Placement head comprising a readjusting mechanism, and placement robot

An assembly head and gripping device technology, which is applied to electrical components, electrical components, etc., can solve the problems that the restoring force cannot be predetermined, the placing force cannot be predetermined, and the assembly process is adversely affected, so as to achieve weight and cost advantages, structure The effect of compactness and improved dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

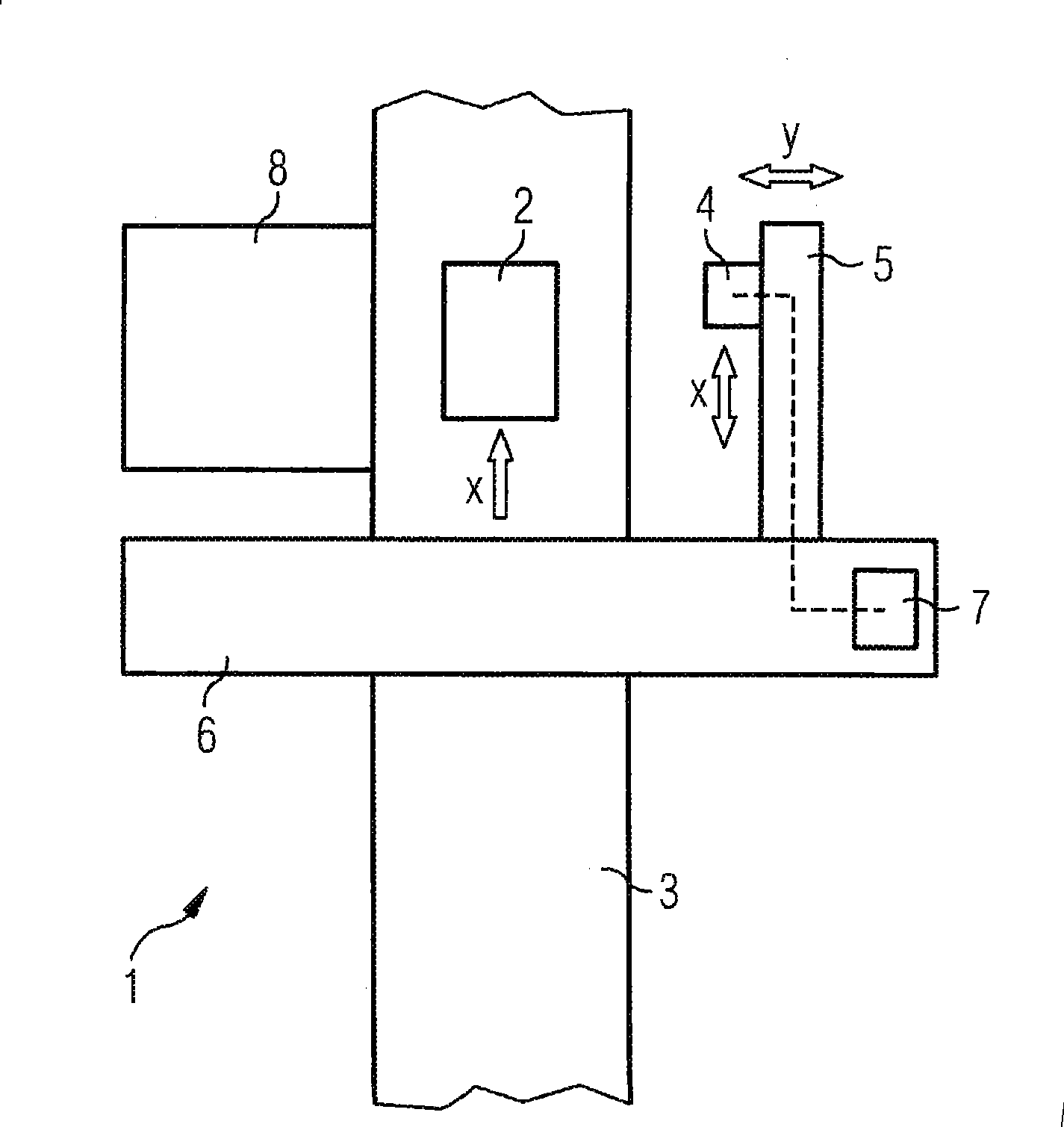

[0027] figure 1 Shown is an automatic assembly machine 1 for equipping substrates with electrical components. The substrate 2 to be assembled is transported by a conveying line 3 (for example a conveyor belt) to an assembly station, where it is equipped with electrical components, and then transported away from the assembly station. The assembly process is carried out by the assembly head 4 . The assembly head 4 is mounted on a positioning arm 5 and is movable on the positioning arm 5 in a direction (arrow x) parallel to the conveying direction (arrow x) of the substrate 2 . The positioning arm 5 is itself mounted on a support 6 straddling the conveying line 3 and is movable on the support 6 in a direction (arrow y) perpendicular to the conveying direction. The automatic assembly machine 1 also includes a control device 7 coupled with the positioning arm 5 and the assembly head 4 for controlling the moving process. A feeding device 8 is provided in the feeding area next to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com