A space-borne dual-band four-channel rotary joint

A rotary joint, dual frequency band technology, applied in the direction of circuits, waveguide devices, electrical components, etc., to achieve the effect of improving stability and reliability, ensuring effective clearance, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

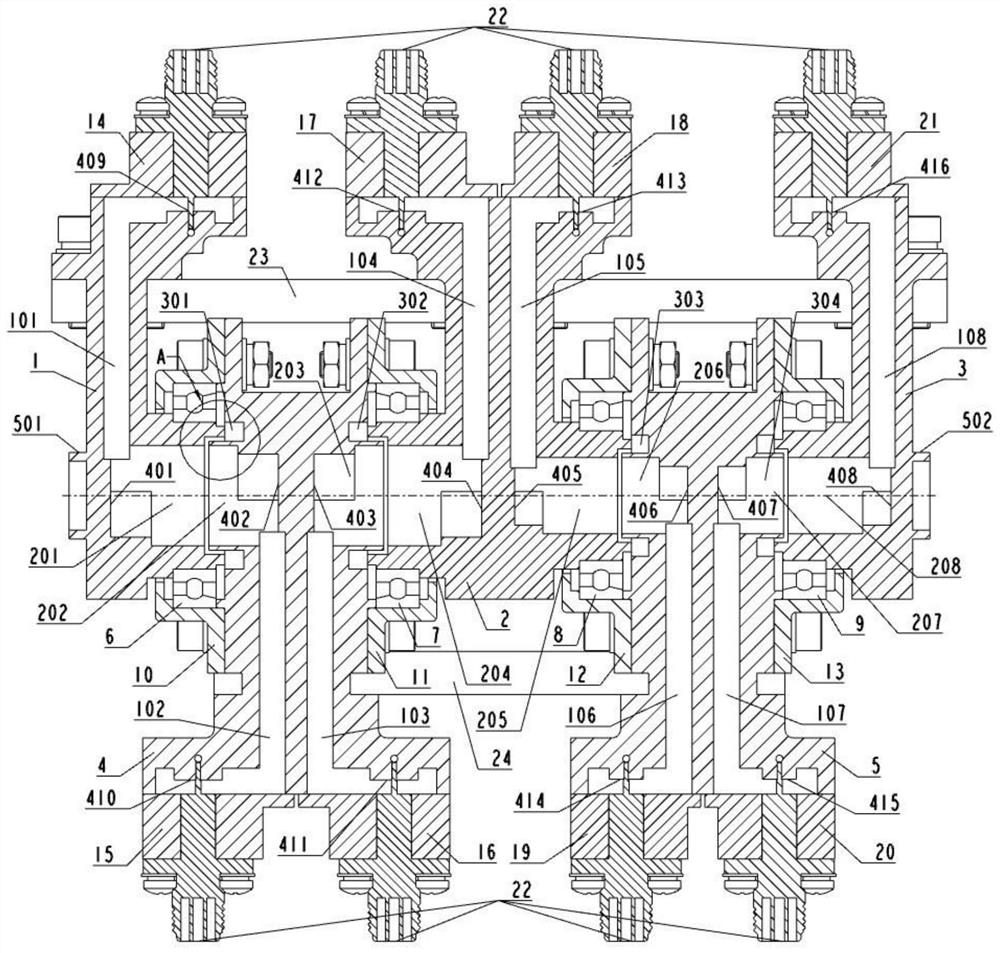

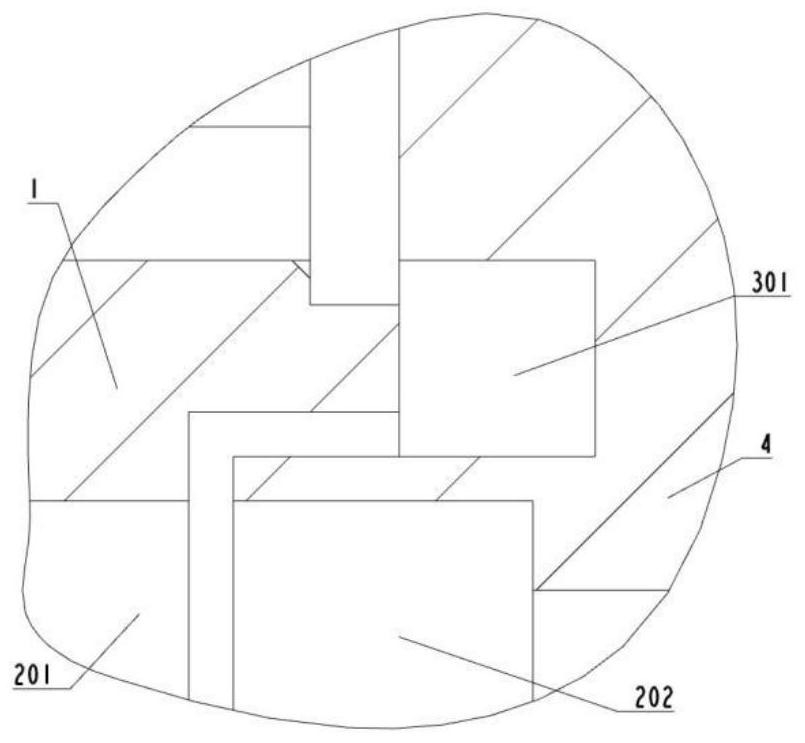

[0042] like figure 1 , figure 2 Distance figure 1 Structure cross-sectional view of the four-channel rotary joint of the star-loaded dual-band; figure 2 for figure 1 A local structure view of the APA (choke).

