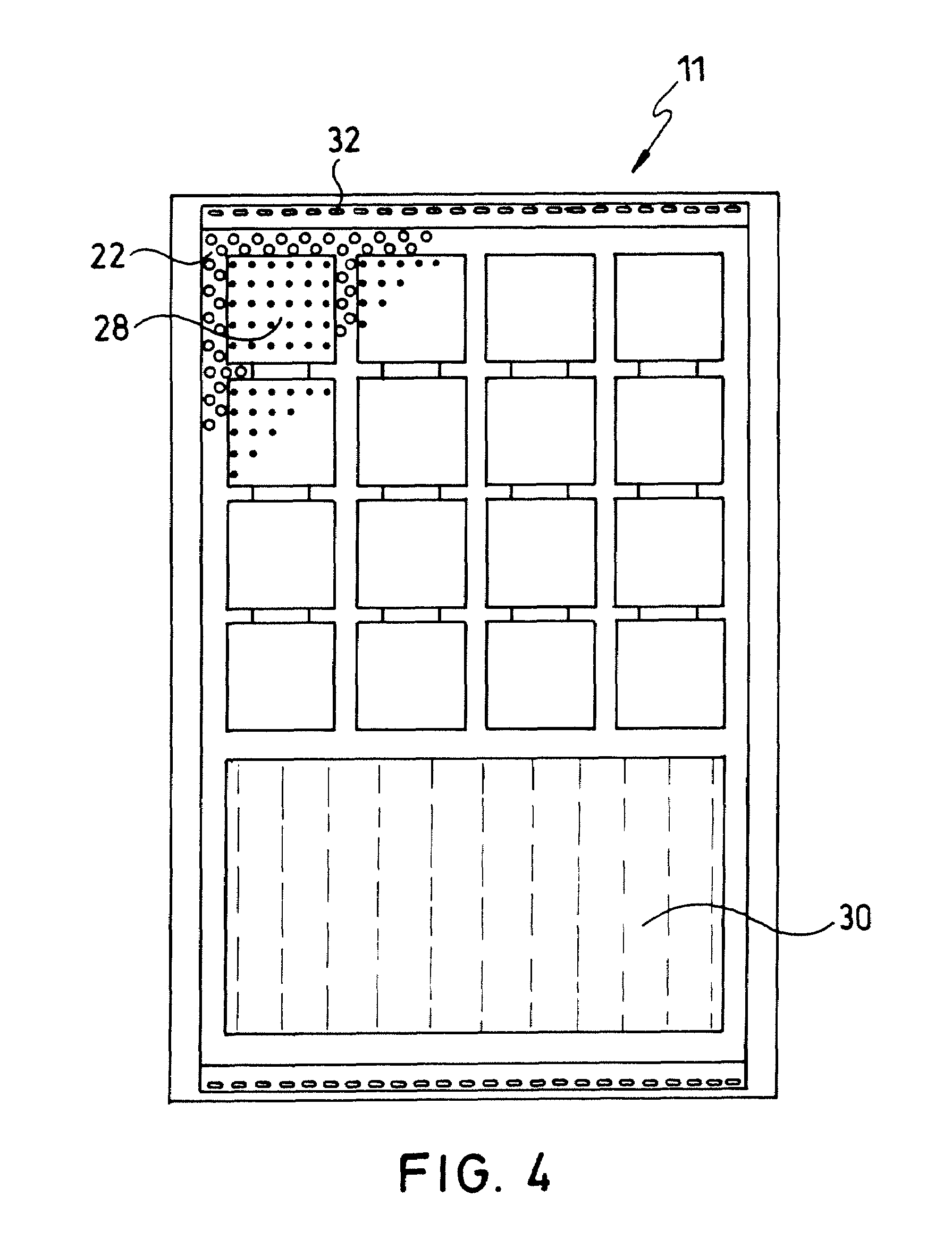

Lamination cooling system formation method

InactiveUS20060026820A1Improve heat transfer efficiencyReduce device sizeMetal-working apparatusMagnetic circuit stationary partsTransformerEngineering

An electric motor, transformer or inductor having a lamination cooling system comprising a stack of laminations, each defining a plurality of apertures at least partially coincident with apertures of adjacent laminations. The apertures define a plurality of cooling-fluid passageways through the lamination stack, and gaps between the adjacent laminations are sealed to prevent a liquid cooling fluid in the passageways from escaping between the laminations. The gaps are sealed by injecting a heat-cured sealant into the passageways, expelling excess sealant, and heat-curing the lamination stack. The apertures of each lamination can be coincident with the same-sized apertures of adjacent laminations to form straight passageways, or they can vary in size, shape and / or position to form non-axial passageways, angled passageways, bidirectional passageways, and manifold sections of passageways that connect a plurality of different passageway sections. Manifold members adjoin opposite ends of the lamination stack, and each is configured with one or more cavities to act as a manifold to adjacent passageway ends. Complex manifold arrangements can create bidirectional flow in a variety of patterns.

