High-current wire connecting apparatus for connecting multiple wires synchronously

A wire connection and simultaneous connection technology, which is applied in the direction of multi-conductor connectors, conductive connections, connections, etc., can solve problems such as messy and irregular wiring of electronic equipment, overheating and burning, and poor contact, so as to improve welding quality and conductivity, and eliminate The effect of wasteful, reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

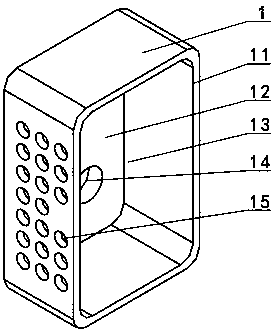

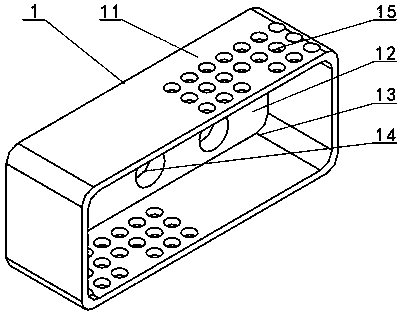

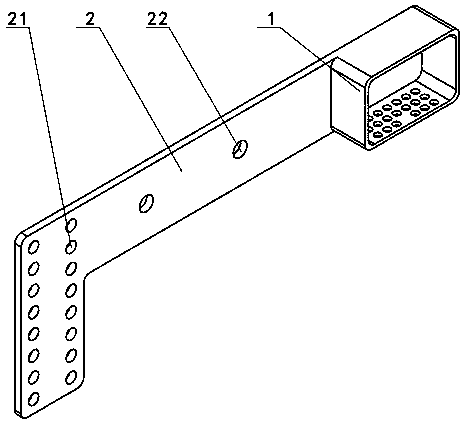

[0032] Such as Figure 1-Figure 8As shown, the high-current wire connection device for simultaneous connection of multiple wires according to the present invention includes a welding box 1, a bus bar 2 and an insulating base 5. The welding box 1 is a copper box whose surface is gold-plated or silver-plated. The top of the box 1 is open, and the bottom 12 of the welding box 1 is installed in the installation groove 51 on the insulating base 5 through the mounting screws 4. The bottom 12 of the welding box 1 is provided with one or more welding boxes for connecting with the insulating base 5 Mounting hole 14, the inner cavity 13 of welding box 1 is used for filling welding material, is provided with the welding box wire hole 15 that is used for wire 3 to pass through on the circumferential box wall 11 of welding box 1, and welding box wire hole 15 can be cylindrical hole , i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com