Patents

Literature

53results about How to "Achieved weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural mat matrix

InactiveUS6146705AReduce contentIncrease volumeNon-fibrous pulp additionRoof covering using tiles/slatesFiberGlass fiber

A structural mat matrix comprises (a) a substrate which consists essentially of from 80% to 99% by weight fiberglass fibers and from 20% to 1% by weight wood pulp and (b) a binder which consists essentially of from 80% to 95% by weight urea formaldehyde and from 20% to 5% by weight acrylic copolymer. The binder bonds the substrate fiberglass fibers and wood pulp together and comprises from 5% to 15% by weight of said matrix, preferably 10% by weight of the matrix.

Owner:ELK PREMIUM BUILDING PROD

An excavator bucket material volume and weight measuring system

ActiveCN109948189AAchieve volumeAchieved weightSpecial data processing applicationsManufacturing computing systemsPoint cloudMeasurement device

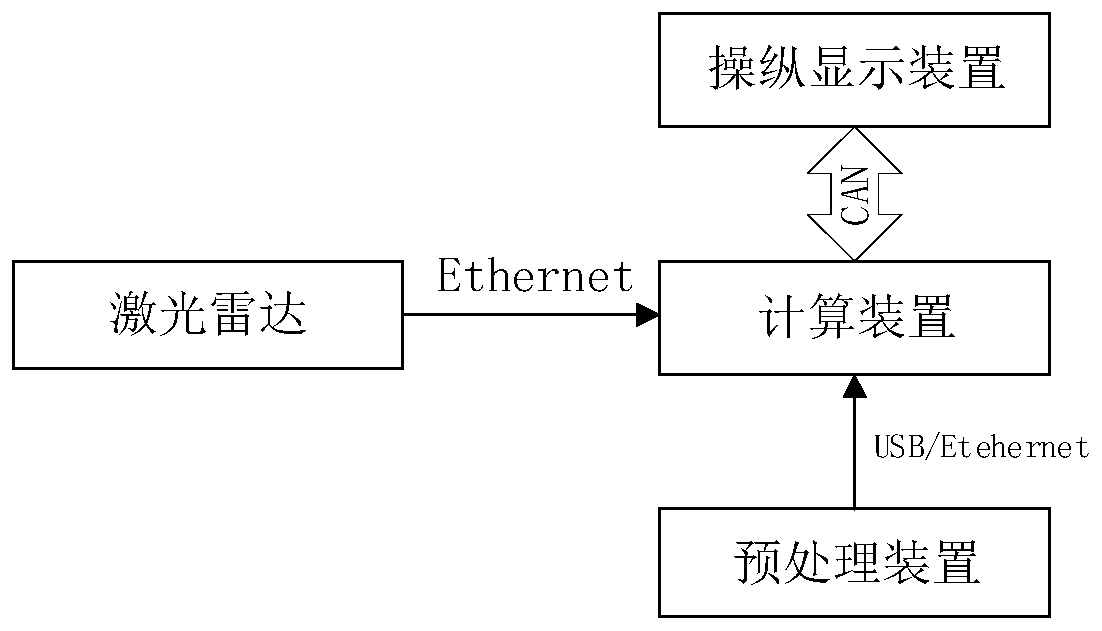

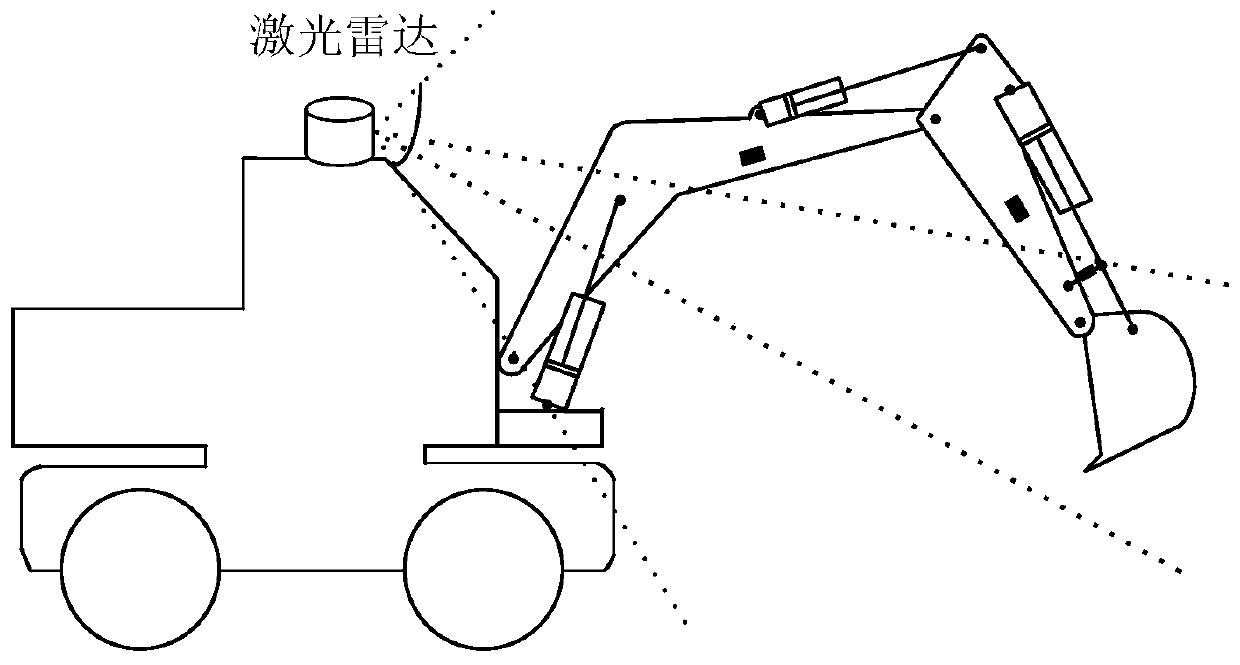

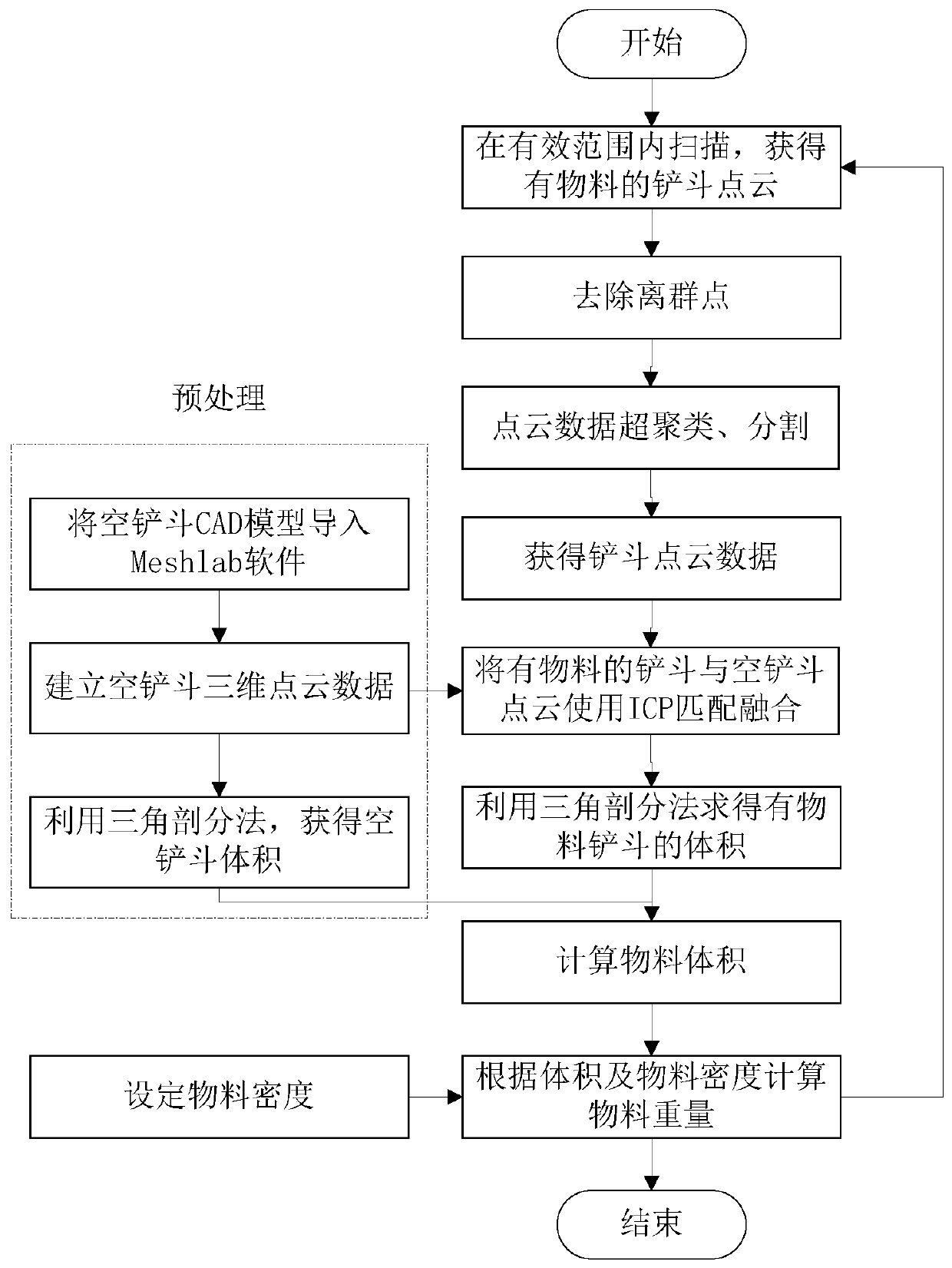

The invention relates to an excavator bucket material volume and weight measuring system, which belongs to the technical field of hydraulic excavator bucket weighing, and comprises a laser radar, a calculating device, a preprocessing device and an operation display device. According to the invention, a laser radar device is used for realizing dynamic volume and weight measurement of materials in the bucket in the operation process of the excavator; effective three-dimensional modeling can be carried out on the empty bucket, point cloud registration fusion is carried out on the bucket filled with materials in the later excavation operation process, the limitation that point cloud data acquisition is blocked by objects and thus point cloud acquisition is incomplete is solved, the measurementprecision is improved, and the complexity of the measurement device is reduced.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

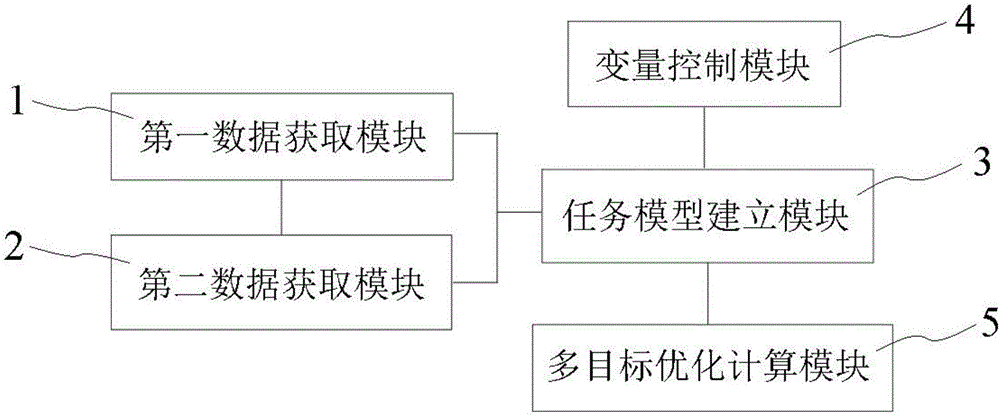

Railway vehicle weight gravity center design optimization method and system based on multi-objective optimization

InactiveCN106845006AAchieved weightImprove space utilizationGeometric CADInternal combustion piston enginesMulti objective optimization algorithmGravity center

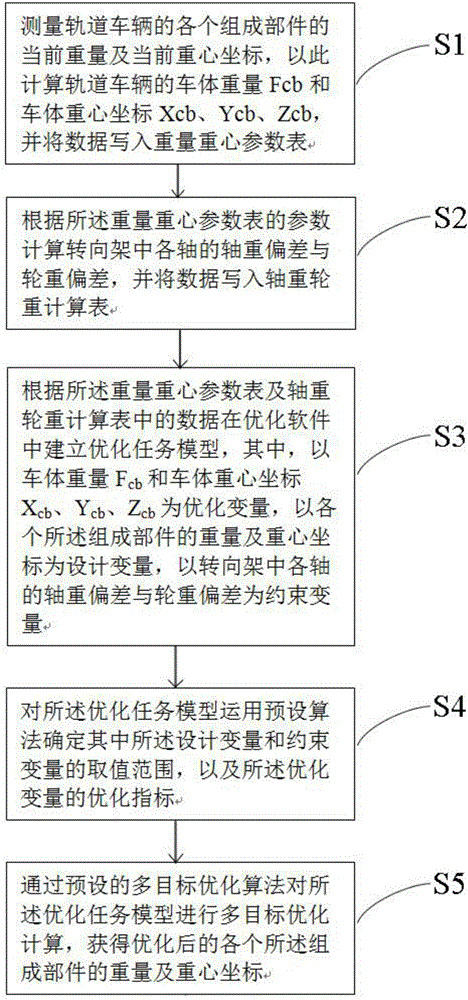

The invention discloses a railway vehicle weight gravity center design optimization method based on multi-objective optimization. The method comprises the steps that a weight gravity center parameter table and an axle weight and wheel weight computation sheet are established, an optimization task model is established in optimization software on the basis, the vehicle body weight and vehicle body gravity center coordinates are used as optimization variables, the weights and gravity center coordinates of constituent parts are used as design variables, and axle weight deviations and wheel weight deviations are used as bound variables; a preset algorithm is applied to determine value ranges of the design variables and the bound variables and optimization indexes of the optimization variables; multi-objective optimization calculation is conducted on the optimization task model through a multi-objective optimization algorithm, and the weights and gravity center coordinates of the constituent parts after optimization are obtained. Weight and distribution optimization of the parts on a railway vehicle can be achieved, the lightweight design purpose is achieved, and meanwhile the utilization rate of space in a vehicle body is improved. the invention further discloses a railway vehicle weight gravity center design optimization system based on multi-objective optimization. The advantages of the method and the system are as mentioned above.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

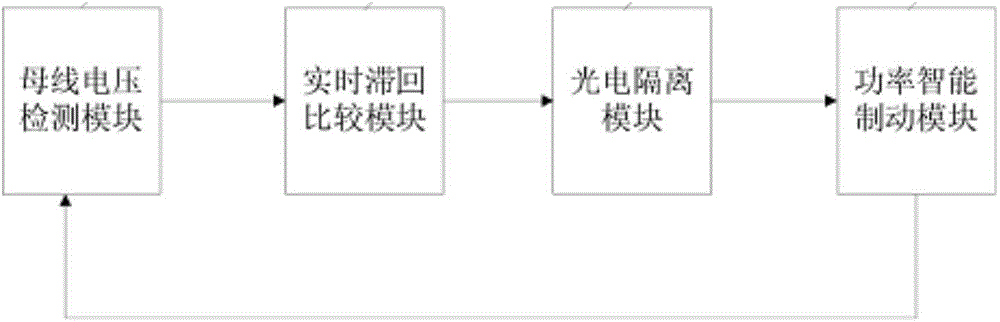

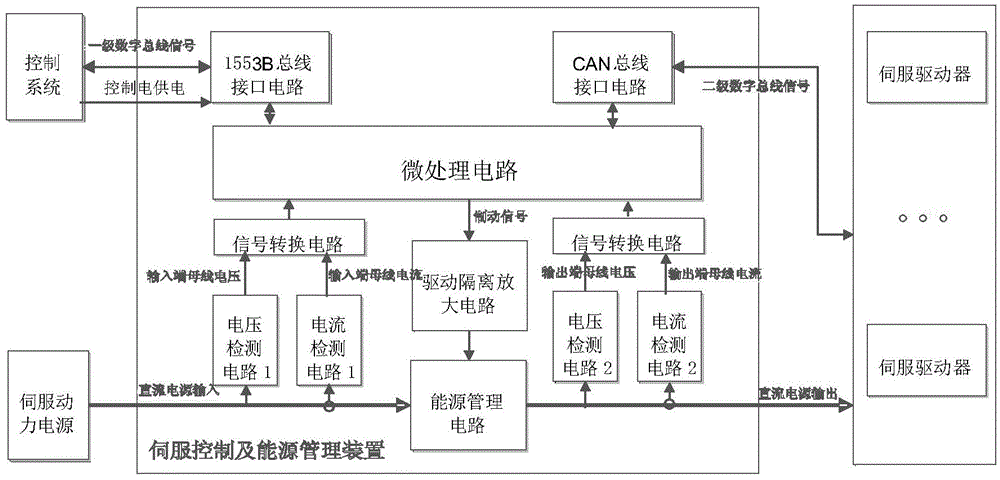

Electromechanical servo comprehensive control and energy source management device

ActiveCN104678830AAchieve volumeAchieved weightProgramme controlComputer controlElectric machineryMotor control

The invention provides an electromechanical servo comprehensive control and energy source management device, which is used for servo motor control and energy source management, and comprises a microprocessing circuit, detecting circuits, a signal conversion circuit, an isolation driving amplifying circuit and an energy source management circuit, wherein the detecting circuits comprise a first voltage detecting circuit, a first current detecting circuit, a second voltage detecting circuit and a second current detecting circuit. The electromechanical servo comprehensive control and energy source management device provided by the invention has the advantages that the comprehensive management of absorption and release of energy sources can be realized, in addition, the system composition is simplified, the system weight is reduced, and meanwhile, the self test of an electromechanical servo system can be realized.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

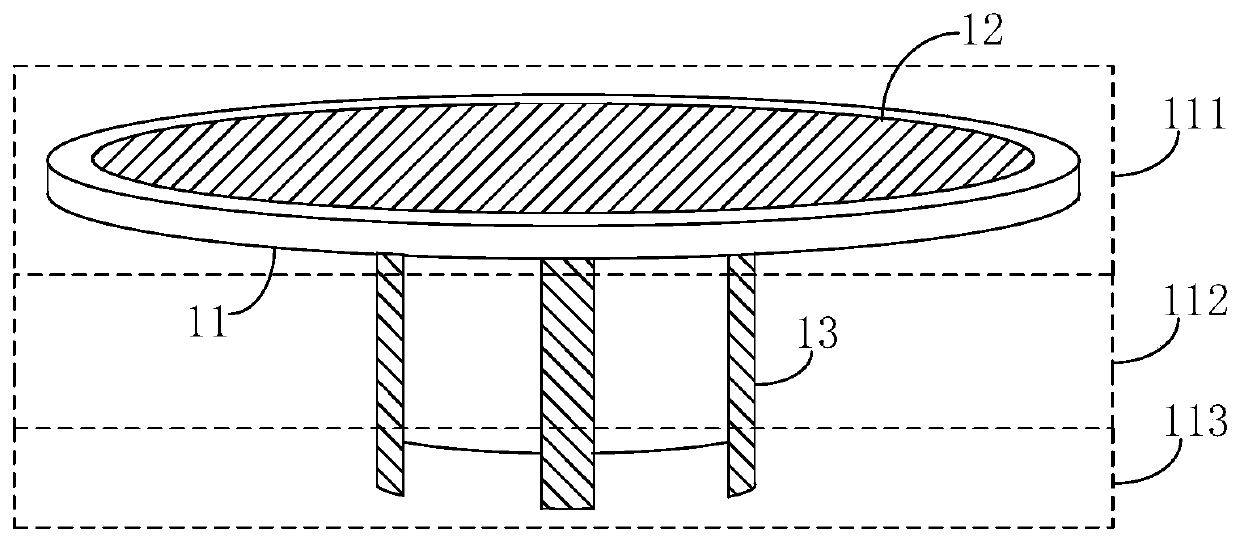

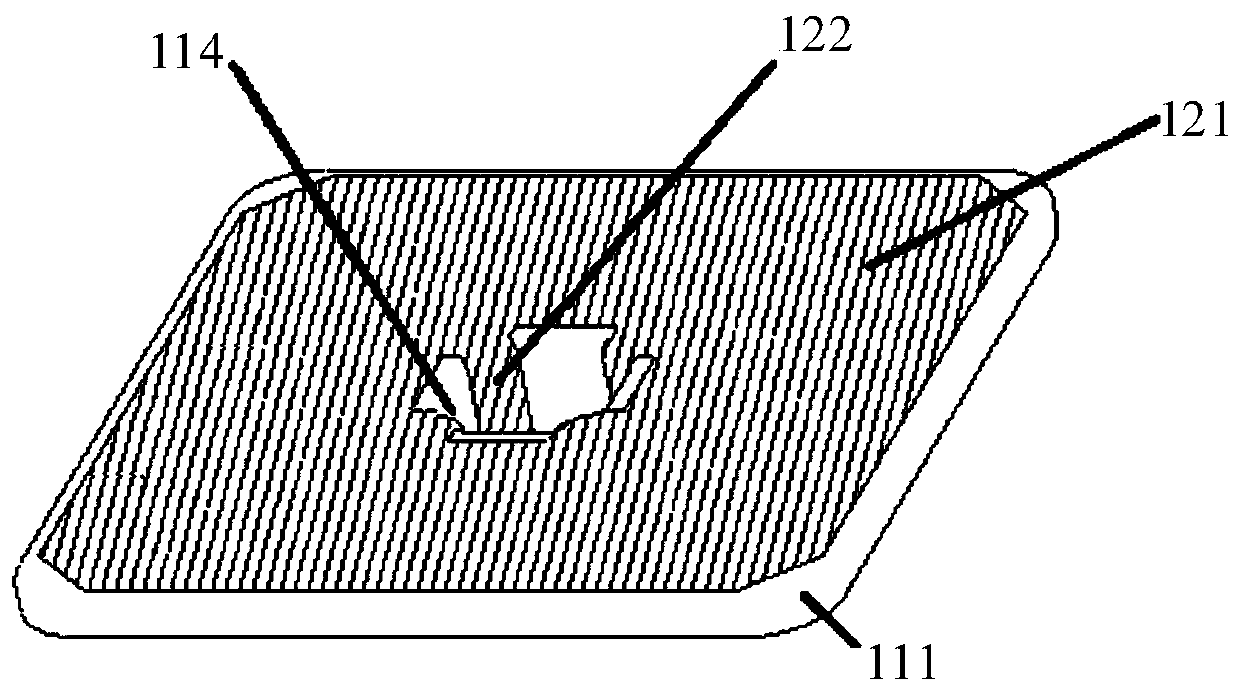

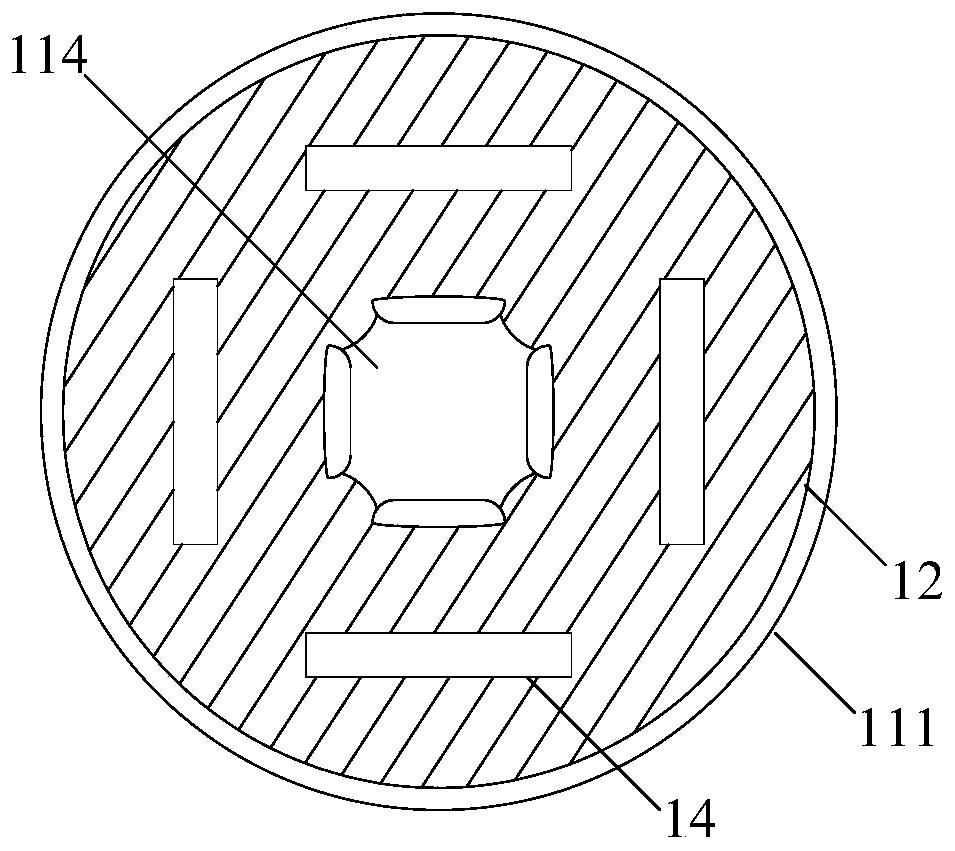

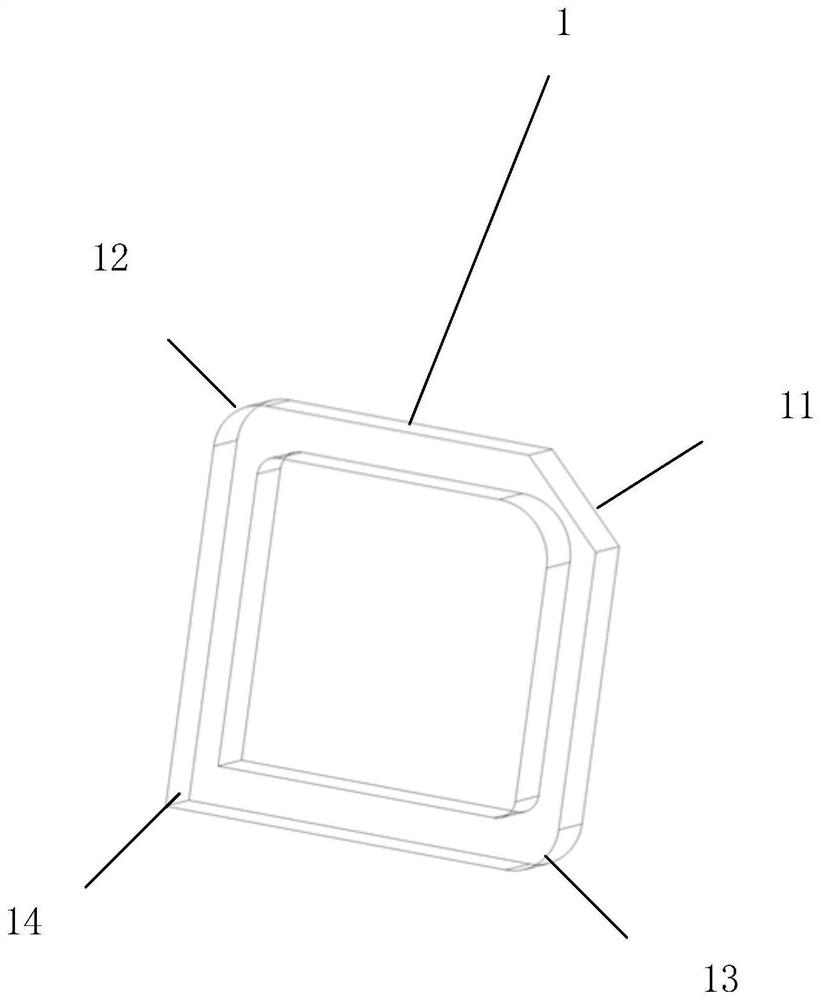

Microstrip radiation unit and array antenna

ActiveCN109755721AReduce weightAchieved weightAntenna supports/mountingsRadiating elements structural formsDielectric substrateOptoelectronics

