Brushless generator

A technology of generators and turntables, applied in the direction of electrical components, electromechanical devices, circuit devices, etc., can solve problems such as replacement and maintenance, poor contact, accidents, etc., and achieve the effect of stable transmission and stable excitation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

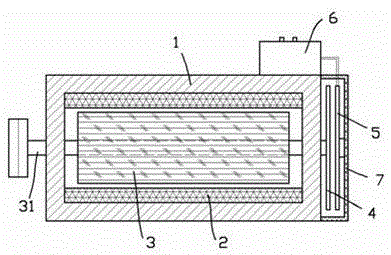

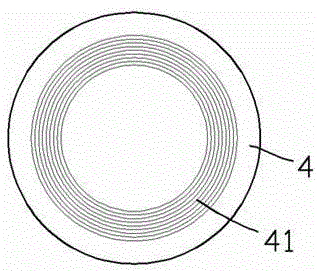

[0016] exist figure 1 , figure 2 In the first embodiment shown, the brushless generator includes a casing 1, a stator 2, and a rotor 3; the stator 2 includes a stator core and a stator winding; the rotor 3 includes a rotating shaft 31, a rotor core, and a rotor winding; The rotating shaft 31 protrudes from the rear end of the casing 1, and is fixedly connected to a non-conductive turntable 4 outside the casing; the turntable 4 is provided with a turntable coil 41 concentric with the turntable 4, and two of the turntable coils 41 The output end is electrically coupled to the rotor winding; the rear end of the housing is also fixed with a non-conductor fixed disk 5 that is close to the turntable 4 and facing each other. 41 fixed disk coils facing each other, the fixed disk coils are connected in series with a fixed capacitor and then connected to a secondary coil of a transformer power supply, the fixed disk coils, fixed capacitors, and secondary coils form an input-side LC os...

Embodiment 2

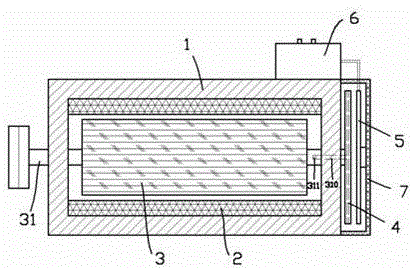

[0020] for image 3 , Figure 4 The second embodiment shown differs from the first embodiment in that: the inside of the turntable 4 is formed with a radial through hole 40, the outer end of the radial through hole 40 runs through the peripheral surface of the turntable 4, and the inner end It communicates with the shaft hole 310 inside the rotor shaft 31 , one end of the shaft hole 310 is blocked, and the other end communicates with the inside of the casing 1 through the wall hole 311 on the shaft 31 . According to the second embodiment, during the rotation of the turntable 4 with the rotor 3, the radial through holes 40 in the turntable 4 are exhausted by the centrifugal force of the air, and the hot air in the inner space of the casing 1 is sucked away to clean the inside of the casing 1. Good cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com