Patents

Literature

62results about How to "Small torque fluctuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

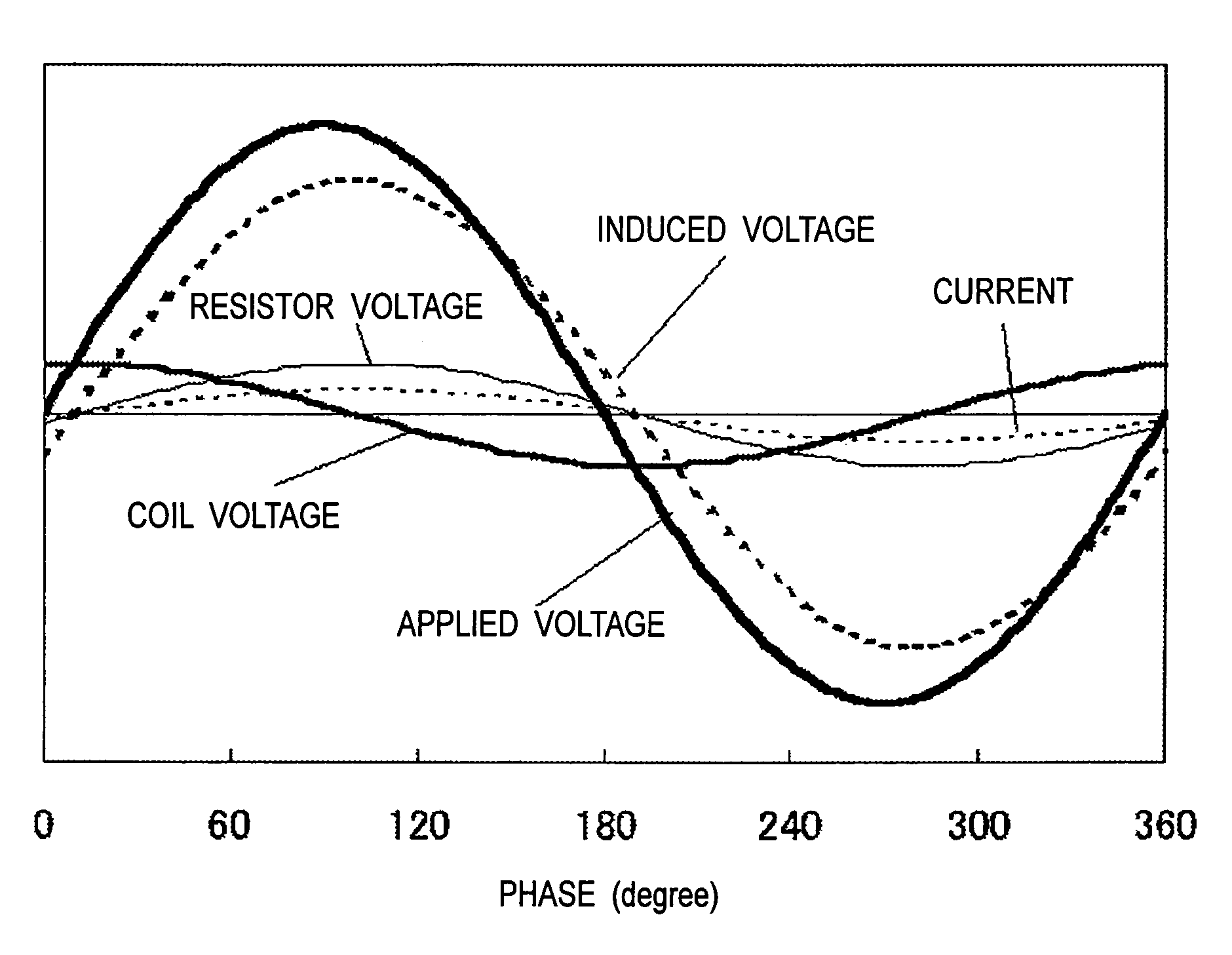

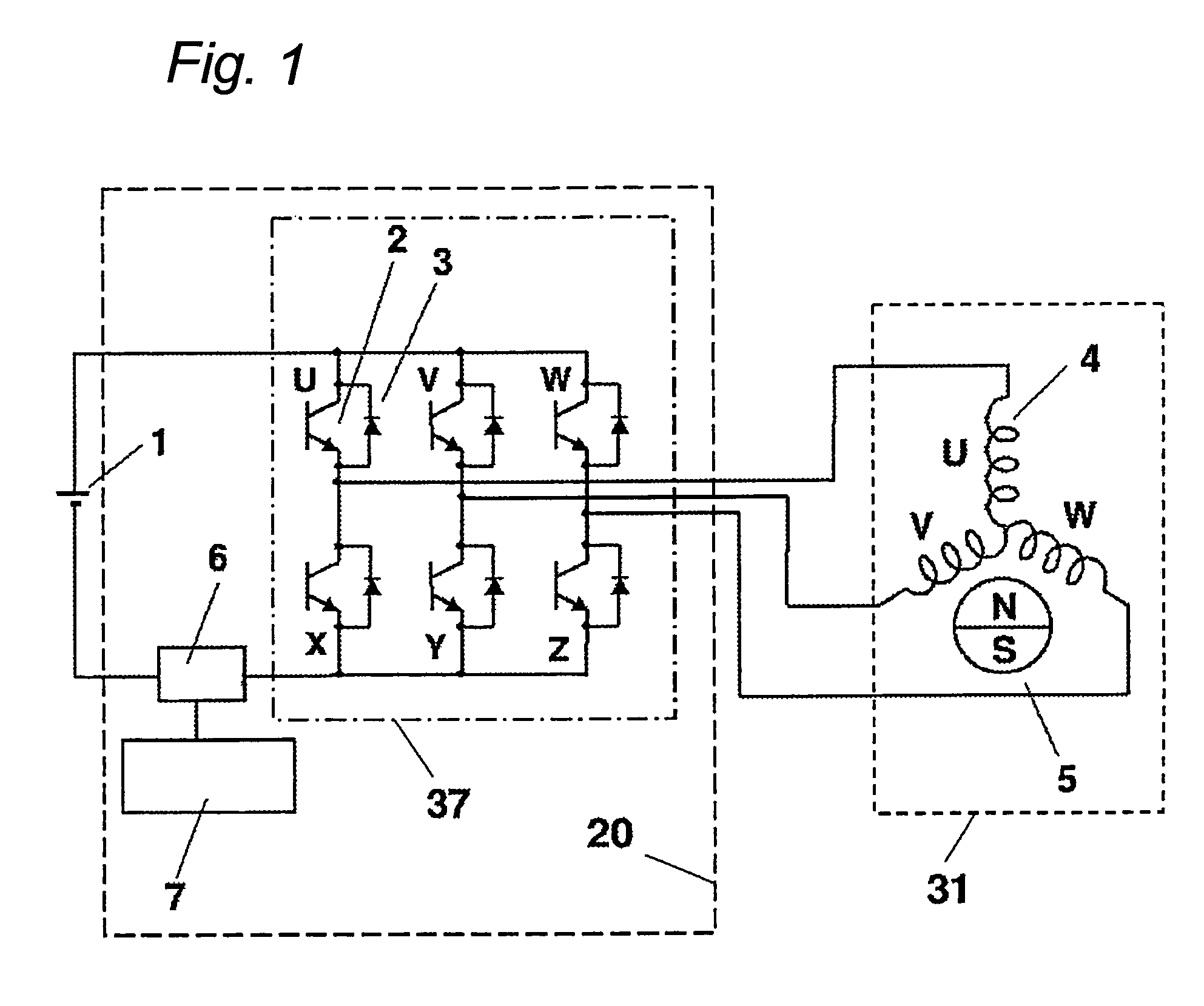

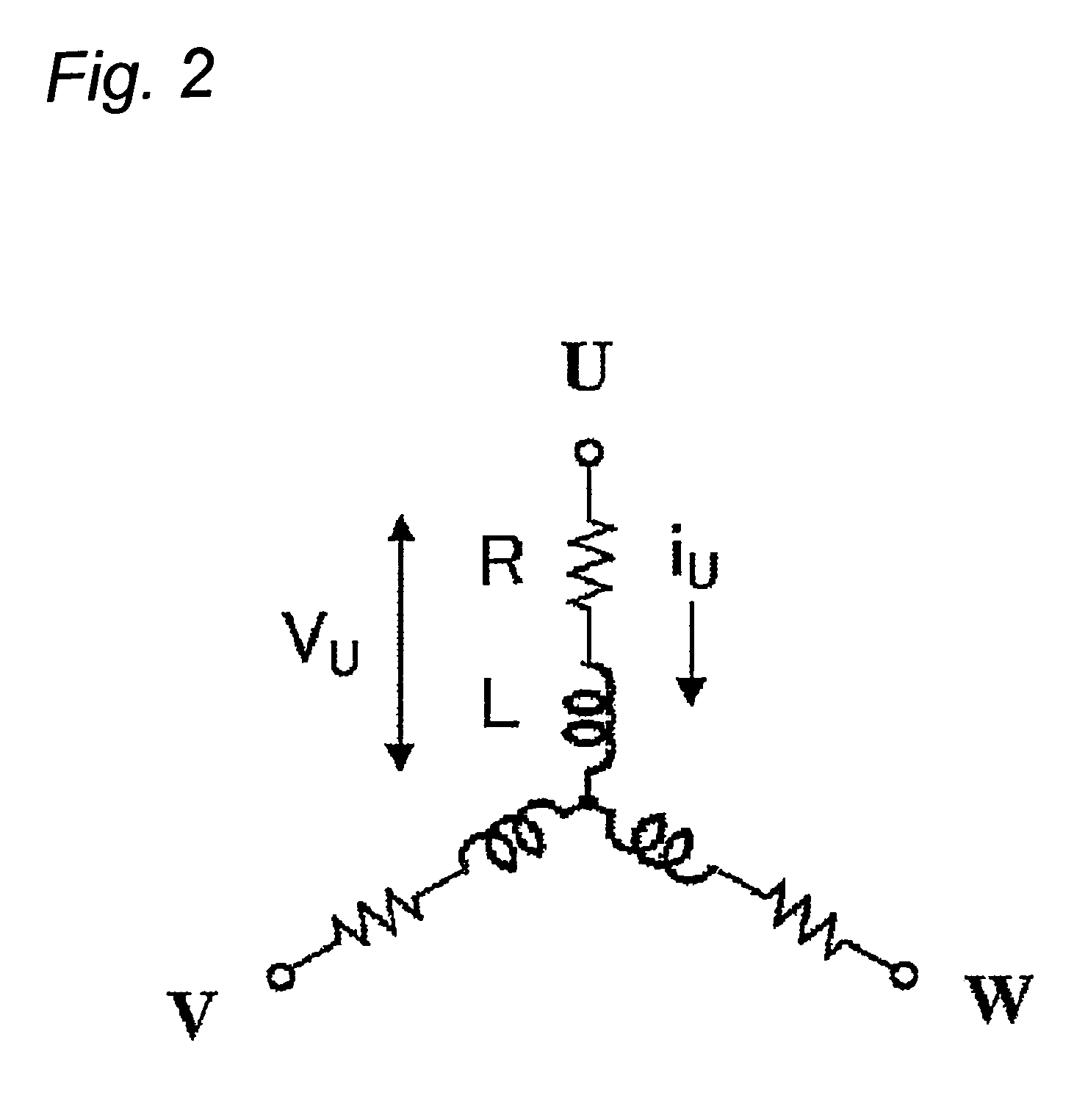

Inverter device and air conditioning system using inverter device

ActiveUS20060150651A1Easy to detectSmall sizeAC motor controlAc-dc conversion without reversalPhase currentsLow noise

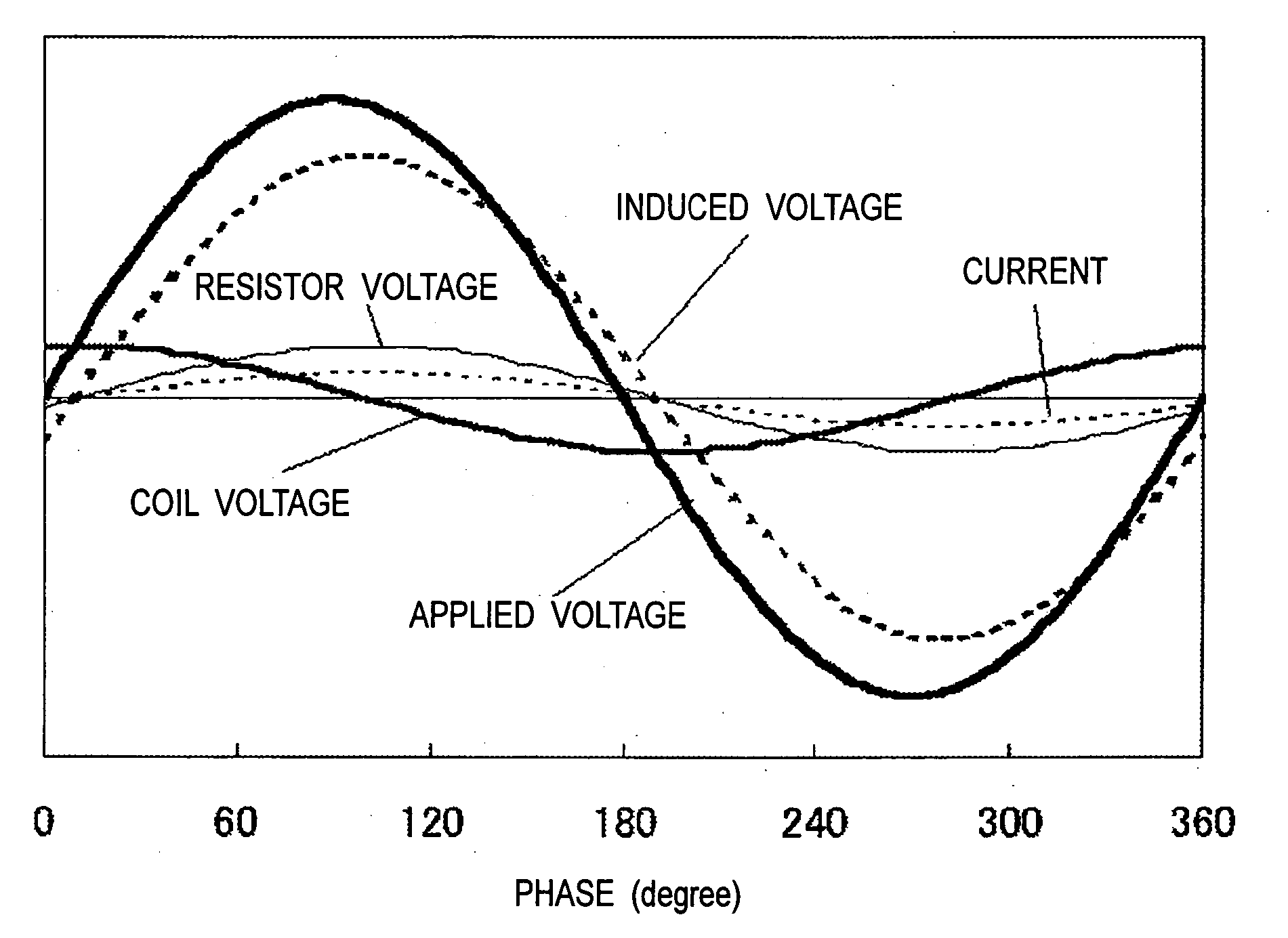

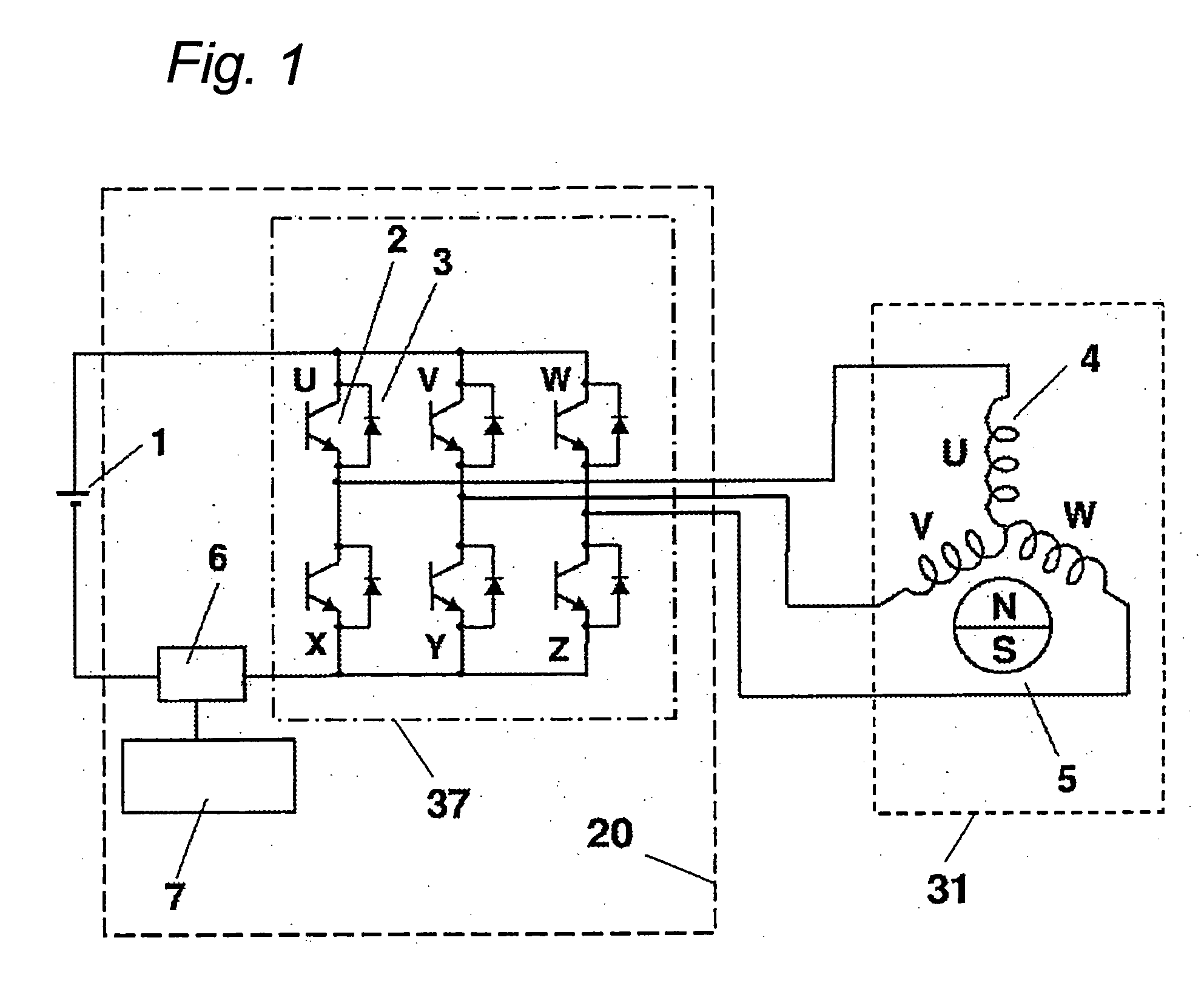

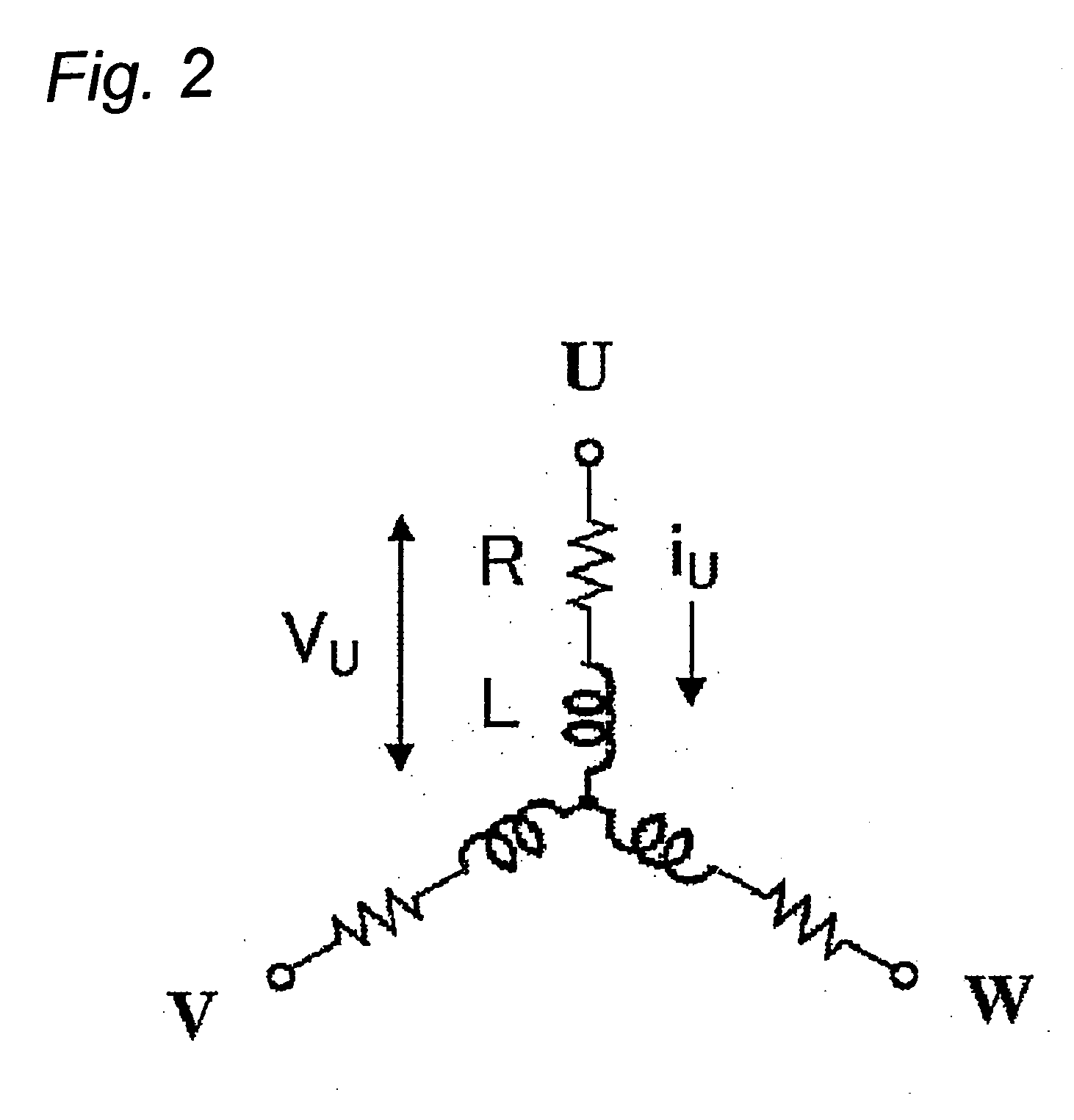

A current sensor for detecting a power supply current is commonly used for detecting a current of a stator winding to detect a rotational position of a magnet rotor, so that a sinusoidal driving is realized without adding two current sensors for detection of a phase current, and also a phase shift circuit and a comparator needed in the conventional 120-degree current feeding are not required, and the number of components can be reduced. Therefore, an inverter device with a low noise and low vibration, having a small size, light weight and high reliability is obtained.

Owner:PANASONIC CORP

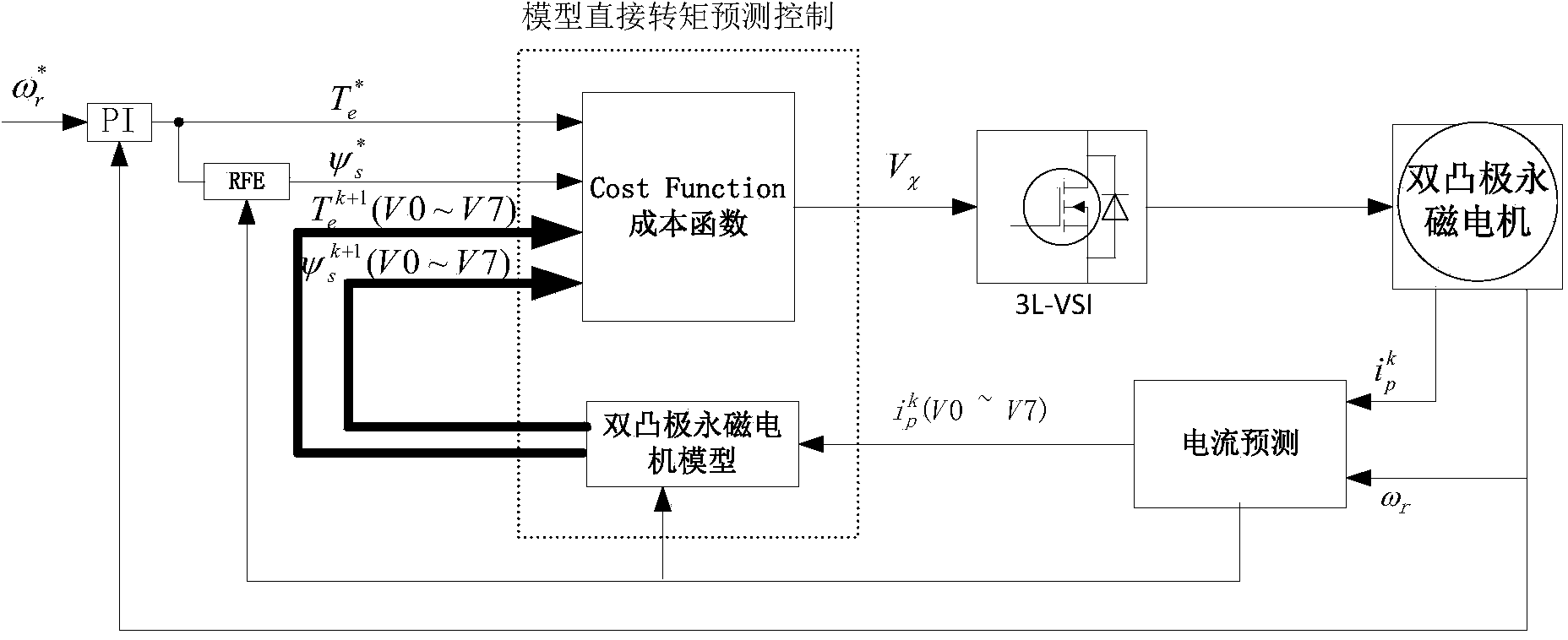

Model prediction-based doubly salient permanent magnet synchronous motor direct torque control method

ActiveCN103715961AReal-time control on and offReduce switching lossesElectronic commutation motor controlAC motor controlVoltage vectorPermanent magnet synchronous motor

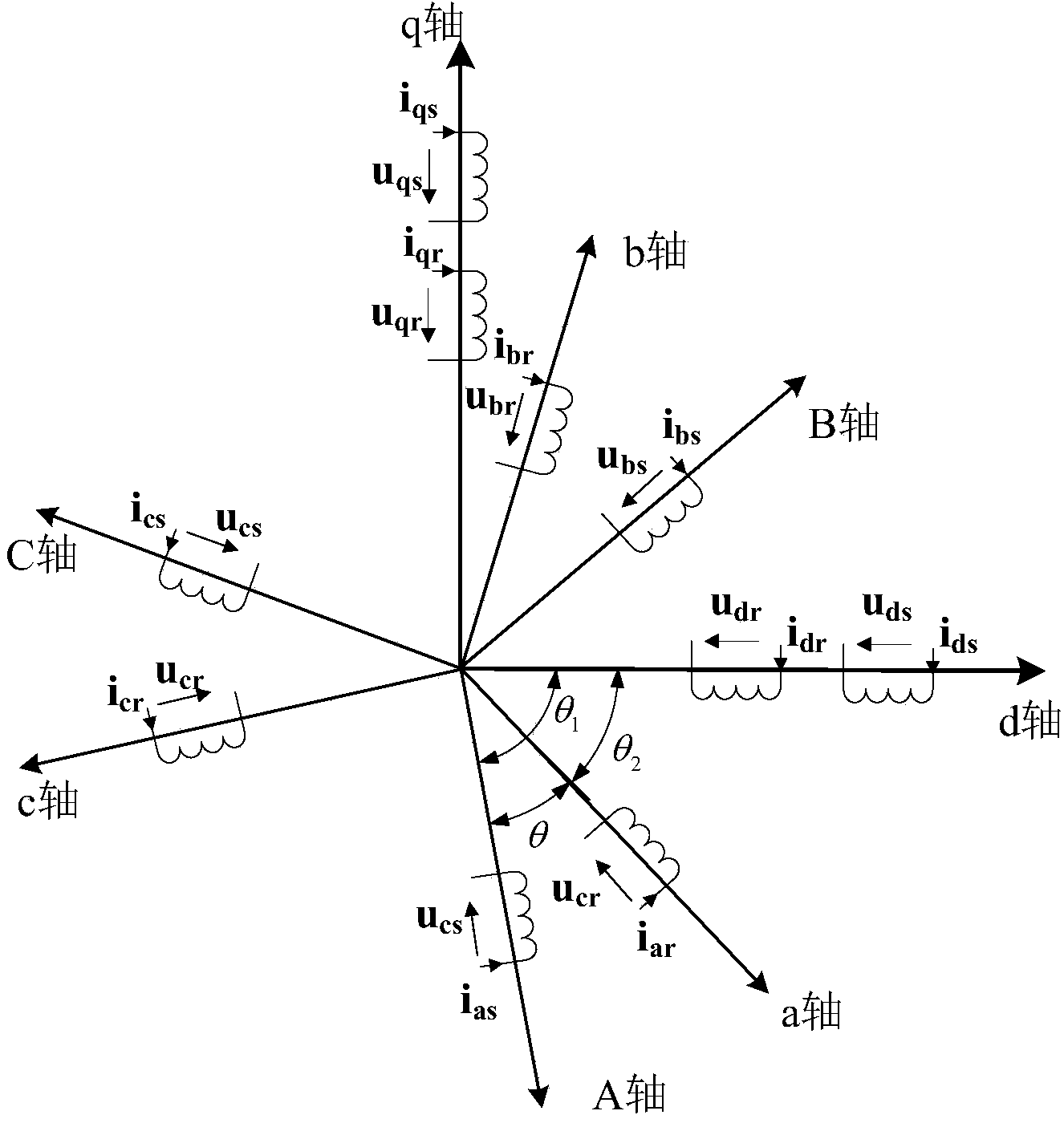

The invention discloses a model prediction-based doubly salient permanent magnet synchronous motor direct torque control method. The model prediction-based doubly salient permanent magnet synchronous motor direct torque control method comprises the following steps that: stator current and rotor angular speed of a doubly salient permanent magnet synchronous motor are acquired; under eight groups of inverter switching vector signals, and based on the stator current and the rotor angular speed, the output current of the motor at a next moment of each kind of inverter switching vector is predicted according to constraint relationships between current variation quantity, micro components and voltage, current under eight kinds of switching states; based on a direct torque control theory, motor torque and motor magnetic flux linkage at the next moment of each kind of inverter switching vector can be further predicted; and related voltage vectors are selected reasonably with realizing minimum total quantity of the torque and the magnetic flux linkage adopted as a target, and therefore, the operation of an inverter can be controlled real time. With the model prediction-based doubly salient permanent magnet synchronous motor direct torque control method of the invention adopted, switching frequency and loss can be effectively decreased, and torque fluctuation of the motor can be decreased.