The embodiment of the invention provides a microstrip radiation unit and an array antenna. The microstrip radiation unit comprises a dielectric substrate, a radiation circuit and a feeding circuit, wherein the dielectric substrate is integrally formed by injection molding and comprises a top part, a support part and a welding part, the support part is connected with the top and the welding part, the radiation circuit is arranged on an upper surface of the top part, and the feeding circuit is arranged on a lower surface of the top part and extends to the welding part along the support part. With the microstrip radiation unit and the array antenna, provided by the embodiment of the invention, integration of the radiation unit is achieved, the structure is simple, no assembly is needed, the reliability and the consistency of the radiation unit are improved, and the microstrip radiation unit and the array antenna are more suitable for manufacturing on a large scale. Moreover, the microstrip radiation unit has favorable low profile characteristic, the height of the radiation unit is effectively reduced, the weight of the radiation unit is further reduced, and the lightness of the radiation unit is achieved.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

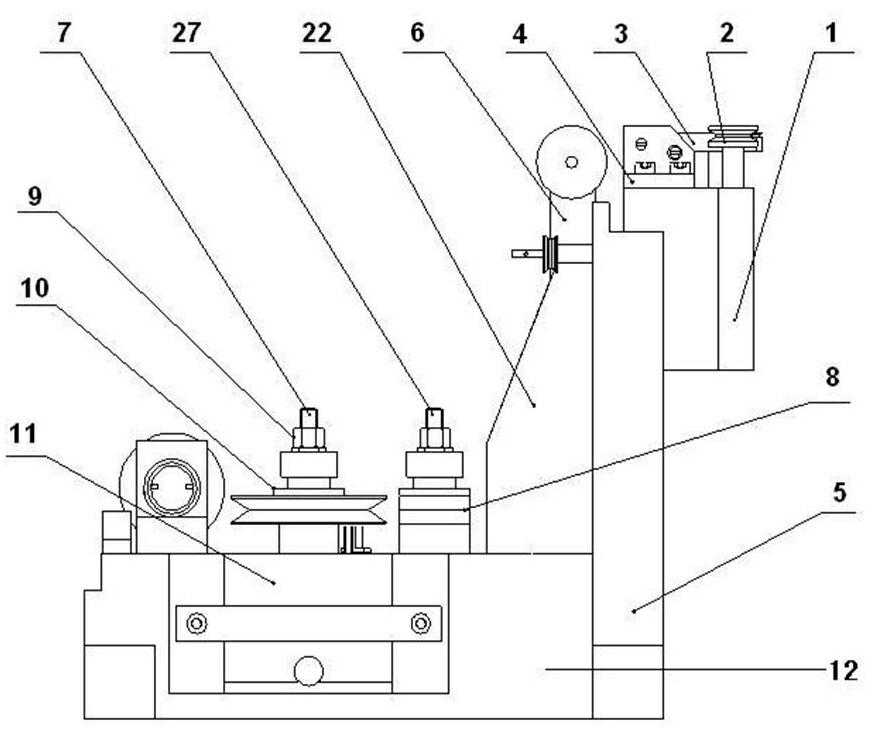

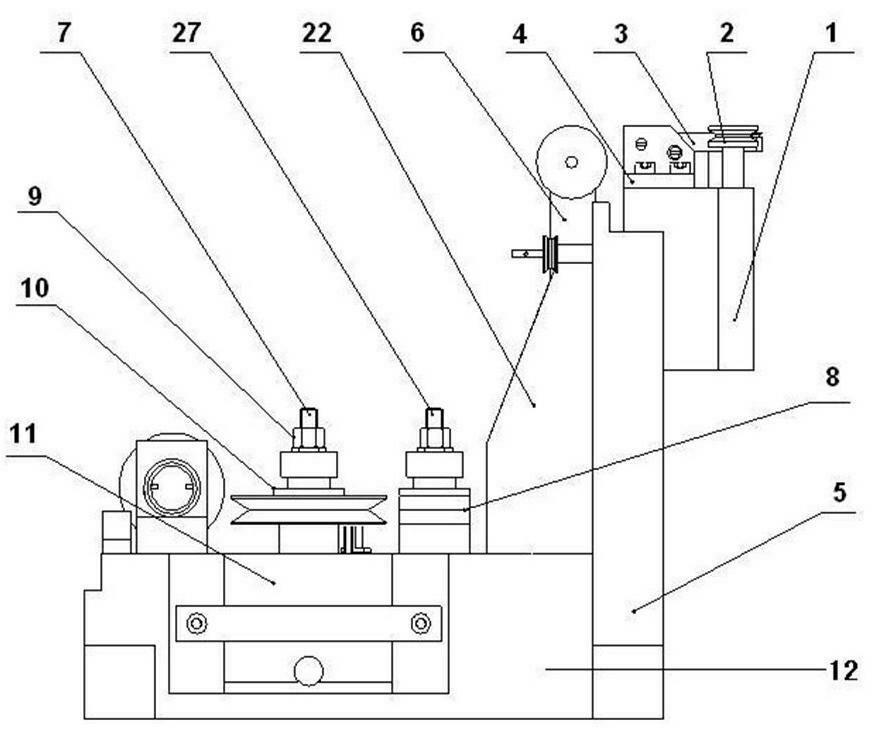

Miniaturized bifunctional line electrode grinding device

InactiveCN102601707AImprove dynamic characteristicsExpansion of comprehensive processing capabilitiesGrinding machine componentsGrinding machinesElectric dischargeMiniaturization

The invention discloses a miniaturized bifunctional line electrode grinding device. A motor assembly, a wire winding wheel, a wire discharging wheel, a damper and a damping fin in the line electrode grinding device are arranged on a bottom supporting plate, and a left grinding head, a right grinding head, a shock absorber, a guide wheel and a transition wheel are arranged on a vertical supporting plate. An electrode wire is wound on the left grinding head and the right grinding head after being led out by the wire discharging wheel and passing through a middle transition device and then passes through corresponding transition devices, and finally, wire winding is realized by the wire winding wheel, so that the whole wire moving process is finished. The motor assembly drives the wire winding wheel to rotate to realize the wire moving function of the electrode wire. All the devices provided by the invention are arranged reasonably, the device can be miniaturized and lightened, and the dynamic characteristic of a workbench can be improved. The spatial size of an electric discharge machining region arranged between the left grinding head and the right grinding head provided by the invention can be flexibly adjusted, the machining requirements of a microarray tool electrode and a non-microarray tool electrode can be met, and the function of a micro-electric machining system is remarkably expanded.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

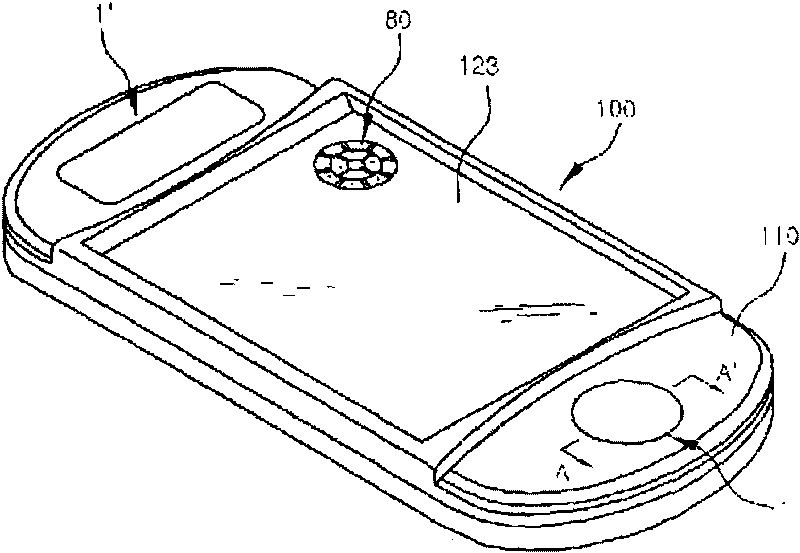

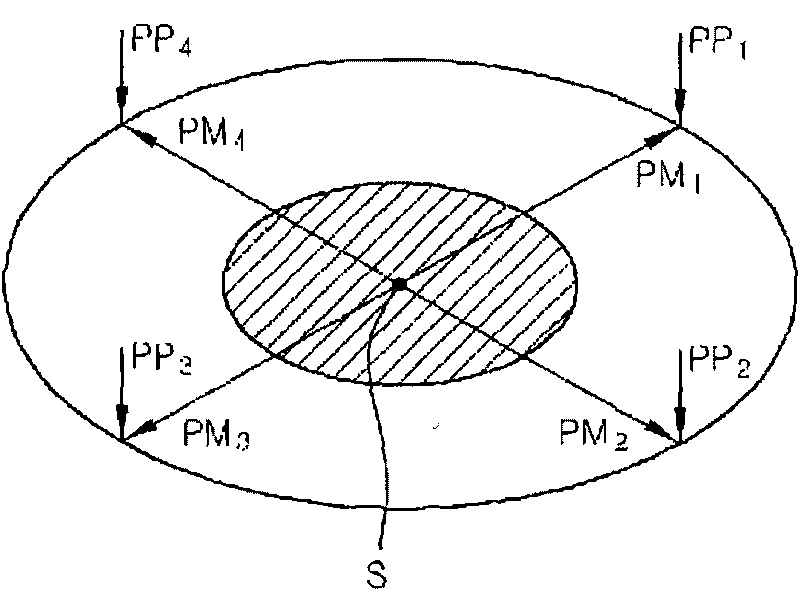

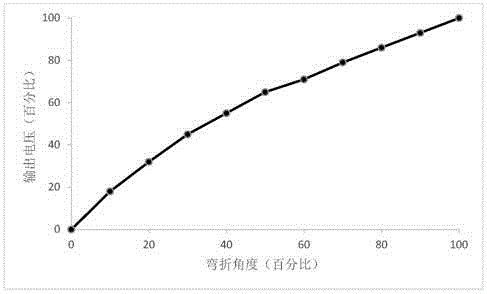

Data input device by detecting finger's moving and the input process thereof

InactiveCN101730875AAccurate operationData entered correctlyInput/output for user-computer interactionContactsComputer scienceControl unit

Disclosed herein are a data input device and an input conversion method using the data input device. The data input device includes a detection unit provided in a predetermined input region, the detection unit processing first directional input that generates a first directional input signal through detection of lateral pressing in a predetermined radial direction by a finger placed at a reference location in the input region, second directional input that generates a second directional input signal through detection of vertical pressing in a predetermined direction in a state in which the finger is placed at the reference location, third directional input that generates a third directional input signal through detection of tilt pressing in a state in which the finger is placed at the reference location, and fourth directional input that generates a fourth directional input signal through detection of a tilt input in a state in which the finger is placed at the reference location; and a control unit configured to determine input locations of a lateral pressing direction, vertical pressing direction, tilt pressing direction and tilting direction of the finger, extract relevant data from memory, and input the extracted data; wherein the data is input through combination of two or more of the first to fourth directional inputs.

Owner:吴谊镇

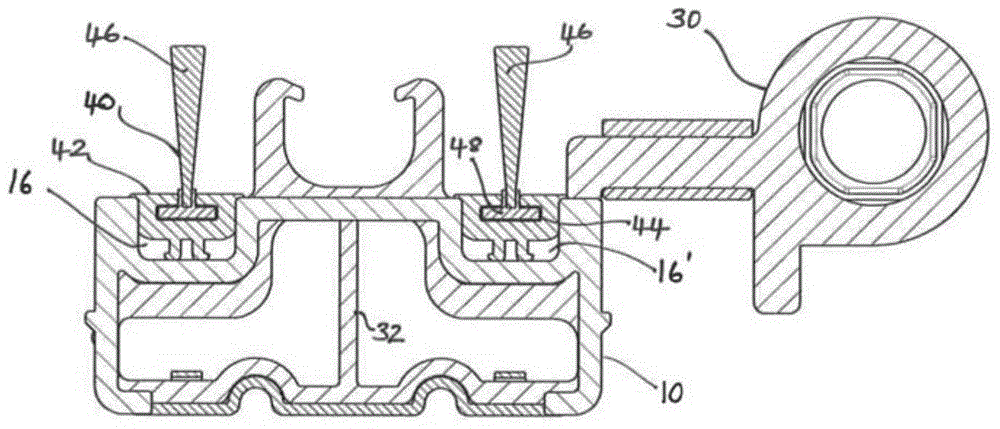

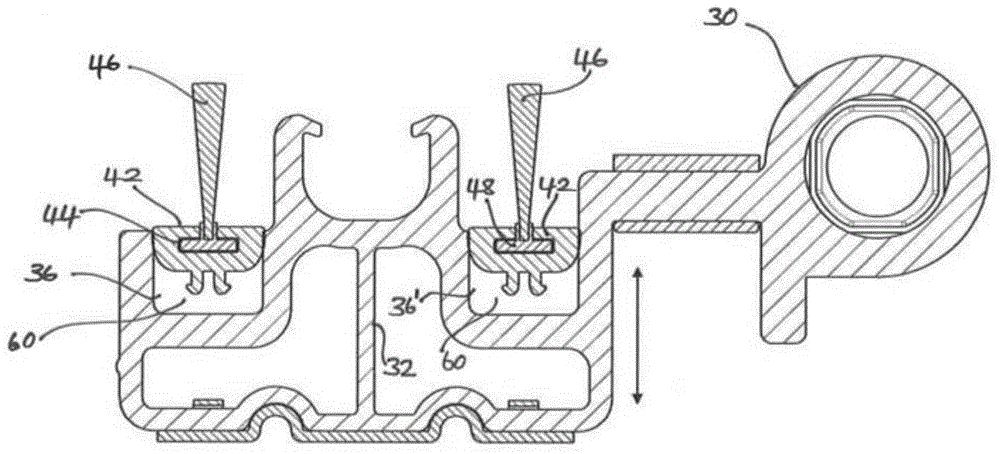

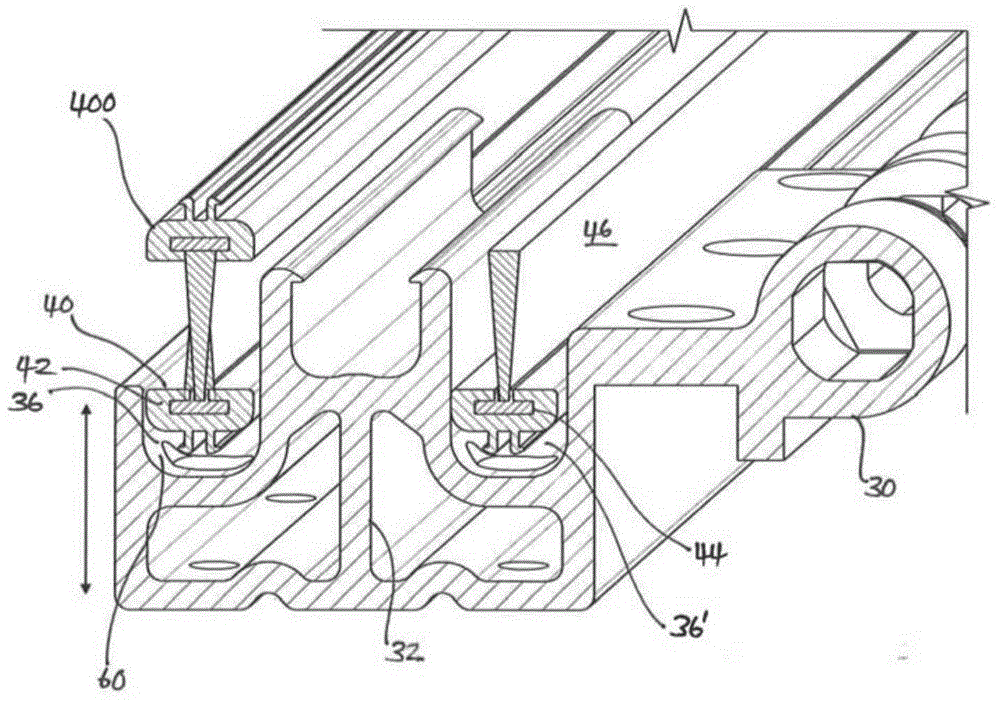

Sash sealing system and method

ActiveCN103912188AChanges and improvements to precise designsAvoid, or at least substantially overcome, the above-mentioned problems of distortedWing accessoriesHingesEngineeringFixed position

Provided is a sash sealing system for installation around the side edges of a sash closure member such as a door or window. The system includes: a seal carrier; a sash profile having a channel adapted to receive and retain the seal carrier in a fixed position; and sash hardware having a channel adapted to align with the sash profile channel when the sash profile and sash hardware are fitted to a sash edge. The sash hardware channel has a depth sufficient to permit adjustment of the hardware into or off the sash edge without deflecting the seal carrier.

