Stone cinerary casket

A technology for urns and lids, applied in the field of urns, which can solve the problems of long-term storage of ashes, influence on cremation methods, poor corrosion resistance, etc., and achieve the effect of ensuring inviolability, legal rights and interests, and stopping the lack of ashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

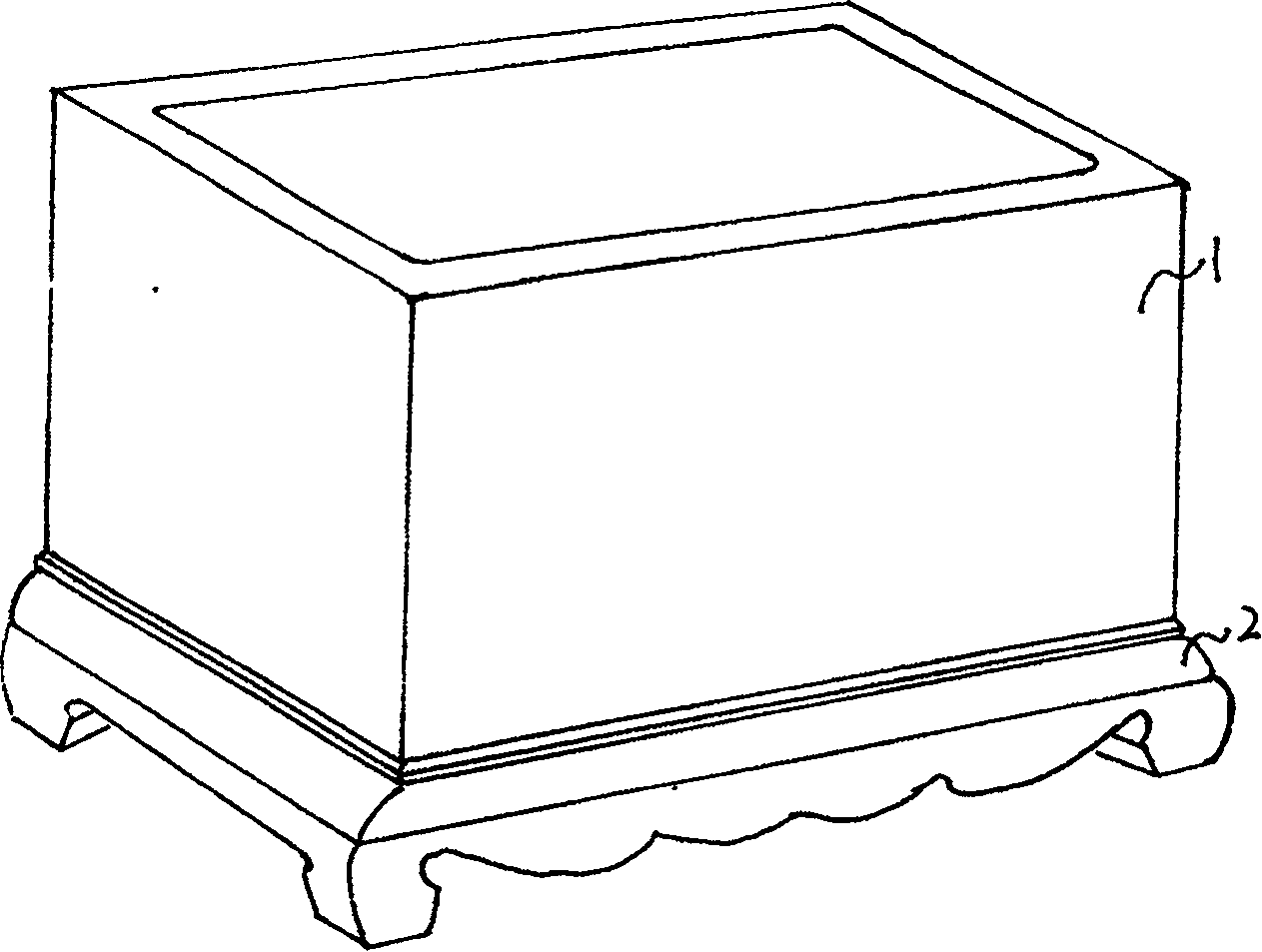

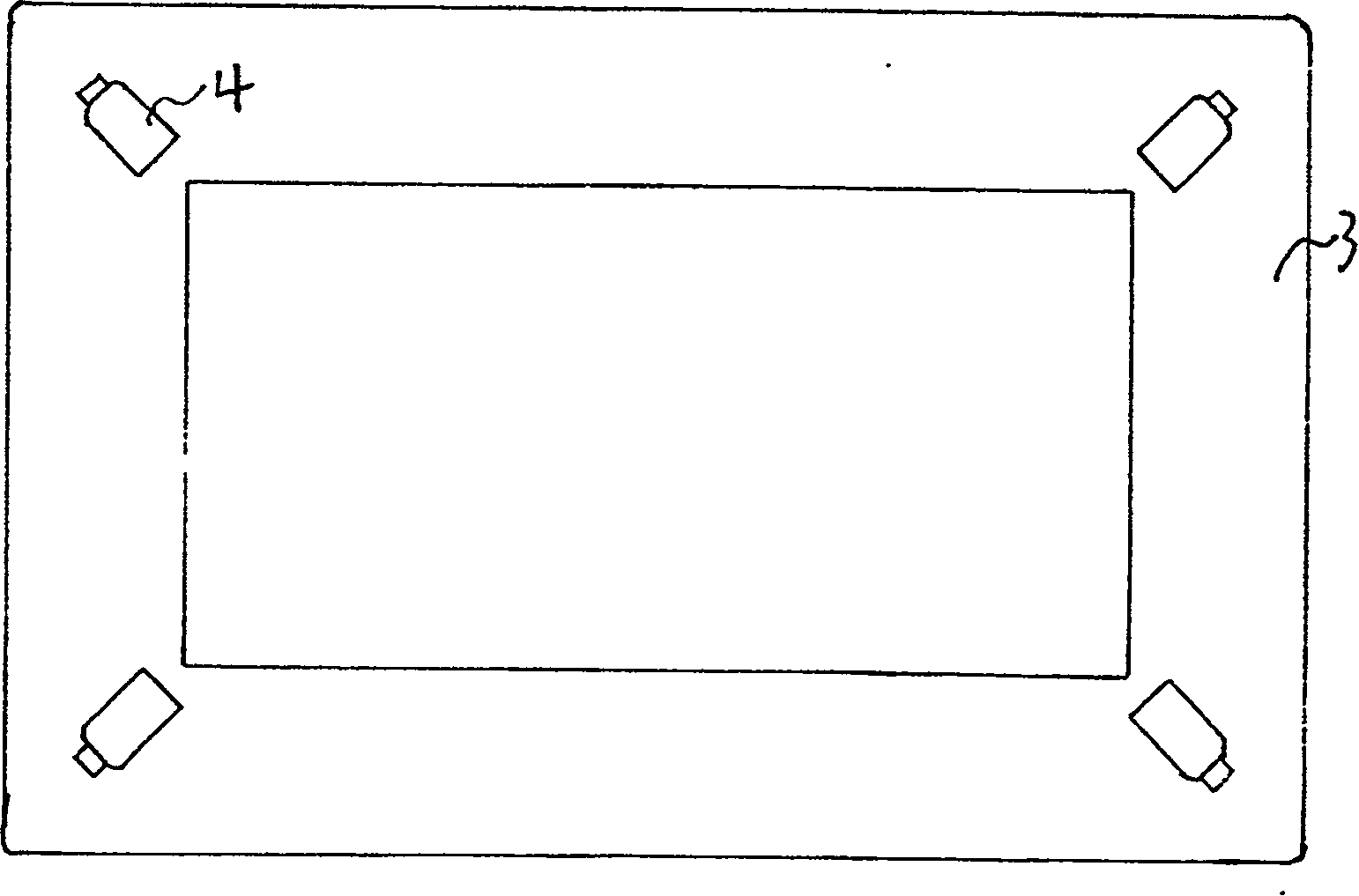

[0011] Embodiment 1: with reference to attached figure 1 and 2 . As for the urn, the stone box body 1 and the stone base 2 are integral or split structures, and the front, left and right sides of the stone box body 1 have carved patterns. The stone box cover 3 is positioned on the box mouth of the box body, the back side of the stone box cover 3 has grooves, and the stone box cover 3 has carved patterns on the surface. Dead bolt 4 or elastic touch ball are equipped with around the stone box cover 3 back sides and form one-way or two-way locking function along with stone box body 1 box mouth inside. The photo frame is inlaid on the front of the stone box. The inner cavity of the urn is provided with wooden boards. Stone refers to natural stone (such as marble, jade, granite, agate, etc.) and artificial stone (such as artificial marble, artificial jade, artificial granite, artificial agate, ceramics, resin, etc.).

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, when the stone box body 1 and the stone base 2 are in a split structure, the stone box body 1 and the stone base 2 are connected by screws or bolts.

Embodiment 3

[0013] Example 3: The manufacturing process of the urn, the inner cavity of the stone urn is cut and shaped by an ultra-high pressure water jet cutting machine or a numerically controlled ultra-high pressure water jet cutting machine, or the cavity is hollowed out with a sleeve cutter, and then the cavity is cut with a diamond cutter. The inside of the stone urn is ground flat, and the outside of the stone urn is cut and shaped by an ultra-high pressure water jet cutting machine or a CNC ultra-high pressure water jet cutting machine, or cut by a stone cutting machine. The stone box cover is cut by an ultra-high pressure water jet cutting machine or CNC ultra-high pressure water jet cutting machine for cutting and shaping, or stone cutting machine for cutting and shaping. Ultra-high pressure water jet cutting machine or CNC ultra-high pressure water jet cutting machine is the existing technology, such as cutting thickness 20 granite, cutting speed 200mm / min, cutting pressure 260...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com