Owner:HUAZHONG UNIV OF SCI & TECH

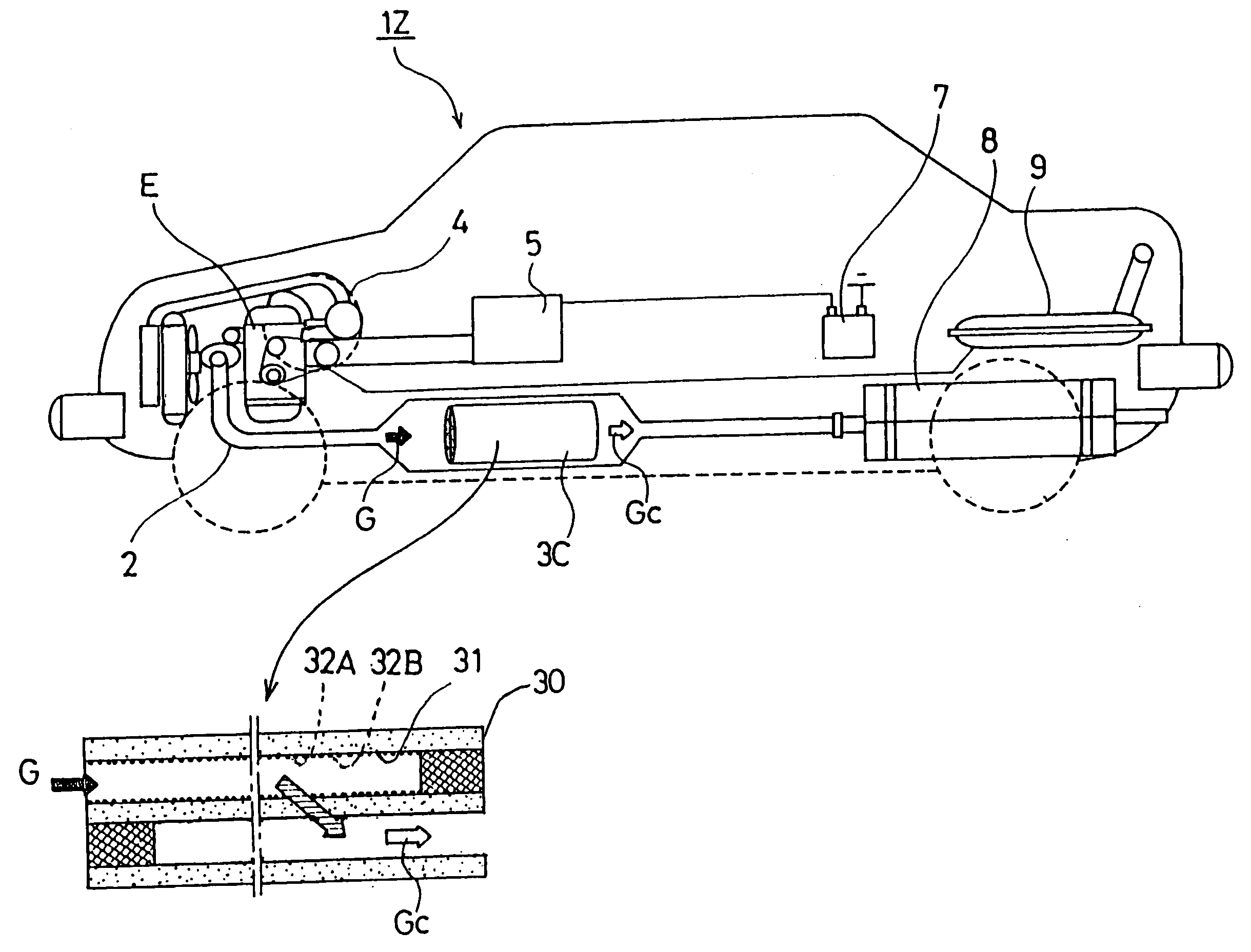

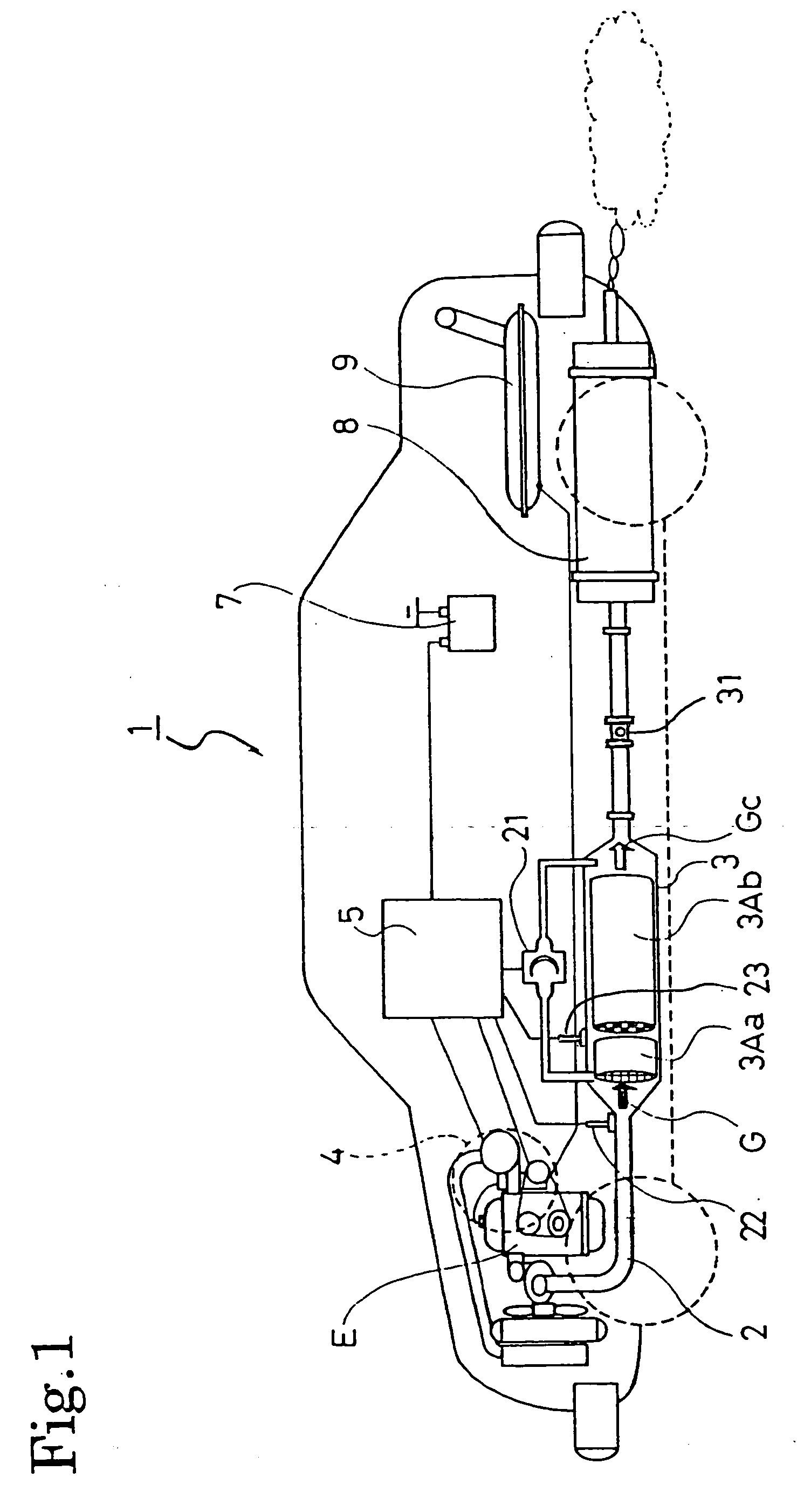

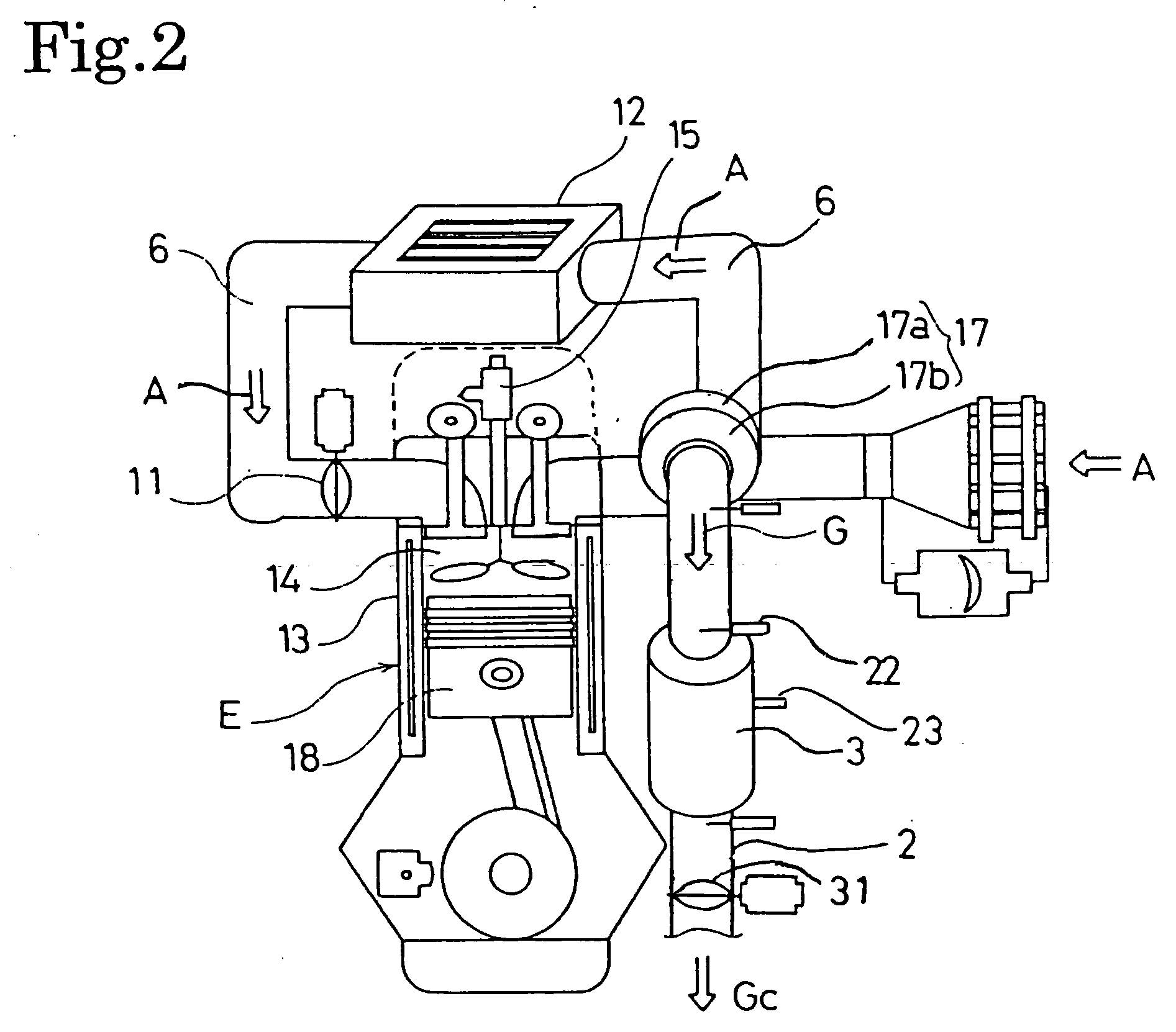

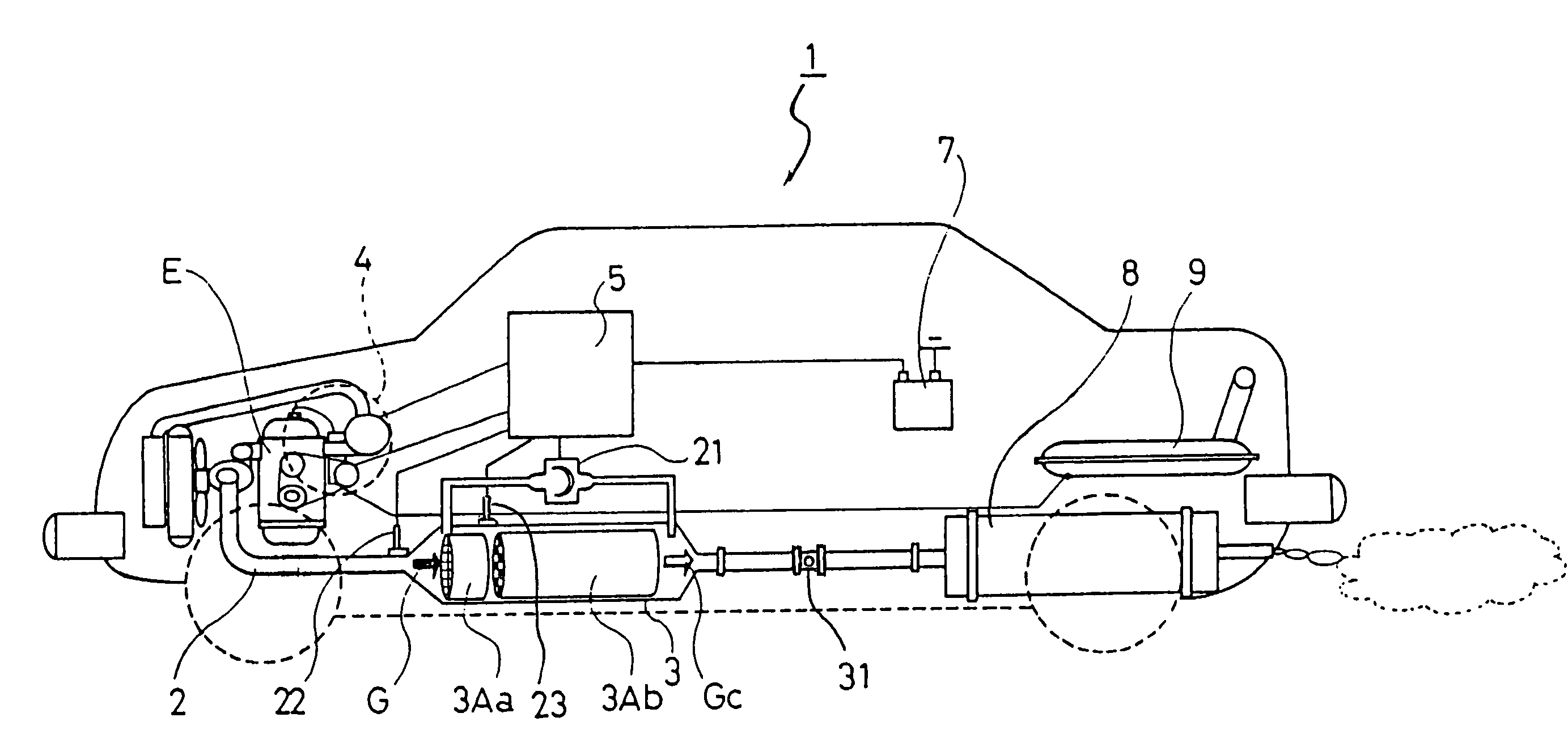

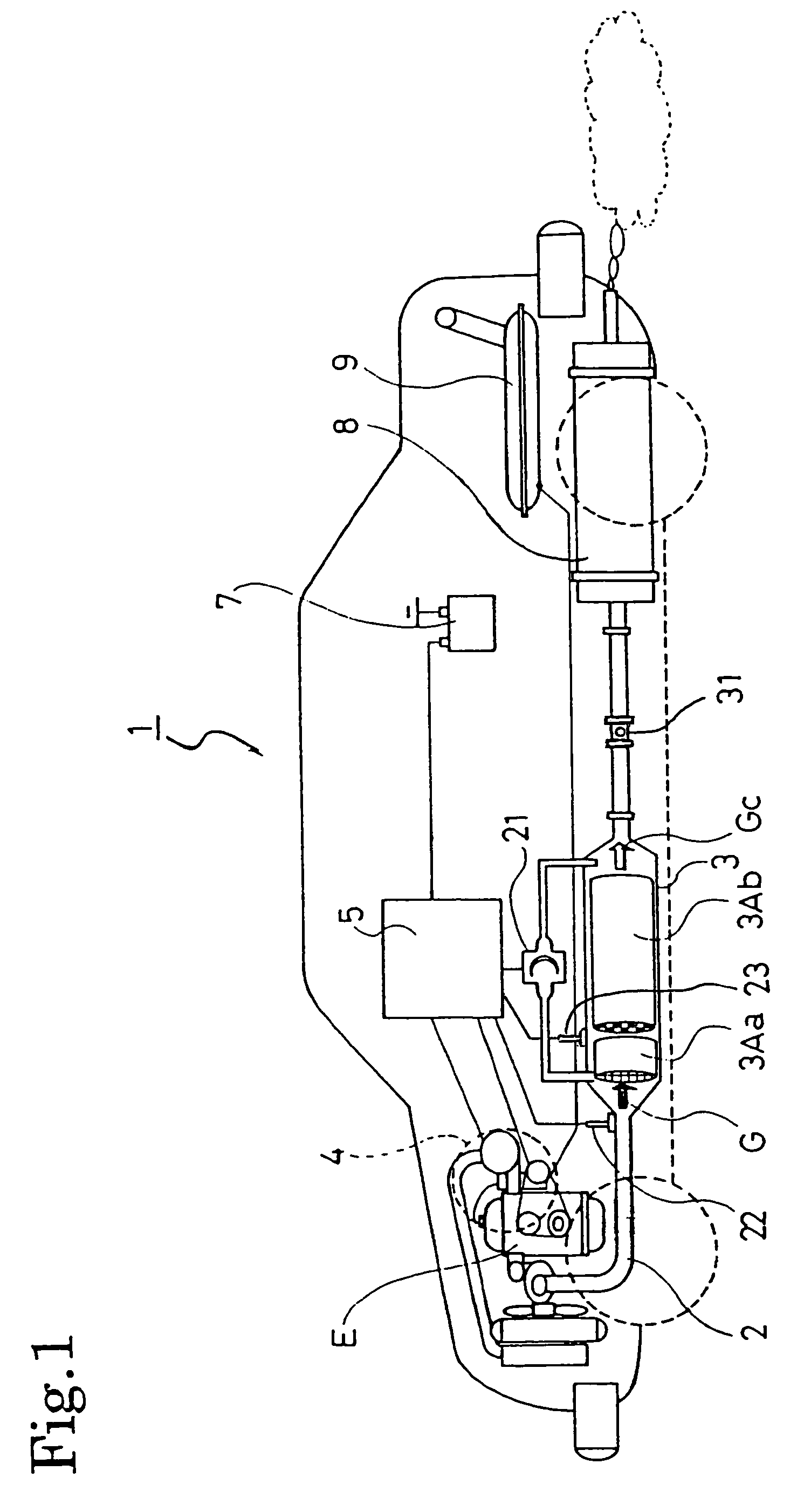

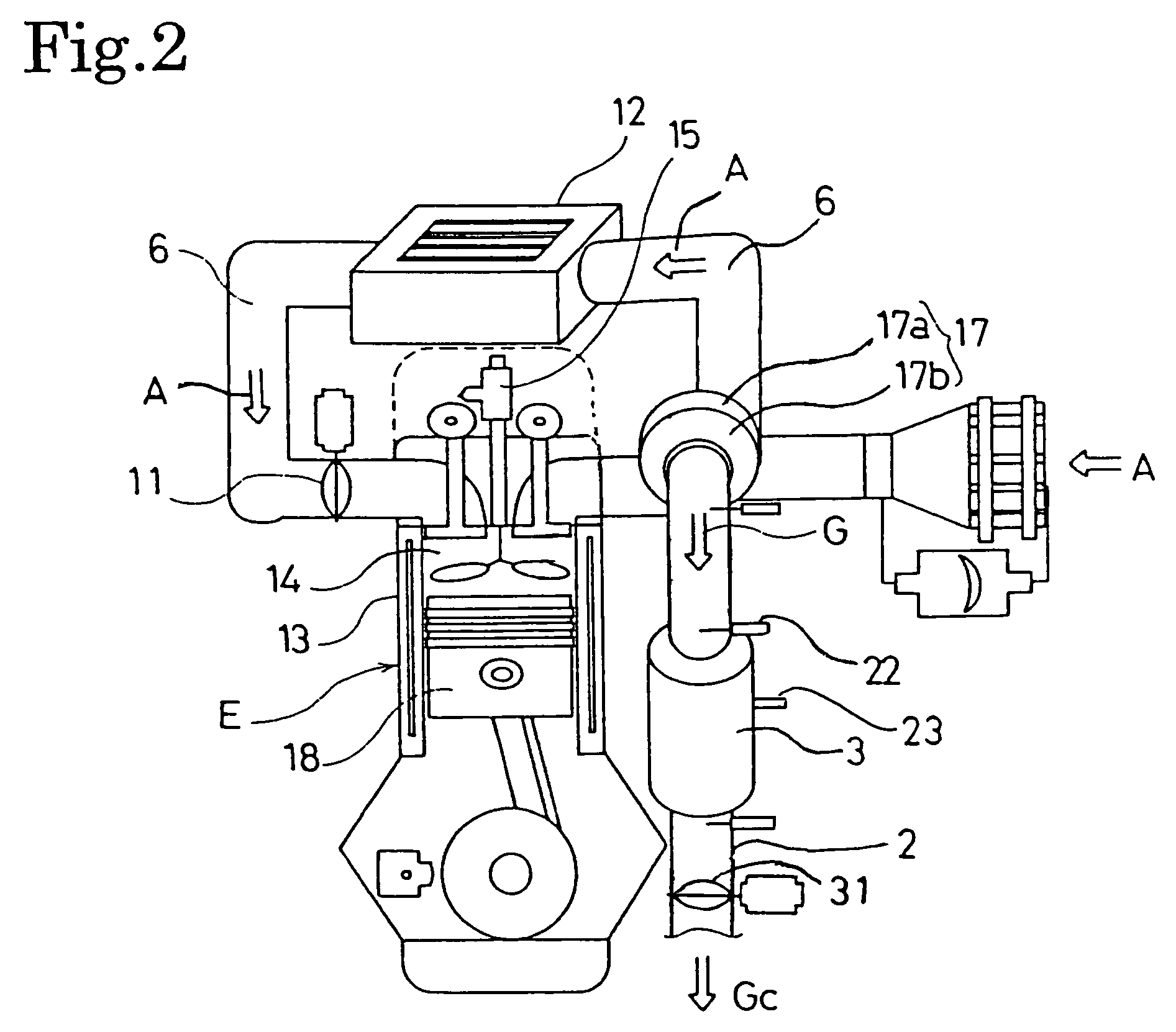

Exhaust gas cleaning system

ActiveUS20060201144A1Improve fuel efficiencyReduce exhaust temperatureElectrical controlInternal combustion piston enginesLower limitCombustion

An exhaust gas purifying system causes less torque fluctuation and is capable of preventing the occurrence of white smoke in a regeneration control operation for regenerating a continuous regeneration DPF 3. When the continuous regeneration DPF 3 with an oxidation catalyst 3Aa on the upstream side of a filter 3Ab is controlled to regenerate, an exhaust throttle valve 31 provided in an exhaust passage 2 is closed and a delay multi-step injection control is performed to increase the temperature of the exhaust gas if an exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa is less than the activation temperature Ta of the oxidation catalyst. After the exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa has risen to the activation temperature Ta of the oxidation catalyst or higher, the exhaust throttle valve 31 is opened in a stepwise or continuous manner so that the exhaust temperature T2 at the inlet of the filter 3Ab rises to a lower limit temperature of PM forced combustion Tb1 or higher.