Owner:AEROVIRONMENT INC

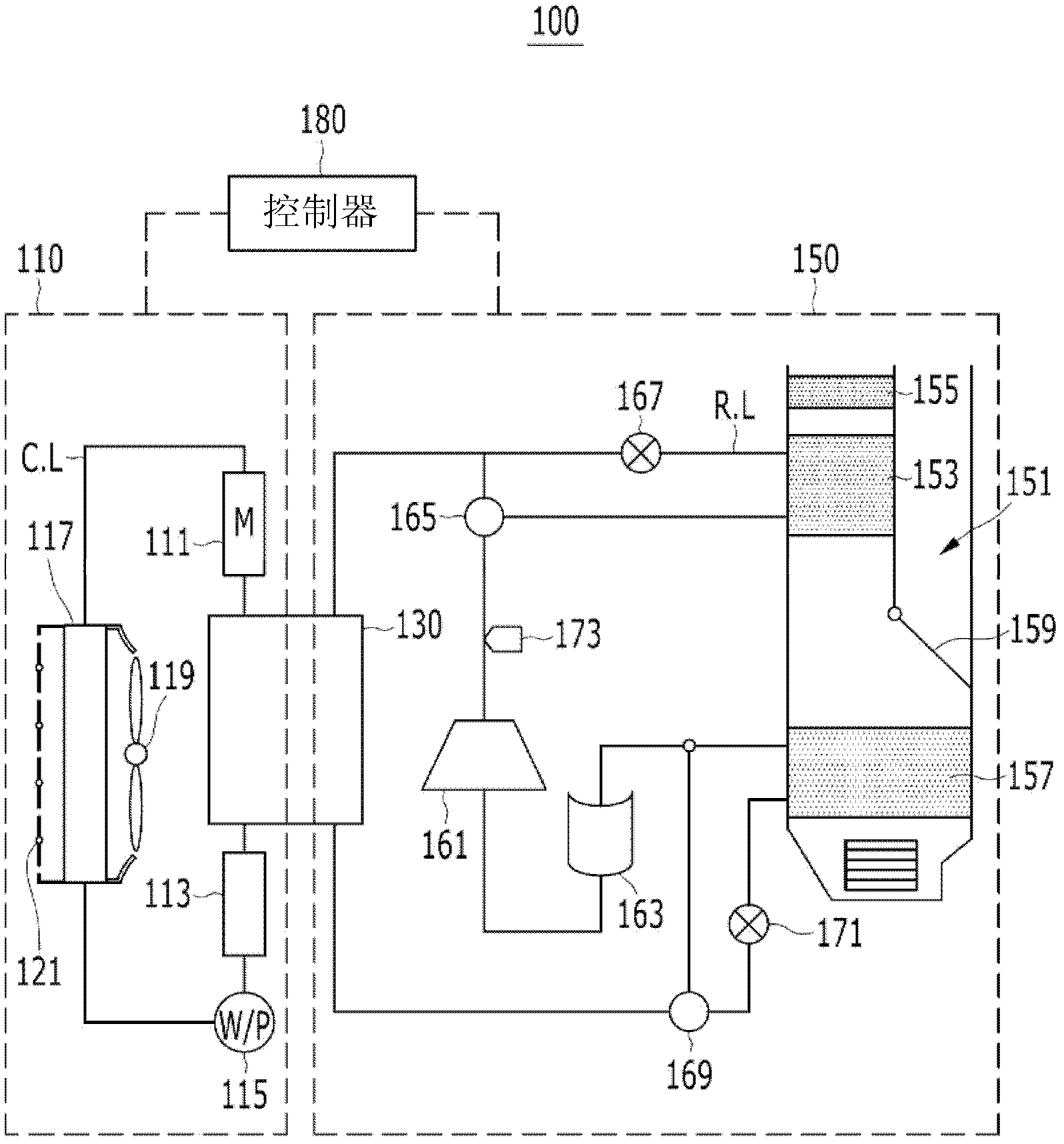

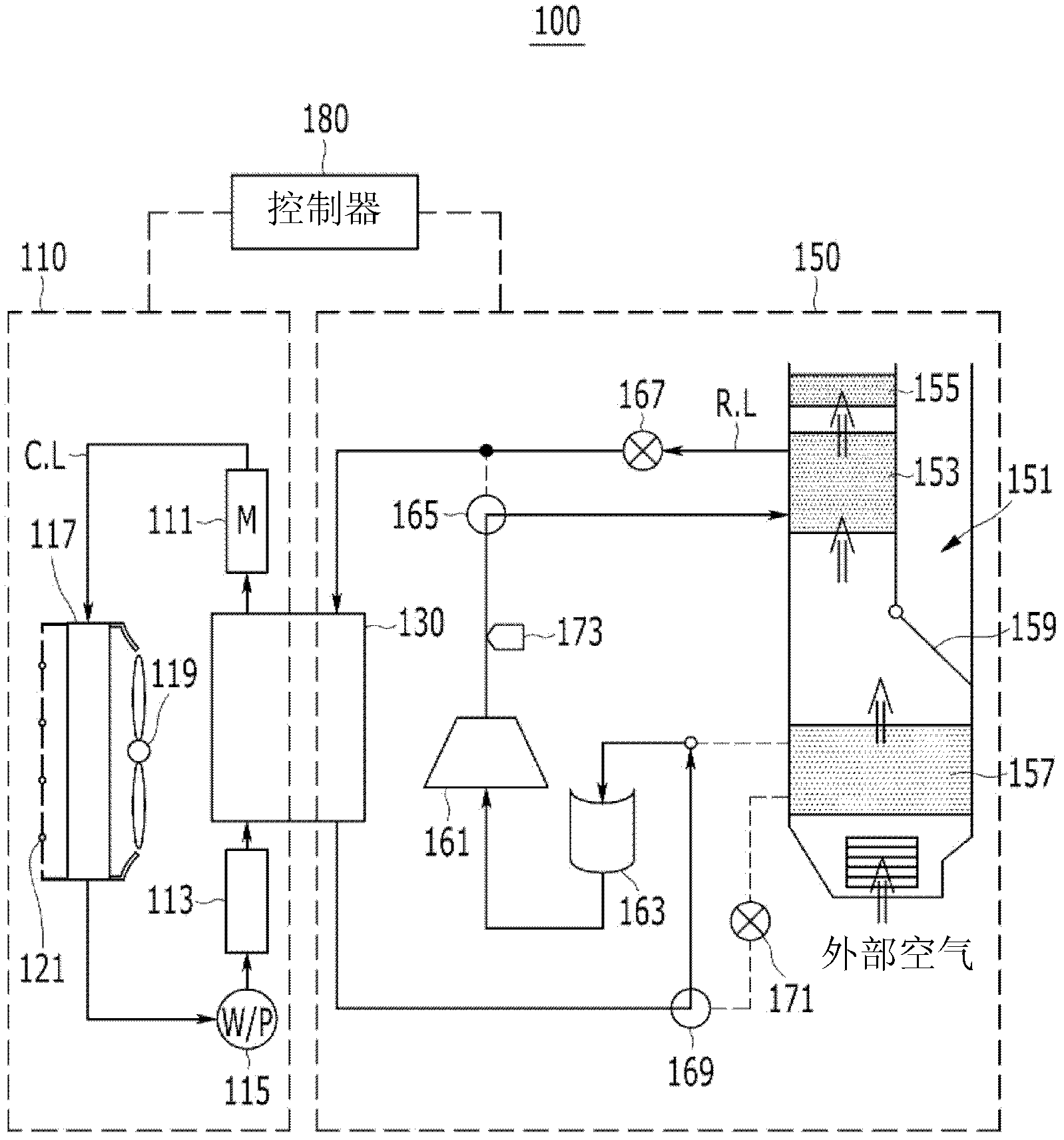

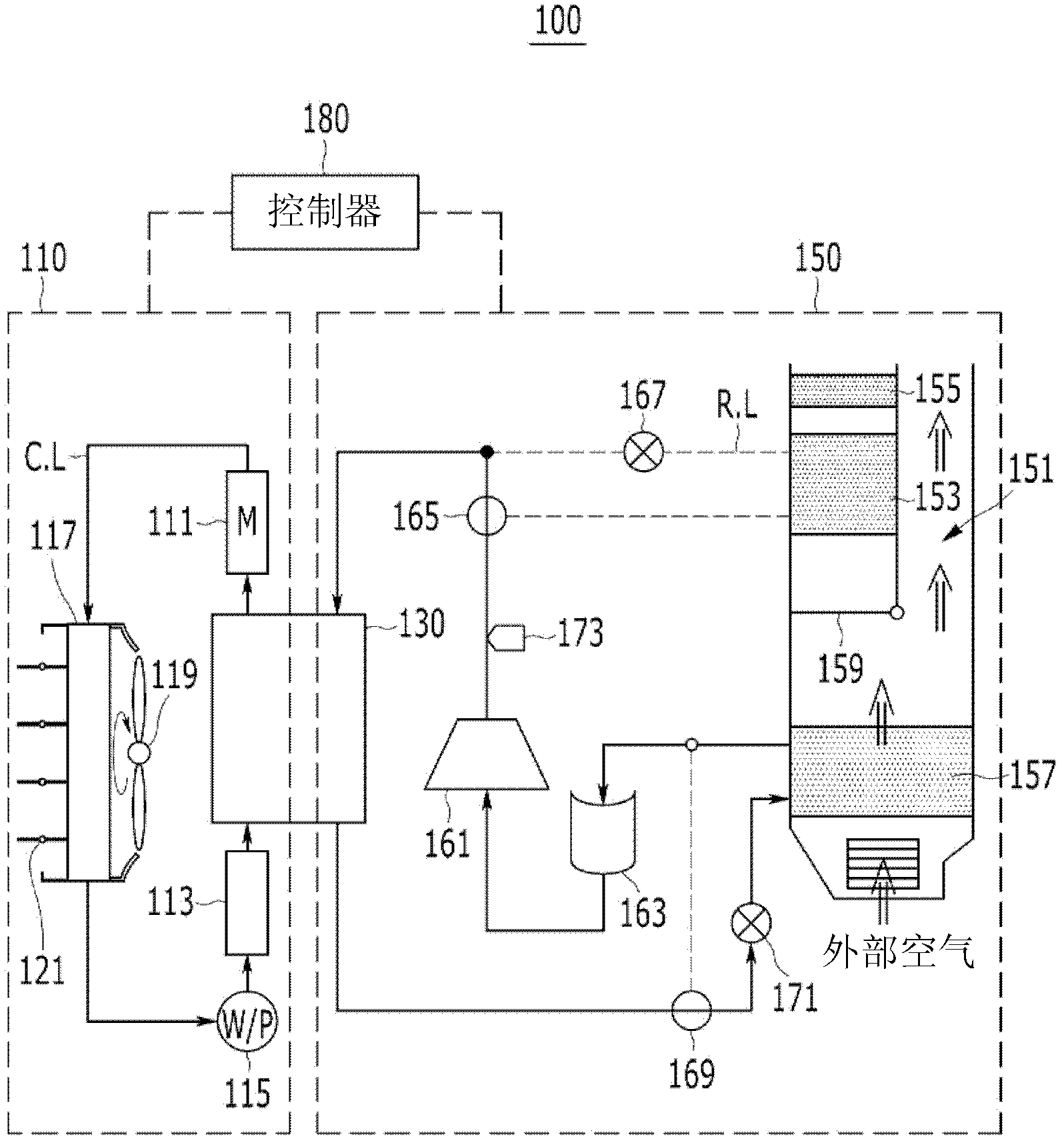

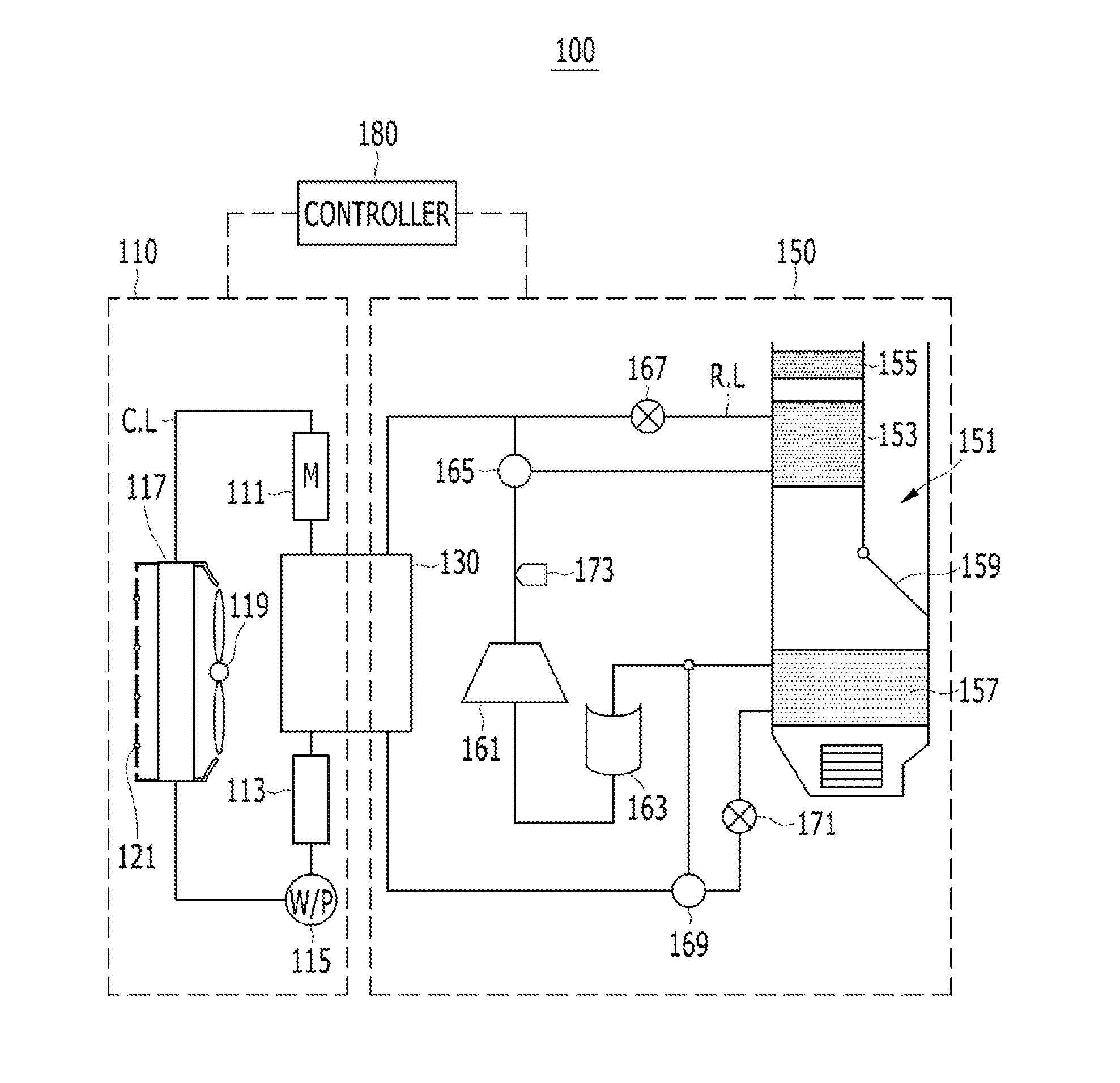

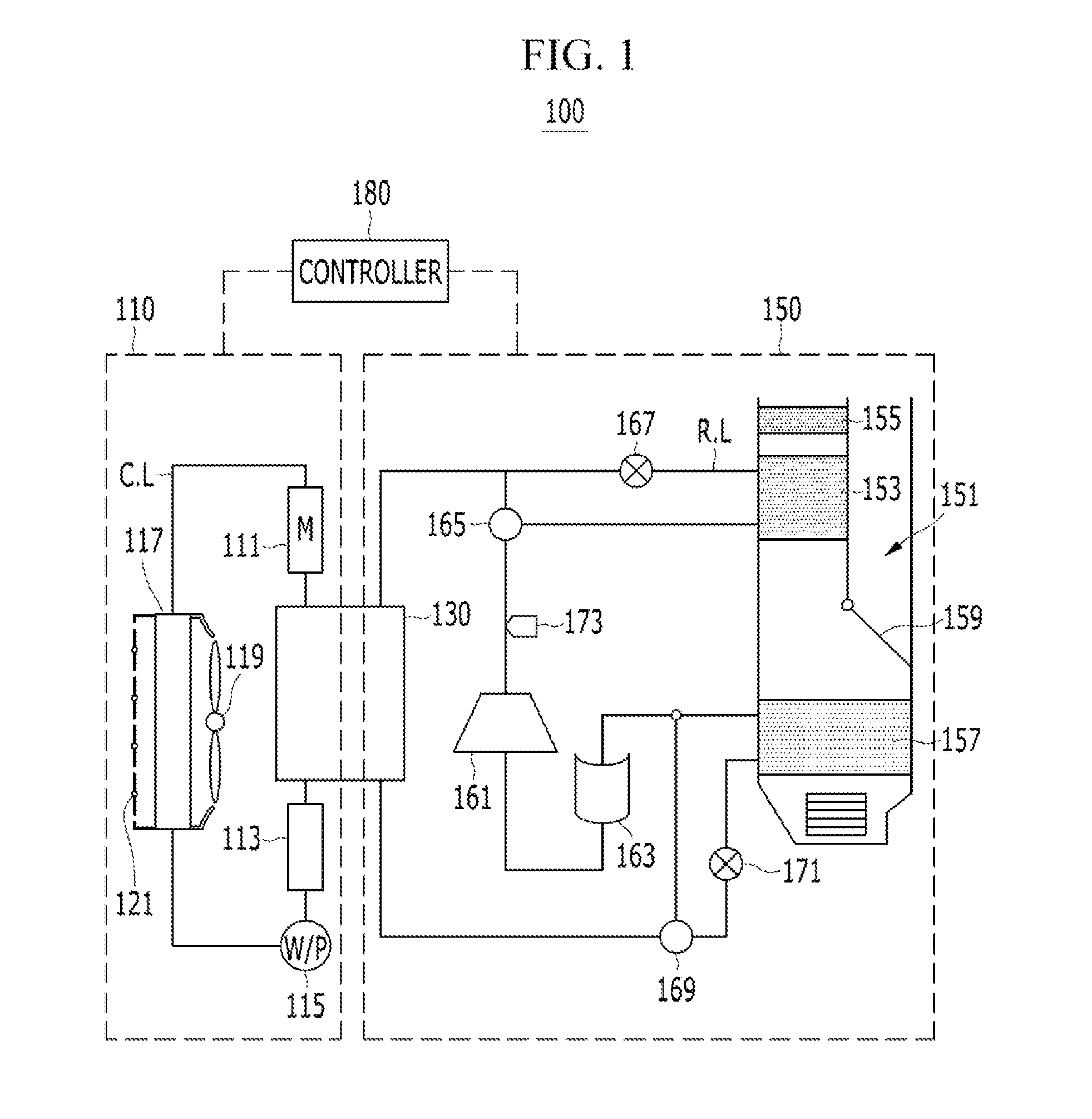

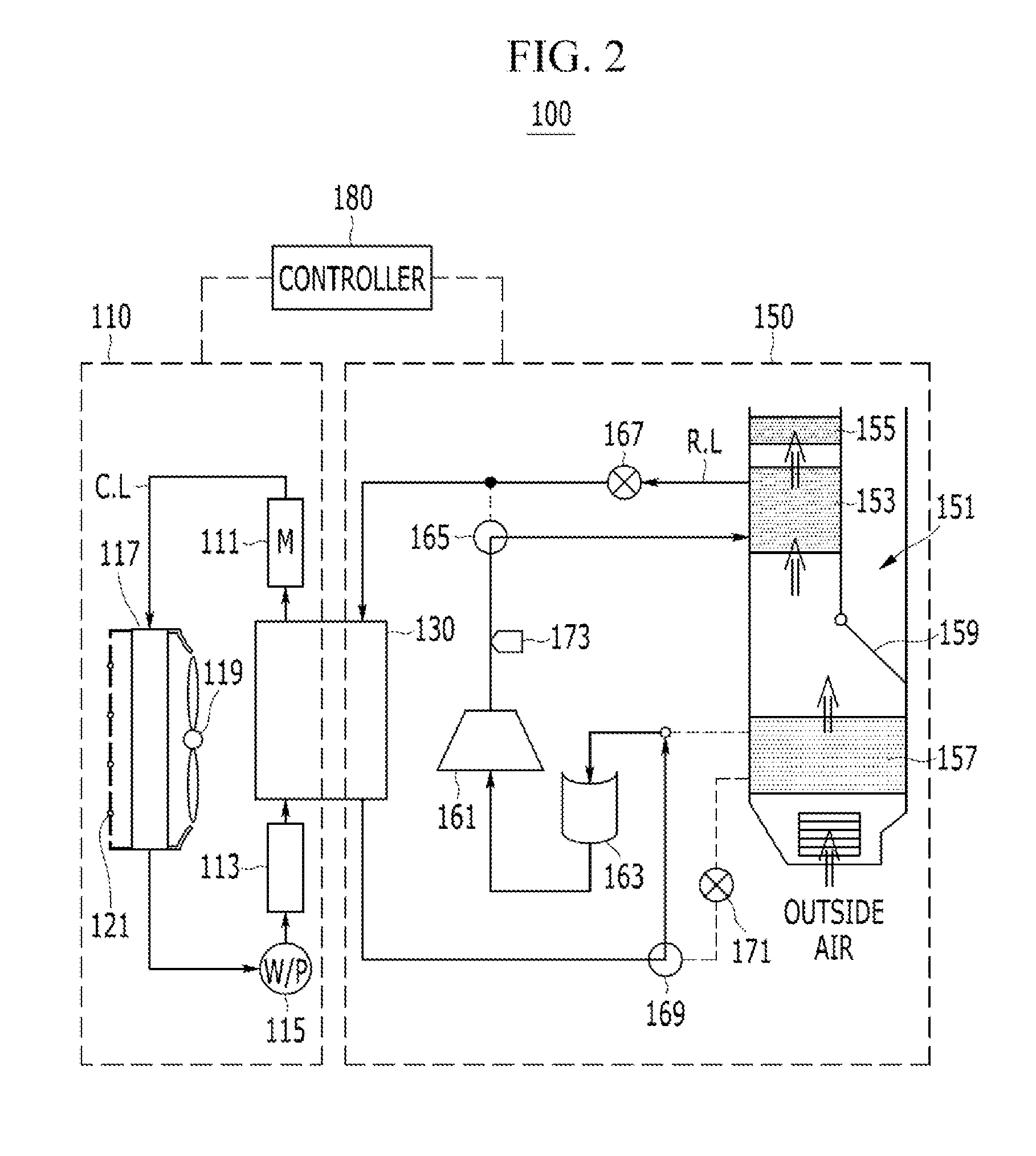

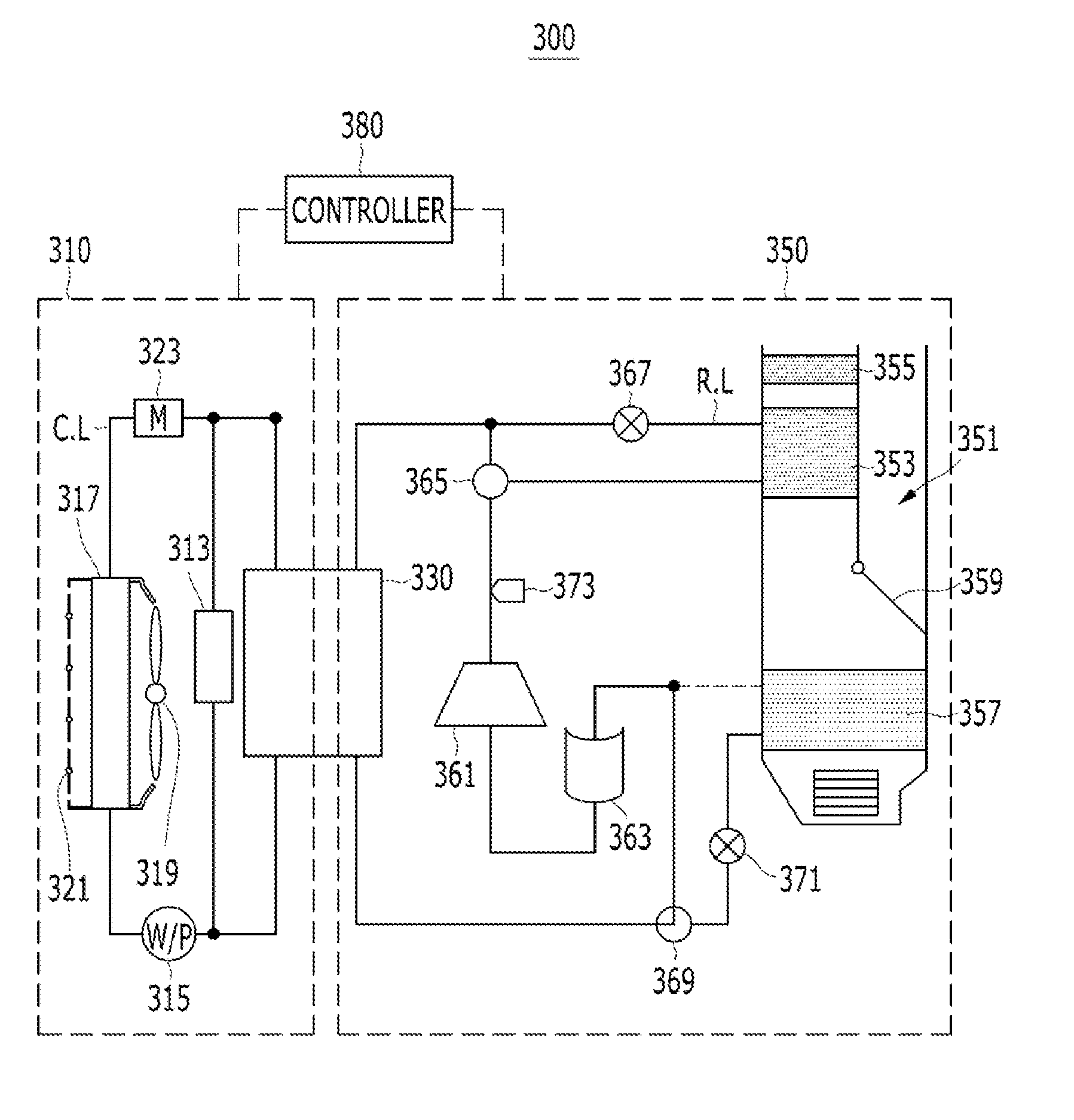

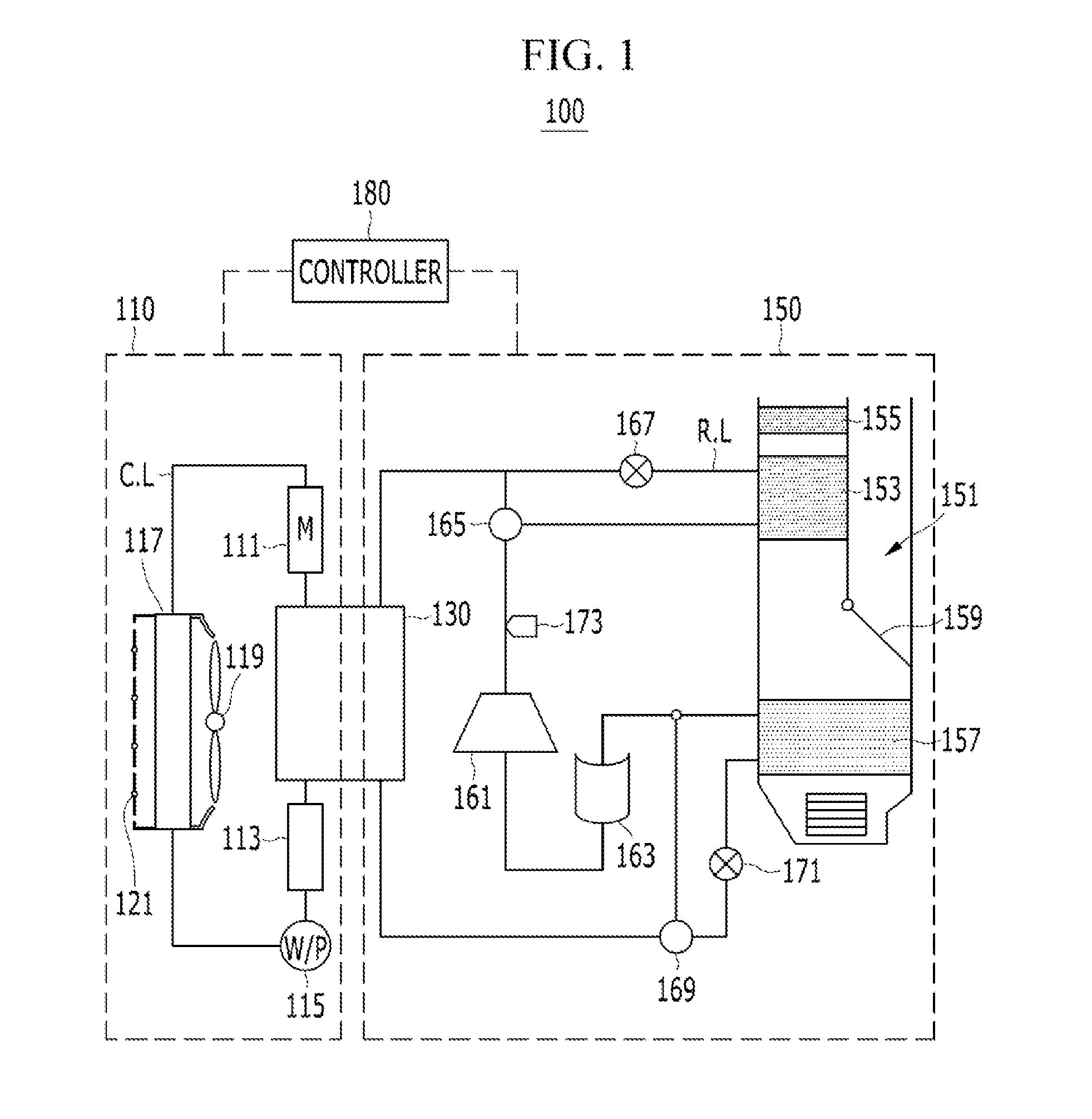

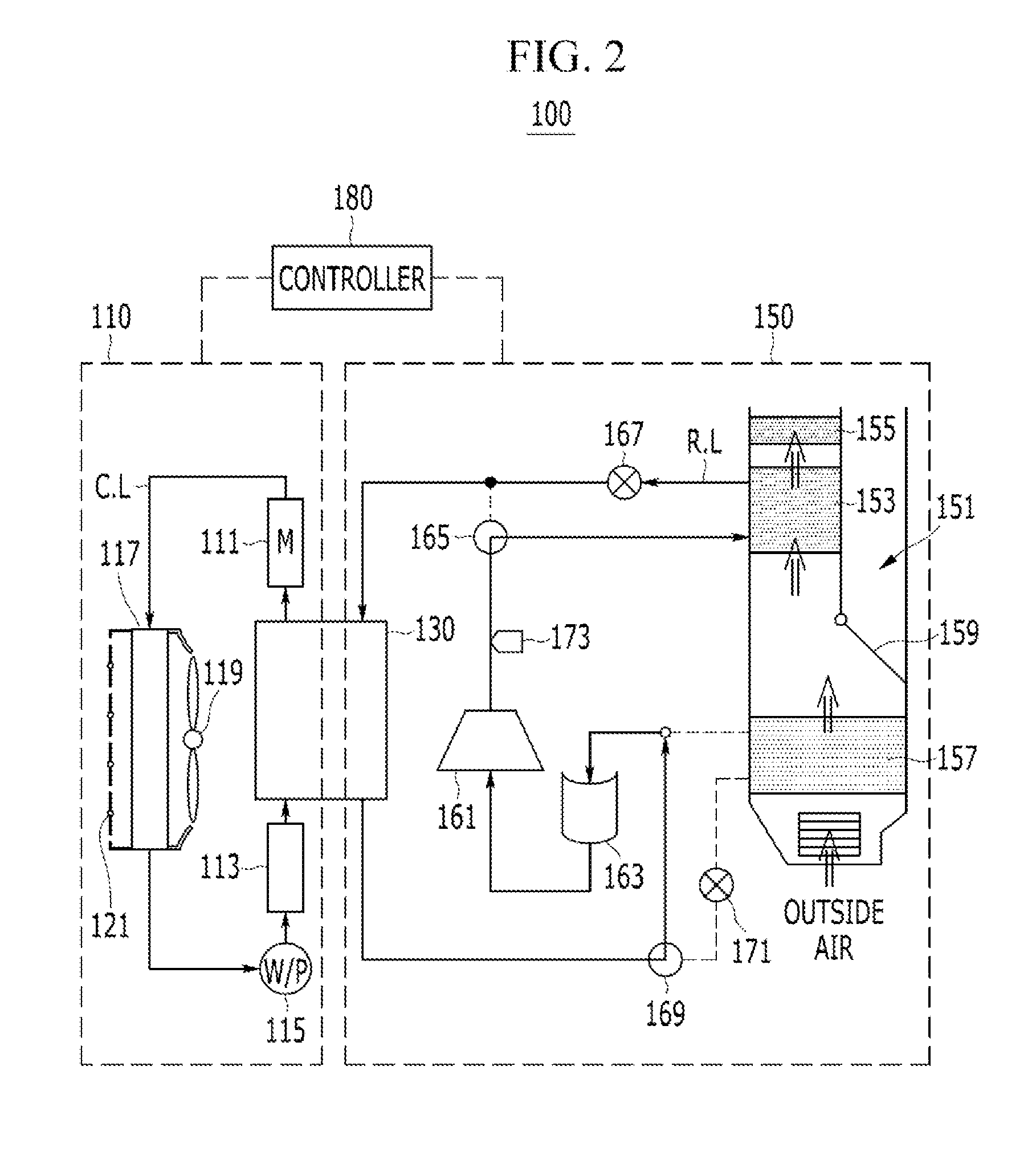

Heat pump system for vehicle

ActiveCN102692095AImprove the heating effectImprove dehumidification effectAir-treating devicesHeat pumpsProcess engineeringHeat pump

The invention discloses a heat pump system for a vehicle, including a water cooled condenser that uses a coolant as a heat exchange media and uses waste heat generated from a motor and an electronic device to improve heating performance, efficiency, and dehumidifying performance. A control method is also described.

Owner:HYUNDAI MOTOR CO LTD +1

Heat pump system for vehicle

ActiveUS20120240604A1Improve efficiencyImprove performanceAir-treating devicesHeat pumpsAutomotive engineeringHeat pump

A heat pump system for a vehicle includes a water cooled condenser that uses a coolant as a heat exchange media and uses waste heat generated from a motor and an electronic device to improve heating performance, efficiency, and dehumidifying performance. A control method is also described.