Owner:ERA HOME SECURITY

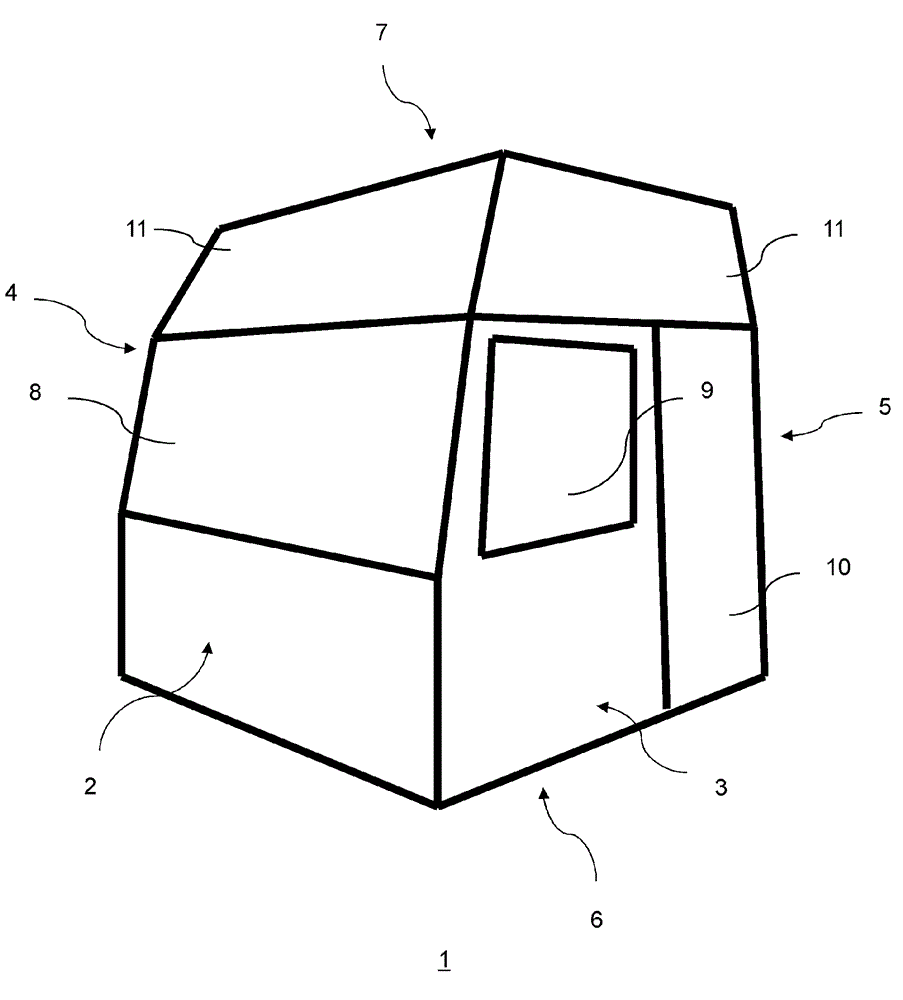

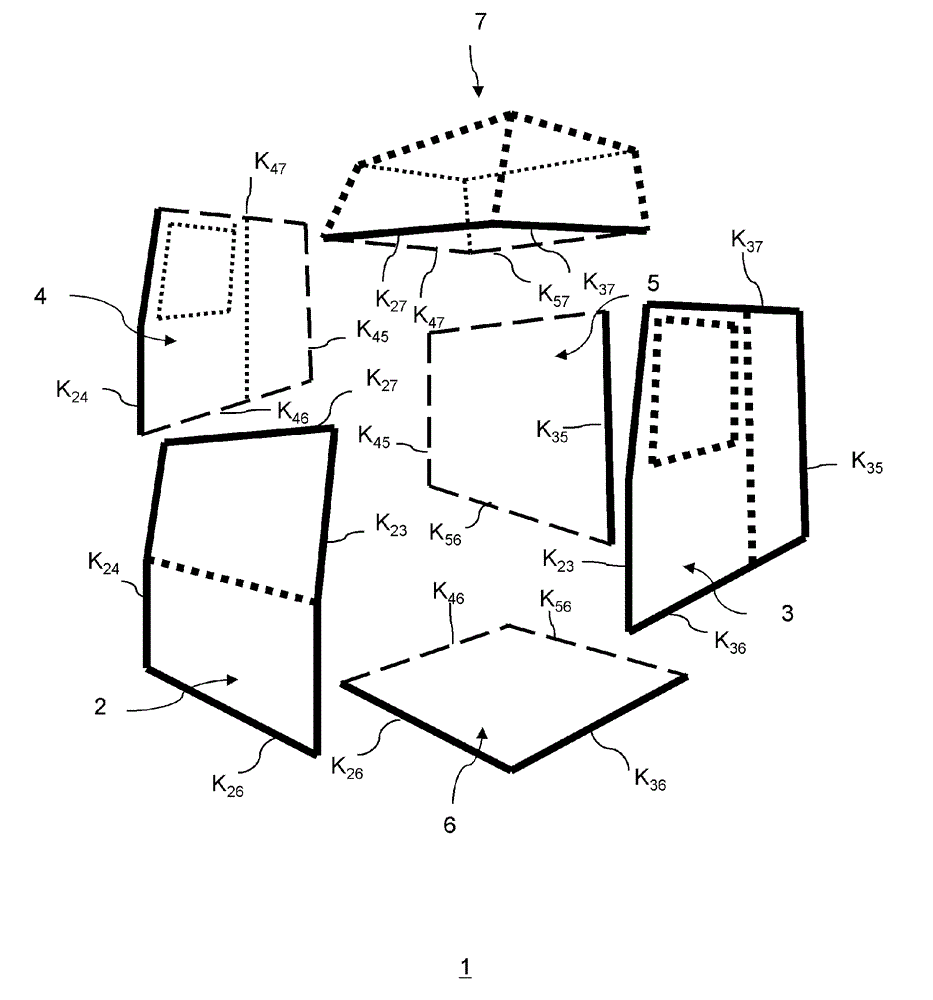

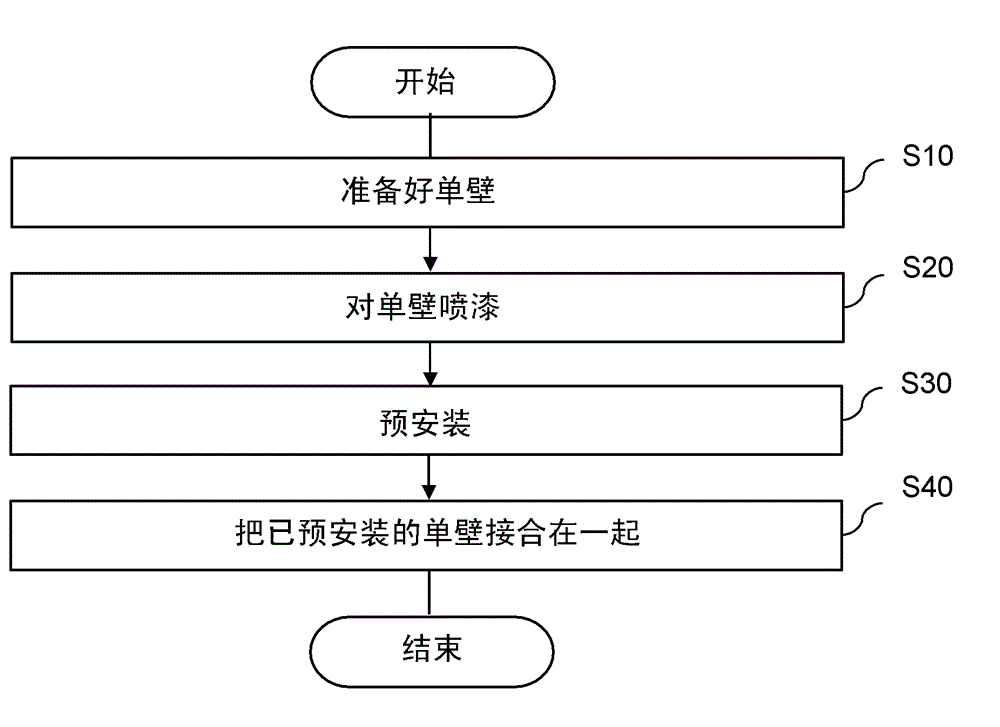

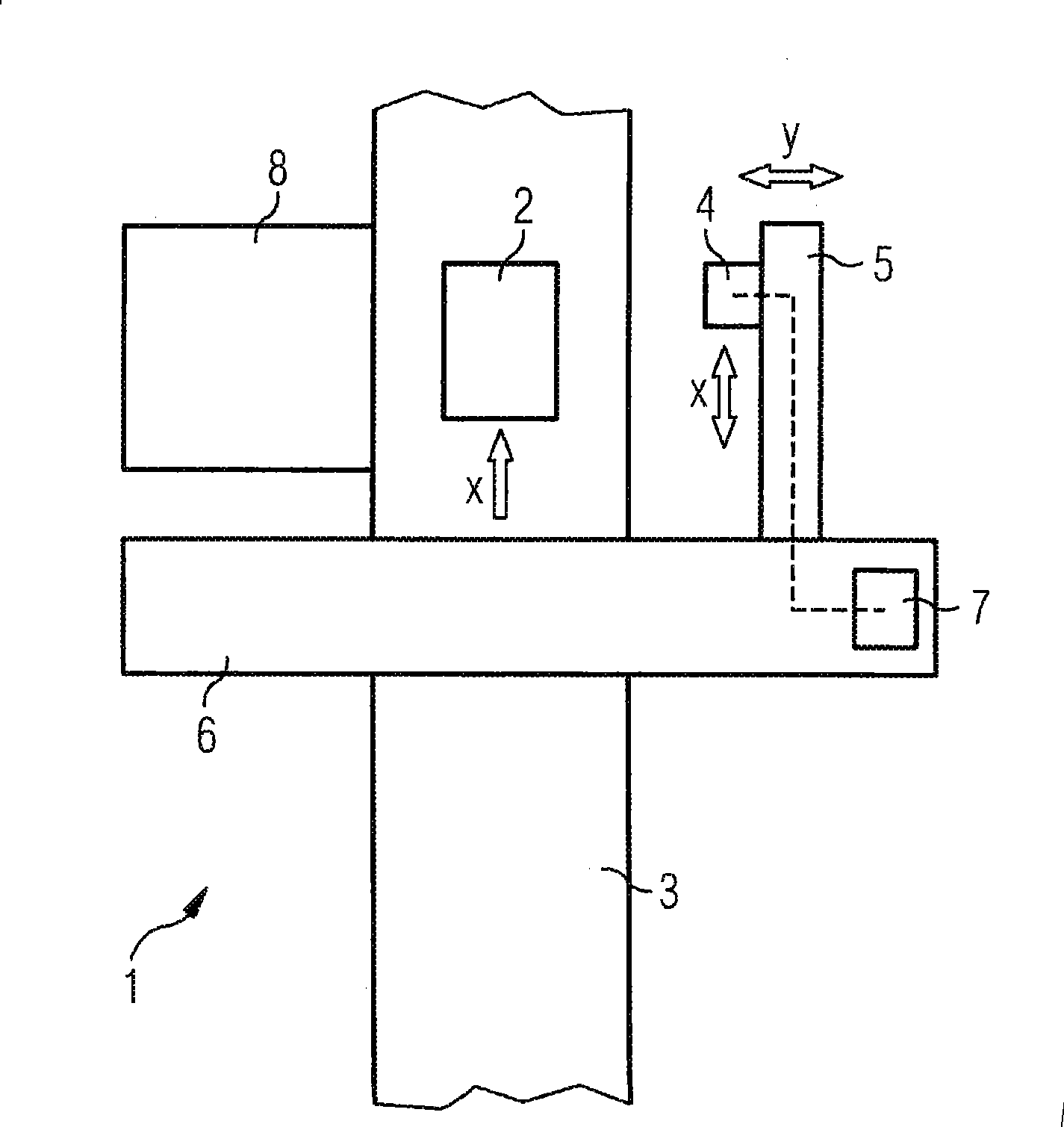

Method for constructing a driver's cab of a commercial vehicle

ActiveCN104340284ALow appearance requirementsAchieved weightVehiclesLoading-carrying vehicle superstructuresEngineeringCommercial vehicle

The invention relates to a method for constructing a driver's cab (1) of a commercial vehicle. The method comprises the steps of: providing individual walls (2-7) of the cab (1) comprising a front wall (2), side walls (3, 4), a rear wall (5 ), a bottom (6) and a roof (7); painting the provided individual walls (2-7); equipping at least one single painted wall (2 to 7) with an equipment element; and joining the single painted walls (2 to 7) to the commercial vehicle cab (1).

Owner:MAN NUTZFAHRZEUGE AG

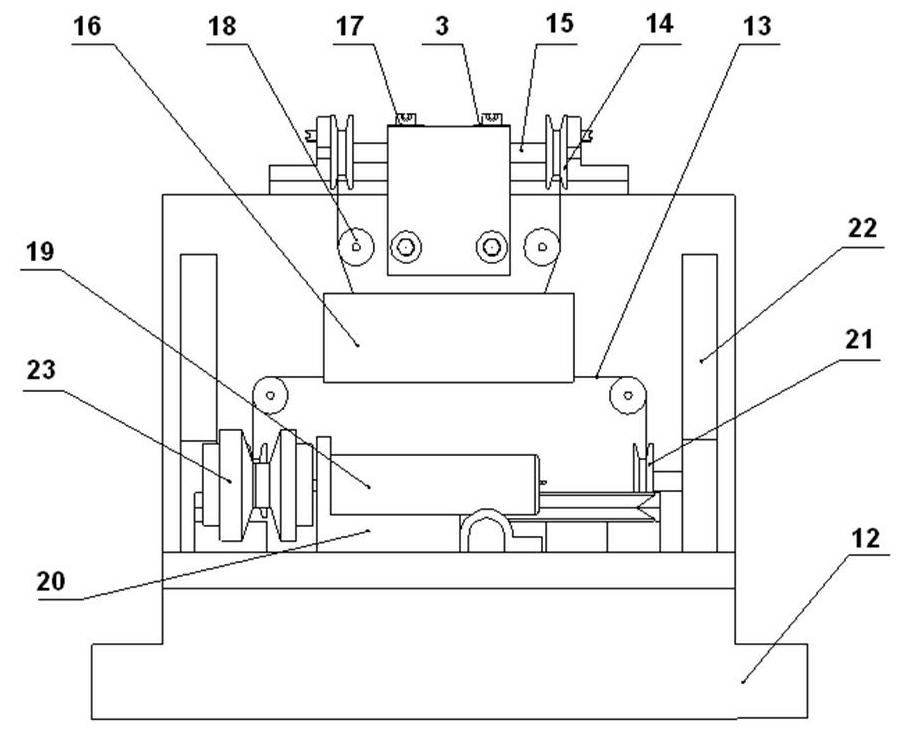

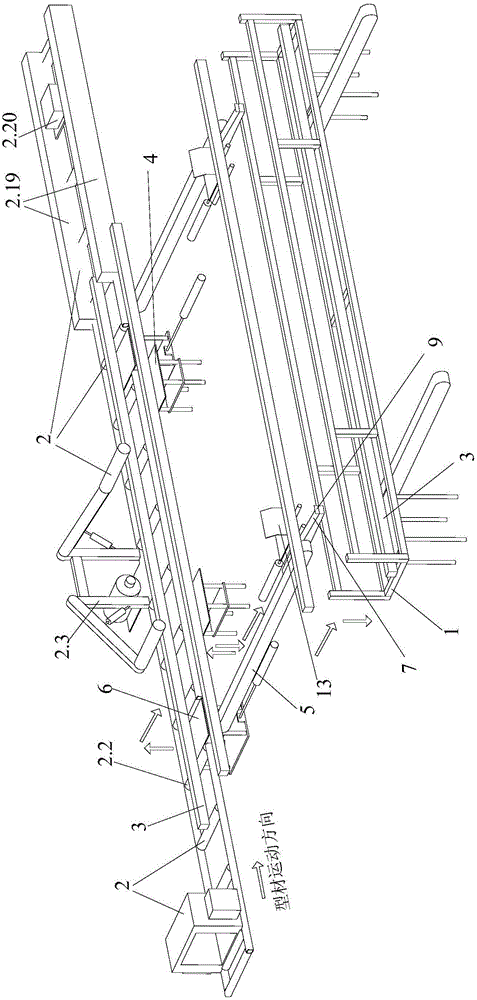

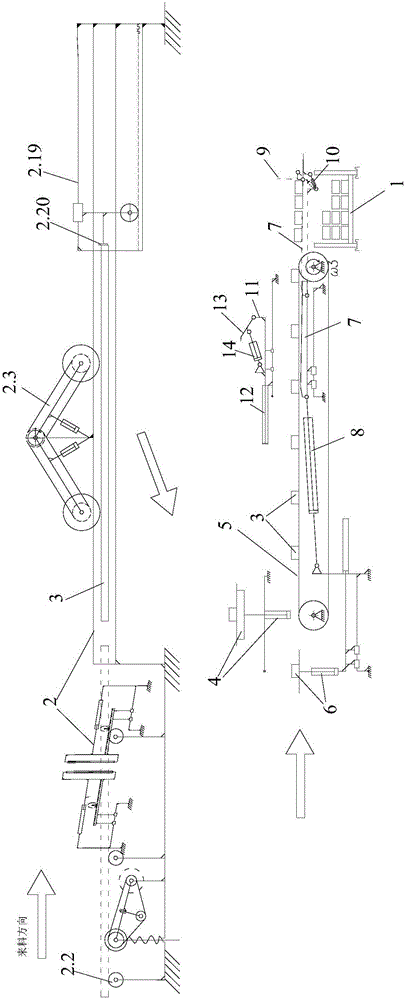

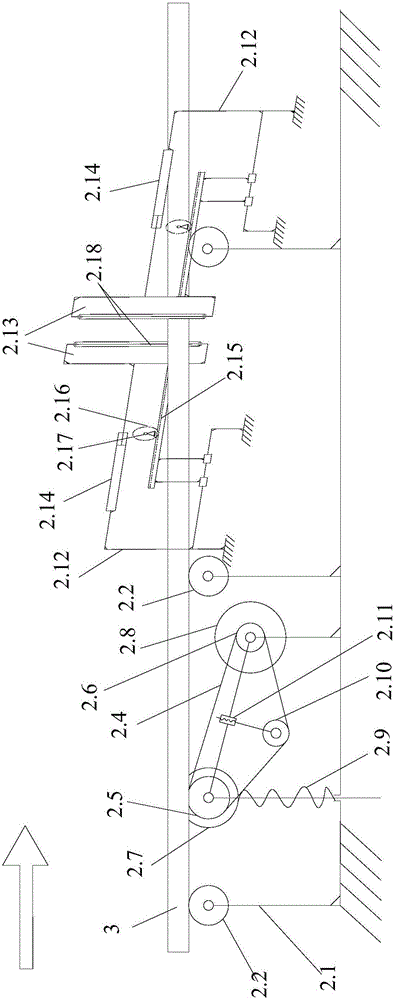

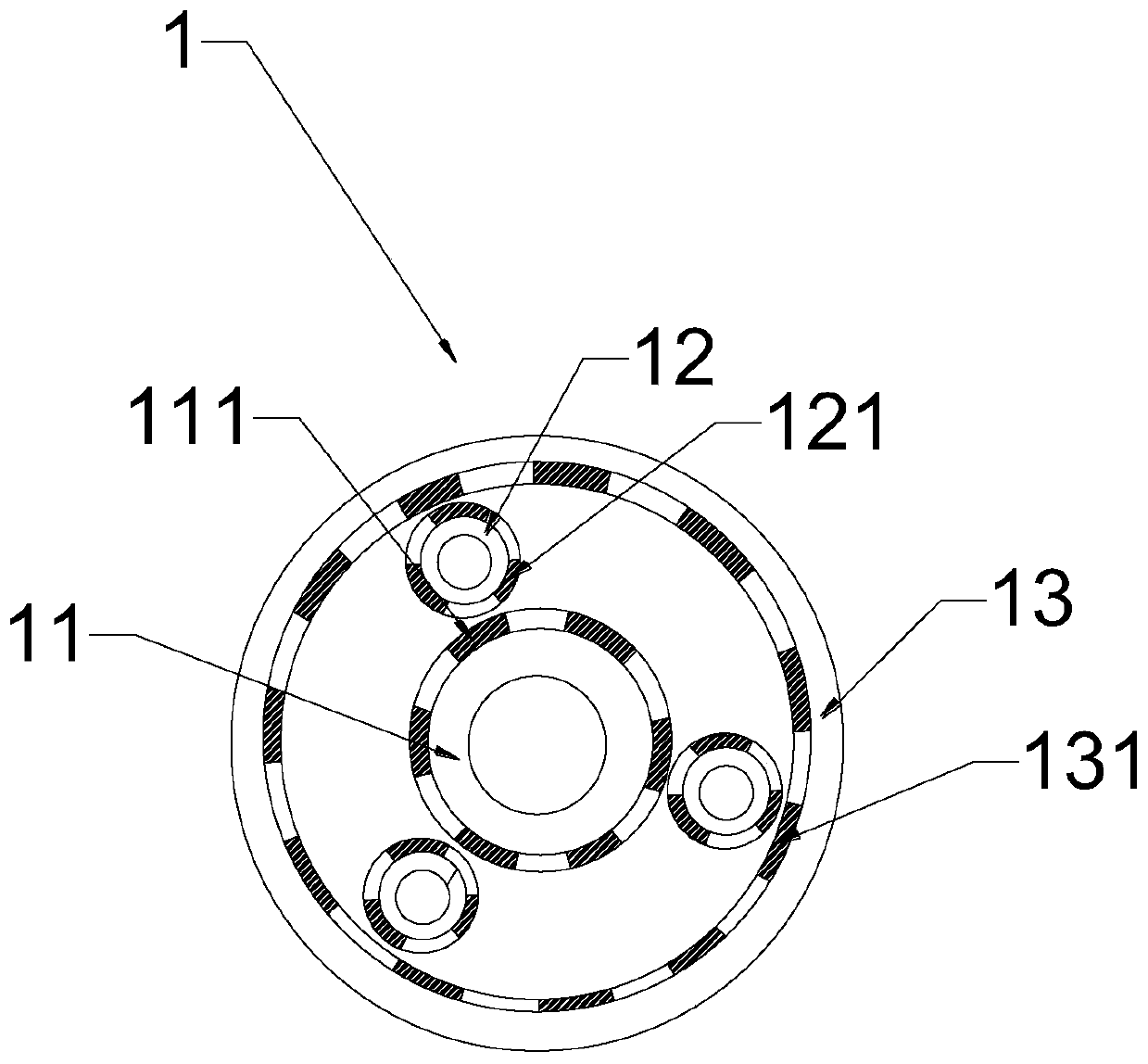

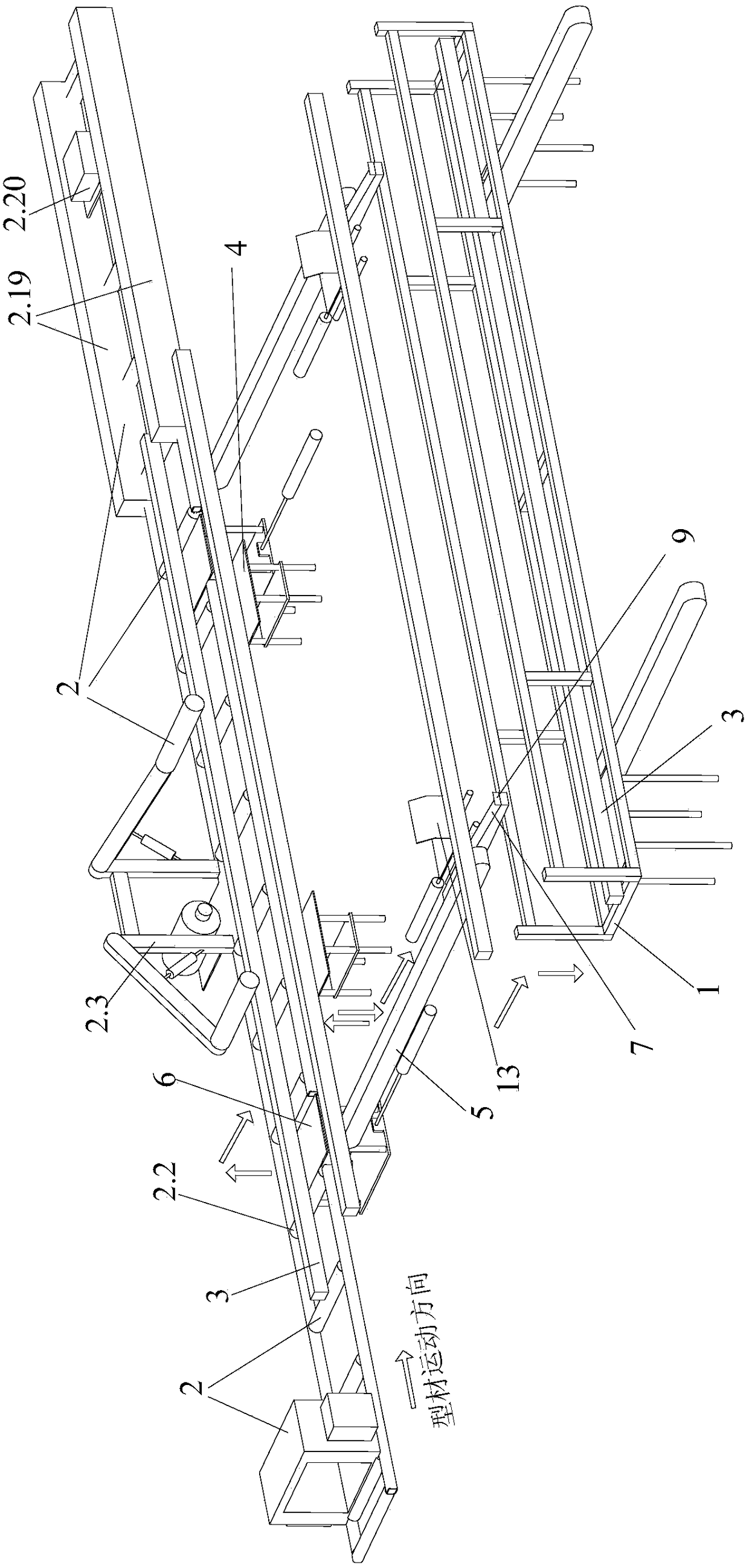

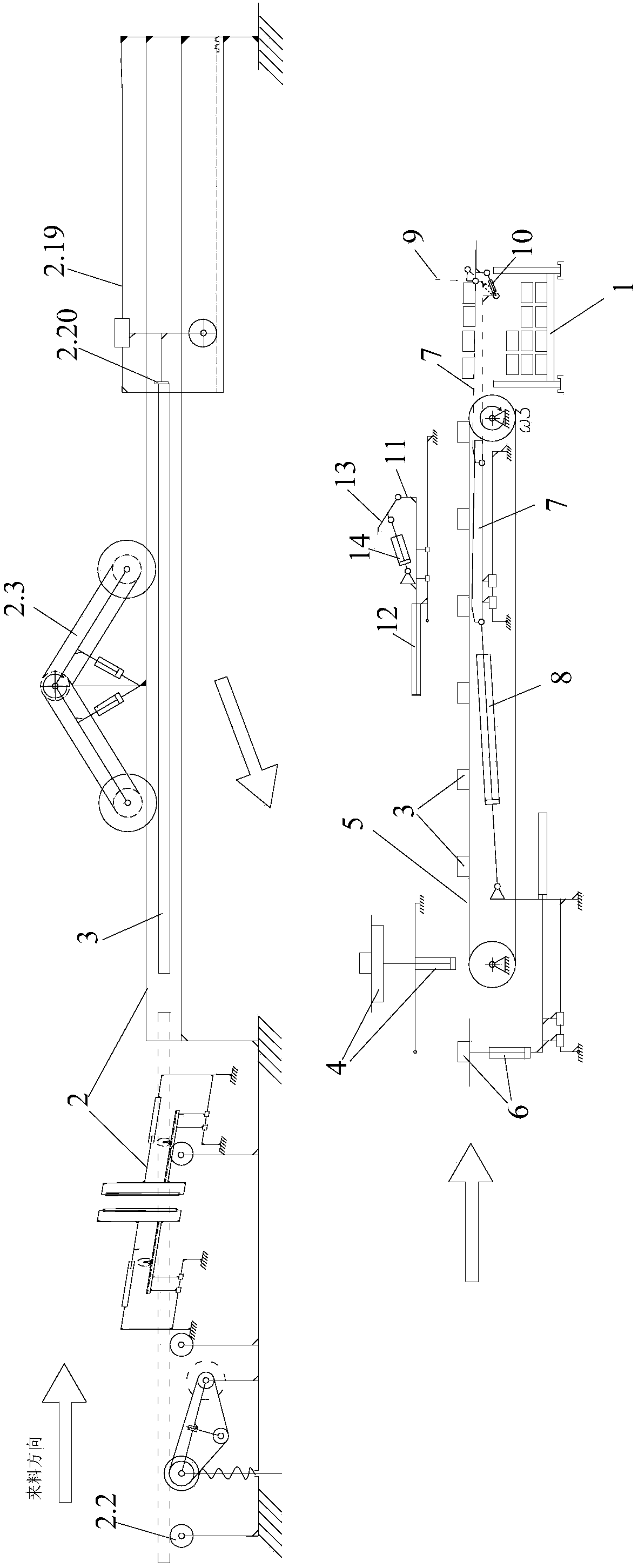

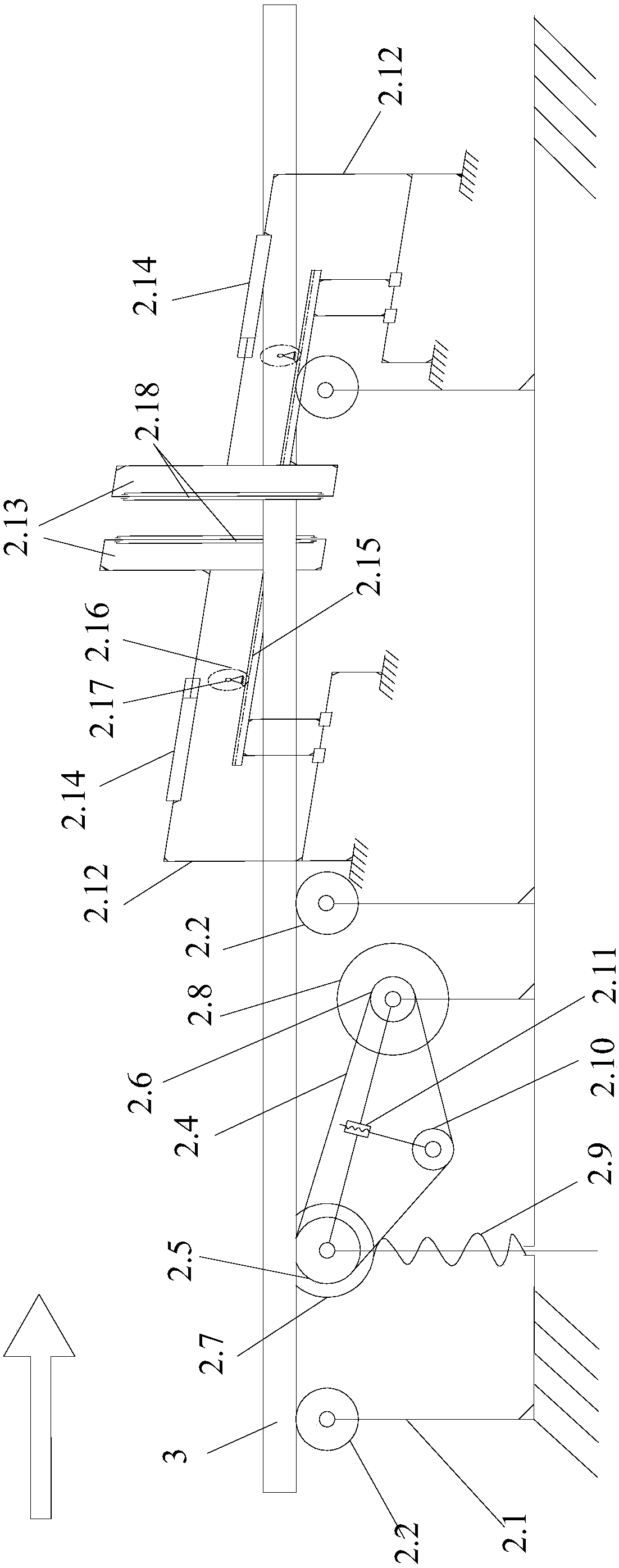

Conveying device for sectional bars

ActiveCN105775762APositioning for easy controlImprove measurement accuracyMeasurement devicesStacking articlesEngineeringAutomation

The invention provides a conveying device for sectional bars. The conveying device comprises a longitudinal sectional bar feeding mechanism, a transverse sectional bar feeding mechanism, a sectional bar sorting mechanism and a control mechanism. The longitudinal sectional bar feeding mechanism is used for measuring the length and the width of the sectional bars and conveying the sectional bars to a transverse conveying station. The transverse sectional bar feeding mechanism is used for measuring the weight of the sectional bars on the transverse conveying station and conveying the sectional bars to a sorting station. The sectional bar sorting mechanism is used for arranging the sectional bars on the sorting station, and therefore the arranged sectional bars can fall into a sectional bar storage frame. The conveying device for the sectional bars is simple in structure, low in cost and high in practicability. The conveying device for the sectional bars conveys the sectional bars and meanwhile can measure the size and the weight of the sectional bars, and a sorting function is achieved. The conveying device for the sectional bars effectively solves the problems that in the current sectional bar machining machine industry, the automation degree is not high, measuring is prone to being disturbed, cost is high, and the production efficiency is low, and therefore the machining efficiency and the machining precision and quality of the sectional bars are improved.