Owner:ISUZU MOTORS LTD

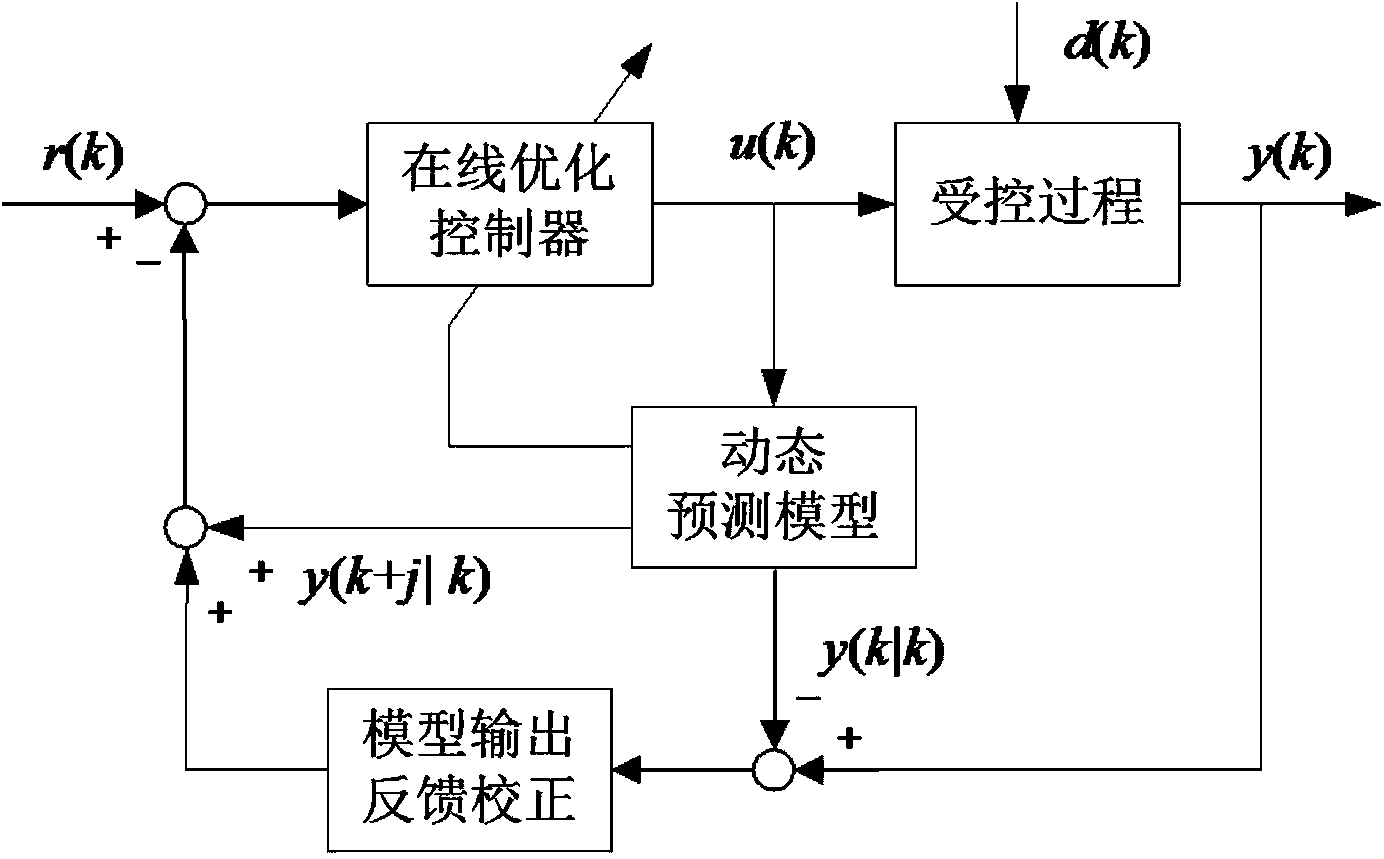

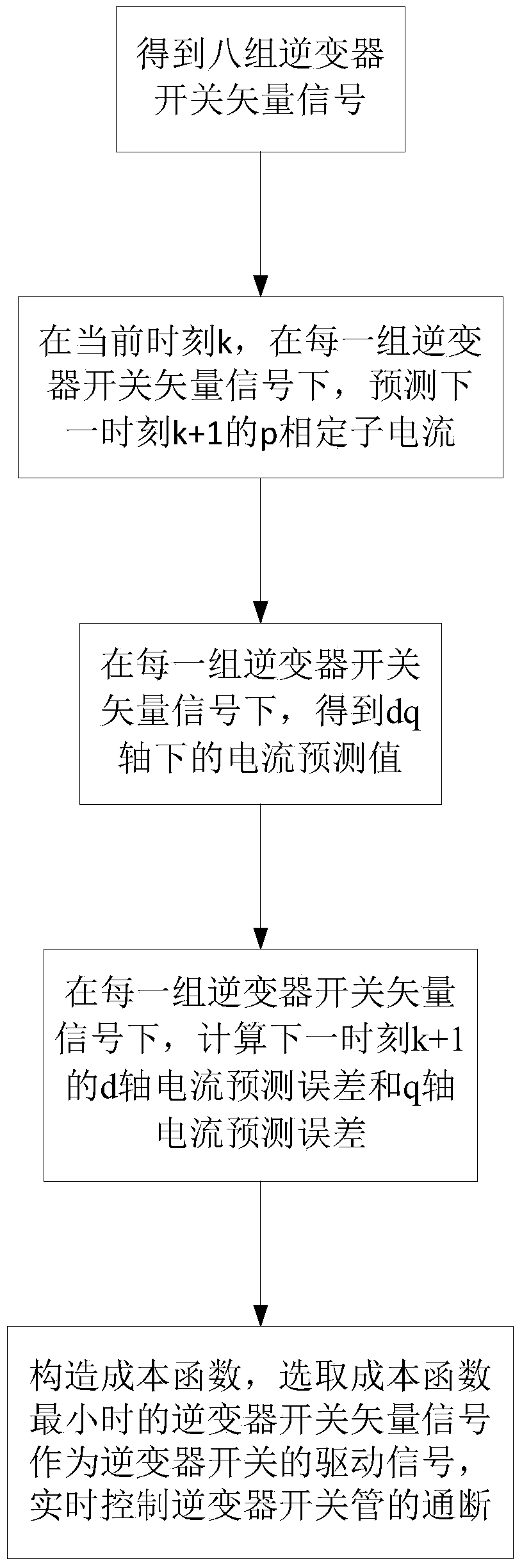

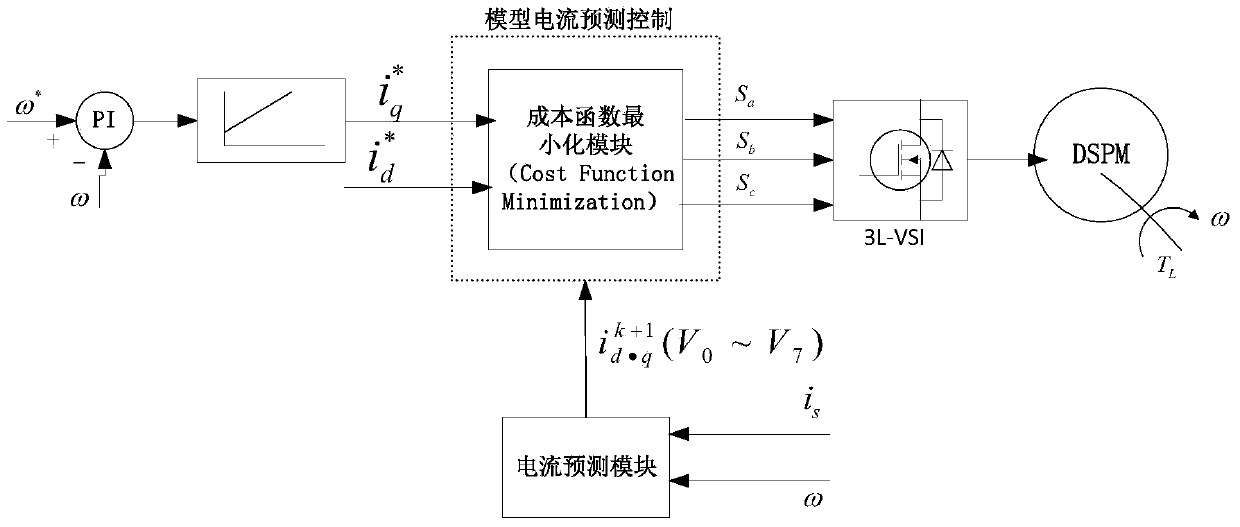

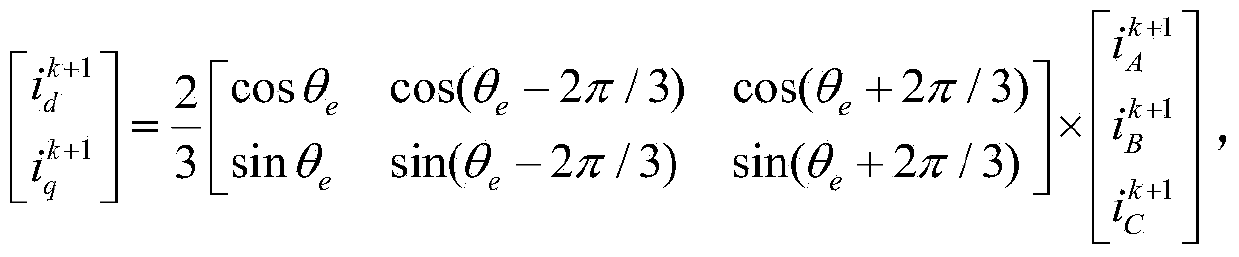

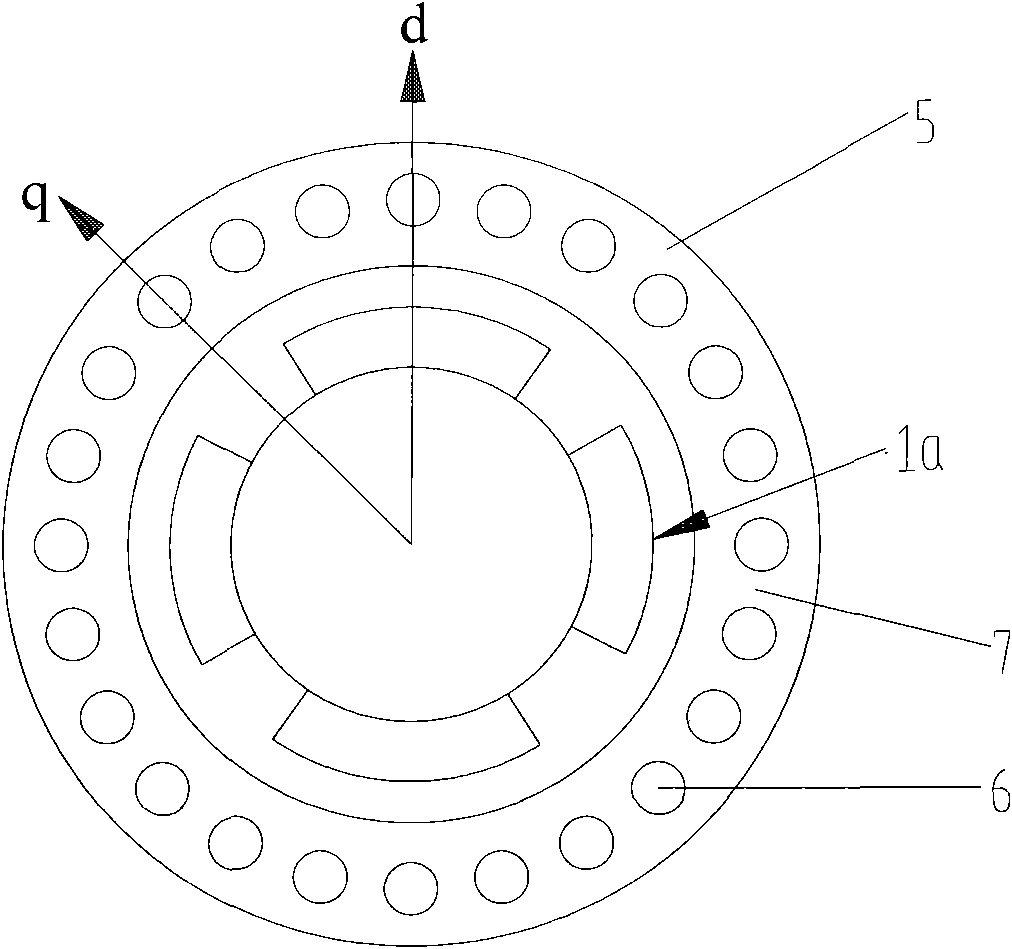

Double salient permanent magnet (DSPM) current control method based on model prediction

ActiveCN103746624AEasy to controlPrecise control of switching vector changesElectronic commutation motor controlVector control systemsTime controlControl theory

The invention discloses a double salient permanent magnet (DSPM) current control method, which comprises the following steps: obtaining eight groups of inverter switching vector signal; at the current time k, predicting p-phase stator current of next time k+1 in each group of inverter switching vector signal (img file='DDA0000448969140000011.TIF' wi='88' he='65' / ), wherein p represents A, B and C phases of a motor; in each group of inverter switching vector signal, obtaining the current predicted value of d -axis and q -axis according to (img file='DDA0000448969140000012.TIF' wi='96' he='64' / ); in each group of inverter switching vector signal, calculating d-axis current prediction error (img file='DDA0000448969140000013.TIF' wi='72' he='64' / ) and q-axis current prediction error (img file='DDA0000448969140000014.TIF' wi='104' he ='68' / ) of the next time k +1; according to (img file='DDA0000448969140000015.TIF' wi='72' he ='66' / ) and (img file='DDA0000448969140000016.TIF' wi='112' he='64' / ), selecting the switching vector signal of the minimum total amount of torque fluctuation and flux fluctuation as a drive signal of the inverter switch, thereby real-time controlling on-off of a inverter switch tube. The method by accurately controlling the DSPM motor output current, accurately control the inverter switching vector change, so that the motor torque fluctuation and flux fluctuation are minimum, the requirement for electrode parameters is low, and the response speed is fast.

Owner:HUAZHONG UNIV OF SCI & TECH

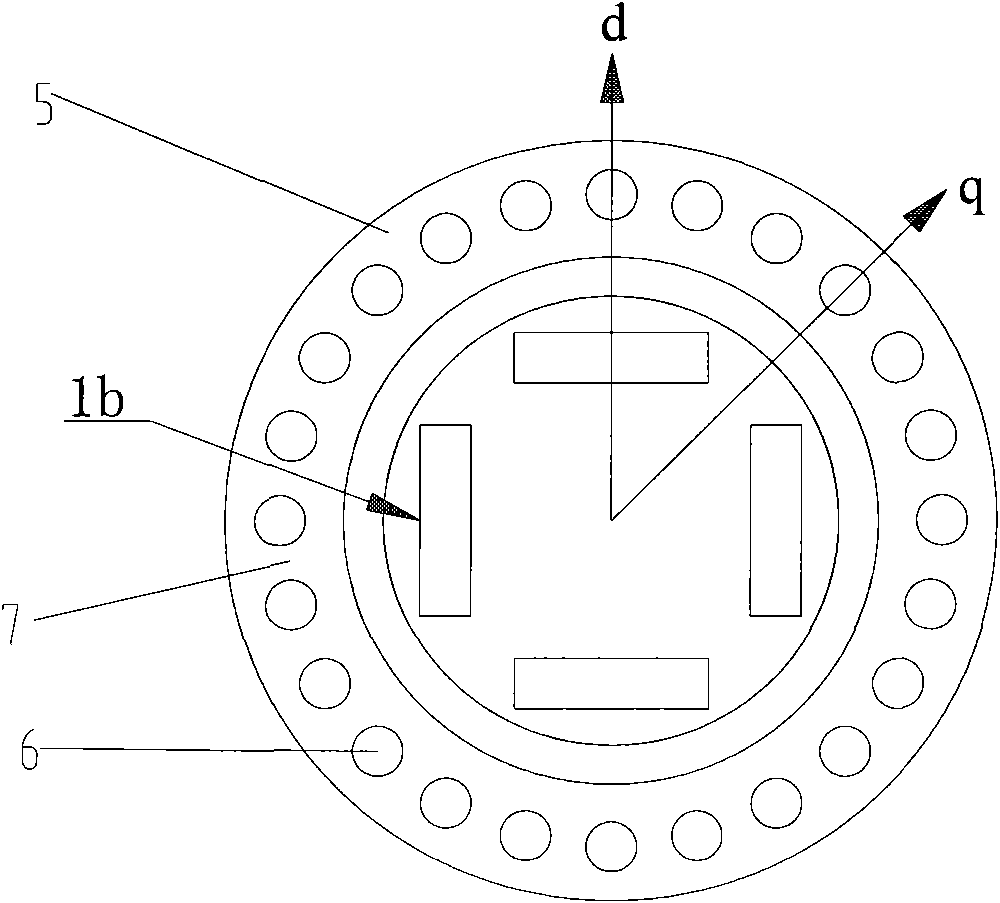

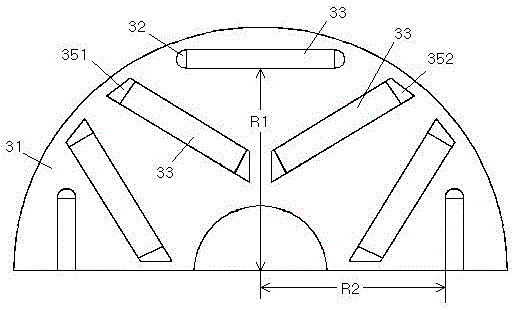

Asymmetric permanent magnet motor for new energy automobile

InactiveCN105449894AImprove power densityImprove reliabilityMagnetic circuit rotating partsLeft halfElectric machine

The invention discloses an asymmetric permanent magnet motor for a new energy automobile, relates to the technical field of motors, and aims to lower torque fluctuation. The motor comprises rotors and a stator, wherein a plurality of permanent magnet units are arranged on the rotors; and the permanent magnet units comprise permanent magnet grooves and magnetic steel embedded into the permanent magnet grooves. The asymmetric permanent magnet motor is characterized in that magnetic pole axes of the rotors partition the permanent magnet units into left halves and right halves; and the left halves and the right halves of the permanent magnet units have different structures. Through adoption of the motor provided by the invention, the comprehensive performance of the motor can be enhanced.

Owner:SHANGHAI TOP MOTOR +1

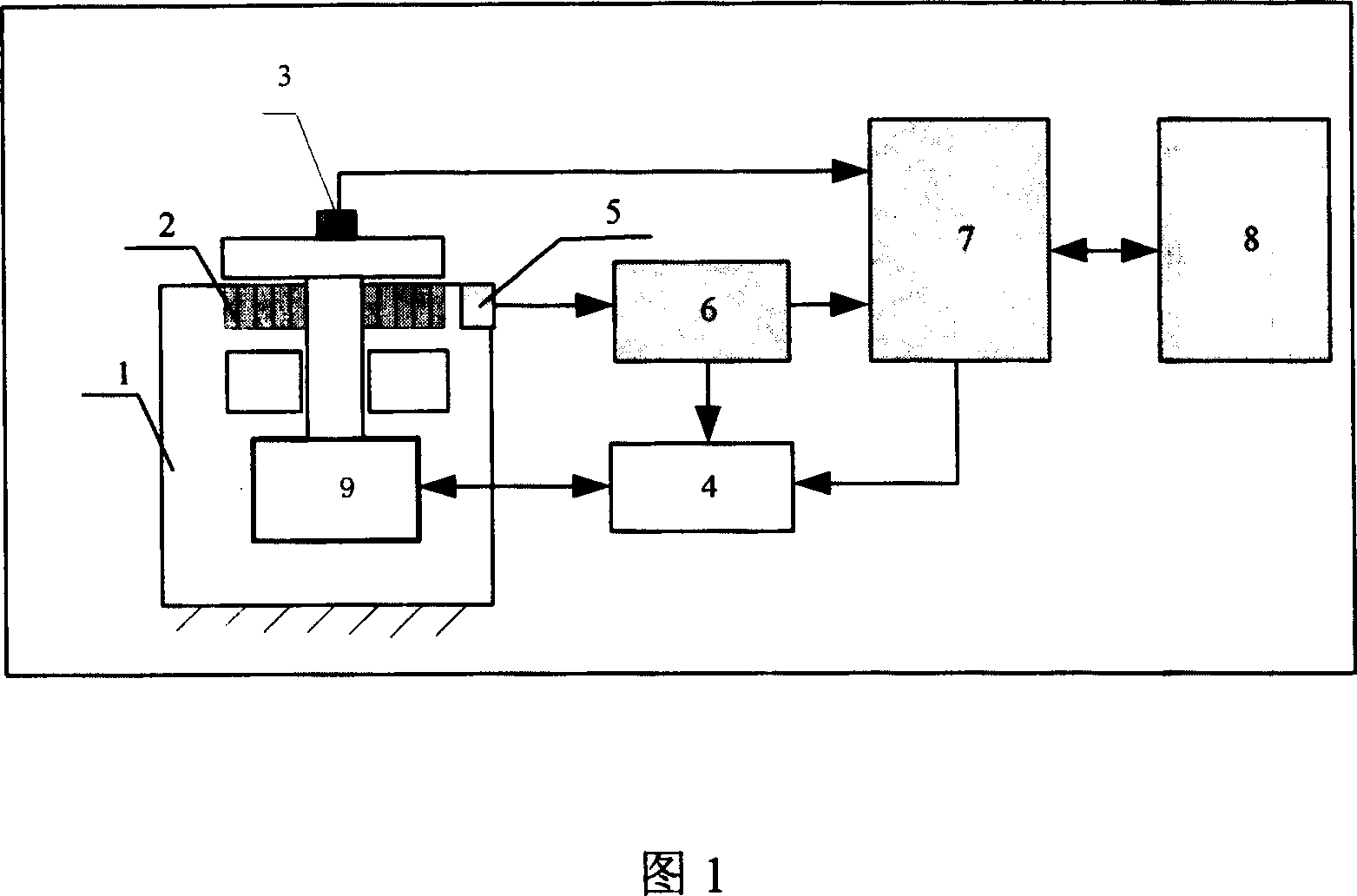

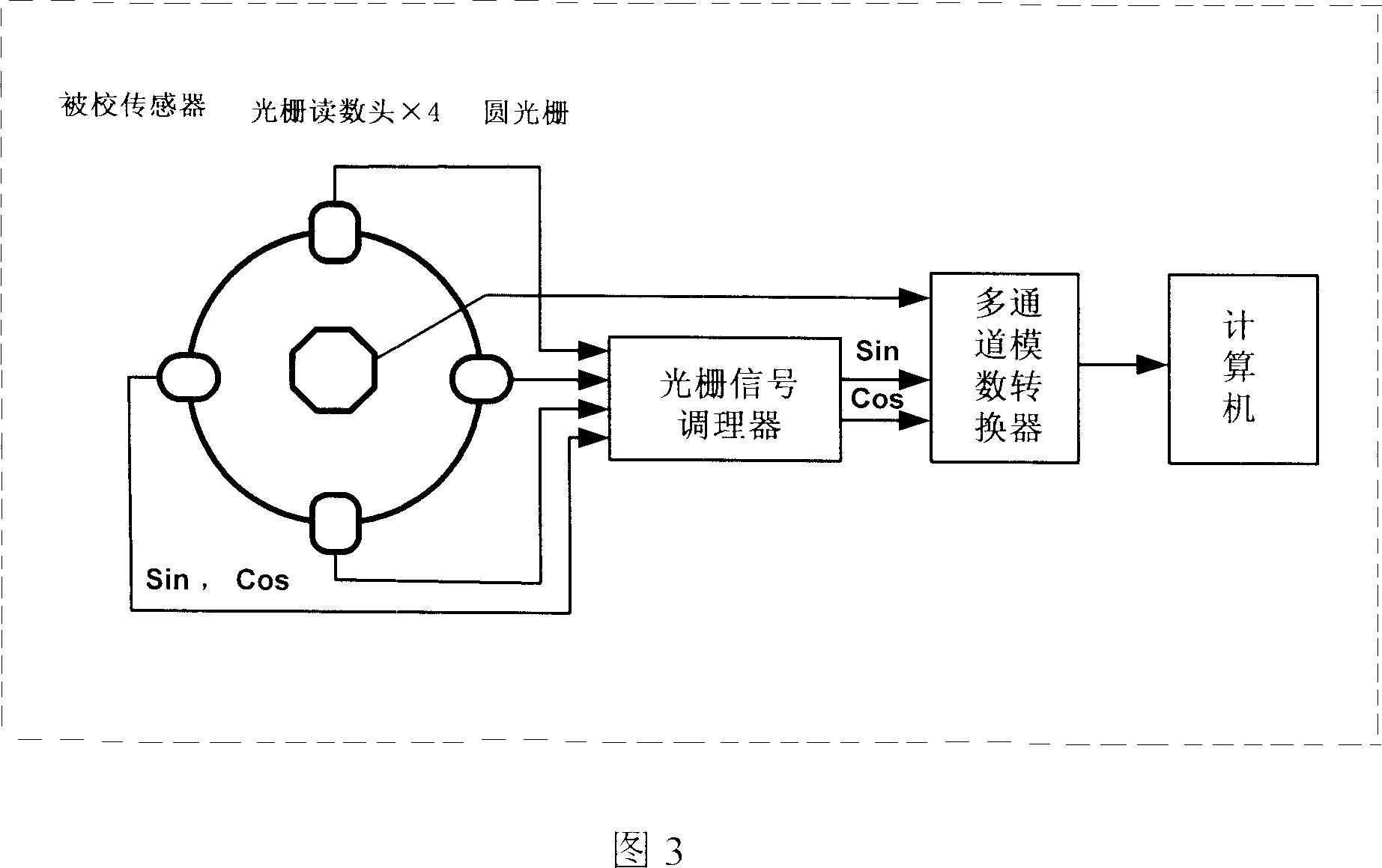

Low frequency angle vibration table

InactiveCN1955644AHigh rotation accuracyImprove athletic abilityTesting/calibration of speed/acceleration/shock measurement devicesSignal qualityGrating

An angular vibration table of low frequency is prepared as using control system to control mechanical vibration table to generate sine vibration according to property of calibrated transducer, sending one path of grating output signal to control system for carrying out closed loop control and another path to data collection system being used to simultaneously collect output signals of grating and calibrated transducer, obtaining relation curve of time and movement amount after said signals are processed by data processing unit then calculating out phase-shift and magnitude sensitivity of calibrated transducer.

