Patents

Literature

30results about How to "Avoid cold welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

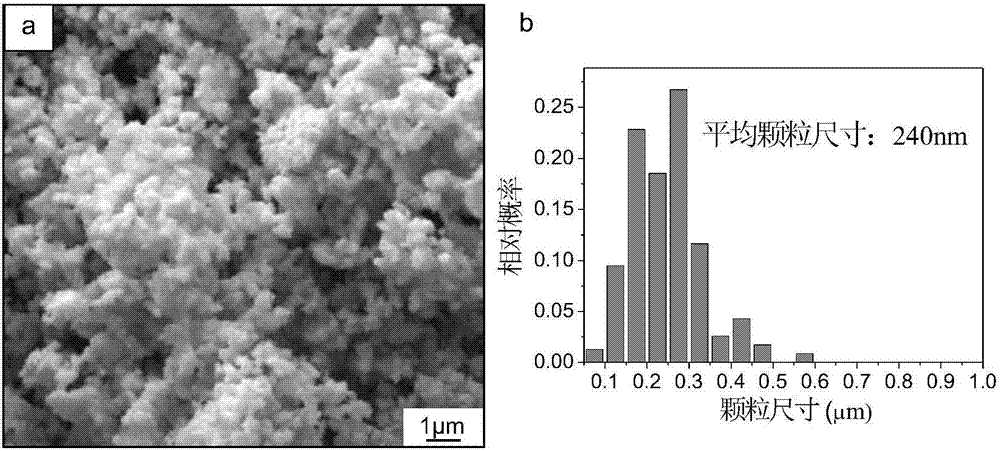

Composite cathode material for lithium ion cell and preparing method thereof

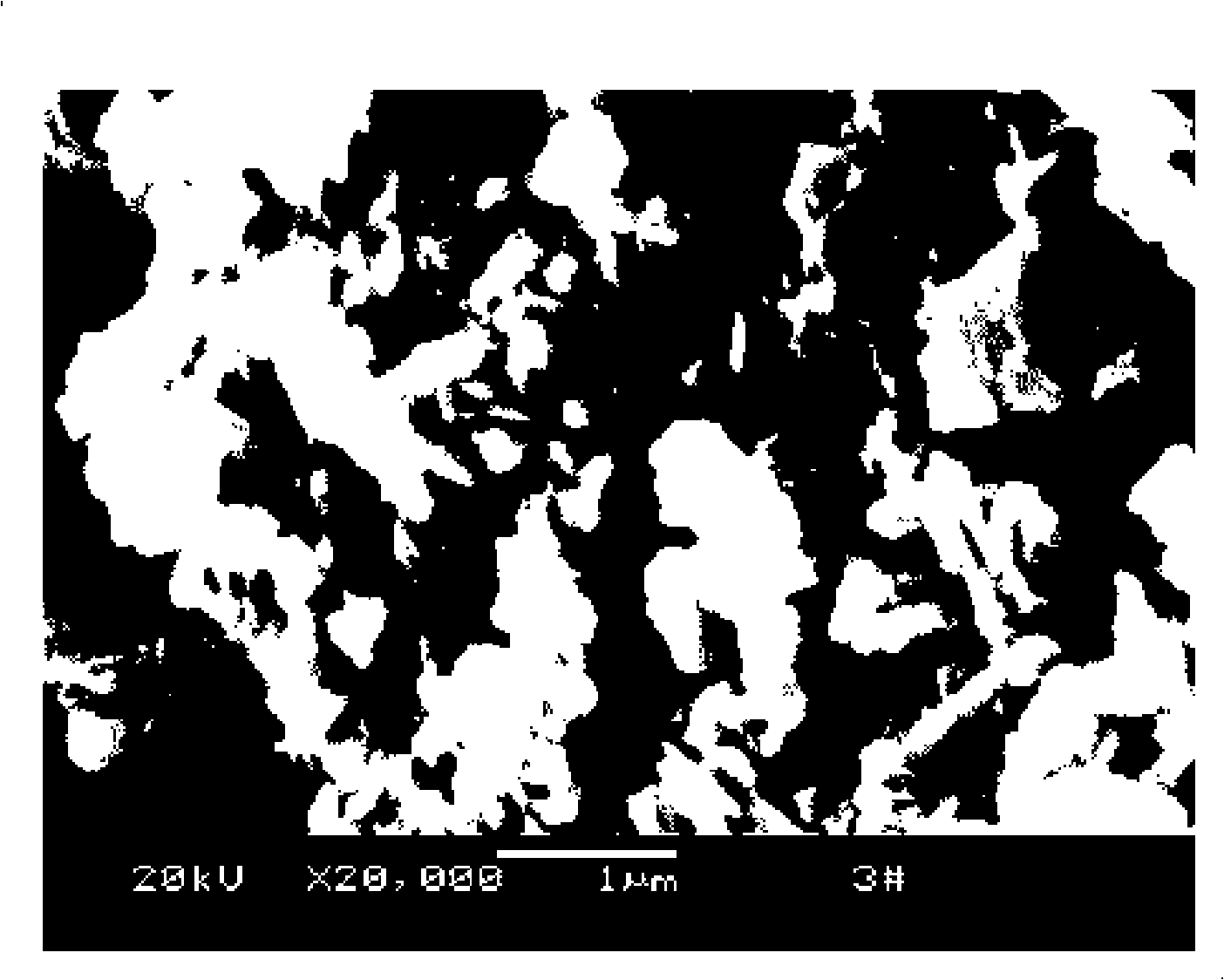

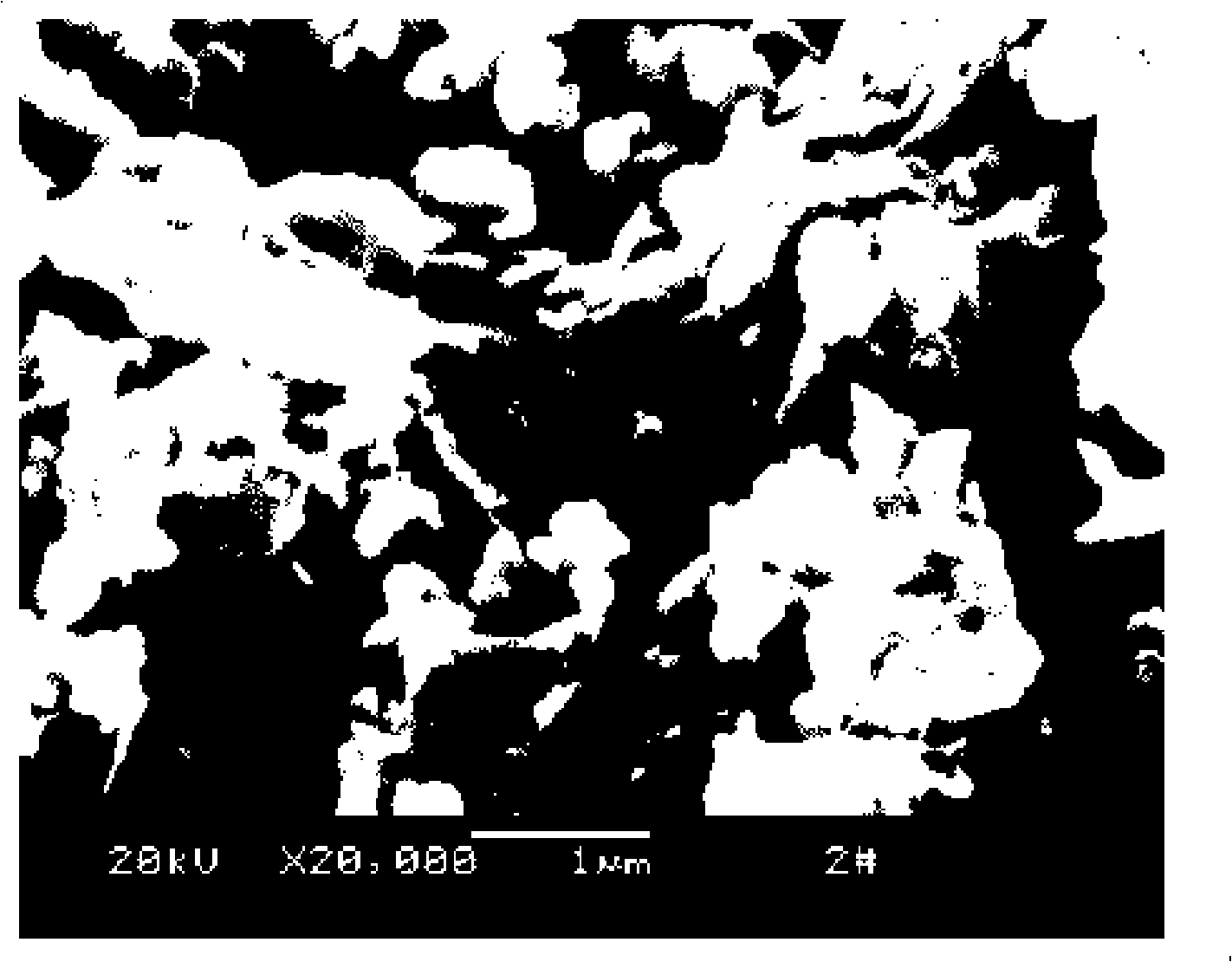

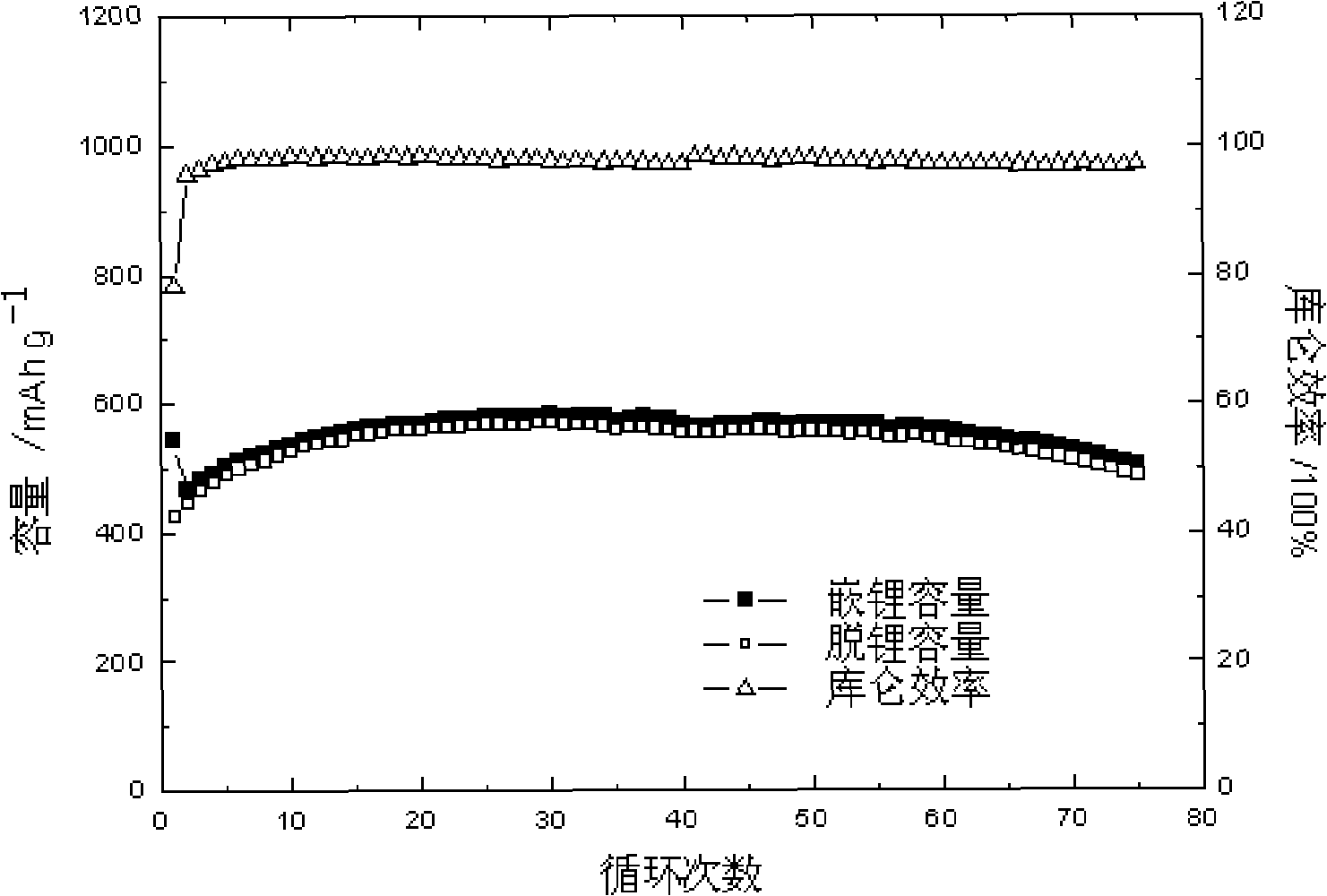

ActiveCN101286560AEvenly dispersedWell mixedElectrode manufacturing processesChemical/physical/physico-chemical processesComposite cathodeGraphite

The invention relates to a lithium ion battery composite cathode material and a preparation method thereof, which belongs to the technical field of lithium ion battery. The invention aims at improving the cycle performance of silicon cathode material at the same time when keeping the high ratio volume of lithium ion battery silicon cathode material. The proposal of the invention is that silica-based material coated by disordered carbon is treated with surface modification processing by utilizing lithium salt, namely, the lithium salt is coated on the surface of Si / G / DC (silicon / graphite / disordered carbon) to be prepared into the composite cathode material, therefore, the lithium-embedding and removing depth of the silicon can be effectively controlled, and the material is the lithium ion battery composite cathode material which has high specific capacity and good cyclical stability; furthermore, the material is safe and pollution-free, and presents higher thermal stability in various lithium salt electrolytes and solvents.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

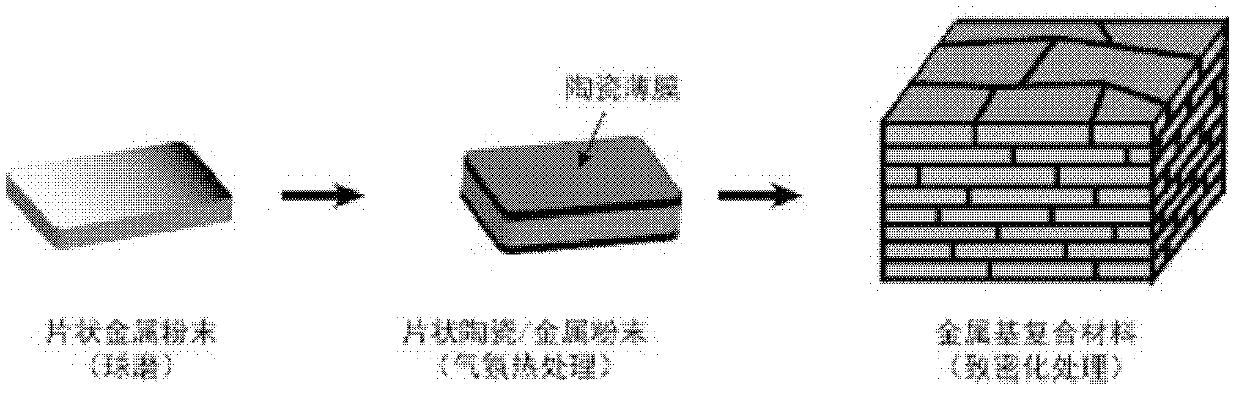

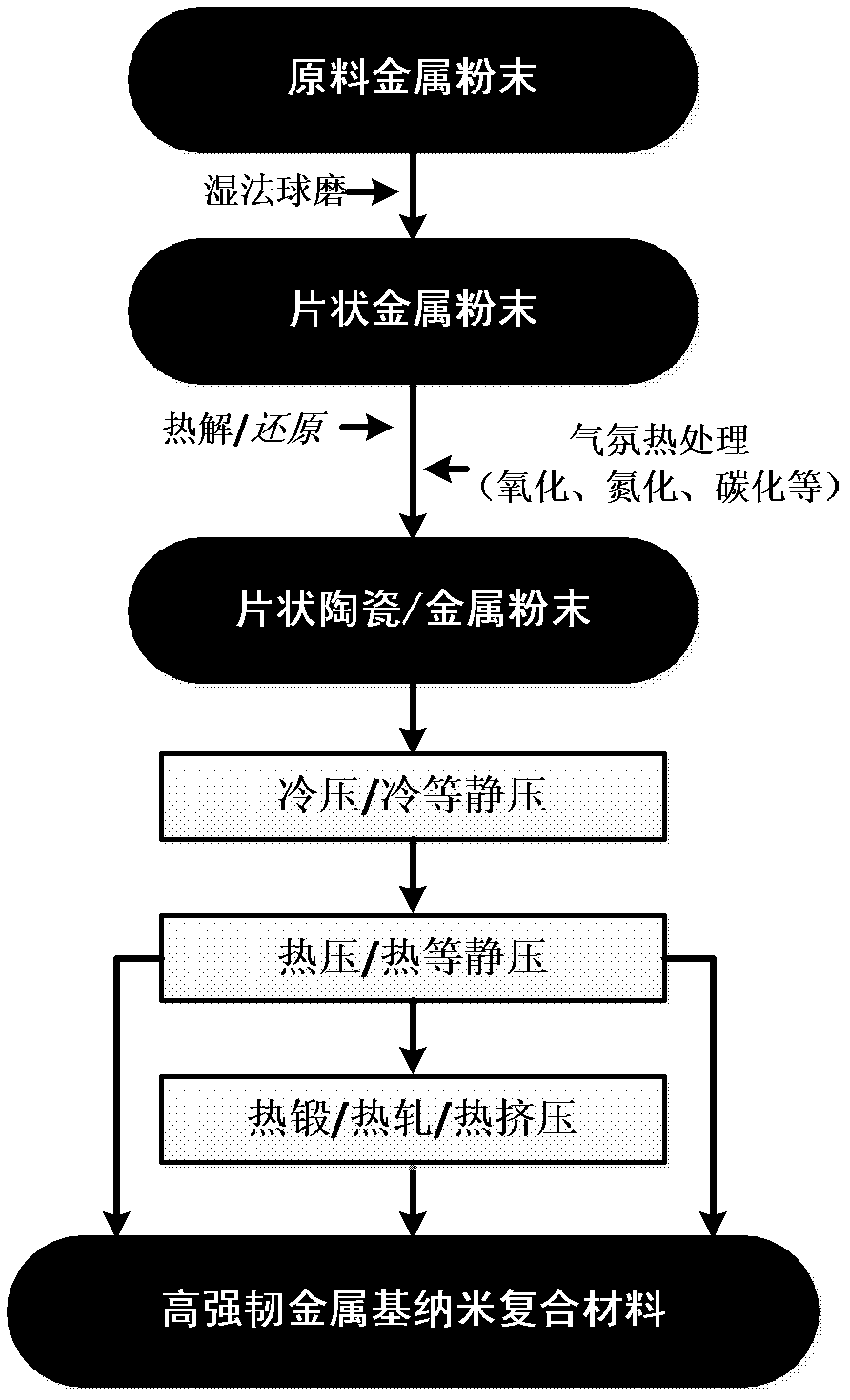

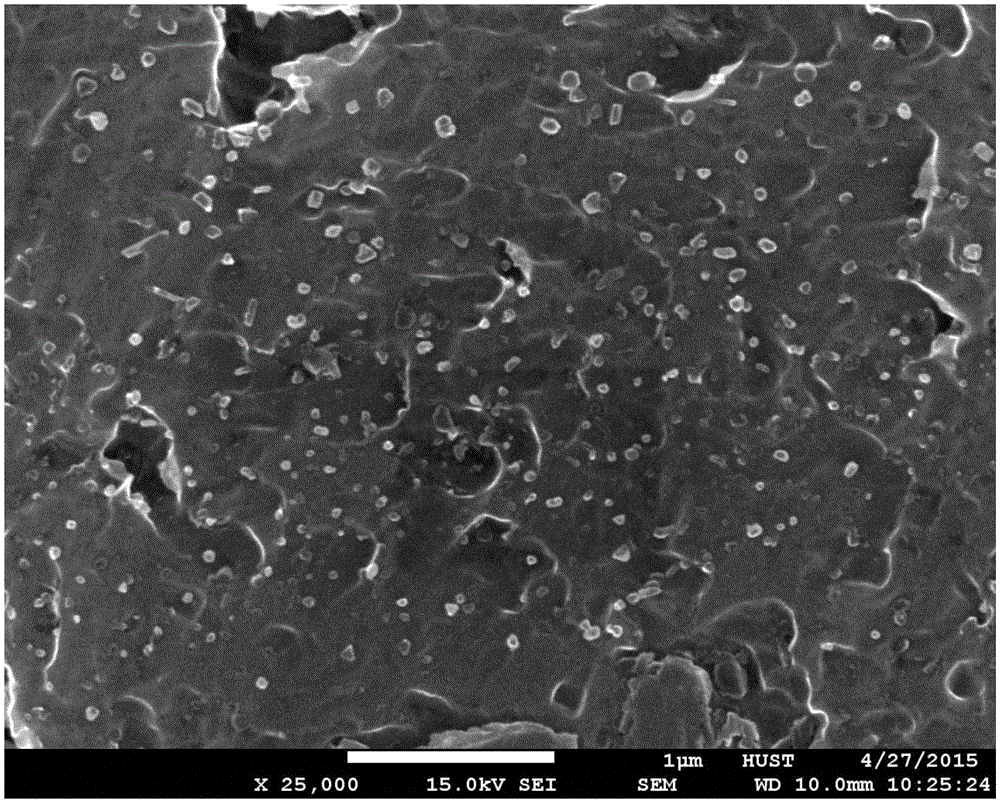

Preparation method of high-toughness metal-based nanometer composite material

The invention provides a preparation method of a high-toughness metal-based nanometer composite material and belongs to the technical field of composite materials. The preparation method provided by the invention comprises the following steps of: firstly, using an atmosphere heat treatment process, generating a layer of a nanometer ceramic thin film on the sheet-shaped metal powder through reaction in-situ; and then carrying out densifying treatment by using a powder metallurgical process, so as to obtain the large compact metal-based composite material. The metal-based composite material prepared by the invention has a metal / ceramic alternative laminated structure, wherein a ceramic layer can be used for effectively restraining the reply of a metal layer and the crystal grain growth, improving the high-position wrong storage capability, keeping a nanometer crystal matrix structure, and causing the rotation and inactivation of fissures, so as to realize mechanical properties matched with the high toughness. The preparation method provided by the invention is simple, convenient and practicable, can be used for realizing the macro-quantized preparation of the large-size composite material, and is good for prompting engineering applications of the metal-based nanometer composite material.