Owner:HYUNDAI MOTOR CO LTD +1

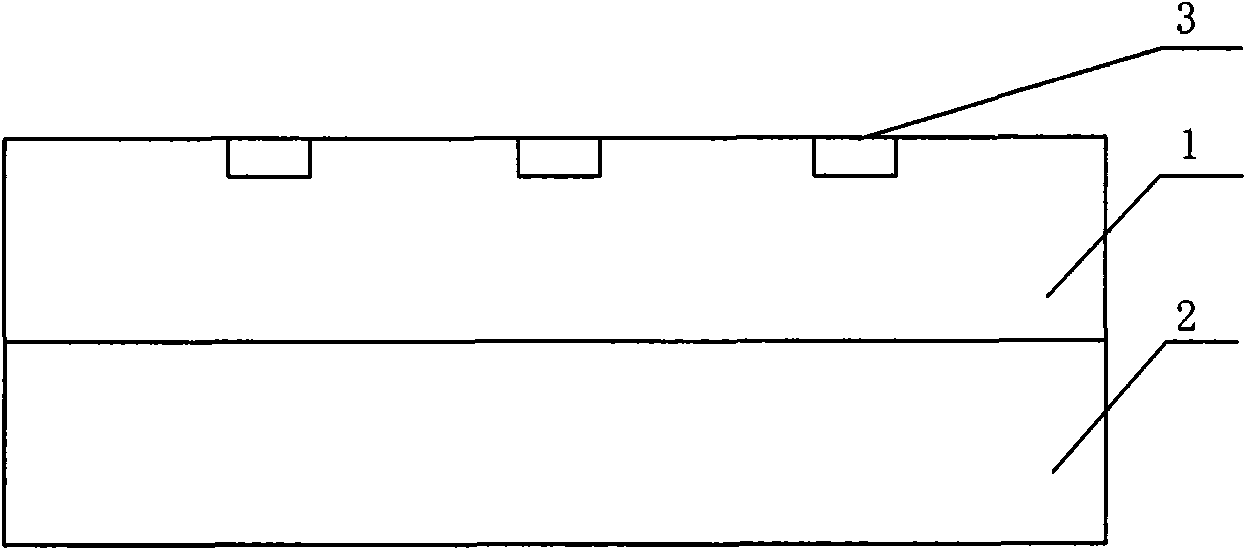

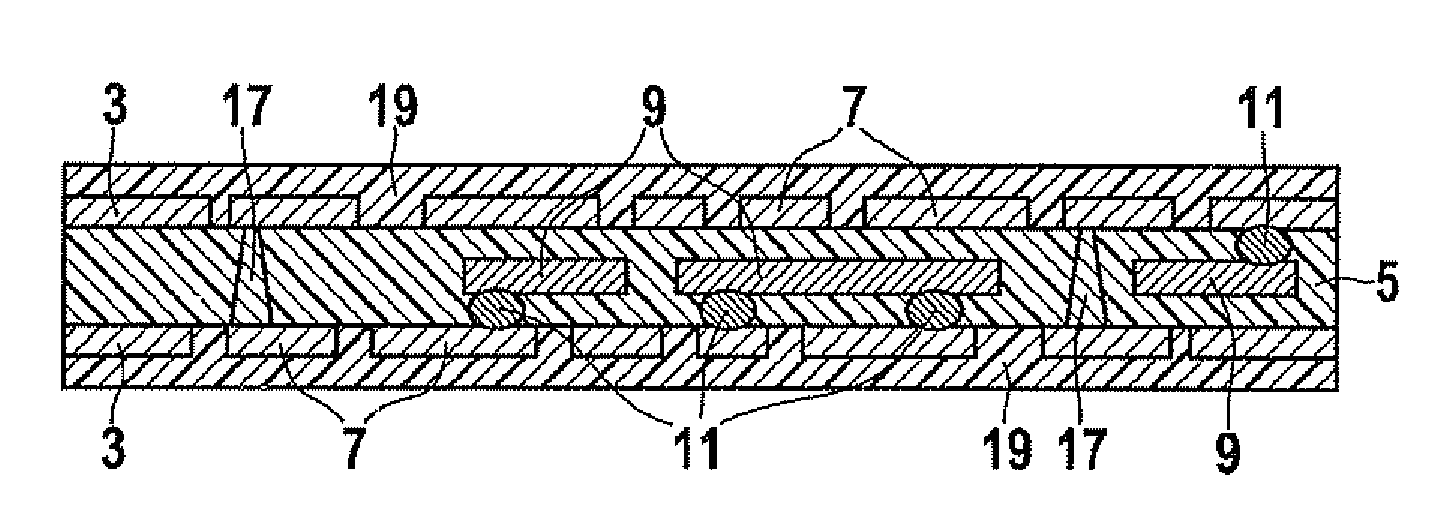

Method of making step groove on PCB

InactiveCN105764258AAvoid damageDamage coverageMultilayer circuit manufactureEngineeringAlkaline etching

The invention relates to the circuit board production technology field and especially relates to a method of making a step groove on a PCB. During inner layer line making, a copper layer to be removed on a step position is firstly kept; during a subsequent pre-formed groove gonging process, only a prepreg above the copper layer to be removed is gonged, the prepreg above the copper layer to be removed is burnt up with no burning copper laser and then a glue refuse is removed by using a plasma glue refuse removing method, and the copper layer to be removed is removed through alkaline etching so that a condition that a bottom of the step groove is damaged when a cover of a gong groove is taken off can be avoided and zero damage of the bottom of the step groove can be guaranteed. A problem that a window at a position of the prepreg corresponding to the step is opened in advance and water is stored so that pressing is layered and becomes white can be avoided and a yield rate is increased.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Lamination cooling system formation method

InactiveUS7530156B2Improve heat transfer efficiencyReduce device sizeMetal-working apparatusMagnetic circuit stationary partsTransformerEngineering

An electric motor, transformer or inductor having a cooling system. A stack of laminations have apertures at least partially coincident with apertures of adjacent laminations. The apertures define straight or angled cooling-fluid passageways through the lamination stack. Gaps between the adjacent laminations are sealed by injecting a heat-cured sealant into the passageways, expelling excess sealant, and heat-curing the lamination stack. Manifold members adjoin opposite ends of the lamination stack, and each is configured with one or more cavities to act as a manifold to adjacent passageway ends. Complex manifold arrangements can create bidirectional flow in a variety of patterns.

Owner:AEROVIRONMENT INC

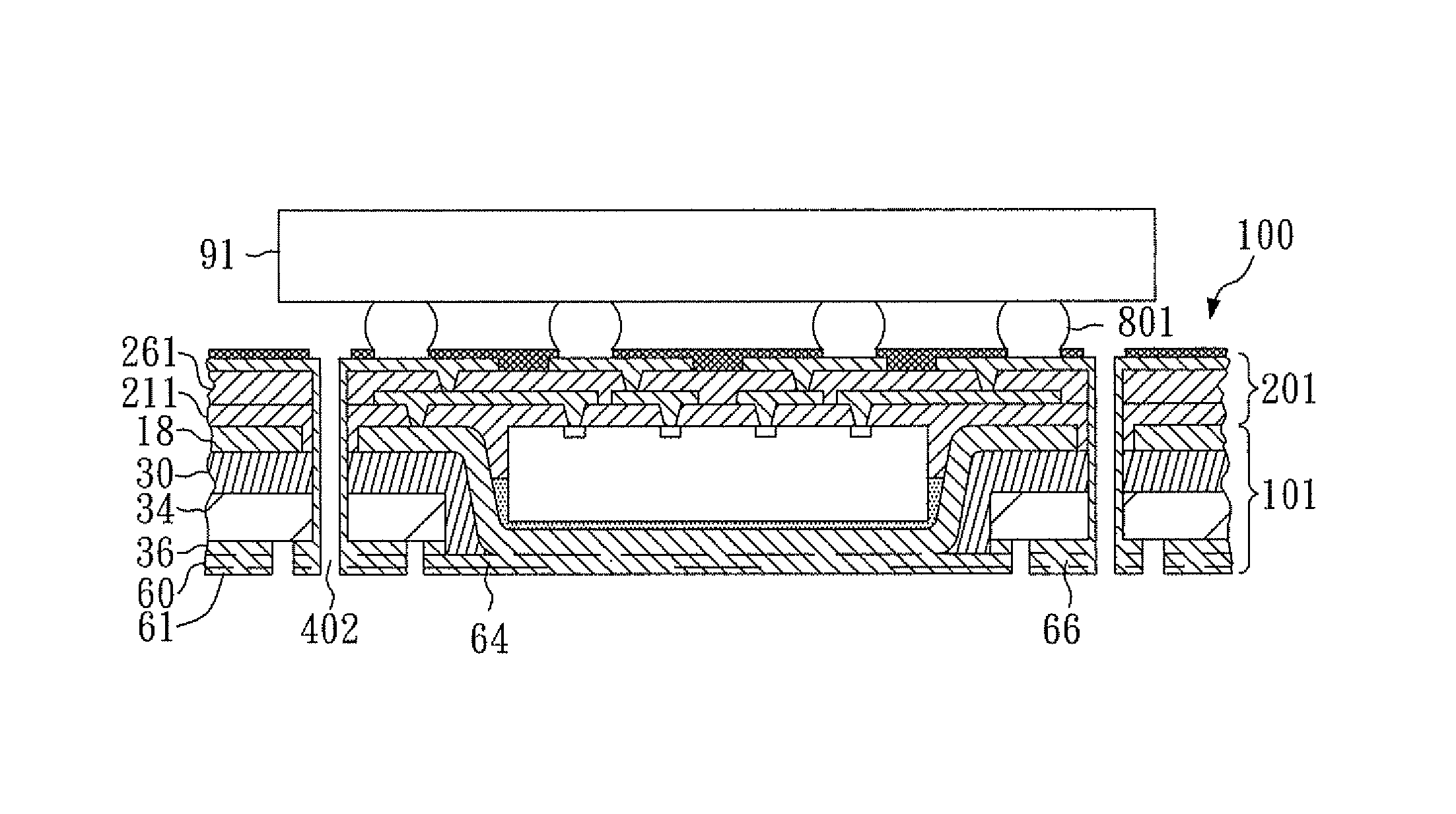

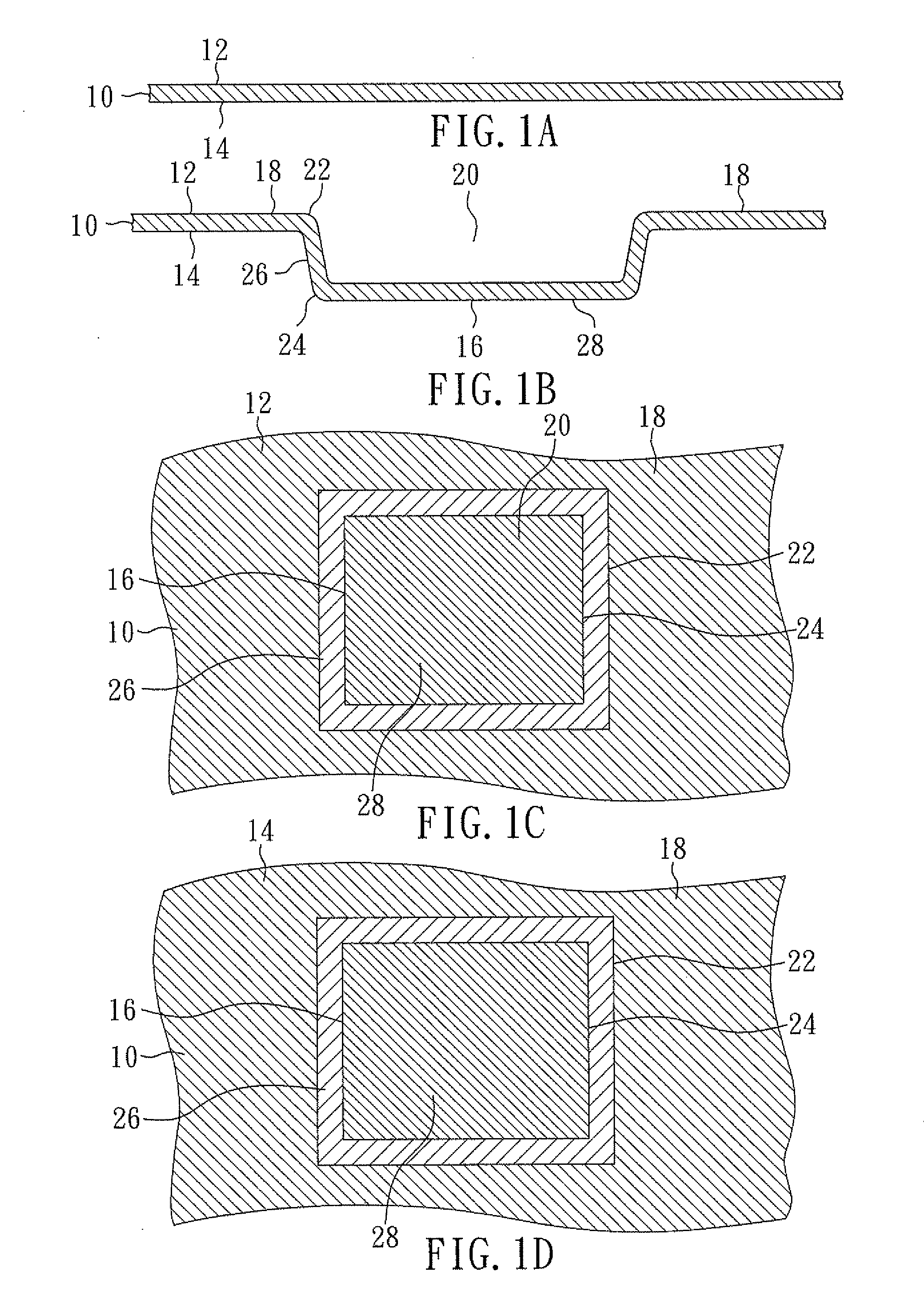

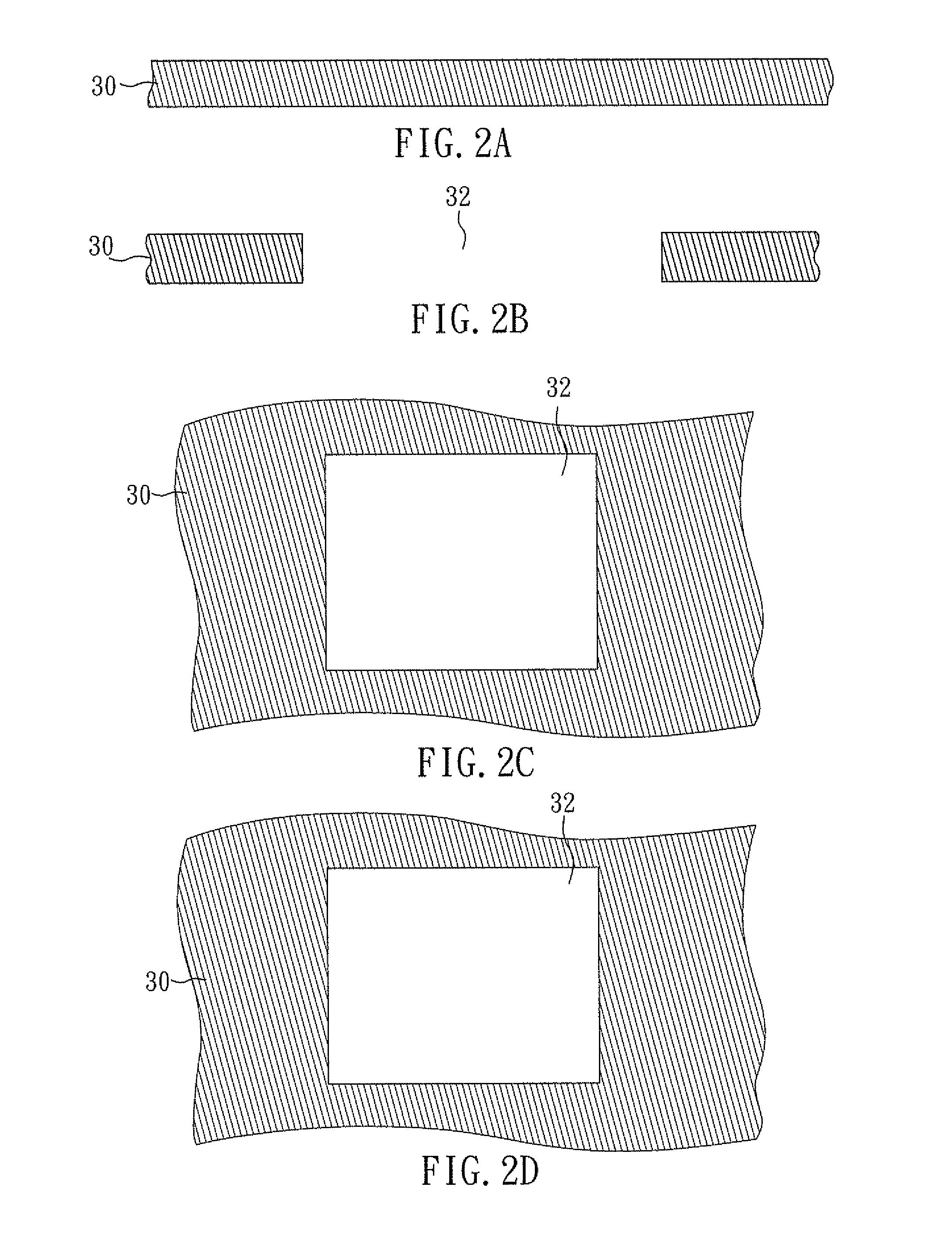

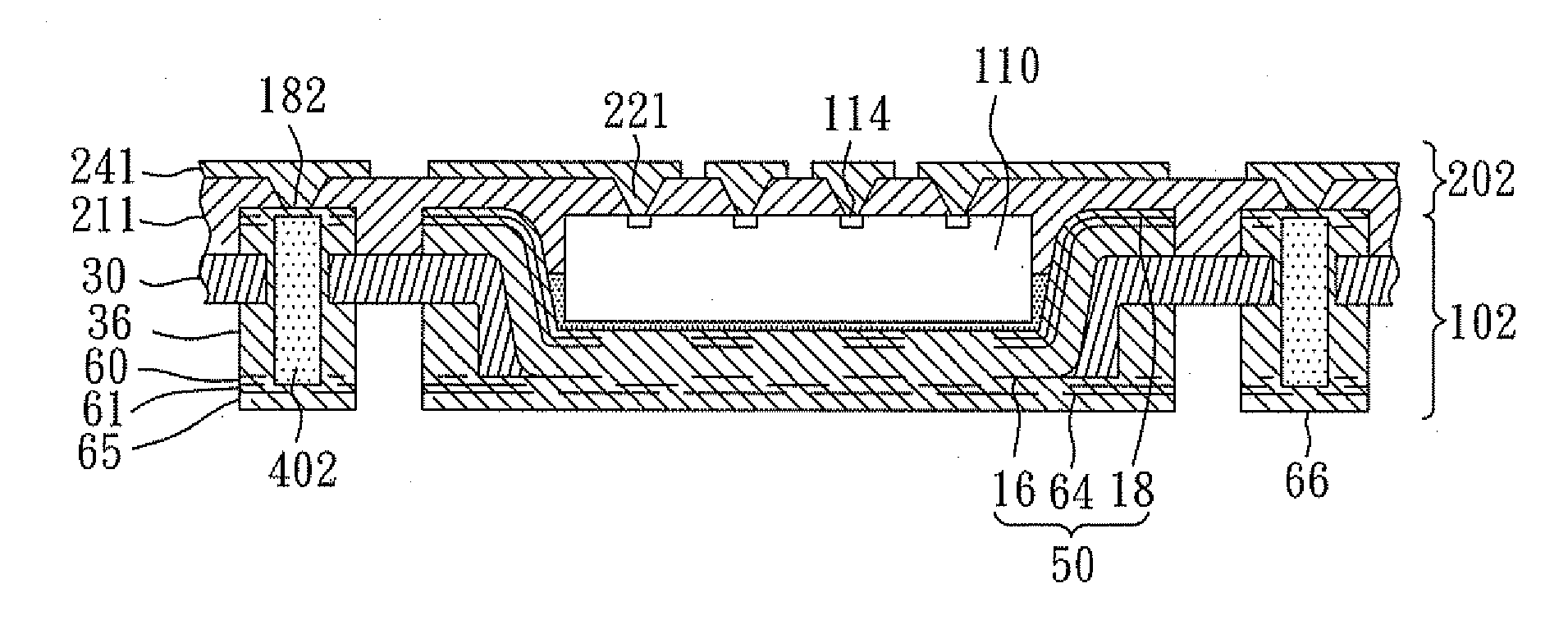

Method of making stackable semiconductor assembly with bump/base/flange heat spreader and build-up circuitry

InactiveUS8343808B2Accelerated dissipationImprove the heating effectSemiconductor/solid-state device detailsSolid-state devicesSignal routingAdhesive

A method of making a stackable semiconductor assembly that includes a semiconductor device, a heat spreader, an adhesive, a terminal, a plated through-hole and build-up circuitry is disclosed. The heat spreader includes a bump, a base and a flange. The bump defines a cavity. The semiconductor device is mounted on the bump at the cavity, electrically connected to the build-up circuitry and thermally connected to the bump. The bump extends from the base into an opening in the adhesive, the base extends vertically from the bump opposite the cavity and the flange extends laterally from the bump at the cavity entrance. The build-up circuitry provides signal routing for the semiconductor device. The plated through-hole provides signal routing between the build-up circuitry and the terminal. The heat spreader provides heat dissipation for the semiconductor device.