Owner:BEIJING CHANGCHENG METERING TEST TECH INST NO 1 GRP CO CHINA AVIATION IND

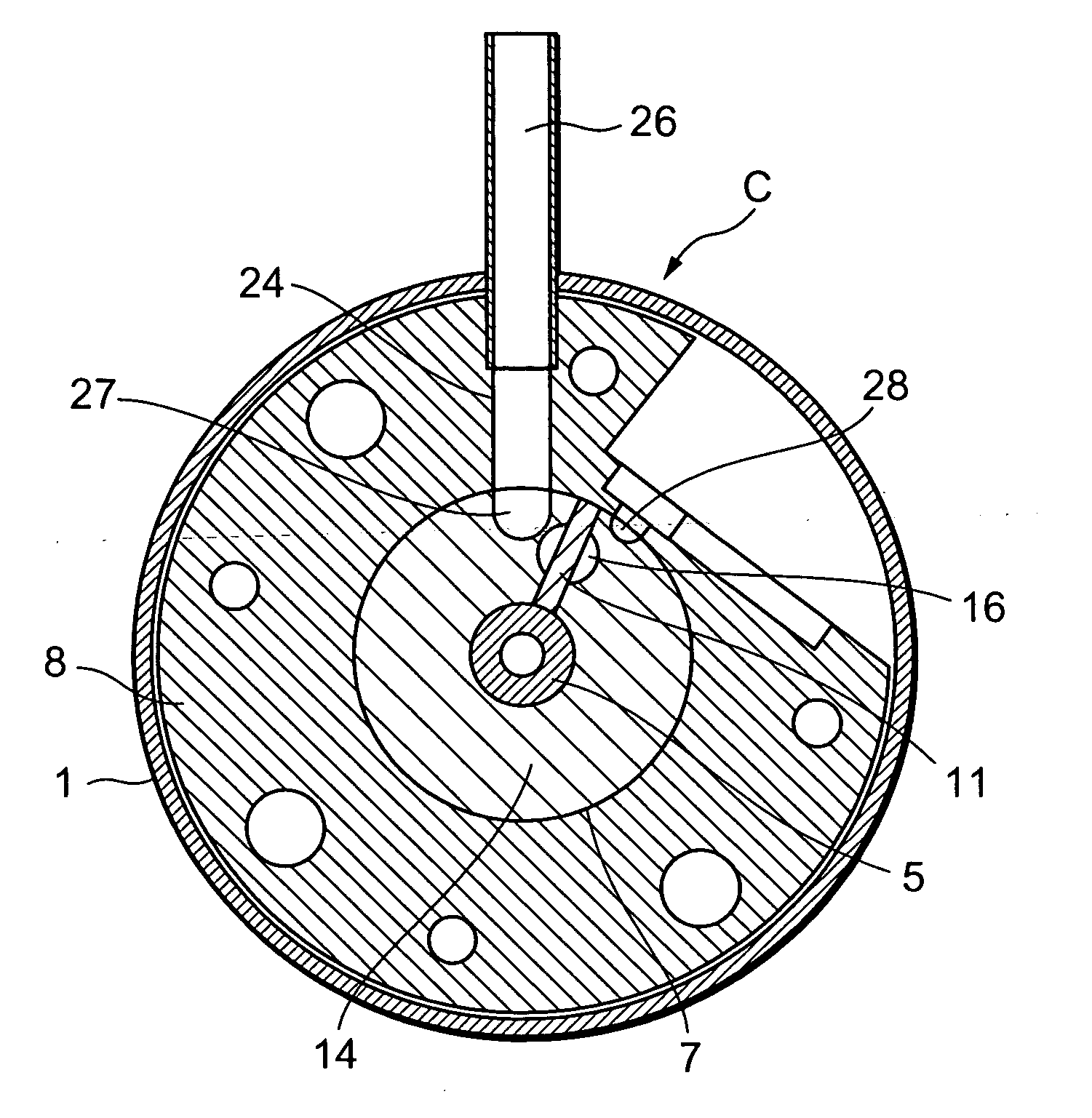

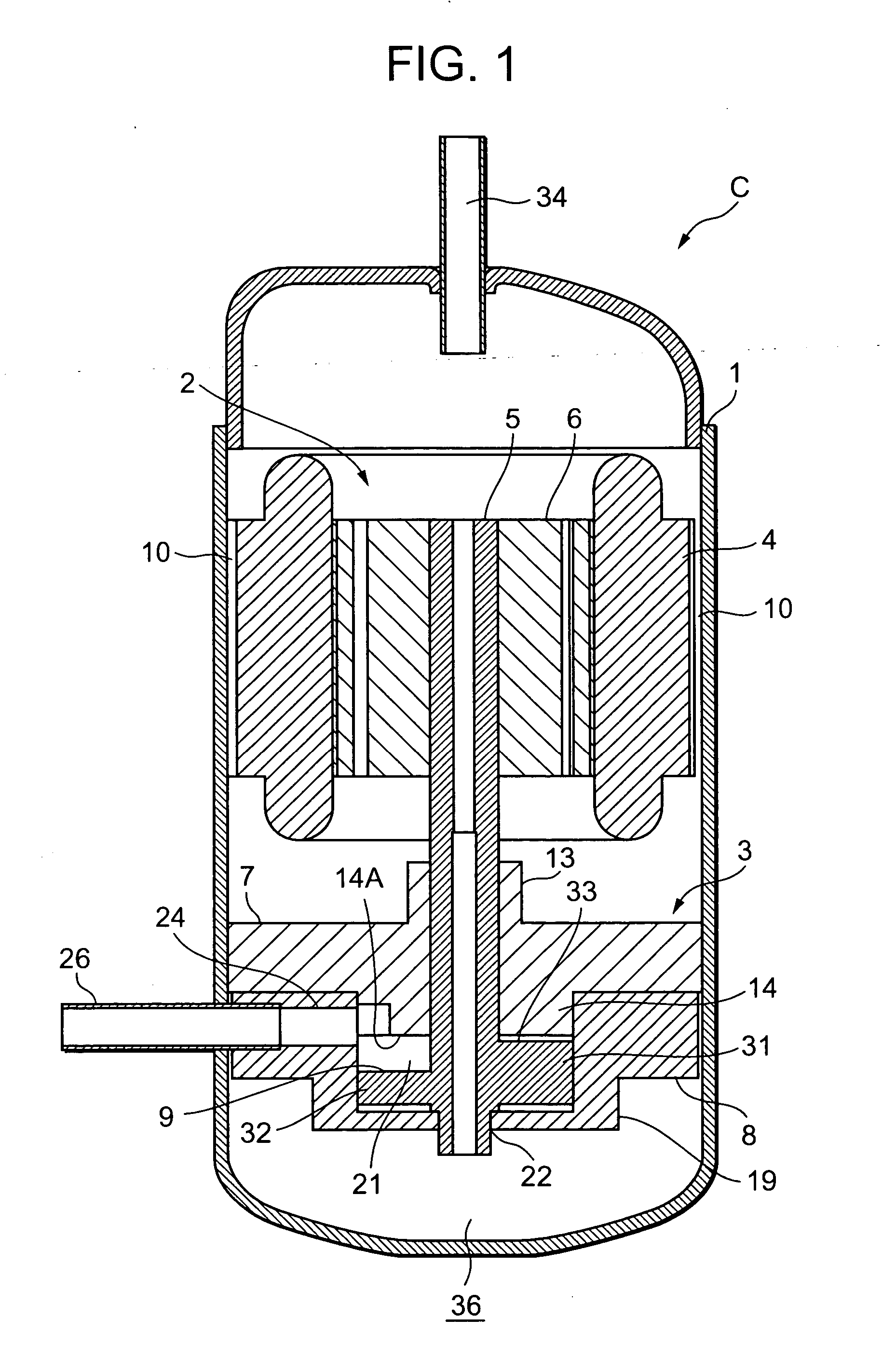

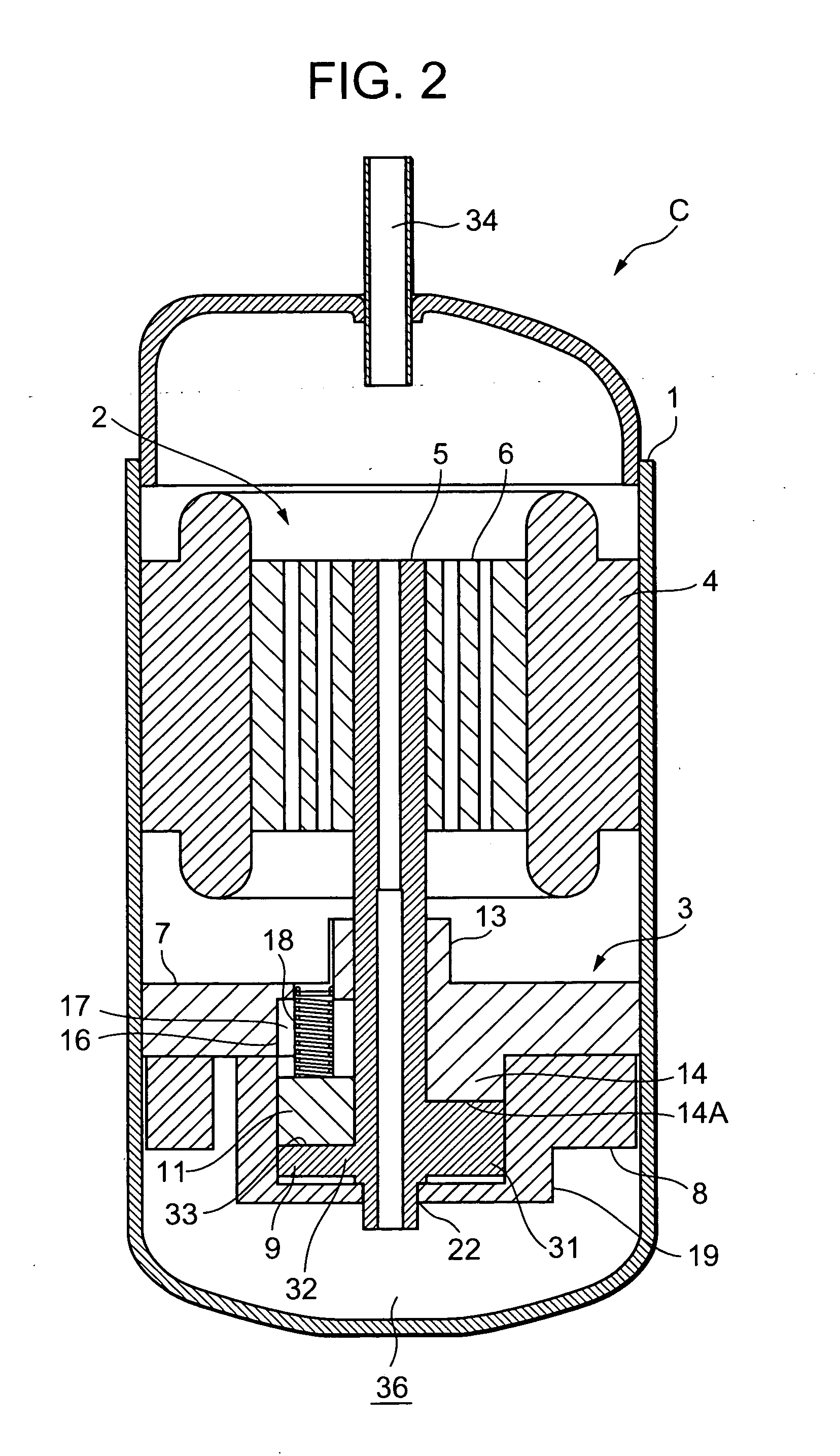

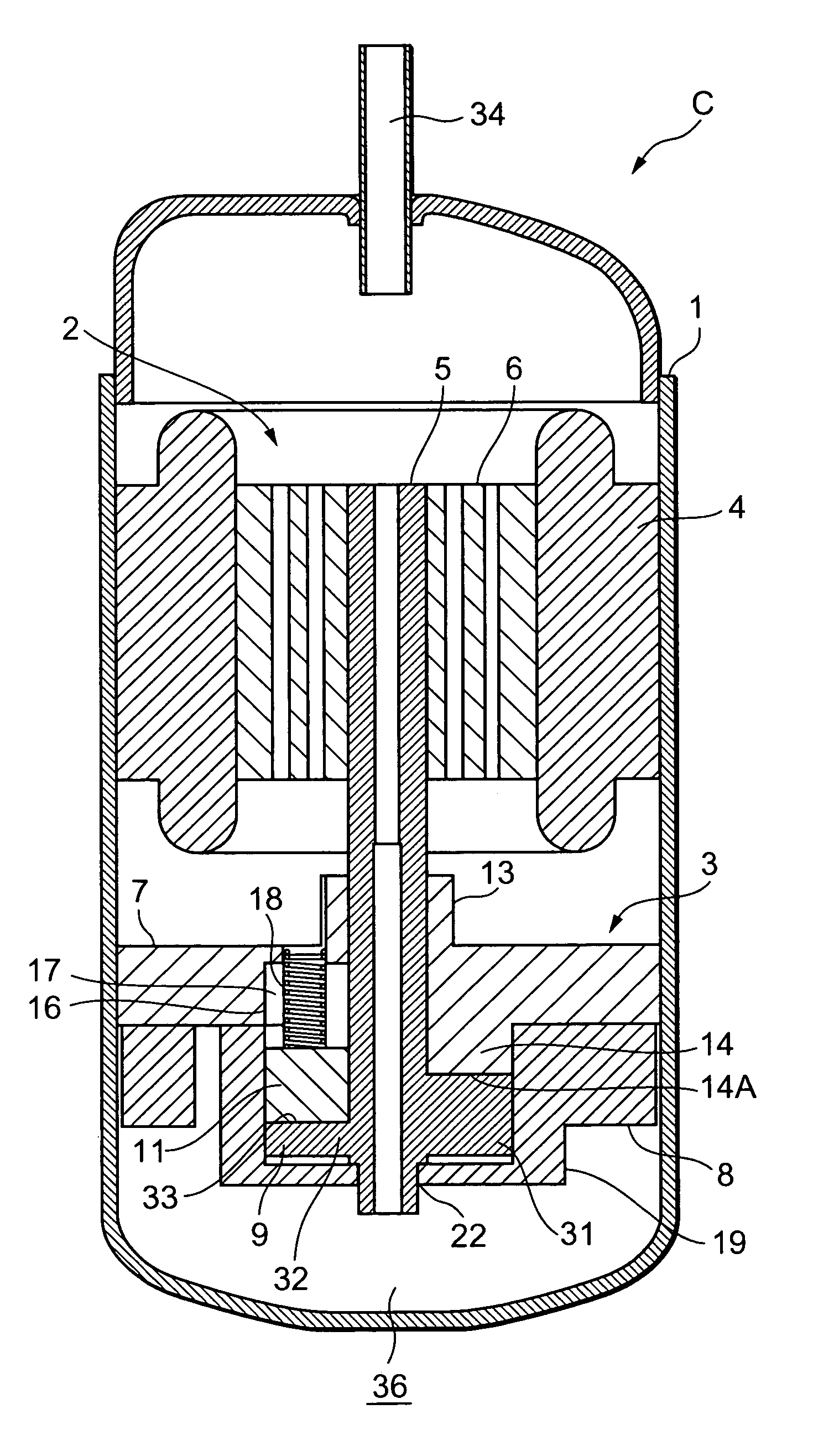

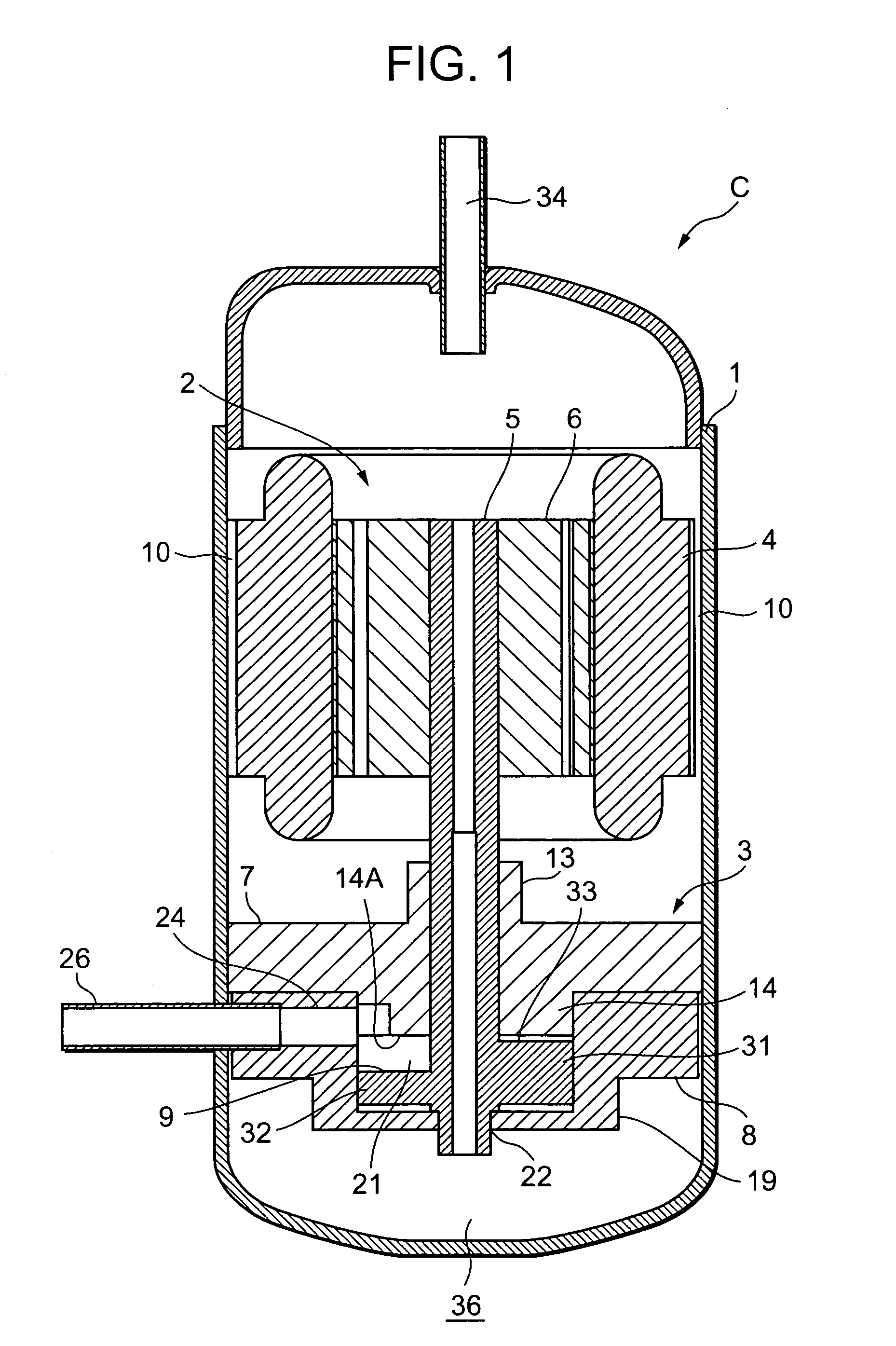

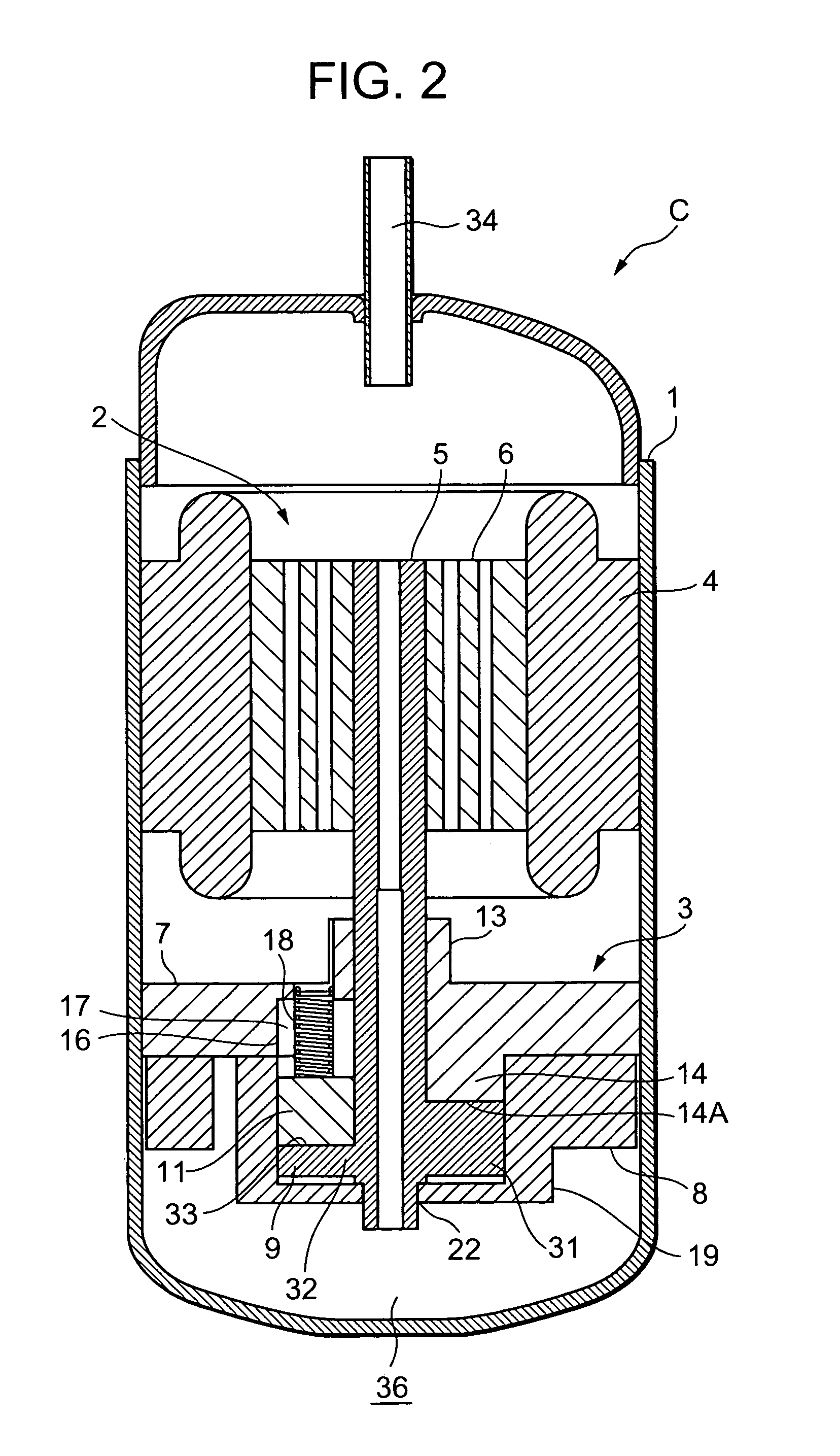

Compressor

InactiveUS20050152792A1Prevention of efficiency deteriorationSimple structureRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesHigh pressure chamberEngineering

There is provided an efficient compressor which is simple in structure and small in torque fluctuation. The compressor comprises a compression element which comprises a cylinder having a compression space formed therein, a suction port and a discharge port which communicate with the compression space in the cylinder, a compression member which comprises continuous thick and thin parts, one surface of which inclines, which is arranged in the cylinder to rotate, and which compresses fluids sucked through the suction port and discharges the compressed fluids through the discharge port, and a vane which is arranged between the suction port and the discharge port to abut on one surface of the compression member, and which partitions the compression space of the cylinder into a low pressure chamber and a high pressure chamber.

Owner:SANYO ELECTRIC CO LTD

Exhaust gas cleaning system

ActiveUS7337608B2Small torque fluctuationElectrical controlInternal combustion piston enginesLower limitCombustion

An exhaust gas purifying system causes less torque fluctuation and is capable of preventing the occurrence of white smoke in a regeneration control operation for regenerating a continuous regeneration DPF 3. When the continuous regeneration DPF 3 with an oxidation catalyst 3Aa on the upstream side of a filter 3Ab is controlled to regenerate, an exhaust throttle valve 31 provided in an exhaust passage 2 is closed and a delay multi-step injection control is performed to increase the temperature of the exhaust gas if an exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa is less than the activation temperature Ta of the oxidation catalyst. After the exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa has risen to the activation temperature Ta of the oxidation catalyst or higher, the exhaust throttle valve 31 is opened in a stepwise or continuous manner so that the exhaust temperature T2 at the inlet of the filter 3Ab rises to a lower limit temperature of PM forced combustion Tb1 or higher.

Owner:ISUZU MOTORS LTD

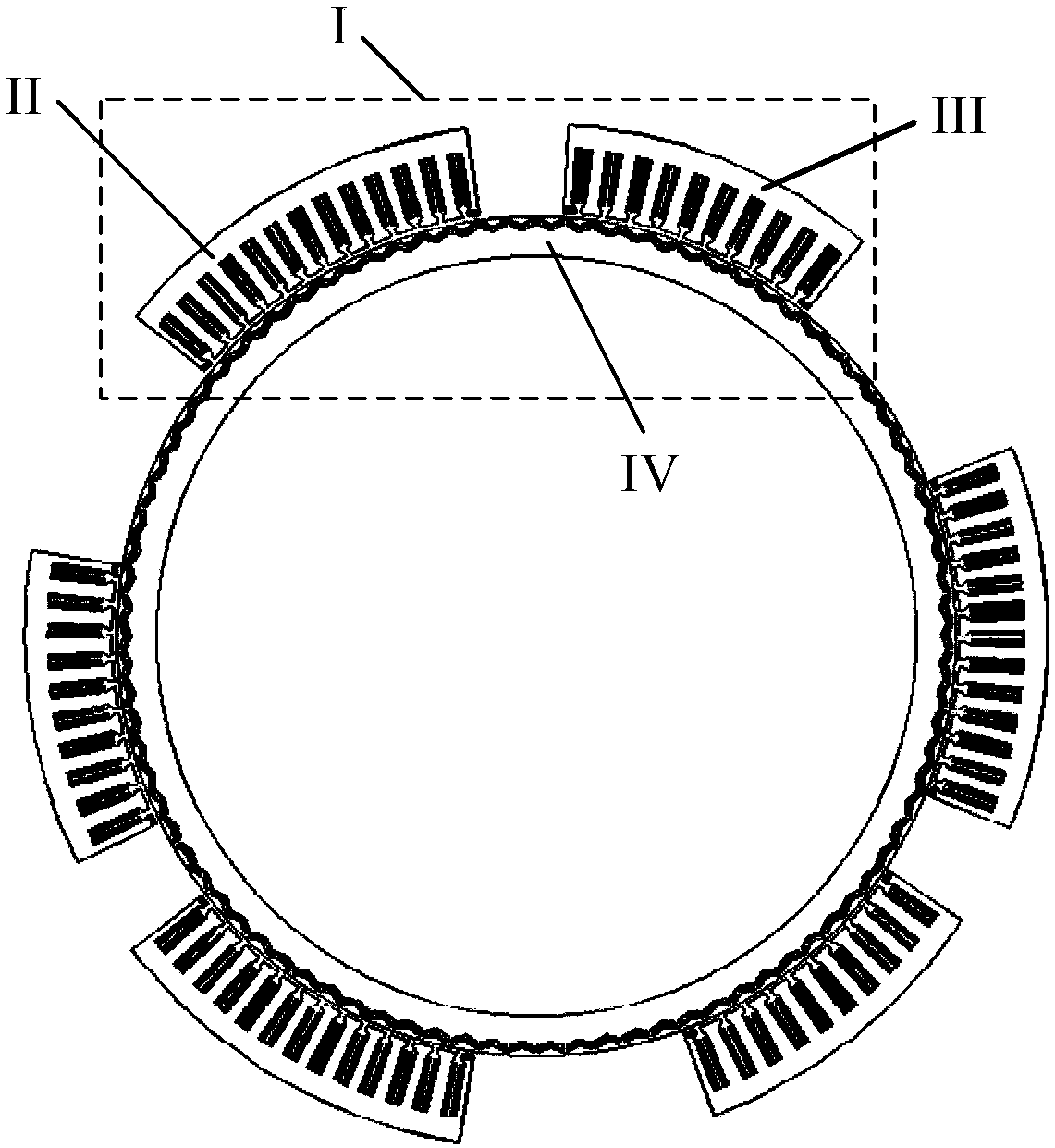

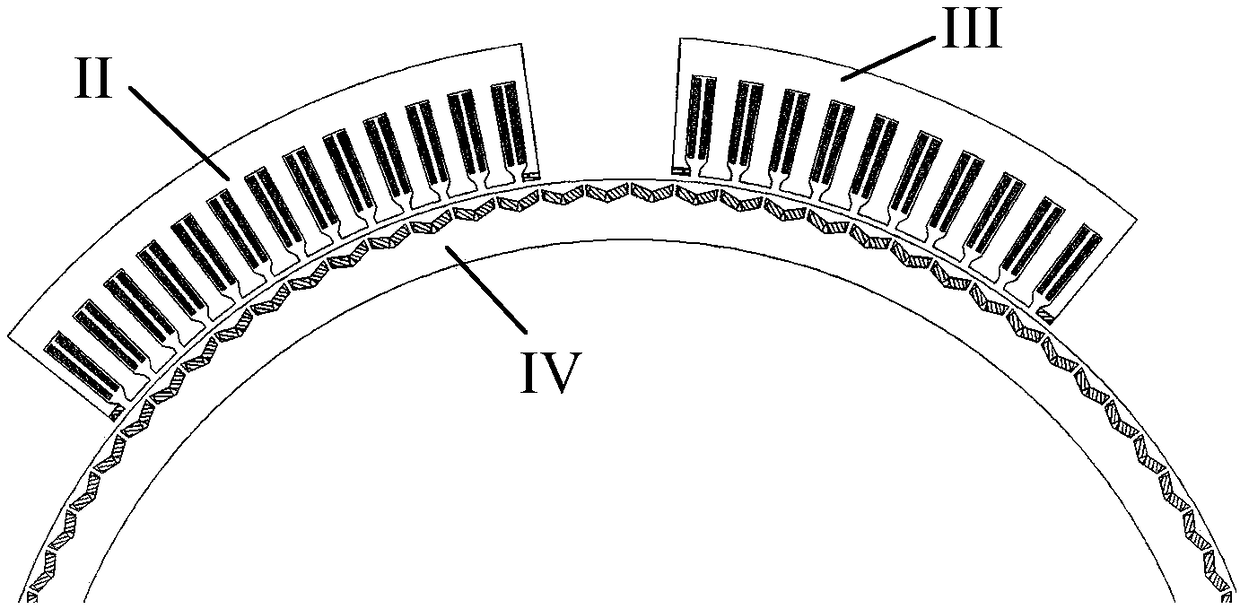

Asymmetric double three phase camber line permanent-magnet synchronous electrical machine

ActiveCN108429420AIncreased torque densityImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic effectLow speed

The invention discloses an asymmetric double three phase camber line permanent-magnet synchronous electrical machine. The electrical machine comprises two parts that are stator combinations (I) and arotor (IV), wherein the three stator combinations (I) form a camber line structure on a circumference outside the rotor (IV), each stator combination (I) comprises a 12-slot stator module (II) and a 9-slot stator module (III) arranged side by side on the circumference outside the rotor (IV), the 12-slot stator module (II) and the rotor (IV) form a 12-slot 10-pole unit motor, the 9-slot stator module (III) and the rotor (IV) form a 9-slot 8-pole unit motor, the stator combinations (I) and the rotor (IV) together form the two-phase three phase electrical machine, permanent magnets are arranged in the rotor in an embedded manner in such a way that a V shape structure is formed, strong assembled magnetic effects are exerted, main magnetic flux can be effectively improved, torque density of theelectrical machine can be improved, the permanent magnets form 120 pairs of electrodes, the electrical machine is enabled to be characterized by low speed and large torque, and the electrical machineis applied to low speed and large torque direct driving occasions and large aperture astronomical telescope driving occasions.

