Satellite-borne dual-band four-channel rotary joint

A rotary joint, dual-band technology, applied in electrical components, circuits, waveguide devices, etc., to improve stability and reliability, ensure effective clearance, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

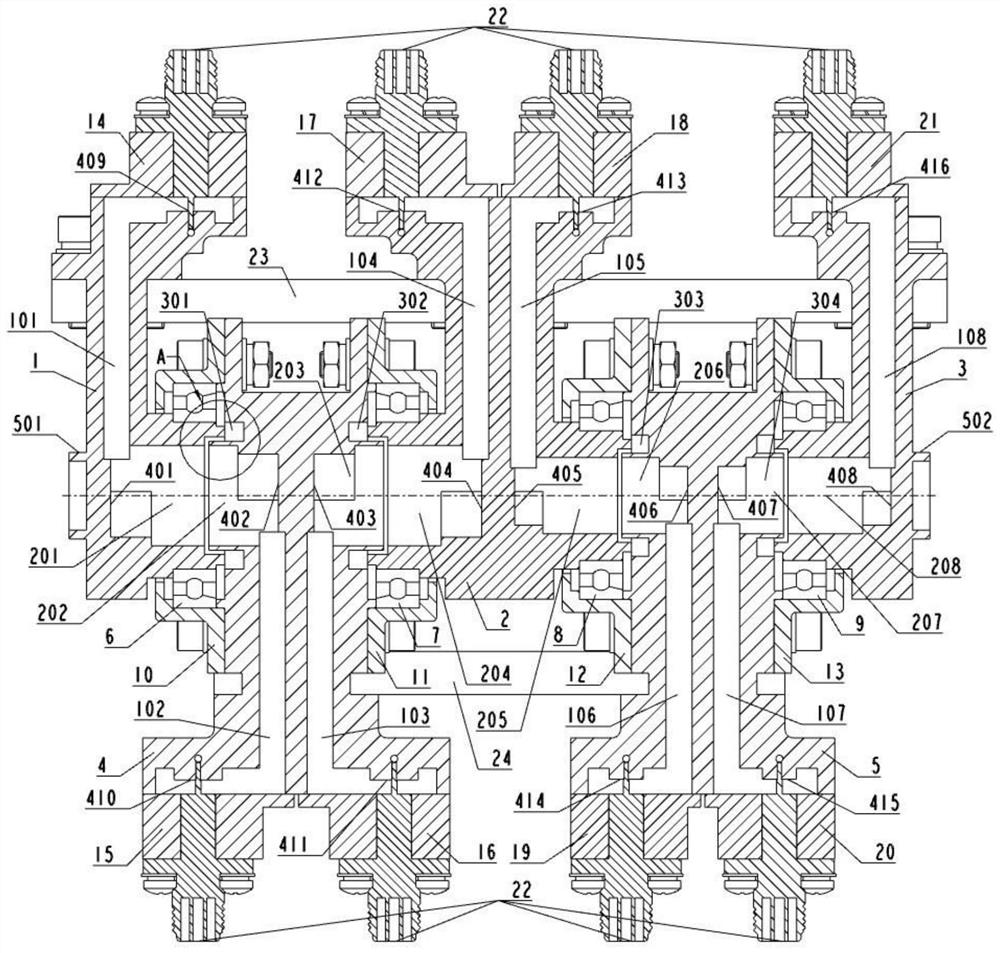

[0042] Such as figure 1 , figure 2 as shown, figure 1 It is a structural sectional view of the spaceborne dual-band four-channel rotary joint; figure 2 for figure 1 Partial structural view of A (choke slot) in middle.

[0043] The space-borne dual-band four-channel rotary joint of the present invention includes a first single-waveguide rotor 1, a first double-waveguide stator 2, a double-waveguide rotor 3, a second double-waveguide stator 4, a second single-waveguide rotor 5, and a first bearing 6. , the second bearing 7, the third bearing 8, the fourth bearing 9, the first bearing cover 10, the second bearing cover 11, the third bearing cover 12, the fourth bearing cover 13.

[0044] The first single-waveguide rotor 1, the double-waveguide rotor 3 and the second single-waveguide rotor 5 are rotors, the first double-waveguide stator 2 and the second double-waveguide stator 4 are stators, and the rotor It is supported and connected with the stator through the first beari...