Owner:BRIDGE SEMICON

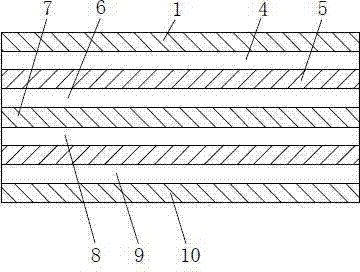

Ink jet advertisement consumable material and production method thereof

ActiveCN104275956AEasy to peelHigh clarityLamination ancillary operationsSynthetic resin layered productsPlastic materialsAdhesive

The invention relates to an ink jet advertisement consumable material and a production method thereof. The ink jet advertisement consumable material sequentially comprises a transparent protection layer, an upper adhesive layer, an upper silicone oil layer, an upper base layer, a lower silicone oil layer, a lower adhesive layer, a lower base layer and an ink jet coating, wherein the upper base layer and the lower base layer are respectively made of plastic materials. According to the ink jet advertisement consumable material, materials for preparing conventional base layers are replaced, and the plastic materials with smooth and flat surfaces are adopted and used for forming the upper base layer and the lower base layer, so that the ink jet advertisement consumable material has the advantages of high definition and high permeability; meanwhile, conventional release paper is omitted, so that forest resources are saved; the ink jet advertisement consumable material is of an integrated structure, the material does not need to be laminated by film again during using; according to the production method, the processes of respectively processing synthetic PP coating paper and a coldly laminating film are omitted, so that the integrated production is achieved; the production efficiency is relatively high; in addition, due to the arrangement manner of the upper layer and the lower layer, the ink jet advertisement consumable material also has the advantage that products are relatively easy to peel off.

Owner:江苏奥力新材料股份有限公司

Heat pump system for vehicle

ActiveUS8910489B2Improve efficiencyImprove performanceHeat pumpsEvaporators/condensersHeat pumpCoolant

A heat pump system for a vehicle includes a water cooled condenser that uses a coolant as a heat exchange media and uses waste heat generated from a motor and an electronic device to improve heating performance, efficiency, and dehumidifying performance. A control method is also described.

Owner:HYUNDAI MOTOR CO LTD +1

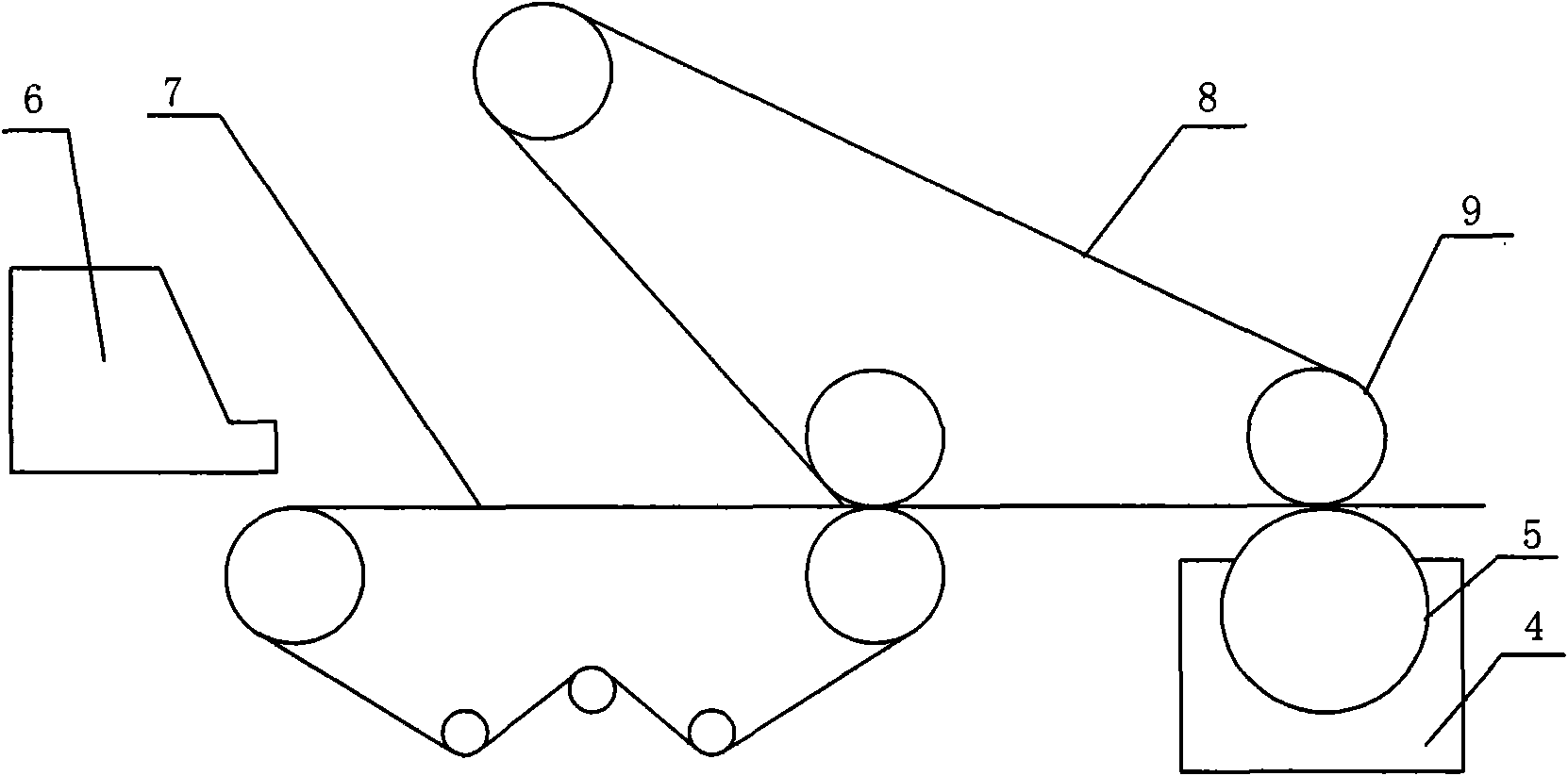

Method for producing anti-counterfeiting card paper with windowed security thread

ActiveCN101581053AAvoid laminationEasy to processNatural cellulose pulp/paperPaper-making machinesFiberPulp and paper industry

The invention relates to a method for producing anti-counterfeiting card paper with a windowed security thread. The anti-counterfeiting surface paper with the windowed security thread is produced by a cylinder mould, the bottom paper is produced by a fourdrinier, and a joint between the wet bottom paper produced by the fourdrinier and the wet anti-counterfeiting surface paper with the windowed security thread, which is produced by the cylinder mould, is pressed to be dewatered by a press roll with felt; the water content in the surface paper and the bottom paper are controlled, so that hydrogen bonds between the surface paper and the bottom paper are combined to form the anti-counterfeiting card paper with the windowed security thread; and the anti-counterfeiting card paper with the windowed security thread is dried and reeled into a finished product. The surface paper and the bottom paper are made of the same pulp, which comprises the following raw materials in proportion: 65 percent of needle pulp and 35 percent of kargeleaf pulp; the degree of beating is between 45 and 48 degrees of SR; and during the combination, the water contents in the surface paper and the bottom paper are controlled to be between 62 and 63 percent. The method has the advantages of being easily processed, having low cost, avoiding lamination processing of the surface paper and the bottom paper, simplifying production flow, and improving the production efficiency. The anti-counterfeiting card paper produced by the method is applied to anti-counterfeiting garment hangtags, covers of anti-counterfeiting books and the like.

Owner:SHANDONG KAILI SPECIAL PAPER

Stackable semiconductor assembly with bump/base/flange heat spreader and electromagnetic shielding

InactiveUS20120126401A1Excellent heat spreading heatImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSignal routingDevice material

A stackable semiconductor assembly includes a semiconductor device, a heat spreader, an adhesive, a terminal, a plated through-hole and build-up circuitry. The heat spreader includes a bump, a base and a flange. The bump defines a cavity. The semiconductor device is mounted on the bump at the cavity, electrically connected to the build-up circuitry and thermally connected to the bump. The bump extends from the base into an opening in the adhesive, the base extends vertically from the bump opposite the cavity and the flange extends laterally from the bump at the cavity entrance. The build-up circuitry provides signal routing for the semiconductor device. The plated through-hole provides signal routing between the build-up circuitry and the terminal. The heat spreader provides heat dissipation for the semiconductor device.

Owner:BRIDGE SEMICON

Stackable semiconductor assembly with bump/flange heat spreader and dual build-up circuitry

InactiveUS8952526B2Improve performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSignal routingAdhesive

Owner:BRIDGE SEMICON

Process for producing a cover with a glass pane and electrical function elements

InactiveUS7360306B2Simple and reliable processEasy to manufacturePV power plantsMetal-working apparatusMobile vehicleEngineering

Owner:WEBASTO AG

Advertising inkjet supply and production method thereof

ActiveCN104228388AHigh clarityHigh transparencyLamination ancillary operationsLaminationPlastic materialsEngineering

The invention relates to an advertising inkjet supply and a production method thereof. The advertising inkjet supply comprises a protective layer, a bonding layer, a silicone oil layer and a basal layer, wherein the basal layer is made of a plastic material; an ink-receptive coating is arranged below the basal layer. The production method comprises the following steps: coating the ink-receptive coating on one side of the basal layer, drying, coating silicone oil on the other side of the basal layer, drying, coating a pressure-sensitive adhesive, drying again, and bonding the protective layer. By replacing a material of the traditional basal layer with a plastic material with a smooth and flat surface, the advertising inkjet supply has the advantages of high definition and high transparency, and use of traditional release paper is avoided, thereby saving forest resources; the advertising inkjet supply has an integrated structure, thus avoiding re-mounting of a film during use; by the production method, separate processing of PP (polypropylene) coating synthetic paper and a cold mounting film is avoided, integrated production is achieved and the production efficiency is high.

Owner:江苏奥力新材料股份有限公司

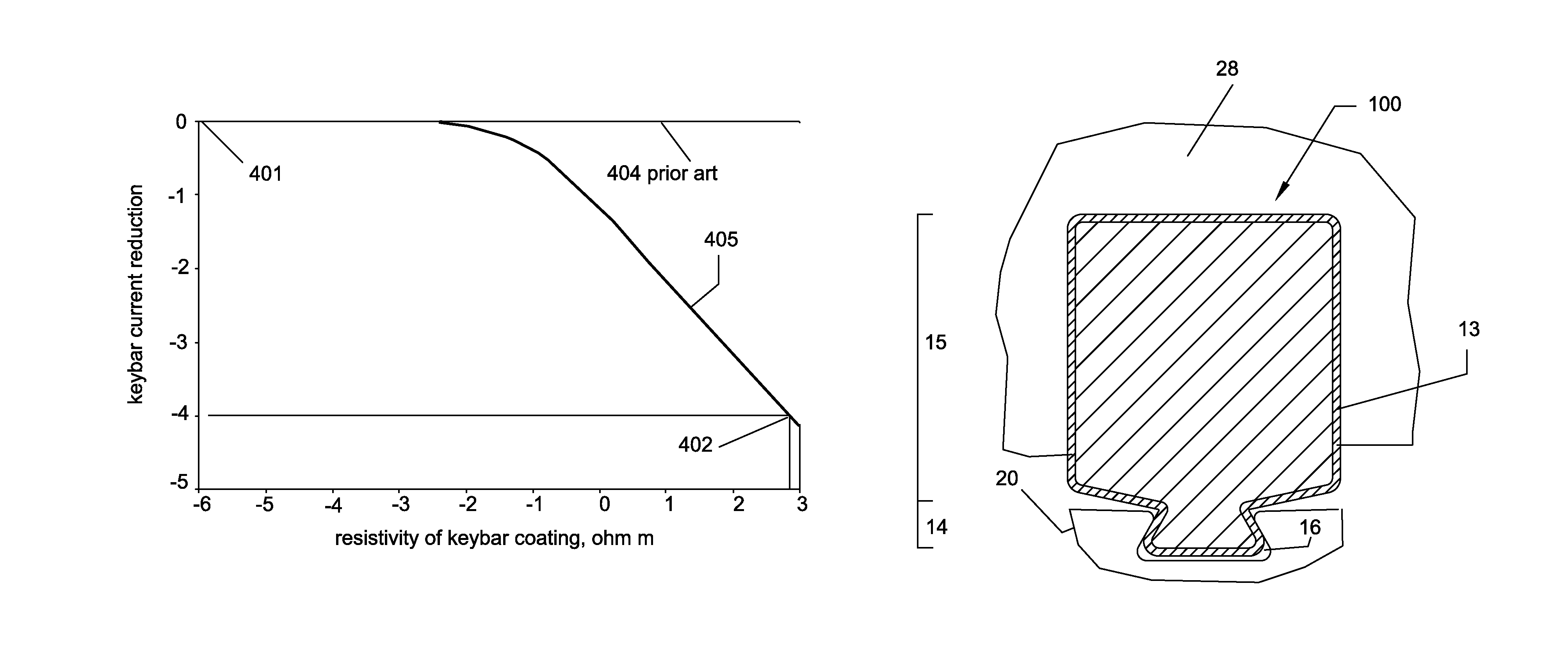

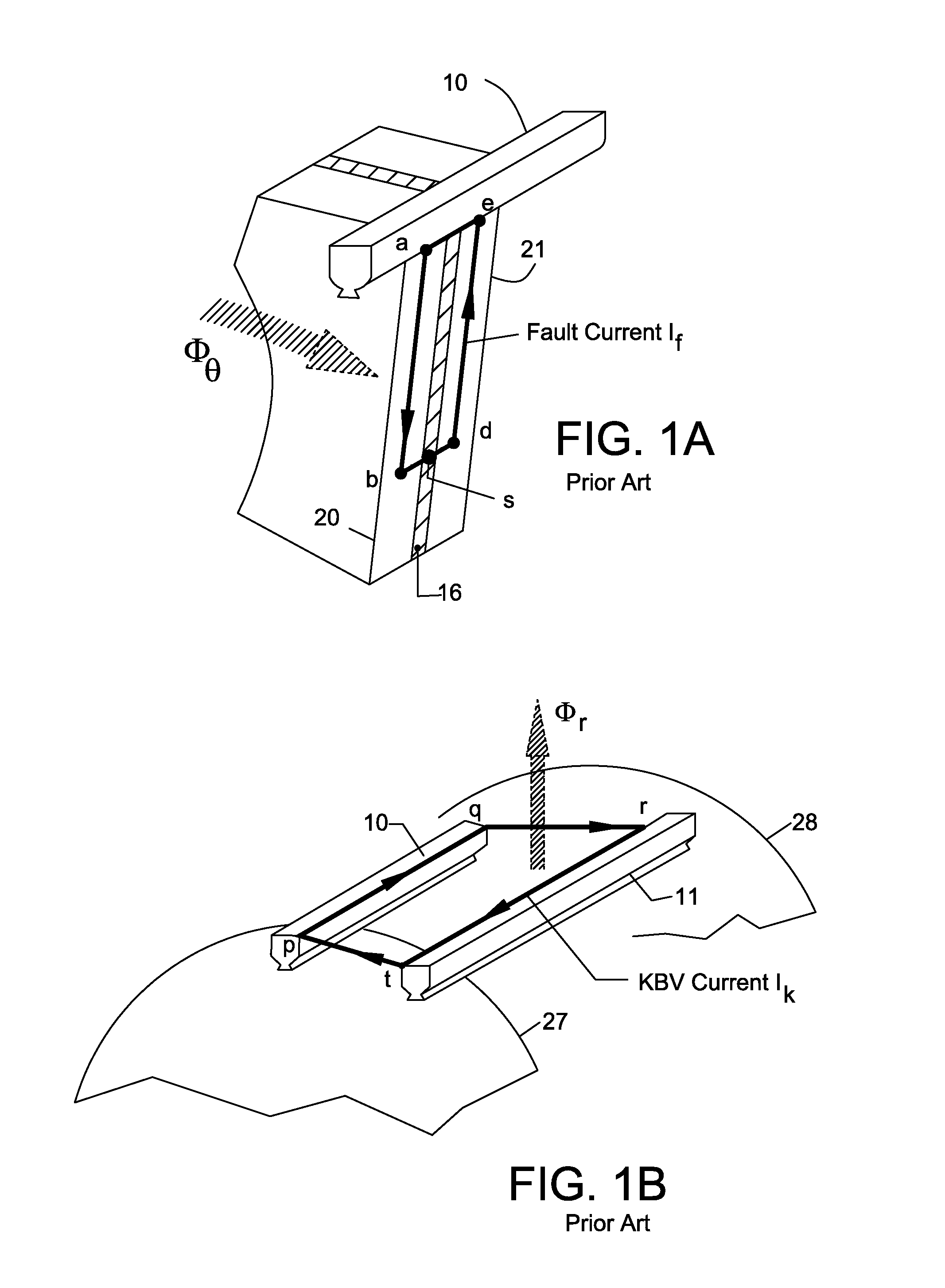

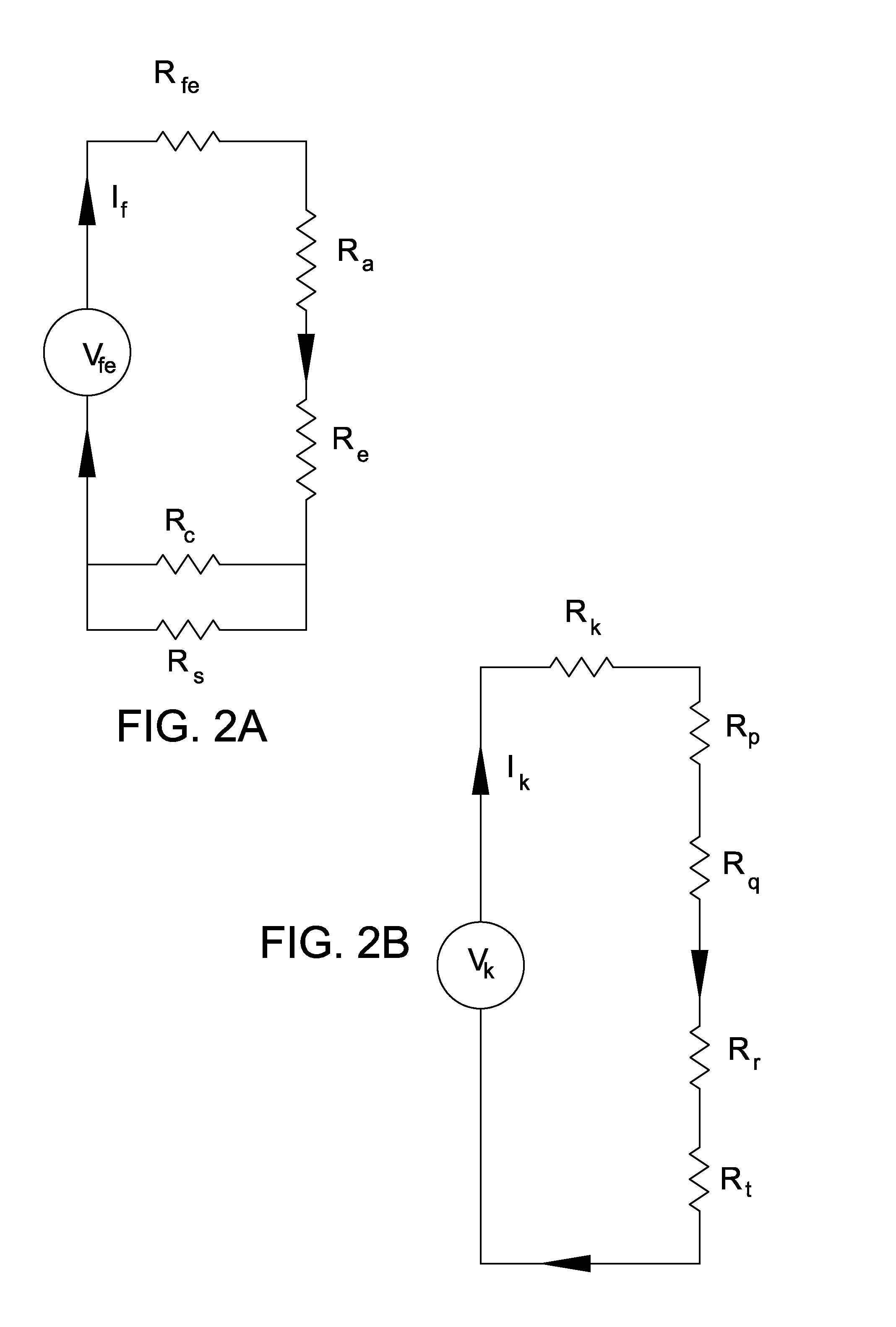

Coated keybar to protect electric machines

InactiveUS8829769B1Prevent deratingHigh leading power factor operating conditionAssociation with grounding devicesBoltsHigh resistanceElectrical resistance and conductance

A keybar or clamping bolt with a high-resistivity coating to protect an electric machine. The coating engages the laminations, flanges and frame rings and forms a part of electrical circuits through which harmful eddy currents circulate. One class of eddy currents, viz., core-fault currents, due to edge burrs or insulation defects, are forced to flow through this coating. The high resistance of the coating weakens the fault currents, preventing creation of hotspots that can cause core failure. Such coated keybar is in inexpensive alternative to traditional recoating and / or core-fault detection. Another class of eddy currents, viz., keybar currents, caused by over-fluxing, are also forced to flow through this coating. The high resistance of the coating weakens the keybar currents, so prevents core-end overheating. A coated keybar also allows the machine to operate at higher leading power factor. It also prevents core-decompression hence protects the machine against loose laminations.