Owner:SOUTHEAST UNIV

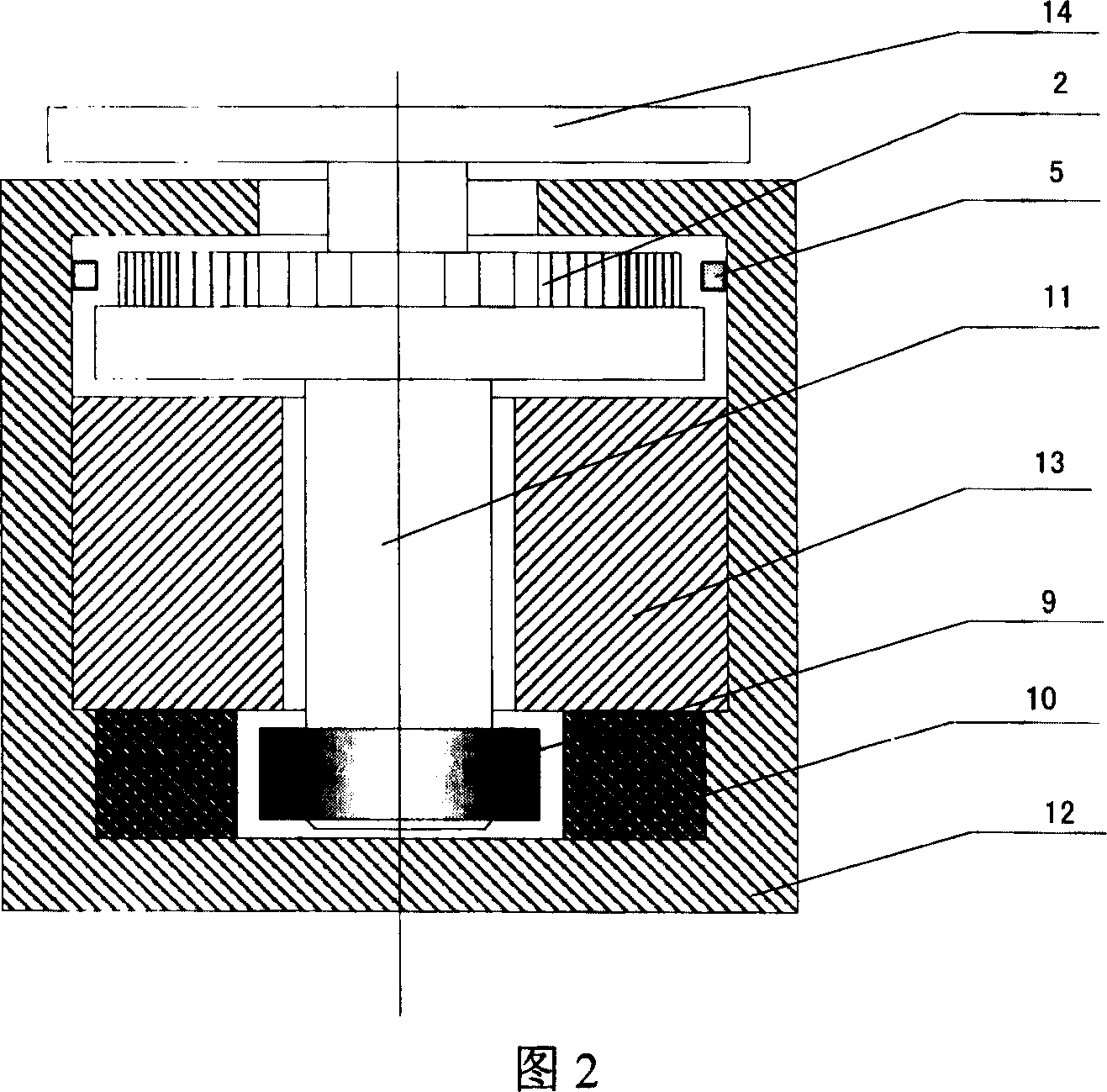

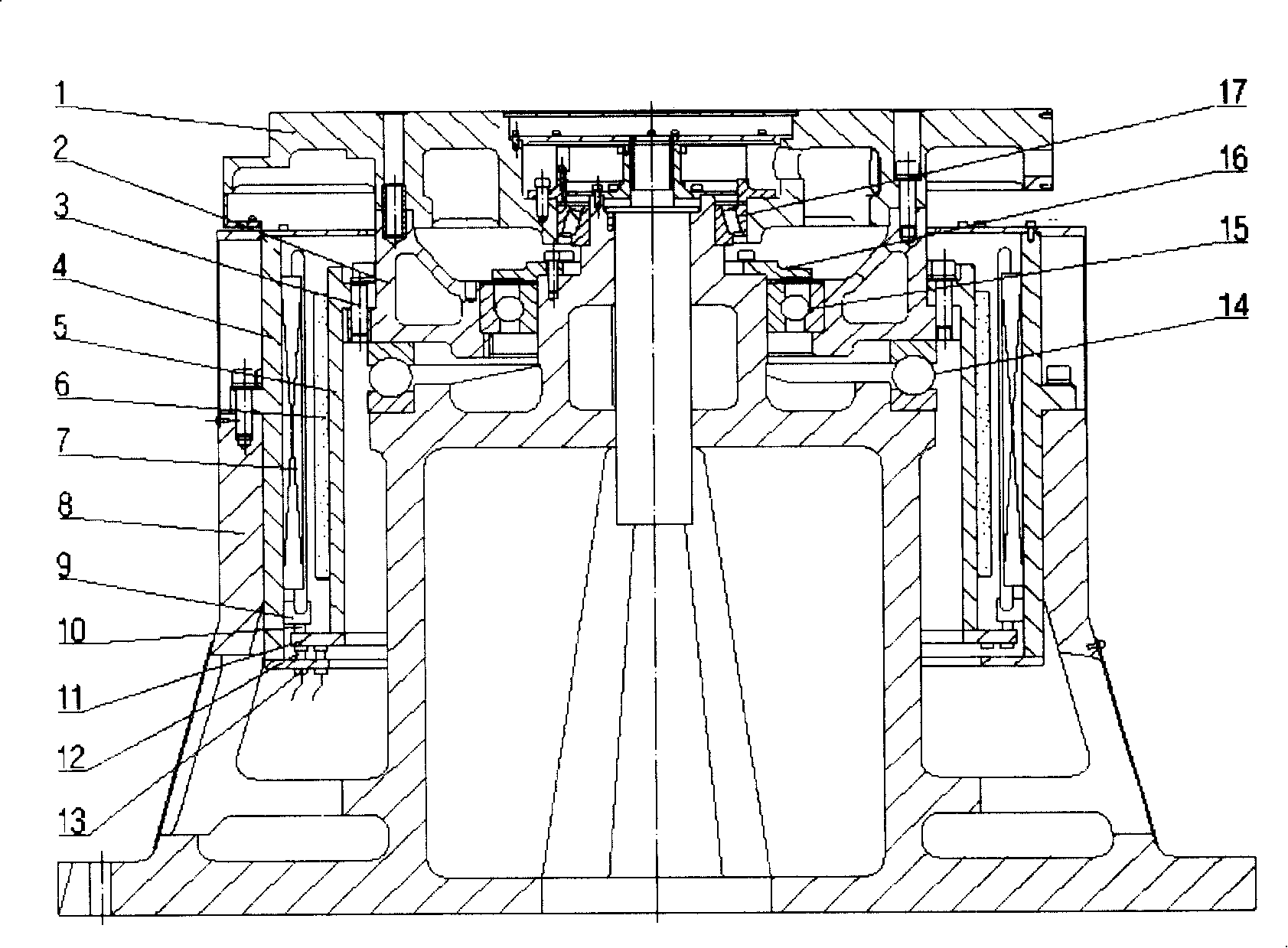

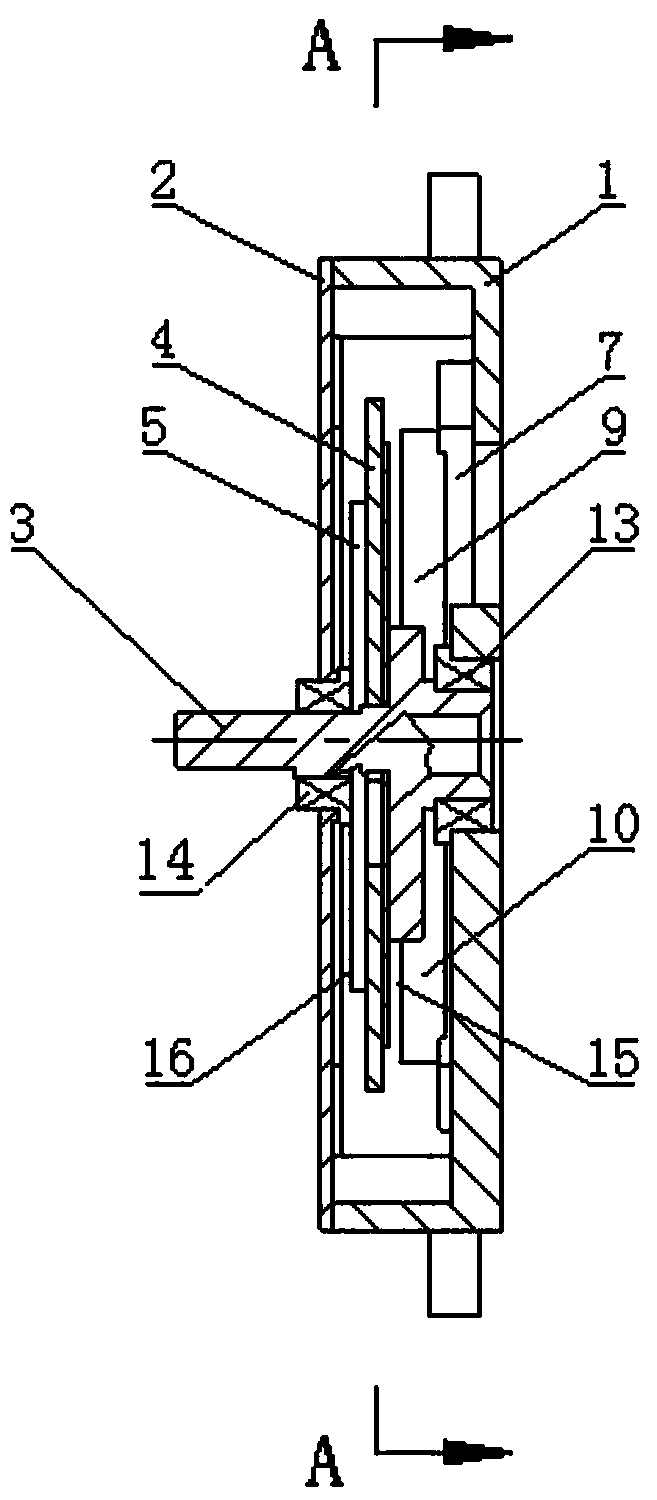

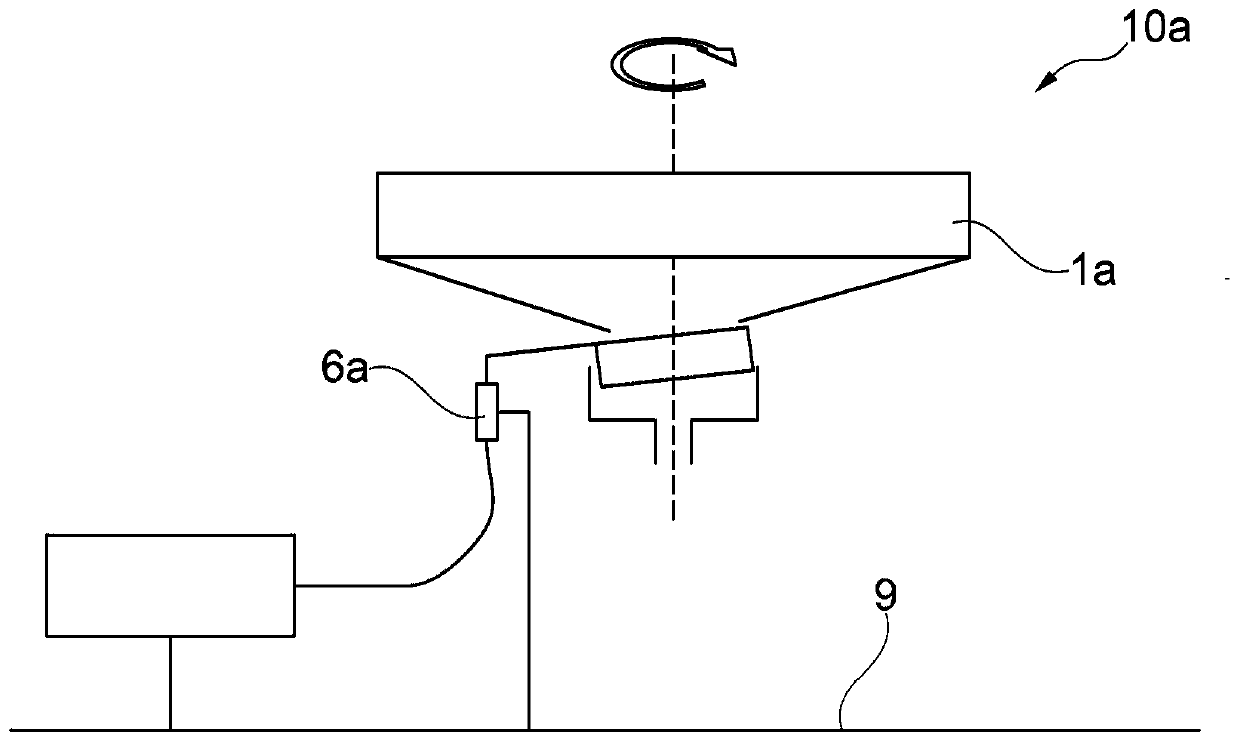

Novel direct current driving turntable structure

InactiveCN101162857ASmall moment of inertiaSmall torque fluctuationMagnetic circuit rotating partsDC commutatorBall bearingThrust bearing

The invention relates to a novel rotary table driven by a DC motor. The motor stator is mounted on a frame, windings and an iron core are mounted on the inner side of the stator, and a commutator is arranged at the lower end of the windings. The wire inlet terminal and the brush of the conducting ring are fixed on the lower end of the stator; the motor stator is fixed on the main shaft; the worktable face is connected to the main shaft by bolts; an alnico is fixed on the stator, the brush with a conducting ring is mounted on the bottom of the stator by a frame; the brush of the commutator is mounted on the brush frame provided with a conducting ring, and the brush of the commutator contacts with the commutator; and the conducting-ring brush contacts with the conducting ring arranged on the brush frame provided with a conducting ring. The part between the main shaft and the frame is supported by a thrust ball bearing and an angular-contact ball bearing, and the part between the worktable face connected with the main shaft and the frame is supported by a tapered roller bearing. The rotary table with such structure has the advantages of that the rotor has small moment of inertia, the fluctuation of moment is small, the speed is low, the performance is sound, and the cost is low; particularly when load acceleration requires relatively high control accuracy, such structure is easy to meet the technical requirements of the rotary table and reduce the cost.

Owner:AVIC BEIJING CHANGCHENG AVIATION MEASUREMENT & CONTROL TECH INST +1

Inverter device and air conditioner using inverter device

ActiveUS7574873B2Small sizeLight weightAC motor controlAc-dc conversion without reversalPhase currentsLow noise

A current sensor for detecting a power supply current is commonly used for detecting a current of a stator winding to detect a rotational position of a magnet rotor, so that a sinusoidal driving is realized without adding two current sensors for detection of a phase current, and also a phase shift circuit and a comparator needed in the conventional 120-degree current feeding are not required, and the number of components can be reduced. Therefore, an inverter device with a low noise and low vibration, having a small size, light weight and high reliability is obtained.