Owner:SHANGHAI JIAO TONG UNIV

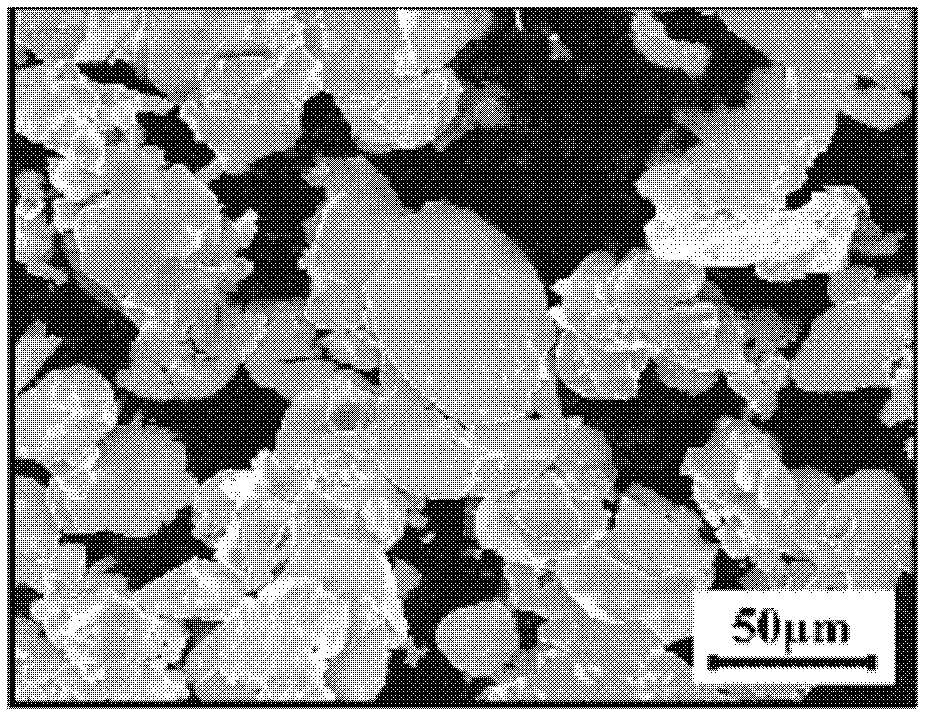

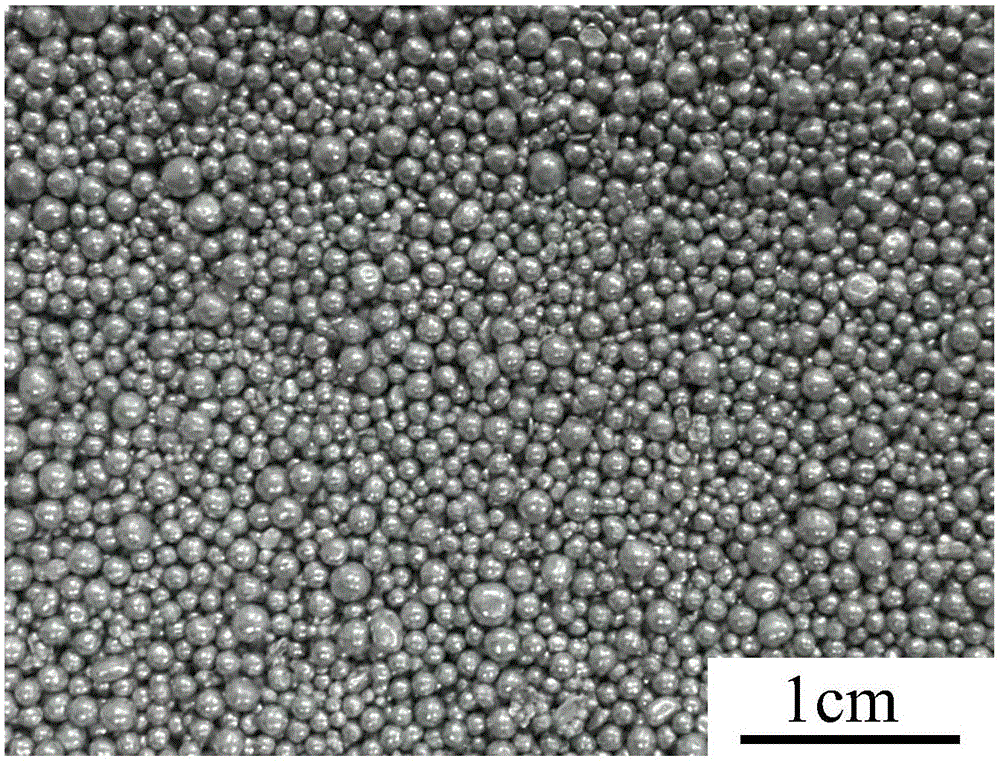

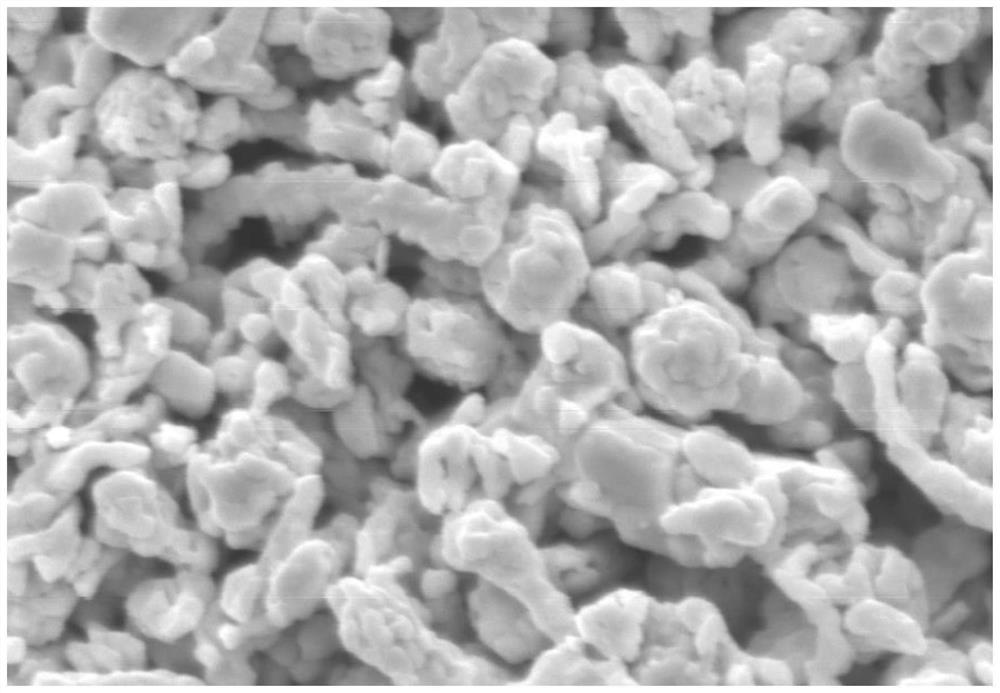

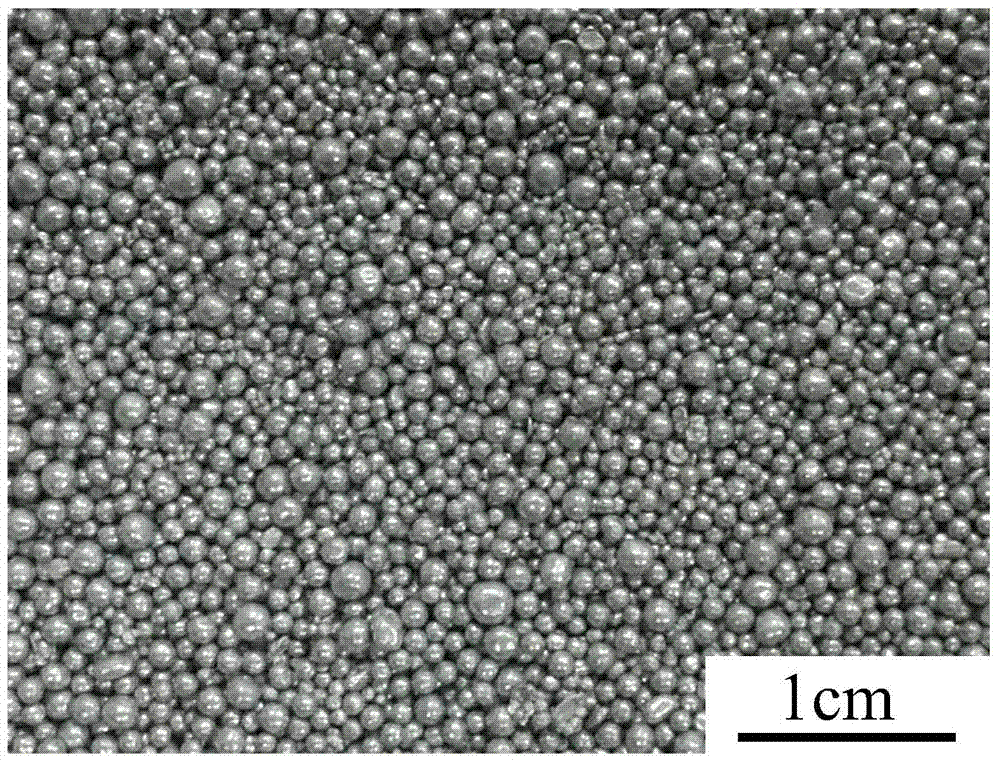

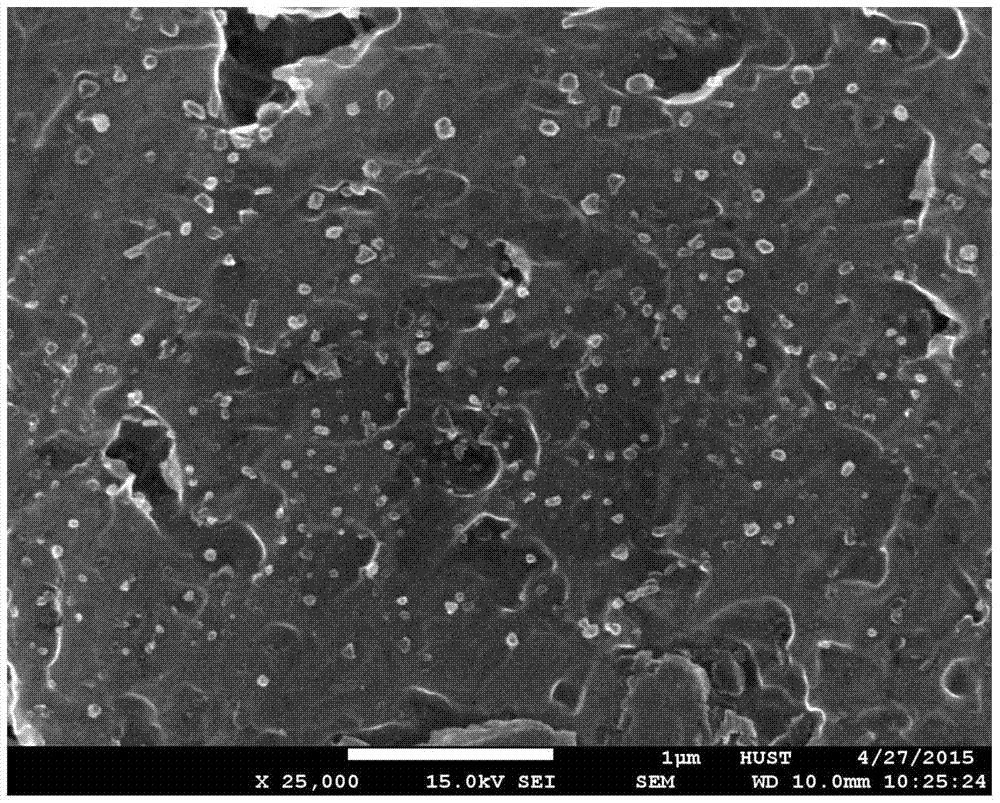

Method for preparing nano particle reinforced aluminum matrix composites

The invention discloses a method for preparing nano particle reinforced aluminum matrix composites. The method comprises the steps that firstly, mixed powder of nano ceramic powder and micron-sized aluminum or aluminum alloy powder is used for preparing millimeter-sized composite particles through a dry high-energy ball mill under the protection of vacuum or argon, wherein the volume fraction of nano ceramic particles in the millimeter-sized composite particles is 10-50%; and secondly, the millimeter-sized composite particles are melted directly or added into aluminum or aluminum melt, and supersonic vibration is applied, so that the nano ceramic particles are promoted to be uniformly dispersed in the metal melt, and the nano particle reinforced aluminum matrix composites are prepared. According to the method for preparing the nano particle reinforced aluminum matrix composites, the millimeter-sized composite particles prepared through a dry milling method can be added into the metal melt easily and completely, the problems that the wettability between the nano ceramic particles and matrix metal is poor, and adding of the particles is difficult are solved, and the advantage of low cost of a casting method for preparing metal matrix composites is given to play; the nano particles in the prepared composites are distributed uniformly, and the material performance is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method and application of MAX-phase enhanced nickel-based high-temperature lubricating composite material

ActiveCN109666815AHigh bonding strengthGood self-lubricating performanceCylinder headsGas turbine plantsAlloyGraphite

The invention discloses a preparation method and application of a MAX-phase enhanced nickel-based high-temperature lubricating composite material. The preparation method comprises the following steps:carrying out mechanical mixing on Ti powder, Si powder and TiC powder; preparing loose block-shaped Ti3SiC2 ceramic through a powder metallurgy method; then carrying out crushing and ball-milling treatment on the prepared loose block-shaped Ti3SiC2 ceramic, so as to obtain Ti3SiC2 ceramic powder; then carrying out mechanical mixing on the sieved Ti3SiC2 powder and NiAl powder; compacting and molding; and finally, preparing a block-shaped NiAl-Ti3SiC2 composite material through hot-pressing sintering, wherein the phase content of NiAl and Ti3SiC2 in the block-shaped NiAl-Ti3SiC2 composite material is 60 to 90 percent and 10 to 40 percent respectively. The NiAl composite high-temperature lubricating material is prepared by adopting the powder metallurgy method and the self-lubricating performance of hot-pressing sintering and synthesis in the composite material is better than that of Ti3SiC2-phase ceramic of graphite and MoS2; and meanwhile, an NiAl alloy has excellent corrosion resistance and abrasion resistance, and has good sintering performance, so that NiAl alloy powder is selected as a matrix of the composite material.

Owner:咸阳瞪羚谷新材料科技有限公司

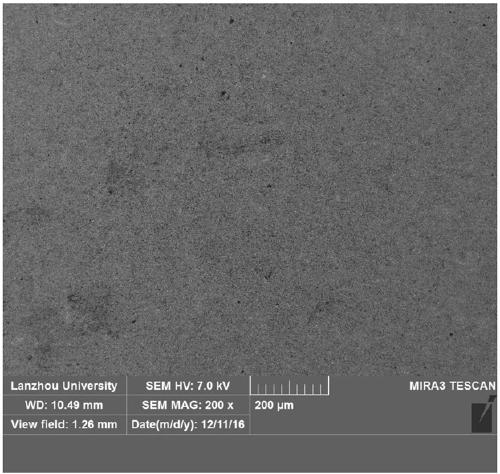

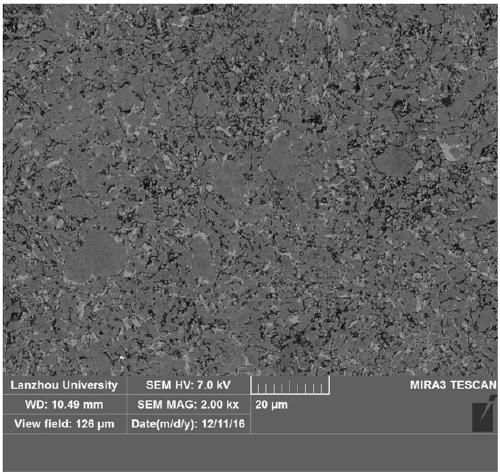

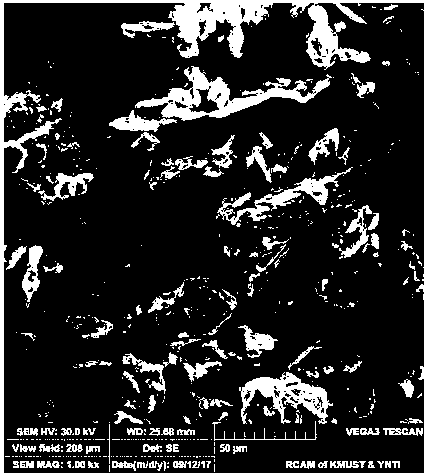

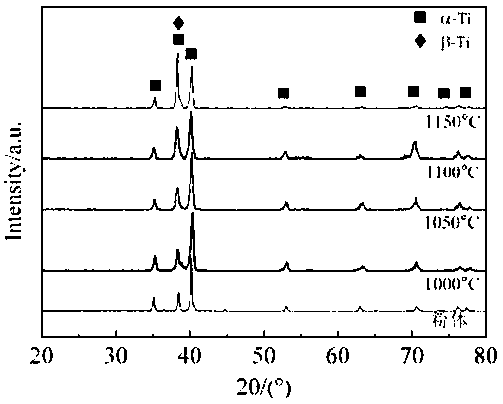

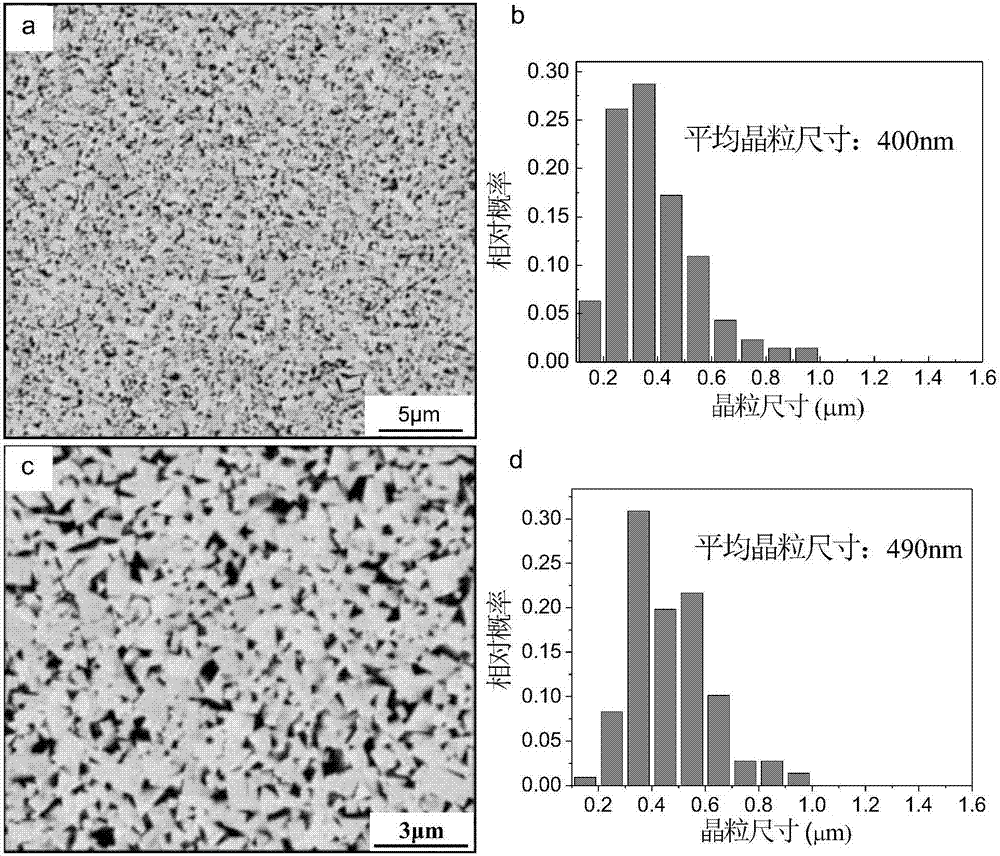

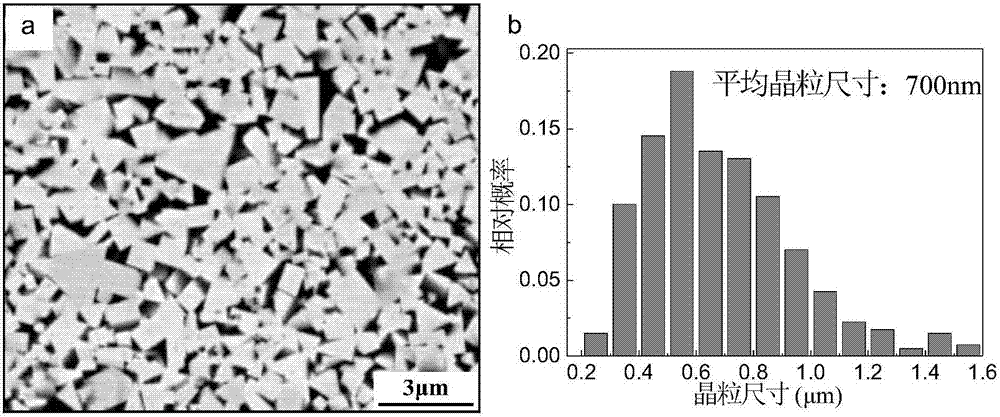

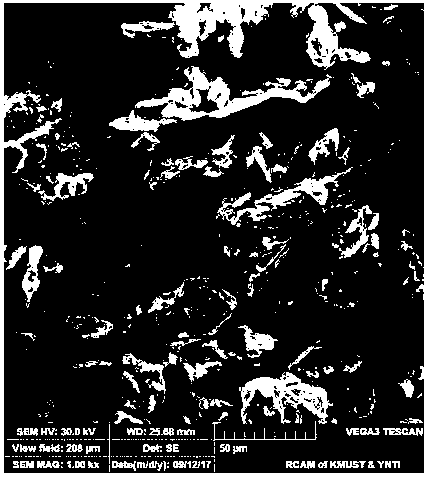

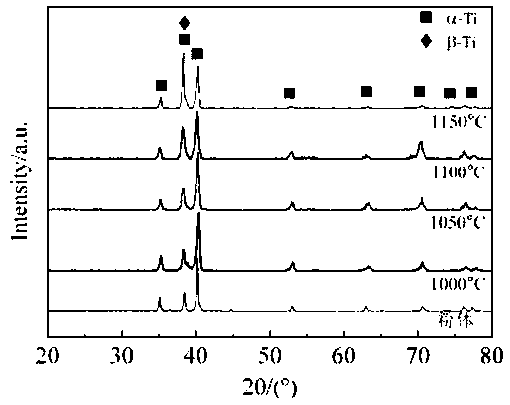

Preparation method of titanium, aluminum, niobium, zirconium and molybdenum alloy

The invention discloses a preparation method of a titanium, aluminum, niobium, zirconium and molybdenum alloy, and belongs to the technical field of preparation of titanium alloys. The method comprises the following steps: weighing Ti, Al, Nb, Zr and Mo metal powder according to certain proportions, mixing the metal powder, performing intermittent dry type ball grinding through a ball grinder to obtain mixed powder, putting the obtained mixed powder into a graphite mold, prepressing the mixed powder, placing the graphite mold into a discharge plasma sintering furnace, applying axial pressure of 10 to 50 MPa for sintering under the condition that the vacuum degree is 2 to 8 Pa, heating the mixed powder in a multi-stage heating mode to 1,000 to 1,150 DEG C, preserving the heat for 3 to 8 min, cooling the mixture to room temperature, and demolding the mixture, thus obtaining the titanium, aluminum, niobium, zirconium and molybdenum alloy material. The titanium, aluminum, niobium, zirconium and molybdenum alloy prepared by the method disclosed by the invention has the advantages of uniform component, high compactness, high intensity, high plasticity and the like; and in addition, the method is easy to operate, short in time, energy-saving and environmentally friendly and has a good popularization value.

Owner:KUNMING UNIV OF SCI & TECH

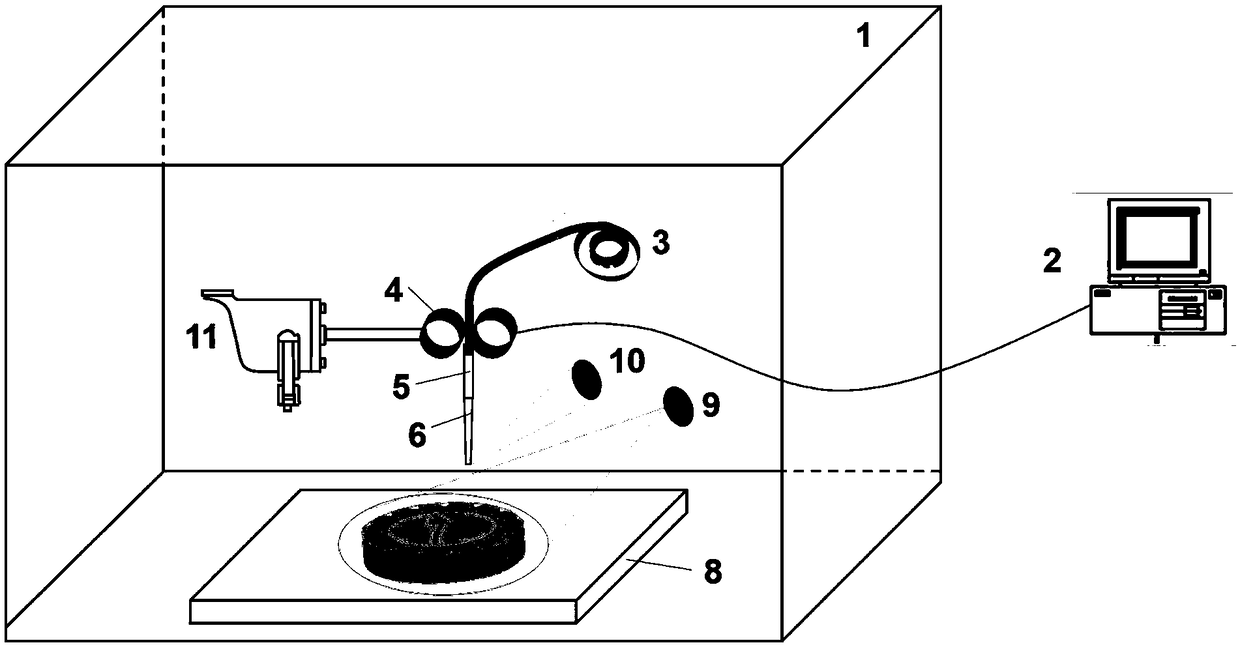

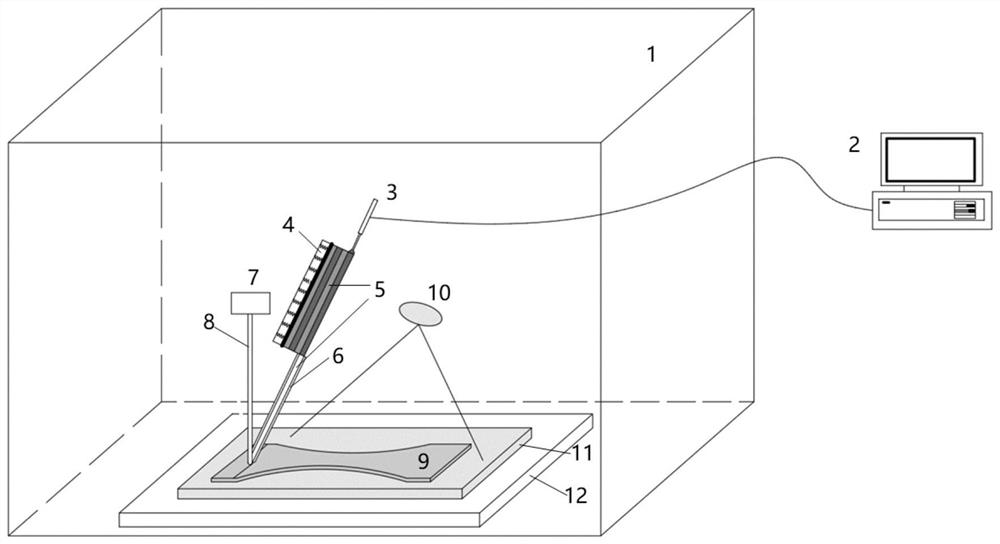

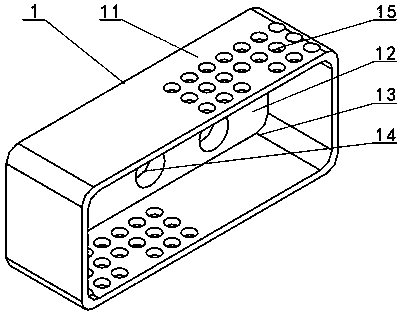

Space 3D printing system based on amorphous alloy superplastic welding

PendingCN109434112AAvoid the risk of high temperature crystallizationImprove job stabilityAdditive manufacturing apparatusSpace environmentOrbit