Owner:RAO DANTAM K

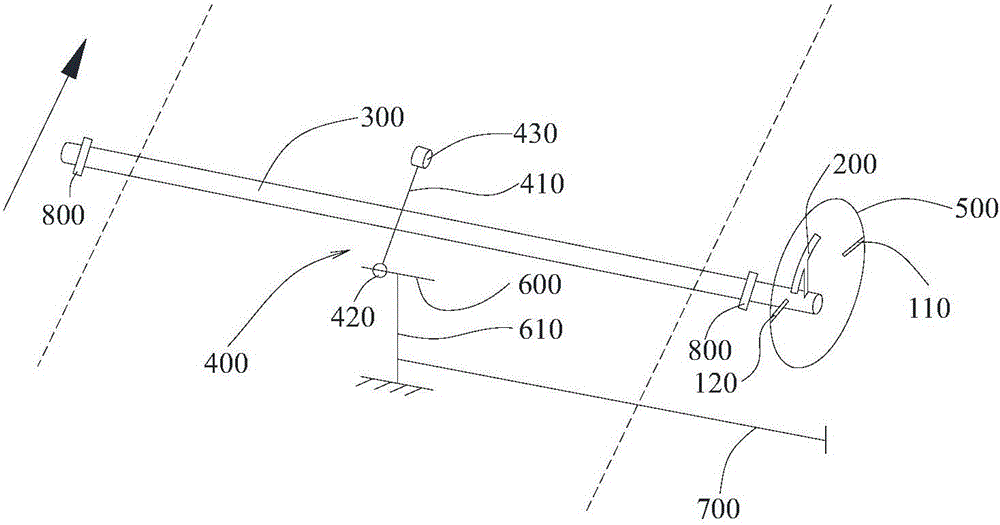

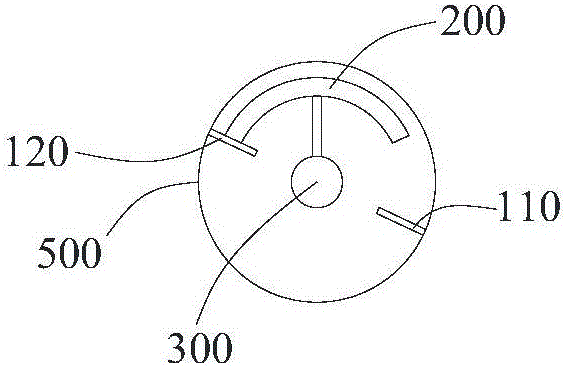

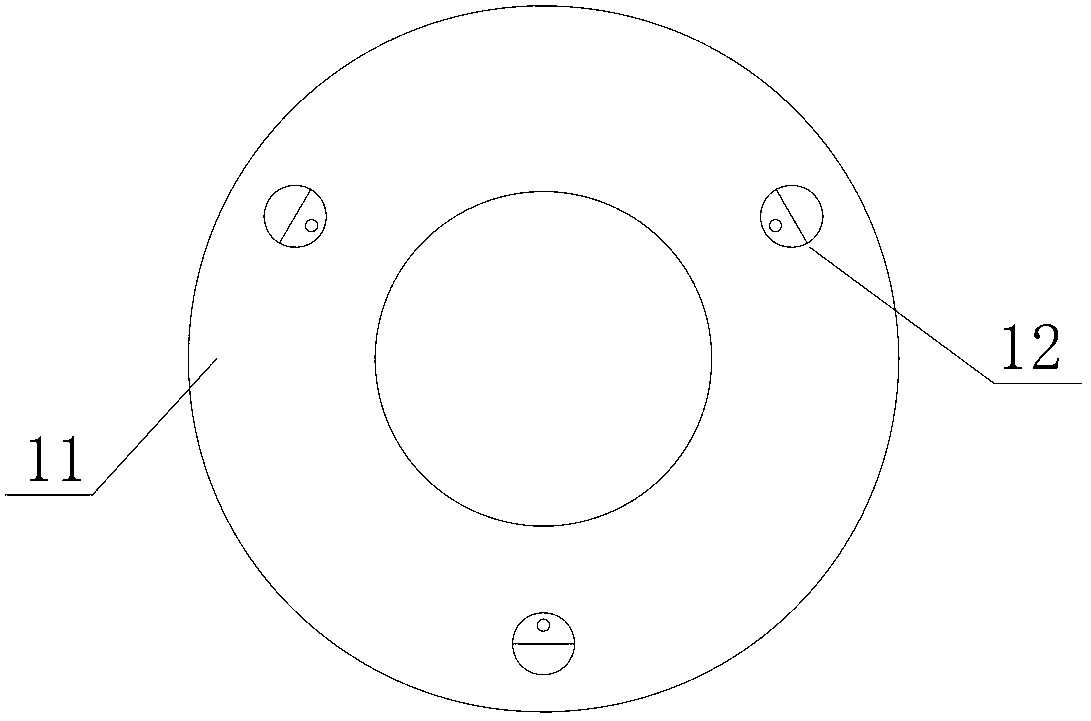

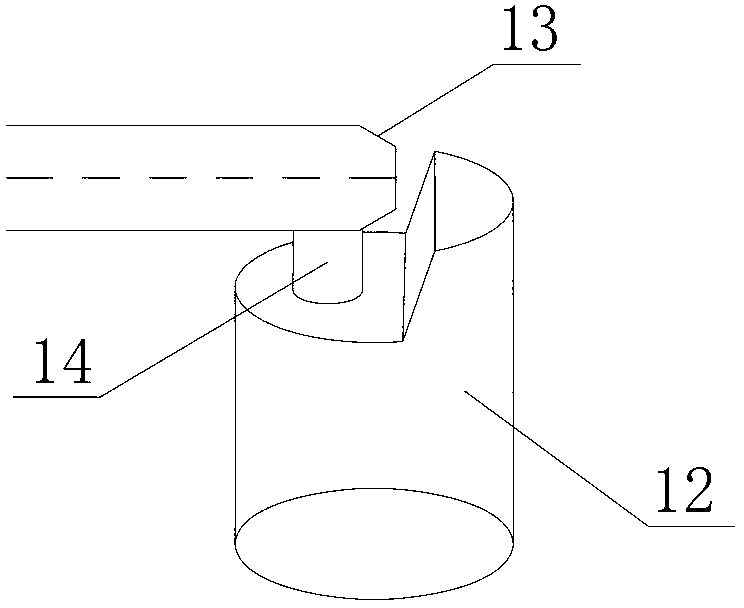

Substrate processing device

InactiveCN105679698AEasy to replaceAvoid downtimePhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineering

The invention provides a substrate processing device comprising a processing chamber, a substrate perception component, a rotating shaft and a driving component. A part of the rotating shaft is arranged in the processing chamber, and at least one of the two end parts of the rotating shaft extends to the outside of the processing chamber. The substrate perception component is arranged on the rotating shaft and positioned outside the processing chamber. The driving component is fixed on the part, which is arranged in the processing chamber, of the rotating shaft. The driving component can drive the rotating shaft to rotate around the axis of the rotating shaft along a first direction when the driving component contacts a substrate to be processed. The driving component can drive the rotating shaft to rotate around the axis of the rotating shaft along a second direction opposite to the first direction when the substrate is away from the driving component. The invention also provides substrate processing equipment. The substrate perception component is arranged outside the processing chamber so that the substrate perception component is not influenced by processing fluid.

Owner:BOE TECH GRP CO LTD +1

Application of polyethylene glycol to dyeing animal tissue section grease

InactiveCN110426259AAvoid destructionPrevent shrinkage deformationWithdrawing sample devicesPreparing sample for investigationSolubilityPolyethylene glycol

The invention belongs to the technical field of pathological tissue section making, and particularly relates to application of polyethylene glycol to dyeing animal tissue section grease. Through the excellent water solubility characteristic of the polyethylene glycol, with the polyethylene glycol as the dehydrating agent, the permeation and embedding formation of a medium are realized by means ofembedding in the dehydrating process, a formed tissue embedding block has the appearance characteristic of a paraffin block, the embedded medium can be removed by washing the tissue embedding block without processing the tissue embedding block with an organic solvent, and the problem that grease loss is caused by organic solvent processing is avoided. Tissue sections prepared by the method have the thickness of 3-5 micron, and the problem that tissue overlapping is caused by the too high thickness of the frozen sections is avoided. After the tissue sections prepared by the method are dyed by oil red O, due to the dehydration and permeation of the polyethylene glycol, most of grease drops are completely preserved in cytoplasm, the problem of displacement of grease drops in the frozen sections is avoided, and the problem that a tissue structure is not complete since ice crystals are generated in the frozen sections at a low temperature is also avoided.

Owner:武汉赛维尔生物科技有限公司

Silver micro powder and preparation method and application thereof

PendingCN114054769AActive connectionImprove conductivityTransportation and packagingMetal-working apparatusSilver iodideSilver bromide

The invention relates to silver micro powder and a preparation method and application thereof, and relates to the technical field of functional materials. The preparation method comprises the following steps: preparing a silver nitrate solution at a temperature of 10-20 DEG C, a dispersant solution at a temperature of 30-60 DEG C, a morphology regulator solution at a temperature of 25-35 DEG C, a pH regulator solution at a temperature of 30-60 DEG C and a reducing agent solution at a temperature of 55-65 DEG C; adding the pH regulator solution into the silver nitrate solution, performing stirring, adding the morphology regulator solution, the reducing agent solution and the dispersing agent solution, performing mixing, adjusting the temperature to 30-60 DEG C, and performing reaction for 30-90 minutes; performing cleaning until the electric conductivity of the reacted product is less than 50 [mu]s / cm, and performing settling and separating; and adding a surface treating agent, performing drying, powdering and sieving to obtain a product. The mass of a morphology regulator is 0.1-0.5% of the mass of the silver micro powder, and the morphology regulator comprises at least one of silver chloride, silver bromide and silver iodide. The preparation method is simple and easy to implement and high in production efficiency.

Owner:广东羚光新材料股份有限公司

Cover with a glass pane and electrical function elements

InactiveUS20080150327A1Simple and reliable processEasy to manufactureEngine sealsSynthetic resin layered productsElectricityMobile vehicle

Owner:WEBASTO AG

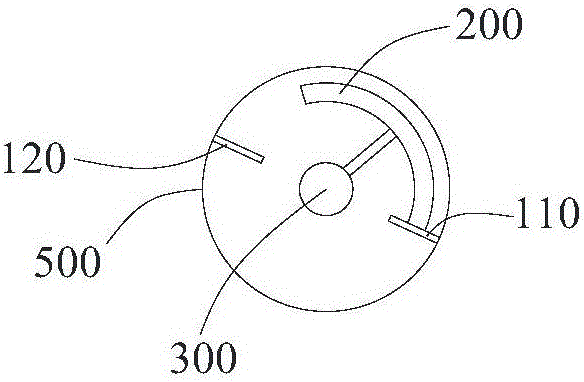

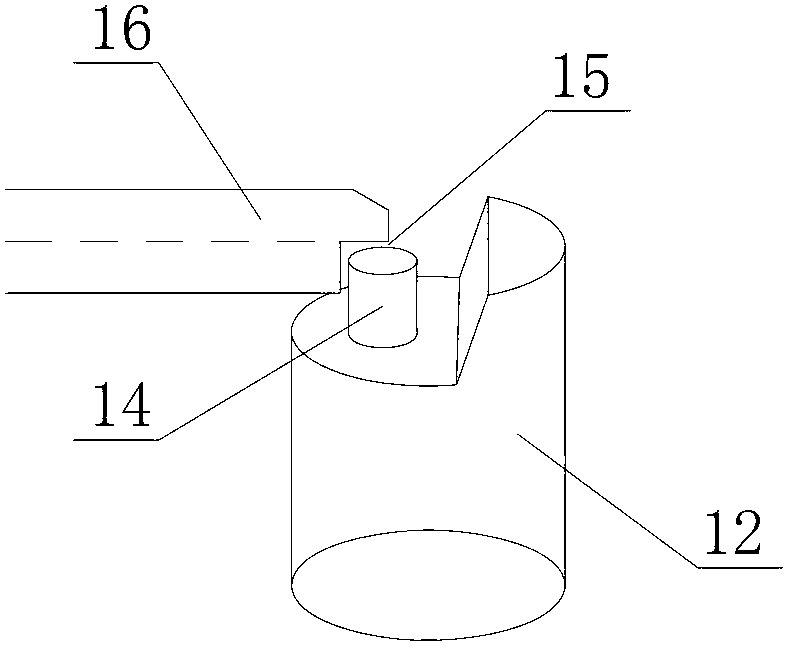

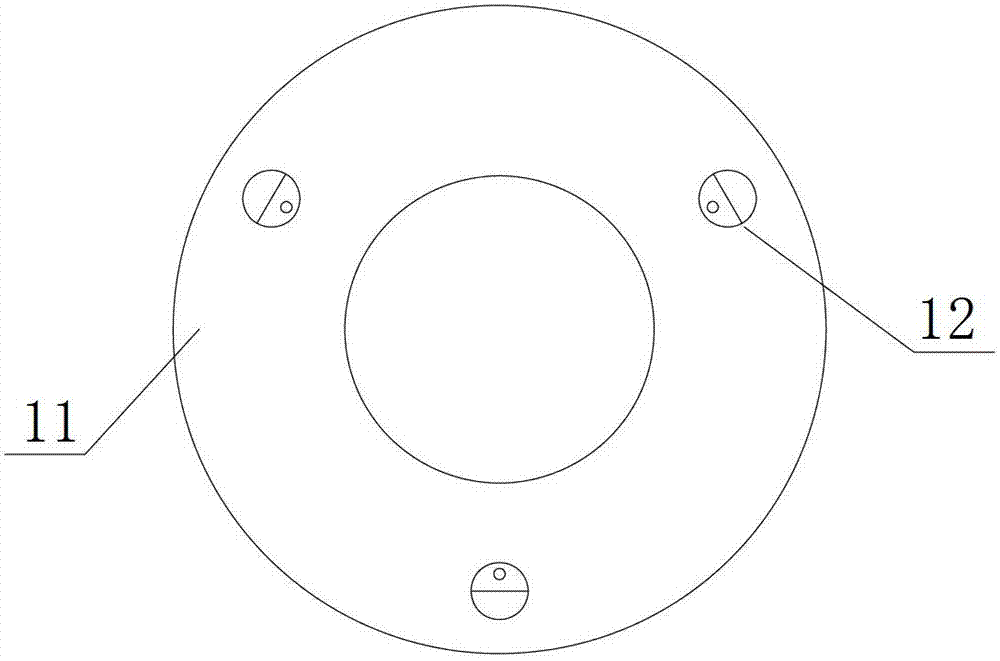

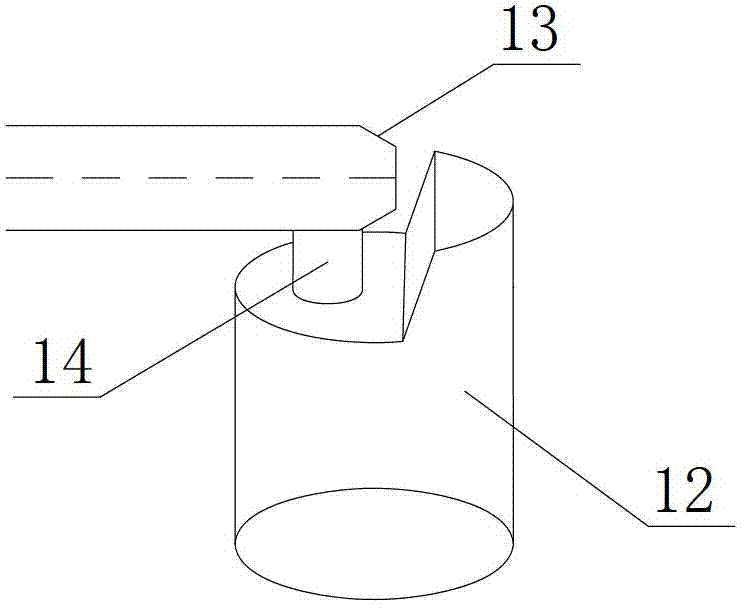

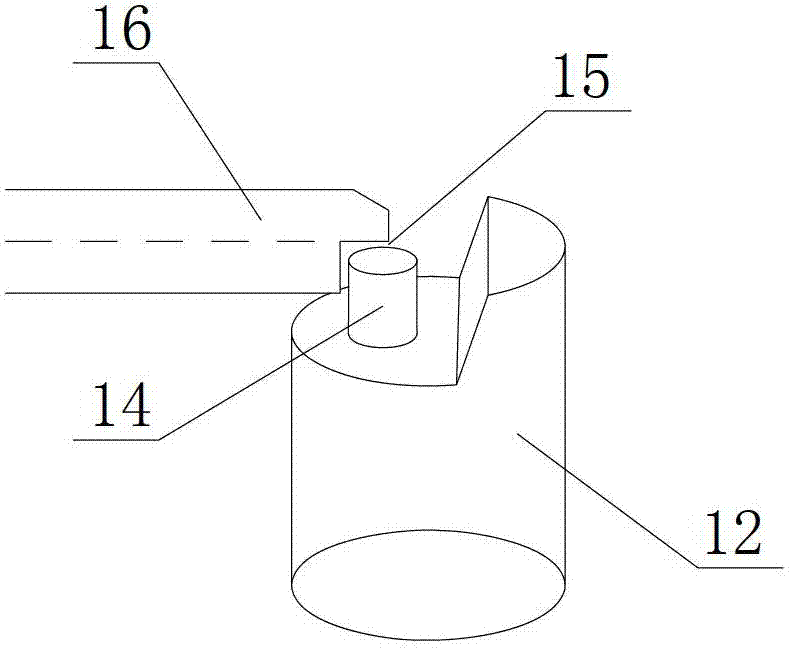

Bearing device and method for carrying out wafer transferring by means of device

ActiveCN103252707AAvoid laminationImprove yieldLapping machinesWork carriersIntegrated circuit manufacturingEngineering

The invention commonly relates to the field of semiconductor integrated circuit manufacturing, in particular to a bearing device and a method for carrying out wafer transferring by means of the device. According to the bearing device and the method for carrying out the wafer transferring by means of the device, multiple groups of sensors are arranged on a bearing platform, an identification detection process is carried out through corresponding groups of sensors according to wafers of different identifications and sizes, wafers with special appearances can be accurately detected and identified, generation of lamination phenomena in the bearing platform can be effectively avoided, risks of scraping caused by the fact that the wafers cannot be identified are reduced, the yield of products is further increased, process cost is reduced, changes for existing equipment are small, and compatibility is strong.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method of making stackable semiconductor assembly with bump/flange heat spreader and dual build-up circuitry

InactiveUS8841171B2Improve performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSignal routingAdhesive

A method of making a stackable semiconductor assembly that includes a semiconductor device, a heat spreader, an adhesive, a plated through-hole, first build-up circuitry and second build-up circuitry is disclosed. The heat spreader includes a bump and a flange. The bump defines a cavity. The semiconductor device is mounted on the bump at the cavity, electrically connected to the first build-up circuitry and thermally connected to the bump. The bump extends into an opening in the adhesive and the flange extends laterally from the bump at the cavity entrance. The first build-up circuitry and the second build-up circuitry extend beyond the semiconductor device in opposite vertical directions. The plated through-hole extends through the adhesive and provides signal routing between the first build-up circuitry and the second build-up circuitry. The heat spreader provides heat dissipation for the semiconductor device.

