Ink jet advertisement consumable material and production method thereof

A production method and technology of consumables, which are applied in the field of inkjet advertising consumables and production, and can solve problems such as rough surfaces, release paper that does not meet protection requirements, and failure to achieve high-definition and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below according to the drawings and embodiments.

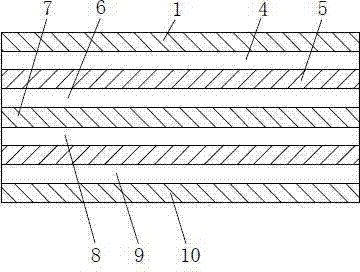

[0031] Such as image 3 As shown, the inkjet advertising consumables described in the embodiment of the present invention, the inkjet advertising consumables, include a transparent protective layer 1, an upper adhesive layer 4 is provided below the protective layer 1, and an upper adhesive layer 4 is provided below the upper adhesive layer 4. There is an upper silicone oil layer 5, an upper base layer 6 is arranged below the upper silicone oil layer 5, a lower silicone oil layer 7 is arranged under the upper base layer 6, and a lower adhesive layer 8 is arranged under the lower silicone oil layer 7; A lower base 9 is provided below, an ink-absorbing coating 10 is provided below the lower base 9, and the upper base 6 and the lower base 9 are respectively made of plastic materials.

[0032] The upper base layer 6 adopts PET synthetic film, and the lower base layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com