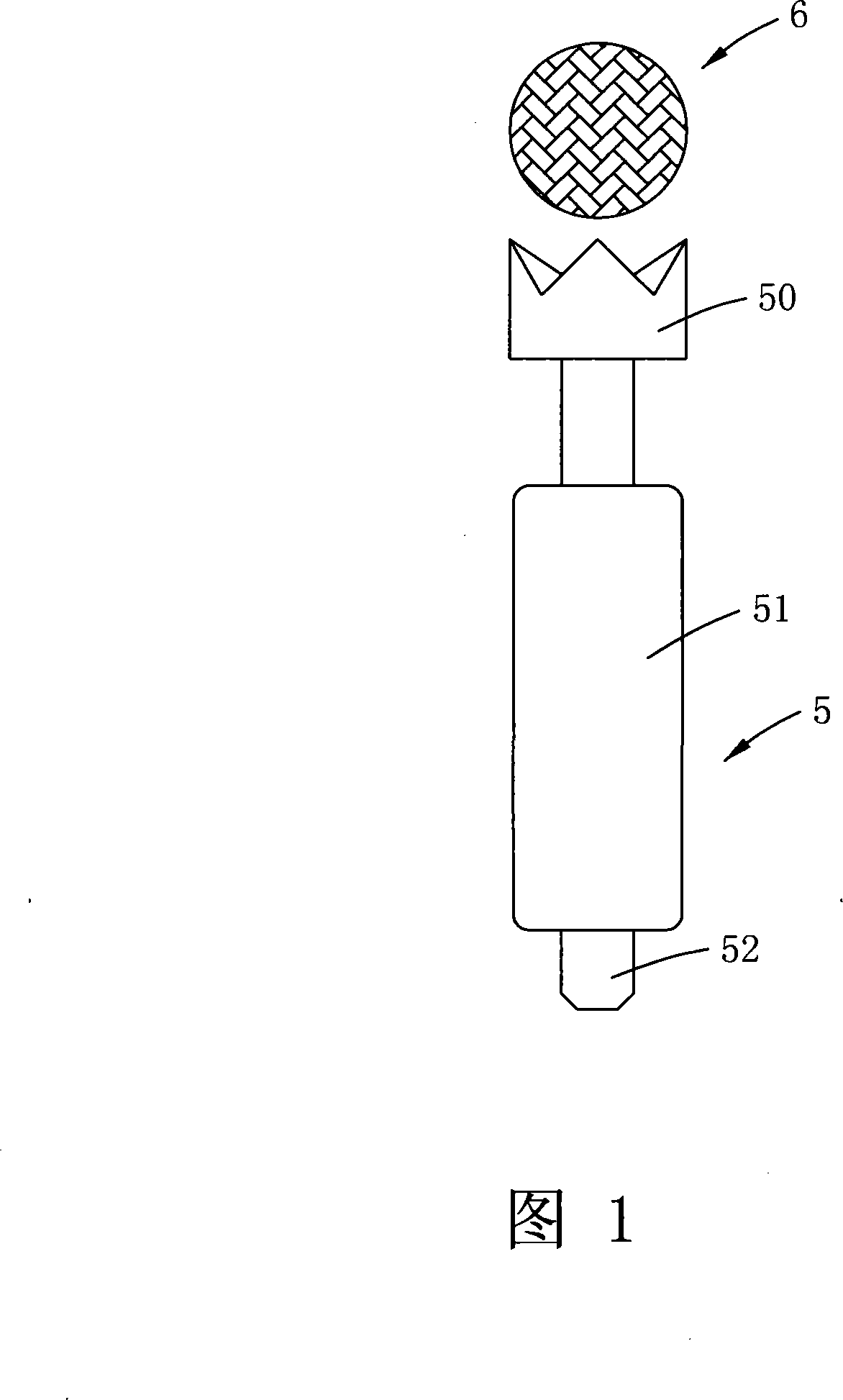

The invention discloses a space 3D printing system based on amorphous alloy superplastic welding. The space 3D printing system comprises a shell (1), a control unit (2), a workbench (8) arranged inside the shell (1), an amorphous alloy material (3), a heating device, a mechanical loading device (11) and a conveying device, wherein the mechanical loading device (11) controls the speed of the conveying device and the pressure load of a spray head (6) according to the material use requirements of 3D printing molding parts, and the heating device performs local heating and welding on the amorphousalloy material (3) to realize part molding. According to the space 3D printing system based on the amorphous alloy superplastic welding, the heating device only heats an area near the spray head, thecrystallization risk of amorphous alloy under a long-time high-temperature condition is avoided, and the amorphous alloy is heated to a superplastic state of a supercooled liquid phase area to realize molding, a laser or electron beam heating device is cancelled, the equipment working stability is increased, and the space 3D printing system based on the amorphous alloy superplastic welding is especially suitable for in-orbit fabrication in the space environment.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY +1

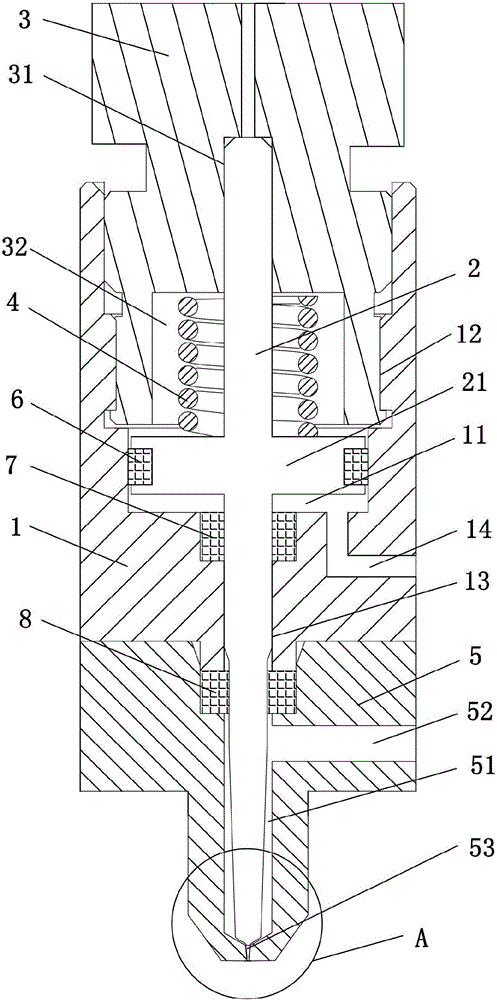

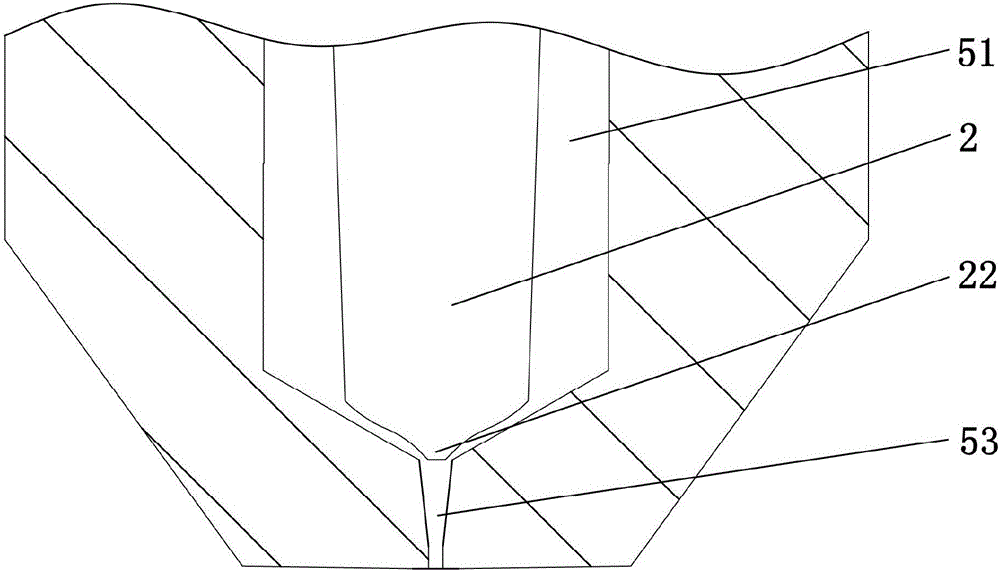

Solder paste injection valve

InactiveCN106076693AAvoid cold weldingIncrease typeLiquid spraying apparatusFluid controlSolder ball

The invention discloses a solder paste injection valve, and belongs to the technical field of fluid control of automatic equipment. The solder paste injection valve comprises a valve body, a striker, a spring regulating base, a drive spring and an injection part, wherein the valve body comprises a piston cavity, a spring base cavity and a valve body shaft hole; a gas inlet is formed in the side wall, which corresponds to the lower portion of the piston cavity, of the valve body; a piston is formed in the middle of the height direction by the striker; the piston is accommodated in the piston cavity; an air runner which communicates with the gas inlet is formed by a gap, which corresponds to the lower portion of the piston, of the piston cavity; a spring cavity is formed at one end, towards the valve body, of the spring regulating base; the drive spring is arranged in the spring cavity and sleeves the striker; an injection part shaft hole for allowing the striker to insert is formed in the middle of the axial direction of the injection part; a solder paste runner is formed by a gap between the inner side wall of the injection part shaft hole and the striker; a feeding hole which communicates with the solder paste runner is formed in the side wall of the injection part; and a spray nozzle is arranged at the bottom end of the injection part. The solder paste injection valve can prevent a solder ball from cold welding due to contact extrusion, expands types of tin solder paste capable of being injected, is convenient to maintain, is long in service life, and is low in cost.

Owner:SUZHOU SOLDER FORCE INC

Automatically expandable autodyne support for outer space

PendingCN109253358ASimple structureReduce volumeNon-mechanical controlsStands/trestlesElectromagnetic lockLocking mechanism

The invention discloses an automatically expandable autodyne support for the outer space. The automatically expandable autodyne support for the outer space comprises a fixing device, an electromagnetic locking device and an automatic expanding device, wherein the fixing device comprises a fixing seat, a first fixing rod, a second fixing rod and a third fixing rod; the first fixing rod, the secondfixing rod and the third fixing rod are successively perpendicularly arranged on the fixing seat; the automatic expanding device comprises a first joint, a first movable rod, a second joint, a secondmovable rod and a camera mounting seat; and torsional springs are separately arranged in the first joint and the second joint. The automatically expandable autodyne support for the outer space uses principles of electromagnetic locking and torsional spring driving, under the condition that the electromagnetic locking device is energized and unlocked, the autodyne support is automatically expandedunder the driving effect of the torsional spring, the problem that an existing expanding device driven by a motor is high in cost, large in size and poor in reliability is solved, and meanwhile, the technical problems that an existing locking mechanism using initiator explosive bolts for the outer space is high in cost, and the safety and reliability of an aircraft are affected are also solved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

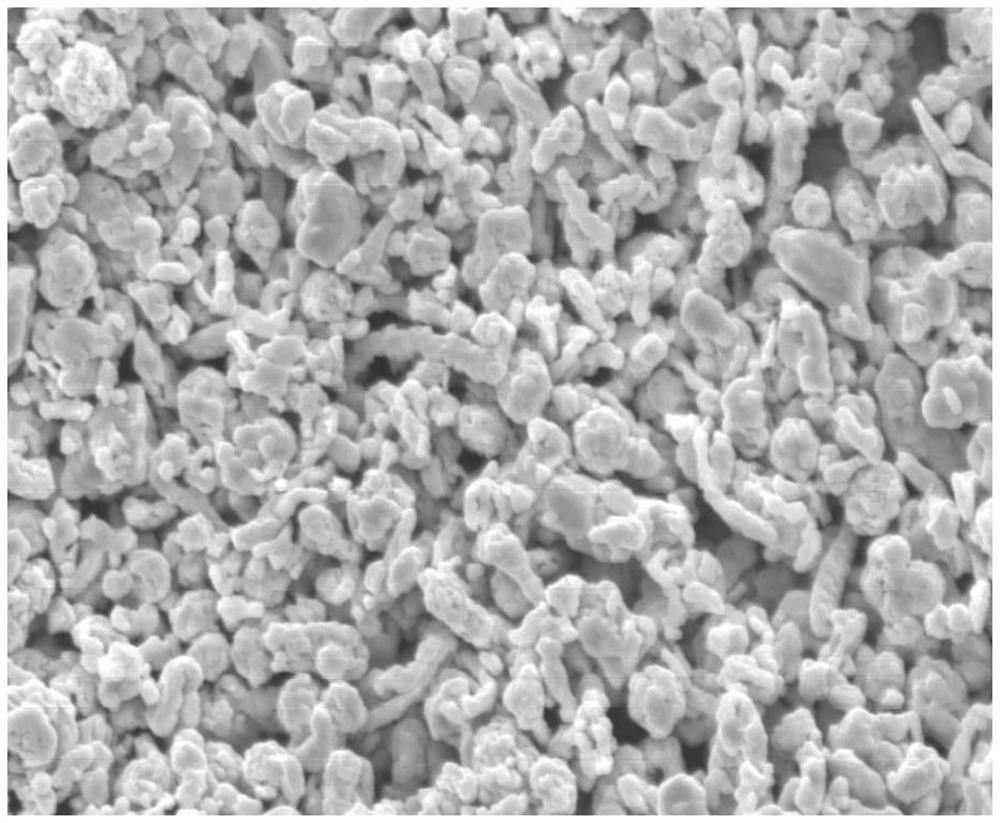

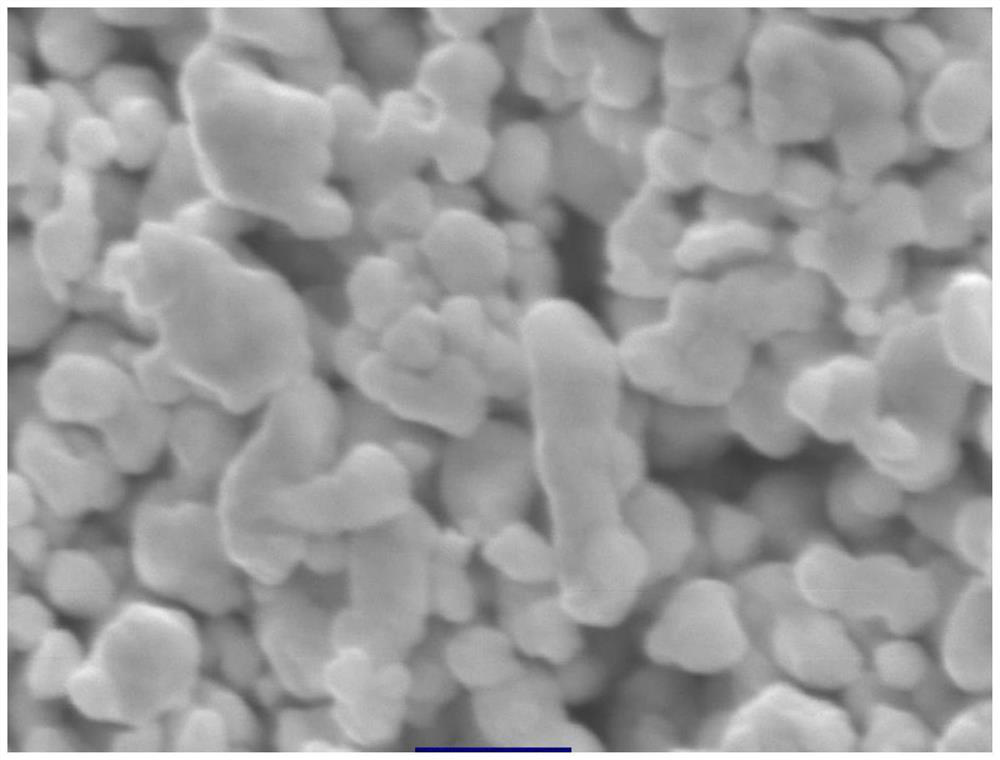

Silver micro powder and preparation method and application thereof

PendingCN114054769AActive connectionImprove conductivityTransportation and packagingMetal-working apparatusSilver iodideSilver bromide

The invention relates to silver micro powder and a preparation method and application thereof, and relates to the technical field of functional materials. The preparation method comprises the following steps: preparing a silver nitrate solution at a temperature of 10-20 DEG C, a dispersant solution at a temperature of 30-60 DEG C, a morphology regulator solution at a temperature of 25-35 DEG C, a pH regulator solution at a temperature of 30-60 DEG C and a reducing agent solution at a temperature of 55-65 DEG C; adding the pH regulator solution into the silver nitrate solution, performing stirring, adding the morphology regulator solution, the reducing agent solution and the dispersing agent solution, performing mixing, adjusting the temperature to 30-60 DEG C, and performing reaction for 30-90 minutes; performing cleaning until the electric conductivity of the reacted product is less than 50 [mu]s / cm, and performing settling and separating; and adding a surface treating agent, performing drying, powdering and sieving to obtain a product. The mass of a morphology regulator is 0.1-0.5% of the mass of the silver micro powder, and the morphology regulator comprises at least one of silver chloride, silver bromide and silver iodide. The preparation method is simple and easy to implement and high in production efficiency.