Owner:PANASONIC CORP

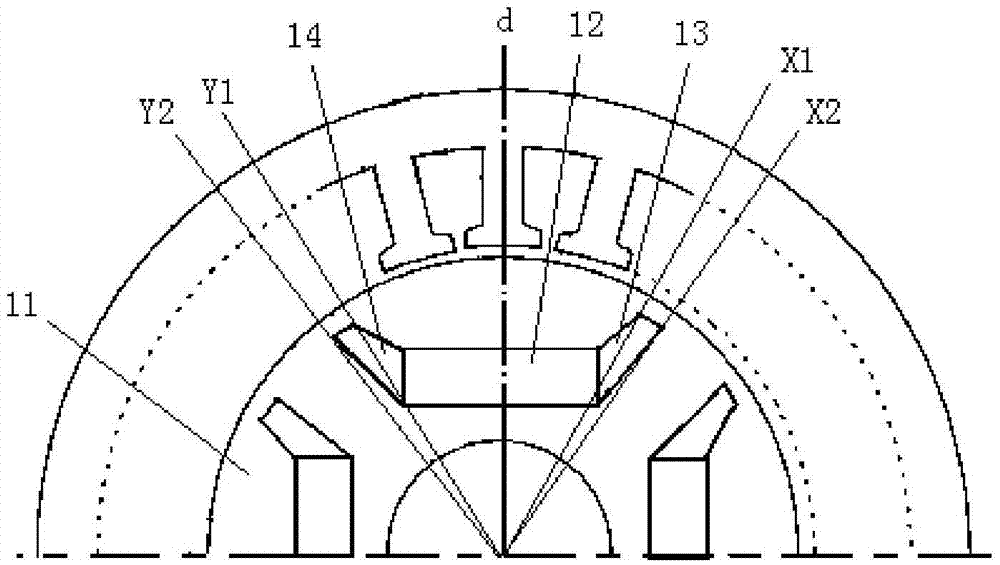

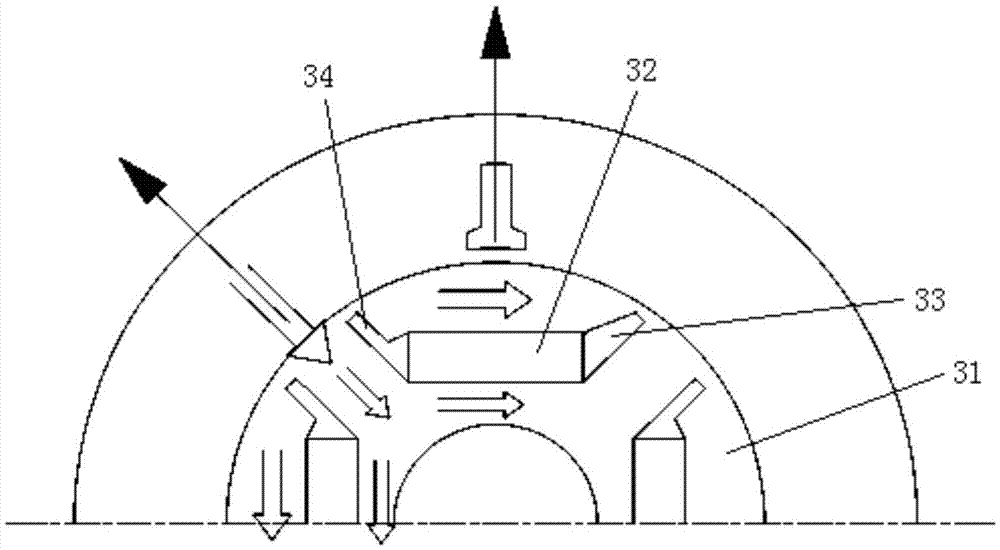

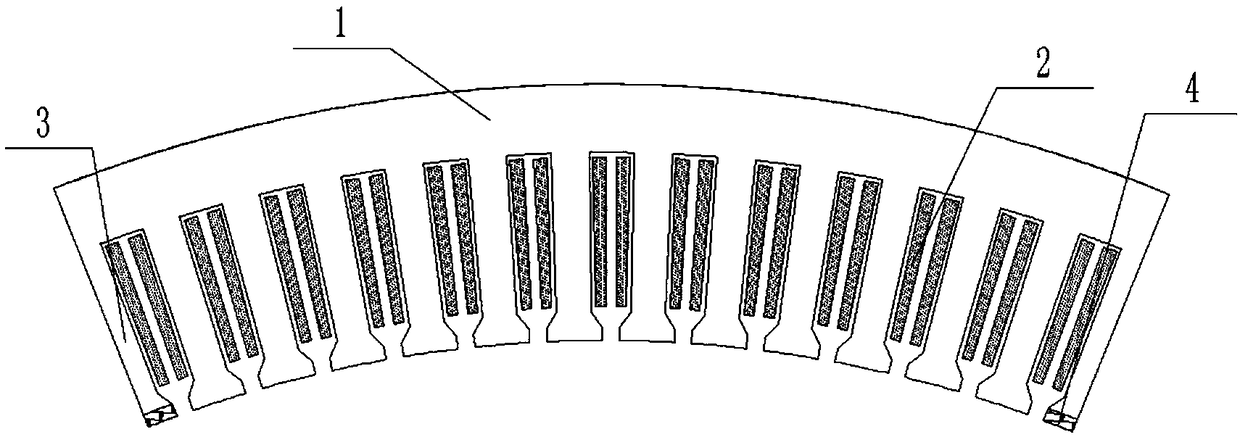

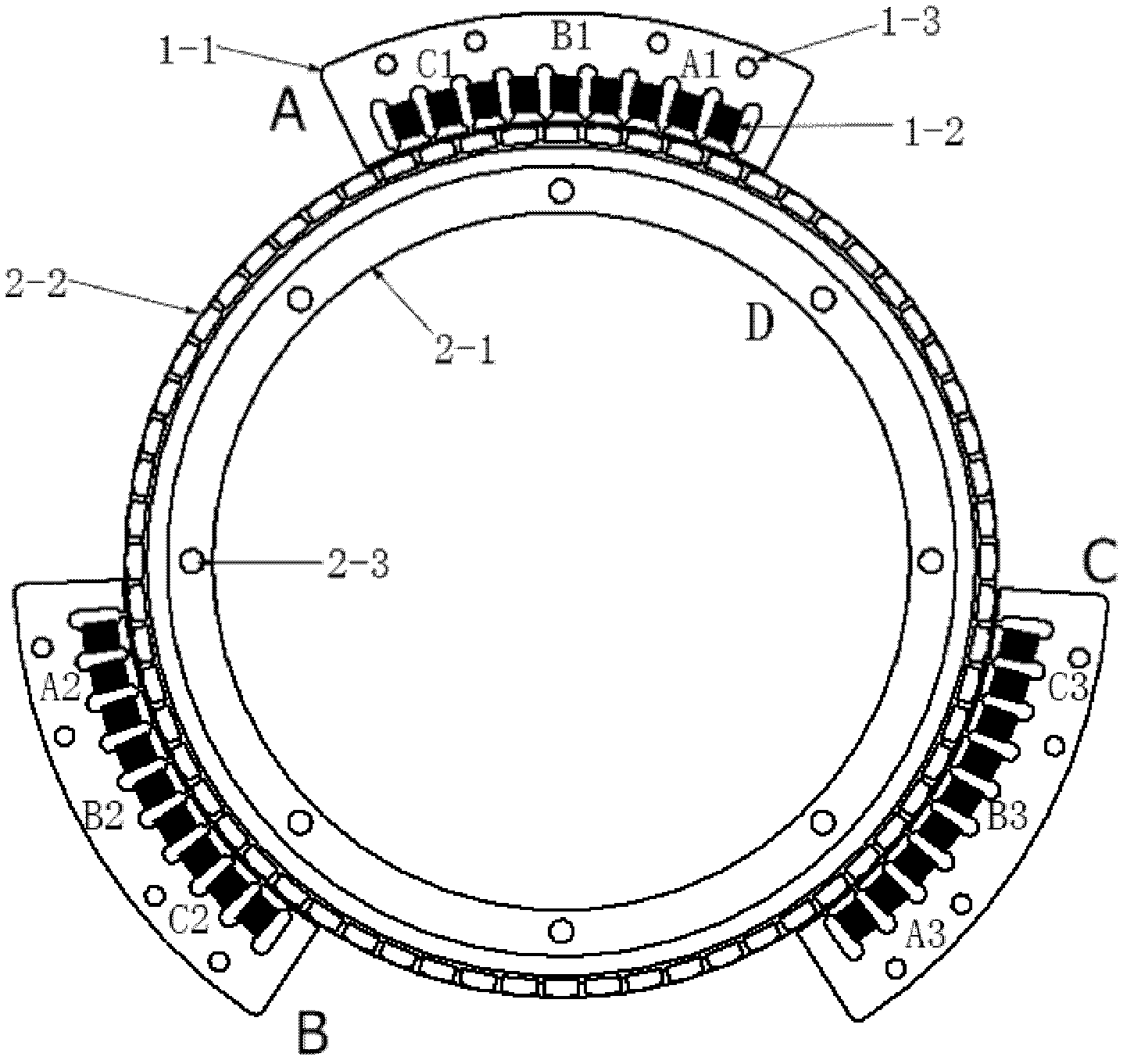

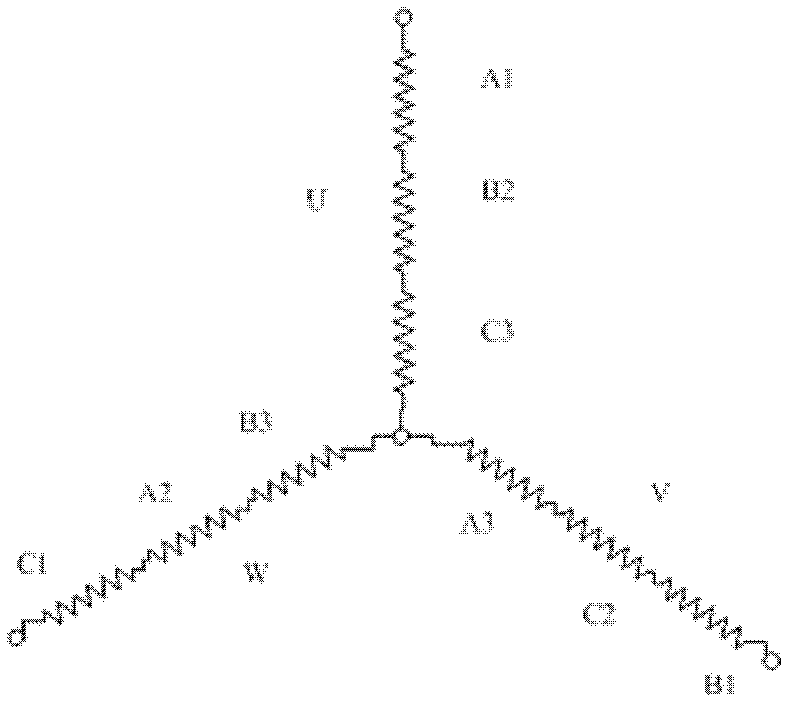

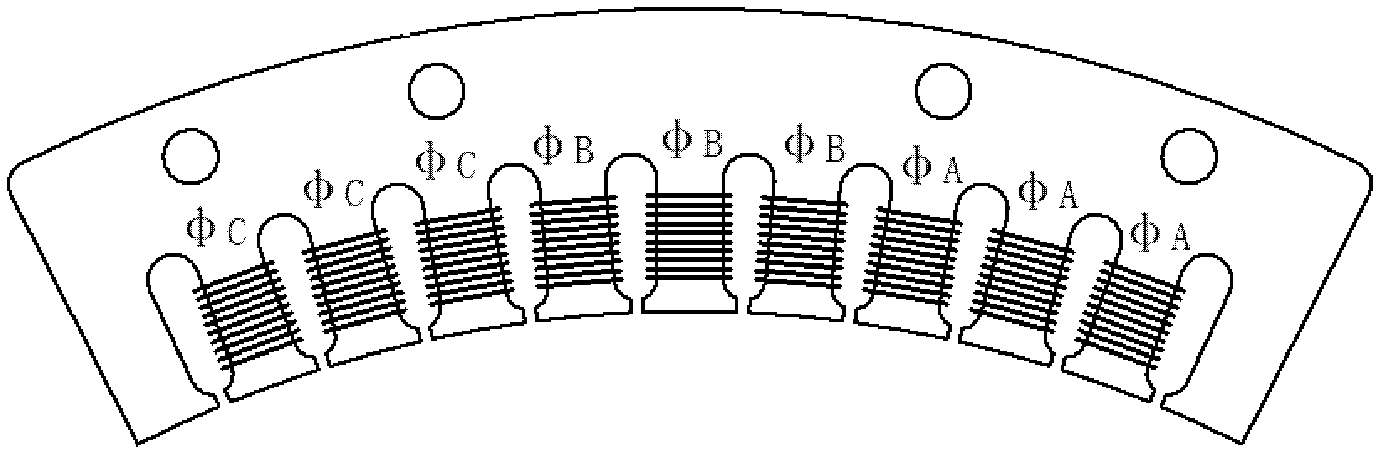

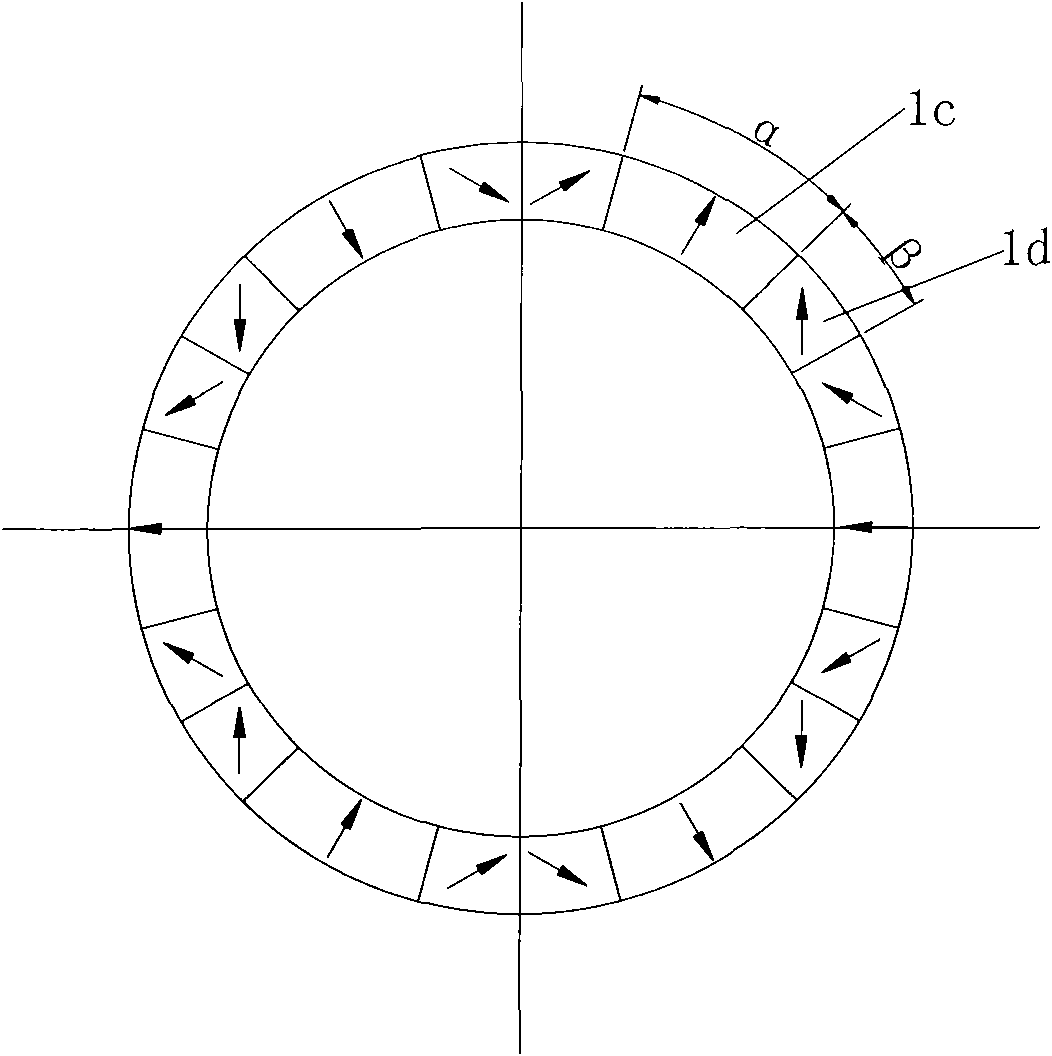

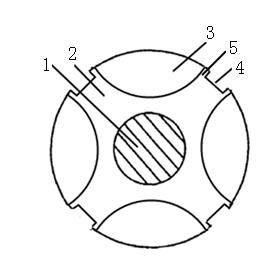

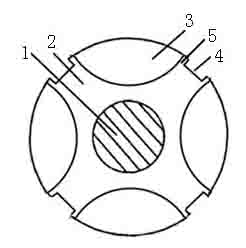

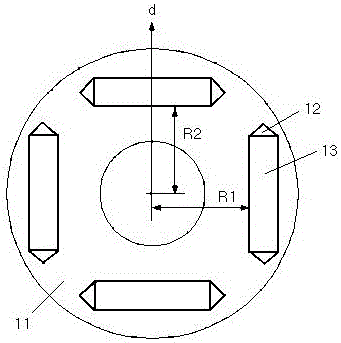

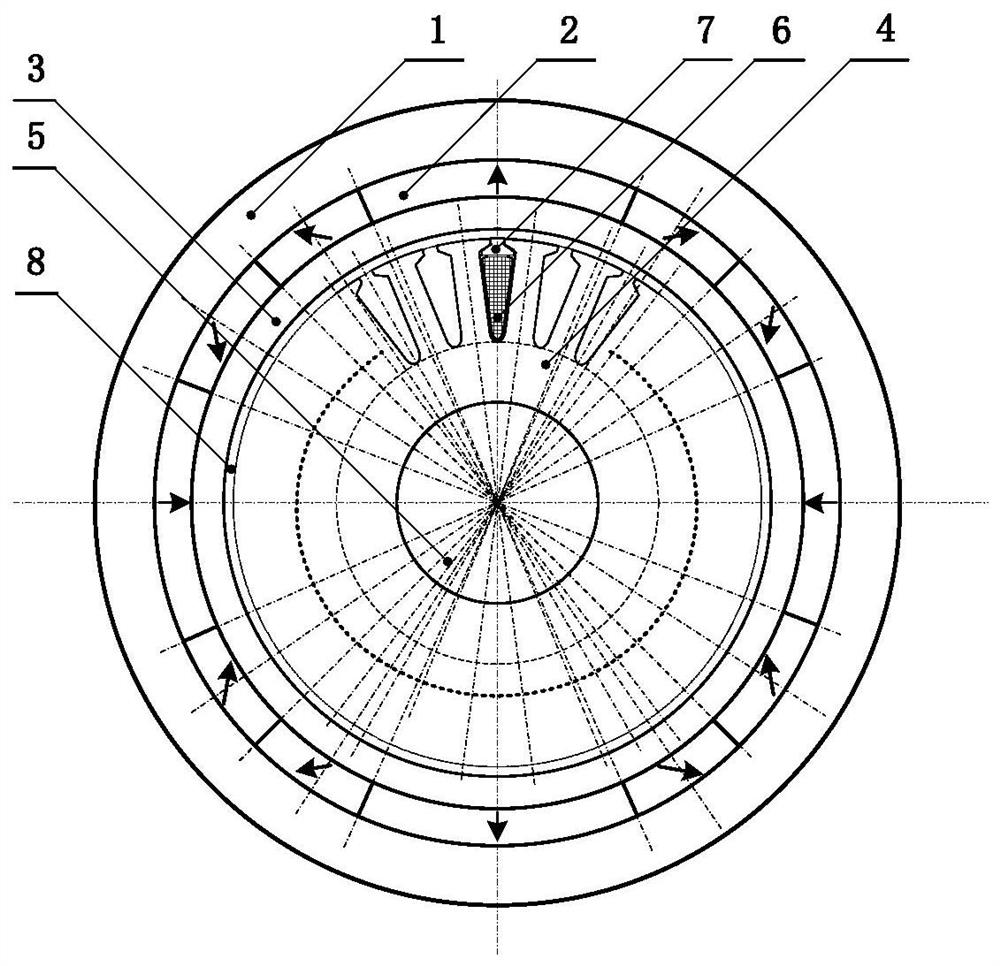

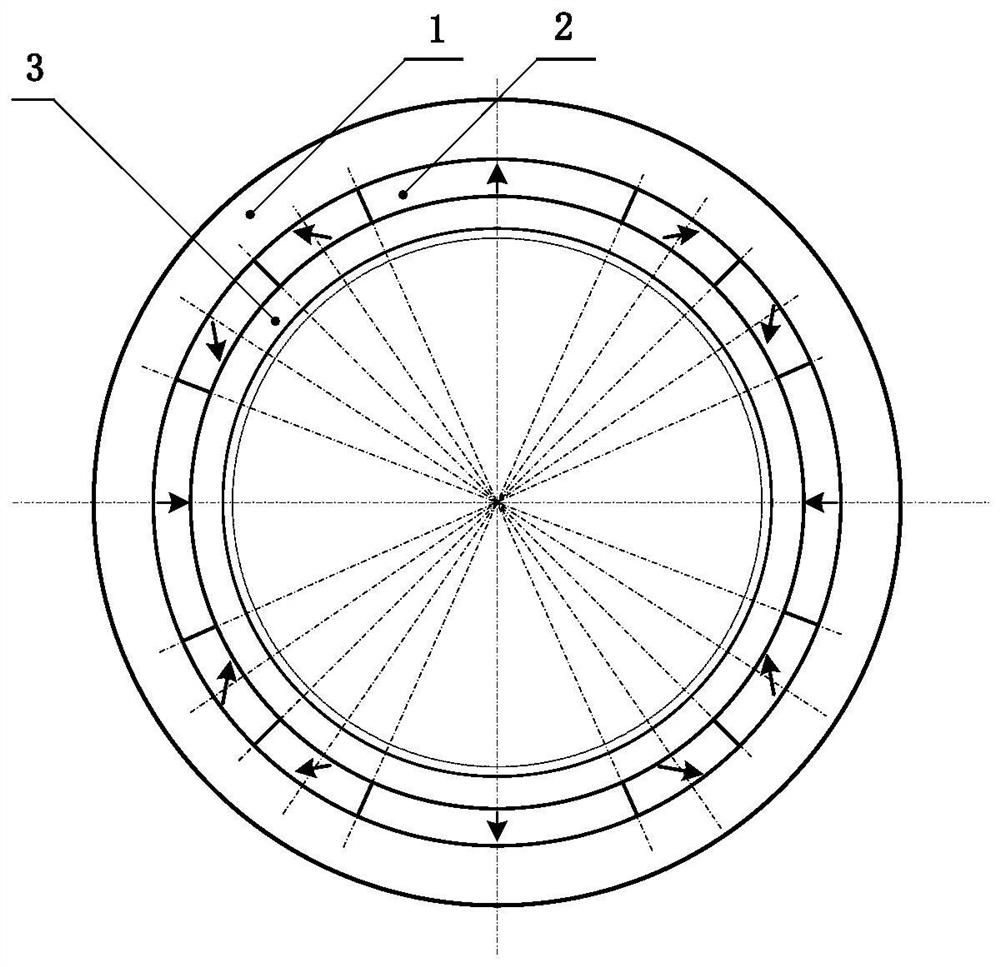

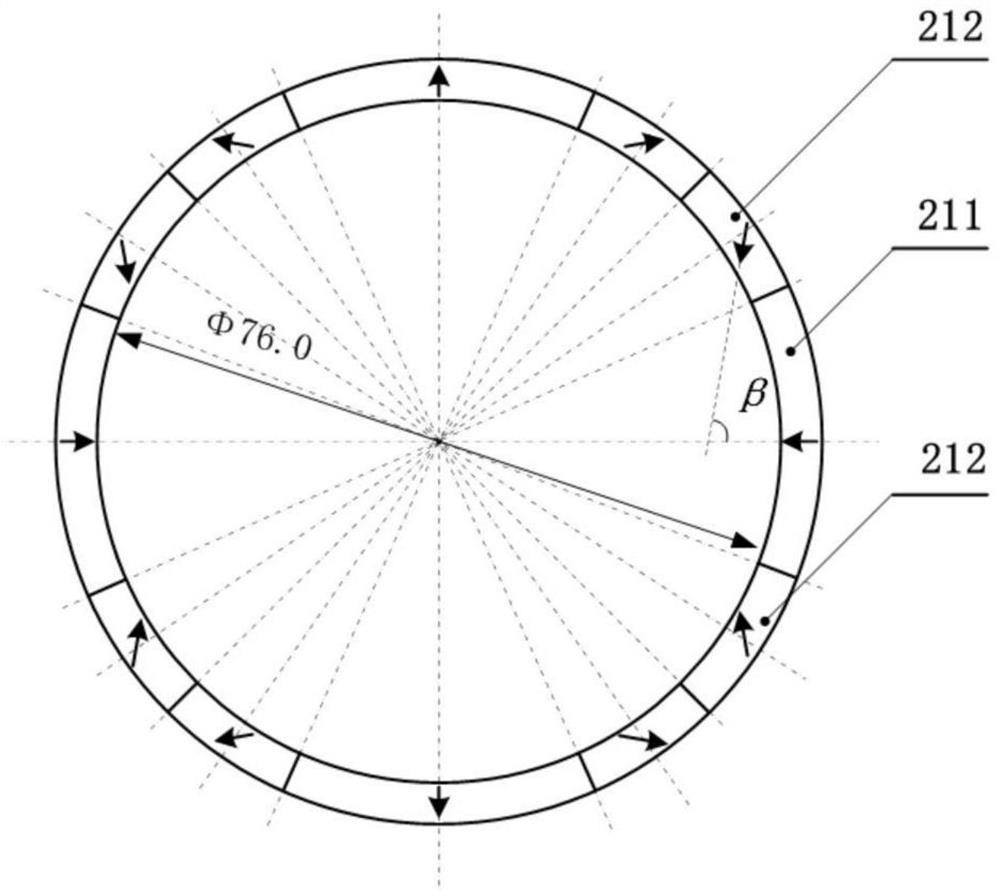

Multi-stator arc linear motor capable of reducing torque fluctuation

InactiveCN102522865ASmall torque fluctuationGuaranteed uptimeMagnetic circuit rotating partsMagnetic circuit stationary partsLow speedElectric machine

A multi-stator arc linear motor capable of reducing a torque fluctuation is a three-phase alternating-current permanent-magnet synchronous arc linear motor. The motor is assembled by three stators with a same structure and one rotor. The three stators, which have a 120 DEG mechanical angle with each other in space, are installed on the rotor. The each stator is formed by a three-phase stator winding comprising an iron core. The three-phase stator windings in the three stators use dislocation phase connection to form new three-phase integrated windings U, V, W. And resistances, inductances and mutual inductances of the formed three-phase integrated windings U, V, W are equal. The three-phase integrated windings U, V, W adopt Y-shaped connection. According to the invention, the torque fluctuation caused by the asymmetric inductances of the motor stator windings can be reduced. Simultaneously, there is the certain mechanical angle between the stators so that end forces generated by the stators can be mutually offset. Therefore, the motor can generate a small torque fluctuation at a low speed. The motor can operate stably with high precision.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

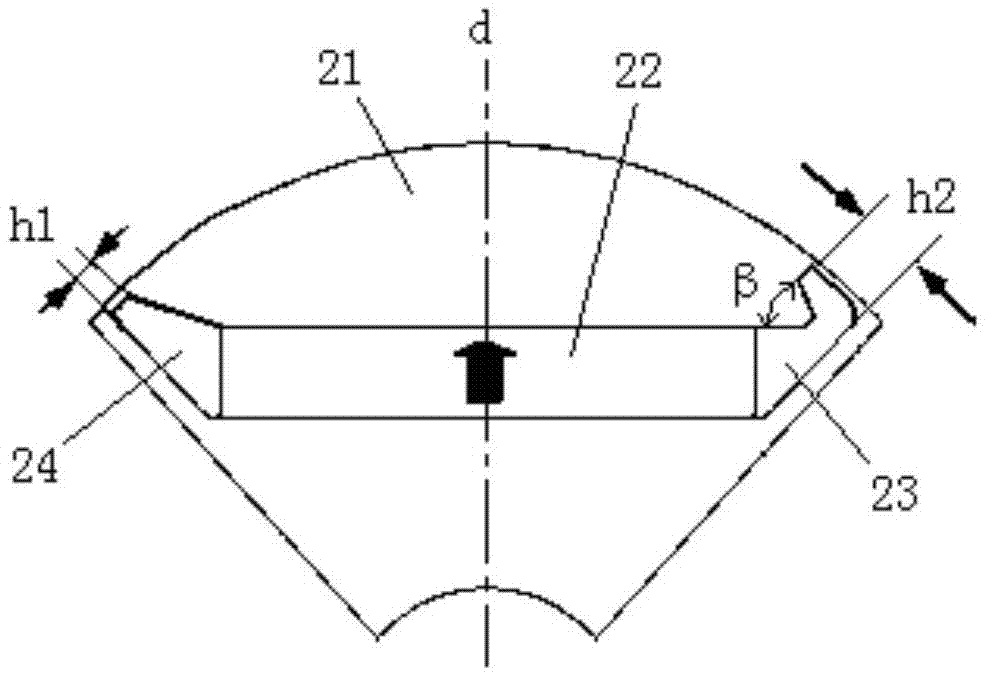

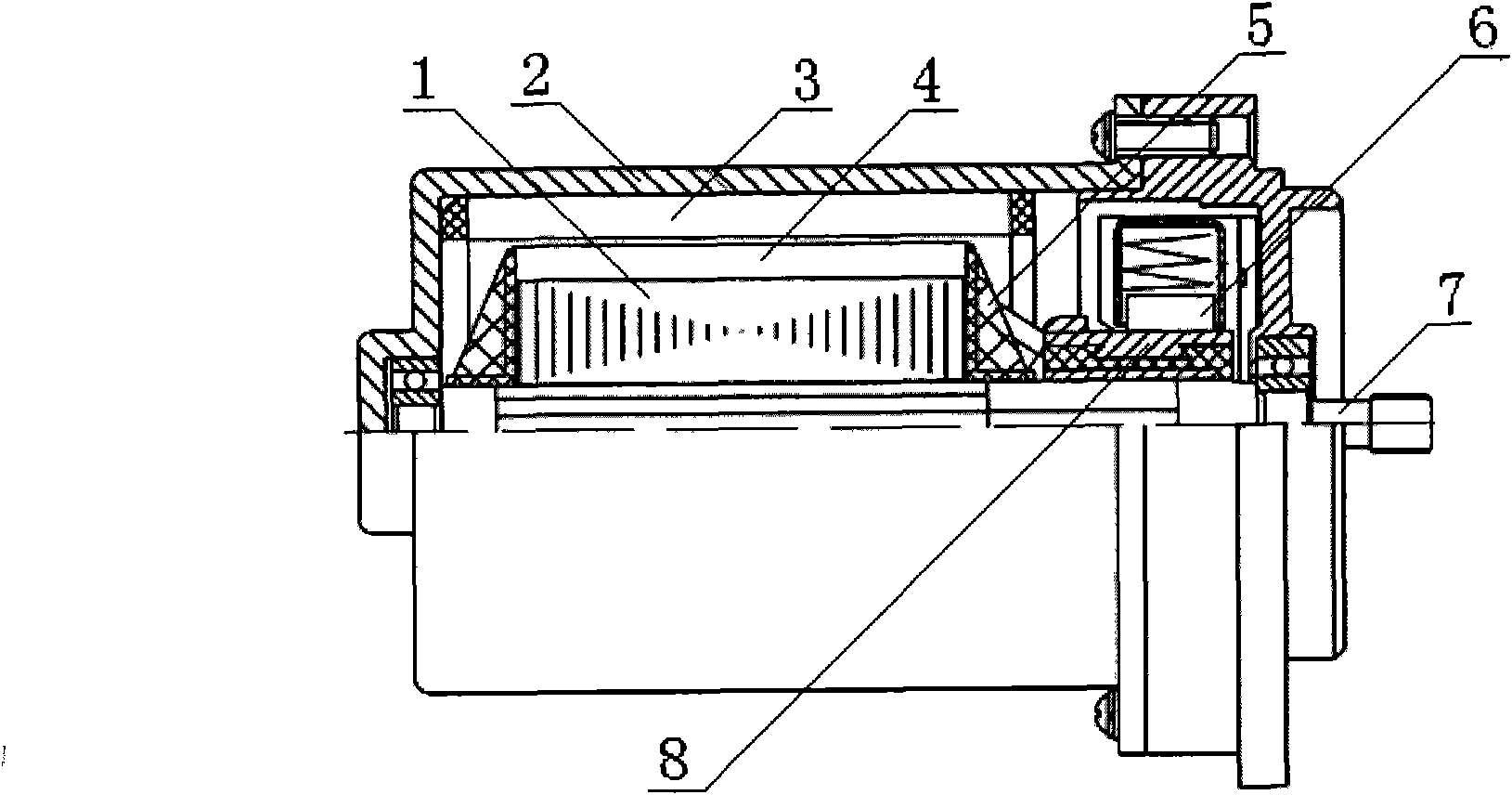

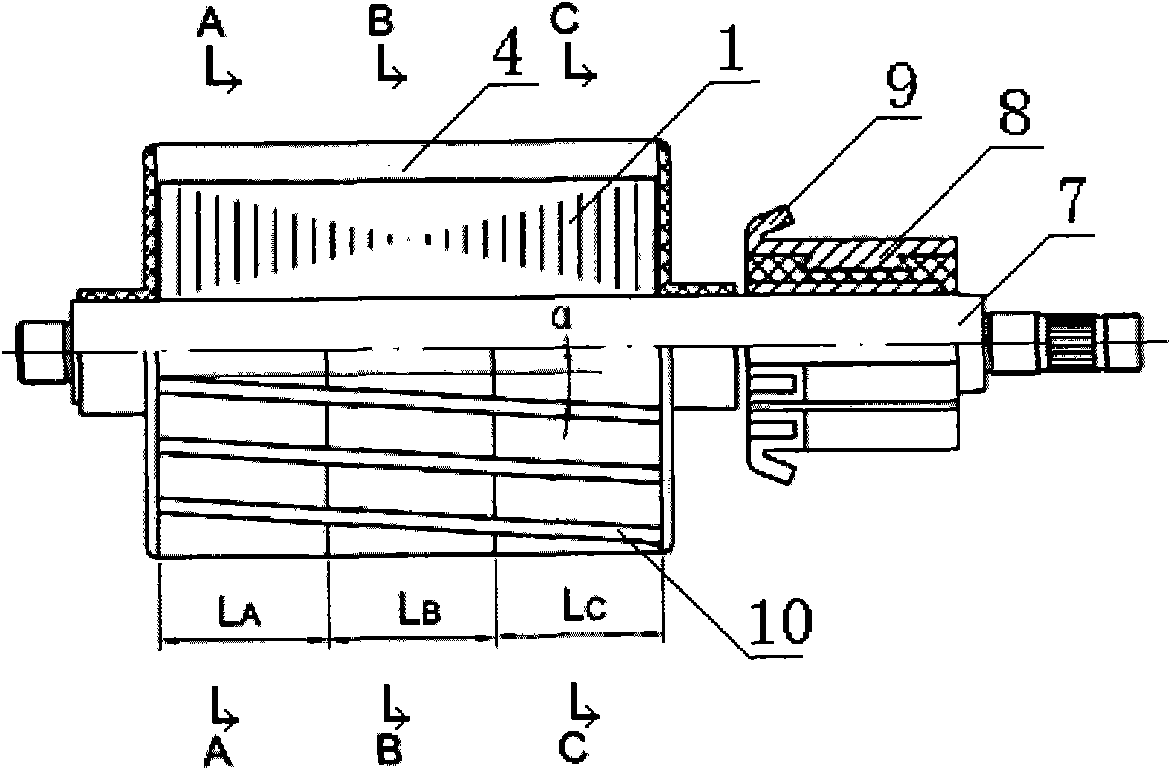

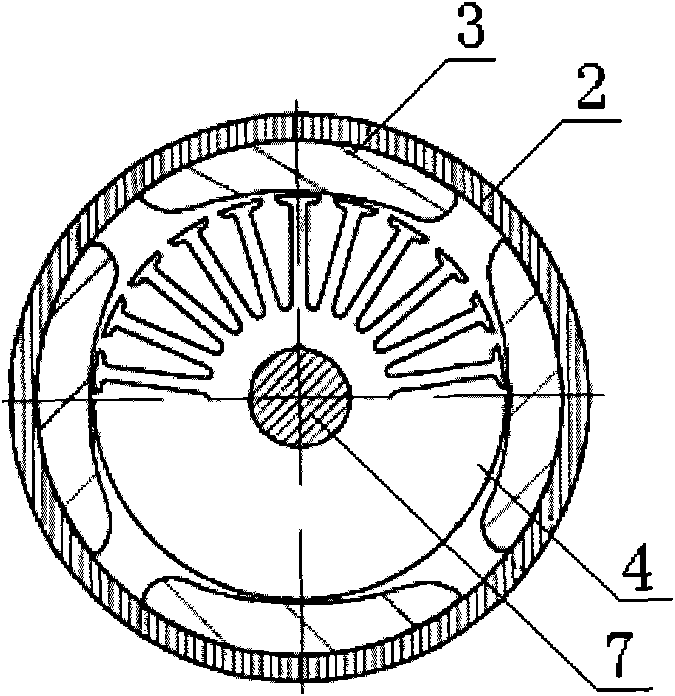

Permanent magnet and direct current brush motor for automobile air conditioner

InactiveCN101917107ASmall torque fluctuationReduce noiseMagnetic circuit rotating partsDC commutatorHarmonicAutomobile air conditioning

The invention discloses a permanent magnet and direct current brush motor for an automobile air conditioner. The motor comprises a casing (2), a permanent magnet (3), a rotor (4), an electrical brush (6) and a commutator (8), wherein the permanent magnet (3) is fixed in the cavity of the casing (2); the permanent magnet (3) has a tile-shaped irregular section which is asymmetrical; the outer arc (3R) and the inner arc (3r) of the tile-shaped irregular section of the permanent magnet are not concentric; and the radius (r) of the inner arc of the tile-shaped irregular section of the permanent magnet is larger than the radius (R) of the outer arc of the tile-shaped irregular section of the permanent magnet. By adopting the technical scheme, the permanent magnet with the tile-shaped irregular section is adopted, so that the distribution form of a magnetic field is closer to the form of a sine wave, and the odd harmonics of the magnetic field are effectively reduced; and a chute structure is adopted by the rotor to reduce the relative magnetic resistance fluctuation in the axial magnetic fields of the permanent magnet and the tooth sockets of the rotor, so that tooth socket moment fluctuation is effectively reduced, the noise of the motor is reduced, and the service life of the motor is prolonged.

Owner:WUHU HOTECH AUTOMOBILE ELECTRIC MOTOR

Compressor

InactiveUS7114930B2Simple structureSmall torque fluctuationRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesCompressed fluidEngineering

There is provided an efficient compressor which is simple in structure and small in torque fluctuation. The compressor comprises a compression element which comprises a cylinder having a compression space formed therein, a suction port and a discharge port which communicate with the compression space in the cylinder, a compression member which comprises continuous thick and thin parts, one surface of which inclines, which is arranged in the cylinder to rotate, and which compresses fluids sucked through the suction port and discharges the compressed fluids through the discharge port, and a vane which is arranged between the suction port and the discharge port to abut on one surface of the compression member, and which partitions the compression space of the cylinder into a low pressure chamber and a high pressure chamber.

Owner:SANYO ELECTRIC CO LTD

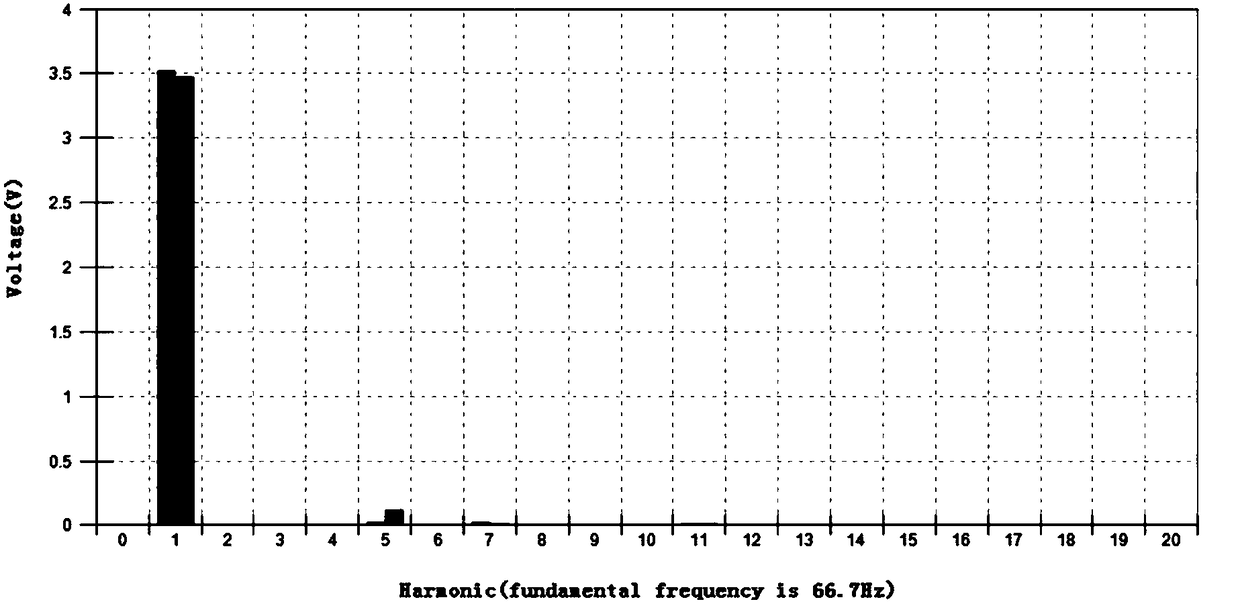

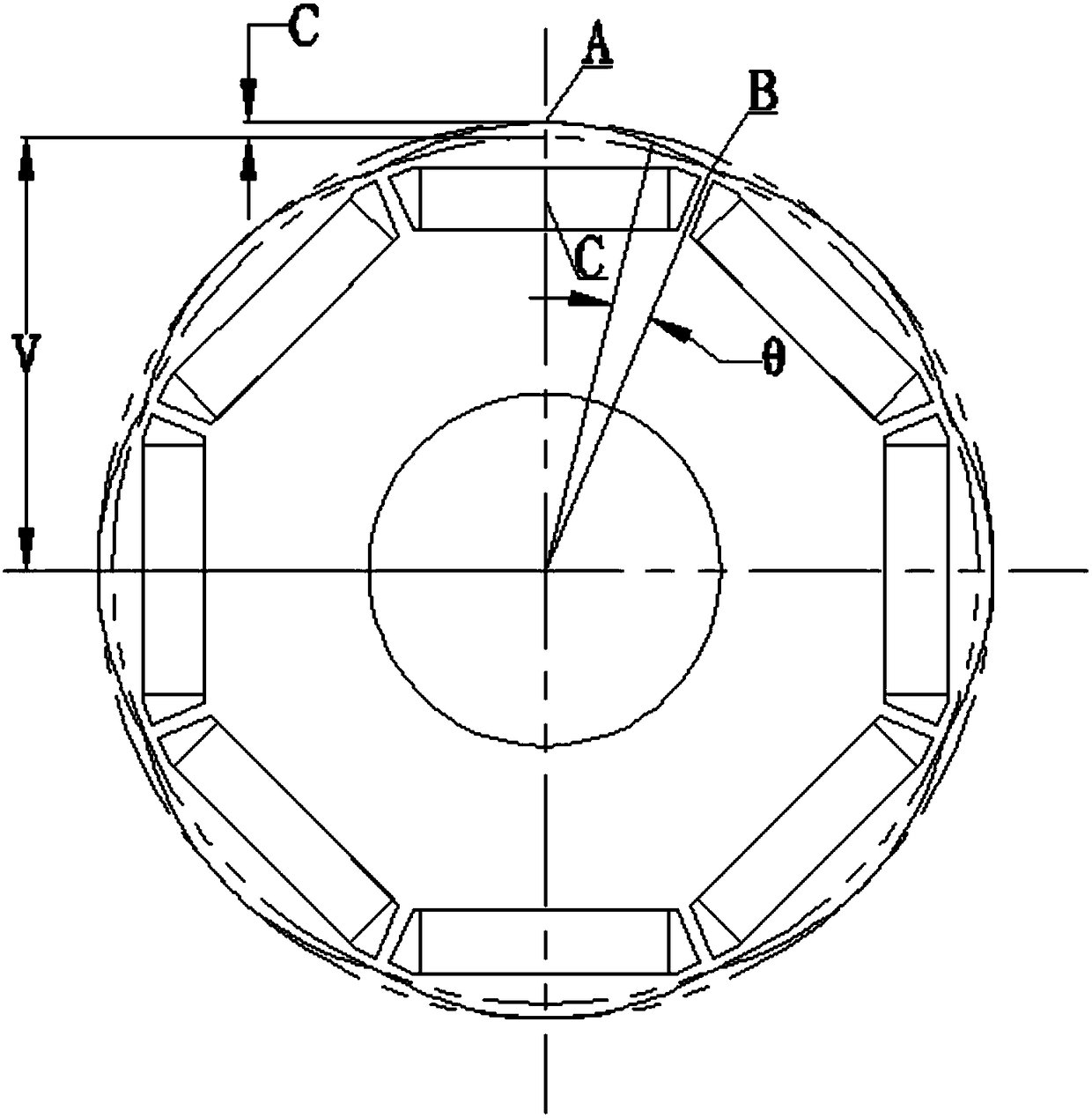

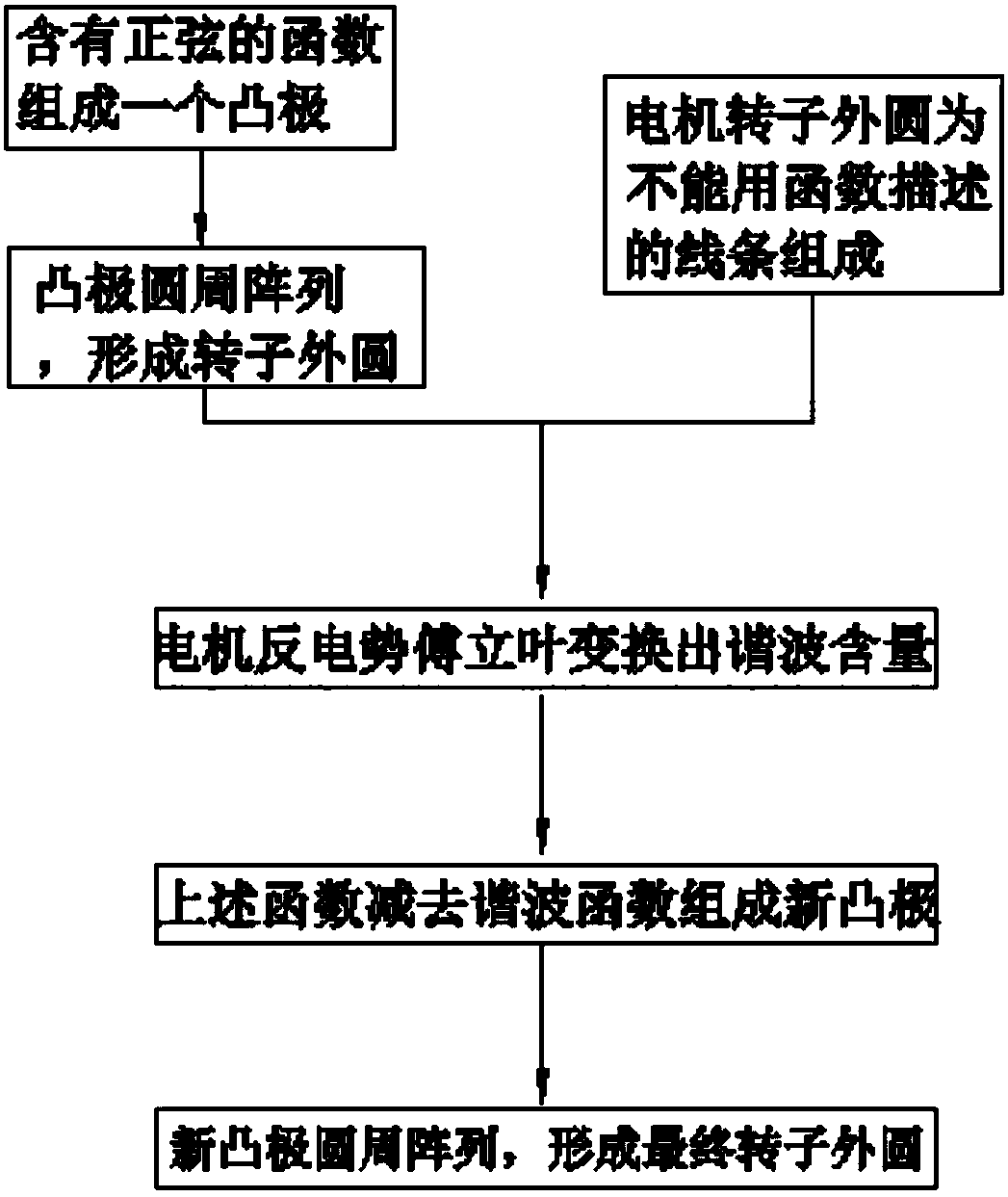

Permanent magnet synchronous motor back potential harmonic suppressing method and permanent magnet synchronous motor

ActiveCN108365721AEliminate harmonicsReduce back EMF harmonic contentSynchronous machine detailsMagnetic circuit rotating partsHarmonicPermanent magnet synchronous motor

The invention discloses a permanent magnet synchronous motor back potential harmonic suppressing method. The method comprises the steps that a function containing a sine forms a salient pole; the salient pole forms the excircle of a motor rotor through a circumferential array, or the excircle of the motor rotor is composed of a line which cannot be described by a function; the back potential waveform of a motor is tested; the harmonic order and amplitude are decomposed through Fourier transform; the sinusoidal function subtracts a harmonic function to form a new salient pole; and the new salient pole finally forms the excircle of the motor rotor through the circumferential array. Motor air gaps made by the method are sinusoidally distributed. An excircle function subtracts the back potential harmonic function. The back potential harmonic result is suppressed. The method has the advantages of simple and effective principle, strong operability, low motor back potential harmonic content,small torque fluctuation and low vibration noise.