[0043] The star-loaded double-band four-channel rotary joint of the present invention includes a first single waveguide rotor 1, a first dual waveguide 2, a dual waveguide rotor 3, a second dual wave guide sub-wave 4, a second single waveguide rotor 5, a first bearing 6 , The second bearing 7, the third bearing 8, the fourth bearing 9, the first bearing cover 10, the second bearing cover 11, the third bearing cover 12, the fourth bearing cover 13.

[0044] The first single waveguide rotor 1, the dual waveguide rotor 3 and the second single waveguide rotor 5 are rotor, the first duplex guide 2 and the second dual wave guide 4 being a stator, the rotor And the stator passes through the first bearing 6, the second bearing 7, the third bearing 8, and the fourth bearing 9 suppor...

Embodiment 2

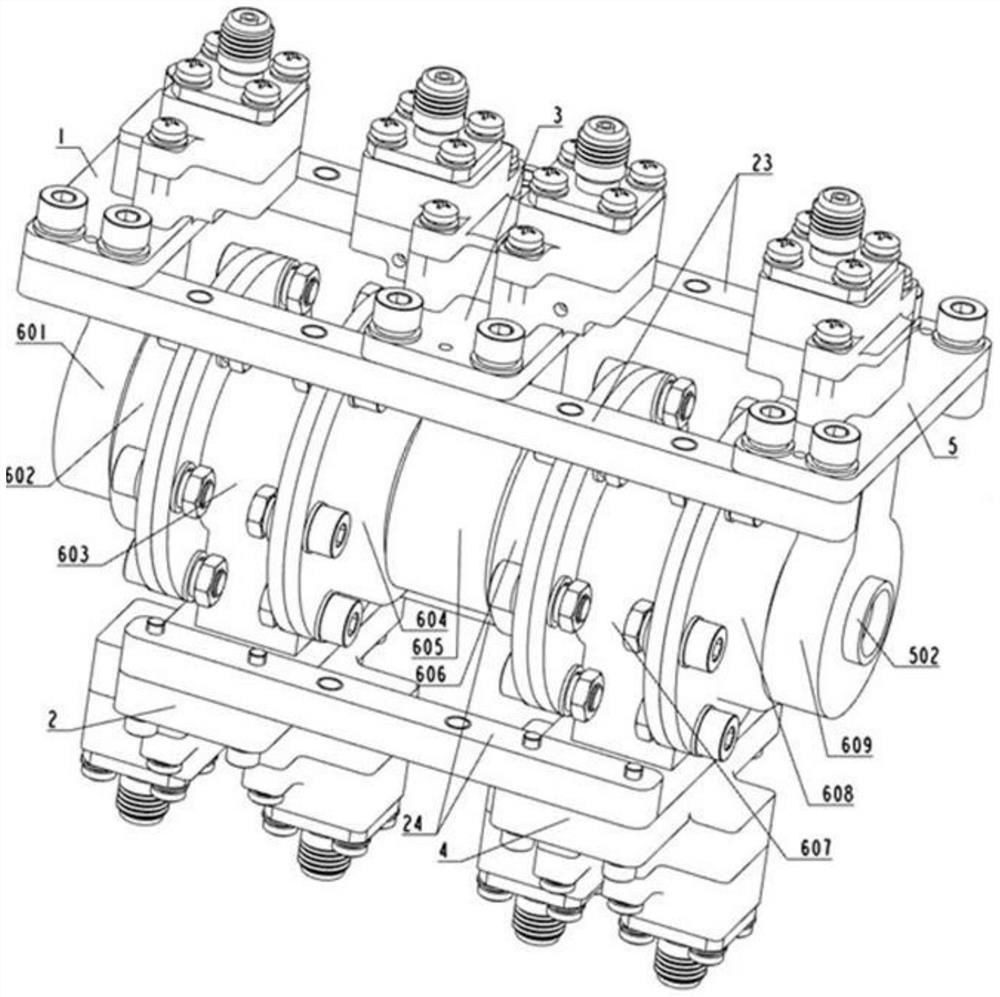

[0075] like image 3 , Figure 4 Distance image 3 Stereoscopic view of the installation structure of the four-channel rotation joint of the star-loaded dual-band; Figure 4 The mounting structure exploding of the four-channel rotation joint of the star-loaded dual-band; preferably, the star-loaded dual-band four-channel rotary joint includes further include a first conformal tool 23 and a second protocol tool 24, The first single waveguide rotor 1, the dual waveguide rotor 3 and the second single waveguide rotor 5 are secured by the first conformal tool 23, the first dual wavefront, and the second The double wave guide 4 is connected to the second conformal tooling plate 24 and the second conformal tooling plate 24 as an assembled tooling, and the star-loaded dual band The four-channel rotary joint is required to remove the first splitting tool 23 and the second protocol tool 24.

[0076]The assembly control method of the first conformal tooling plate 23 and the second conformal tool...

Embodiment 3

[0078] like Figure 5 , Image 6 , Figure 7 Distance Figure 5 Stereoscopic view of the structure of the first single waveguide rotor; Image 6 A cross-sectional view of the structure of the first single waveguide rotor; Figure 7 The structural explosive of the first single waveguide rotor.

[0079] correspond Image 6 The first single waveguide rotor 1 includes a first single waveguide rotor body portion and a first coaxial waveguide conversion unit 14 (double dotted upper side portion), the first single waveguide rotor body portion and the first Coaxial waveguide transform unit 14 integrated processing preparation.

[0080] The first single waveguide rotor body portion (double dotted underside) includes the first rectangular waveguide chamber 101, the first cylindrical waveguide chamber 201 and the first rectangular waveguide chamber 101 and the first rectangular waveguide chamber 101 A transition conversion structure portion formed between the first matching block 401 is formed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com