Rewinding device for aerogel composite coiled material and operation method

A composite roll and airgel technology, applied in the direction of cleaning method using gas flow, winding strip, cleaning method and utensils, etc., can solve the problems of time-consuming and labor-intensive, manual removal and transfer, harm to human body and environment, etc. , to achieve the effect of improving the working environment, improving product quality and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

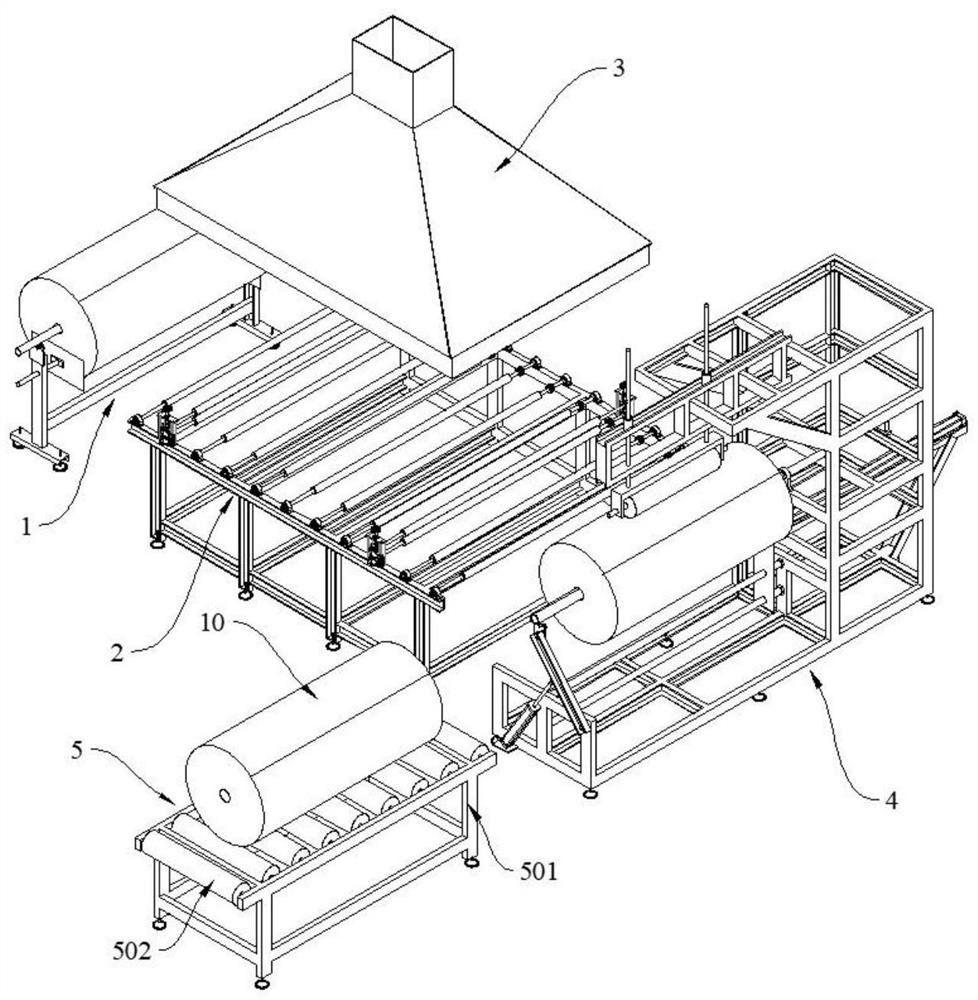

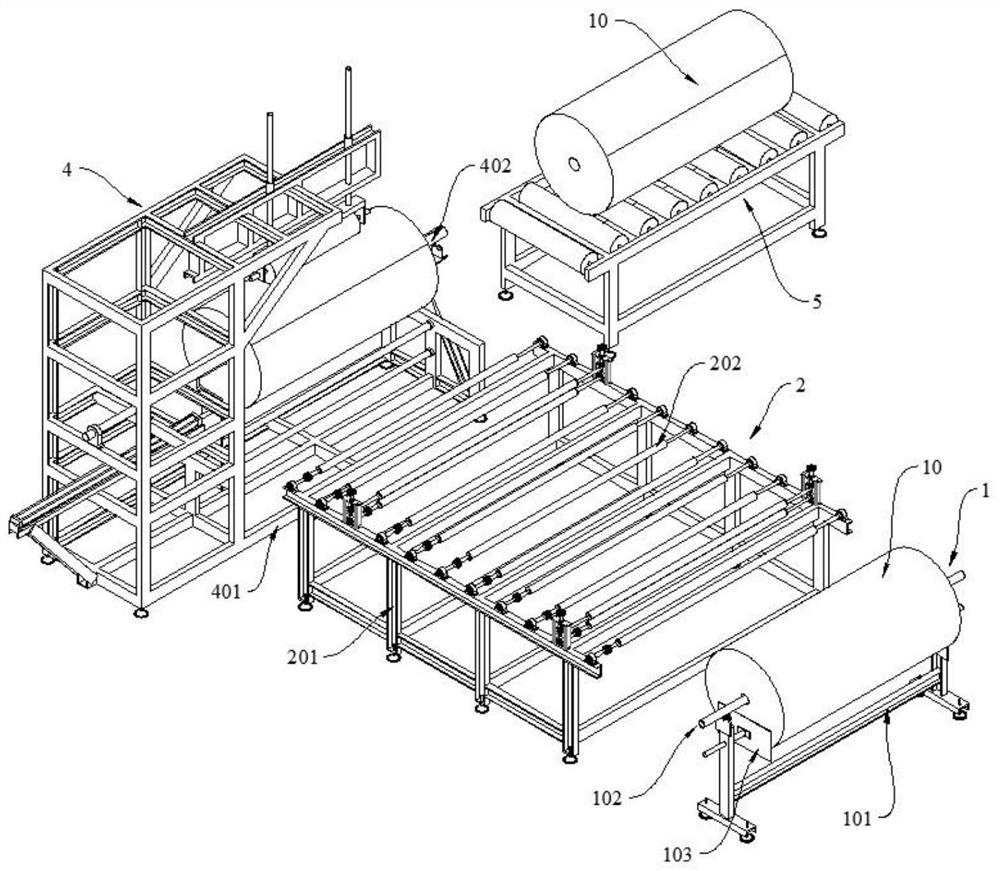

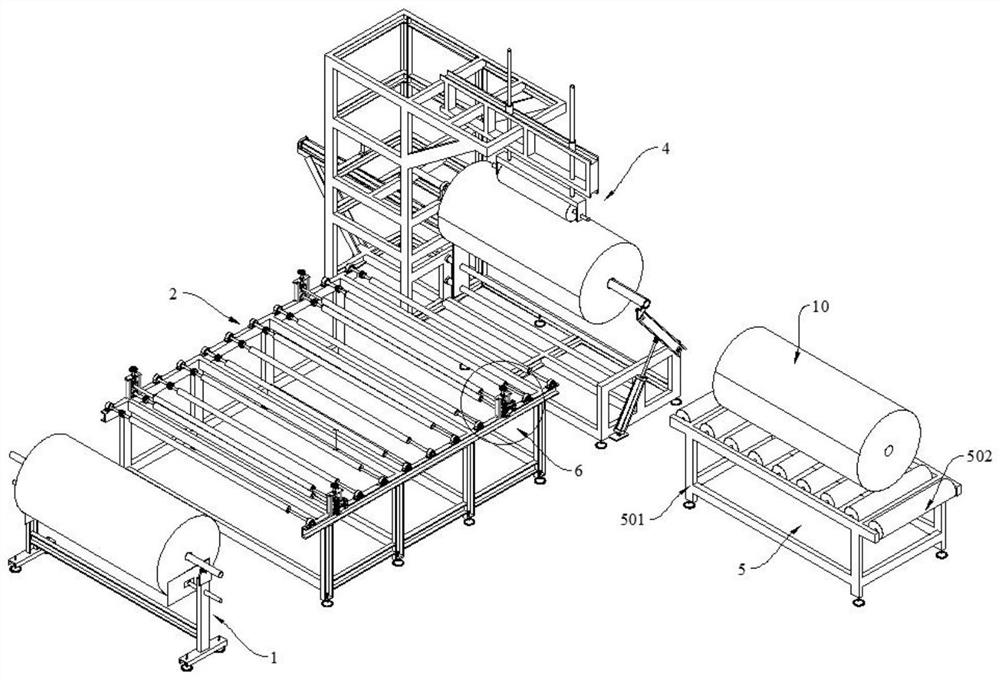

[0042] see Figure 1-Figure 7 As shown, the present invention is a rewinding device for airgel composite coils, including an unwinding mechanism 1, a transmission mechanism 2, a dust suction mechanism 3, a winding mechanism 4 and a transfer mechanism 5, and the unwinding mechanism 1 includes The unwinding support 101 , above the unwinding support 101 is fixedly installed a first roller shaft 102 on which the airgel composite roll 10 is placed. The transmission mechanism 2 includes a transmission bracket 201, a plurality of second roller shafts 202 are fixedly installed above the transmission bracket 201, and the plurality of second roller shafts 202 are connected to each other through a transmission chain. motor.

[0043] Wherein, the dust suction mechanism 3 is located above the conveying mechanism 2. When the airgel composite coiled material 10 is rolled out and passes through the conveying mechanism 2, the dust suction mechanism 3 can effectively absorb the dust on the sur...

Embodiment 2

[0057] see figure 2 As shown, on the basis of the first embodiment, the limiting plates 103 are fixedly installed on both sides of the unwinding support 101 . The airgel composite coil 10 is prevented from shifting during transmission from the unwinding mechanism 1 to the conveying mechanism 2 .

Embodiment 3

[0059] see Figure 4 As shown, a meter counter 203 is fixedly installed on the upper surface of the transmission bracket 201 . Realize the measurement and control of the length and weight of the airgel composite coil 10, and ensure the consistency of the diameter and weight of each roll of the airgel composite coil 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com