Owner:FOSHAN UNIVERSITY

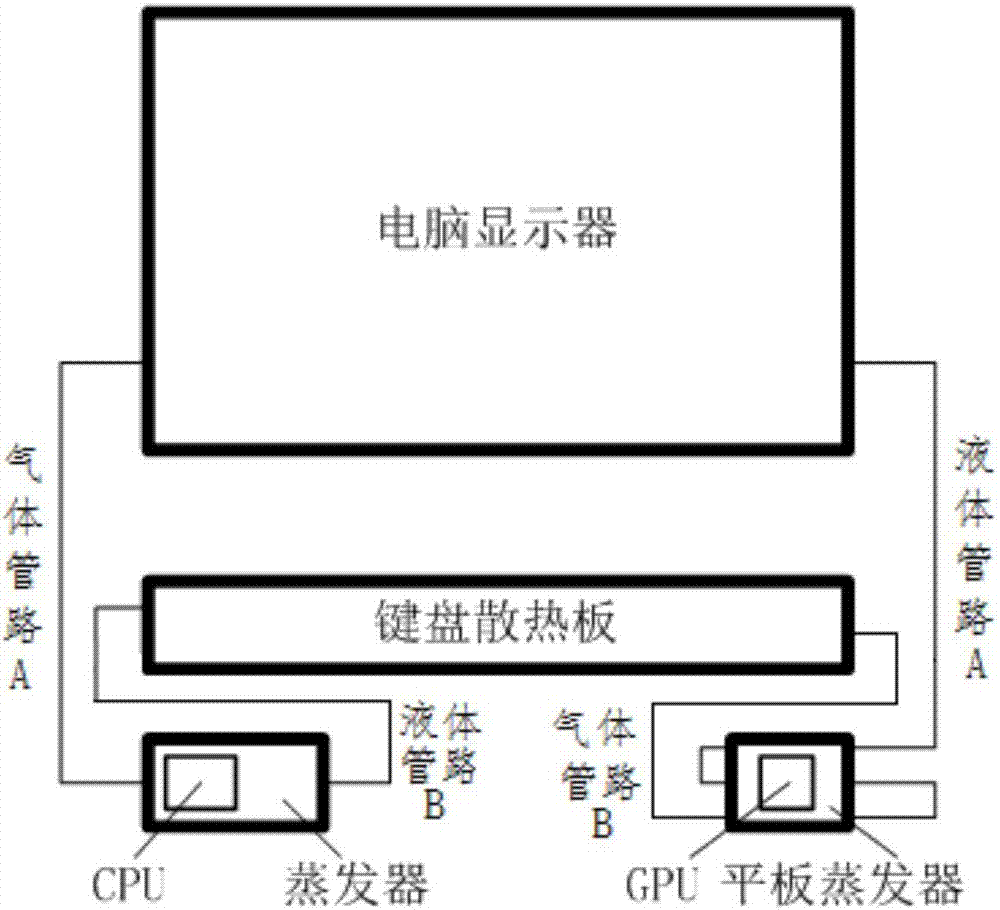

Notebook computer heat radiation system based on tablet loop heat tube

InactiveCN107145205AImprove heat transfer performanceSolve the cooling problemDigital data processing detailsEnergy efficient computingNatural convectionEngineering

The invention discloses a notebook computer heat radiation system based on tablet loop heat tubes. The notebook computer heat radiation system comprises a tablet loop heat tube evaporator, a screen back plate heat radiator, a keyboard bottom plate heat radiator and a tablet evaporator, wherein the tablet loop heat tube evaporator is clung to a computer CPU (Central Processing Unit) chip; steam flows through the screen back plate heat radiator through a pipeline, and then heat is diffused and condensed into a liquid through natural air convection; the liquid flows to the tablet evaporator which is clung to a display card GPU (Graphics Processing Unit) chip and is evaporated into steam; the steam flows to the keyboard bottom plate heat radiator through another pipeline and is cooled into a liquid through natural air convection, and then the liquid flows back to a liquid reservoir of the tablet loop heat tube evaporator. By adopting the heat radiation system, internal layout of a notebook computer is facilitated, a mounting space is effectively reduced, noise caused by a fan can be eliminated as fans and heat radiator components are not used, electric power consumption is reduced, and the standby and lasting time of a computer is prolonged.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

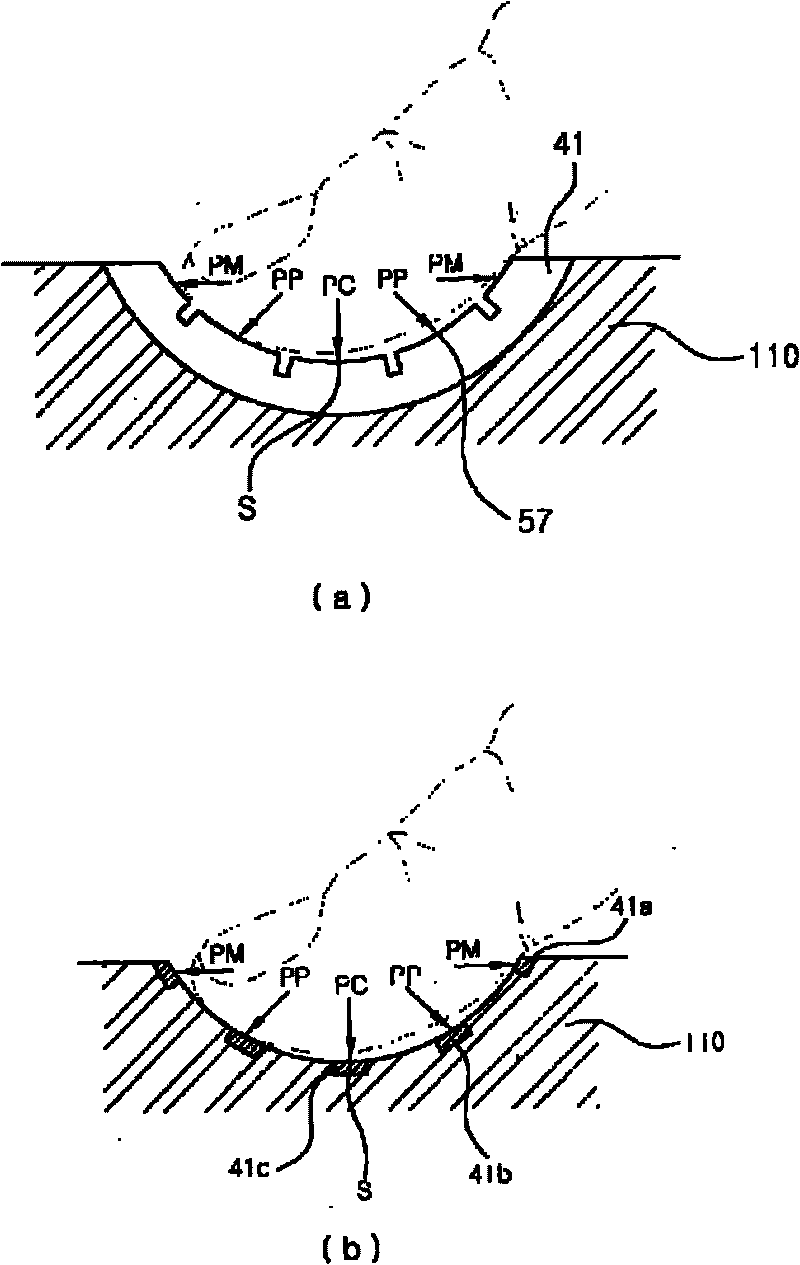

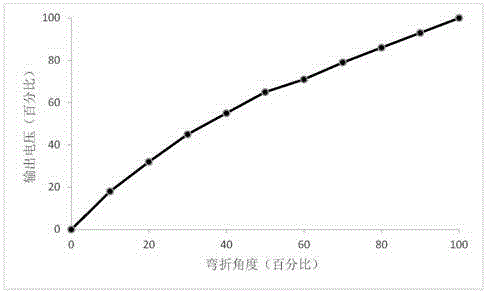

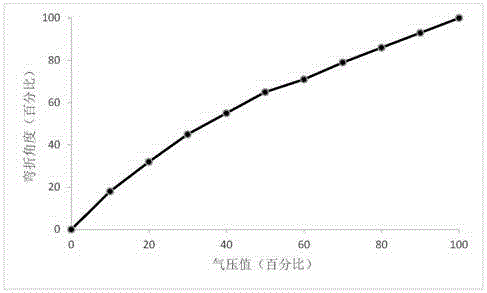

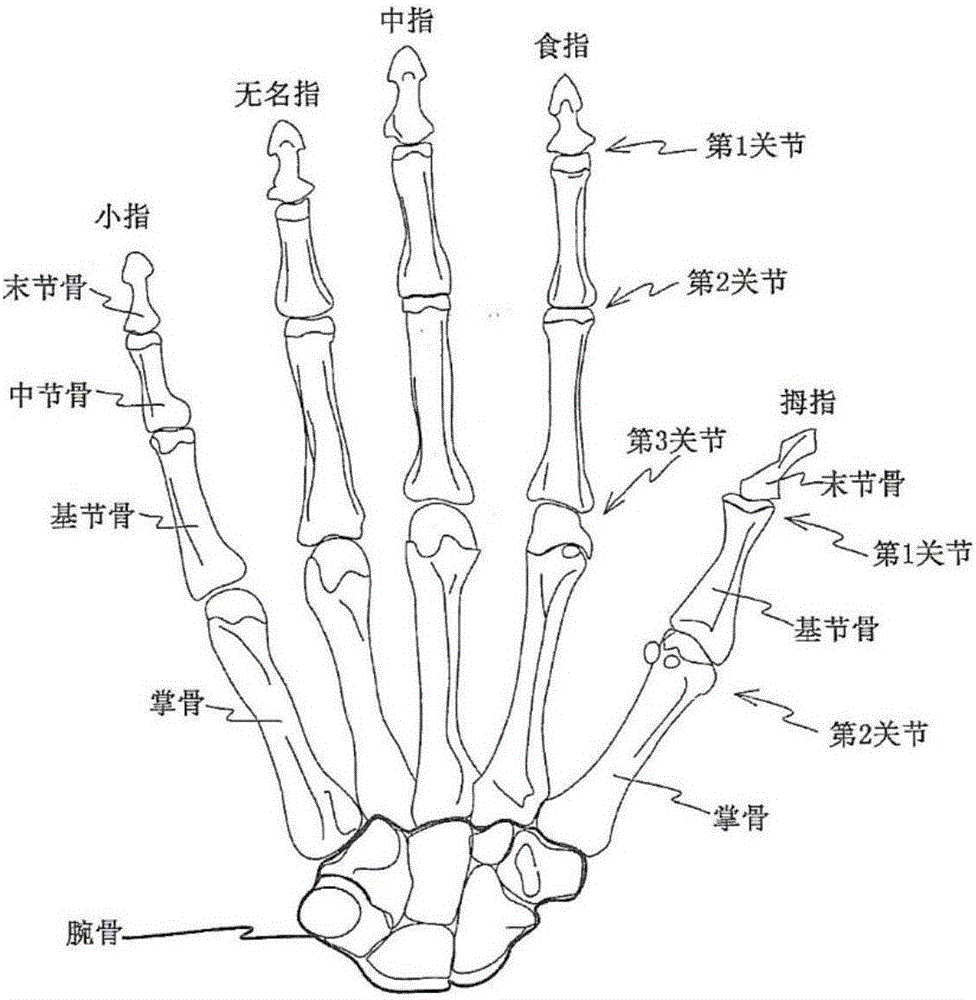

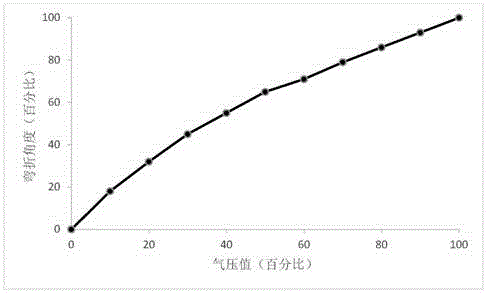

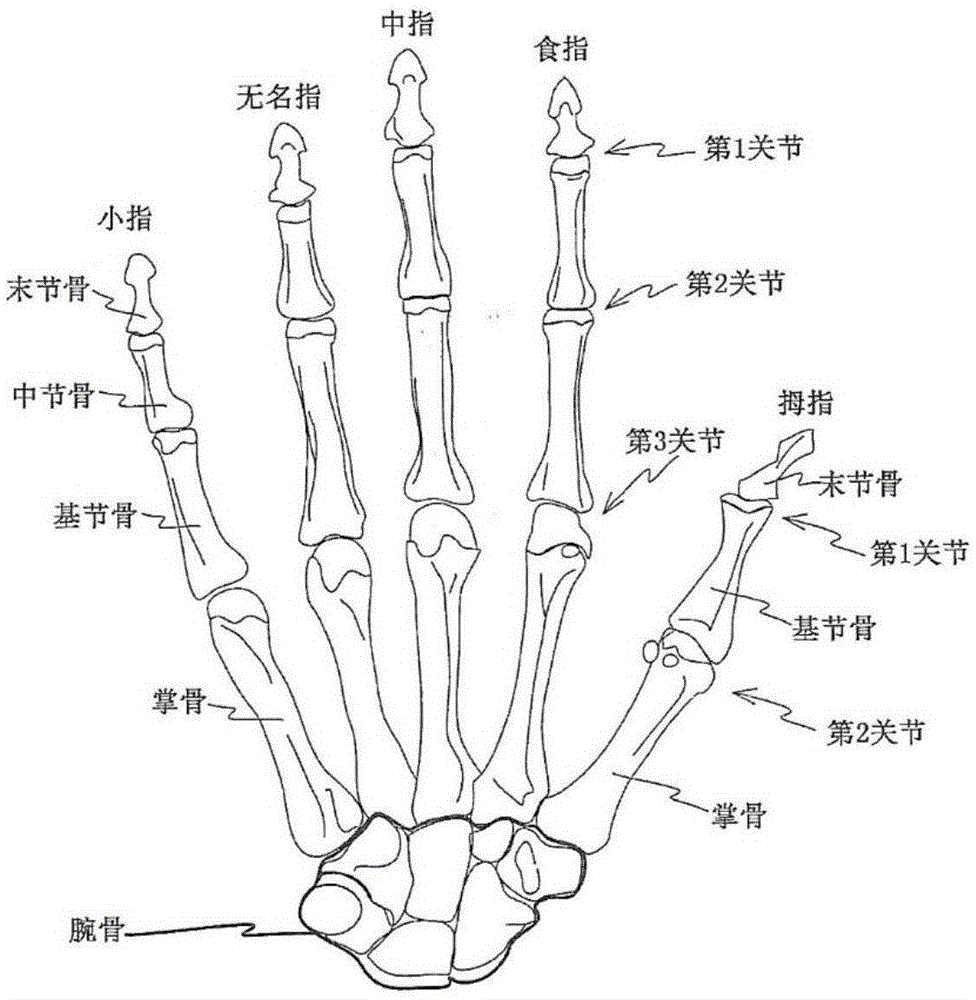

Joint movement assist device independently assisting joint

The invention discloses a joint movement assist device independently assisting a joint, comprising at least one auxiliary structure set.Each auxiliary structure set comprises: at least one freely telescopic airbag; at least two transfer fasteners fastening part of the airbags at two ends and fixing the fastened part of the airbags; at least one corrugated part located between two transfer fasteners on the airbags and not fastened in the part of airbags fastened by the transfer fasteners, wherein the corrugated part telescopes and produces force assisting in joint movement at the premise that the corrugated part is arranged around a joint axis in a direction approximately perpendicular to the joint axis; a distributing tube, one end of which is detachably connected with the airbag and the other end of which is connected with an adjusting portion to adjust air pressure in the airbags; a first wearable portion.In this manner, the joint of a user can be assisted independently, and secondary injury caused by assisting in unmovable joints of the user is avoided.

Owner:ZHONGSHAN CHANGYAO MEDICAL EQUIP CO LTD

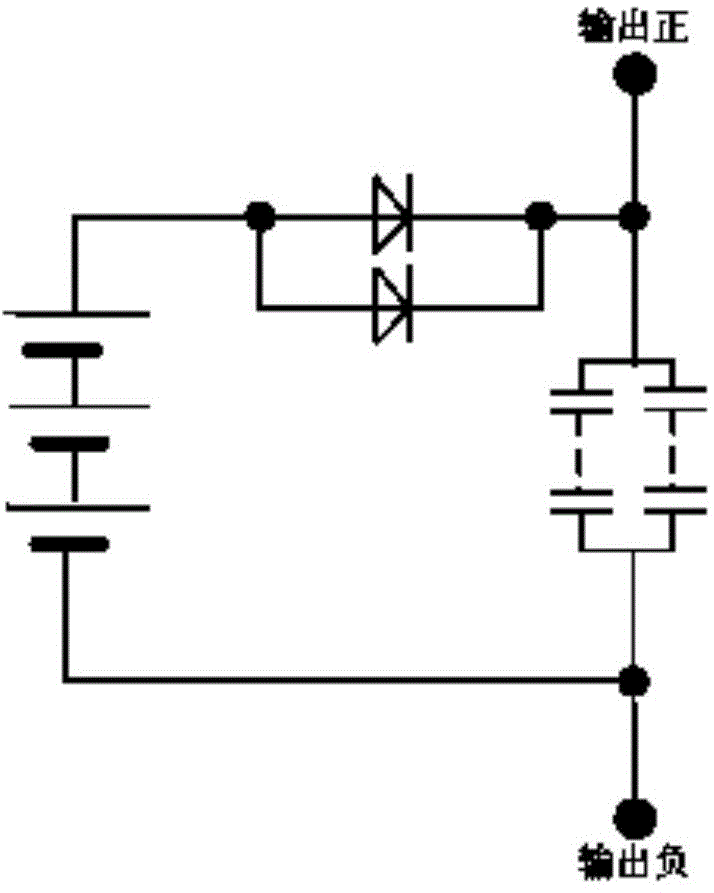

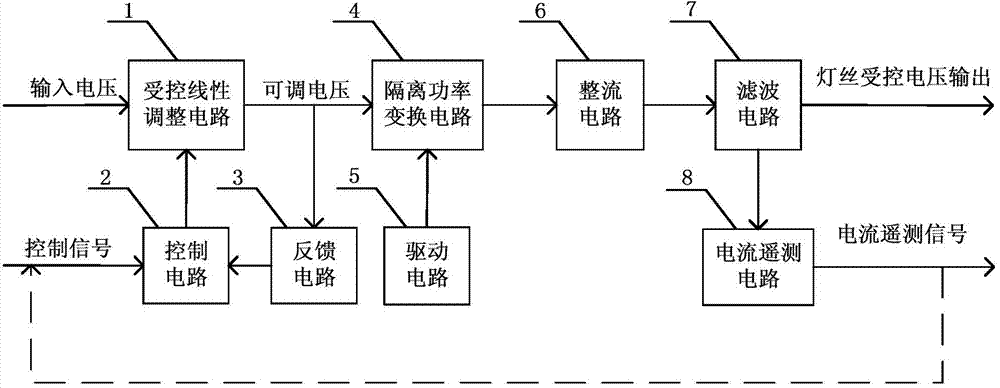

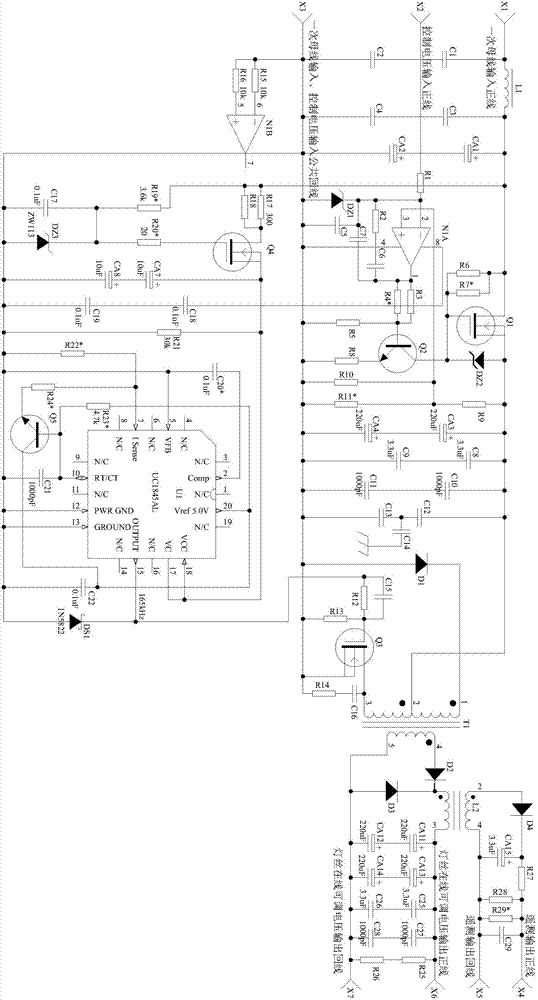

On-line adjustable filament voltage source circuit for magnetic deflection mass spectrometer

ActiveCN103702498AReduce volumeReduce quality problemsElectrical apparatusElectric lighting sourcesLinear regulatorControl signal

The invention belongs to the technical field of power electronics, and particularly relates to an on-line adjustable filament voltage source circuit for a magnetic deflection mass spectrometer. A controlled linear regulator circuit, a current feedback remote metering circuit and a working mode that filament power supply voltage slowly raises to the required working voltage from extremely low working voltage along the action of a control signal are adopted, a method for supplying power by a voltage source replaces a method for supplying power by a constant current source needed because the cold resistance of a filament is far smaller than the hot resistance, and the on-line adjustable filament voltage source circuit has the capacity of adjusting the electron emissivity of the filament online; a power supply circuit of the filament is isolated from other circuits, so that the filament voltage source can be applied to high voltage environment. The on-line adjustable filament voltage source circuit ensures that a filament supply is adjustable online, high in reliability, miniaturized and light.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