Owner:NIDEC KAIYU AUTO ELECTRIC JIANGSU

High-precision low-fluctuation permanent magnetic brushless servomotor for solar tracking system

InactiveCN101572468AHigh precisionImprove overload capacityMagnetic circuit rotating partsLight radiation electric generatorLow noiseMagnetic poles

The invention relates to a high-precision low-fluctuation permanent magnetic brushless servomotor for a solar tracking system, which comprises a machine shell as well as a stator and a rotor in the machine shell, wherein the stator comprises a stator core fixed on the inner wall of the machine shell and a stator winding; the rotor comprises a main shaft and a rotor core; the outer circumference of the rotor core is sleeved with an annular magnetic pole consisting of radial magnetized magnetic steels which are evenly arranged along the circumferential direction and adjacent oblique angled magnetized magnetic steels; one radial magnetized magnetic steel and two adjacent oblique angled magnetized magnetic steels in the annular magnetic pole form a rotor magnetic pole; the radial magnetized magnetic steels are main magnetic poles; and the two adjacent oblique angled magnetized magnetic steels on both sides are auxiliary magnetic poles. Radial and oblique angled mixed anisotropic magnetized magnetic poles in the annular magnetic pole of the rotor ensure that the motor can also remarkably improve air gap flux density waveform of the motor even if the even air gap is adopted, obtain a sinewave magnetic field, does not reduce power output, can also reduce moment fluctuation, and improve the precision of the solar tracking system. The motor can perform steady operation with high efficiency, low fluctuation, low noise, quick response and high precision.

Owner:苏州工业园区美能新能源有限公司 +1

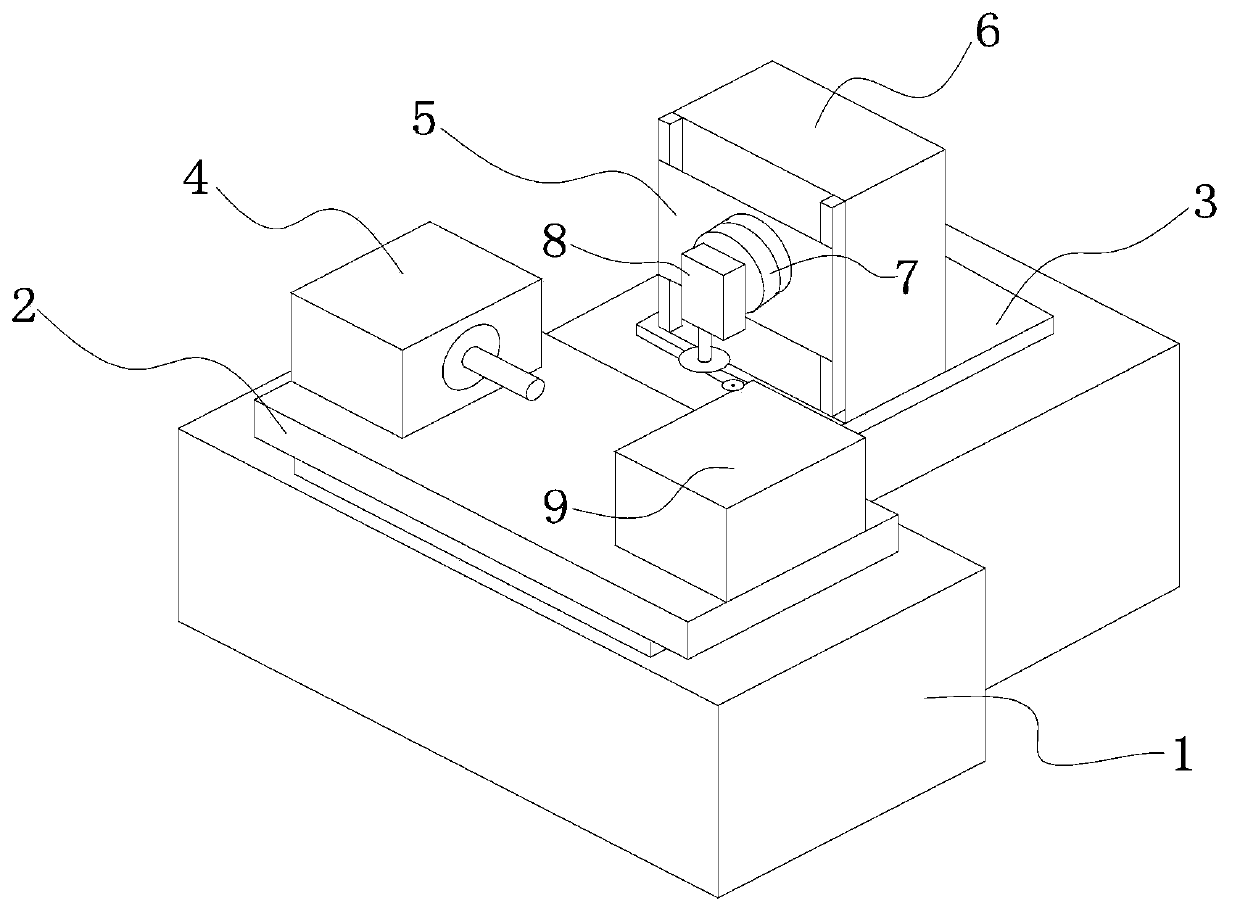

Numerical control shaping gear grinding machine tool

InactiveCN103962653AReduce speedIncrease speedFeeding apparatusGear-cutting machinesGear grindingGrating

The invention discloses a numerical control shaping gear grinding machine tool, which comprises a numerical control system, a machine tool body and an upright column vertical to the machine tool body, wherein a longitudinal workbench and a transverse workbench are arranged on the machine tool body. The machine tool is characterized in that a work piece spindle box is arranged on the longitudinal workbench; the upright column is fixed on the transverse workbench, a vertical workbench is arranged along the upright column, and a grinding wheel spindle box is arranged on the vertical workbench; a circular grating ruler which is in feedback connection with the numerical control system and is used for detecting angular displacement is arranged on a motor shaft in the work piece spindle box; furthermore, the numerical control system is respectively in feedback connection with straight grating rulers arranged in the feeding directions of the longitudinal workbench, the transverse workbench and the vertical workbench. The numerical control shaping gear grinding machine tool can adapt to the machining of gears with different moduli, is simple and convenient to operate, facilitates the improvement on the production efficiency, meanwhile can perform real-time feedback of feeding amount and achieves accurate control so as to improve machining precision.

Owner:CHONGQING XINGWANG TOOL MFG

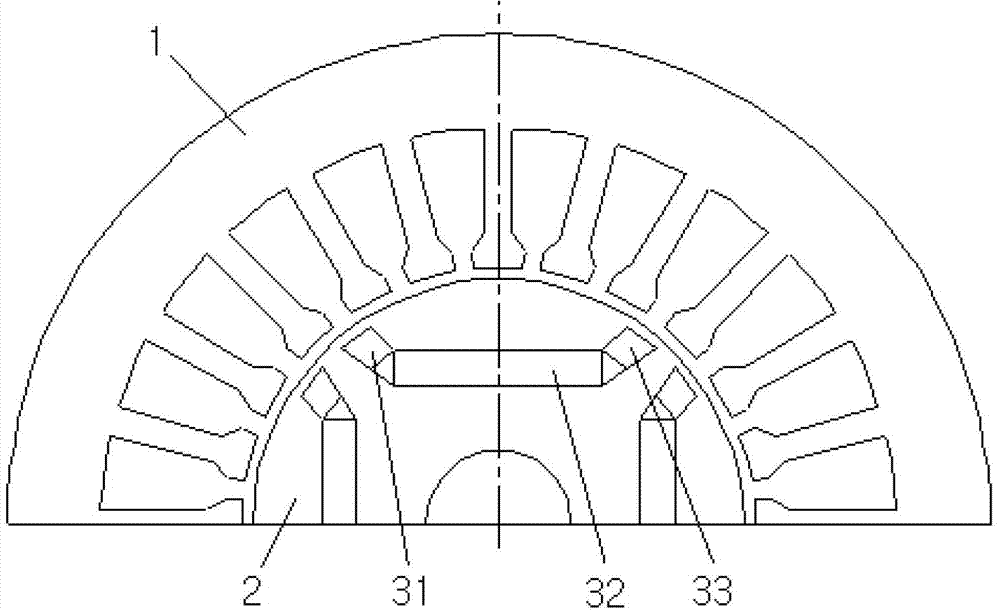

Built-in permanent magnet synchronous motor

ActiveCN103078464AImprove qualityImprove air gap flux density waveformMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsBand shapePermanent magnet synchronous motor

The invention discloses a built-in permanent magnet synchronous motor, relates to the technical field of a motor and aims to solve the technical problem of improving the comprehensive quality of the motor. Multiple permanent magnet slots are axially and symmetrically arranged in a rotor of the motor along the central axis of the rotor at intervals, three permanent magnets distributed in an arc band shape are arranged in each permanent magnet slot, wherein one permanent magnet is a middle steel magnet, and the other two permanent magnets are side steel magnets; the built-in permanent magnet synchronous motor is characterized in that each middle steel magnet adopts the normal magnetization vertical to the surface of the steel magnet, and each two side steel magnets in one slot adopt the non-normal magnetization, so that the arc center of a magnet arrangement arc of each permanent magnet slot is enabled not to coincide with the magnetization orientation point of permanent magnets in the corresponding permanent magnet slot. According to the motor provided by the invention, the comprehensive quality of the motor is greatly improved.

Owner:SHANGHAI TOP MOTOR +2

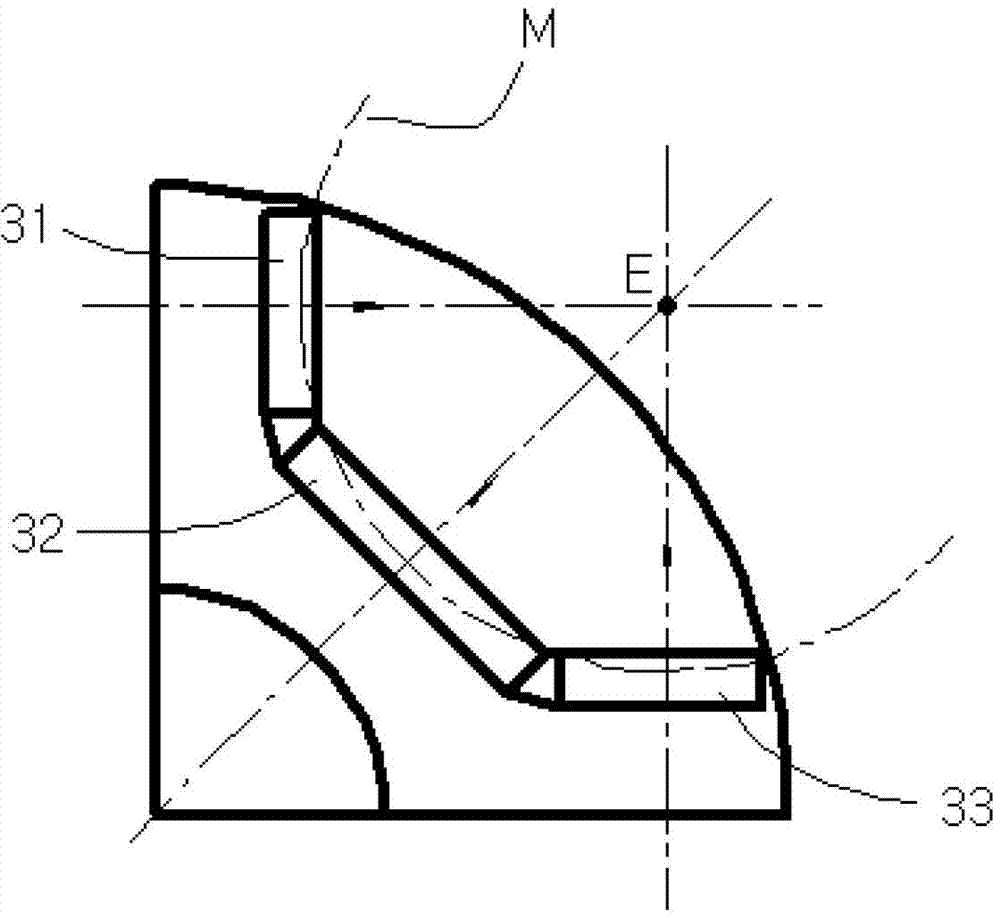

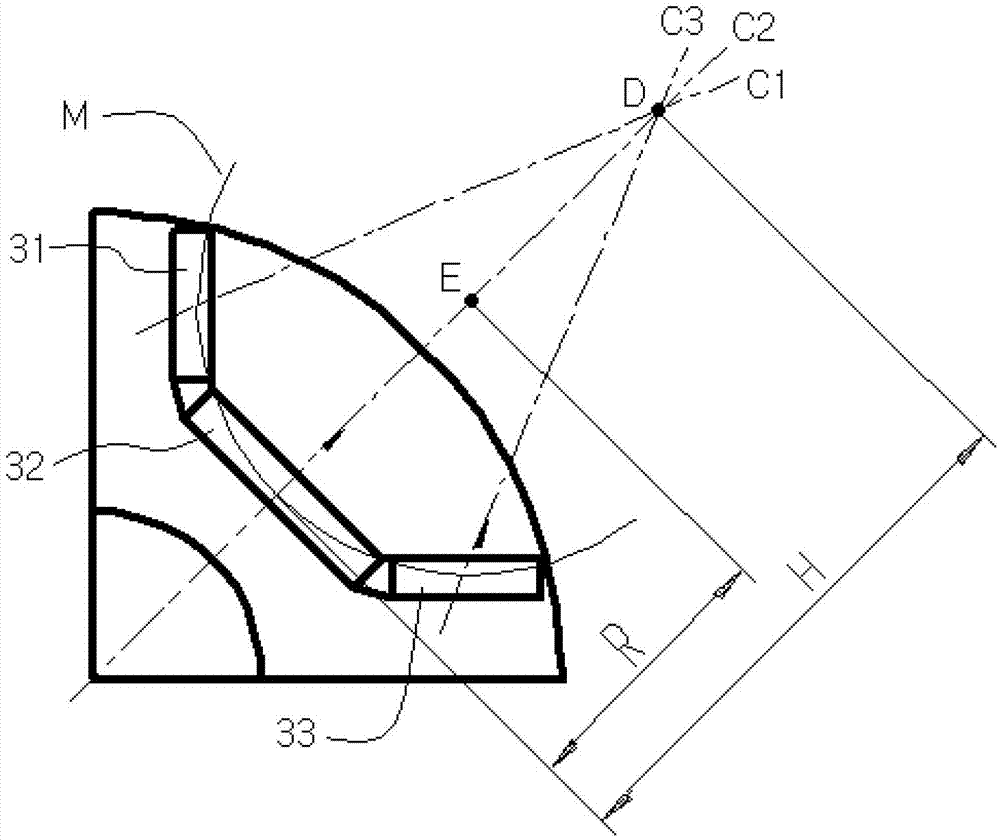

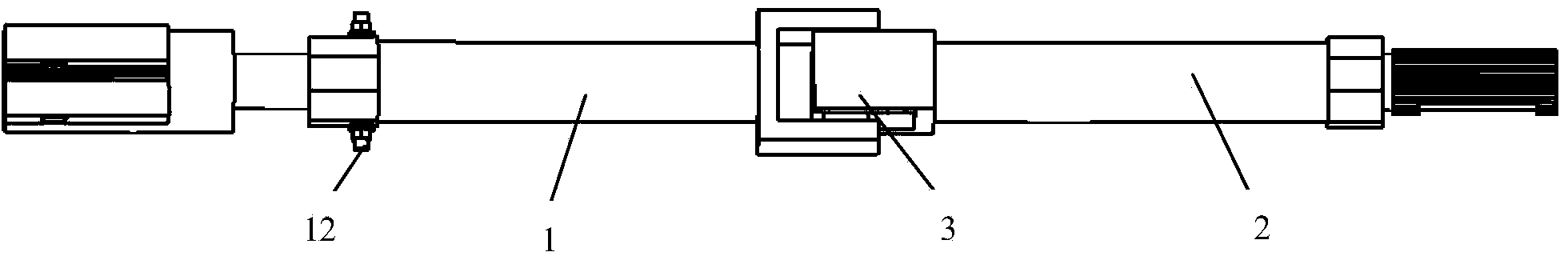

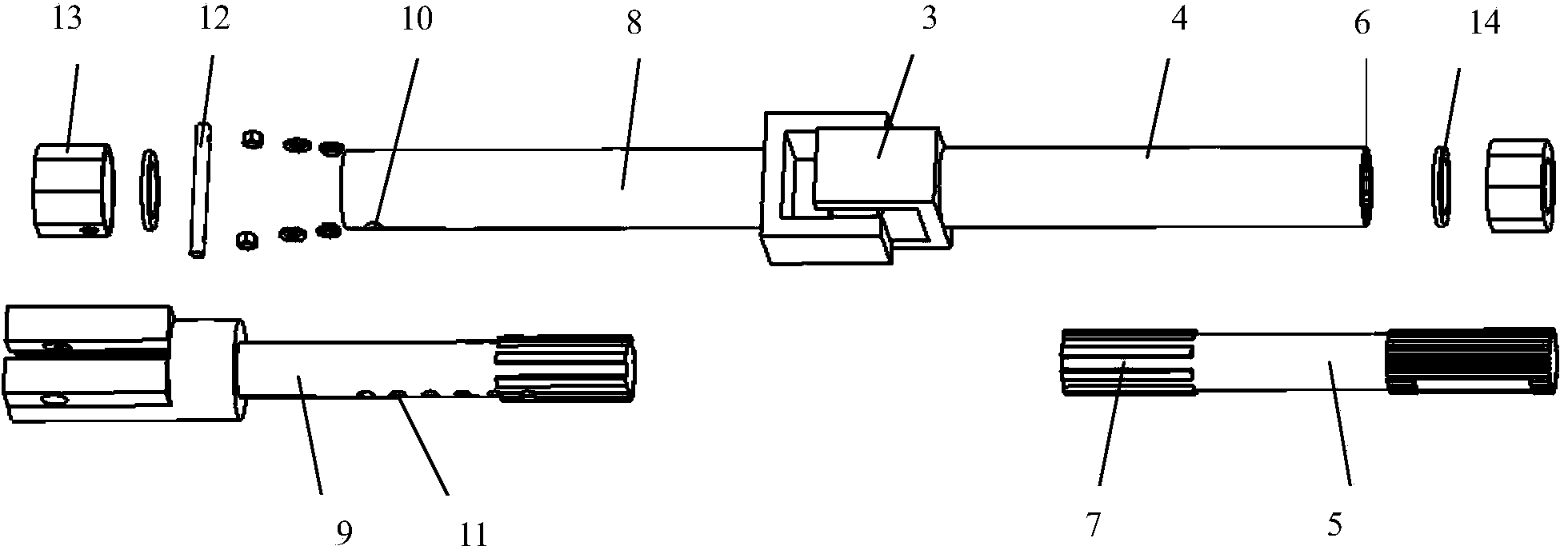

Steering shaft, automobile steering mechanism and automobile

ActiveCN104228926ASmall torque fluctuationOptimize layoutSteering columnsSteering columnUniversal joint

The invention discloses a steering shaft, an automobile steering mechanism and an automobile. The steering shaft comprises a first shaft and a second shaft which are connected through a universal joint, wherein one of the first shaft and the second shaft is used for being connected with an automobile steering column and the other of the first shaft and the second shaft is used for being connected with an automobile steering gear. The steering shaft provided by the invention comprises the first shaft and the second shaft which are connected through the universal joint, so that an included angle between the first shaft and the second shaft can be adjusted, an included angle between the first shaft and the steering column and an included angle the second shaft and the steering gear can be adjusted, an included angle condition which does not generate moment fluctuation is easy to achieve because of the adjustable included angles, and the moment fluctuation generation probabilities of the automobile steering mechanism during the transmission process of the rotating force are reduced by adjusting the above included angles compared with an ungovernable rotary shaft in the prior art.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

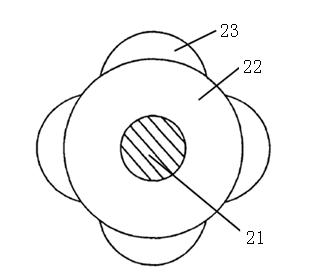

Permanent magnet synchronous motor (PMSM) with high torque density

InactiveCN102158032ADoes not reduce the area of the air-gap magnetic field waveformImproved air gap magnetic field waveformMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machinePermanent magnet synchronous motor

The invention provides a permanent magnet synchronous motor (PMSM) with high torque density, relating to the technical field of motors and being used for solving the technical problem that the existing motors with low torque ripple are low in torque density and output power. A rotor of the motor comprises a spindle, a rotor yoke and a plurality of permanent magnetic poles, wherein the rotor yoke is fixedly connected with the spindle coaxially; the permanent magnetic poles is fixed on the external surface of the rotor yoke in an axial symmetry mode; the radial sections of the permanent magnetic poles are elliptical, and the external surfaces and inner surfaces of the permanent magnetic poles are both of cambered surfaces; the external surface of the rotor yoke is provided with multiple fixed grooves of magnetic poles in an axial symmetry mode; each permanent magnetic pole is respectively fixed in each fixed groove of the magnetic pole on the external surface of the rotor yoke; the inner surface of each permanent magnetic pole is fitted with the groove bottom and the groove wall of the fixed groove in which the permanent magnetic pole is fixed; edges at the two sides of each permanent magnetic pole are leveled with the notch of the fixed groove in which the permanent magnetic pole is fixed; and the external surface of each permanent magnetic pole and the external surface of the rotor yoke are arranged on the same peripheral surface. The motor provided by the invention is low in the torque ripple and high in the torque density and output power.