Owner:广东羚光新材料股份有限公司

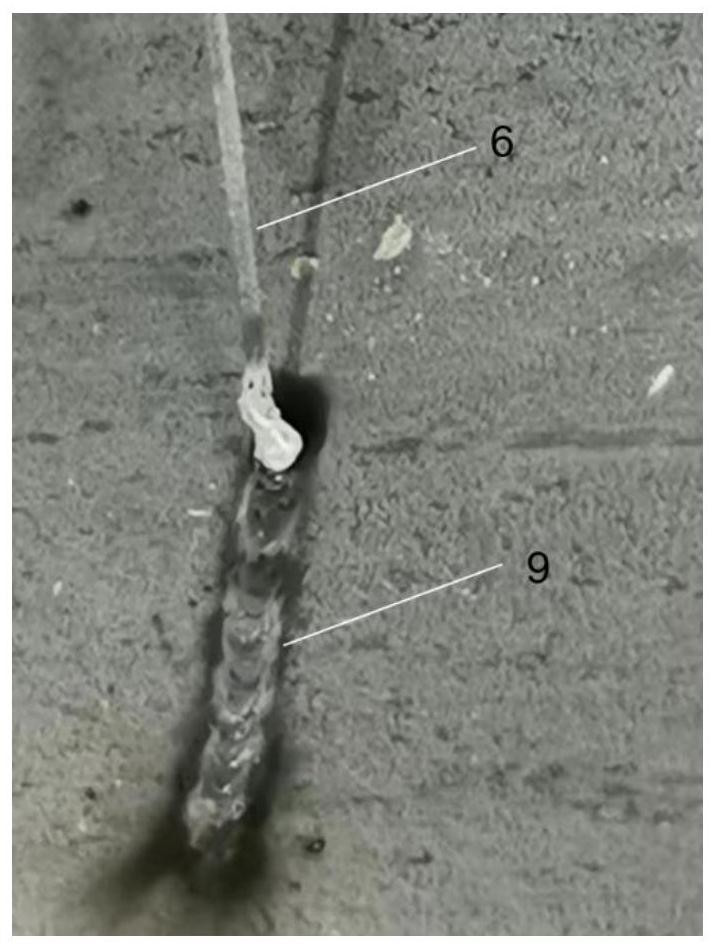

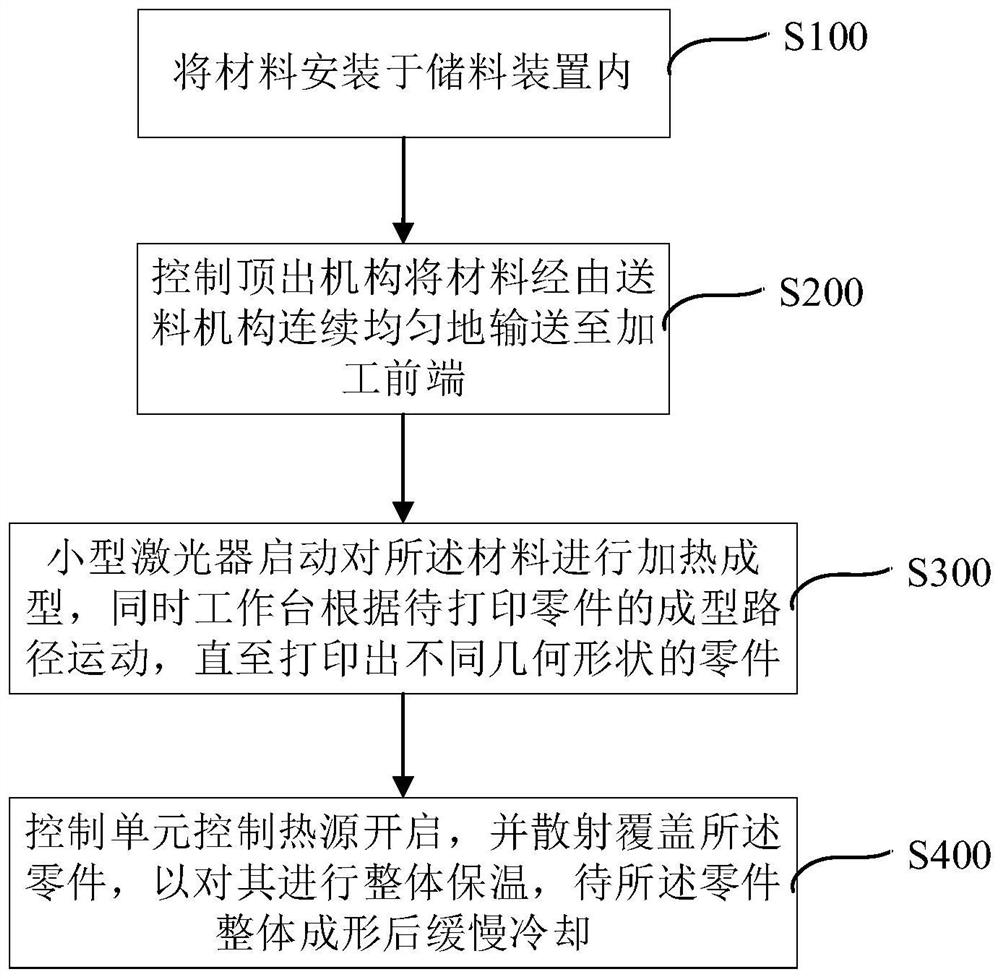

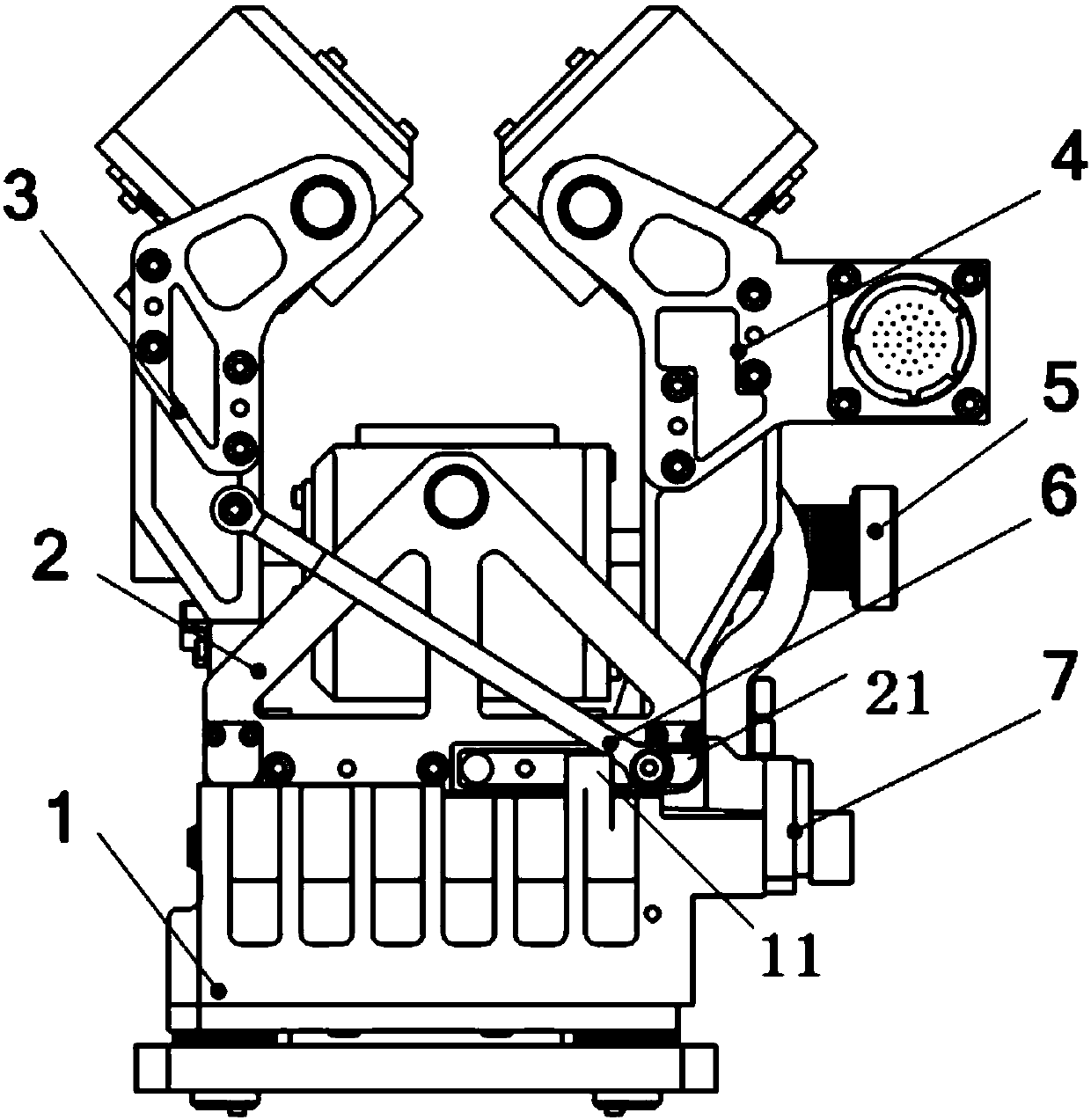

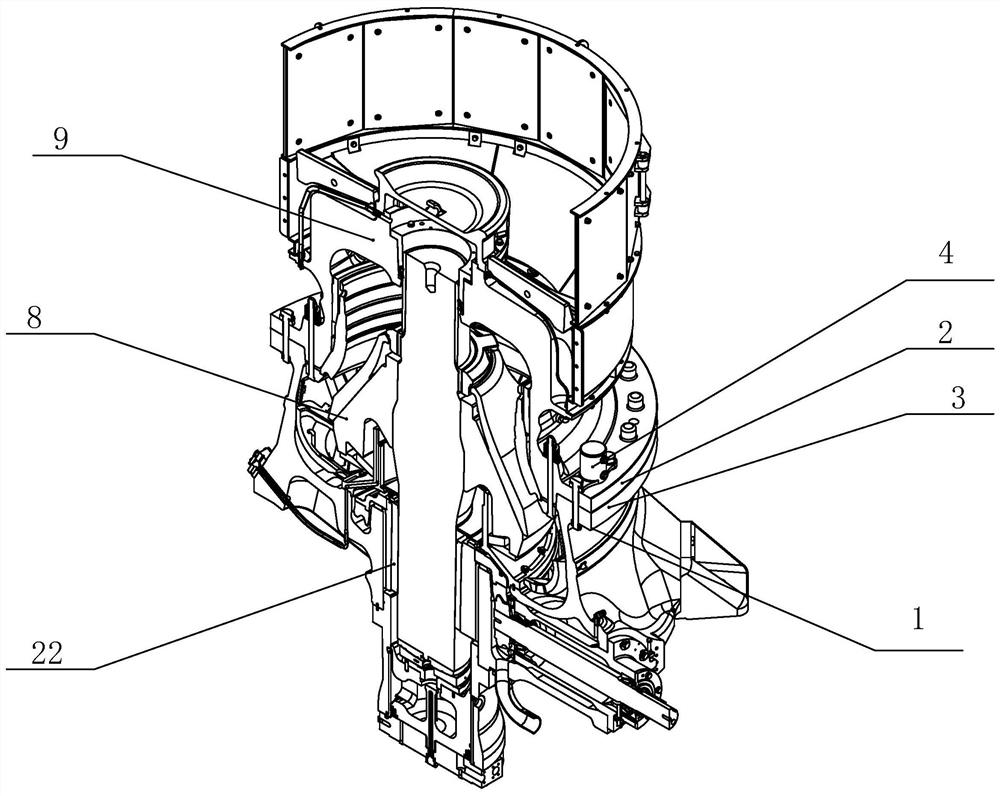

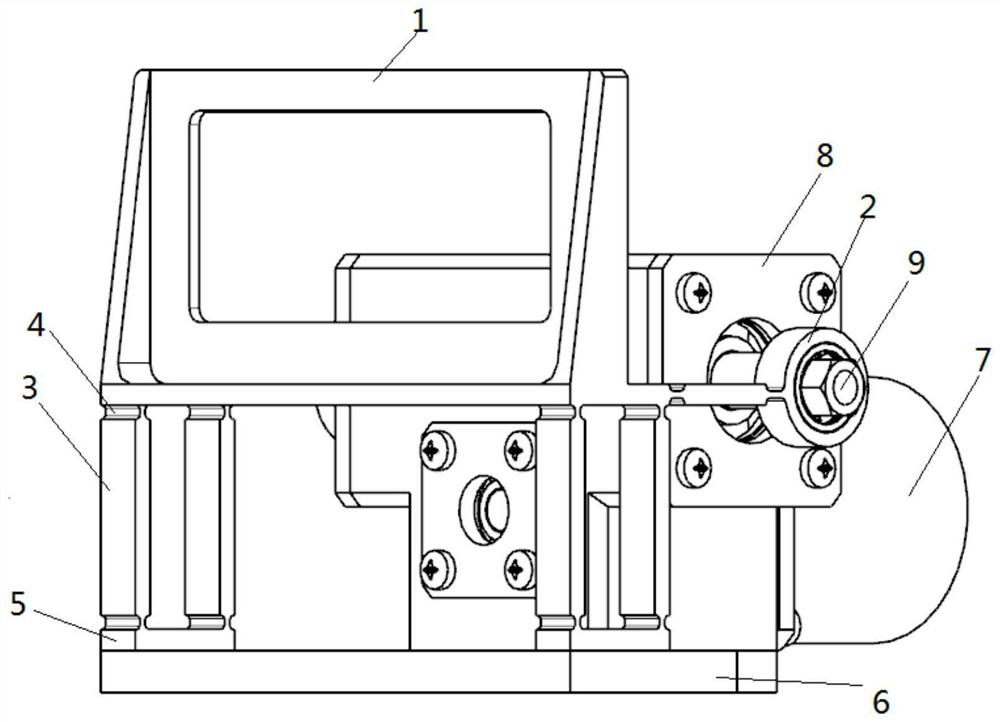

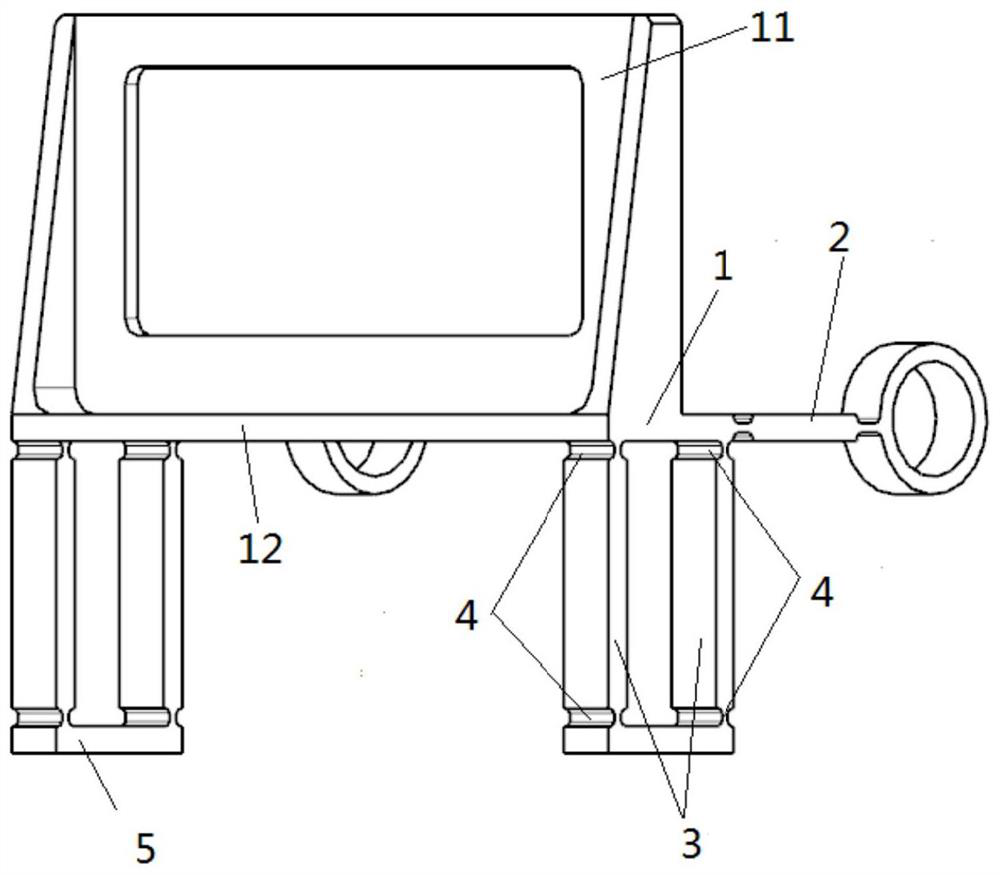

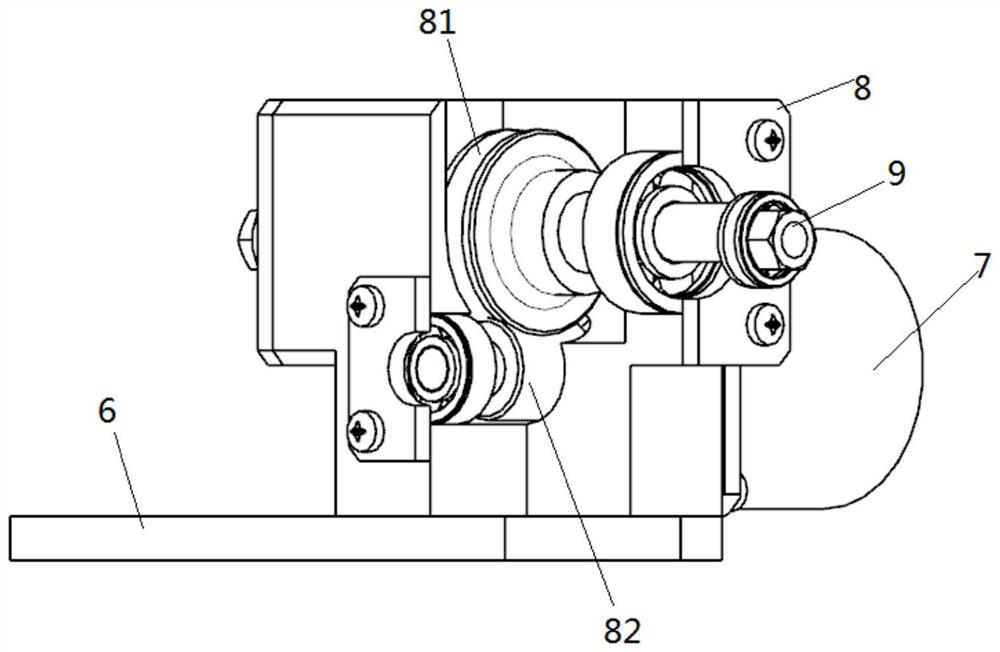

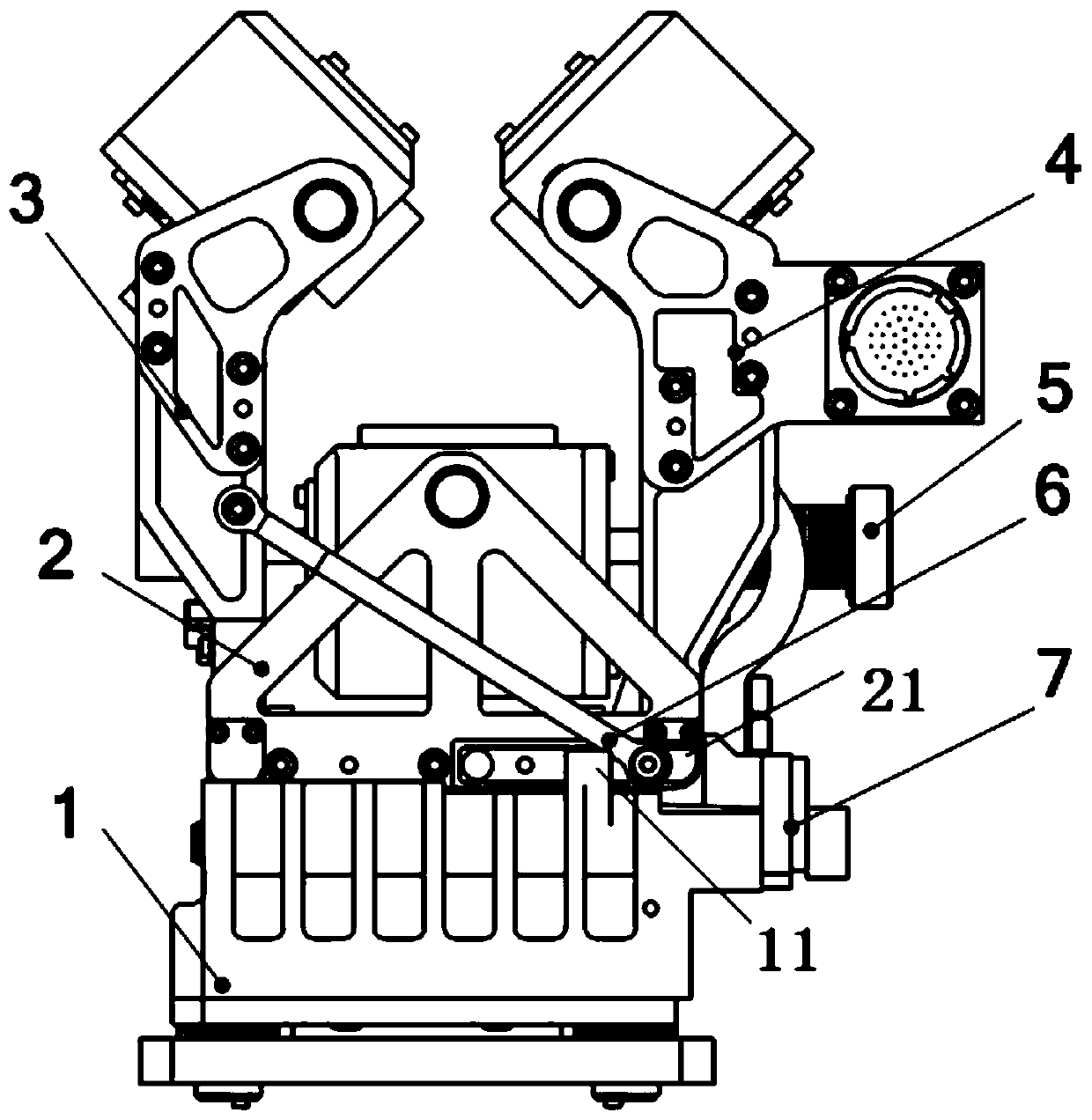

3D printing system and method suitable for micro-gravity space environment

InactiveCN111761063AResistant to atomic oxygen ablationAvoid cold weldingAdditive manufacturing apparatusControl cellEngineering

The invention discloses a 3D printing system suitable for a micro-gravity space environment. The 3D printing system comprises a housing (1) and a control unit (2) as well as a workbench (12) arrangedinside the housing (1), a base plate (11) arranged on the workbench (12), a feeding unit, and a processing head part, wherein the feeding unit comprises a storage device (4), a feeding mechanism (6) arranged at one end of the storage device (4) and an ejecting-out mechanism (3) arranged at the other end of the storage device (4); and the processing head part comprises a small laser unit (7). The invention further discloses a 3D printing method suitable for the micro-gravity space environment. The system avoids the crystallization risk that an amorphous alloy is connected and formed in a thermoplastic mode under a long-time high-temperature condition, can achieve coaxial feeding, is high in forming efficiency, guarantees uniform and continuous discharge, can form a part of any shape, can obtain a large-dimension amorphous alloy part with high forming quality, can keep good equipment work stability, and is especially suitable for on-track manufacturing in the space environment.

Owner:HUAZHONG UNIV OF SCI & TECH

Powder metallurgy refractory multi-principal-element high-entropy alloy and preparation method thereof

The invention relates to the technical field of powder metallurgy preparation of refractory metal materials, and specifically discloses a preparation method of a powder metallurgy refractory multi-principal-element high-entropy alloy. The preparation method of the powder metallurgy refractory multi-principal-element high-entropy alloy specifically comprises the following steps: step S1, refractory metal element powder is sieved through a 300-mesh sieve and mixed in a multi-element powder mixing mode, so that a mixture is obtained; the mixture comprises at least four elements of Ti, Zr, Hf, V, Nb, Ta, Cr, Mo and W; the atomic percent of each element in the mixture is 5%-35%; and the total percentage is 100%; step S2, pressing forming is carried out, and a pressed blank is obtained; and S3, vacuum high-temperature solid-phase sintering is carried out to obtain a sintered block. The preparation method of the powder metallurgy refractory multi-principal-element high-entropy alloy has the advantages that the components are easy to regulate and control, the production efficiency is high, and near-net forming is achieved; the prepared powder metallurgy refractory multi-principal-element high-entropy alloy is stable in structure and performance and low in cost; and the powder metallurgy refractory multi-principal-element high-entropy alloy has remarkable advantages in research and development of high-performance powder metallurgy refractory multi-principal-element high-entropy alloy and flexible batch production of products of various shapes and varieties.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Satellite-borne dual-band four-channel rotary joint

ActiveCN112909450ARealize stable transmissionReduce stable transmission problemsWaveguide type devicesHigh isolationControl theory

The invention discloses a satellite-borne dual-band four-channel rotary joint which comprises a first single-waveguide rotor, a first dual-waveguide stator, a dual-waveguide rotor, a second dual-waveguide stator and a second single-waveguide rotor. The first single-waveguide rotor, the double-waveguide rotor and the second single-waveguide rotor are rotors, and the first double-waveguide stator and the second double-waveguide stator are stators; the first double-waveguide stator is arranged between the first single-waveguide rotor and the double-waveguide rotor and is supported and connected through a bearing, the second double-waveguide stator is arranged between the second single-waveguide rotor and the double-waveguide rotor and is supported and connected through a bearing, and the rotors and the stators can rotate relatively. The dual-band four-channel rotary joint is a Ka-high-band four-channel rotary joint and a K-high-band four-channel rotary joint and has the advantages of being high in working frequency and large in number of channels, the channels are independent of one another due to the concentric stacking structure, and the requirement for high isolation between the channels is met.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

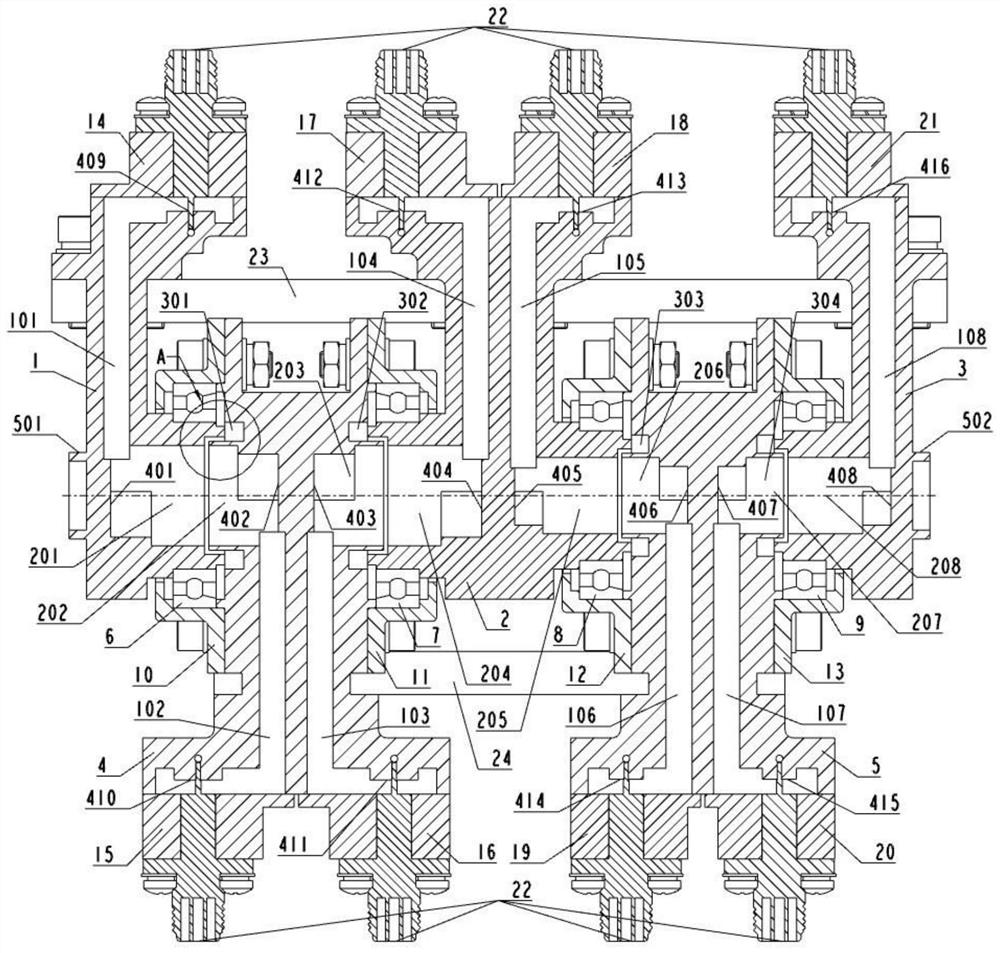

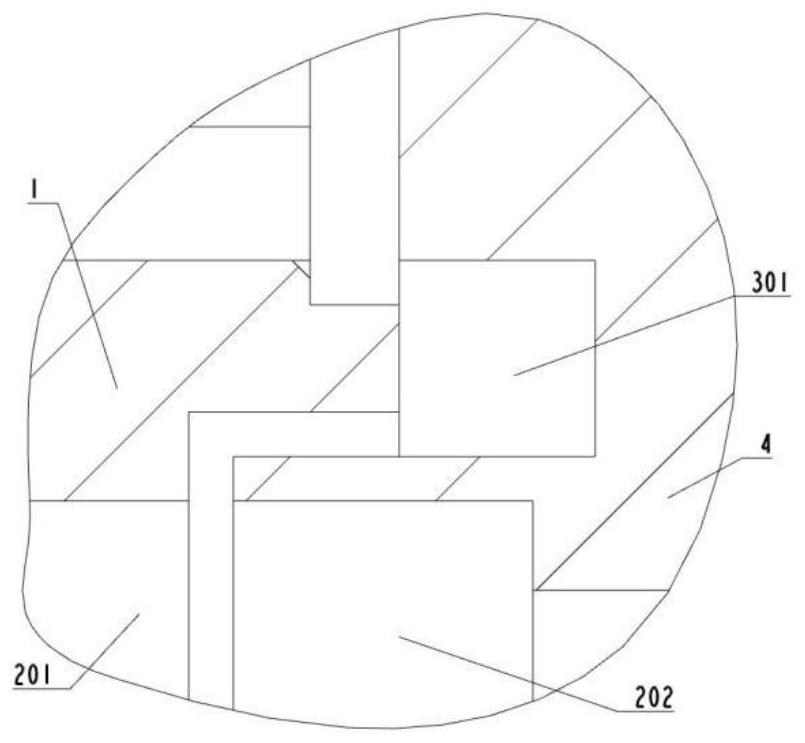

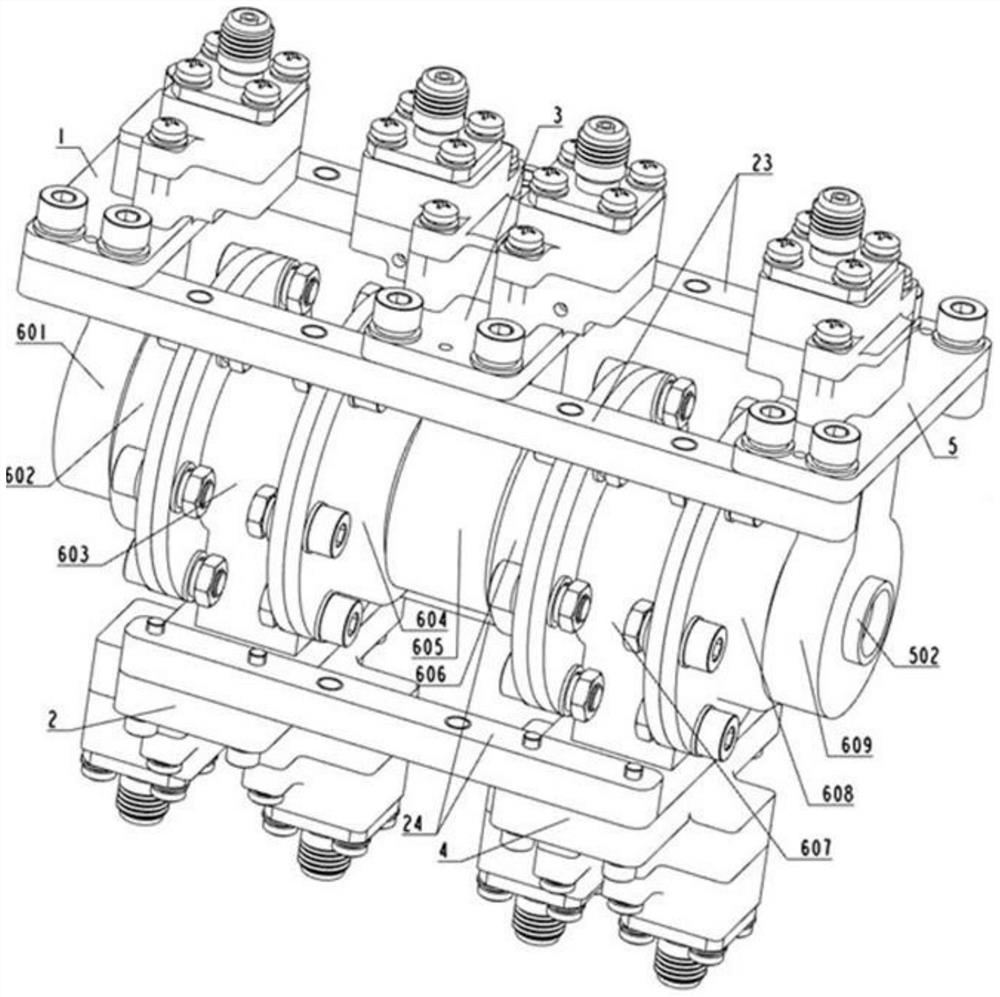

High-current wire connecting apparatus for connecting multiple wires synchronously