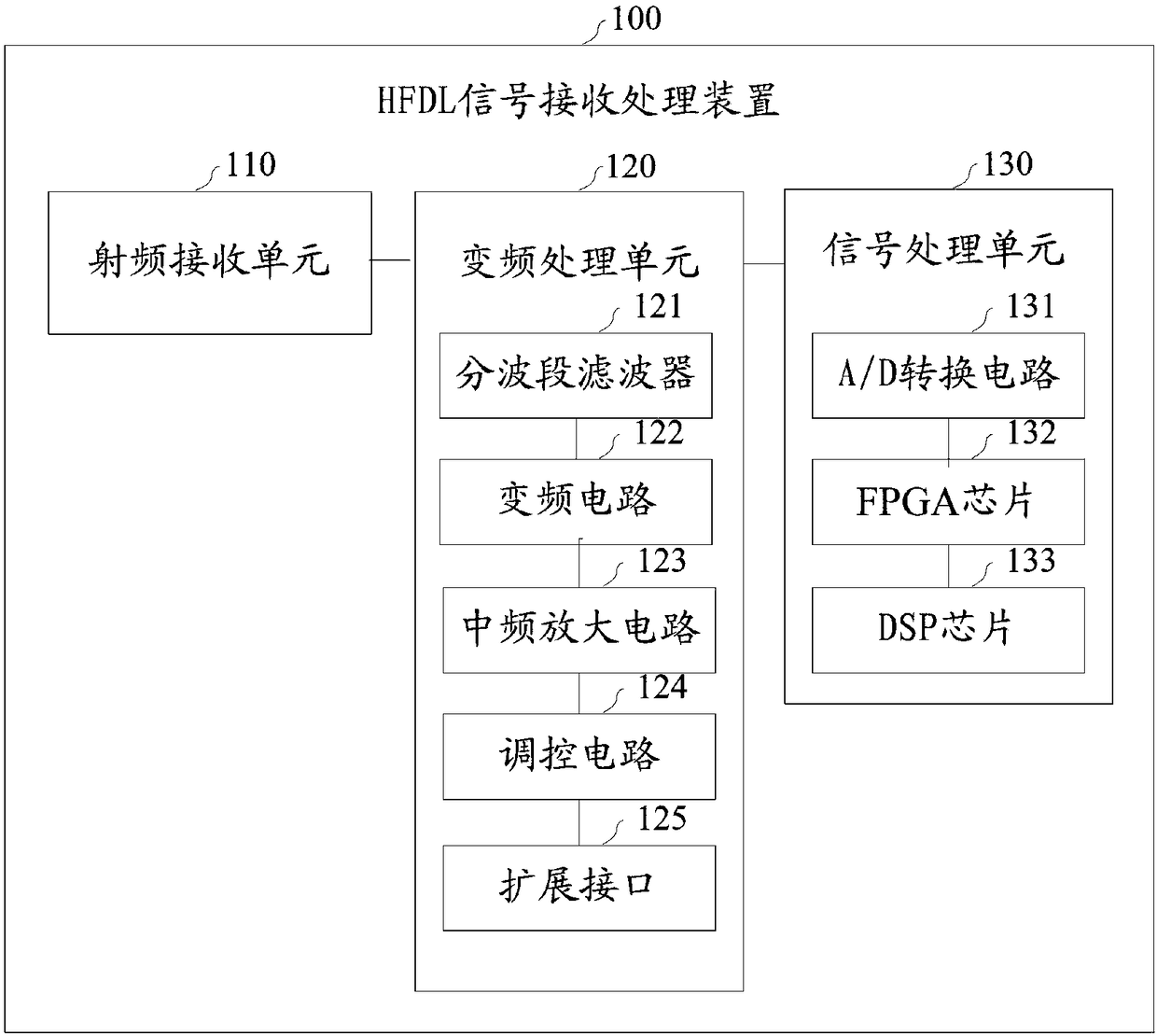

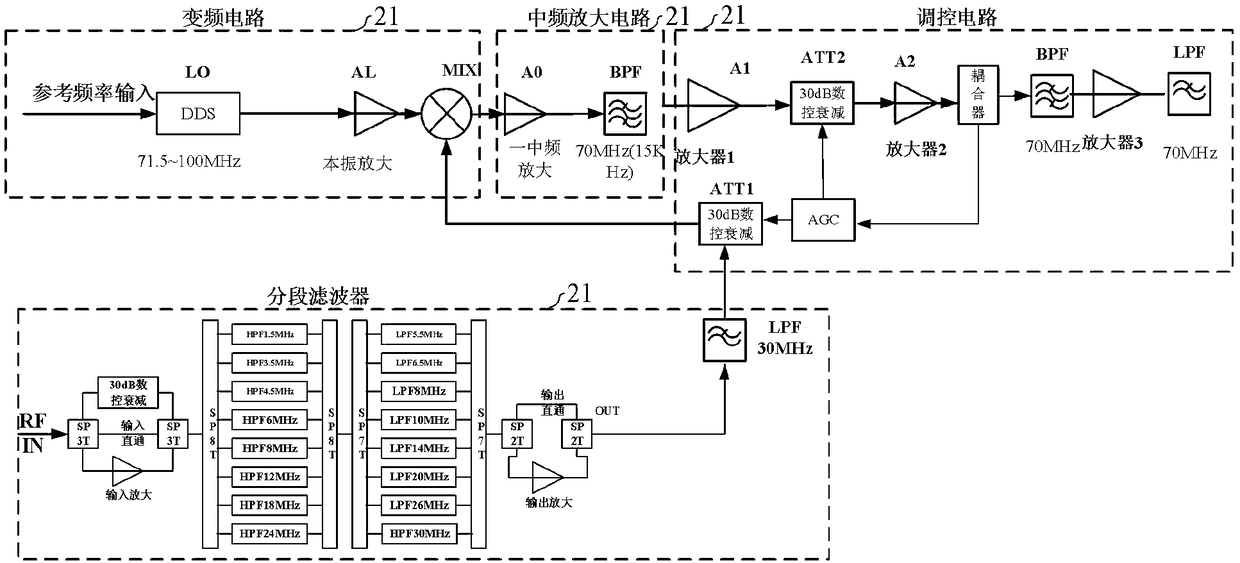

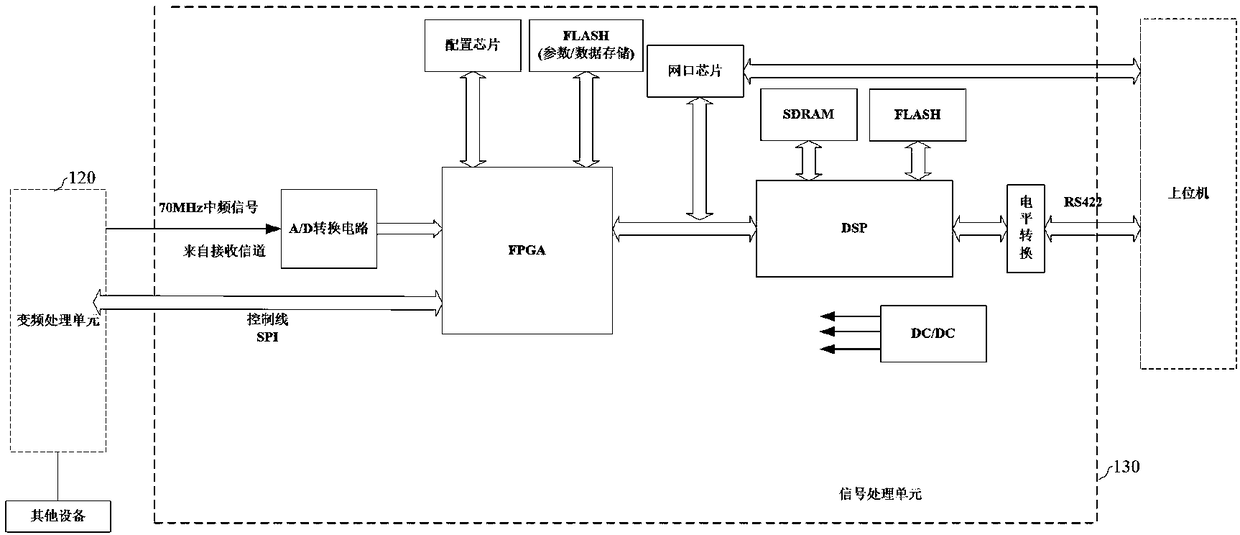

HFDL signal receiving and processing device

ActiveCN108092682AAchieved weightAchieve expensive priceTransmissionDigital down conversionIntermediate frequency

The invention discloses an HFDL signal receiving and processing device. The device comprises a radio frequency receiving unit, a frequency conversion processing unit and a signal processing unit. Theradio frequency receiving unit is used for receiving short wave radio frequency signals of 1.5 MHz to 30 MHz, filtering the received radio frequency signals to remove interference signals outside theworking frequency band, carrying out adaptive gain adjustment, and sending the gain-adjusted radio frequency signal to the frequency conversion processing unit. The frequency conversion processing unit is used for upconverting the radio frequency signal to an intermediate frequency signal of 70 MHz, and sending the intermediate frequency signal to the signal processing unit. The signal processingunit is used for sampling the intermediate frequency signal to acquire a digital signal, digitally downconverting, detecting, demodulating and Turbo-equalizing the digital signal, encapsulating the processed data, and sending the data to a host computer through a network interface. According to the invention, HFDL signals are received and processed; the HFDL signal receiving and processing devicehas the advantages of simple structure, small size, low cost, portability, convenient deployment, unlimited deployment number, long interception distance and large dynamic range; and intercepted signals have the advantages of comprehensive type and excellent performance.

Owner:36TH RES INST OF CETC

Satellite-borne dual-band four-channel rotary joint

ActiveCN112909450ARealize stable transmissionReduce stable transmission problemsWaveguide type devicesHigh isolationControl theory

The invention discloses a satellite-borne dual-band four-channel rotary joint which comprises a first single-waveguide rotor, a first dual-waveguide stator, a dual-waveguide rotor, a second dual-waveguide stator and a second single-waveguide rotor. The first single-waveguide rotor, the double-waveguide rotor and the second single-waveguide rotor are rotors, and the first double-waveguide stator and the second double-waveguide stator are stators; the first double-waveguide stator is arranged between the first single-waveguide rotor and the double-waveguide rotor and is supported and connected through a bearing, the second double-waveguide stator is arranged between the second single-waveguide rotor and the double-waveguide rotor and is supported and connected through a bearing, and the rotors and the stators can rotate relatively. The dual-band four-channel rotary joint is a Ka-high-band four-channel rotary joint and a K-high-band four-channel rotary joint and has the advantages of being high in working frequency and large in number of channels, the channels are independent of one another due to the concentric stacking structure, and the requirement for high isolation between the channels is met.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

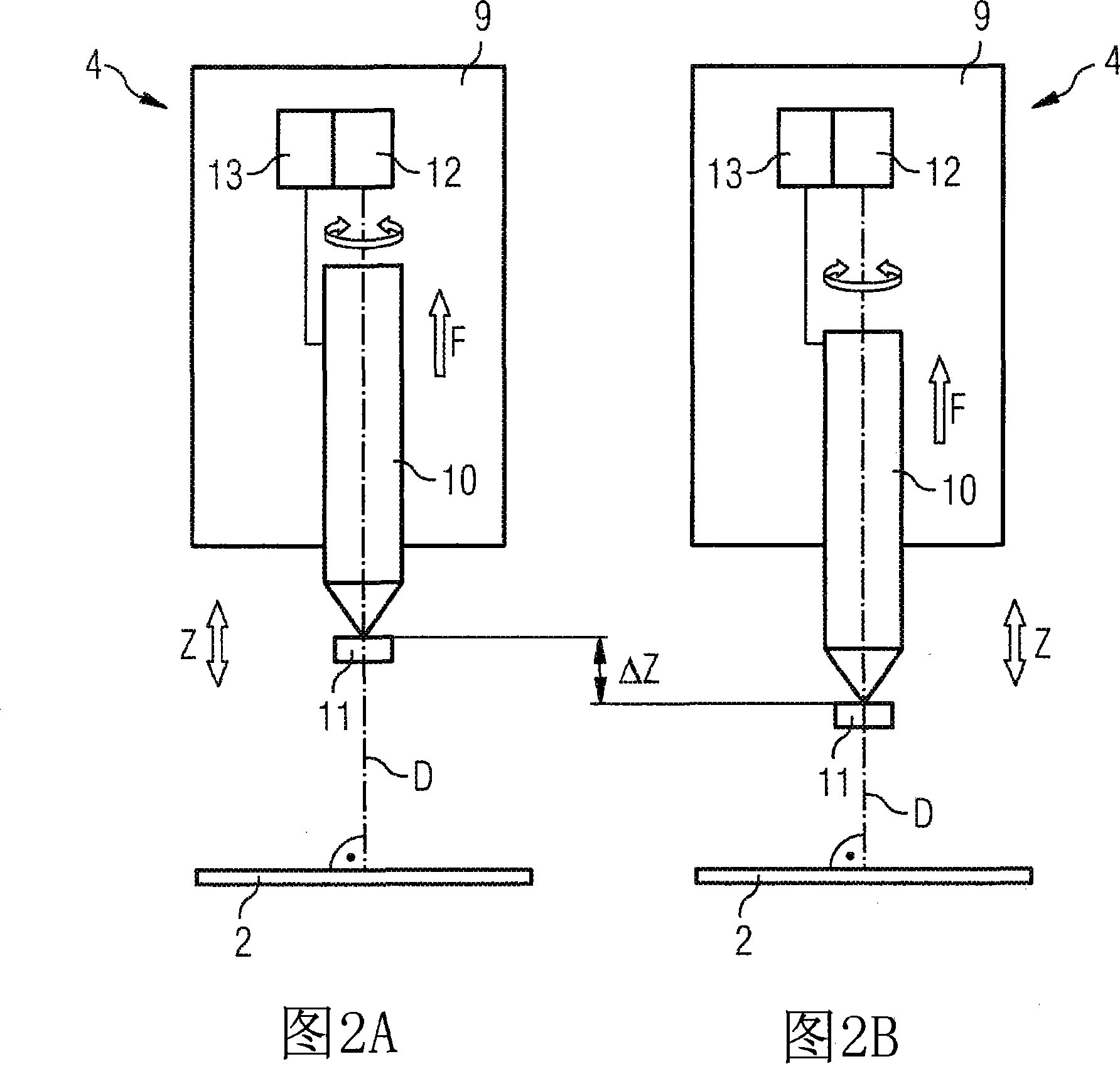

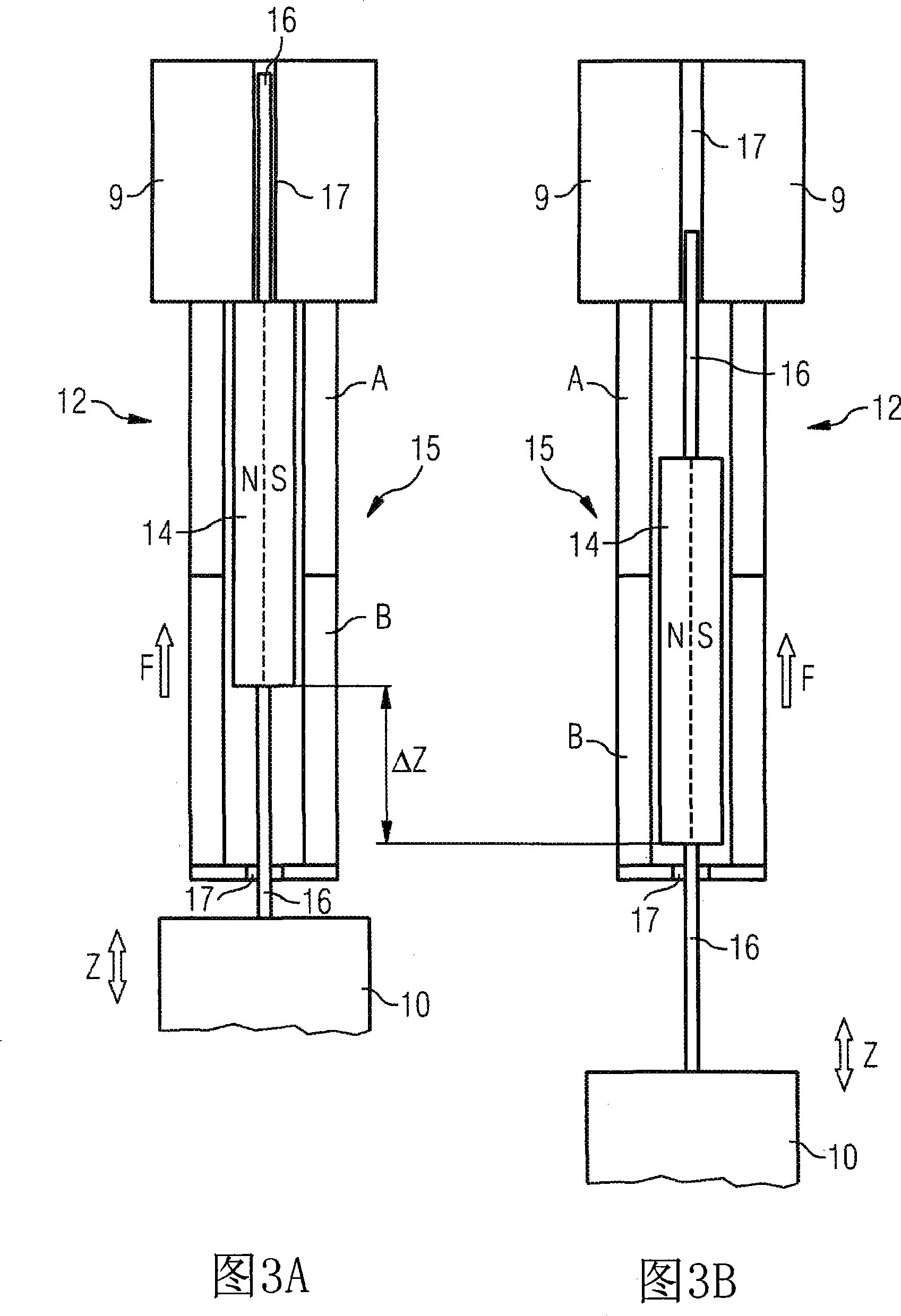

Placement head comprising a readjusting mechanism, and placement robot

InactiveCN101366327AHigh adjustment accuracyImprove dynamic characteristicsElectrical componentsMagnetic fluxMagnet

A placement head (4) comprises a holding device (10) for holding components (11) and is received on a housing (9) so as to be displaced in a direction of displacement between a rest position and a working position, the rest position and the working position being interspaced by a travel path (Delta z) in the direction of displacement.; The placement head also comprises a readjusting mechanism (12) with a permanent magnet (14) which is magnetized at a right angle to the direction of displacement, a magnetic return path element (15) which interacts with the permanent magnet (14) in such a manner as to generate magnetic flux, the permanent magnet (14) being displaceable by the travel path (Delta z) in the direction of displacement relative to the magnetic return path element (15), and the magnetic return path element (15) comprising at least two sections (A, B) of different magnetic resistance in the direction of displacement and being configured in such a manner that the permanent magnet (14) overlaps at least two sections (A, B) at a time of the magnetic return path element (15) when it is displaced across the travel path (Delta z).; The readjusting mechanism (12) is coupled to the housing (9) and the holding device (10) in such a manner that the readjusting mechanism (12) exerts a readjusting force (F) on the holding device (10) across the travel path (Delta z), said readjusting force forcing the holding device (10) into the rest position.

Owner:ASM ASSEMBLY SYST GMBH & CO

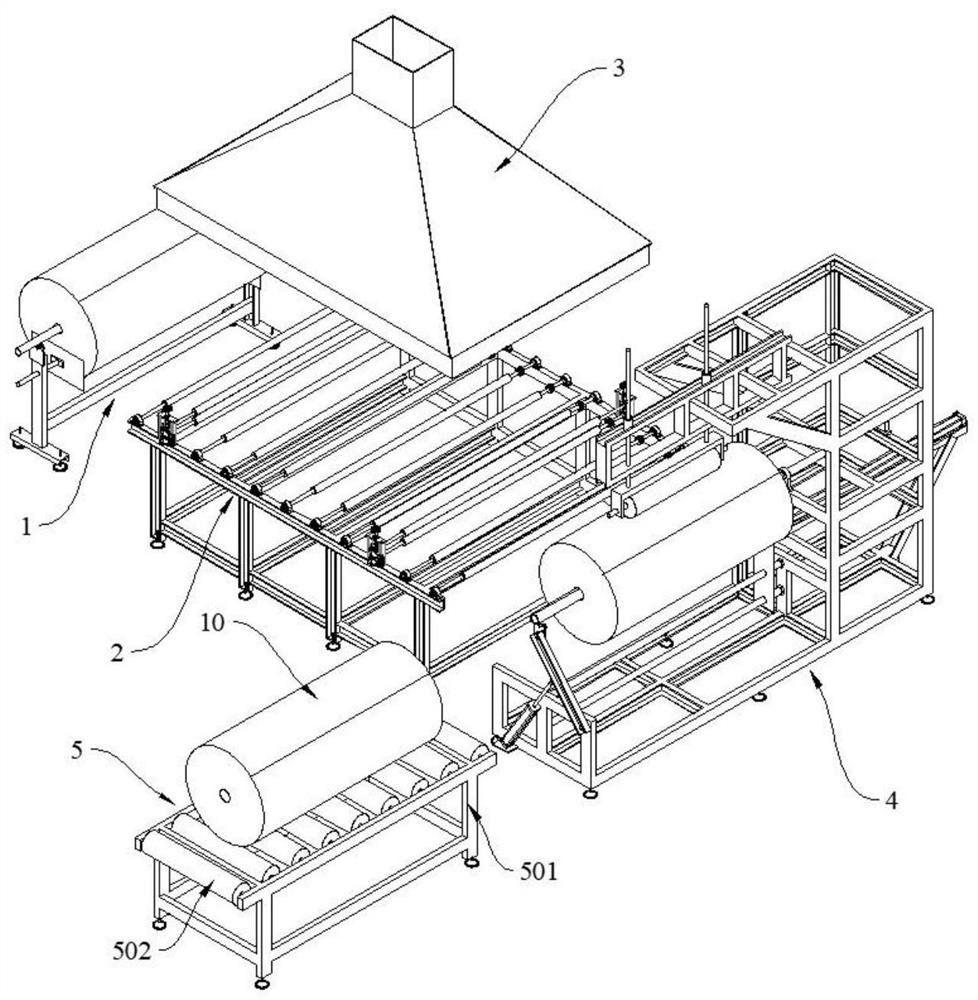

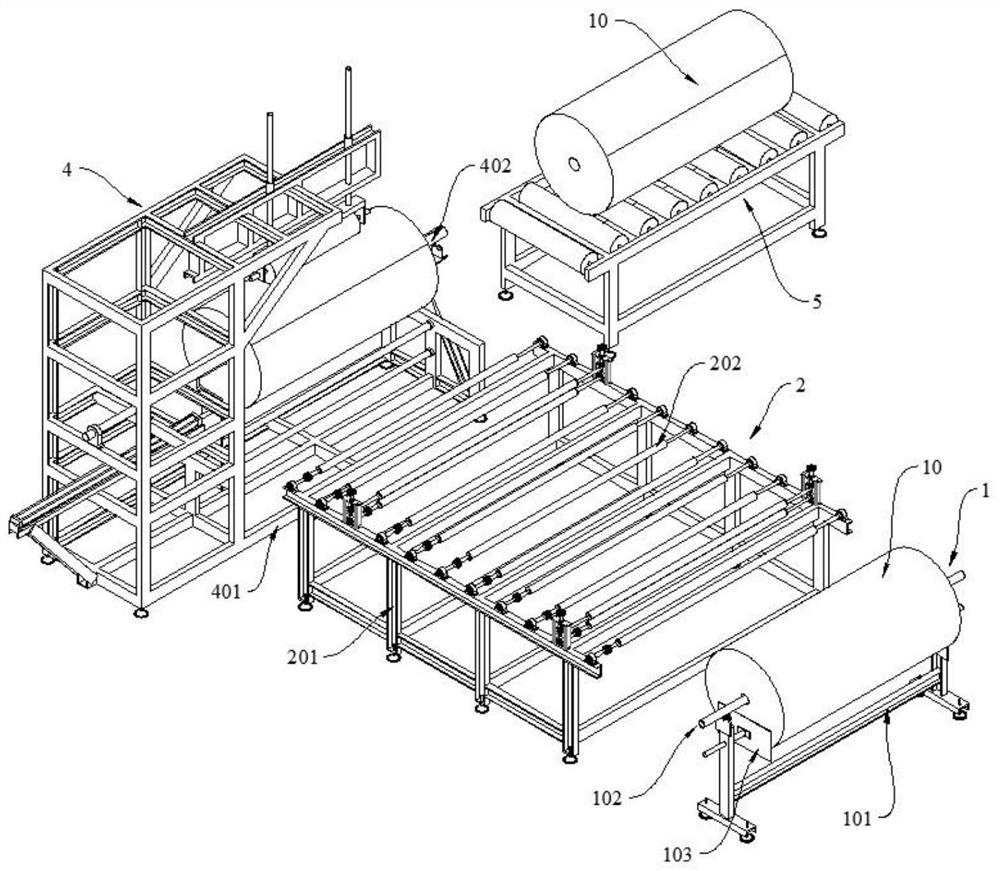

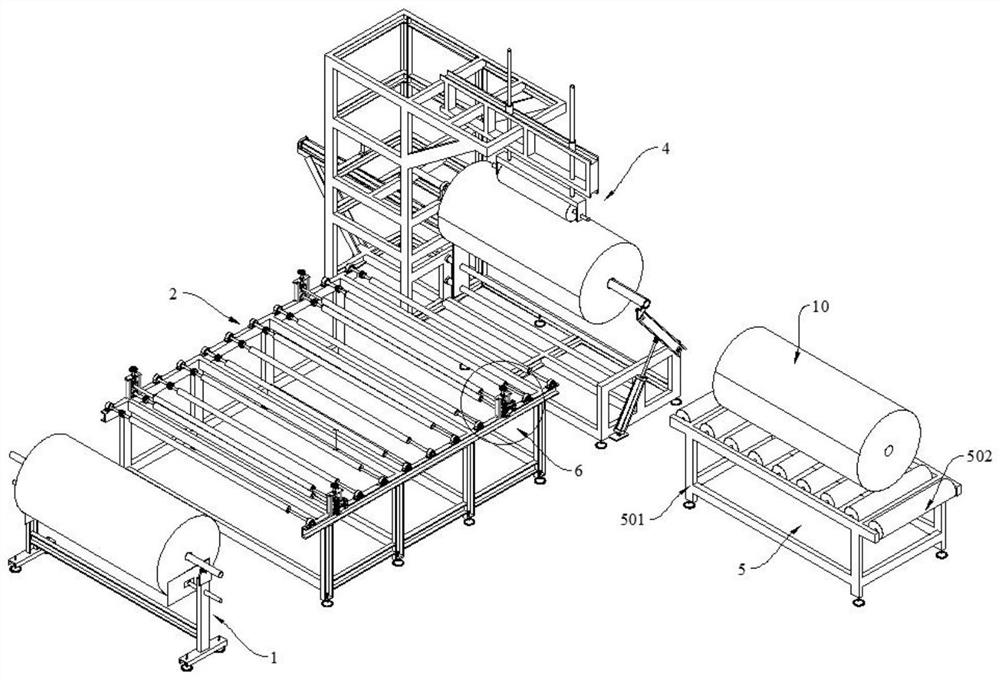

Rewinding device for aerogel composite coiled material and operation method

PendingCN113651155AImprove production efficiency and product qualityReduce damageDirt cleaningCleaning using gasesTransfer mechanismManufacturing engineering