Owner:BRIDGE SEMICON

Bearing device and method adopting same to transfer wafers

ActiveCN103317437AAccurate identification and detectionAvoid laminationSemiconductor/solid-state device manufacturingWork carriersEngineeringSemiconductor

The invention generally relates to the field of manufacture of semiconductor integrated circuits, particularly to a bearing device and a method adopting the device to transfer wafers. In the bearing device and the method adopting the device to transfer wafers, a movable sensor is arranged on a bearing platform, the position of the sensor can be set as per wafers of different specifications and sizes, so that the movable sensor can be used for recognizing and detecting wafers of different sizes and accurately detecting and recognizing wafers with special shapes, and overlapped wafers in a bearing platform can be effectively avoided, the danger of crushing wafers as wafers cannot be recognized is reduced, the yield of products is improved, the process cost is reduced, little modification is carried out to the conventional equipment, and the compatibility of the device is stronger.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

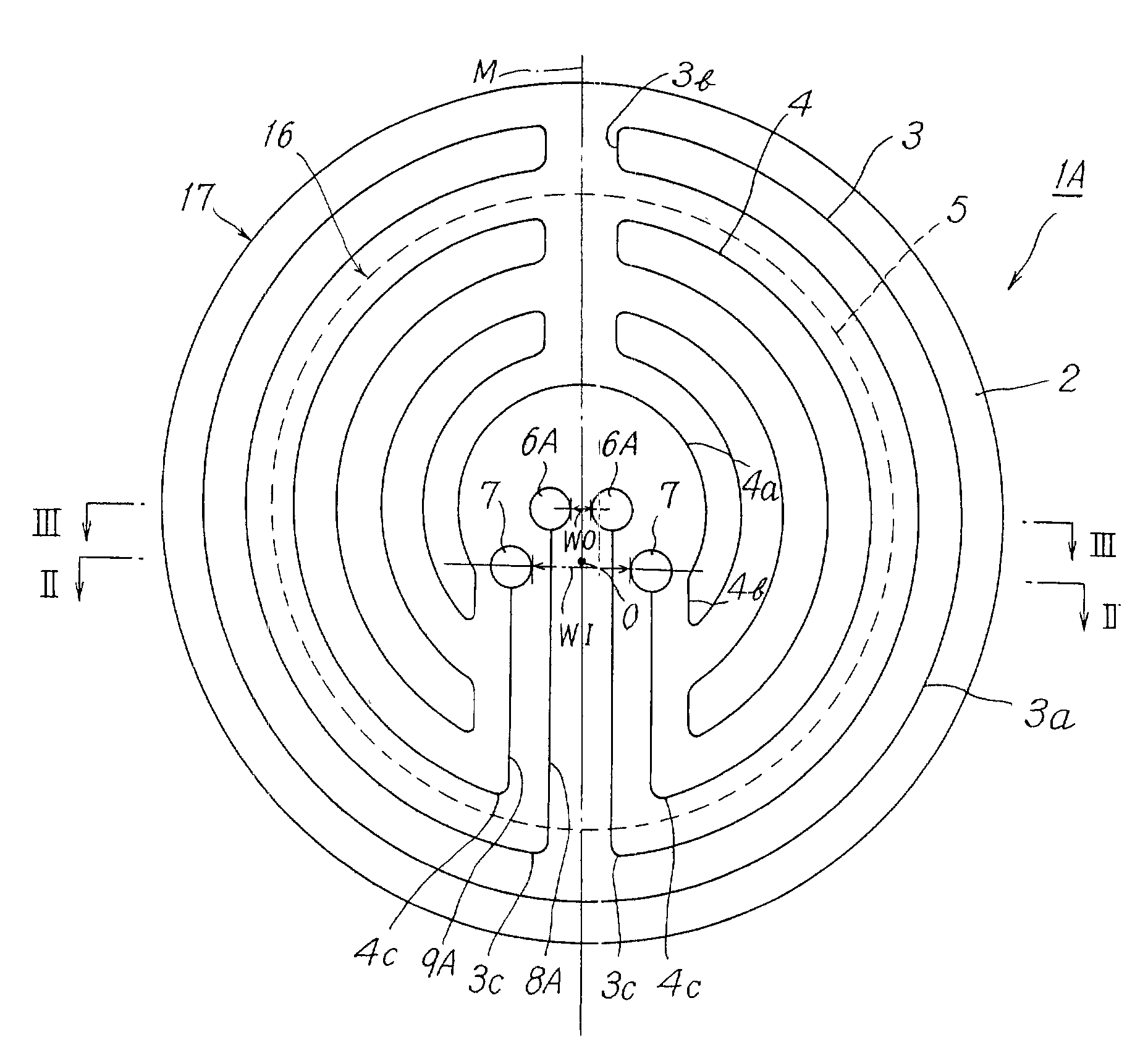

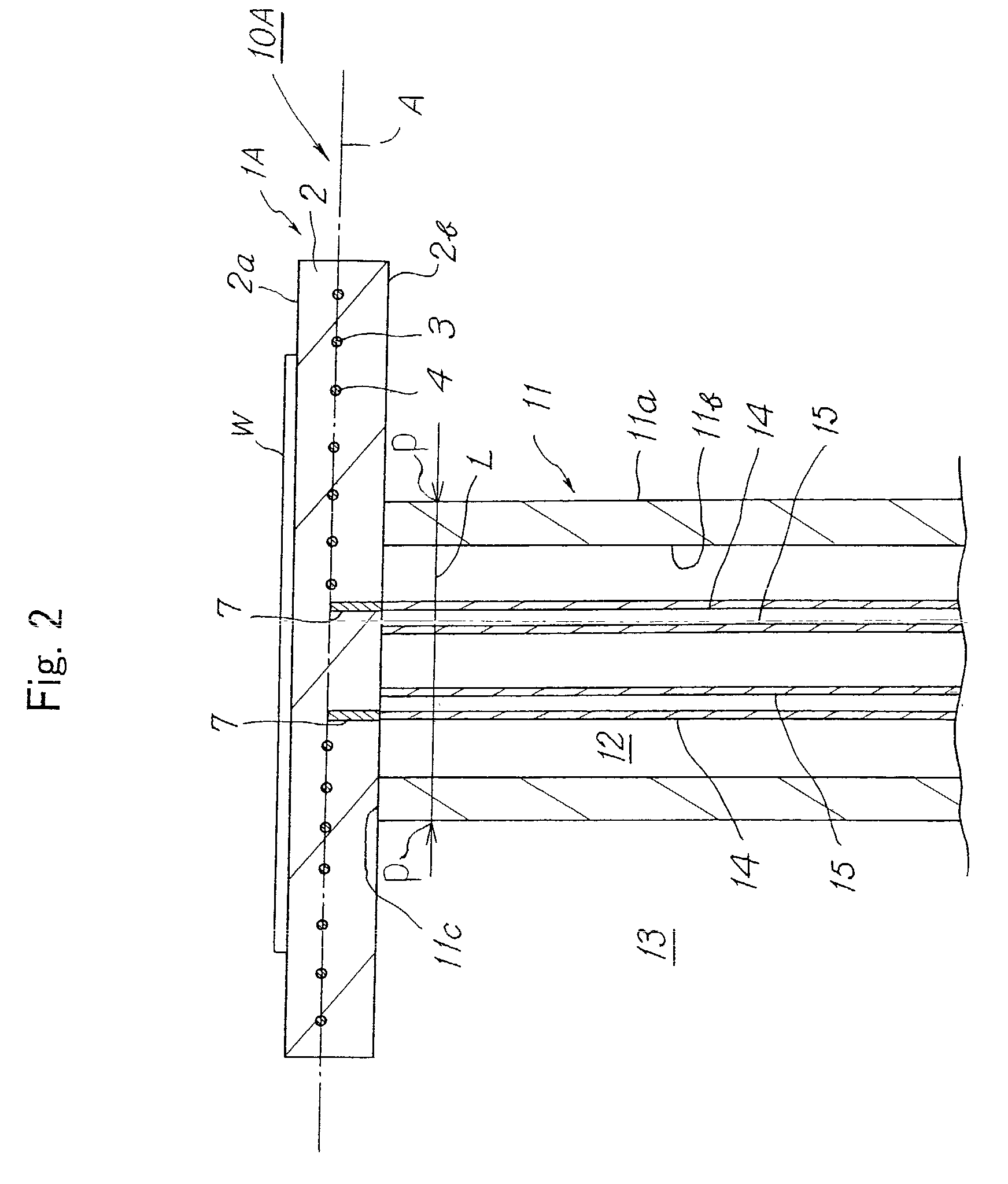

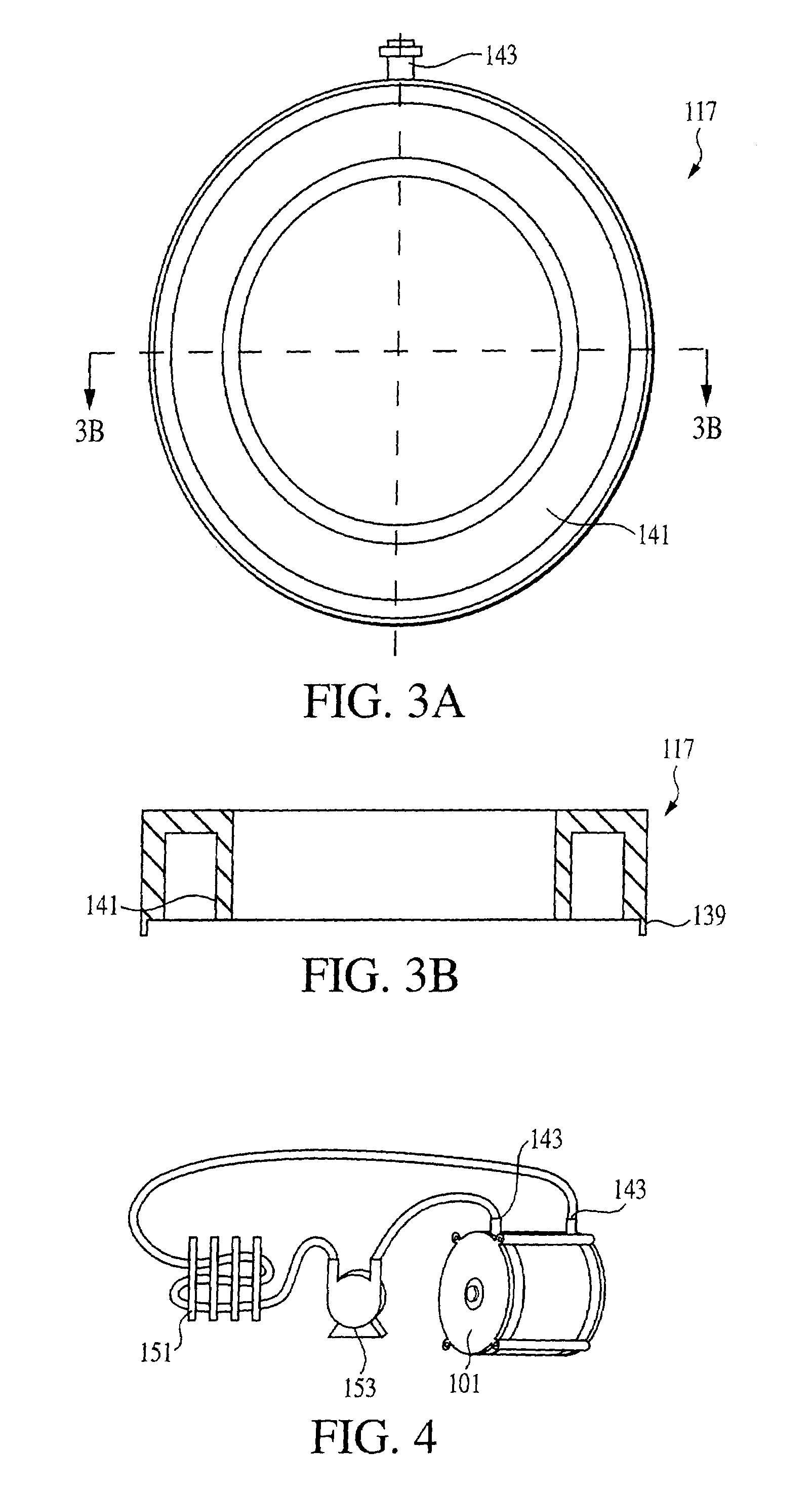

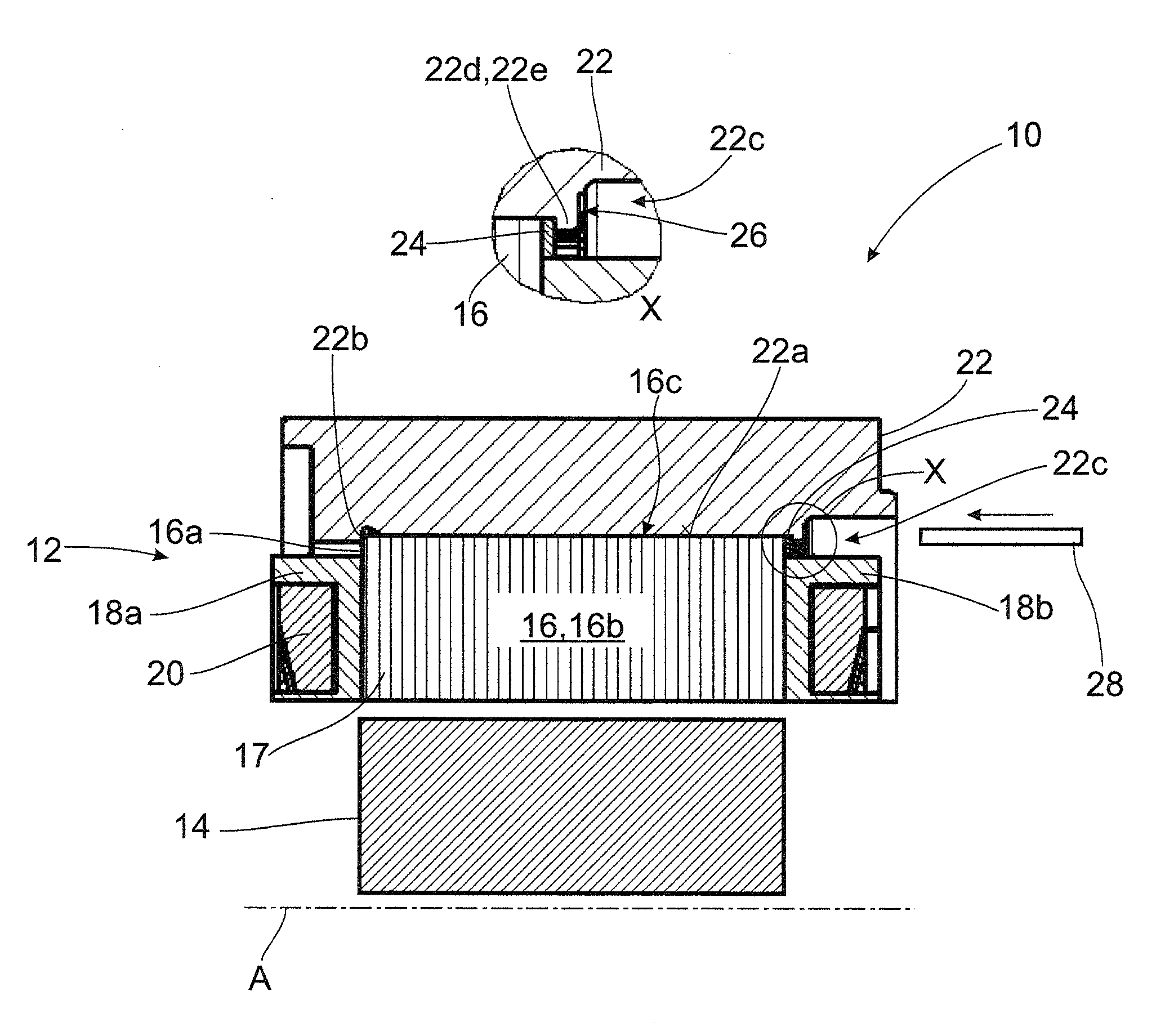

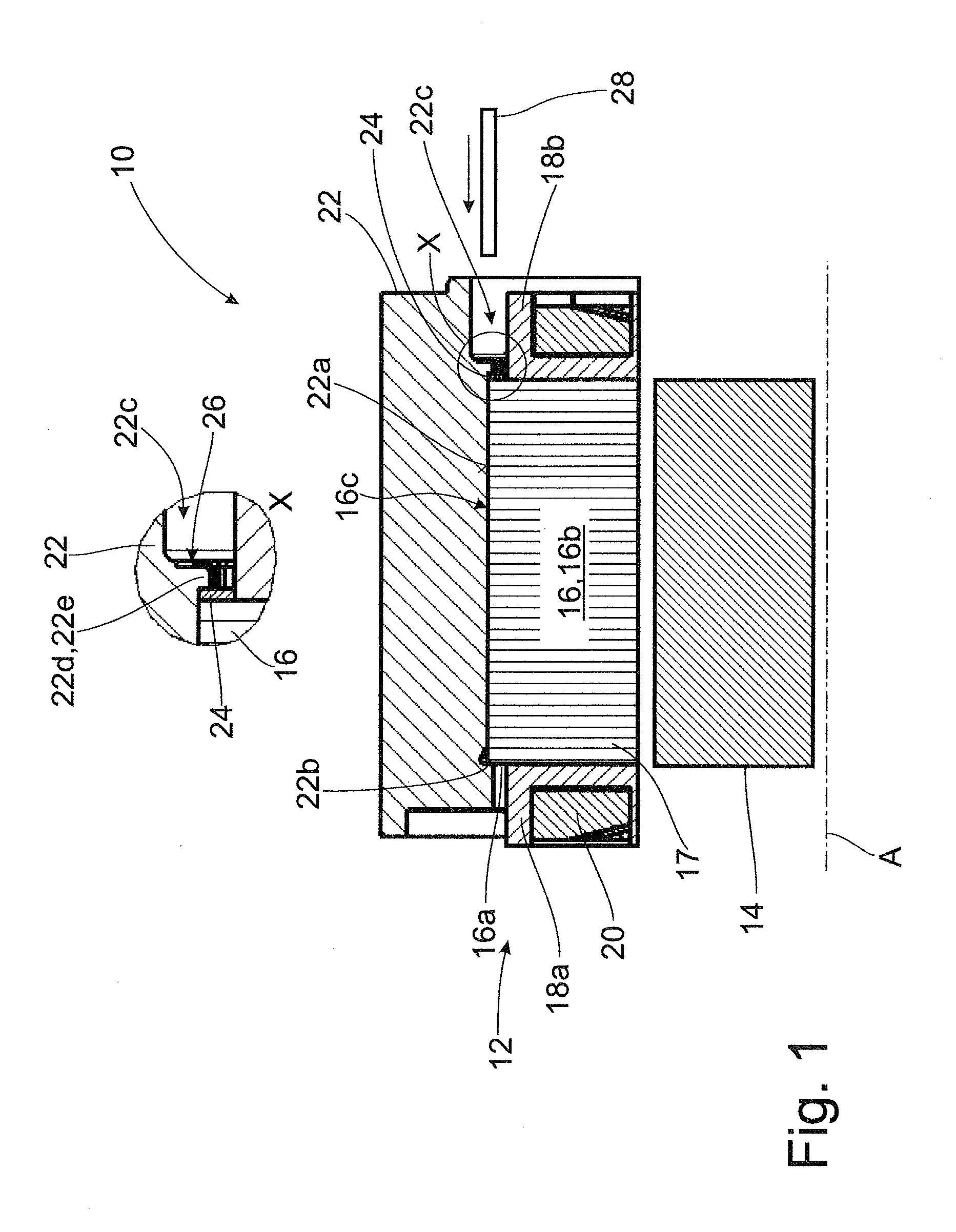

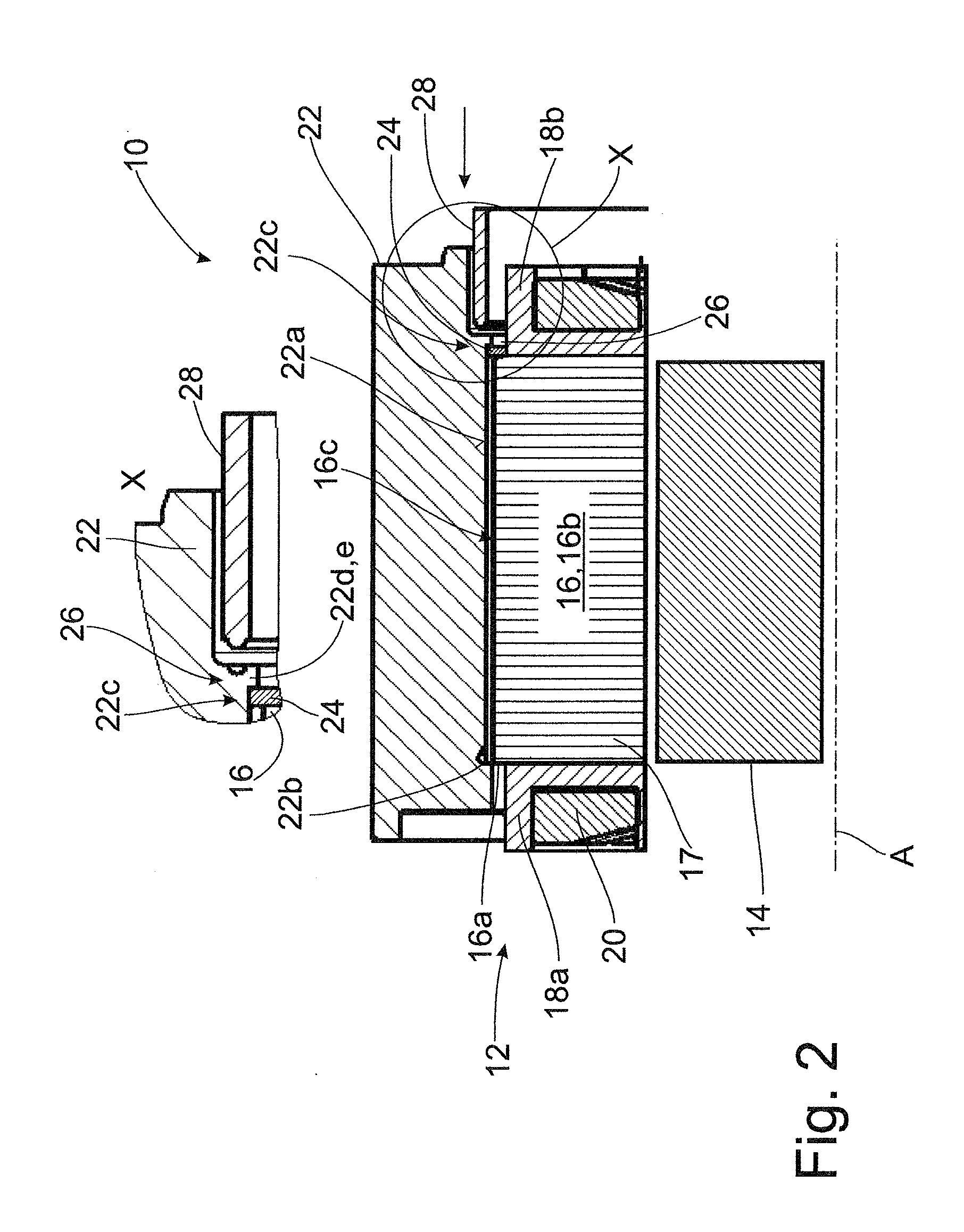

Modular Unit Comprising A Laminate Stack For An Electric Machine, Method For Producing Such A Modular Unit, And Electric Machine

ActiveUS20170040852A1Avoid laminationImprove plastic deformationMagnetic circuit stationary partsManufacturing dynamo-electric machinesEngineeringMechanical engineering

A component unit for an electric machine includes an annular lamination stack formed of a plurality of axially stacked laminations. The lamination stack is secured by an inner or outer cylindrical fastening portion to a cylindrical receiving portion of a carrier element. The carrier element has two stops between which the lamination stack is axially clamped in a frictionally engaging manner. At least one of the axial stops has an annular supporting element arranged at the receiving portion and supports the lamination stack and which is fixed at the carrier element by at least one staking region.