ActiveCN107611625AFast fillAvoid wastingSoldered/welded conductive connectionsMultiple conductors connectorEngineeringCold welding

The invention discloses a high-current wire connecting apparatus for connecting multiple wires synchronously. The high-current wire connecting apparatus at least comprises a welding box and an insulating base; an opening is formed in the top of the welding box, and the bottom of the welding box is mounted on the insulating base; welding box wire holes for allowing wires to pass through are formedin the circumferential box wall of the welding box; and an inner cavity of the welding box is filled with a welding material. By mounting the welding box on the insulating base and by forming the welding box wire holes in the welding box, the wires can pass through the welding box wire holes in a one-to-one correspondence manner to be put in the inner cavity of the welding box to be positioned temporarily, so that cold welding and insufficient welding caused by wire movement in the welding process can be avoided, the welding quality and conductive performance can be obviously improved, waste of the welding material is eliminated, and a phenomenon of contact surface oxidization caused by long-term high-current passing can be solved once for all, thereby solving the problems existing in reliable high-current wiring, mounting and connecting fundamentally.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

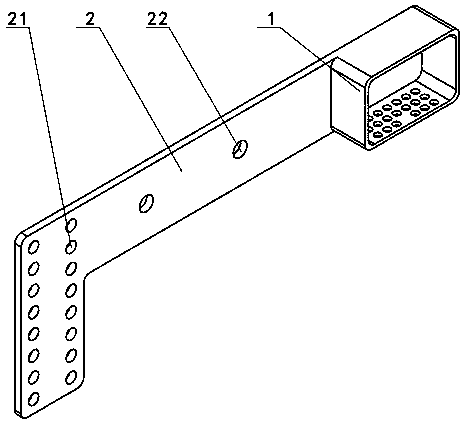

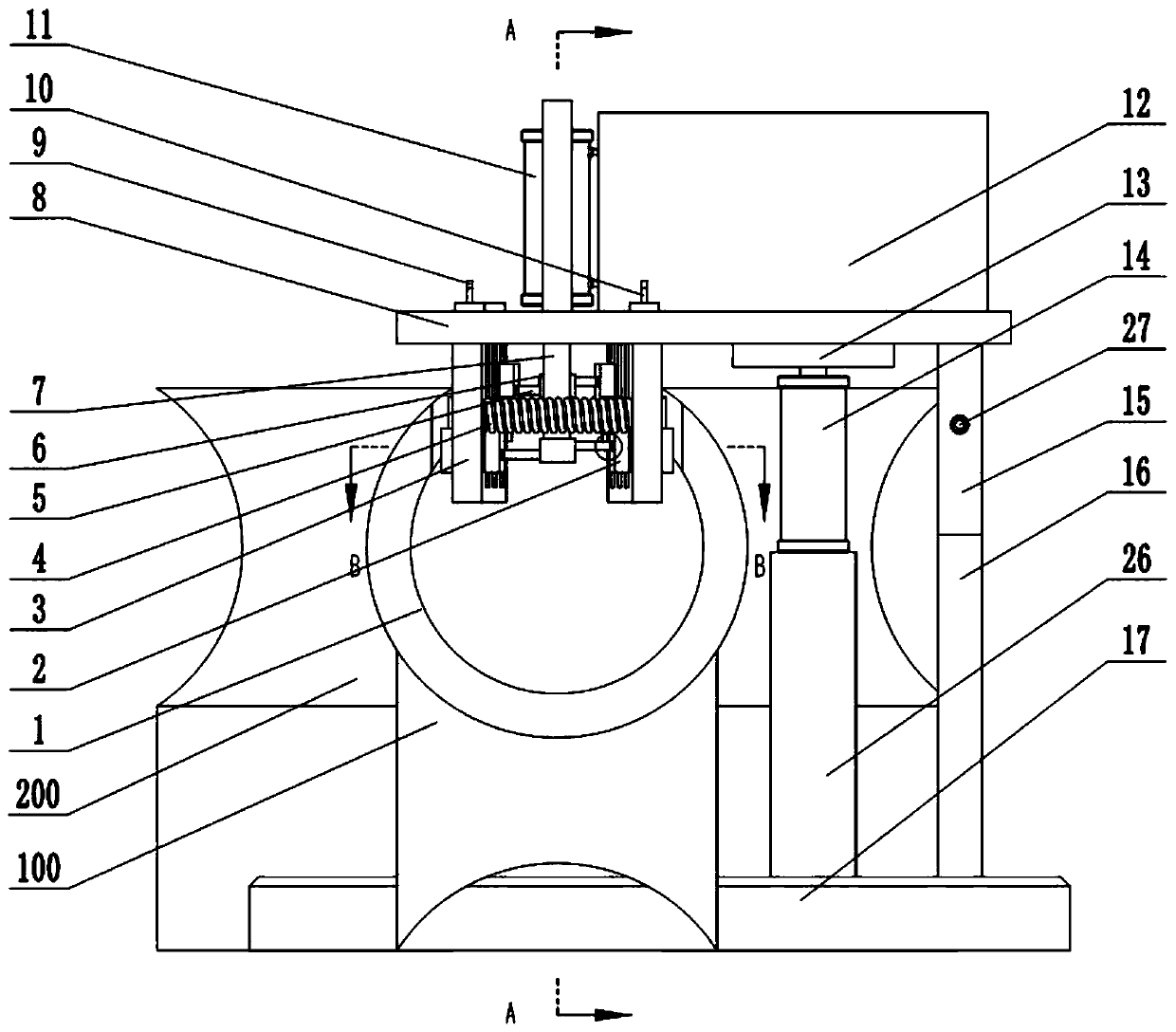

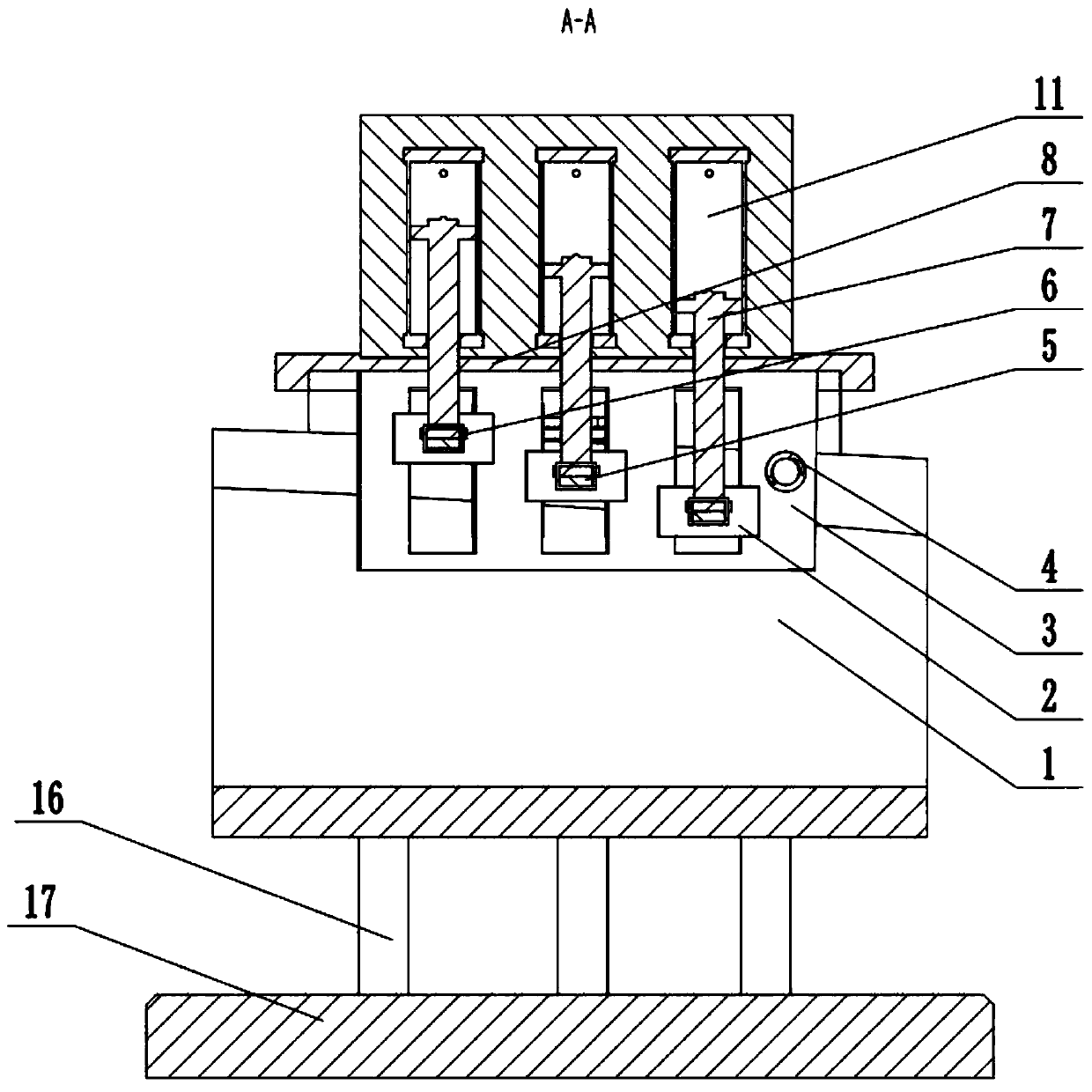

Lateral load application device and lateral load application method for ERW pipe

ActiveCN110000456ASolve the problem of asymmetrical weldsEnsure consistencyResistance welding apparatusHydraulic cylinderElectricity

The invention discloses a lateral load application device for an ERW pipe. The lateral load application device for the ERW pipe comprises electrode blocks, electrode panels, a pressure spring, an electrode connection rod, a workbench, a telescoping mechanism, a support plate, a lifting device, a base and a conductive plate, wherein under the pressure effect of the pressure spring, the electrode blocks in the electrode panels cling to the side surface of a pipe blank. The invention further provides a lateral load application method for the ERW pipe. A hydraulic rod on an electrode hydraulic cylinder is fixed to a connection rod sleeve, and the two electrode plates at corresponding positions on the electrode panels at the two sides can be driven simultaneously, so that the problem that the two electrode blocks are asymmetric with respect to a welding joint is solved; a high-frequency current is loaded onto the side surface of the pipe blank, uniform temperature distribution of the welding joint of the pipe blank in a wall thickness direction is realized by properly adjusting the relative positions of the electrode blocks on the side surface of the pipe blank, and then the defects ofcold welding, overburning and the like which are brought by non-uniform temperature distribution is avoided, and the quality of the welding joint of the pipe blank is improved.