The invention discloses a rewinding device for an aerogel composite coiled material and an operation method, and relates to the technical field of aerogel composite coiled material production. The rewinding device comprises an unwinding mechanism, a conveying mechanism, a dust collection mechanism, a winding mechanism and a transferring mechanism, wherein the unwinding mechanism comprises an unwinding support, a first roll shaft is fixedly installed on the upper side of the unwinding support, the conveying mechanism comprises a conveying support, a plurality of second roller shafts are fixedly installed on the upper side of the conveying support, a plurality of transmission assemblies are further fixedly installed on the upper side of the conveying support, the winding mechanism comprises a winding support and a winding roller shaft, one end of the winding roller shaft is fixedly installed on one side face of the winding support, and a pressing assembly and a discharging assembly are fixedly installed on the winding support. By arranging the conveying mechanism and the winding mechanism, the operation that an aerogel composite coiled material needs to be manually spread for heat dissipation and then manually wound in an existing production process is avoided, time and labor are saved, comprehensive inspection of a product is facilitated, and the production efficiency and the product quality are improved.

Owner:安徽弘徽科技有限公司

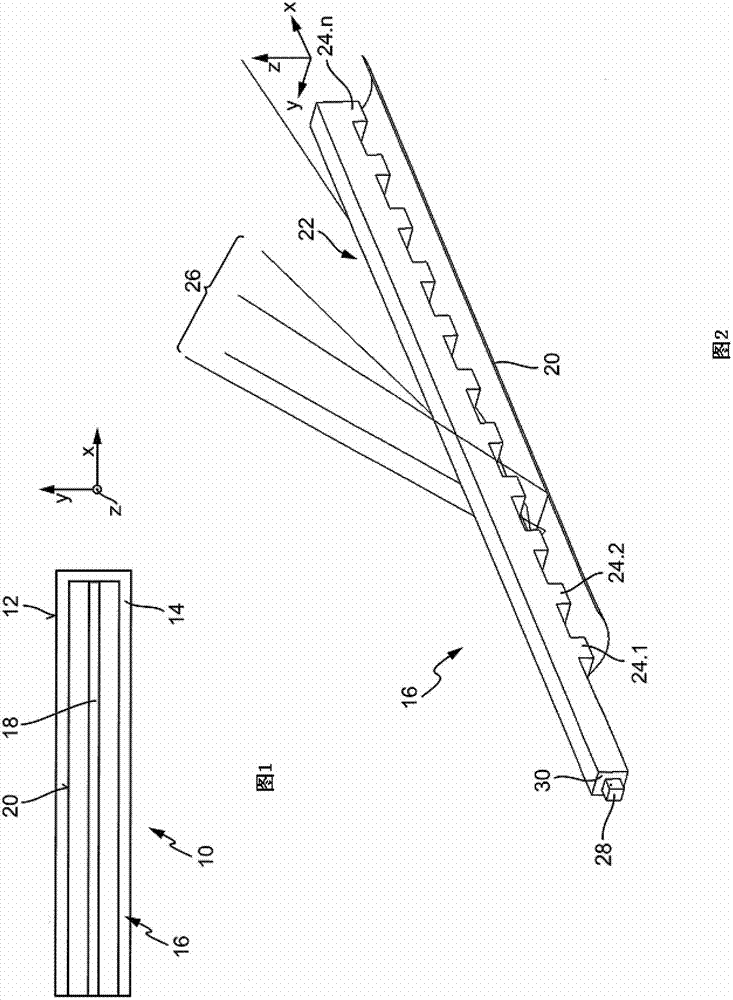

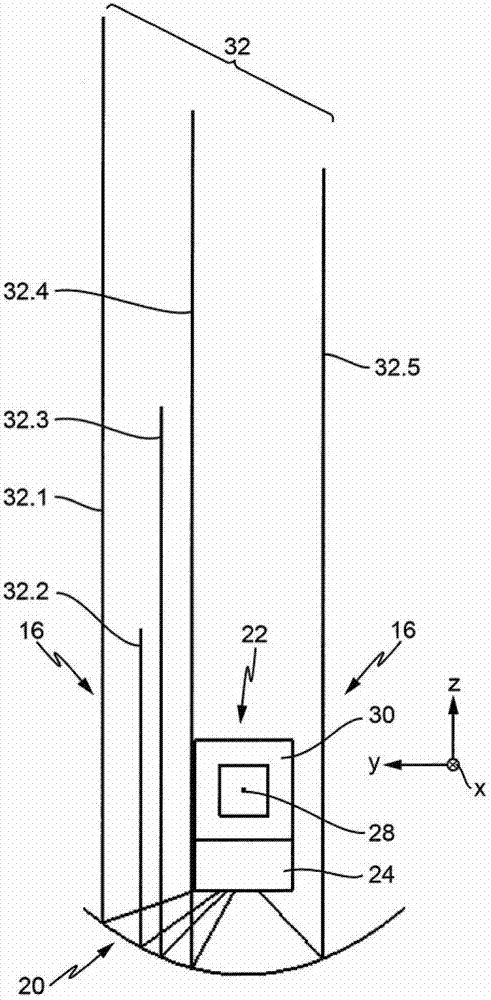

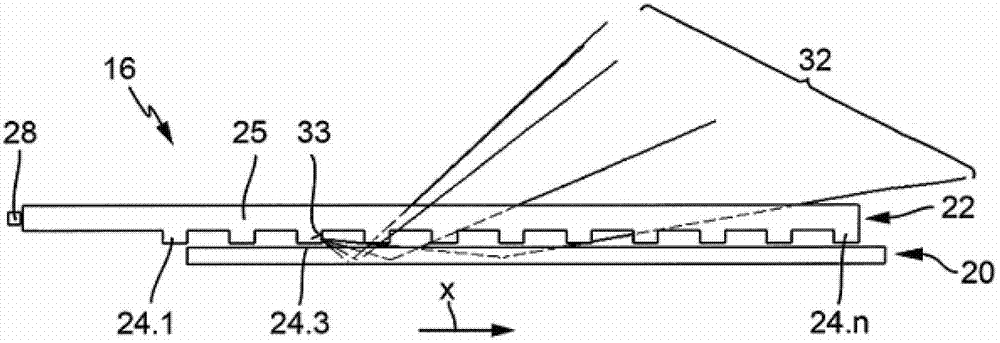

Motor vehicle lighting device for producing band-shaped light-emitting surface

ActiveCN102818202AFew partsLow costMechanical apparatusOptical signallingLight equipmentOptical Module

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

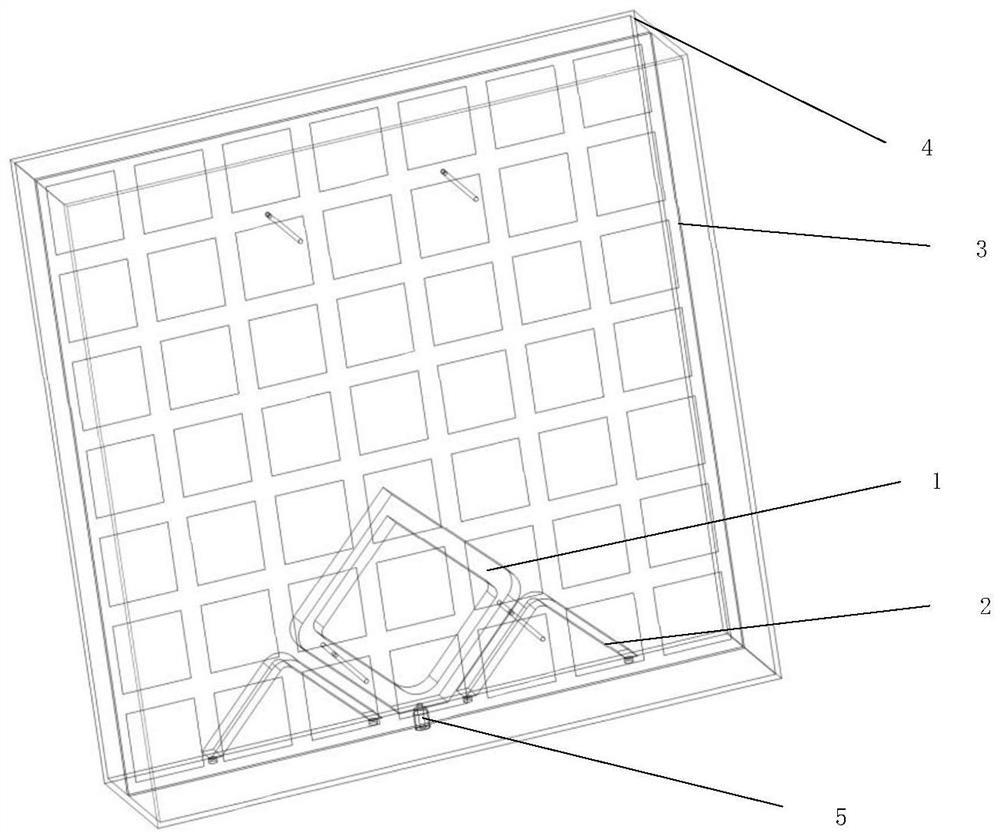

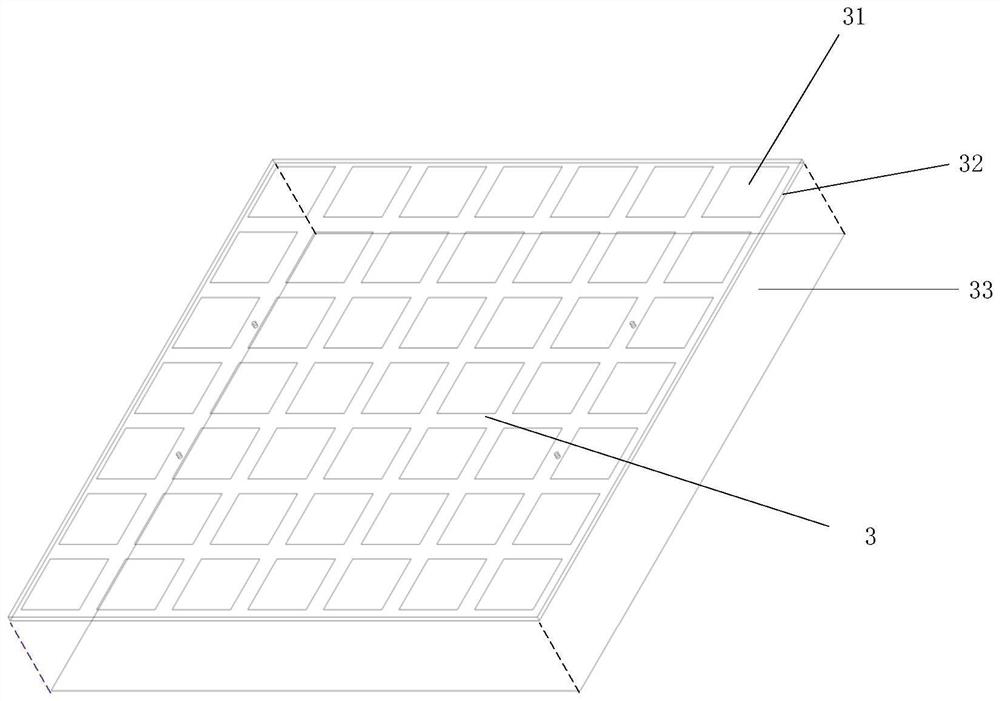

Broadband low-profile miniaturized AMC cavity monopole antenna

ActiveCN114374092AAchieved weightReduce weightSimultaneous aerial operationsRadiating elements structural formsSquare arrayAntenna bandwidth

The broadband low-profile miniaturized AMC cavity monopole antenna comprises a monopole antenna body, parasitic structures, a broadband AMC structure and a metal cavity, the monopole antenna body is installed on the side wall of the cavity, the parasitic structures are located on the two sides of the monopole antenna body and are flush with the opening face of the cavity, and the broadband AMC structure is a square patch type AMC structure with an air layer. The dielectric substrate is located between the monopole antenna and the bottom surface of the cavity, a square array is printed on the dielectric substrate, and an air layer is arranged between the dielectric substrate and the bottom surface of the cavity. According to the invention, the monopole and the parasitic structure are placed on the side wall of the cavity, so that wide beam coverage in the broadband of the antenna is realized, the space of the cavity is effectively utilized, and miniaturization and light weight of the antenna are realized; moreover, based on the broadband AMC structure, the profile of the antenna is reduced by 40% under the condition of keeping 32% bandwidth of the cavity monopole antenna, and the whole antenna has good impedance and radiation characteristics in a small-size cavity.

Owner:XIDIAN UNIV

Wear-resistant and heat-resistant aluminum alloy material for mobile phone shell and preparation method thereof

InactiveCN108425045AImprove corrosion resistanceImprove thermal conductivityWear resistantHeat resistance

The invention discloses a wear-resistant and heat-resistant aluminum alloy material for a mobile phone shell and a preparation method thereof. The ear-resistant and heat-resistant aluminum alloy material comprises the following components in percent by mass: 0.65-0.9% of Li, 1.2-2% of Mg, 0.04-0.1% of B, 0.15-0.32% of Zn, 0.25-0.4% of Mn, 2.5-3.2% of Si, 0.1-0.2% of Ti, 0.1-0.2% of Fe, 0.8-1.8% ofCu, 0.08-0.15% of Nb, 0.08-0.14% of Mo, 0.01-0.03% of Re, 0.05-0.1% of Ce and the balance of Al and unavoidable impurities. According to the wear-resistant and heat-resistant aluminum alloy materialfor the mobile phone shell and the preparation method thereof, provided by the invention, the wear-resistant and heat-resistant aluminum alloy material has good wear resistance, corrosion resistance,heat resistance, heat conductivity and mechanical properties, and has good falling resistance and plasticity and long service life.

Owner:安徽酷米智能科技股份有限公司

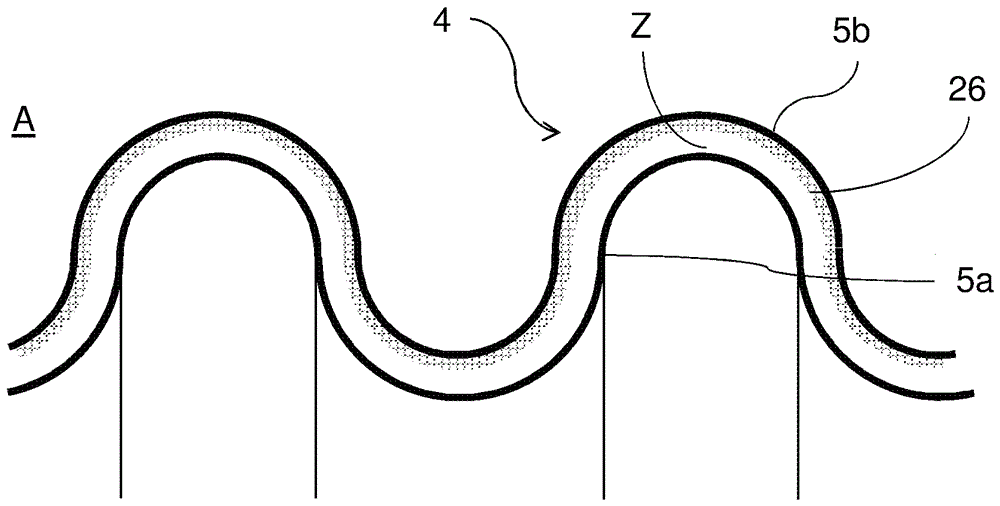

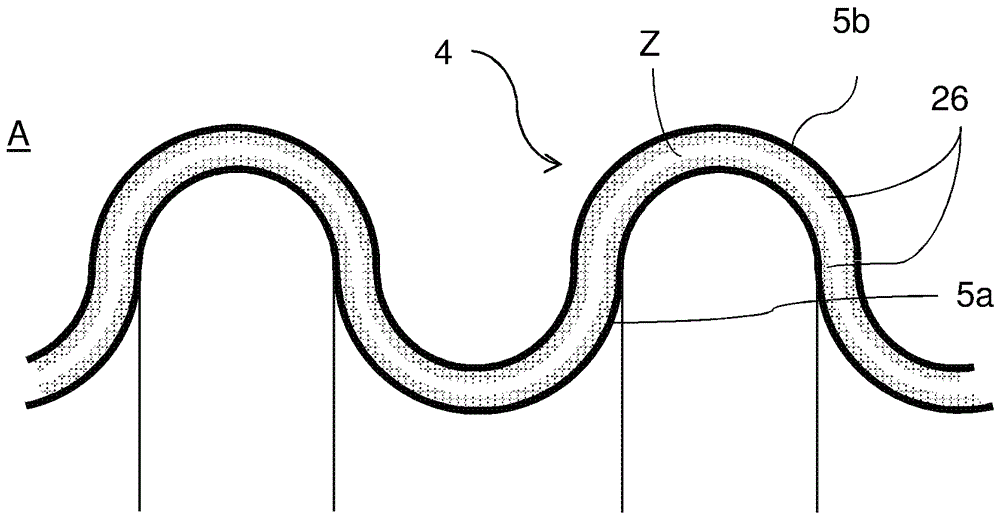

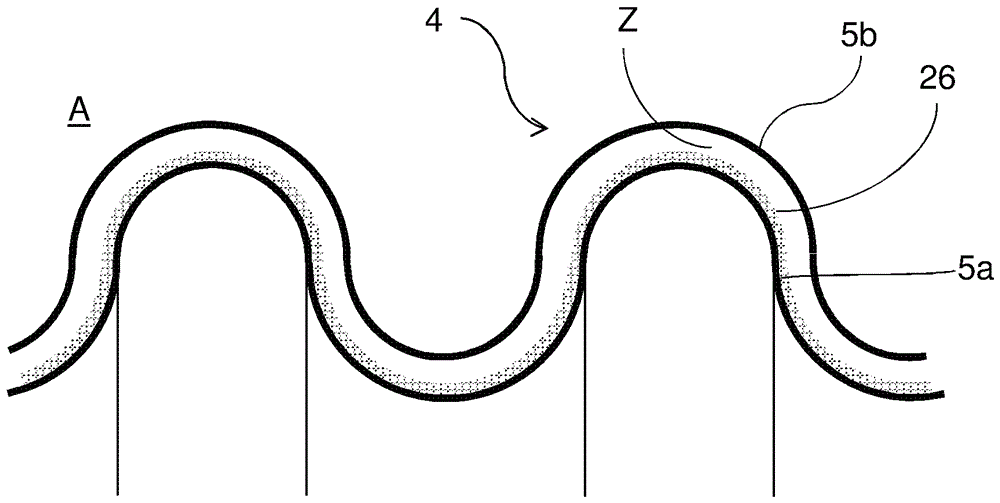

Compensator, in particular for motor vehicle applications

InactiveCN106352189AImprove temperature resistanceReduce liquidityPipeline expansion-compensationExhaust apparatusEngineeringFriction reduction

The invention relates to a compensator (1) used for compensating two pipeline elements, in particular for motor vehicle applications. The compensator (1) comprises a multi-layer corrugated pipe (4), which is used as a wall, and comprises at least two stacked layers (5a,5b). A gap (Z) is correspondingly formed between the layers. In order to prevent forming of cracks, friction reduction agent (6) exists in the at least one gap (Z).

Owner:MAN NUTZFAHRZEUGE AG

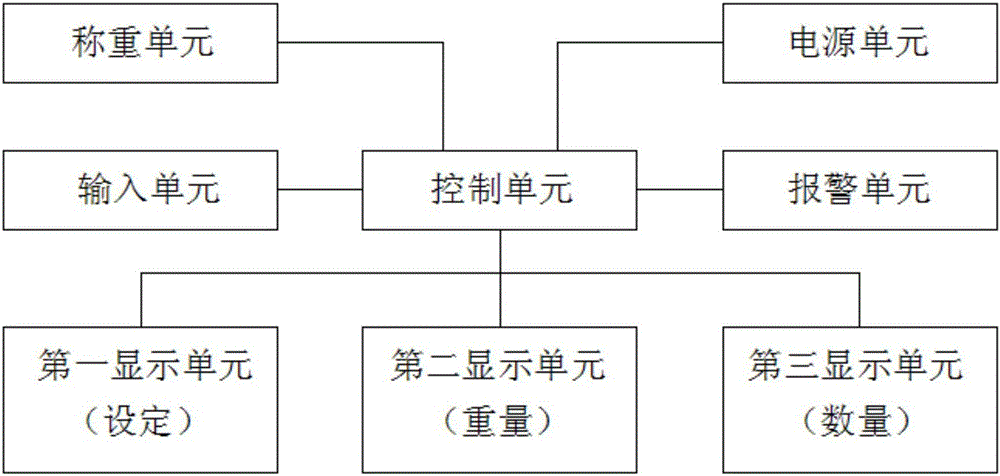

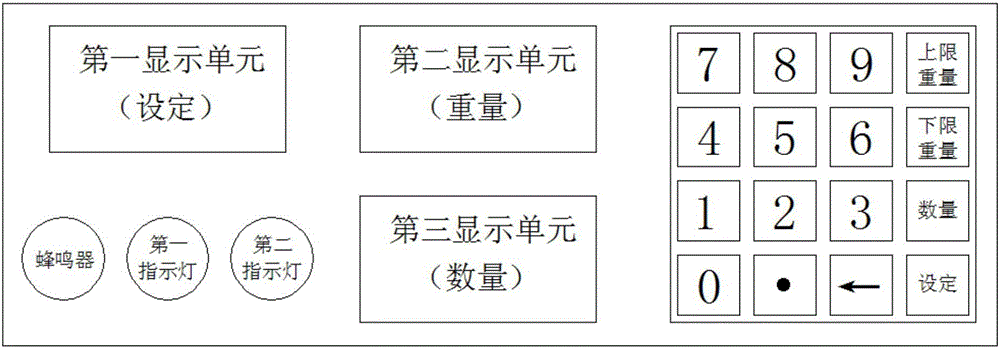

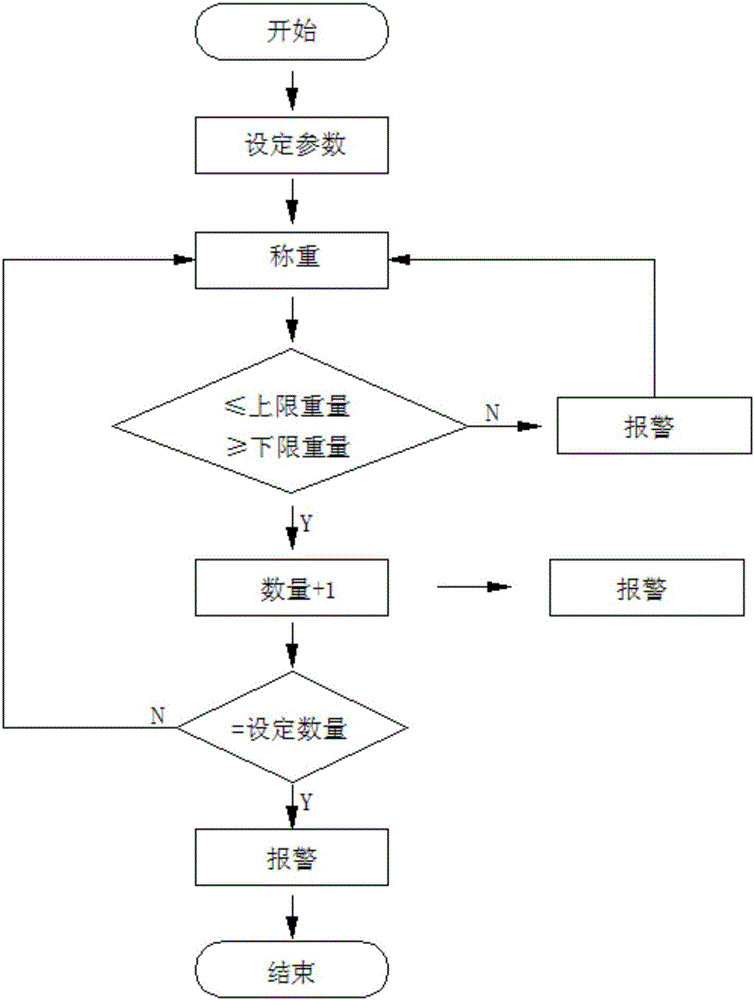

Electronic scale for weighing experimental animal and screening control method thereof

InactiveCN106768223AAchieved weightRealize functionWeighing apparatus for materials with special property/formElectrical bondingElectronic waste

The invention relates to an electronic scale for weighing an experimental animal and a screening control method thereof, belongs to the technical field of electronic scales, and is intended to solve the technical problem that an existing electronic scale has single functionality. The electronic scale according to the technical scheme comprises an input unit, a weighing unit, a control unit, a display unit, an alarm unit and a power supply unit, wherein the signal output end of the input unit and the signal output end of the weighing unit are electrically connected to the signal input end of the control unit respectively; the signal output end of the control unit is electrically connected to the signal input end of the alarm unit and the signal input end of the display unit; the power supply unit is electrically connected to various electrical units; the screening control method of the electronic scale comprises the steps of 1) setting parameters by the input unit, and transmitting to the control unit; 2) weighing an experimental animal by the weighing unit, and transmitting to the control unit; 3) acquiring, by the control unit, weight acquired by the weighing unit, and comparing the weight, and issuing a corresponding command.

