Substrate processing device

A substrate processing device and substrate technology, applied in optics, instruments, optomechanical equipment, etc., can solve problems such as sensor failure, and achieve the effect of avoiding equipment outage and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

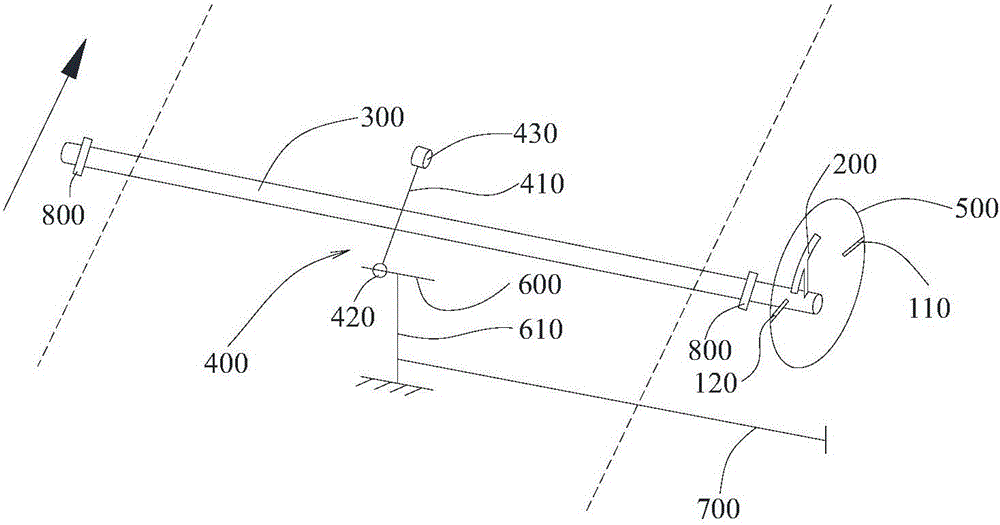

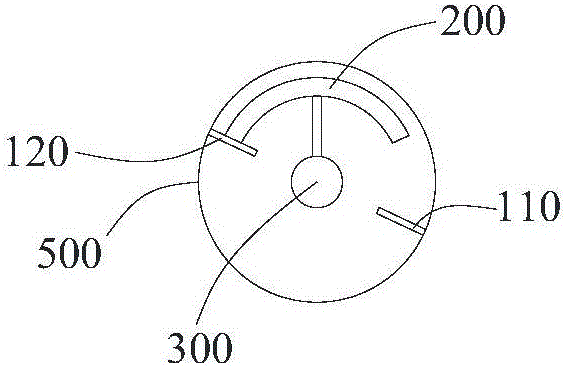

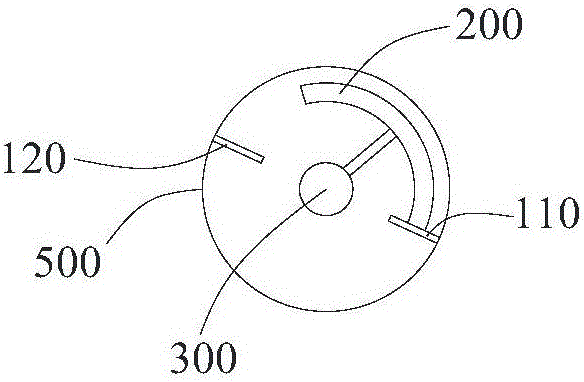

[0056] As a preferred embodiment of the present invention, the substrate sensing component includes a substrate sensing sensor 110 and a sensing sheet 200 . One of the substrate sensing sensor 110 and the sensing sheet 200 is installed on the rotating shaft 300, and the other of the substrate sensing sensor 110 and the sensing sheet 200 is statically arranged relative to the processing chamber.

[0057] When the rotation shaft 300 rotates through the predetermined angle along the first direction, the substrate sensing sensor 110 and the sensing sheet 200 approach each other until the sensing sheet 200 enters the sensing range of the substrate sensing sensor 110, and the substrate sensing sensor 110 sends out the first sensory signal.

[0058] When the rotation shaft 300 rotates through the predetermined angle along the second direction, the substrate sensing sensor 110 and the sensing sheet 200 are far away from each other until the sensing sheet 200 leaves the sensing range o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com