Owner:徐州博创建设发展集团有限公司

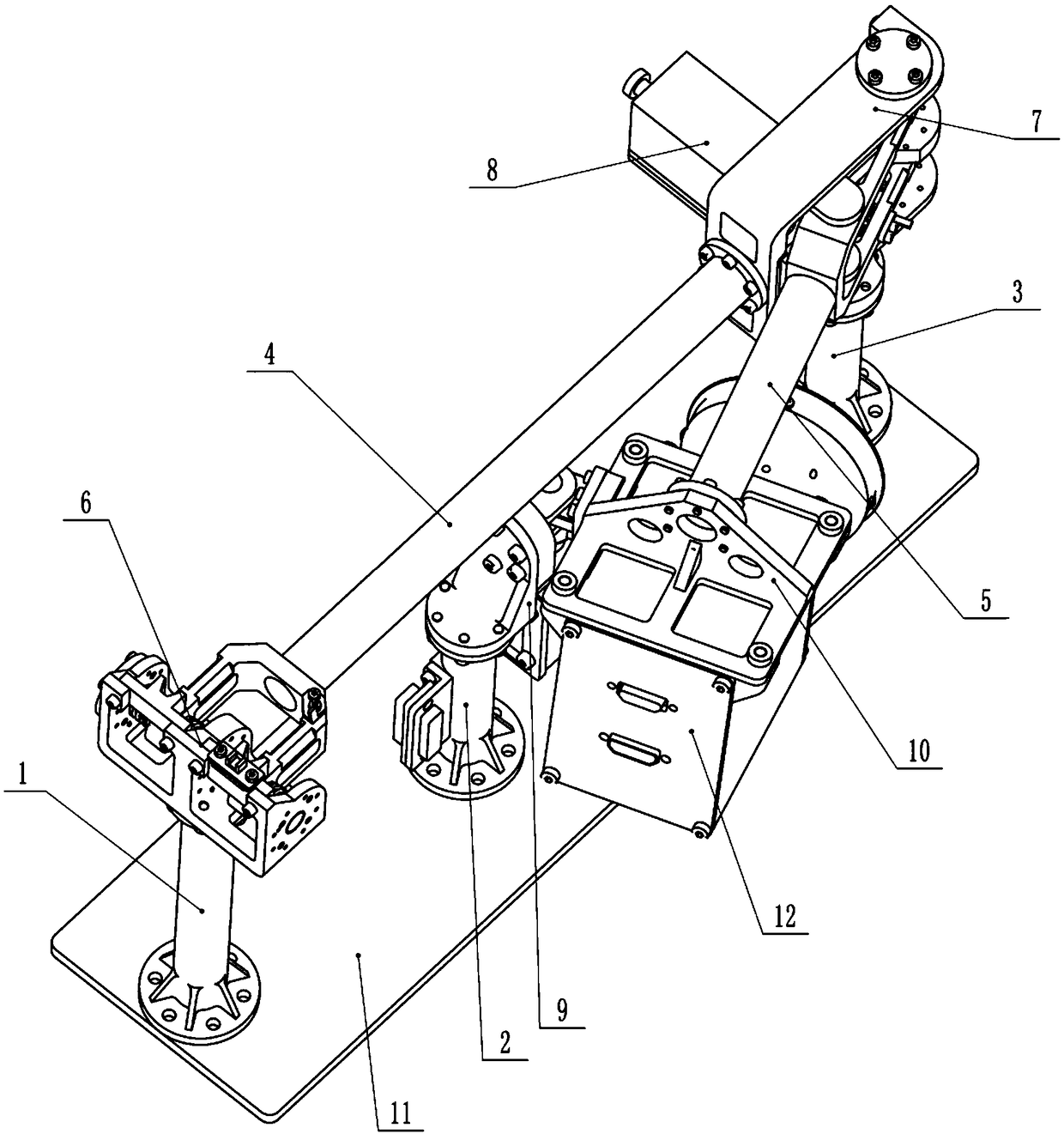

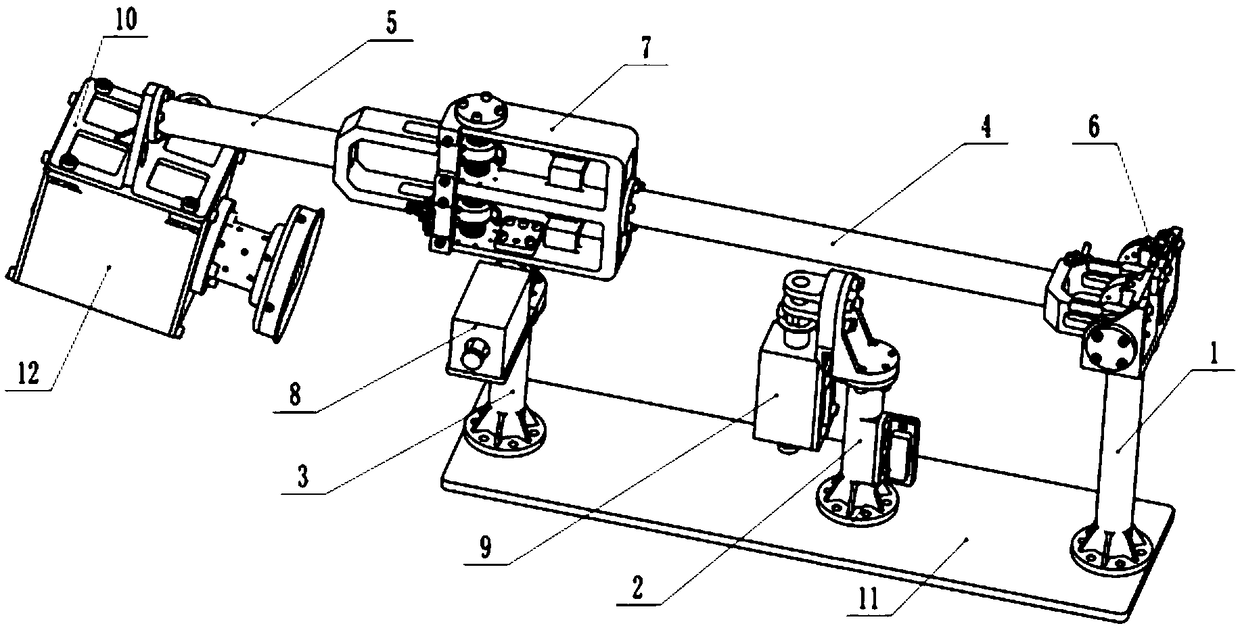

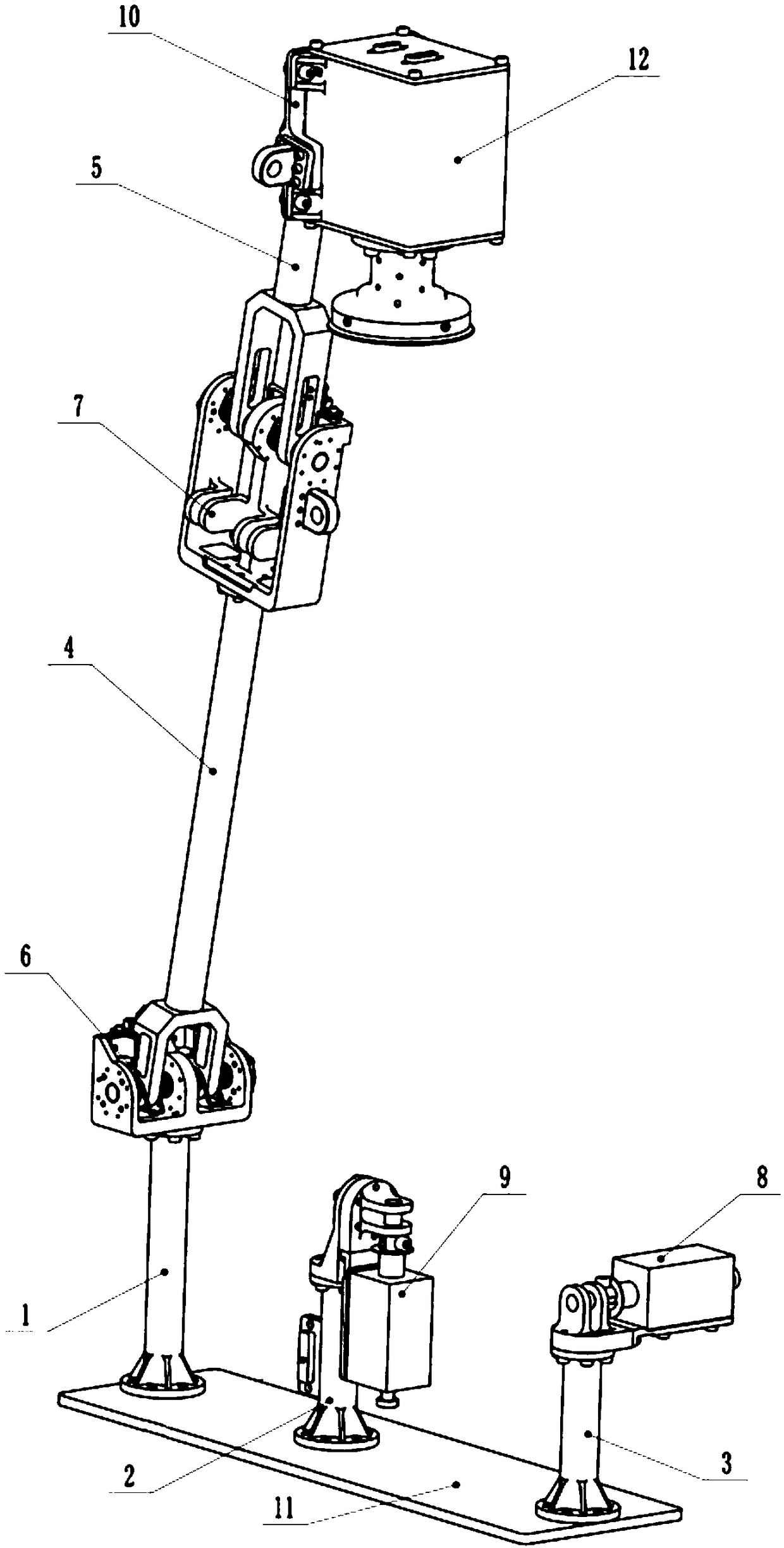

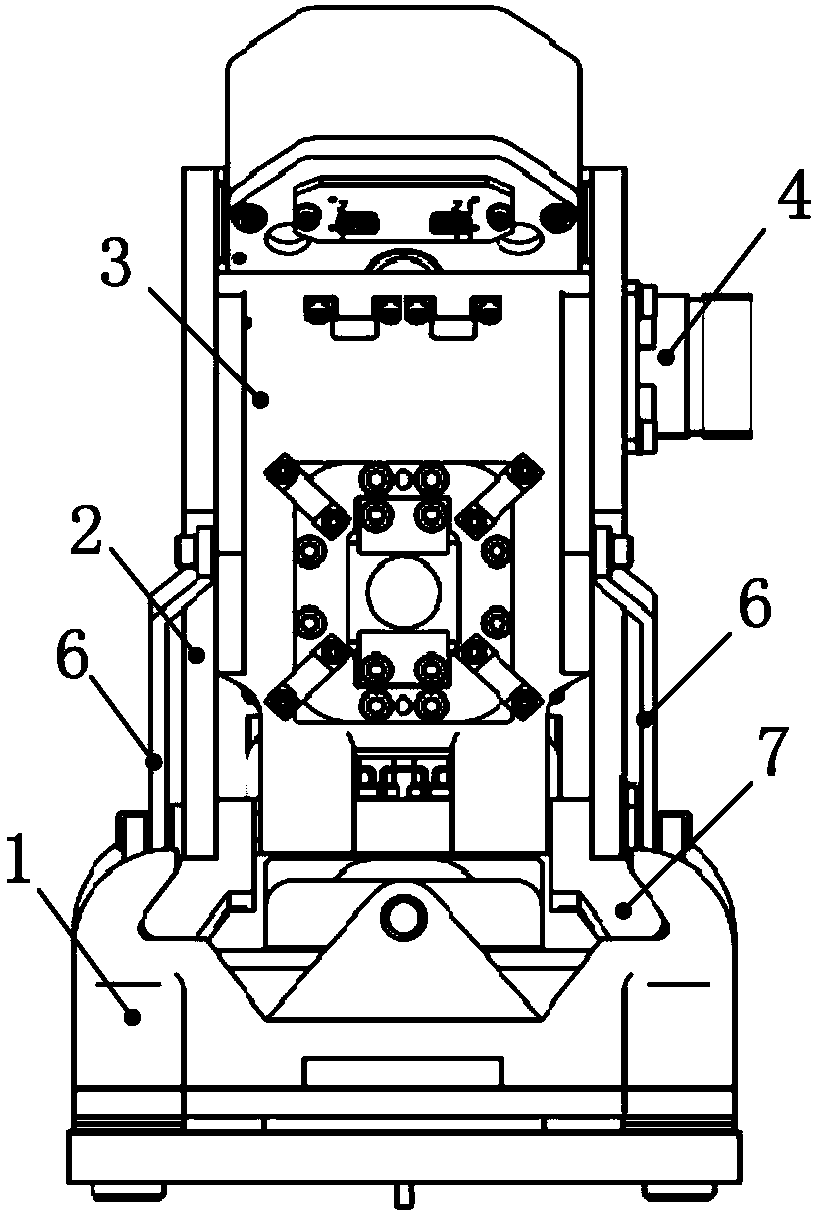

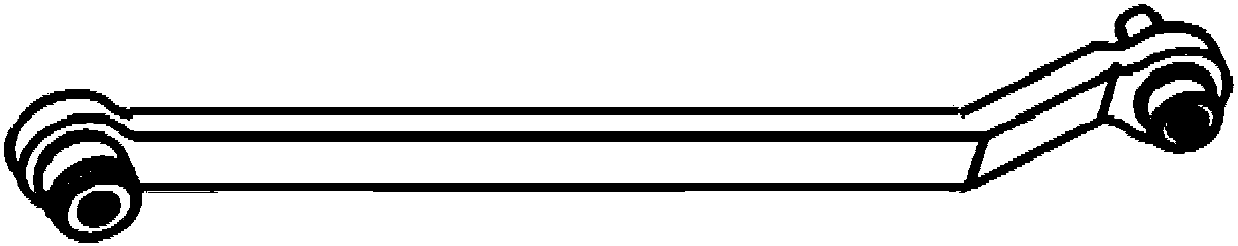

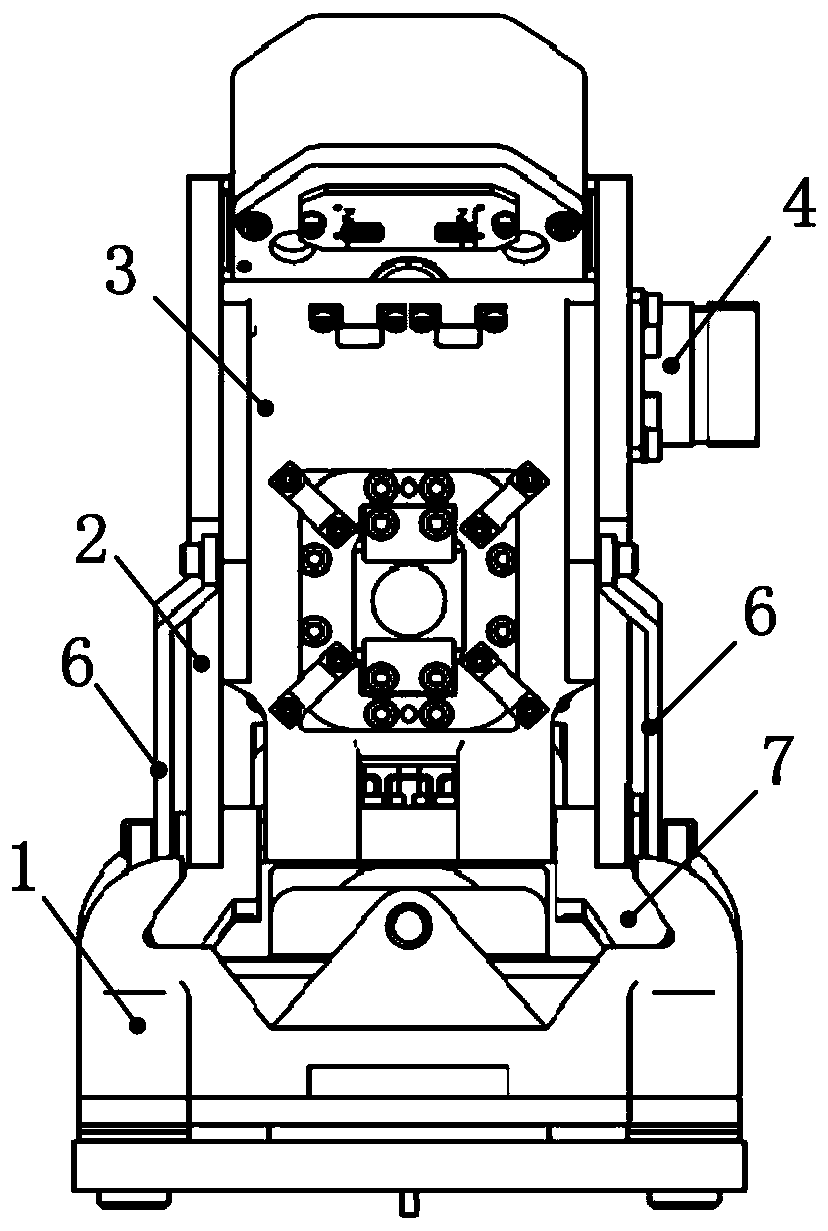

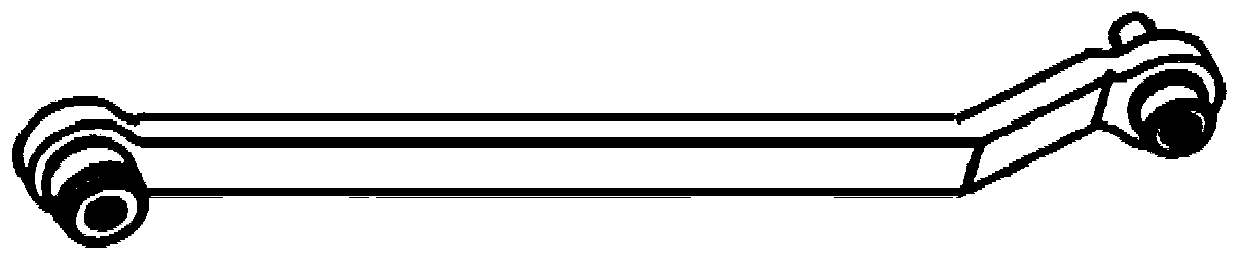

Pull rod device for facilitating on-orbit maintenance of rolling support assembly

The invention relates to a pull rod device for facilitating on-orbit maintenance of a rolling support assembly. The rolling support assembly includes a clamping device which is arranged on a sliding table. The sliding table is slidably connected on a mounting base. The rolling support assembly includes a first clamping arm, a second clamping arm and a bottom clamping arm. Both sides of the first clamping arm are rotatably connected with the bottom clamping arm through a pull rod device. The pull rod device comprises a pull rod. An end A of the pull rod is rotatably connected with the first clamping arm, and an end B is connected with the bottom clamping arm in a slidable and rotatable manner. The mounting base is provided with a projection thereon. During on-orbit mounting, the sliding table slides slowly towards the mounting base, the angle between the first clamping arm and the sliding table is large and remains unchanged, when the end B of the pull rod is against the projection, theend B slides on the bottom clamping arm, as the sliding table continues to slide, the pull rod gradually lifts the first clamping arm and the angle between the first clamping arm and the sliding table gradually becomes smaller. The technical problem of tedious on-orbit replacement steps, long time consumption and the like of the rolling support component in the prior art are solved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

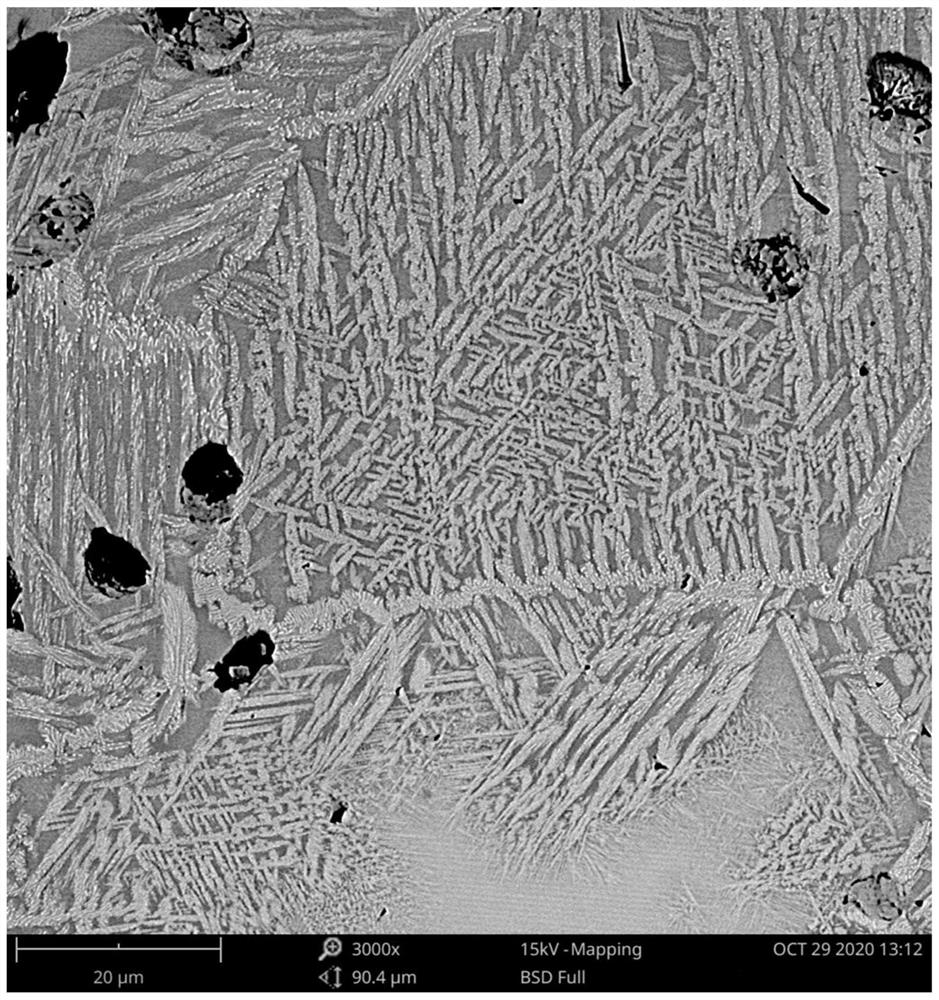

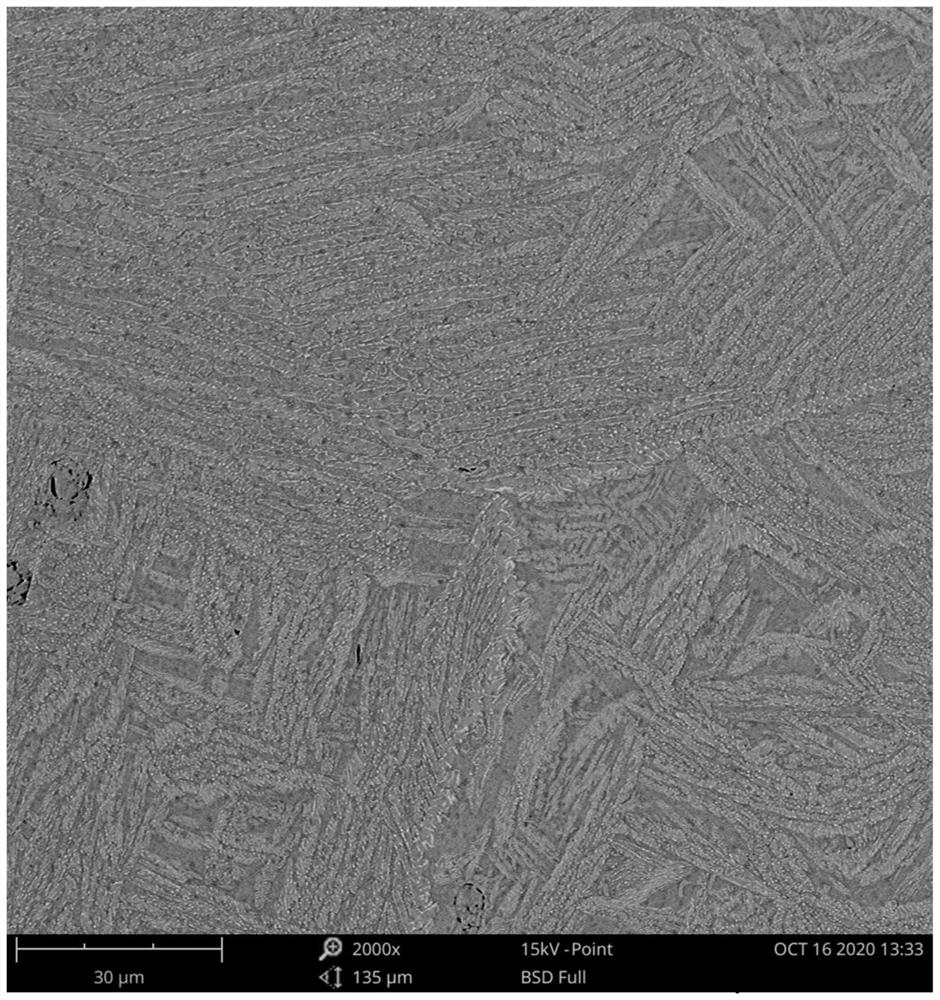

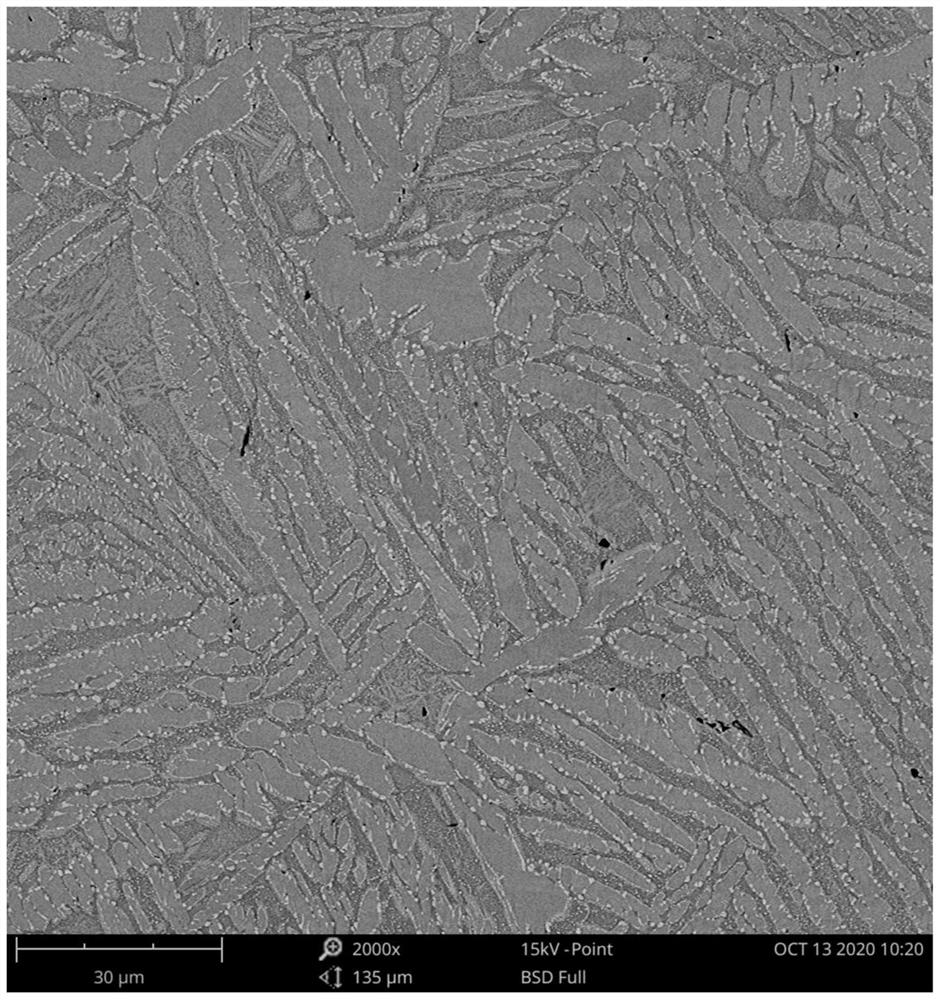

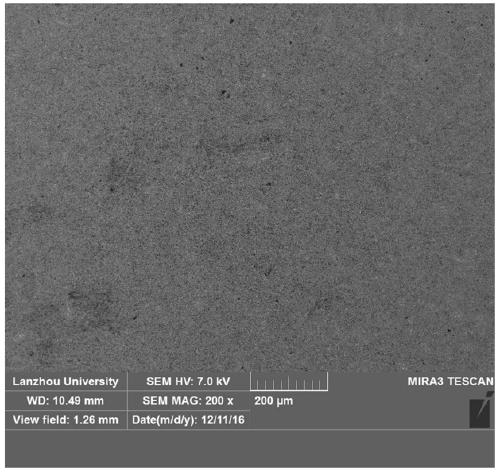

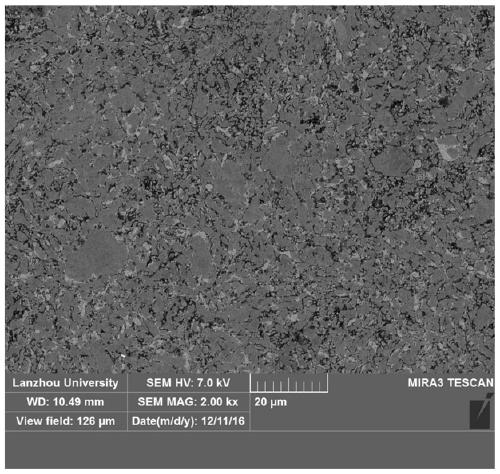

Nanometer aluminum oxide reinforced 316L stainless steel composite material and preparation method thereof

InactiveCN113201680AFast processingImprove efficiencyAdditive manufacturing apparatusAluminium oxides/hydroxidesNano al2o3SS - Stainless steel

The invention discloses a nanometer aluminum oxide reinforced 316L stainless steel composite material and a preparation method thereof. The preparation method comprises the following steps that mixed powder A is subjected to powder laying and laser forming, and a formed body is obtained; stress regulation and control are carried out on the formed body, and the nanometer aluminum oxide reinforced 316L stainless steel composite material is obtained; the mixed powder A is a mixed powder obtained by ball-milling 316L steel powder and pretreated Al2O3 powder together; and the pretreatment process of the Al2O3 powder comprises the steps that spherical Al2O3 is placed in NH4OH to be subjected to erosion treatment, washing and drying are carried out after erosion, and the pretreated Al2O3 powder is obtained. The nanometer aluminum oxide reinforced 316L stainless steel composite material contains 0.1%-0.2% of nanoscale Al2O3 particles and the balance a 316L matrix. According to the method, the nanometer aluminum oxide reinforced 316L stainless steel composite material is prepared through the laser melting technology, the method has the characteristics of being high in machining speed, high in efficiency and short in working procedure, meanwhile, the ceramic material Al2O3 can be evenly distributed in a 316L stainless steel matrix, the strength of 316L is remarkably improved, and the method has important significance for expanding the applicability of 316L.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

PE drain pipe and production process thereof

ActiveCN111533985AHigh thermal conductivityGuaranteed stabilityGeneral water supply conservationPhysical chemistryFire retardant

The invention belongs to the technical field of plastic products. The invention discloses a PE drain pipe and a production process thereof. The PE drain pipe is prepared from, by weight, 80-100 partsof PE, 3-5 parts of nano MgO, 0-5 parts of nano MnS, 5-15 parts of ground calcium carbonate, 2-5 parts of a coupling agent, 0-3 parts of EVA, 3-5 parts of a flame retardant, 3-10 parts of a tougheningagent, 1-5 parts of a heat stabilizer and 0-2 parts of a processing aid. Beneficial effects of the PE drain pipe and the process are that the nano MgO can enhance the heat-conducting property of a PEproduct and avoid the cold welding phenomenon in a PE pipe welding process; the nano MnS can keep the stability of a polyethylene molecular chain in the welding process, and thermal oxidation of polyethylene when the welding temperature is too high is avoided; the ground calcium carbonate, the nano MgO and the nano MnS have a synergistic effect, so that the stability of a welding part can be improved, and the firmness of the welding part is improved; by adding the nano MgO, the nano MnS and the ground calcium carbonate, the temperature range of the PE pipe during welding can be widened, and the welding stability of the PE pipe is improved.