Owner:SHANXI MEDICAL UNIV

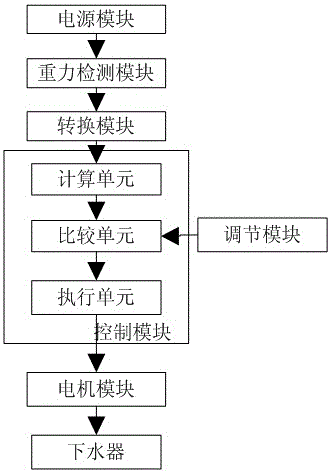

Drainer overturning control system based on gravity detection

The invention discloses a drainer overturning control system based on gravity detection, which comprises a power module, a gravity detection module, a conversion module, a control module and a motor module, wherein the gravity detection module is used for detecting the weight of water in a basin to form an analog signal which is input to the conversion module; the conversion module is used for converting the input analog signal into a digital signal; the control module comprises a computing unit, a comparing unit and an executing unit; the computing unit is used for receiving the digital signal to compute a detected weight value; the comparing unit is used for presetting the weight value of water in the basin and conducting comparison; when the detected weight value is greater than or equal to the preset weight value, the executing unit generates and outputs a driving signal; the rotating shaft of the motor module is fixedly connected with a drainer through a connecting piece; and the rotating shaft drives the drainer to overturn, and forms a sewer between the drainer and a drain outlet or completely close the drainer. The drainer overturning control system based on gravity detection has the functions of automatic detection and automatic control, and can be conveniently used in the draining process of the basin.

Owner:WUXI COCIS ELECTRONICS TECH

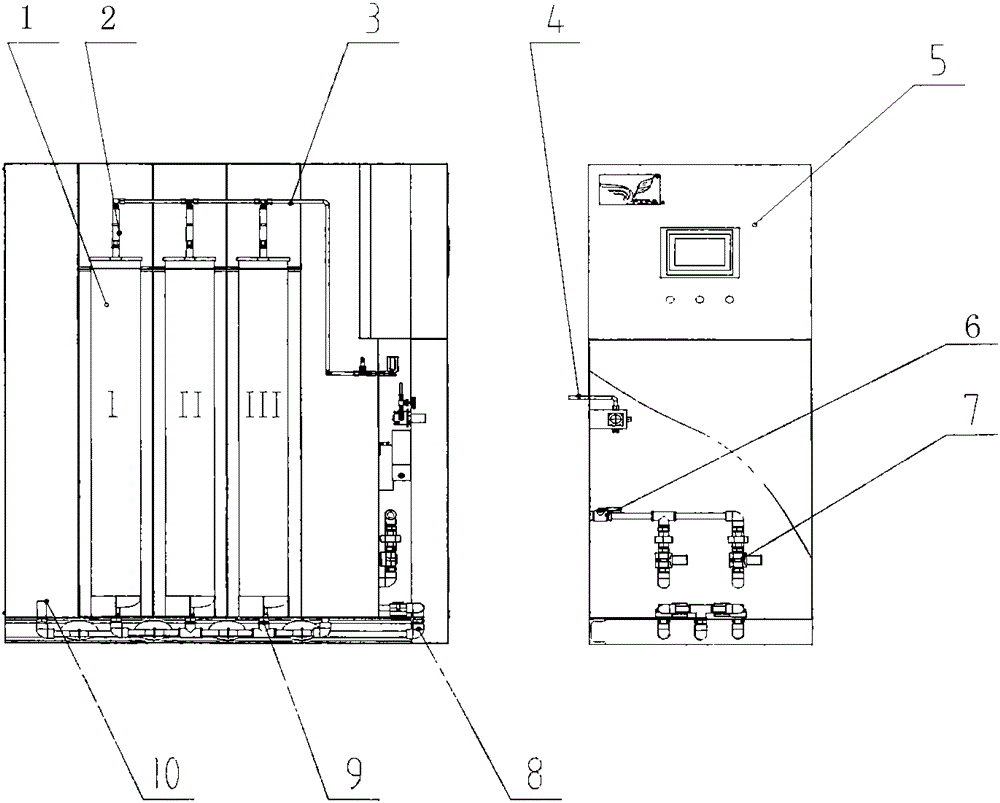

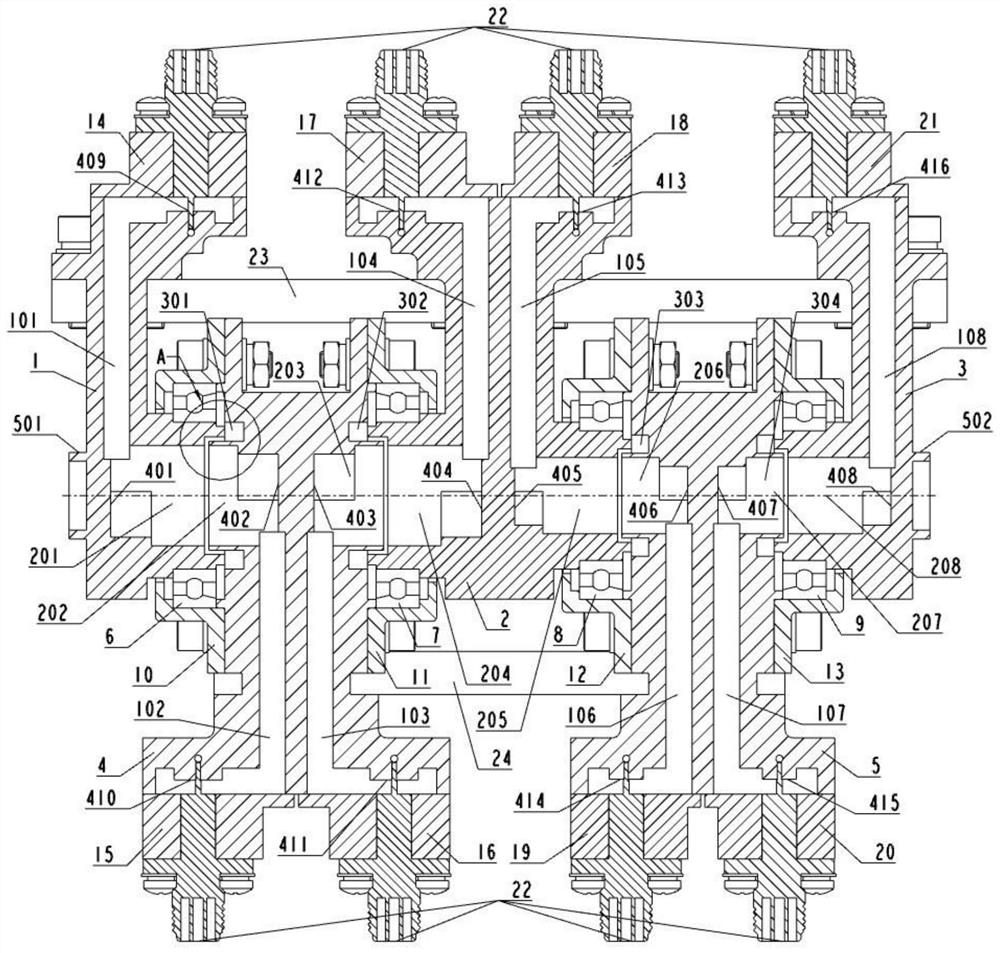

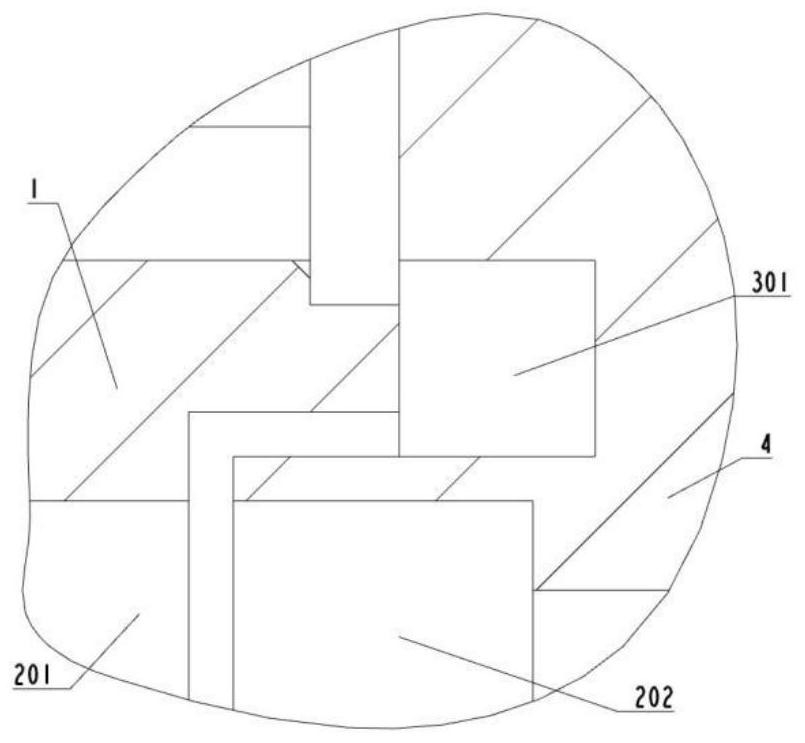

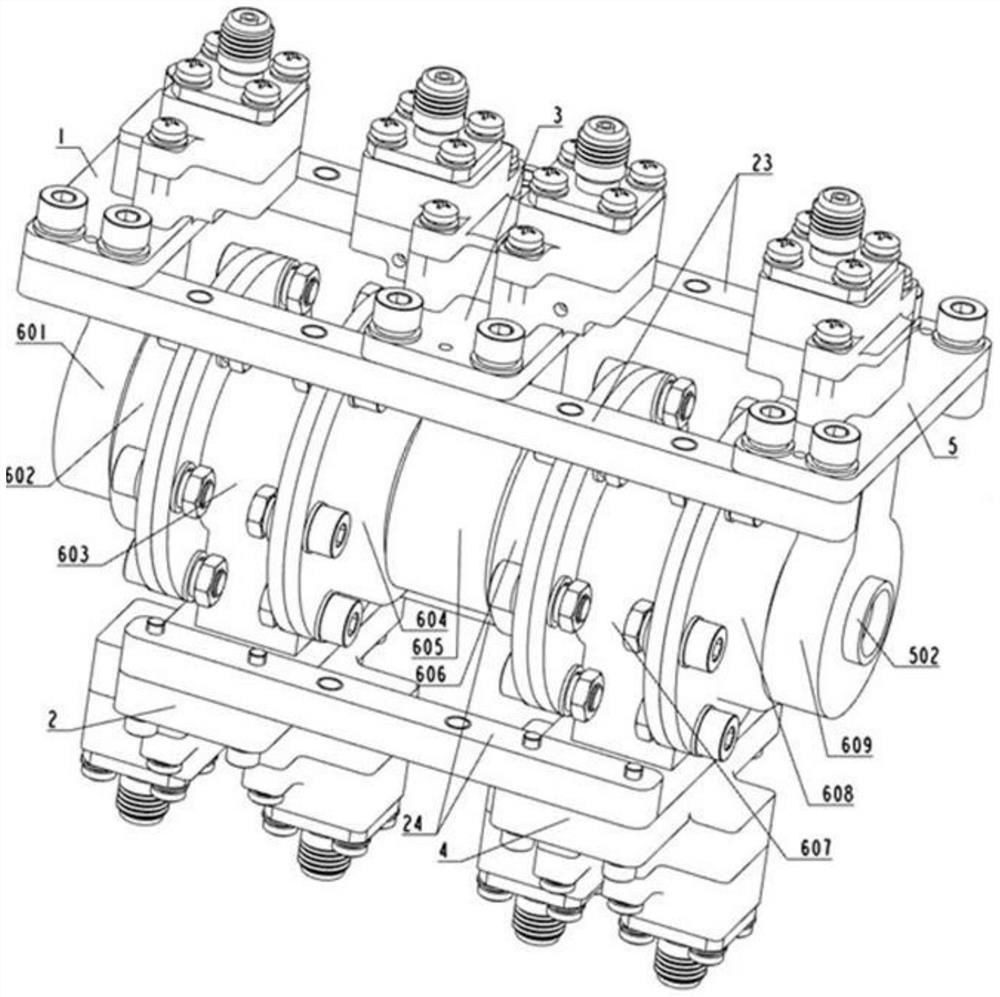

Pressure swing adsorption nitrogen making device capable of replacing membrane separation nitrogen making

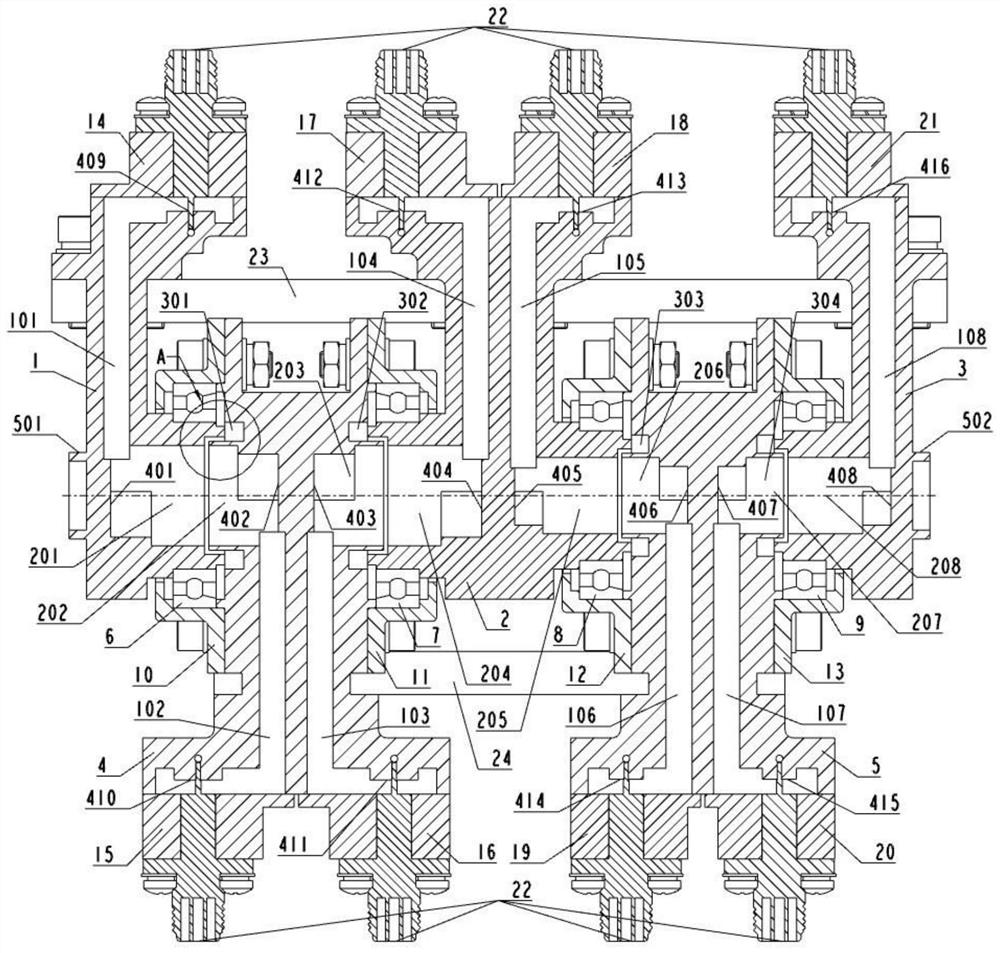

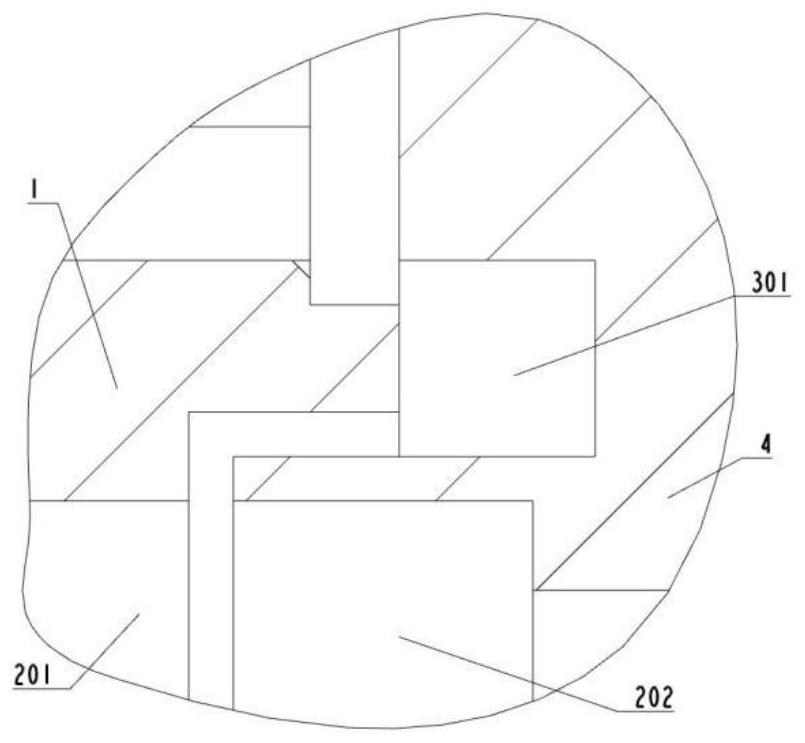

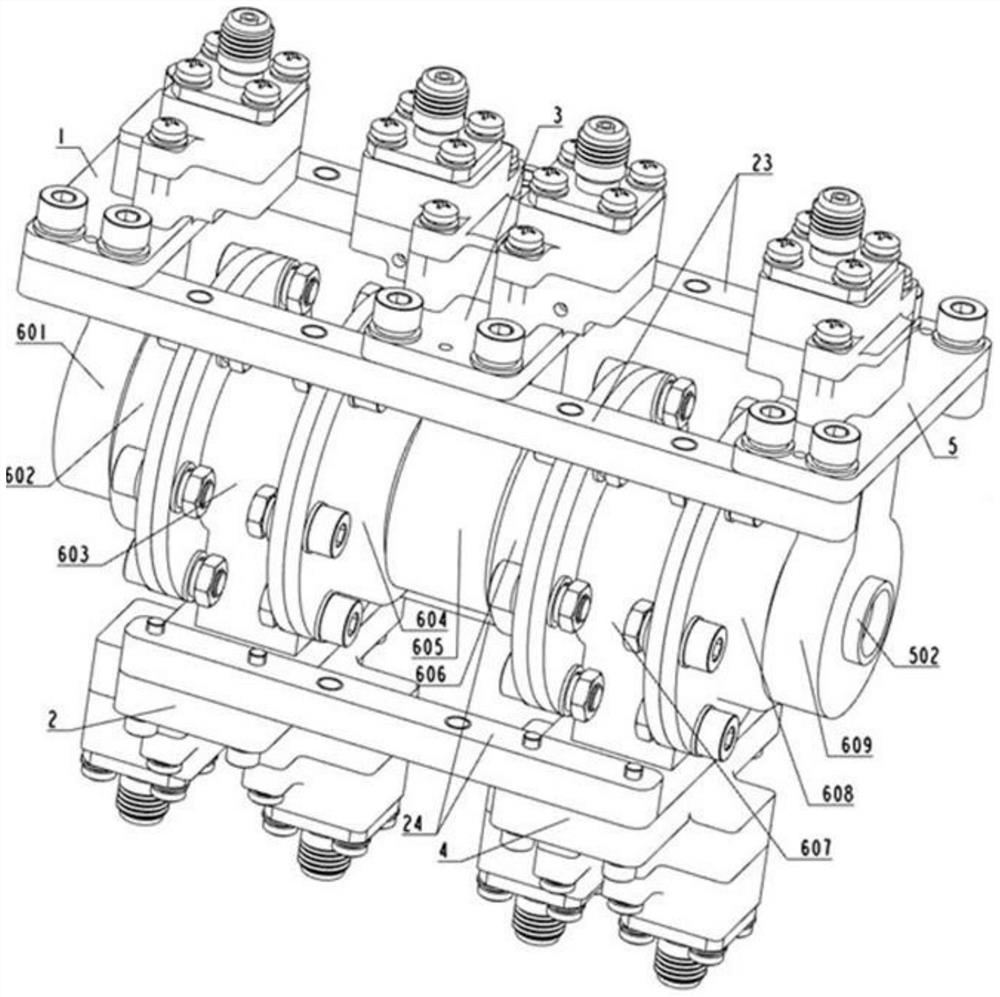

InactiveCN105692570AReduce weightAchieved weightNitrogen purification/separationMolecular sieveExhaust valve

The invention provides a pressure swing adsorption nitrogen making device capable of replacing membrane separation nitrogen making and relates to the field of air separation nitrogen making. The device is composed of adsorption tower sets, gas inlet and outlet pipelines and valves, an electronic control pneumatic system and the like. The adsorption tower sets can be composed of two or three or four and even more towers. Conventional adsorption towers are made into unpressurized vessel type adsorption towers easy to replace, and the adsorption towers are assembled through high-pressure carbon molecular sieves, threads and hoses and assembled by referring to a membrane barrel combination mode. The adsorption towers can be filled with the molecular sieves with different pressure bearing capacities according to the requirements of users, one device can be composed of the multiple adsorption tower sets, each adsorption tower is provided with independent gas inlet, outlet and exhaust valves and pipelines connected with main gas inlet, outlet and exhaust pipelines, replacement and maintenance of each adsorption tower can be achieved, modular assembly is achieved, and maintenance and replacement are convenient for the users. The adsorption towers are low in weight and convenient to replace, the device is assembled in a modular mode, the gas outlet pressure of nitrogen reaches up to 1.5 MPa, the device can completely replace membrane separation nitrogen making, and the requirements of the users are met.

Owner:BEIJING FEDA HIGHT-TECH GAS CO LTD

Joint follow-up assisting device

The invention discloses a joint follow-up assisting device which comprises at least one sensor, a data processor and a control portion. The sensors are worn at joints of a first user and record joint movement data, the data processor is connected with the sensors and receives and processes the joint movement data, the control portion is connected with the data processor, receives the joint movement data and controls a joint movement assisting device, and the joint movement assisting device is worn at a joint of a second user and controlled by the control portion to assist joint movement of the second user. In this way, the first user can perform movement assisting on corresponding joints of the second user through the joint follow-up assisting device, and convenience in use is realized.