Owner:ZF FRIEDRICHSHAFEN AG

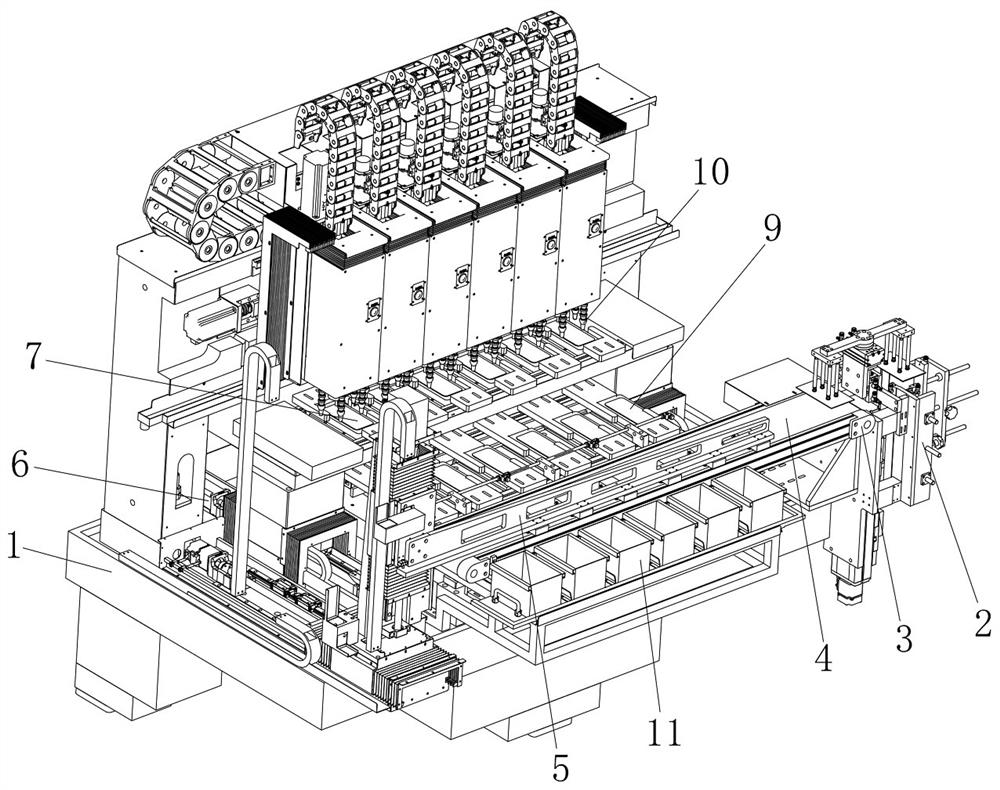

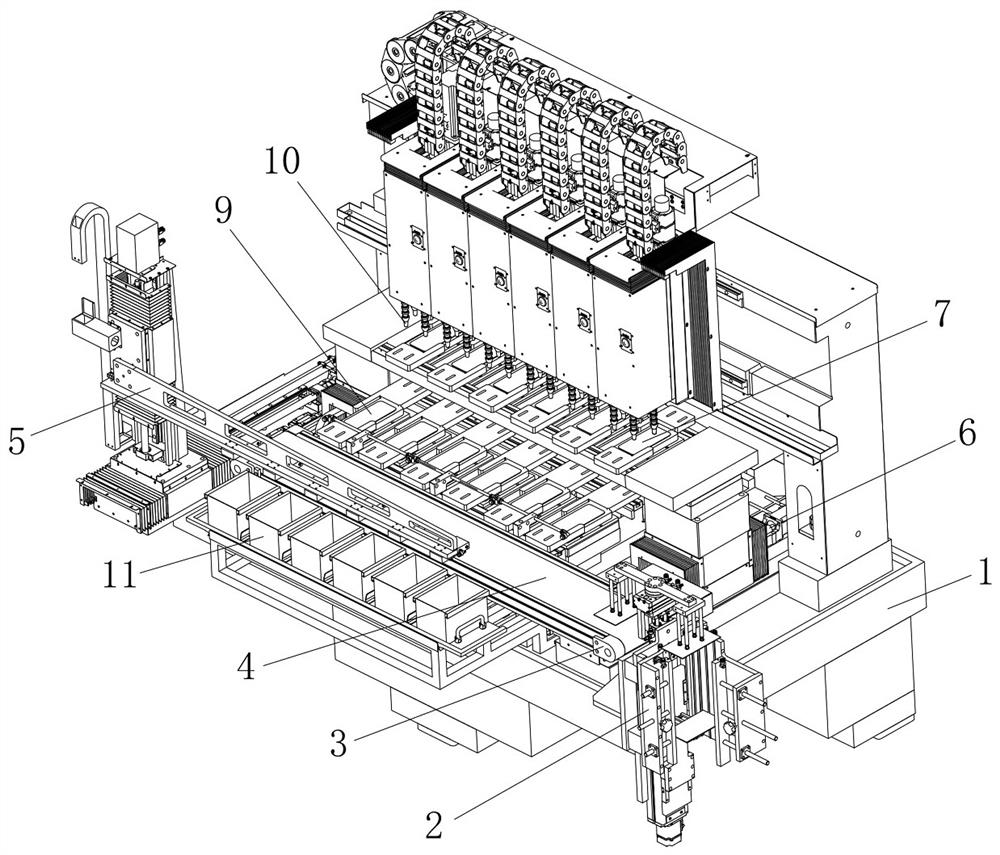

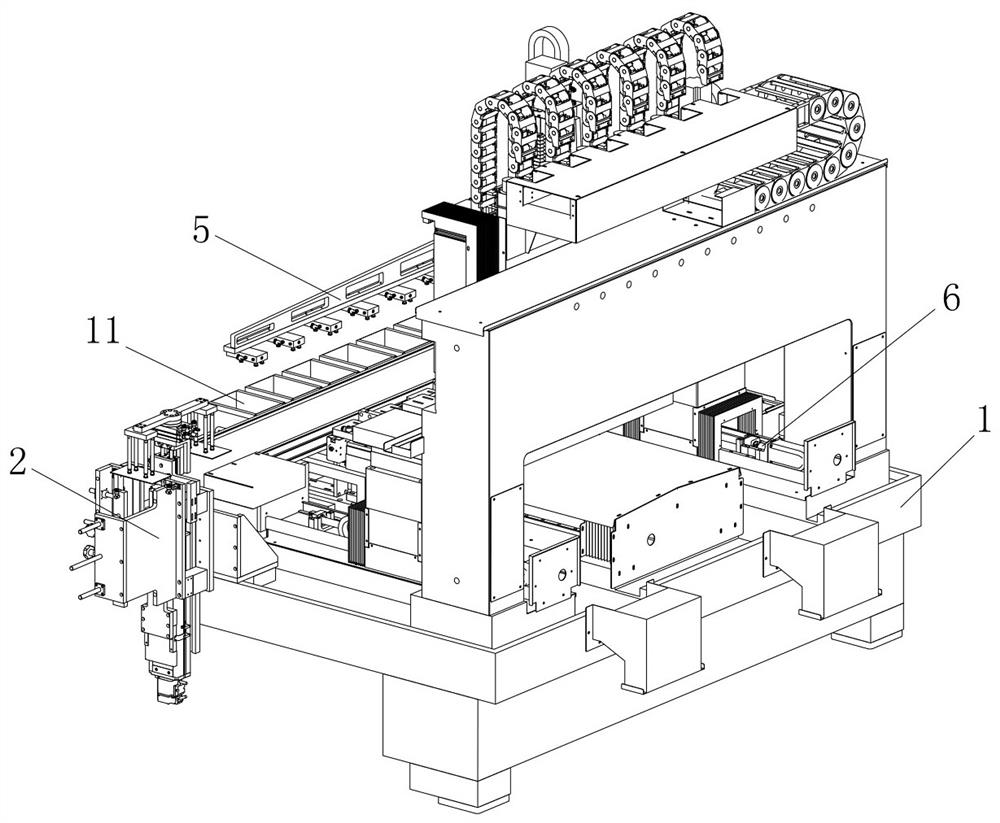

Full-automatic mobile phone curved screen engraving and milling machine and engraving and milling process thereof

PendingCN112388458AReduce standby timeImprove work efficiencyCharge manipulationGrinding machinesEngravingRobot hand

The invention discloses a full-automatic mobile phone curved screen engraving and milling machine and an engraving and milling process thereof. The full-automatic mobile phone curved screen engravingand milling machine comprises a machine table, a lifting feeding mechanism, a conveying mechanism, a mechanical arm, a material platform, an engraving and milling head and a discharging box; the lifting feeding mechanism is arranged at one corner of the machine table and comprises a lifting assembly, a limiting assembly and a feeding assembly; the conveying mechanism is arranged on the side portion of the lifting feeding mechanism; the engraving and milling head is arranged at the rear side of the conveying mechanism; the material platform is arranged between the conveying mechanism and the engraving and milling head; a carrier is arranged on the material platform; the material platform comprises an upper-layer material platform and a lower-layer material platform, and the upper-layer material platform and the lower-layer material platform alternately receive materials from the conveying mechanism and then feed the materials to the position below the engraving and milling head; the discharging box is arranged at the front side of the conveying mechanism; and the mechanical arm is arranged among the material platform, the conveying mechanism and the discharging box in a striding manner. By means of the full-automatic mobile phone curved screen engraving and milling machine, automatic circulating feeding is achieved, the materials of different specifications are limited, air is blown while the materials are lifted to prevent material lamination, and chippings generated after engraving and milling of the materials can be removed.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