Owner:宜昌宜硕塑业有限公司

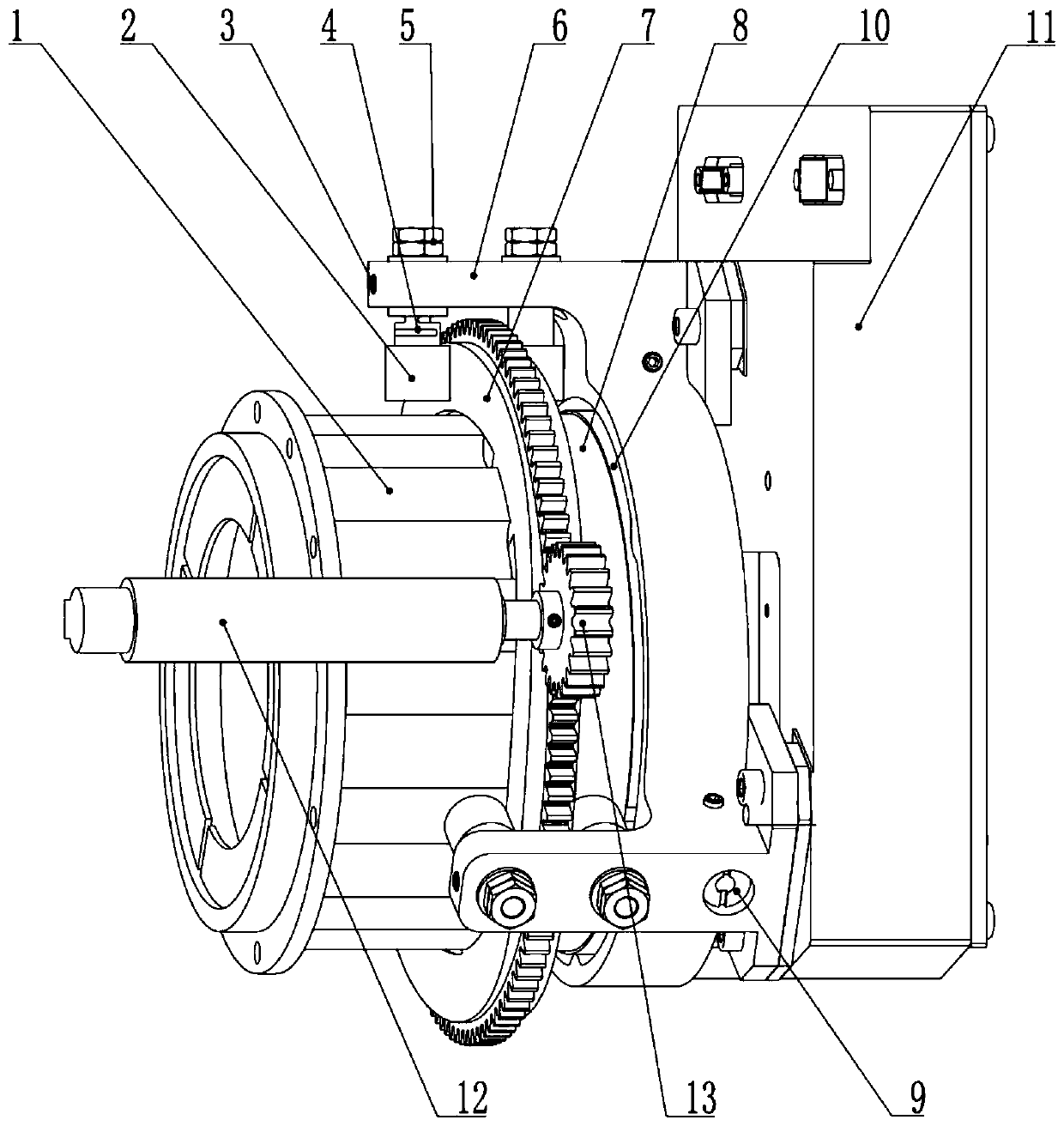

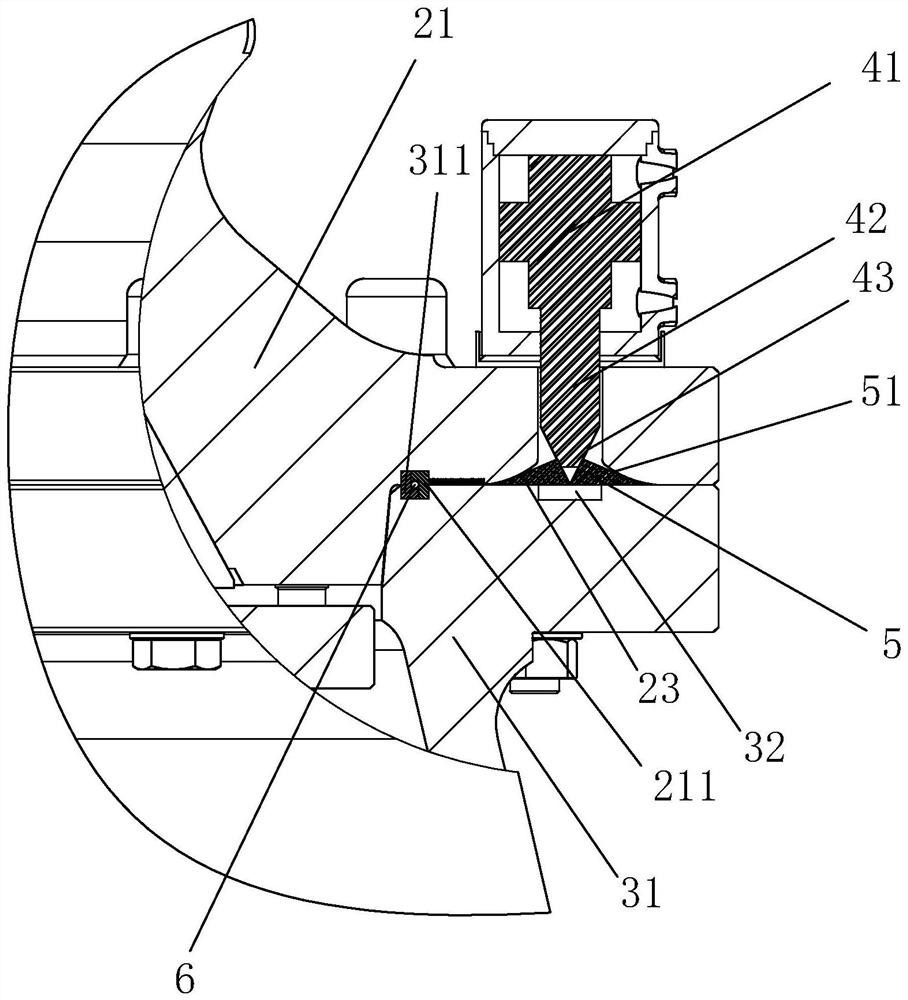

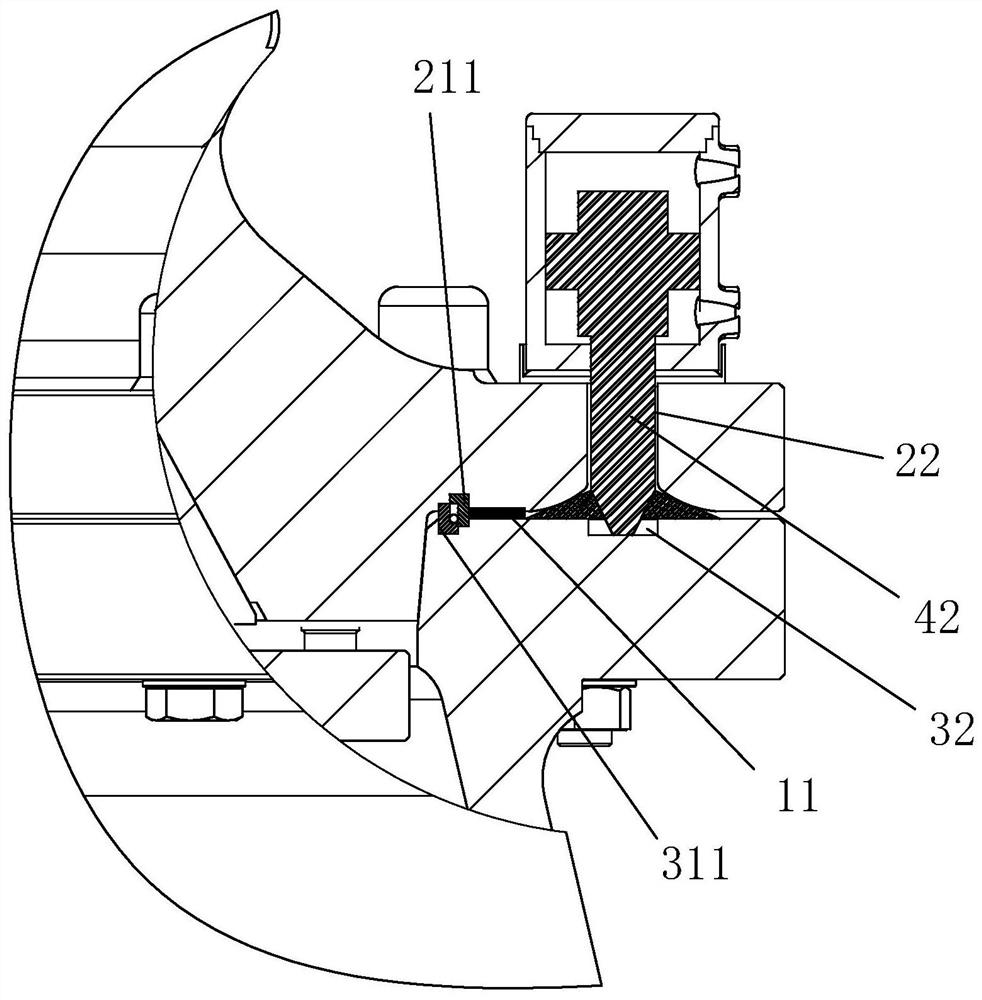

Space camera focusing mechanism

PendingCN111208692AEasy to processHigh precisionProjector focusing arrangementCamera focusing arrangementCMOSElectric machinery

The invention provides a space camera focusing mechanism. The focusing mechanism comprises an optical lens barrel, a motor assembly and a focusing cam roller assembly. The motor assembly comprises a motor and a small gear arranged on an output shaft of the motor in a sleeving mode. The focusing cam roller assembly comprises a cam gear, a CMOS bracket, and at least one set of cam roller clamps which is assembled on the CMOS bracket and is used for clamping the cam gear, wherein the cam gear and the CMOS bracket sleeve the optical lens barrel; and the cam gear is engaged with the small gear, andwhen the cam gear rotates, rotation motion of the cam gear is converted into reciprocating linear motion of the CMOS assembly fixed on the CMOS bracket so as to change a distance between a CMOS focalplane of the CMOS assembly and an optical lens group in the optical lens barrel. An outer wall of the optical lens barrel serves as a rotating shaft of the cam gear, axial support is provided for thecam gear, self-lubrication is achieved through a molybdenum disulfide material of a cam roller and a PEEK material of the cam gear, and lubricating grease does not need to be used. Therefore, self-lubricating continuous reciprocating focusing in a vacuum environment can be simply realized.

Owner:CHANGCHUN UP OPTOTECH

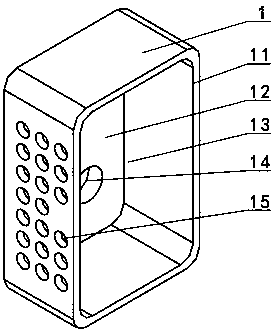

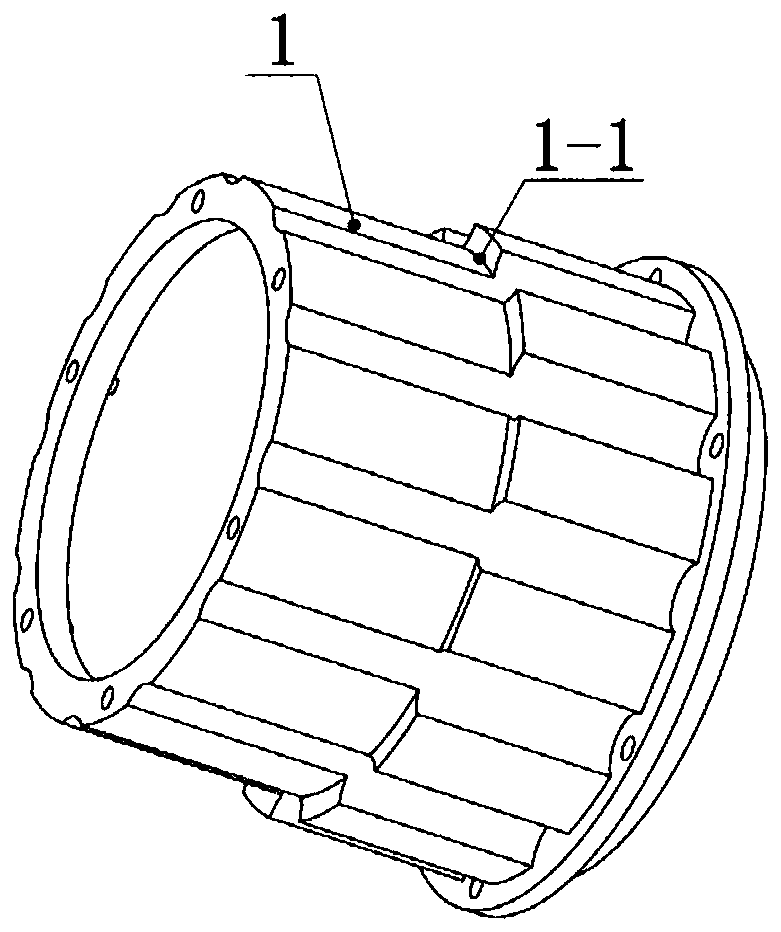

Crusher rack convenient to disassemble and assemble

InactiveCN113333066ASlow down cold welding progressEasy to disassembleGrain treatmentsPunchingStructural engineering

The invention discloses a crusher rack convenient to disassemble and assemble. The crusher rack comprises a rack shell, the rack shell comprises an upper rack body and a lower rack body, and an auxiliary disassembling and assembling assembly is arranged at the joint of the upper rack body and the lower rack body. The auxiliary disassembling and assembling assembly comprises a driving part, a punching rod is arranged on the driving part, separating inclined blocks located on the joint face of the upper rack body and the lower rack body are arranged on the two sides of the punching rod, and the separating inclined blocks can move in the radial direction of the rack shell. By arranging the auxiliary disassembling and assembling assembly between the upper rack body and the lower rack body, it is guaranteed that during disassembling, the joint face of the rack bodies can be laterally cut through the separating inclined blocks, the cold welding phenomenon caused by metal atom diffusion is avoided, and disassembling of the crusher rack bodies is facilitated.

Owner:埃里斯克矿山工程机械有限公司

A method for preparing nanoparticle-reinforced aluminum matrix composites

The invention discloses a method for preparing nano ceramic particles reinforced aluminum matrix composite material. Firstly, the mixed powder of nano-ceramic powder and micron-sized aluminum or aluminum alloy powder is prepared by dry-type high-energy ball milling under vacuum or argon protection to prepare millimeter-sized composite particles with a volume fraction of nano-ceramic particles of 10-50%. Then the millimeter-scale composite particles are directly melted or added to the aluminum or aluminum alloy melt, and ultrasonic vibration is applied to promote the uniform dispersion of the nano-ceramic particles in the metal melt, and the nano-ceramic particle-reinforced aluminum matrix composite material is prepared. The millimeter-scale composite particles prepared by the dry grinding method in the present invention can be easily and completely added to the metal melt, which solves the problem of poor wettability between the nano-ceramic particles and the base metal and difficulty in adding them. The low-cost advantage of composite materials. The nano particles are evenly distributed in the prepared composite material, and the material performance is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method and application of max phase reinforced nickel-based high temperature lubricating composite material

ActiveCN109666815BHigh bonding strengthGood self-lubricating performanceCylinder headsGas turbine plantsAlloyGraphite

Owner:咸阳瞪羚谷新材料科技有限公司

Method for manufacturing engine connecting rod through aluminum-base powder metallurgy and forging

InactiveCN107695340AGood release effectAvoid cold weldingTransportation and packagingMetal-working apparatusSolventPowder metallurgy

The invention discloses a method for manufacturing an engine connecting rod through aluminum-base powder metallurgy and forging. The method comprises the following steps that a plasticizer is dissolved in a plasticizer solvent, and thus a plasticizer solution is formed; powder materials obtained after batch calculation and weighing are added into the plasticizer solution, wherein the powder materials comprise, by weight, 93.5% of aluminum powder, 5% of copper powder, 1% of silicon powder and 0.5% of magnesium powder; a demoulding lubricant is added, and all materials are placed in a mixer to be mixed to be uniformly distributed; the power materials are pressed into a preformed blank on a pressing machine; the preformed blank is sintered at the temperature of 610-620 DEG C in a vacuum sintering chamber with the vacuum degree being 720-740 mmH2O till the preformed blank is completely alloyed; then a sintered body is moved into a heat preservation furnace with an oxidation-free atmosphereto be subjected to heat preservation for 30 min; and the sintered body is heated again and forged after being cooled to the indoor temperature.

Owner:ZHEJIANG YUEJIN MACHINERY

Anti-wear lubricating punch structure of power metallurgy die

The invention discloses an anti-wear lubricating punch structure of a power metallurgy die. The anti-wear lubricating punch structure comprises a first punch and a second punch fitly inserted into the first punch. The side of the second punch is provided with a fixing channel, and a sheet lubricating bearing is locked in the fixing channel. The outer side of the lubricating bearing projects out of the side of the second punch and is abutted to the inner side of the first punch. The outside of the lubricating bearing is provided with a cavity used for accommodating lubricating liquid. The anti-wear lubricating punch structure has the advantages that the lubricating bearing is added between the punches of the power metallurgy die, lubricating liquids such as grease are added to the lubricating bearing, abrasion between the punches can be reduced, and friction between the punches during die stripping is reduced accordingly; through the addition of the lubricating bearing, cold welding during formation of the punches can be prevented, stripping force between the dies is reduced, and the punches are protected.

Owner:GUANGDONG DONGMU NEW MATERIALS

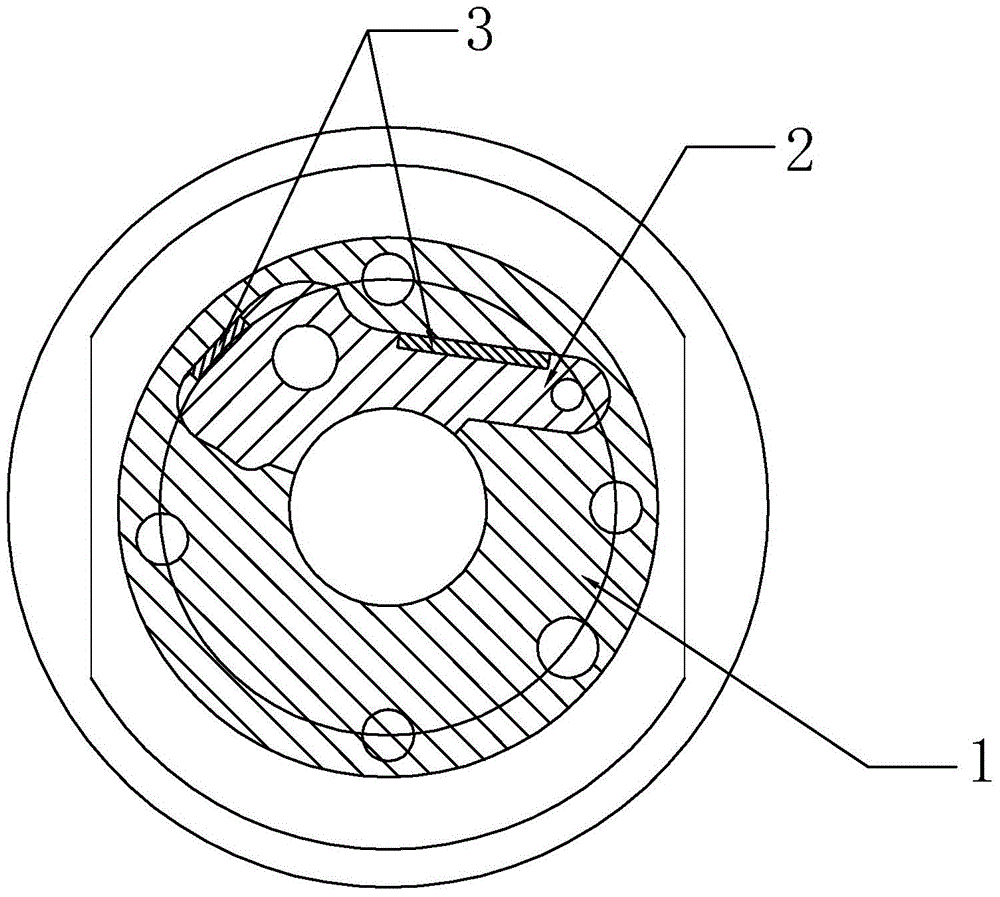

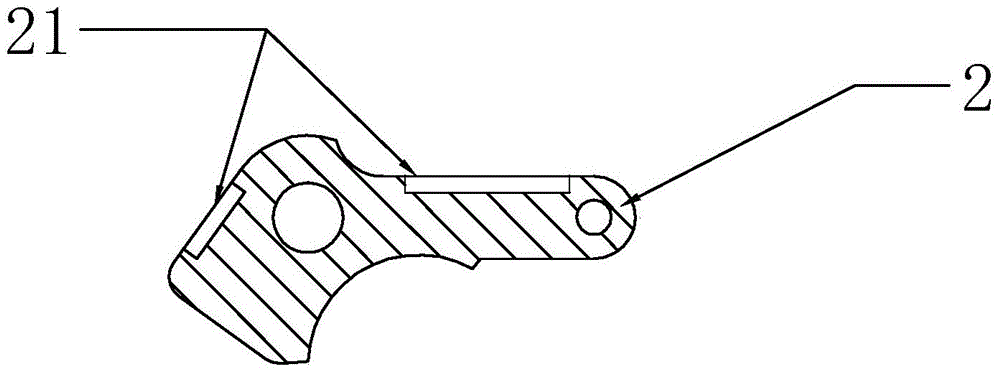

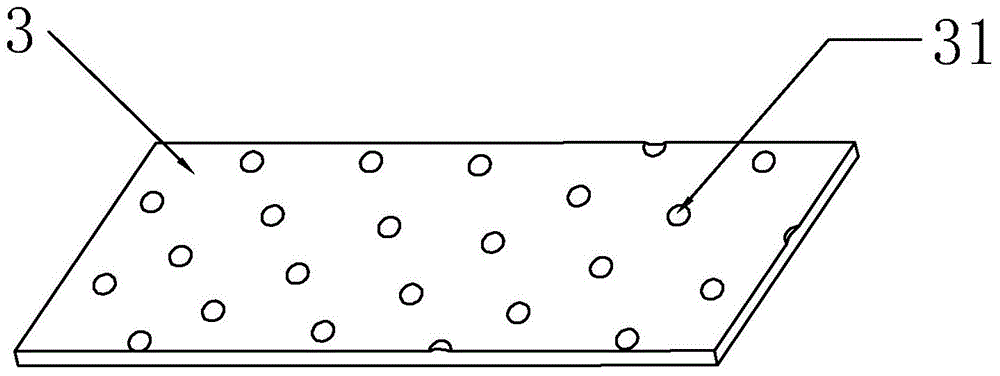

Focusing mechanism

The present invention is applicable to the technical field of space remote sensing, and provides a focusing mechanism. By using flexible hinges at both ends of the supporting connecting rod in the flexible parallel four-bar mechanism to connect the transmission base and the fixed end respectively, the entire flexible parallel four-bar mechanism has elastic deformation Ability, when the focal plane assembly is set on the four-bar mechanism, the elastic deformation of the four-bar mechanism can not only adjust the position of the focal plane, but also does not have the gap and mechanical friction caused by the moving parts of the general transmission mechanism, effectively preventing the remote sensing camera from flying at high altitude. The environment is due to the loss of precision of the focusing mechanism due to slide rails, cam gaps, etc., and the occurrence of cold welding of moving parts at high altitude or in a vacuum environment.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

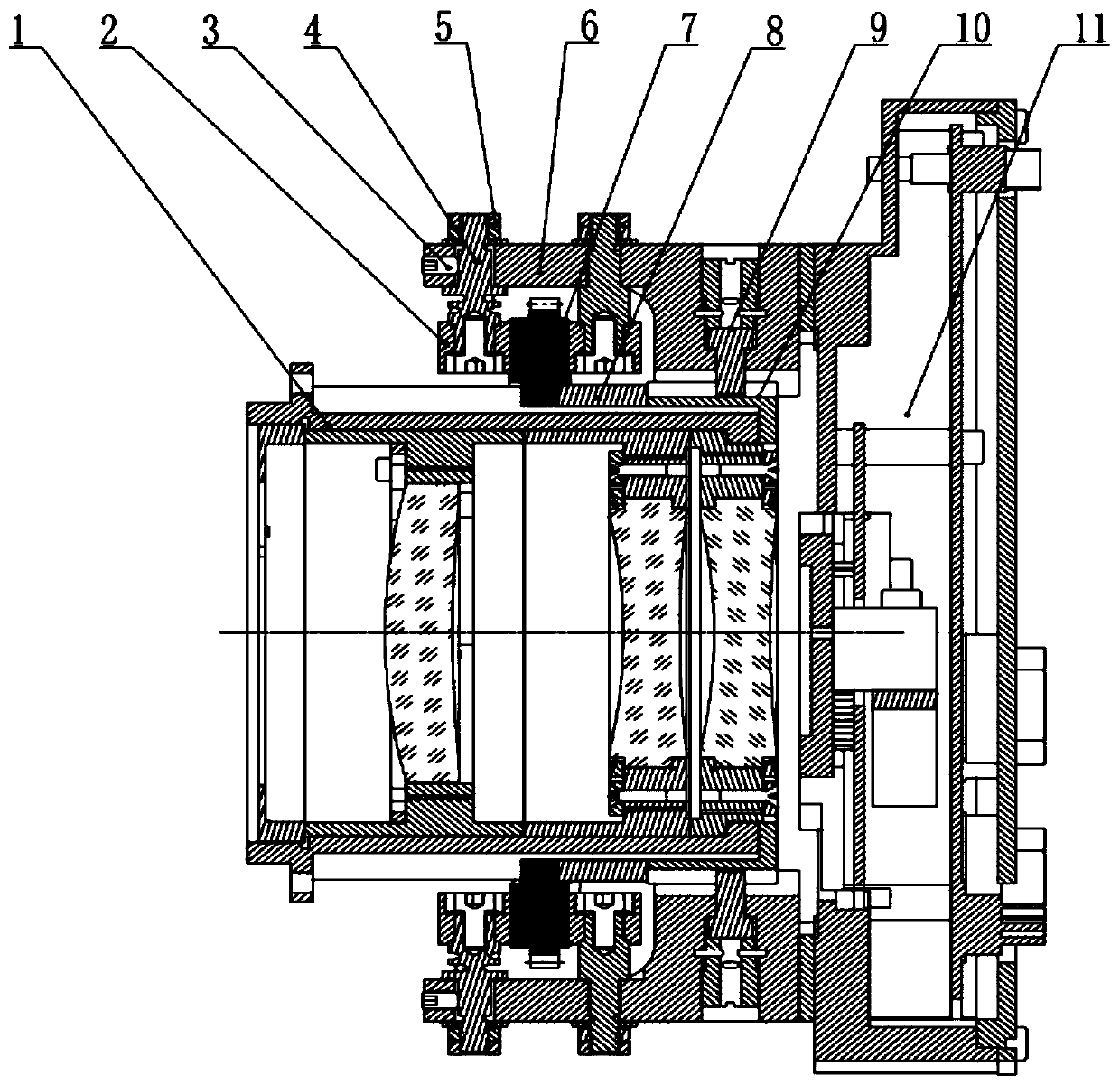

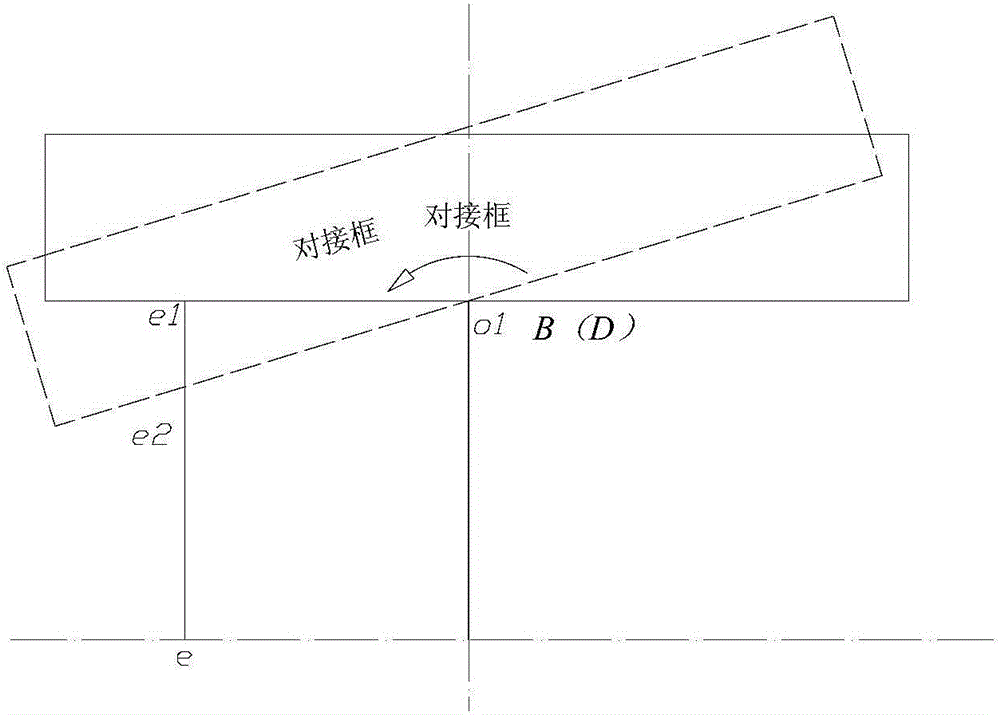

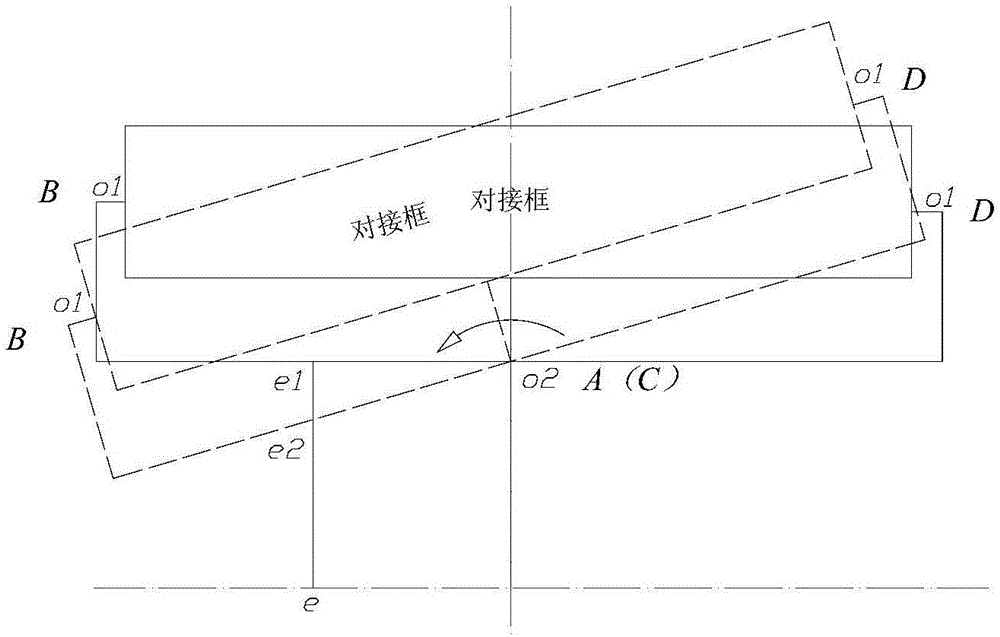

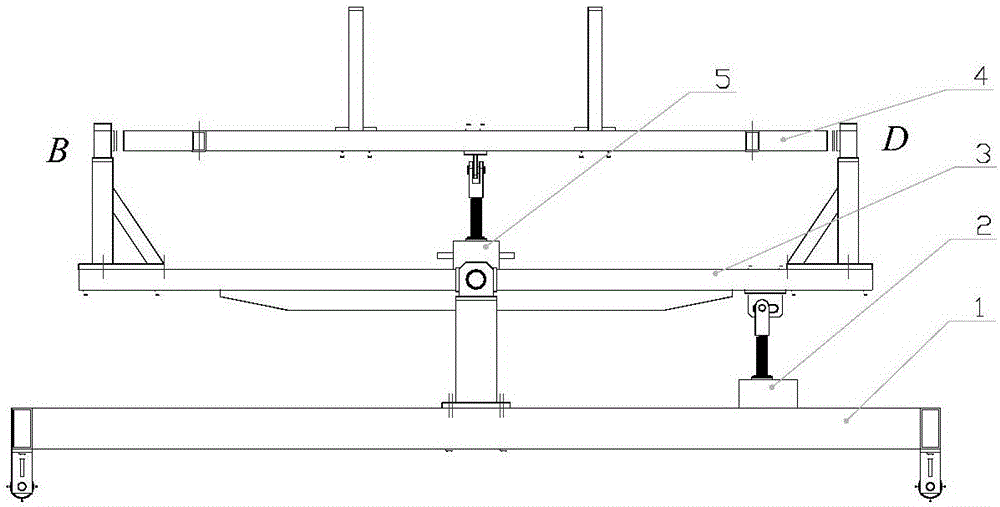

Satellite Dynamic Angle Adjustment Mechanism in Low Temperature Vacuum Environment

