Method for producing anti-counterfeiting card paper with windowed security thread

A production method and safety thread technology, applied in papermaking, paper machine, textile and papermaking, etc., can solve the problems of paper warping, high production cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

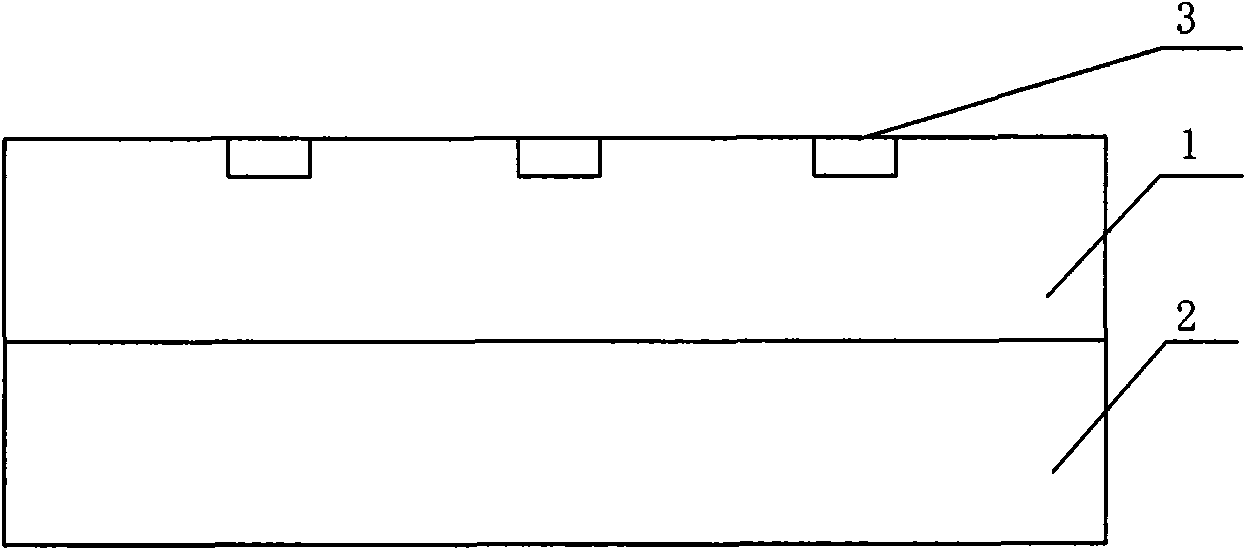

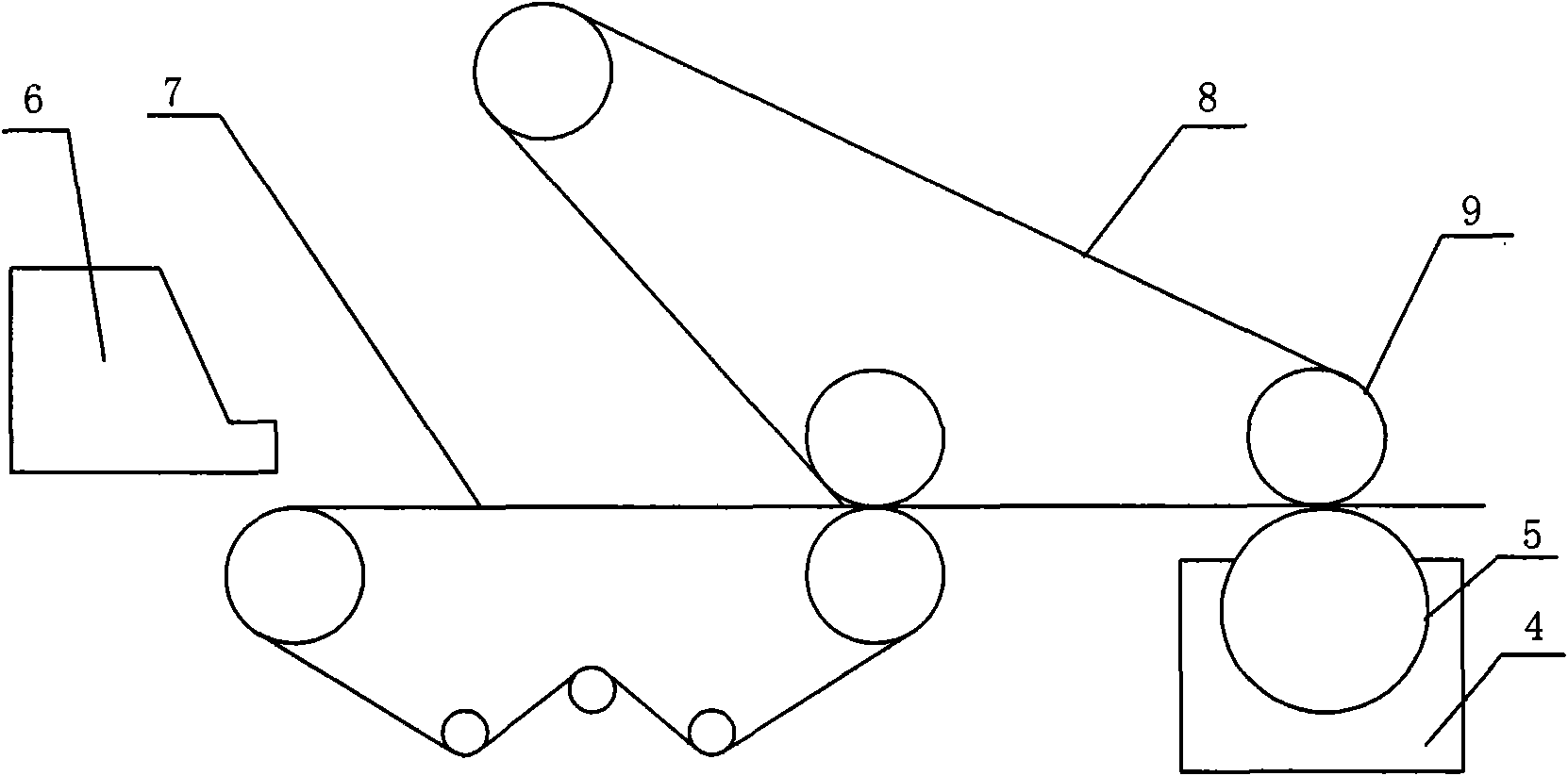

[0024] 200g / m 2 The production of anti-counterfeiting jams for window security lines.

[0025] 100g / m sizing by rotary net 2 Produce surface paper with window-opening safety thread, produced by fourdrinier wire 100g / m 2 The bottom layer of paper, two wet paper sheets are combined at the cylinder, and dehydrated through the felt cloth into the press, the moisture is controlled at 62%, so that the two wet paper sheets are combined together, dried, coiled, and become 200g / m 2 Security card with window security thread. The anti-counterfeit cardboard is mainly used in anti-counterfeit clothing tags, covers of anti-counterfeit books, etc.

Embodiment 2

[0027] 300g / m 2 The production of anti-counterfeiting jams for window security lines.

[0028] 150g / m sizing by rotary net 2 Produce surface paper with window-opening safety thread, produced by fourdrinier wire 150g / m 2 The bottom layer paper, two wet paper sheets are combined at the cylinder wire, and dehydrated through the felt cloth into the press, the moisture is controlled at 63%, so that the two wet paper sheets are combined together, dried and coiled, and become 300g / m 2 Security card with window security thread.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com