Silver micro powder and preparation method and application thereof

A technology of silver micropowder and silver nitrate, which is used in transportation and packaging, metal processing equipment, cable/conductor manufacturing, etc., can solve problems such as the difficulty of conductivity to meet the requirements of conductive paste, poor surface contact of silver micropowder, and printing disconnection. , to achieve the effect of photoelectric conversion rate, high production efficiency, and reduced contact resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

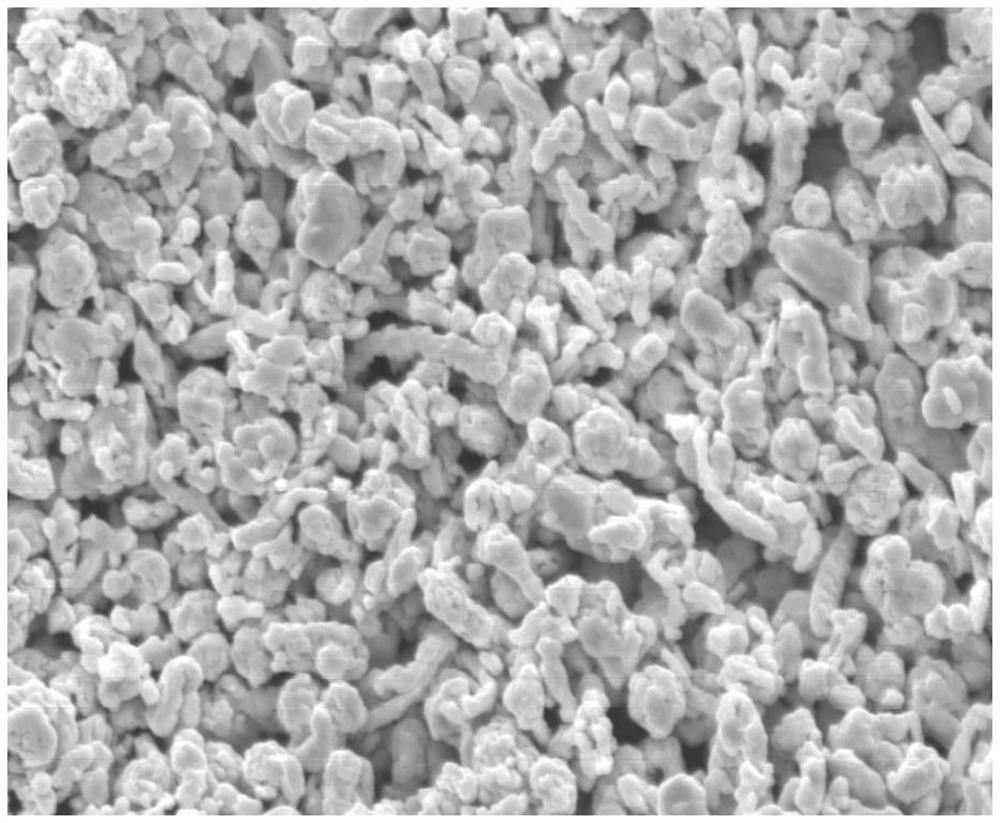

Embodiment 1

[0062] A preparation method of silver micropowder.

[0063] Preparation of silver nitrate solution: Dissolve 1kg of silver nitrate in 5L of deionized water to make a silver nitrate solution, and control the temperature of the solution to 15±2°C;

[0064] Preparation of dispersant solution: Weigh 1.5g of PVA and dissolve it in 20ml of deionized water to make a dispersant solution, and control the temperature of the solution to 30°C;

[0065] Prepare the shape modifier solution: weigh 2g of silver chloride and dissolve it in 30ml of deionized water to make a shape modifier solution, and control the solution temperature to 30°C;

[0066] Preparation of pH adjuster solution: Weigh 50g of sodium carbonate, add deionized water to dissolve into 200ml of pH adjuster solution, and control the temperature at 30-60°C;

[0067] Preparation of reducing agent solution: Weigh 0.8Kg of ascorbic acid into the batching bucket, add water to dissolve and prepare a 3L reducing agent solution, and...