InactiveCN103674591BSolve the need for angle adjustmentCompact designStructural/machines measurementElevation angleLong arm

The invention relates to a satellite dynamic angle adjusting mechanism in a low-temperature vacuum environment. The mechanism contains a satellite coupling square frame and a crossbeam positioned below the coupling square frame. A bracket vehicle used for supporting is arranged below the crossbeam. The coupling square frame is connected to the crossbeam through rotating shafts at two ends of the square frame and a spiral elevator. Lifting motion of a lead screw of the spiral elevator drives the coupling square frame to rotate along the axis. The crossbeam is connected to the bracket vehicle through a rotating shaft positioned on a short arm and a spiral elevator positioned at one side of the rotating shaft. Elevation angle of the coupling square frame is realized when the spiral elevator pushes a long arm of the crossbeam. Angle adjustment of a satellite in two directions is realized, mutual interference during motions in the two directions is eliminated, and an adaptive design is performed in allusion to the vacuum low-temperature operating environment so as to make the mechanism meet the requirement of being used in vacuum at low temperature.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

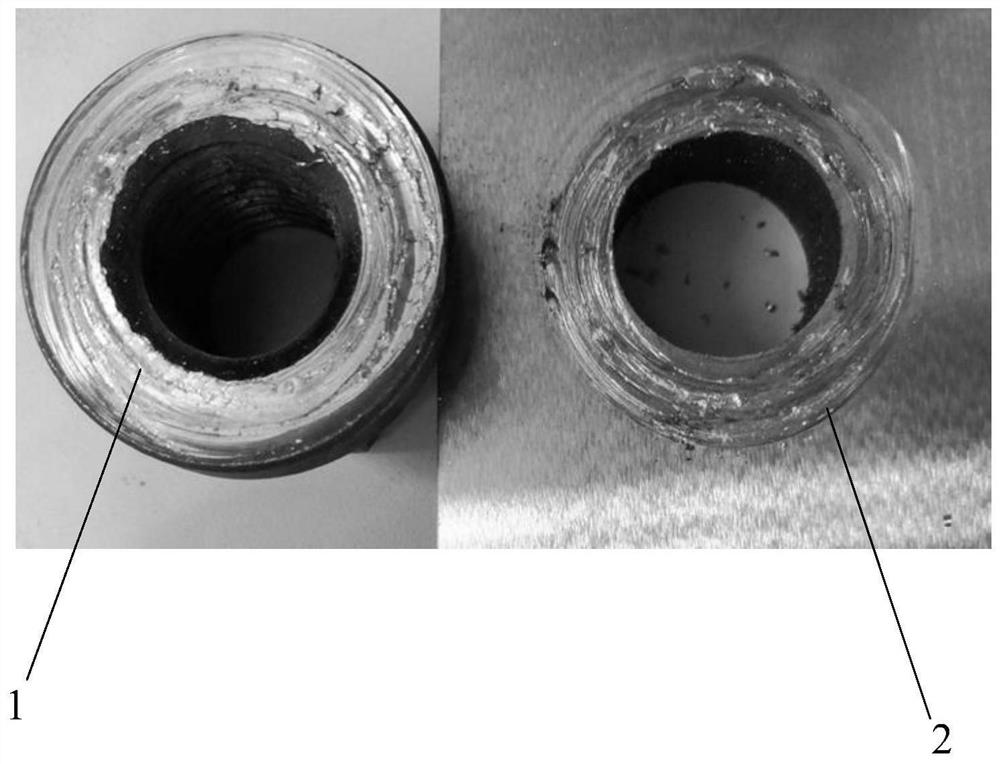

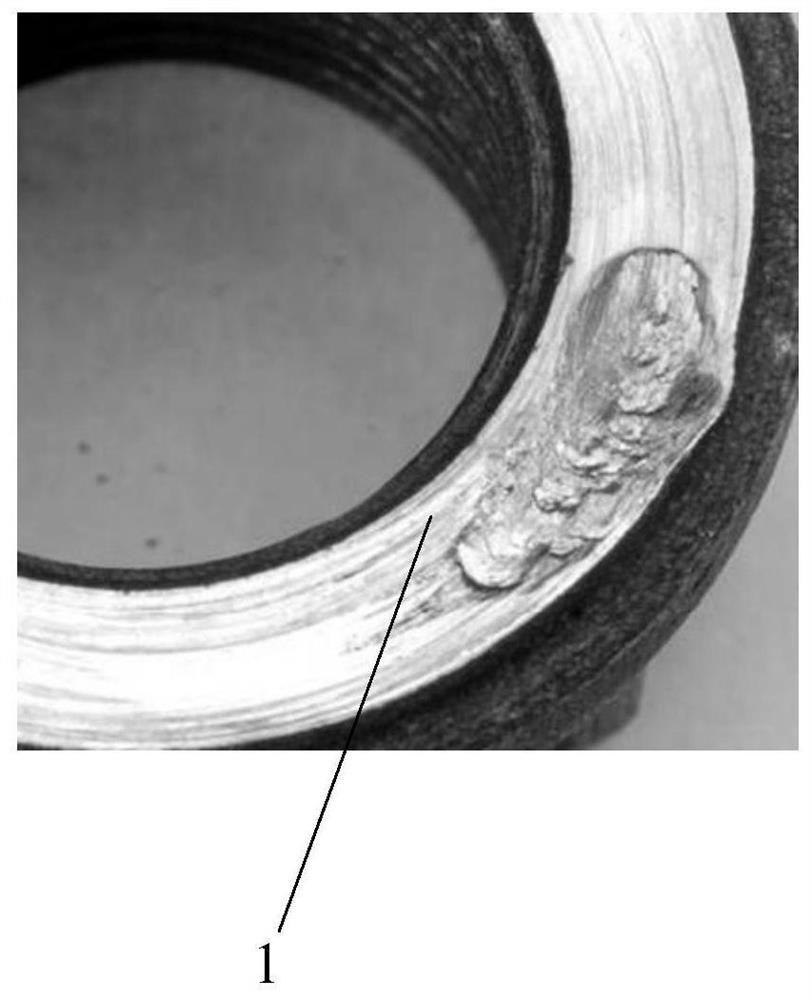

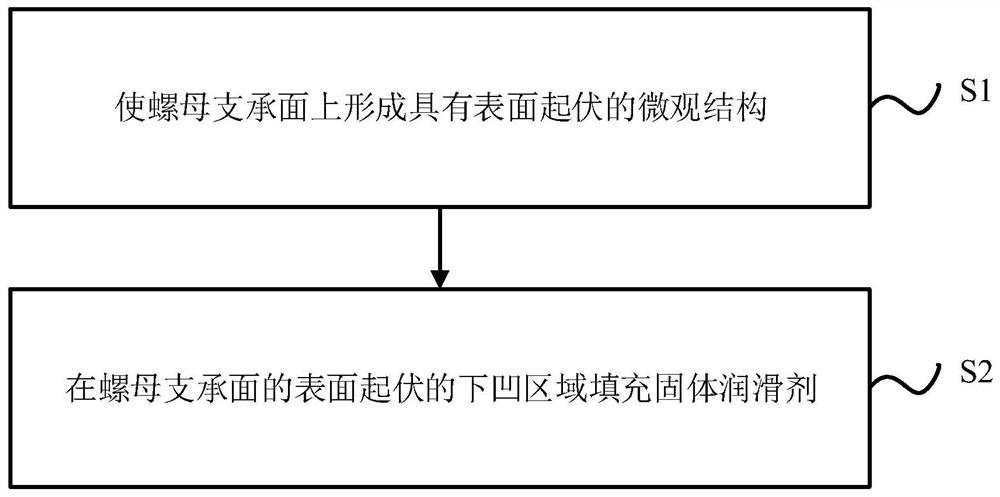

Method for stabilizing friction coefficient of nut supporting surface and nut

The invention discloses a method for stabilizing the friction coefficient of the nut supporting surface and a nut, and relates to the technical field of fastener connection, the method comprises the following steps that S1, a microstructure with surface undulation is formed on the nut supporting surface; and S2, a concave area of the surface undulation of the nut supporting surface is filled witha solid lubricant. According to the method for stabilizing the friction coefficient of the nut supporting surface and the nut, the friction coefficient of the nut supporting surface can be stabilized,the abrasion of the supporting surface in the nut tightening process is reduced, and the cold welding phenomenon is avoided.

Owner:DONGFENG COMML VEHICLE CO LTD

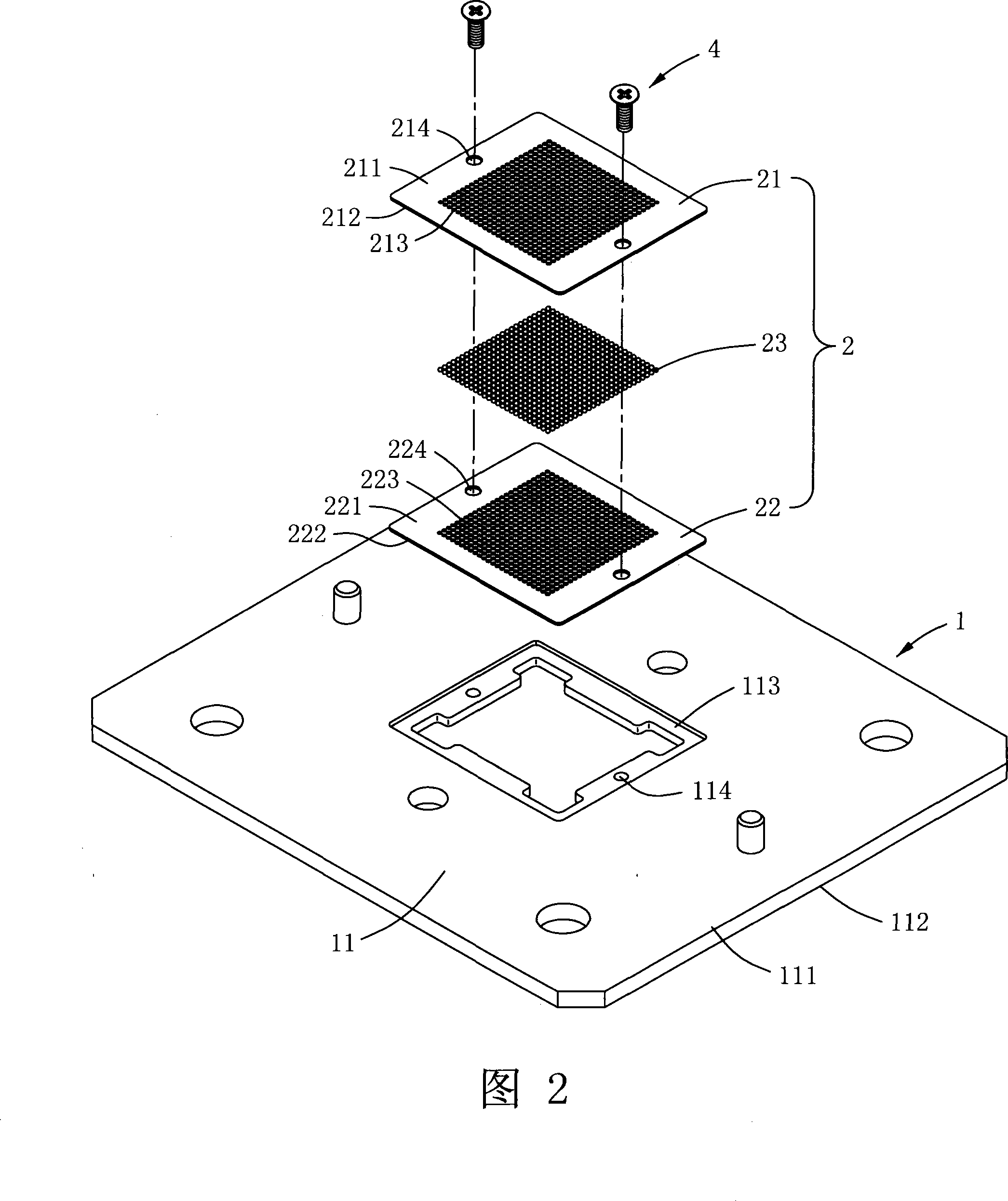

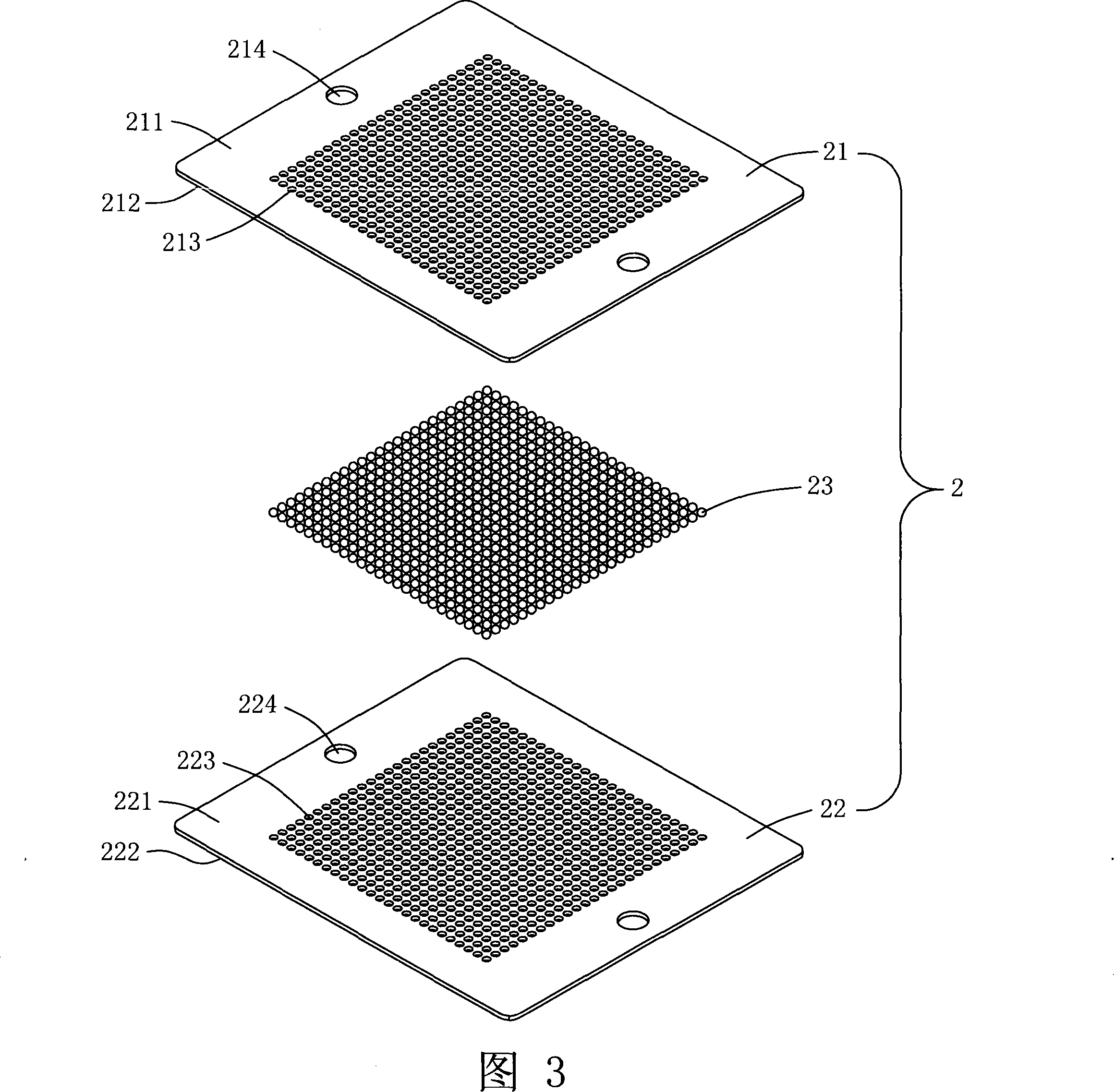

Integrated circuit test seat and its test interface

ActiveCN101241143ASimple structureIt is easy to cause the tested IC package to be manufactured in the subsequentElectronic circuit testingMeasurement leads/probesEngineeringTest board

The present invention provides an IC testing seat and testing interface thereof. The IC testing seat comprises of a testing seat body, a top surface, a bottom surface and a hatch through the top and bottom surface. The testing interface is set in the testing seat body which comprises of first and second non-electric conductivity flexible sheet space and many conductive spheres. The first, second non-electric conductivity flexible sheet space has one top surface and bottom surface respectively and many first, second via holes corresponding to meeting points on bottom of IC encapsulation parts. The first, second via holes have identical number and vertical contraposition through combination of first, second non-electric conductivity flexible sheet space and conductive spheres can accepted and fixed in it, and one end of each conductive sphere extends outside the top surface of testing seat body to contact electrically with corresponding meeting points on bottom of IC encapsulation parts, the other end extends outside of the bottom of testing seat body to contact electrically with corresponding meeting points on testing board.

Owner:ADVANCED SEMICON ENG INC

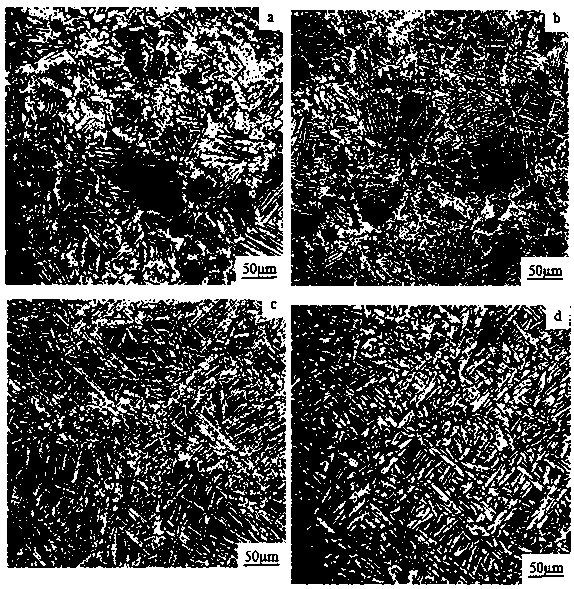

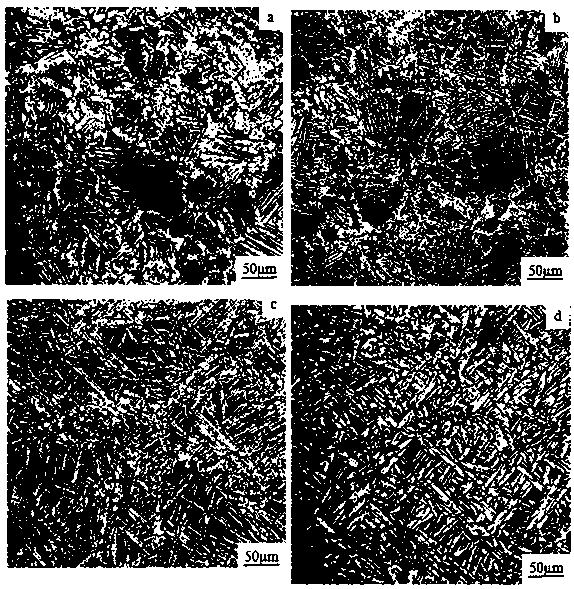

A method for grain refinement and size distribution homogenization of ultrafine-grained cemented carbide

The invention relates to a superfine crystal hard alloy grain refinement and size distribution uniformization method, belonging to the technical fields of hard alloys and powder metallurgy. The method comprises the following steps: by using tungsten oxide, cobalt oxide and carbon black as raw materials, carrying out in-situ reaction synthesis to prepare WC-Co composite powder; adding a small amount of Cr3C2 or Cr3C2 and VC in the WC-Co composite powder as a grain growth inhibitor; and carrying out ball milling mixing, passing through the powder through a screen, drying, carrying out long-term annealing treatment on the dried powder at lower temperature by using argon and hydrogen as protective gases, and carrying out pressure molding and low-pressure sintering to obtain the hard alloy block material. The method effectively inhibits the grain in the hard alloy of the superfine crystal or nanocrystal structure from quick growth in the sintering process, and enhances the microscopic structure uniformity of the hard alloy block material.

Owner:北硬科技香河有限公司

A kind of preparation method of titanium aluminum niobium zirconium molybdenum alloy

The invention discloses a preparation method of a titanium, aluminum, niobium, zirconium and molybdenum alloy, and belongs to the technical field of preparation of titanium alloys. The method comprises the following steps: weighing Ti, Al, Nb, Zr and Mo metal powder according to certain proportions, mixing the metal powder, performing intermittent dry type ball grinding through a ball grinder to obtain mixed powder, putting the obtained mixed powder into a graphite mold, prepressing the mixed powder, placing the graphite mold into a discharge plasma sintering furnace, applying axial pressure of 10 to 50 MPa for sintering under the condition that the vacuum degree is 2 to 8 Pa, heating the mixed powder in a multi-stage heating mode to 1,000 to 1,150 DEG C, preserving the heat for 3 to 8 min, cooling the mixture to room temperature, and demolding the mixture, thus obtaining the titanium, aluminum, niobium, zirconium and molybdenum alloy material. The titanium, aluminum, niobium, zirconium and molybdenum alloy prepared by the method disclosed by the invention has the advantages of uniform component, high compactness, high intensity, high plasticity and the like; and in addition, the method is easy to operate, short in time, energy-saving and environmentally friendly and has a good popularization value.

Owner:KUNMING UNIV OF SCI & TECH

A tie rod device for on-rail maintenance of rolling support components

The invention relates to a pull rod device for facilitating on-orbit maintenance of a rolling support assembly. The rolling support assembly includes a clamping device which is arranged on a sliding table. The sliding table is slidably connected on a mounting base. The rolling support assembly includes a first clamping arm, a second clamping arm and a bottom clamping arm. Both sides of the first clamping arm are rotatably connected with the bottom clamping arm through a pull rod device. The pull rod device comprises a pull rod. An end A of the pull rod is rotatably connected with the first clamping arm, and an end B is connected with the bottom clamping arm in a slidable and rotatable manner. The mounting base is provided with a projection thereon. During on-orbit mounting, the sliding table slides slowly towards the mounting base, the angle between the first clamping arm and the sliding table is large and remains unchanged, when the end B of the pull rod is against the projection, theend B slides on the bottom clamping arm, as the sliding table continues to slide, the pull rod gradually lifts the first clamping arm and the angle between the first clamping arm and the sliding table gradually becomes smaller. The technical problem of tedious on-orbit replacement steps, long time consumption and the like of the rolling support component in the prior art are solved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com