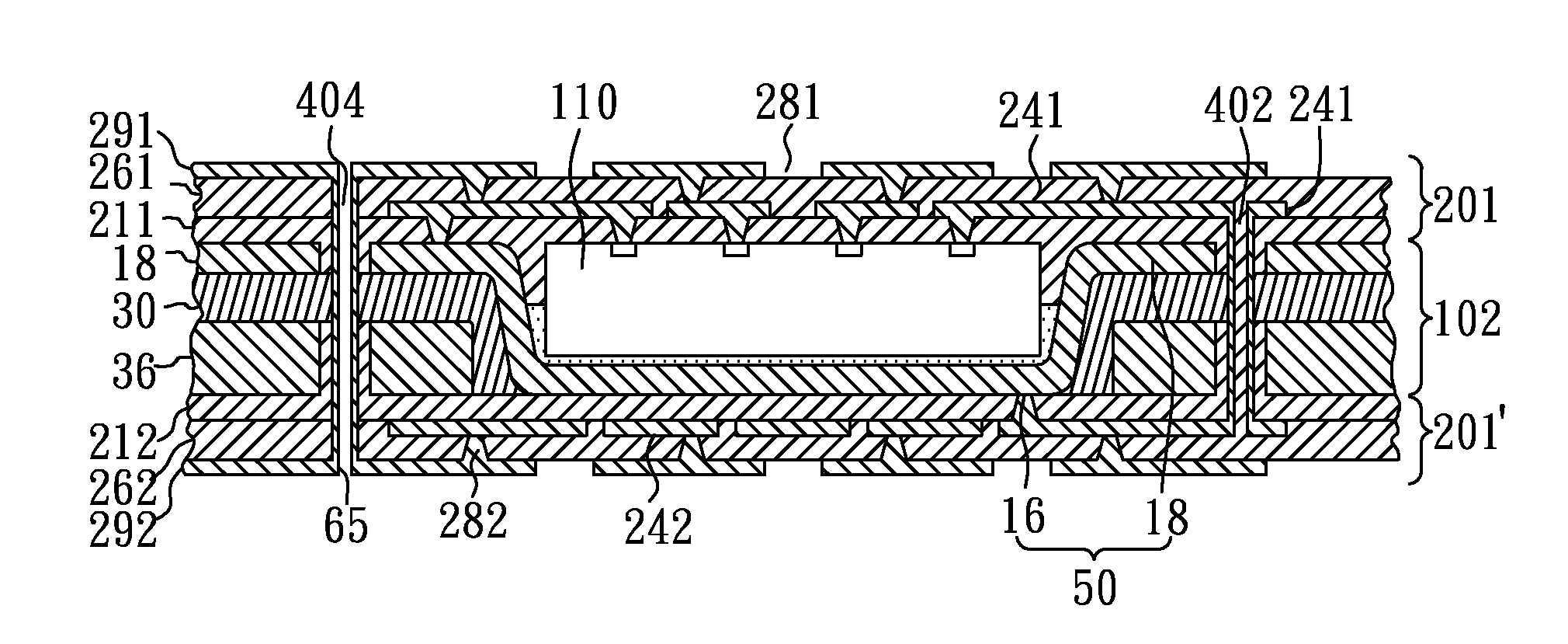

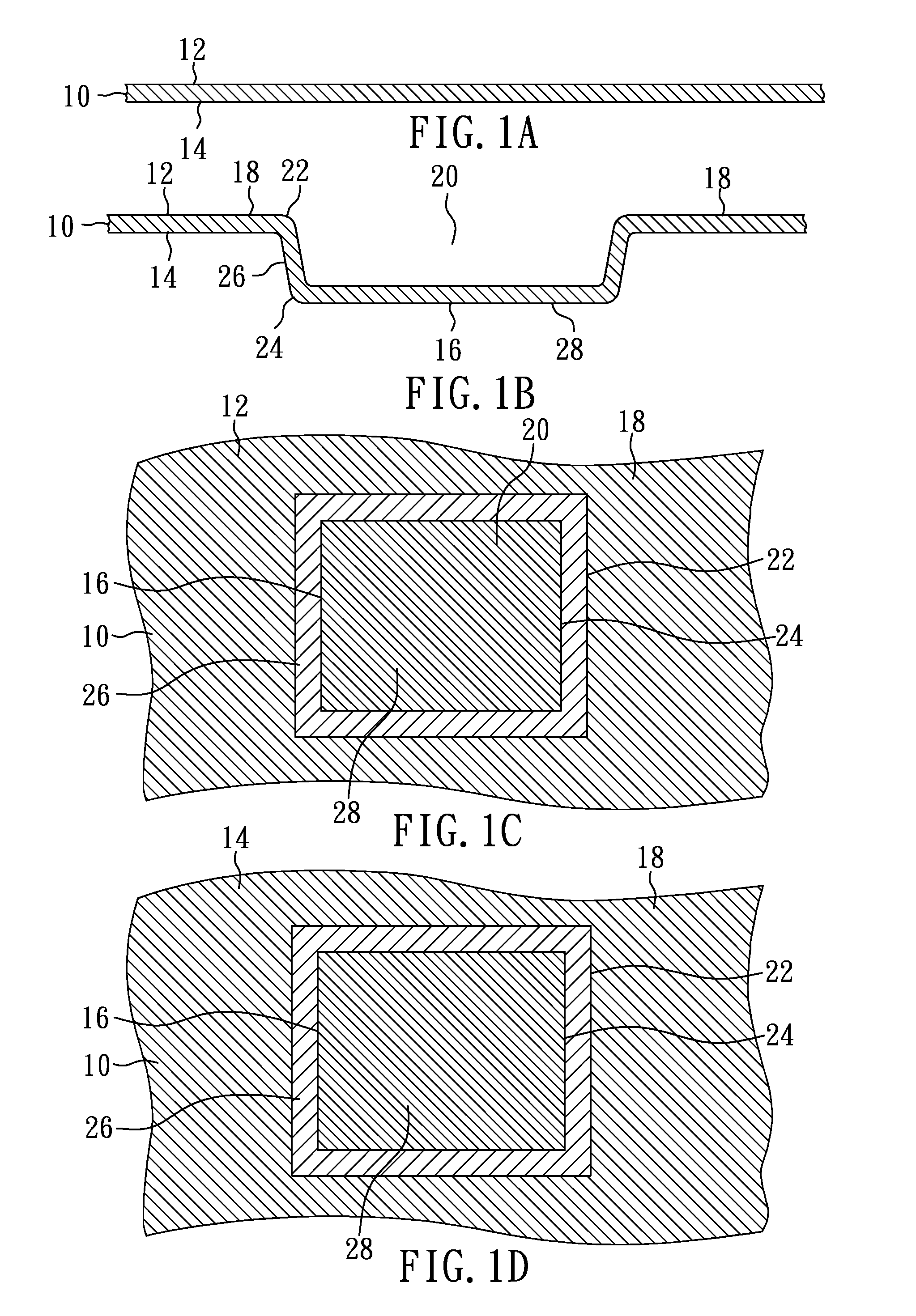

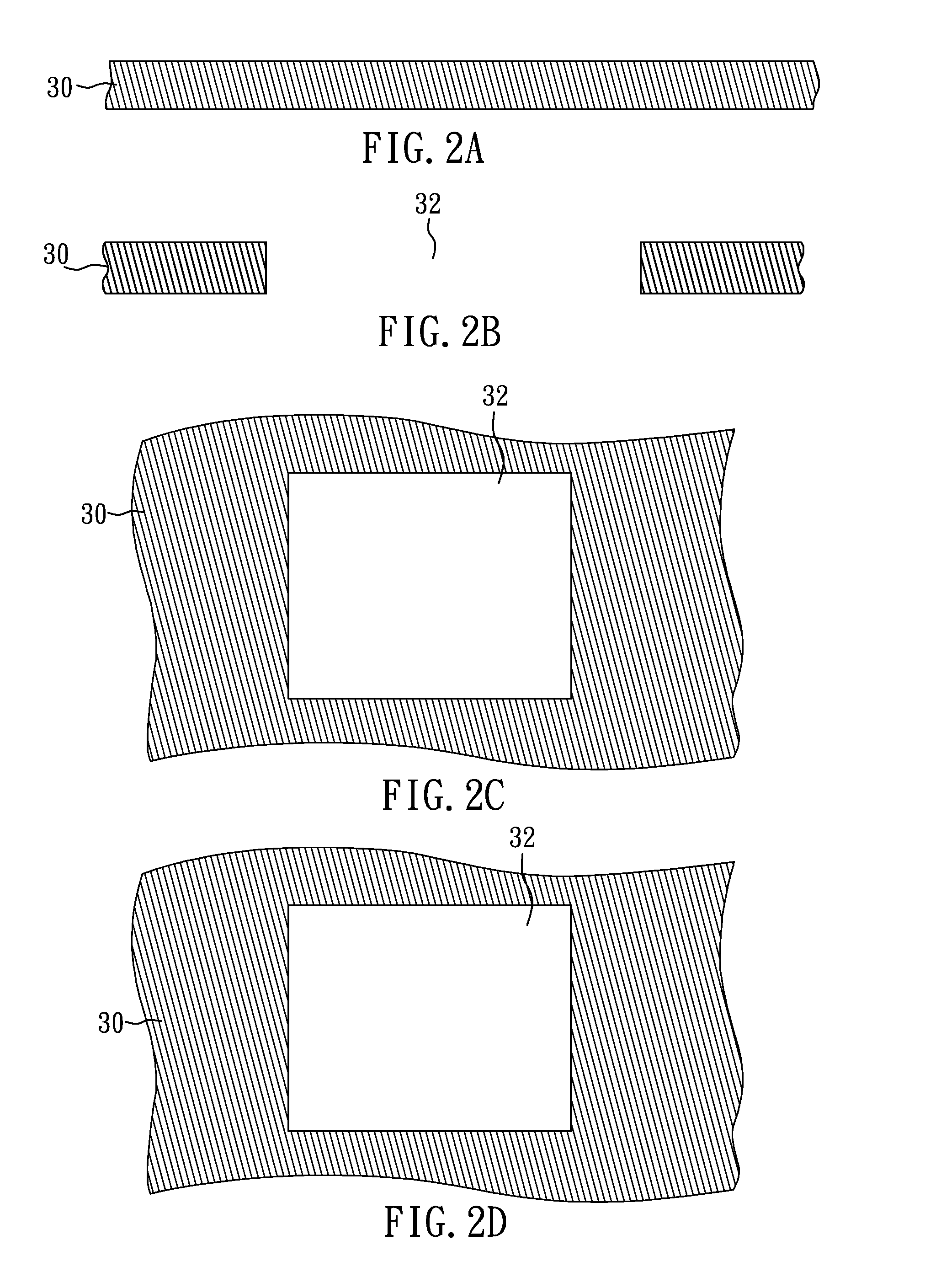

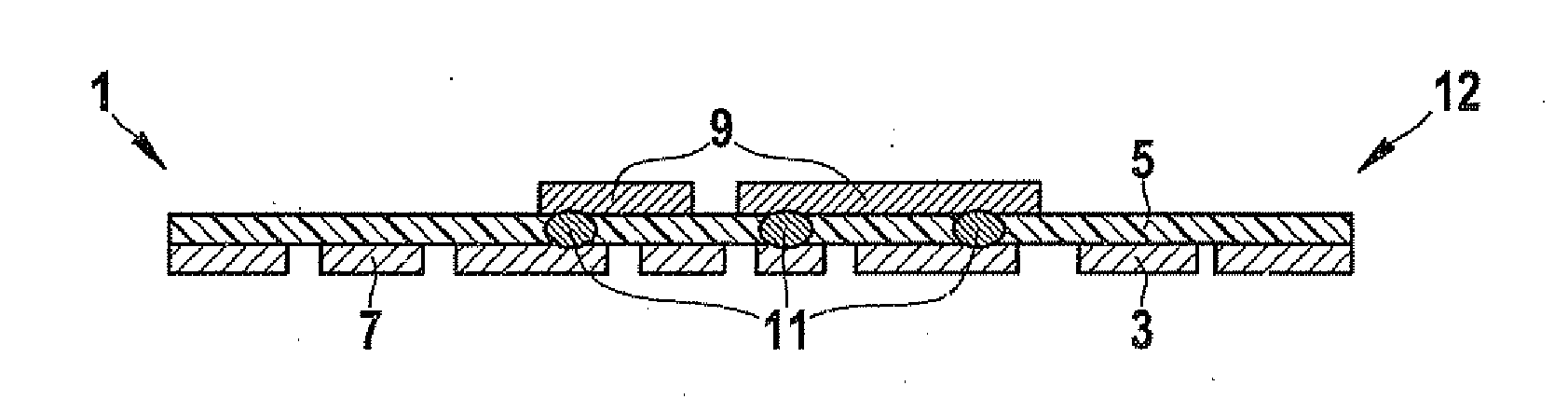

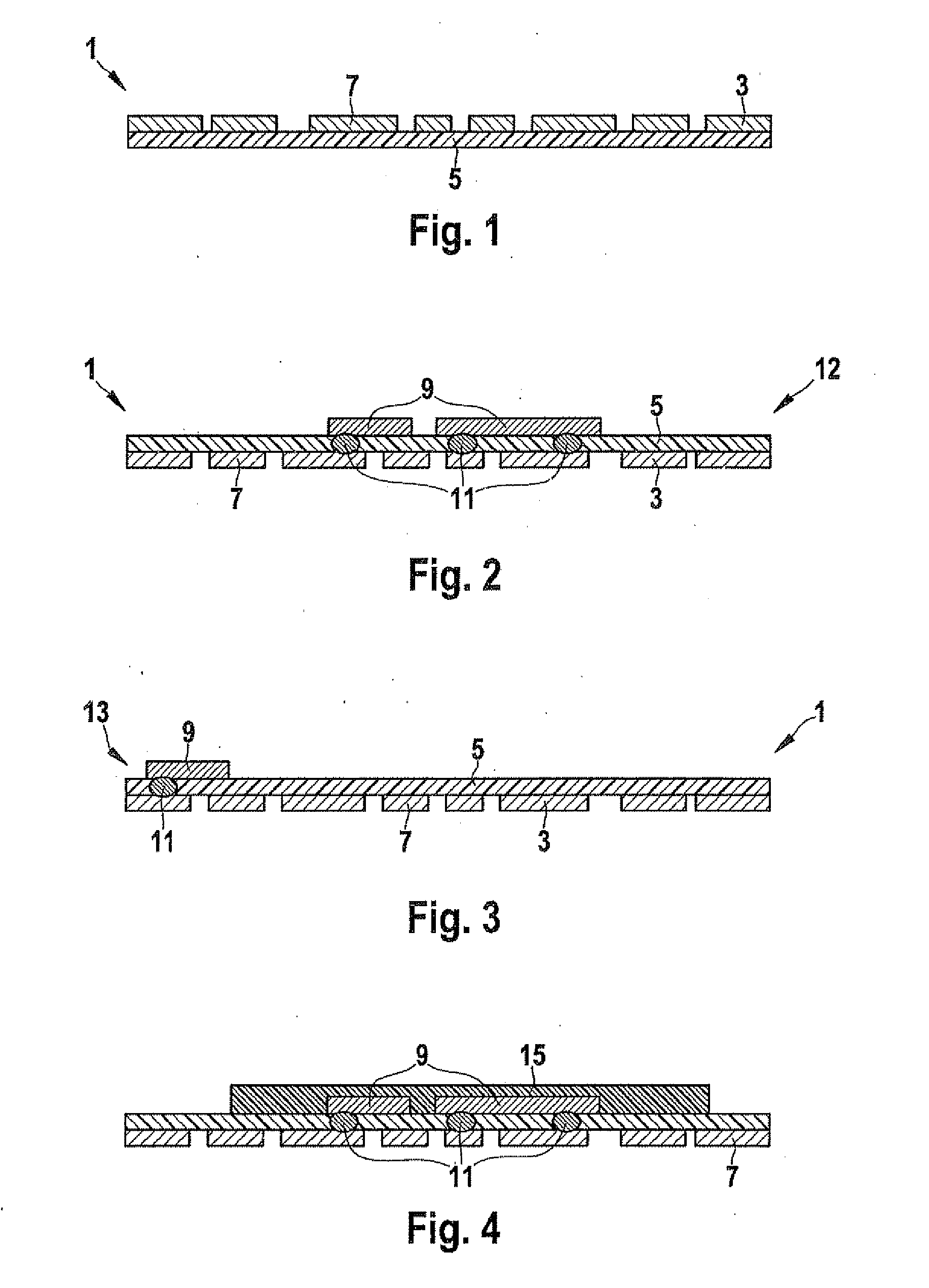

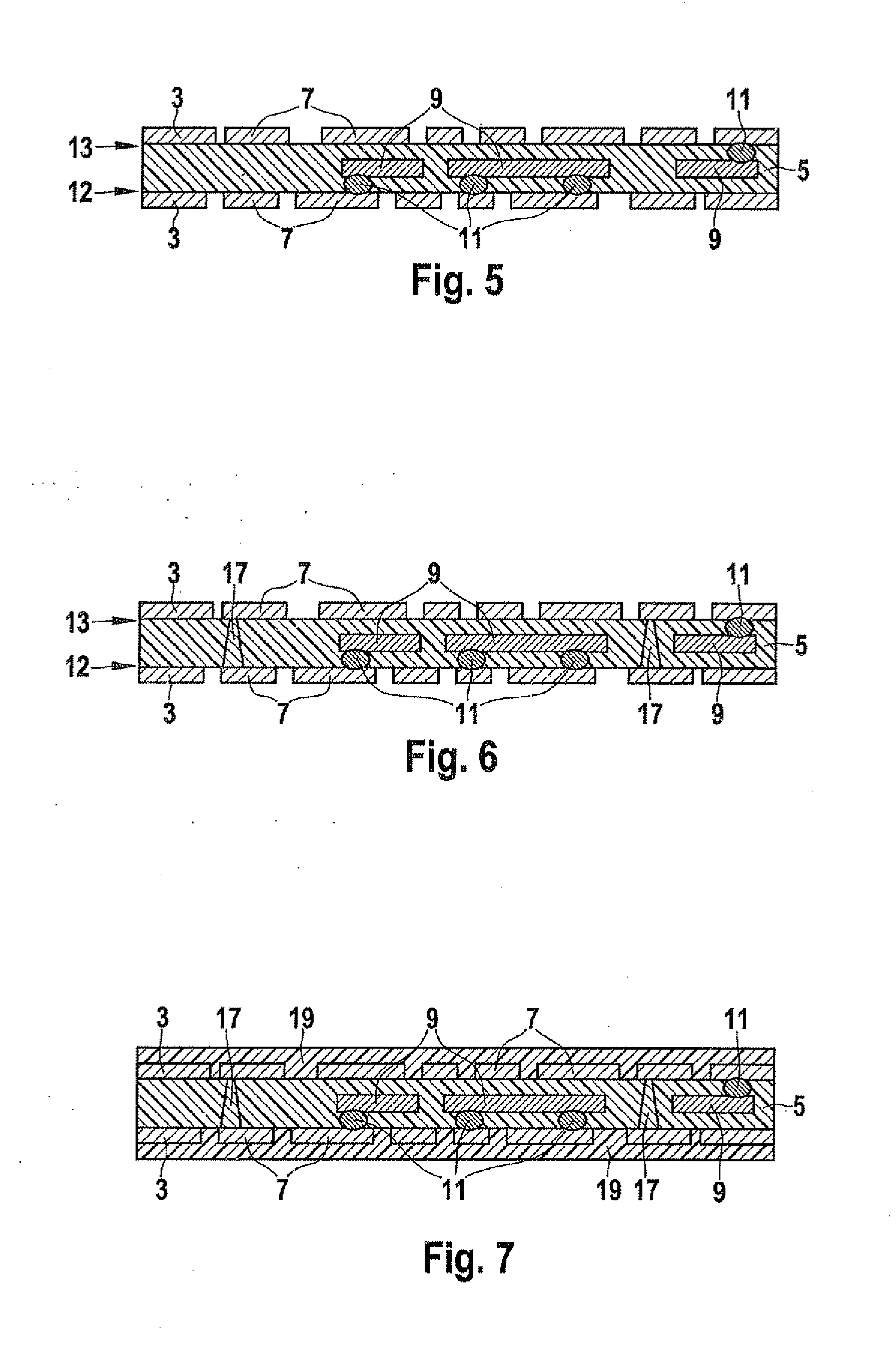

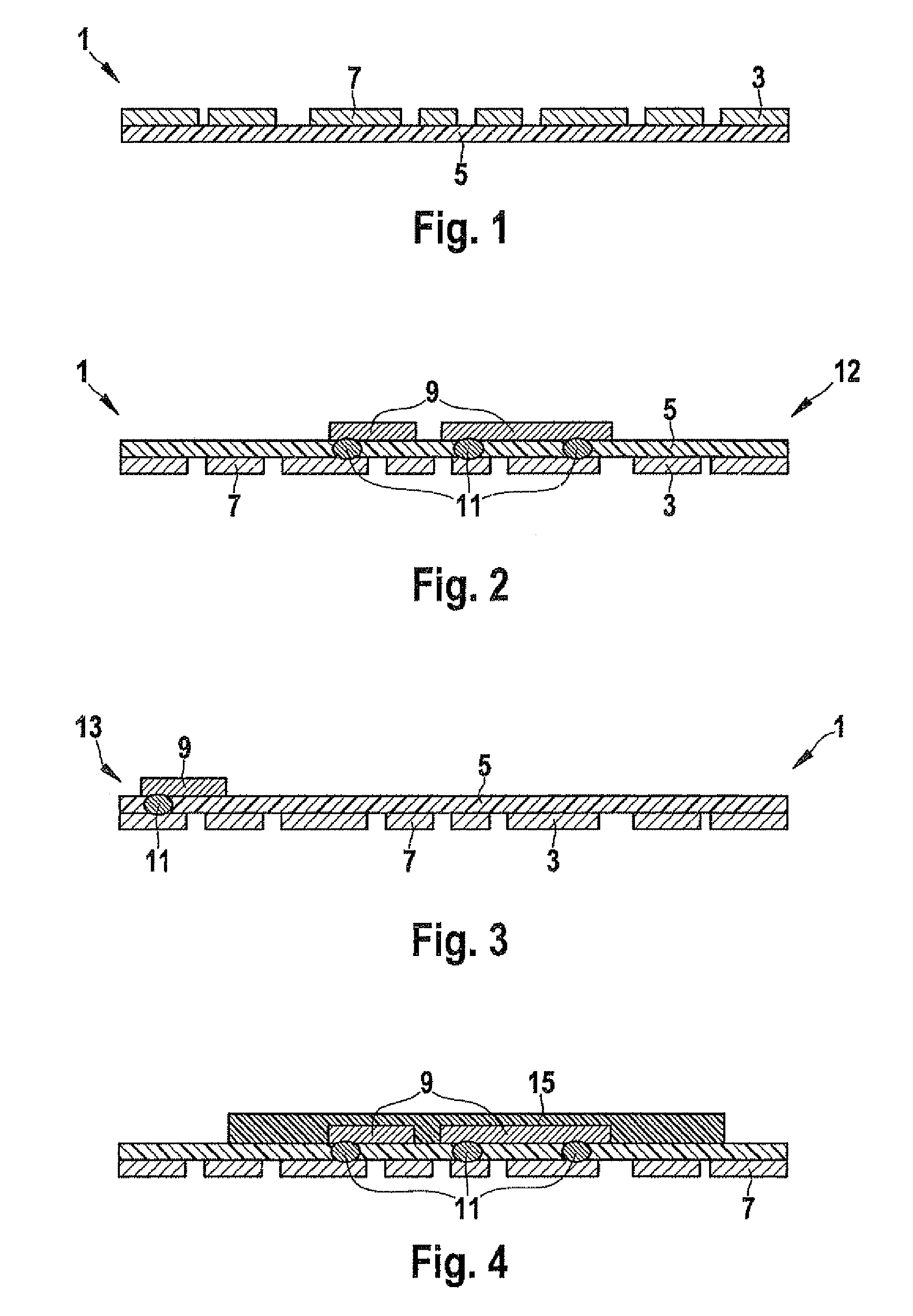

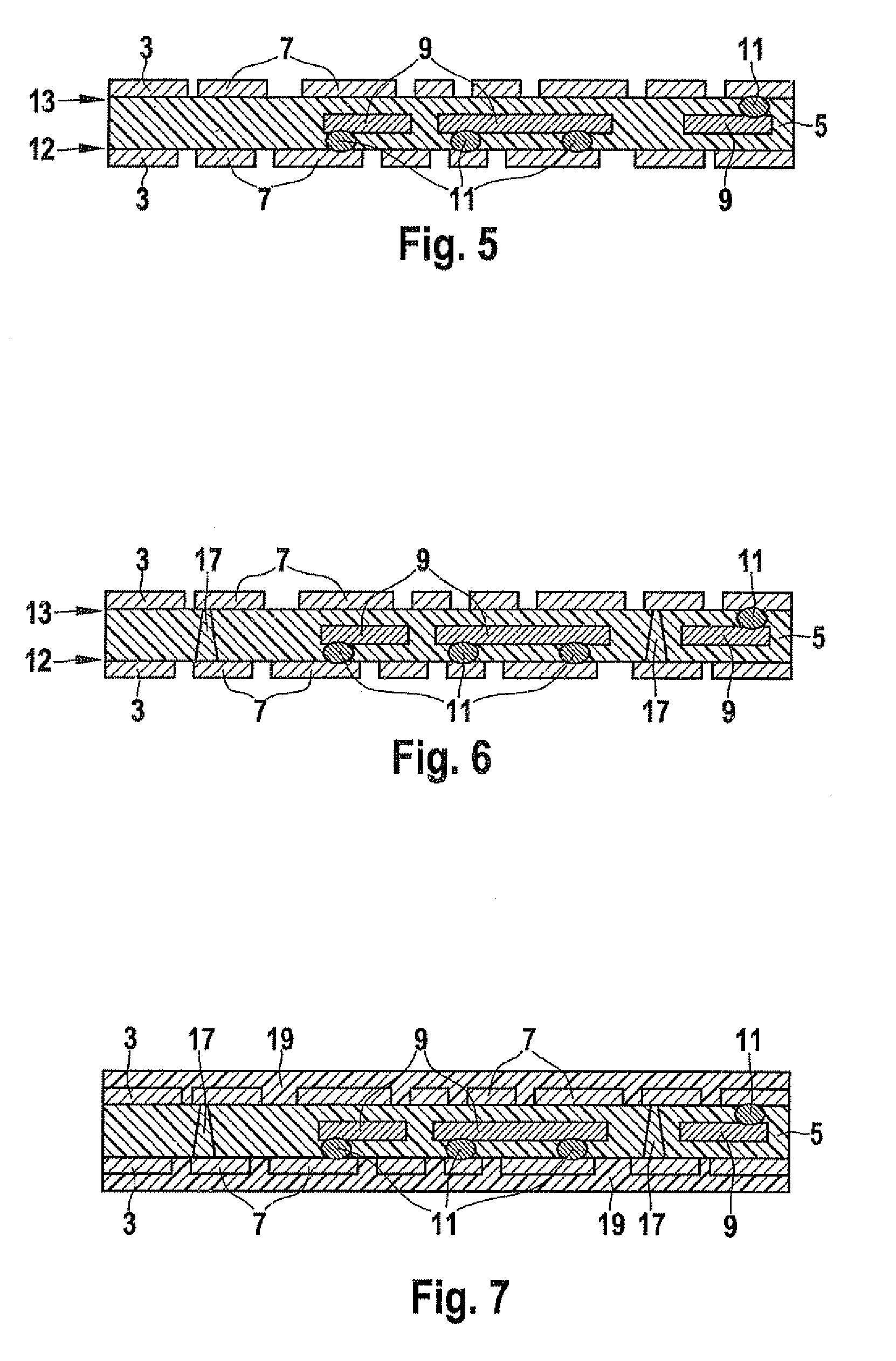

Method for manufacturing an electronic assembly

ActiveUS20110138620A1Cost effective wiring and encapsulationCost-effectivePrinted circuit assembling3D rigid printed circuitsEngineeringElectronic assemblies

A method for manufacturing an electronic assembly, including at least one electronic component and a circuit trace structure, by which the at least one electronic component is contacted. In the method, a conductive foil is patterned in a first step to form the circuit trace structure. In a second operation, the circuit trace structure is equipped with the at least one electronic component. In a final operation, another foil is laminated onto the conductive foil equipped with the at least one electronic component on the side on which the conductive foil is equipped with the at least one electronic component.

Owner:ROBERT BOSCH GMBH

Core for electrical machine

ActiveUS20170025906A1Minimizes eddy currentLess copperMagnetic circuit rotating partsMagnetic circuit stationary partsTransverse fluxEngineering

A transverse flux electrical machine comprising a rotor portion and a stator portion is presented, the stator portion comprising a plurality of cores for use in conjunction with the rotor, each of the plurality of cores comprising a plurality of ferromagnetic sheet material layers substantially bent in a “U” configuration and stacked one on top of the other, a surface of each sheet material layer being substantially parallel with a core axis of the “U” configuration for reducing eddy currents therein and a pair of legs including, respectively, a reduction portion along the legs, toward a pair of poles thereof.

Owner:EOCYCLE TECH

Method for manufacturing an electronic assembly

ActiveUS8505198B2Improve reliabilityImprove area utilizationPrinted circuit assembling3D rigid printed circuitsEngineeringElectronic component

A method for manufacturing an electronic assembly, including at least one electronic component and a circuit trace structure, by which the at least one electronic component is contacted. In the method, a conductive foil is patterned in a first step to form the circuit trace structure. In a second operation, the circuit trace structure is equipped with the at least one electronic component. In a final operation, another foil is laminated onto the conductive foil equipped with the at least one electronic component on the side on which the conductive foil is equipped with the at least one electronic component.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com