Lateral load application device and lateral load application method for ERW pipe

An application device, tube side technology, applied in the direction of metal processing equipment, resistance welding equipment, welding equipment, etc., to improve welding quality, avoid cold welding and over-burning, and achieve the effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

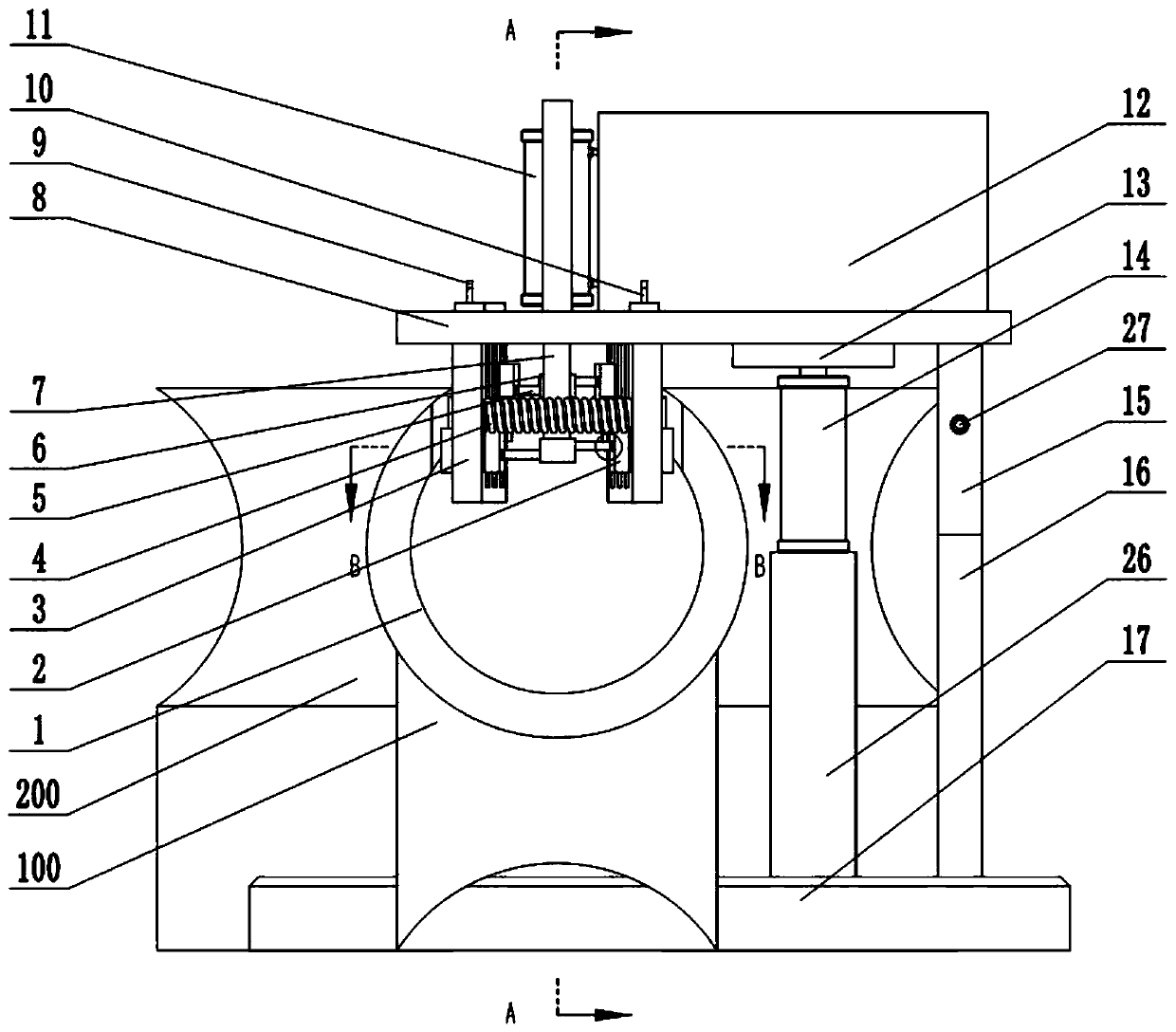

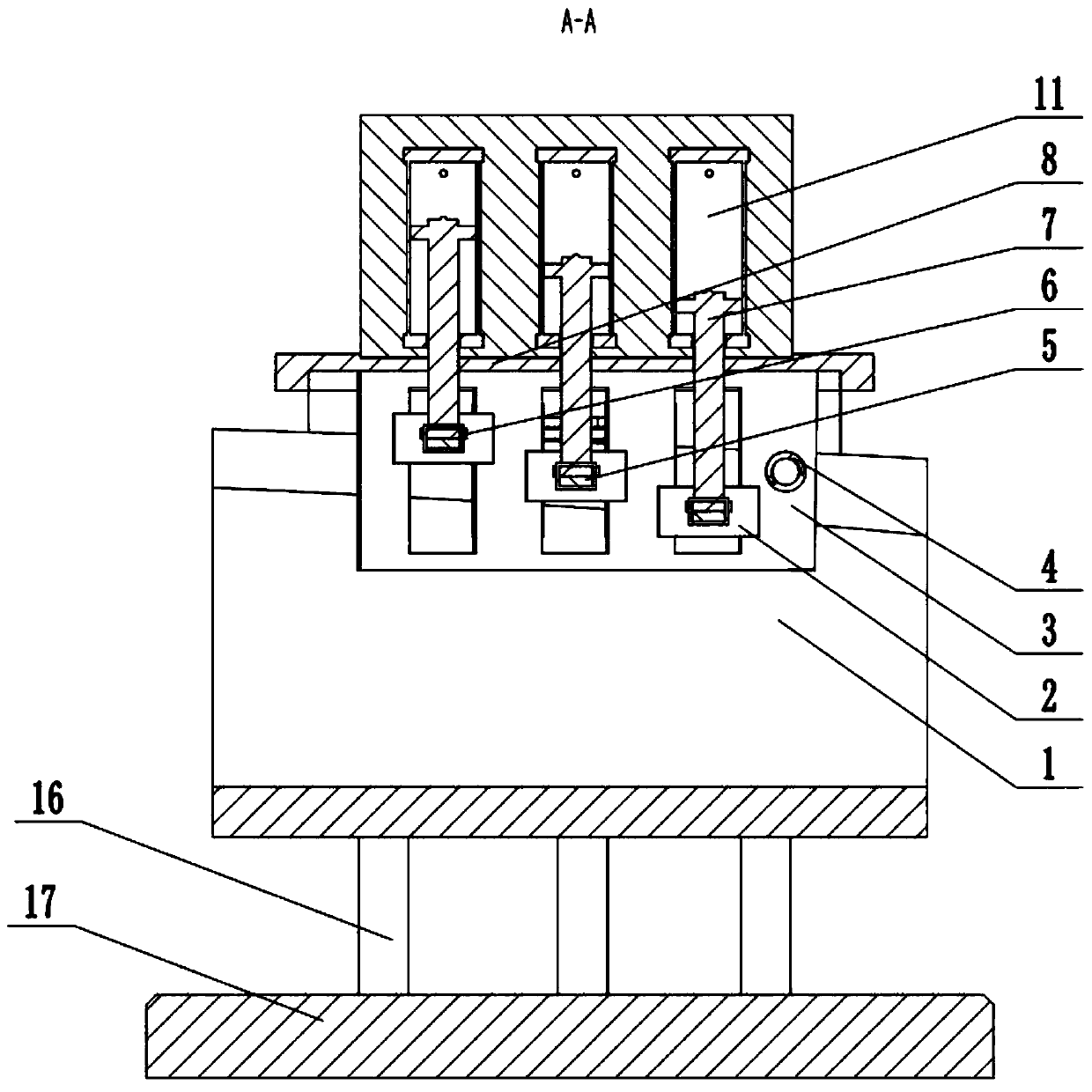

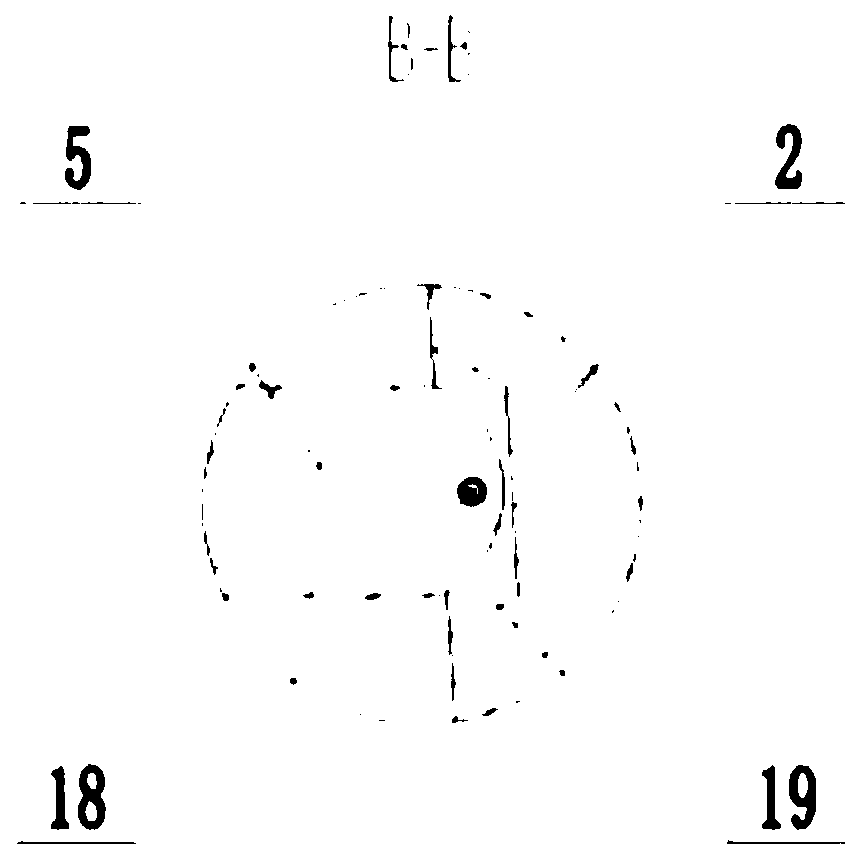

[0031] Such as figure 1 As shown, the ERW pipe lateral load applying device of the present invention includes an electrode block 2, an electrode panel 3, a pressure spring 4, an electrode connecting rod 5, a workbench 8, a telescoping mechanism, a support plate 13, a lifting device, a base 17 and a conductive plate twenty two. The telescopic mechanism includes an electrode hydraulic cylinder 11 , a hydraulic pump 12 and a hydraulic rod 7 , and the lifting device includes a platform hydraulic cylinder 14 , a chute member 15 , a fixed bracket 16 and a column 26 .

[0032] Such as figure 1 As shown, the workbench 8 is supported by a lifting device capable of adjusting its height. The lifting device includes three columns. The first column is fixed between the base 17 and the workbench 8. The first column includes a platform hydraulic cylinder 14 and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com