Embodiment 2

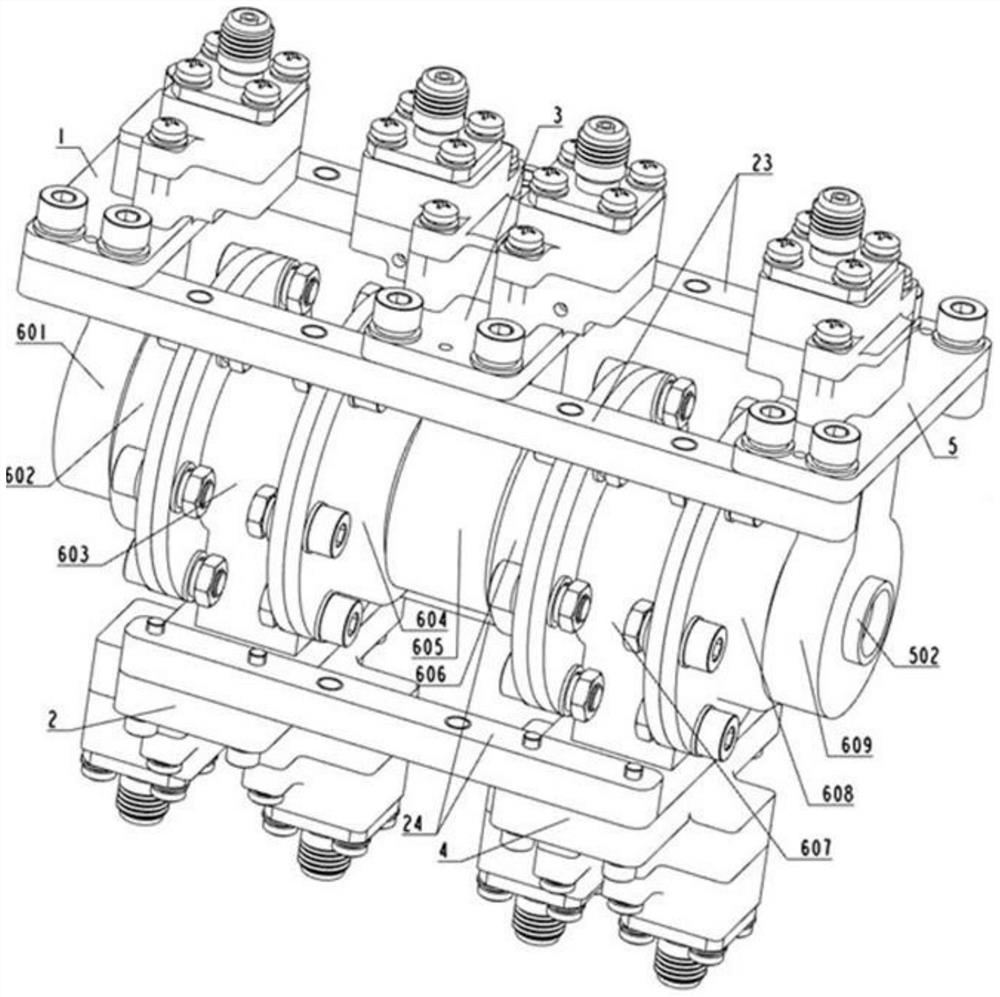

[0075] Such as image 3 , Figure 4 as shown, image 3 It is a three-dimensional view of the installation structure of the spaceborne dual-band four-channel rotary joint; Figure 4 It is an exploded view of the installation structure of the space-borne dual-band four-channel rotary joint; preferably, the space-borne dual-band four-channel rotary joint also includes a first shape-conforming tooling plate 23 and a second shape-keeping tooling plate 24, The first single-waveguide rotor 1, the double-waveguide rotor 3 and the second single-waveguide rotor 5 are connected and fixed through the first conformal tooling plate 23, and the first double-waveguide stator 2 and the second The double-waveguide stator 4 is connected and fixed through the second shape-conserving tooling plate 24, the first shape-keeping tooling plate 23 and the second shape-keeping tooling plate 24 are tooling for assembling and conforming to the shape, and the space-borne dual-band After the four-channel ...

Embodiment 3

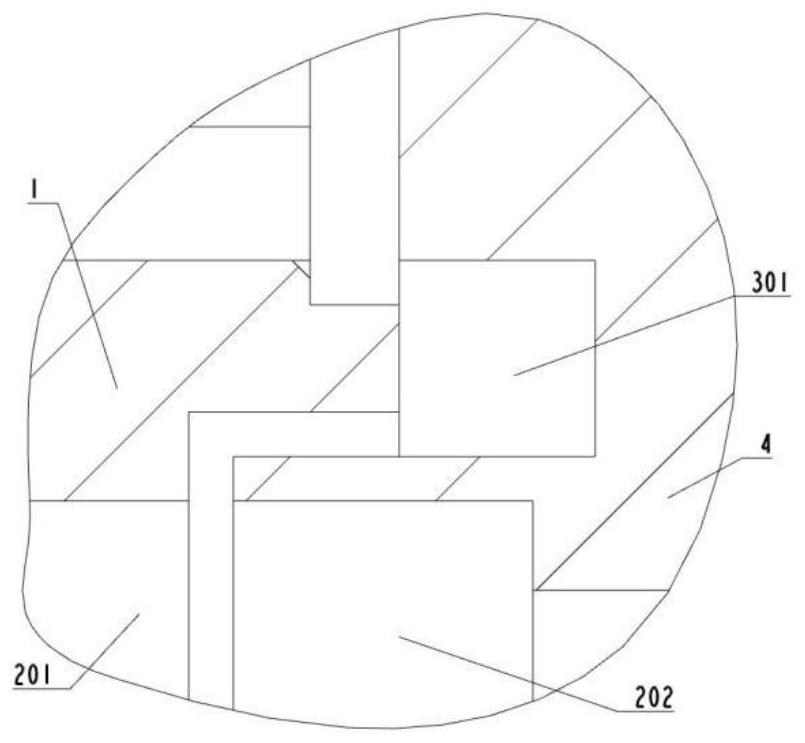

[0078] Such as Figure 5 , Figure 6 , Figure 7 as shown, Figure 5 is a structural perspective view of the first single waveguide rotor; Figure 6 is a structural sectional view of the first single waveguide rotor; Figure 7 is an exploded view of the structure of the first single waveguide rotor.

[0079] correspond Figure 6 , the first single-waveguide rotor 1 includes a first single-waveguide rotor body part and a first coaxial waveguide conversion part 14 (upper part on double dot-dash line), the first single-waveguide rotor body part and the first The coaxial waveguide transformation part 14 is obtained through integral processing.

[0080] The main body part of the first single waveguide rotor (the lower part of the dot-dash line) includes the first rectangular waveguide cavity 101, the first cylindrical waveguide cavity 201, and the first rectangular waveguide cavity 101 and the first rectangular waveguide cavity 101. A transitional transformation structure pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com