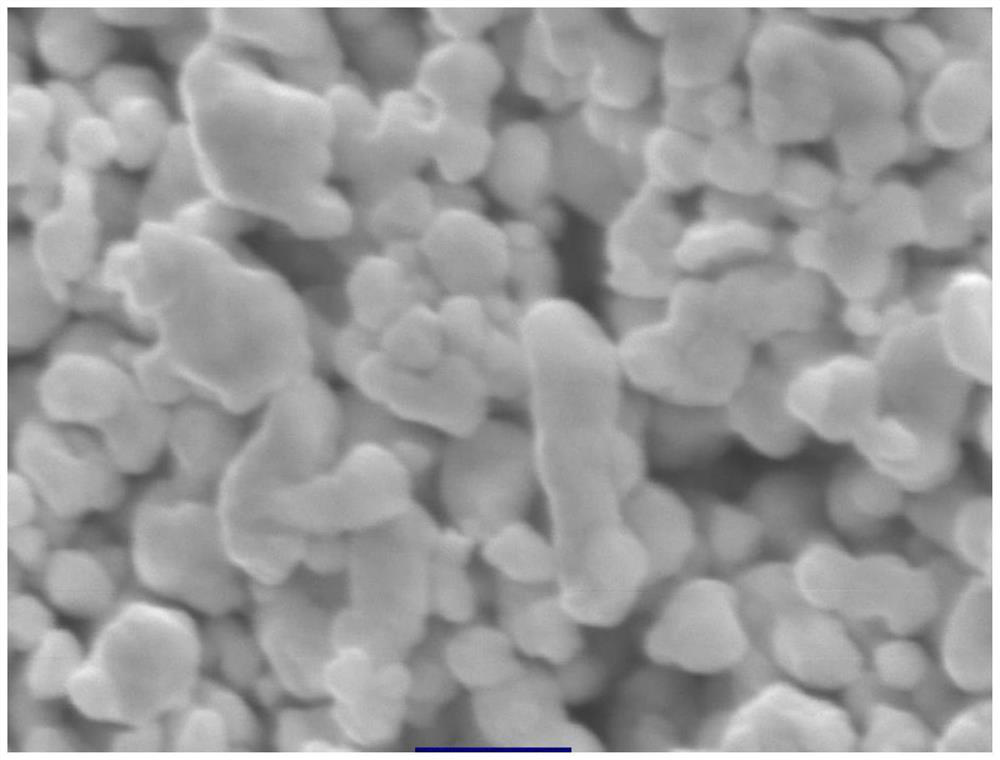

Embodiment 2

[0073] A preparation method of silver micropowder.

[0074] Preparation of silver nitrate solution: Dissolve 1kg of silver nitrate in 5L of deionized water to make a silver nitrate solution, and control the temperature of the solution to 15±2°C;

[0075] Preparation of dispersant solution: Weigh 1.5g of PVA and dissolve it in 20ml of deionized water to make a dispersant solution, and control the solution temperature to 30°C;

[0076] Prepare the shape modifier solution: weigh 2g of silver chloride and dissolve it in 30ml of deionized water to make a shape modifier solution, and control the solution temperature to 30°C;

[0077] Preparation of pH adjuster solution: Weigh 50g of sodium hydroxide, add deionized water to dissolve into 200ml of pH adjuster solution, and control the temperature at 30-60°C;

[0078] Preparation of reducing agent solution: Weigh 0.8Kg of ascorbic acid into the batching bucket, add water to dissolve and prepare a 3L reducing agent solution, and heat t...

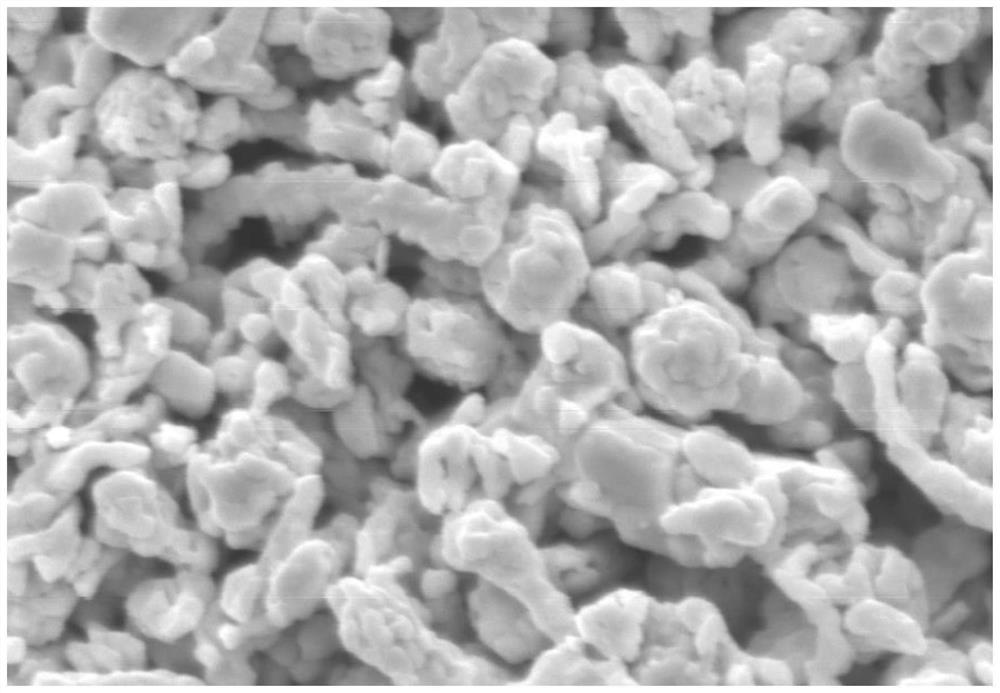

Embodiment 3

[0084] A preparation method of silver micropowder.

[0085] Preparation of silver nitrate solution: Dissolve 1kg of silver nitrate in 5L of deionized water to make a silver nitrate solution, and control the temperature of the solution to 15±2°C;

[0086] Preparation of dispersant solution: Weigh 1.5g of PVA and dissolve it in 20ml of deionized water to make a dispersant solution, and control the solution temperature to 30°C;

[0087] Prepare the shape modifier solution: weigh 2g of silver chloride and dissolve it in 30ml of deionized water to make a shape modifier solution, and control the solution temperature to 30°C;

[0088] Preparation of pH regulator solution: Add deionized water to ammonia water to prepare 200ml of pH regulator solution with a concentration of 1.5mol / L, and control the temperature at 30-60°C;

[0089] Preparation of reducing agent solution: Weigh 0.8Kg of ascorbic acid into the batching bucket, add water to dissolve and prepare a 3L reducing agent solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com