Owner:ZHONGSHAN CHANGYAO MEDICAL EQUIP CO LTD

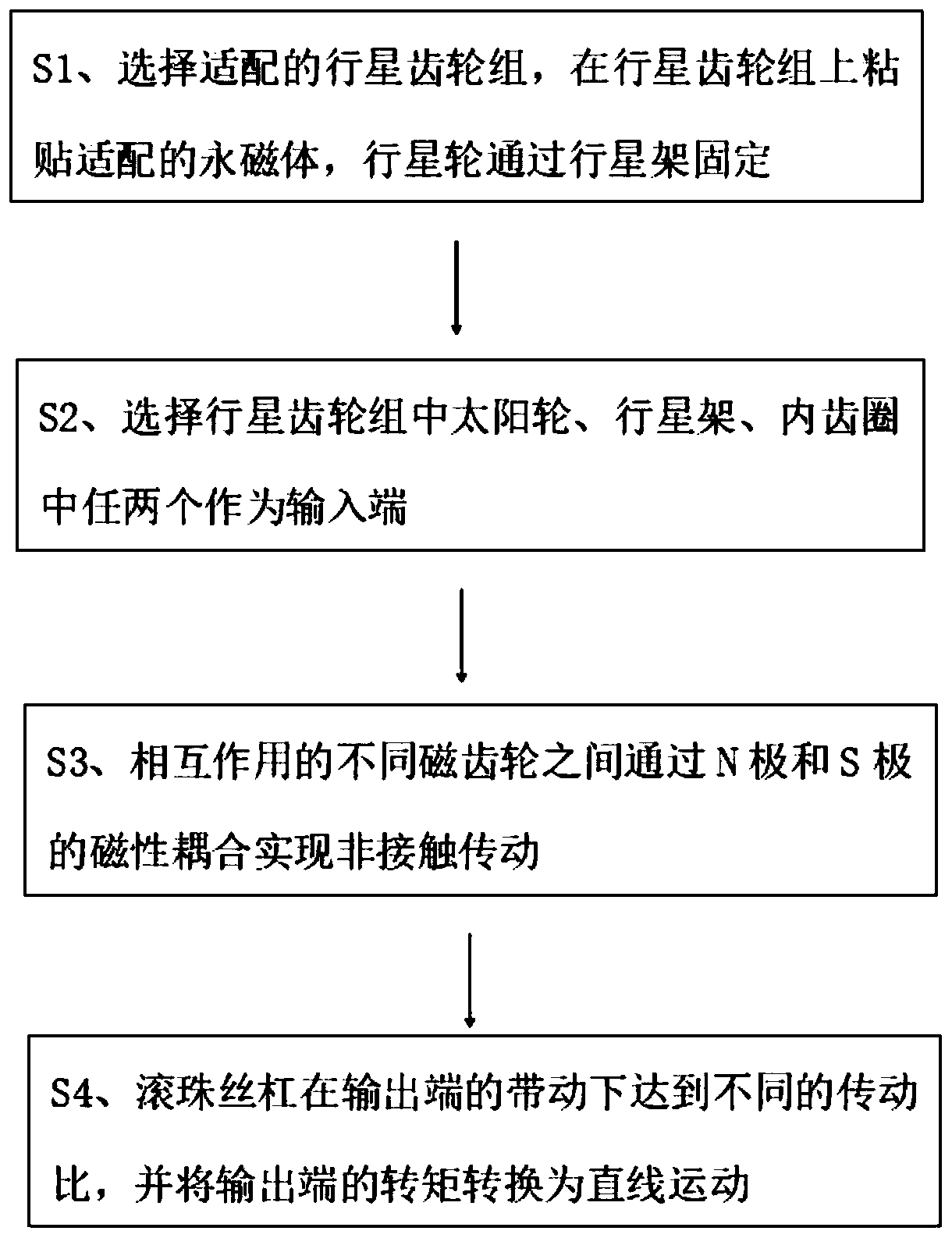

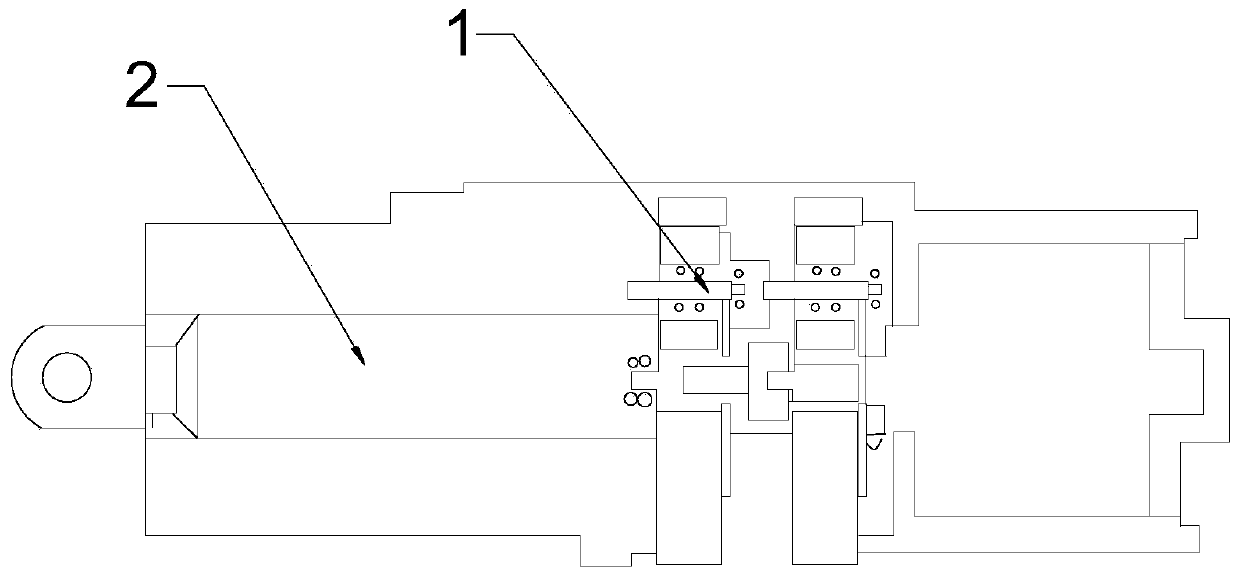

Adsorption transmission-based transmission method for aerospace

ActiveCN110848354ALarge torque fluctuationSmall torque fluctuationGearingPermanent-magnet clutches/brakesLinear motionPull force

The invention relates to an adsorption transmission-based transmission method for aerospace. The transmission method comprises the following steps: S1, selecting an adaptive planetary gear set, bonding an adaptive permanent magnet to the planetary gear set, and fixing a planetary gear through a planetary carrier; S2, selecting any two of a sun wheel, the planetary carrier and an inner gear ring ofthe planetary gear set to serve as an input end, selecting another one as an output end, connecting the input end to a driving system, and connecting the output end to an input end of a ball screw; S3, realizing non-contact transmission between different magnetic gears which act mutually through magnetic coupling of an N pole and an S pole; and S4, making the ball screw achieve different transmission ratios under the driving of the output end, converting the torque of an output end into linear motion, and transferring the linear motion to an operating mechanism to complete the connection between a power system and the operating mechanism. According to the transmission mechanism provided by the invention, the torque is transferred by the magnetic pulling force formed by coupling a plurality of magnetic fields, and small size and light weight of the transmission mechanism are realized.

Owner:ZHONGBEI UNIV

A transmission device for profiles

ActiveCN105775762BHigh precisionImprove processing qualityMeasurement devicesStacking articlesProcess engineeringComputer science

The invention provides a profile transmission device, which includes: a profile longitudinal feeding mechanism, used to measure the length and width of the profile and transfer the profile to a horizontal transfer station; The profiles at the transfer station are weighed and delivered to the material sorting station; the profile material sorting mechanism is used to arrange the profiles on the material sorting station, so that the arranged profiles fall into the profile storage box; and the control mechanism . The profile conveying device of the present invention has simple structure, low cost and strong practicability. The profile conveying device can realize the size and weight measurement of the profile while transmitting the profile, and has the function of sorting materials; the profile conveying device effectively solves the problem of the current profile processing machinery industry Low degree of automation, susceptible to interference of measurement, high cost and low production efficiency, so as to improve the processing efficiency, processing accuracy and quality of profiles.

Owner:FOSHAN UNIVERSITY

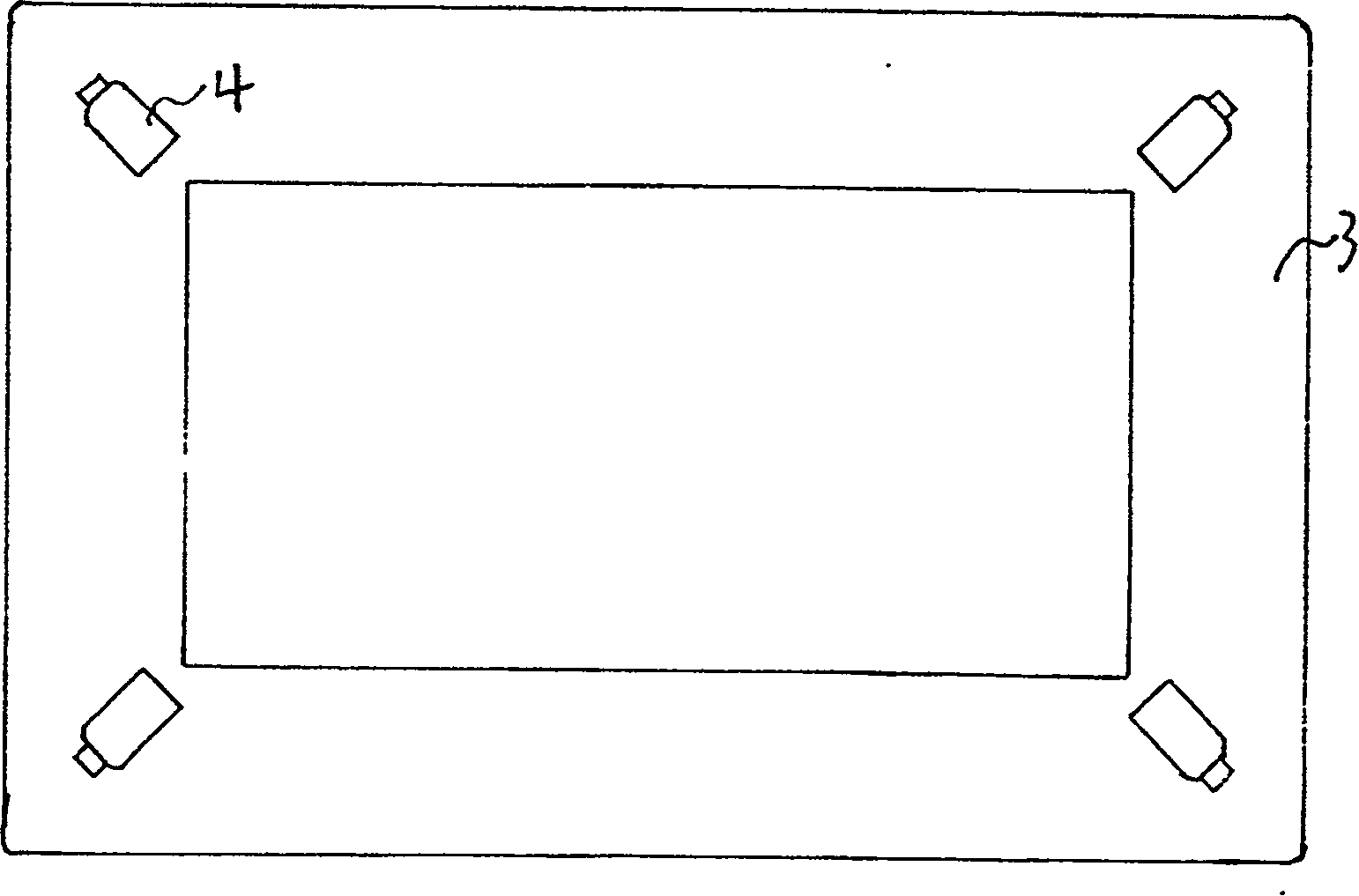

Stone cinerary casket

The present invention relates to cinerary casket made of stone material and belongs to the field of the making of cinerary casket. The cinerary casket of stone material has inner cavity formed with superhigh pressure water jetting cutting machine, numerically controlled superhigh pressure water jetting cutting machine, or muff cutter to hollow out and diamond cutter to flat; outer surface formed with superhigh pressure water jetting cutting machine or numerically controlled superhigh pressure water jetting cutting machine; and cover formed with superhigh pressure water jetting cutting machine, numerically controlled superhigh pressure water jetting cutting machine, or stone cutting machine.

Owner:厉国苗

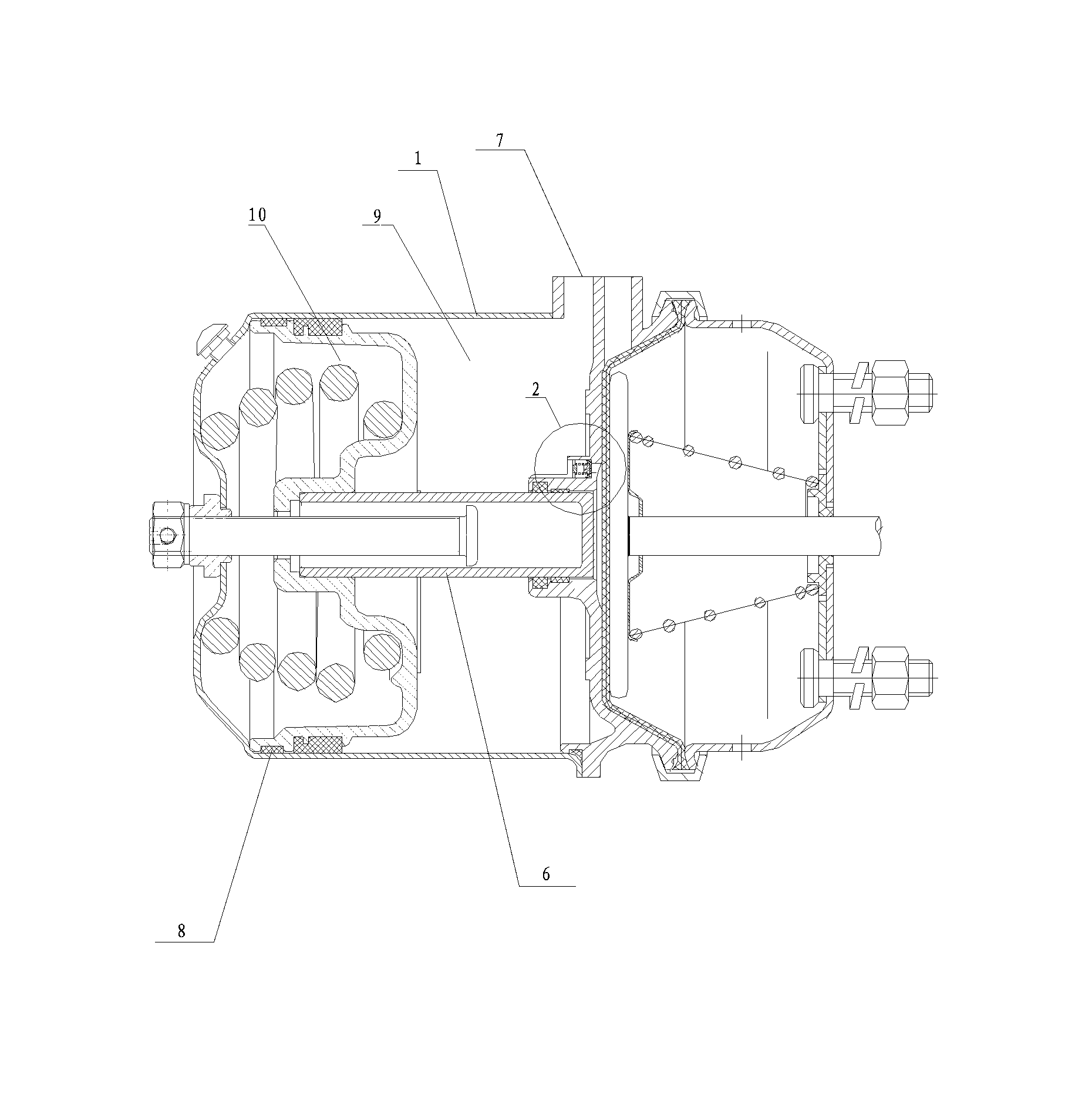

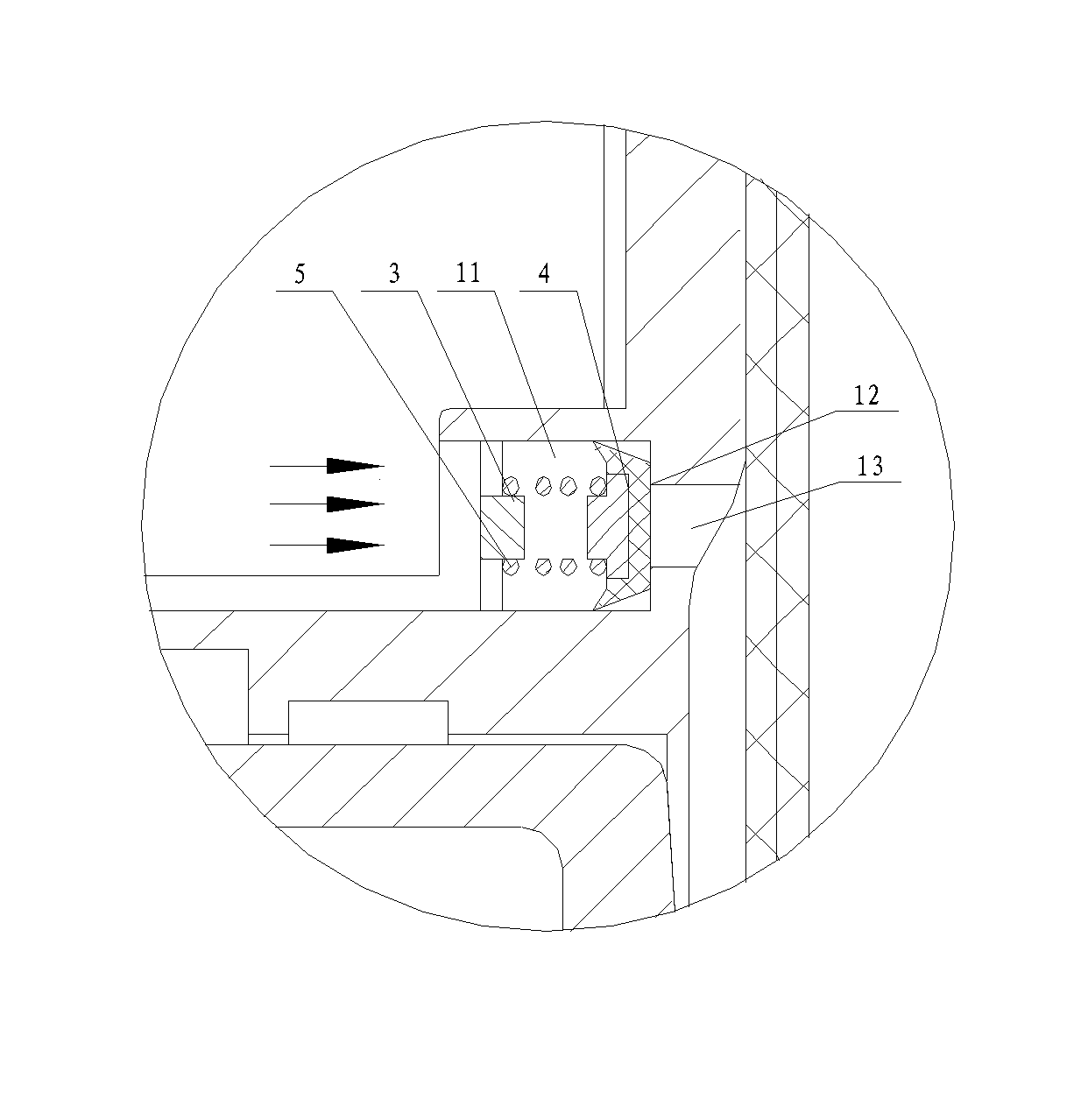

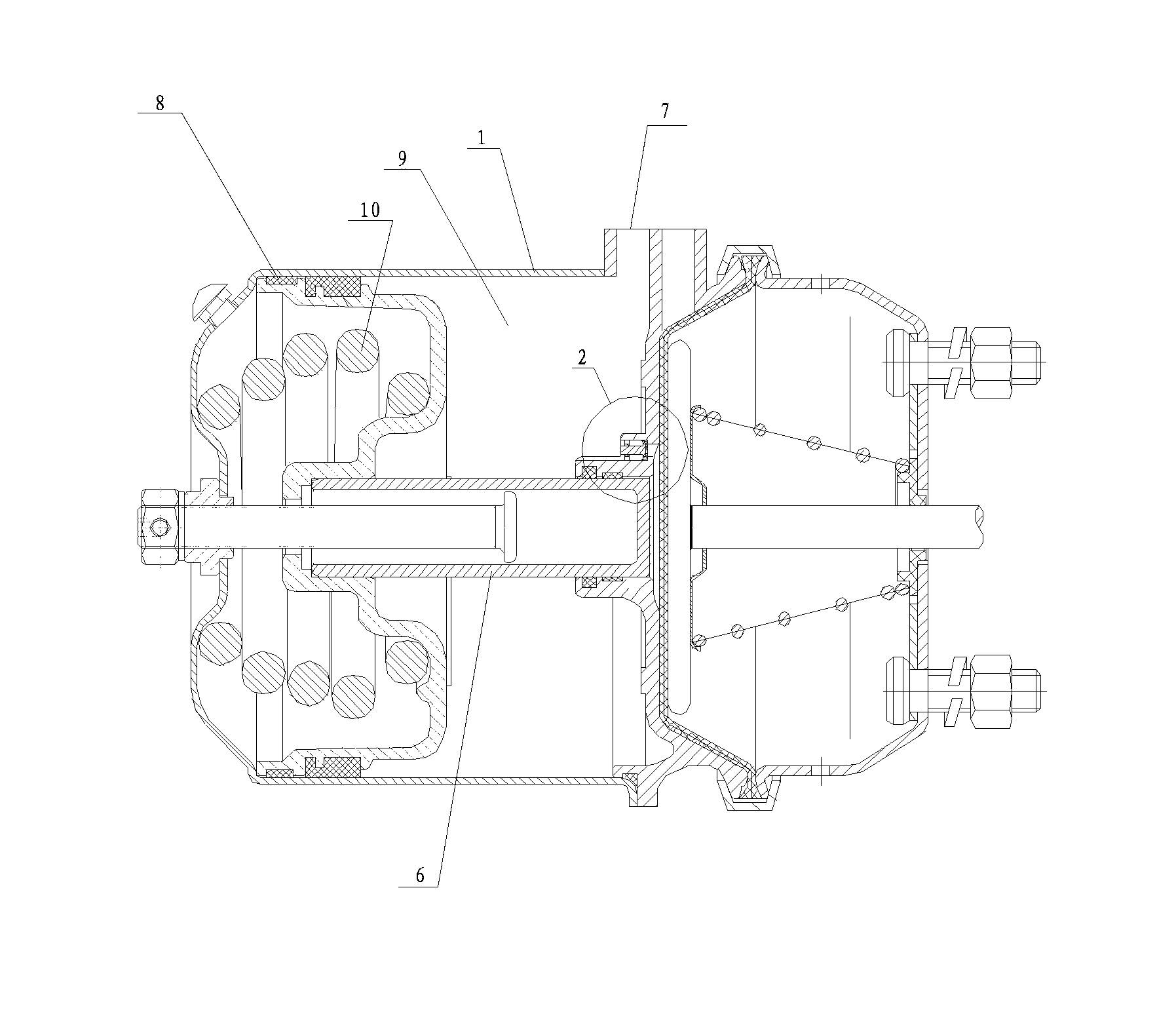

Spring brake chamber capable of preventing braking force superposition

ActiveCN102410320BFunction increaseAchieved weightBraking action transmissionBrake actuating mechanismsControl theoryParking brake

The invention provides a spring brake chamber capable of preventing braking force superposition. In the invention, a bypass valve is arranged in the spring brake chamber, and the bypass valve comprises a valve seat and a one-way valve and optionally comprises a return spring; the spring brake chamber is of an external respiration structure or an internal respiration structure; and the bypass valve can be arranged on a middle shell at a piston shaft of the spring brake chamber, a middle shell of a parking brake port, an energy storage piston or in a parking brake port. By adopting the spring brake chamber capable of preventing braking-force superposition, the conventional differential relay valve or dual-way check valve is omitted, and the function of preventing braking force superpositionis realized; and meanwhile a brake pipeline can be more simple and convenient in connection, a brake system can be more economically configured, and failure modes are reduced.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

A space-borne dual-band four-channel rotary joint

ActiveCN112909450BRealize stable transmissionReduce stable transmission problemsWaveguide type devicesEngineeringHigh isolation

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com