Owner:SHANGHAI TOP MOTOR +1

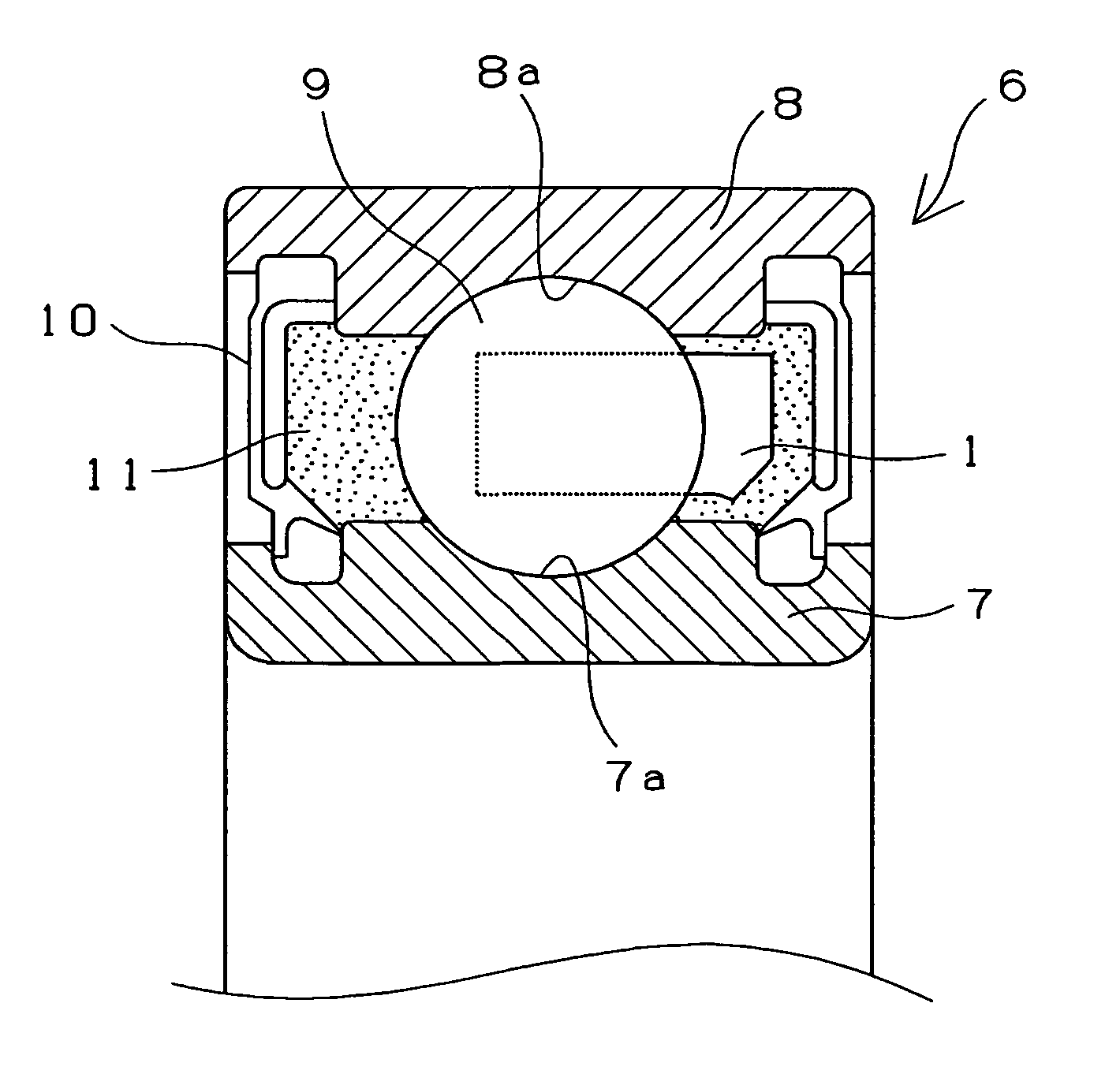

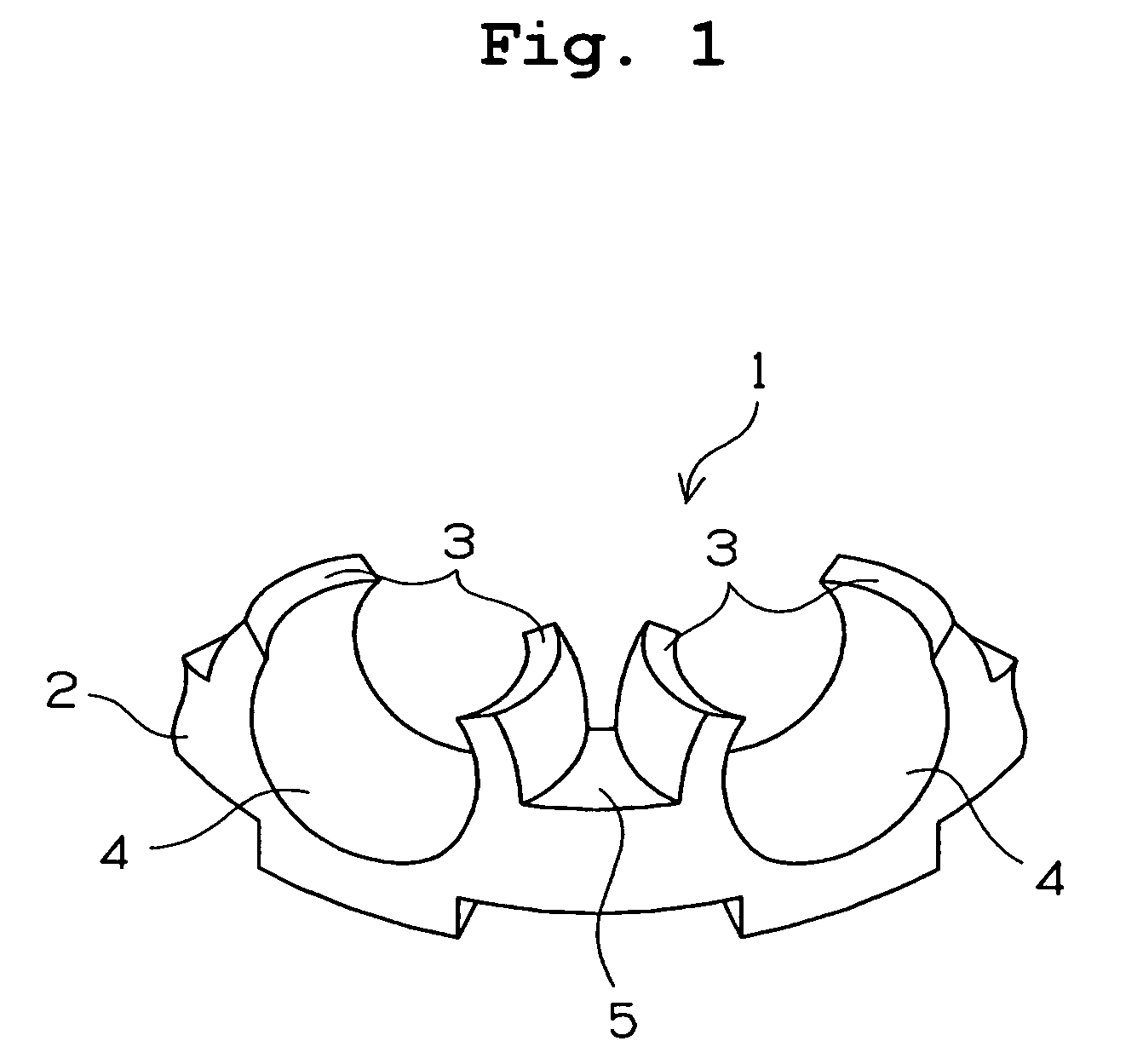

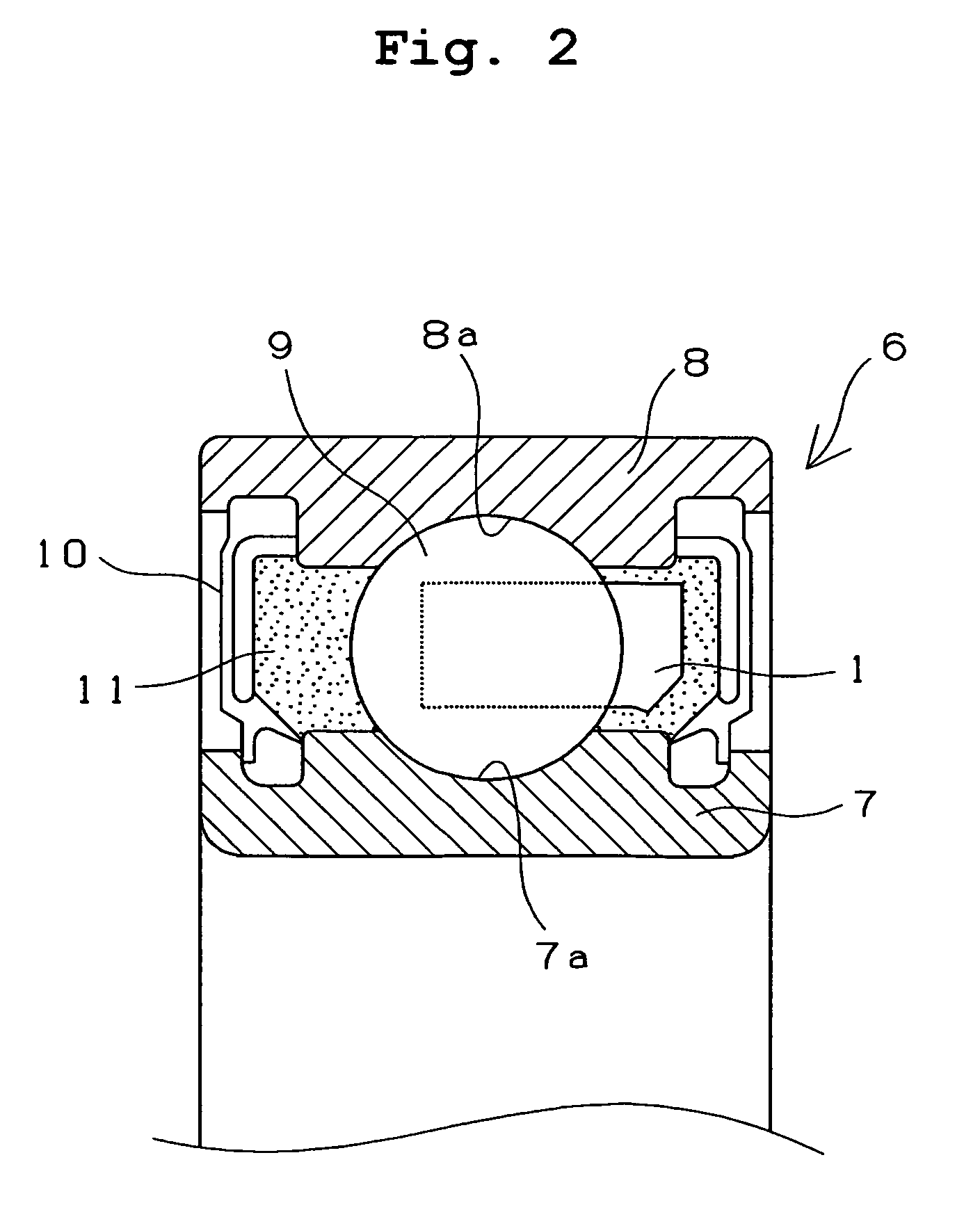

Retainer for rolling bearing, and rolling bearing

A retainer for a rolling bearing, which is used for a food machine or a vacuum apparatus, containing an increased amount of a lubricating oil and enhancing a use efficiency of the lubricating oil and rolling bearing is described. The retainer consists of a molding, of a synthetic resin composition, which holds a rolling element of a rolling bearing. The molding is composed of a resinous porous article having an interconnected hole porosity not less than 30% and a lubricating oil which impregnates the resinous porous article. The resinous porous article has an interconnected hole are formed by molding a resin containing a pore-forming substance having a melting point higher than that of the resin and can be used as a food material, and by extracting said pore-forming substance from the molding with a solvent which dissolves the pore-forming substance and does not dissolve the resin.

Owner:NTN CORP

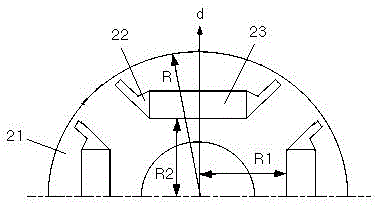

Flat limited angle torque motor

ActiveCN107947514AReduce axial sizeSave spaceMagnetic circuit stationary partsWindings conductor shape/form/constructionTorque motorEngineering

The invention relates to a flat limited angle torque motor, which comprises a gland, a case, a motor shaft, a bearing I, a bearing II, a magnetic steel base I, a magnetic steel base II, magnetic steelI, magnetic steel II, magnetic steel III, magnetic steel IV, a rotor skeleton, a coil I and a coil II, wherein the gland is arranged on the case; an installation hole is formed in the middle of eachof the gland and the case; the motor shaft is arranged in the gland and the case to form a shaft of the motor; the magnetic steel I and the magnetic steel II are arranged on the magnetic steel base I;the magnetic steel III and the magnetic steel IV are arranged on the magnetic steel base II; the magnetic steel base I and the magnetic steel base II are fixed on the inner side wall of the gland through bolts to form a stator of the motor; the coil I and the coil II are fixed on the rotor skeleton; and a hole is formed in the middle of the rotor skeleton and fixed to the motor shaft in a matchedmanner to form a rotor of the motor. The flat limited angle torque motor provided by the invention has the advantages of being very small in axial size, high in volume utilization rate and light in weight and is very suitable for application in a lightweight system.

Owner:TIANJIN NAVIGATION INSTR RES INST

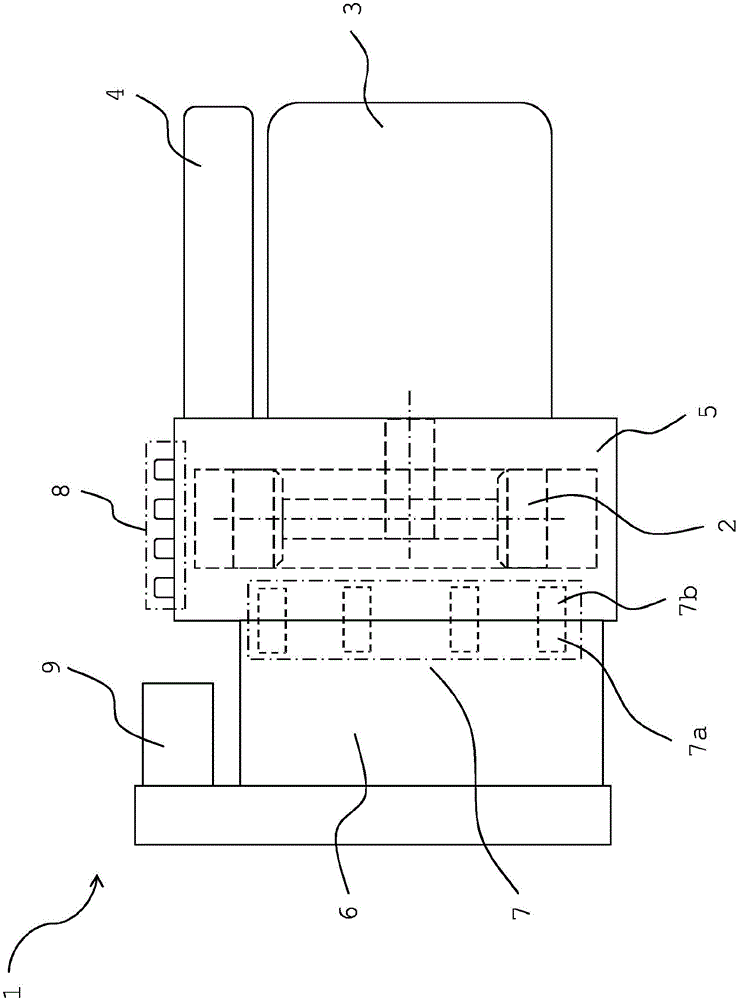

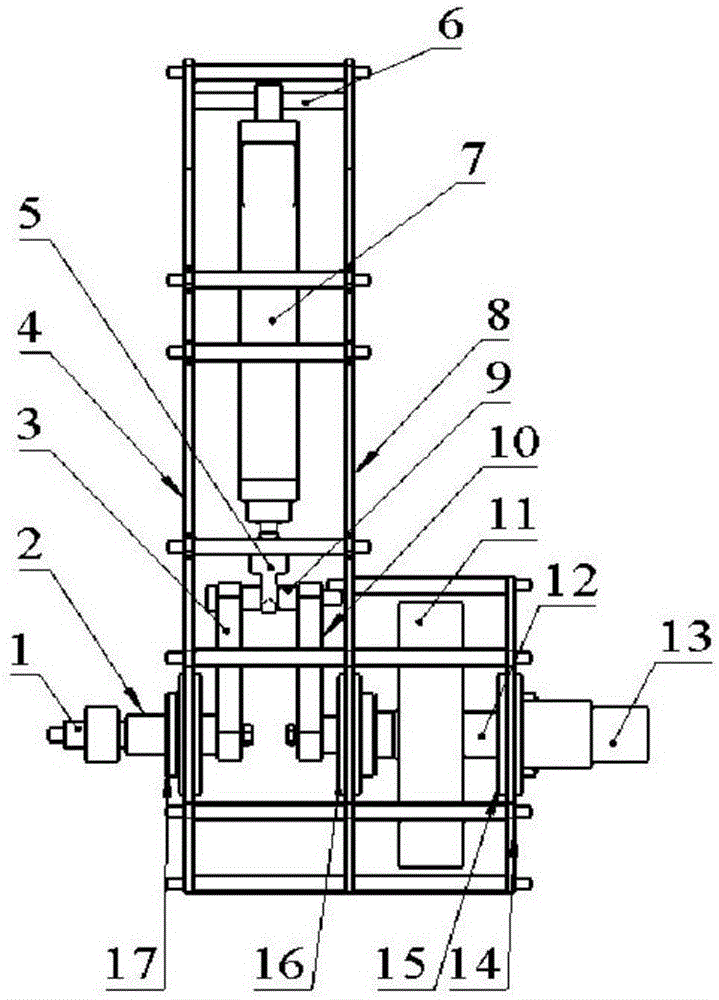

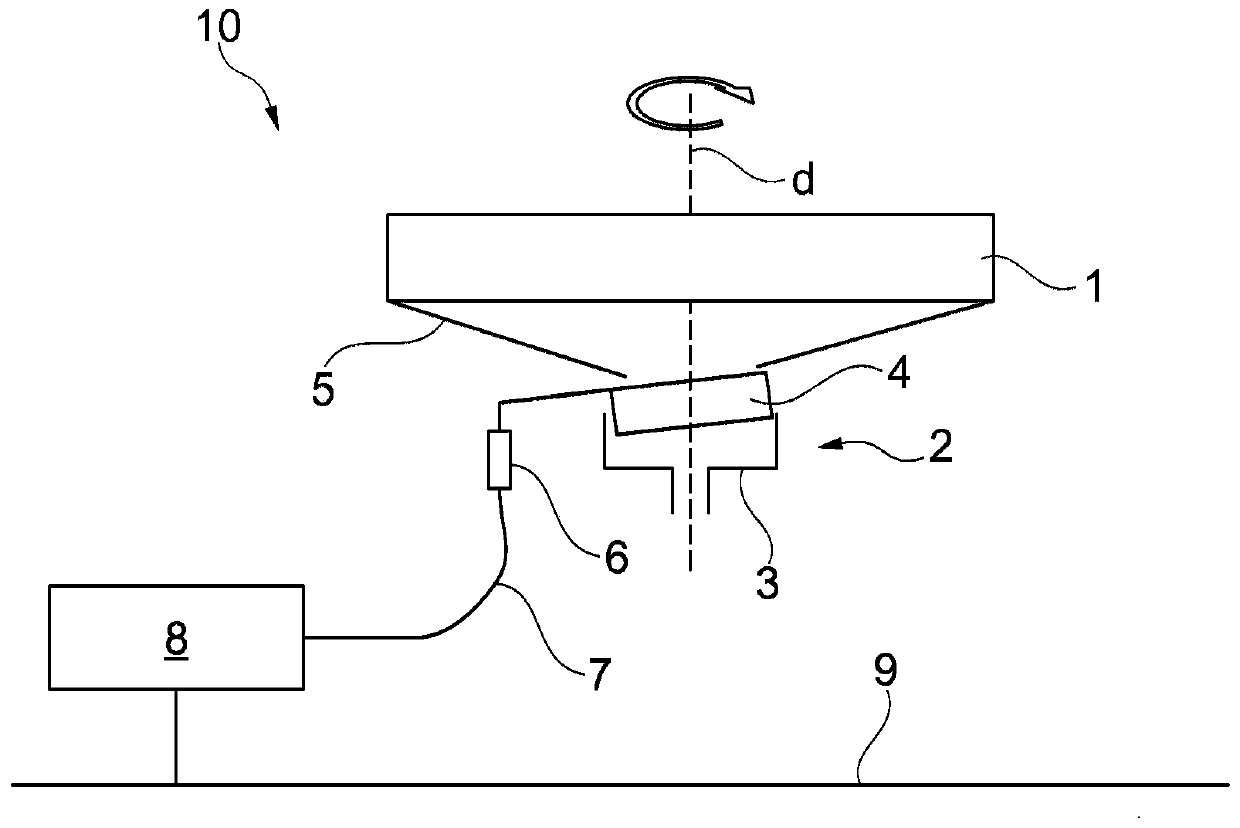

Integrated air-supply unit

ActiveCN106232398AExtended run timeReduce loadPositive displacement pump componentsVehicle sub-unit featuresElectric machineAir compressor

The invention relates to an integrated air-supply unit (1), in particular for air-suspension systems for motor vehicles, said unit comprising an air compressor (2) having an electric motor (3) and an air dryer (4). The air compressor (2) together with the electric motor (3), air dryer (4) and a number of pneumatic connections (8) form a functional unit.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

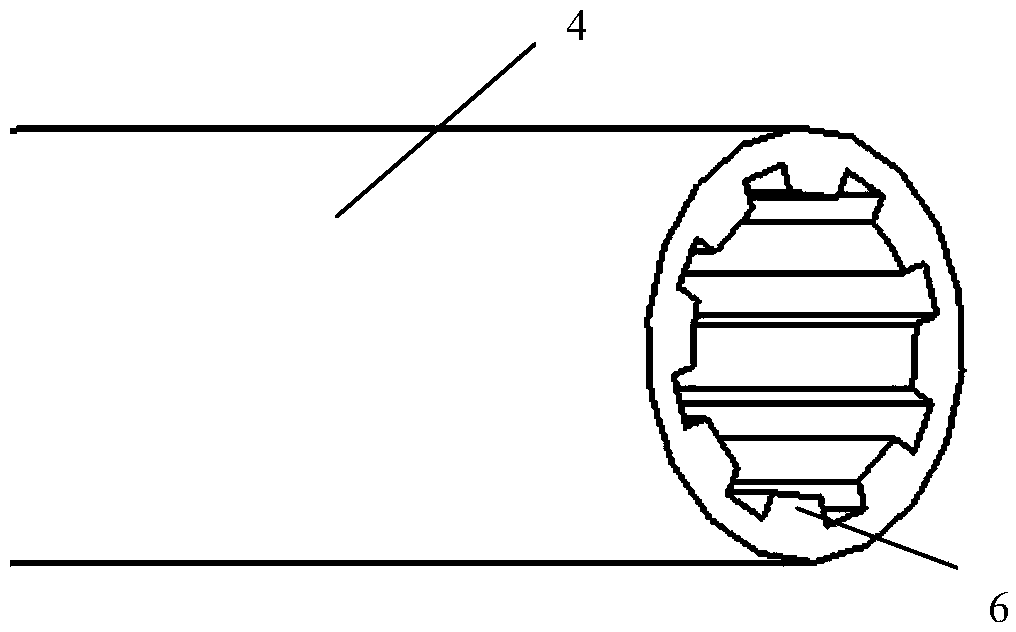

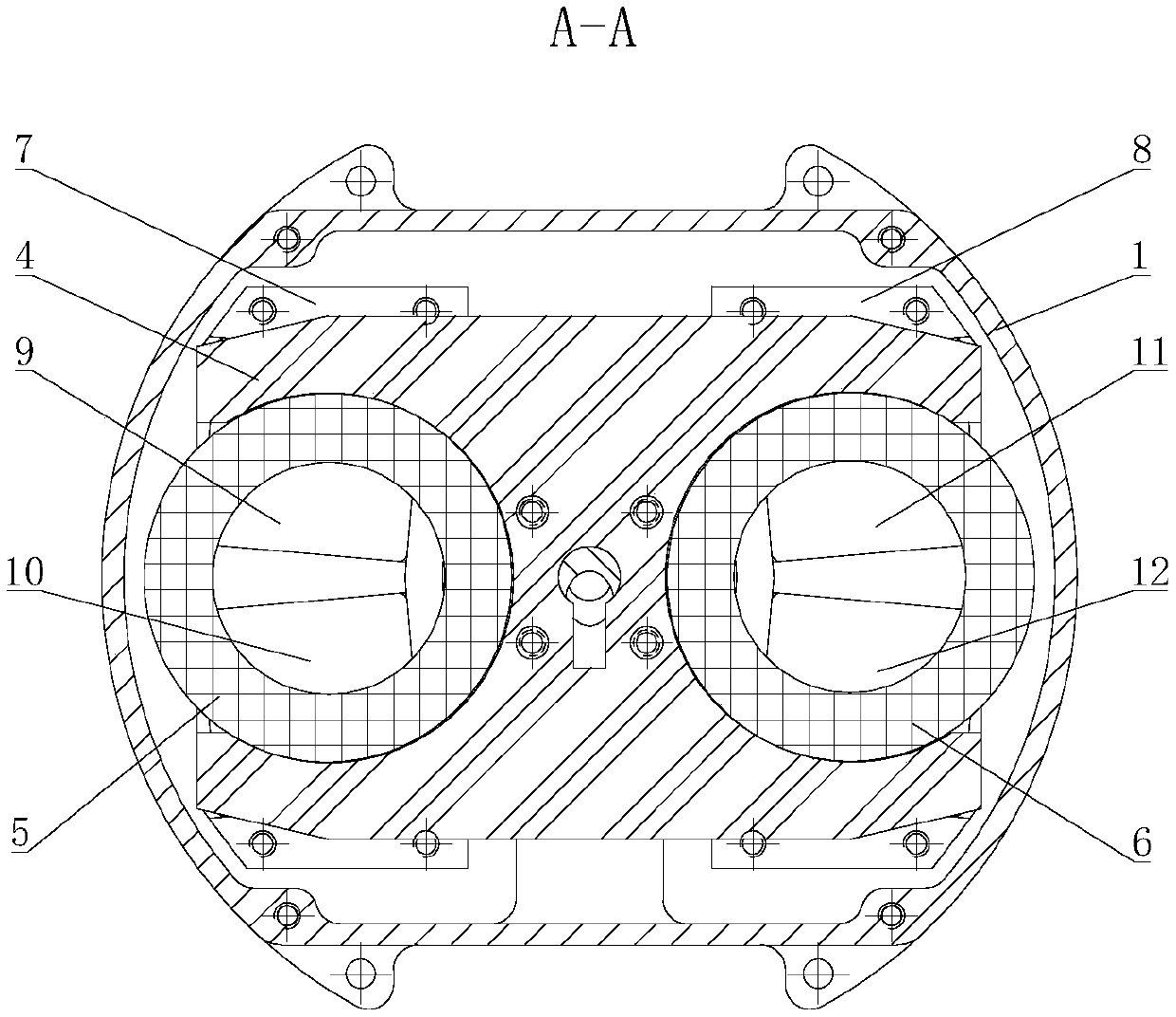

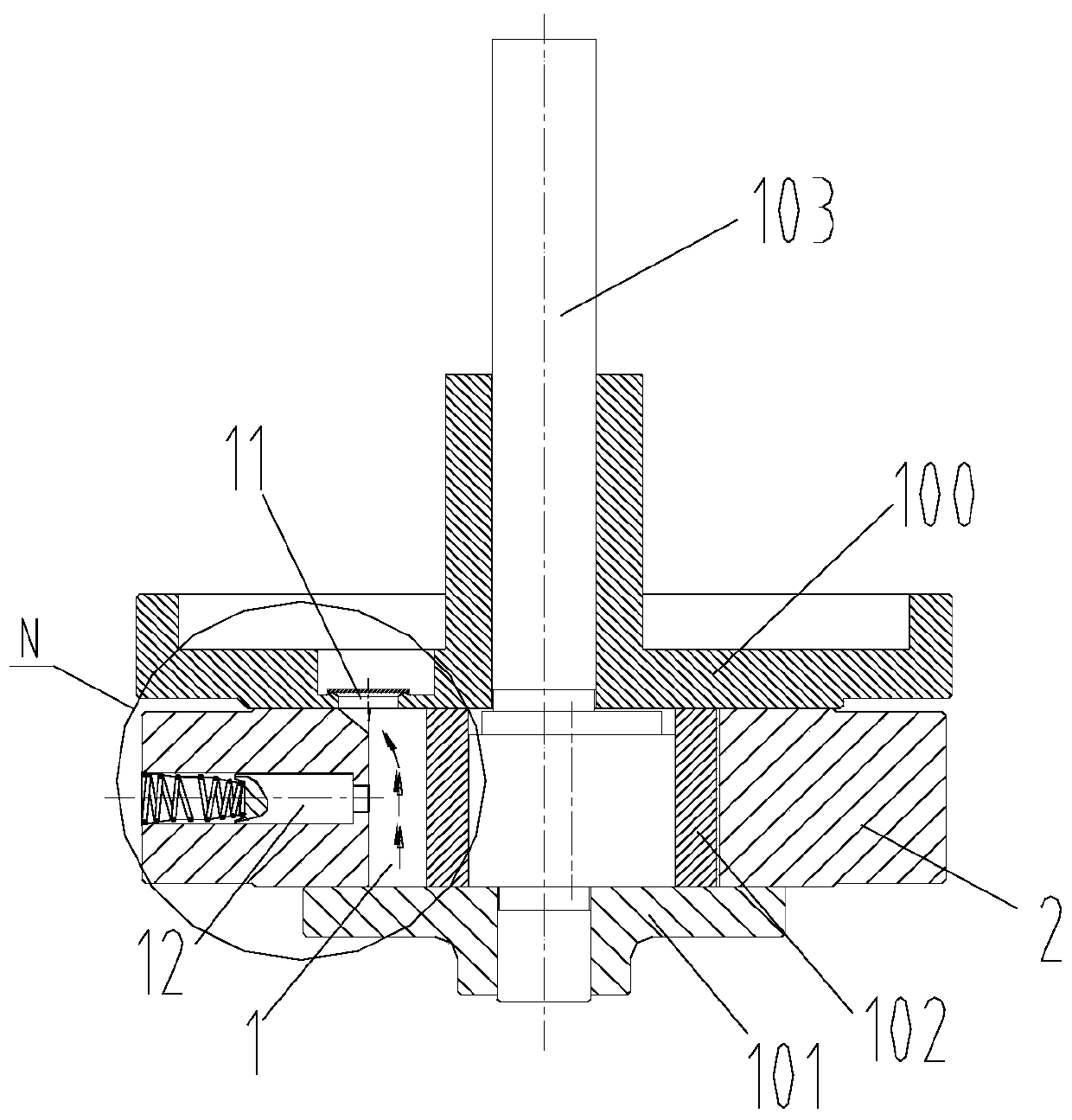

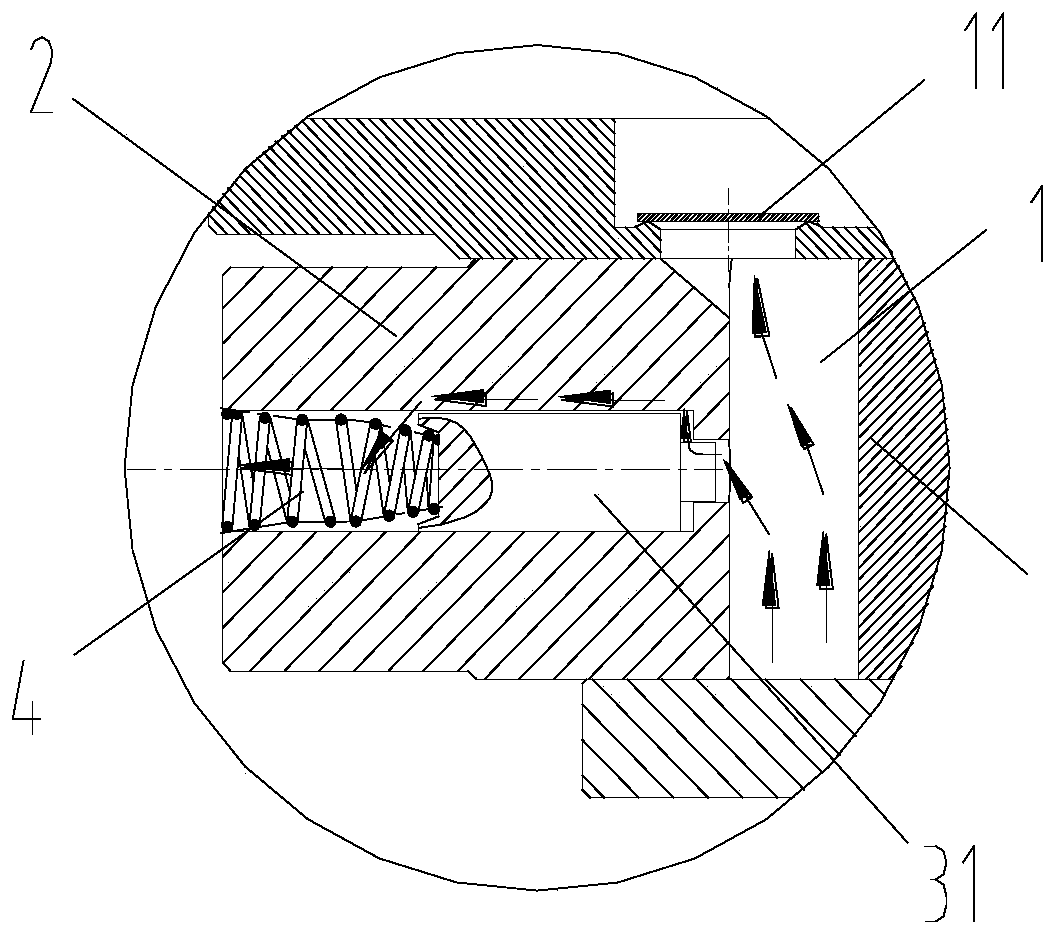

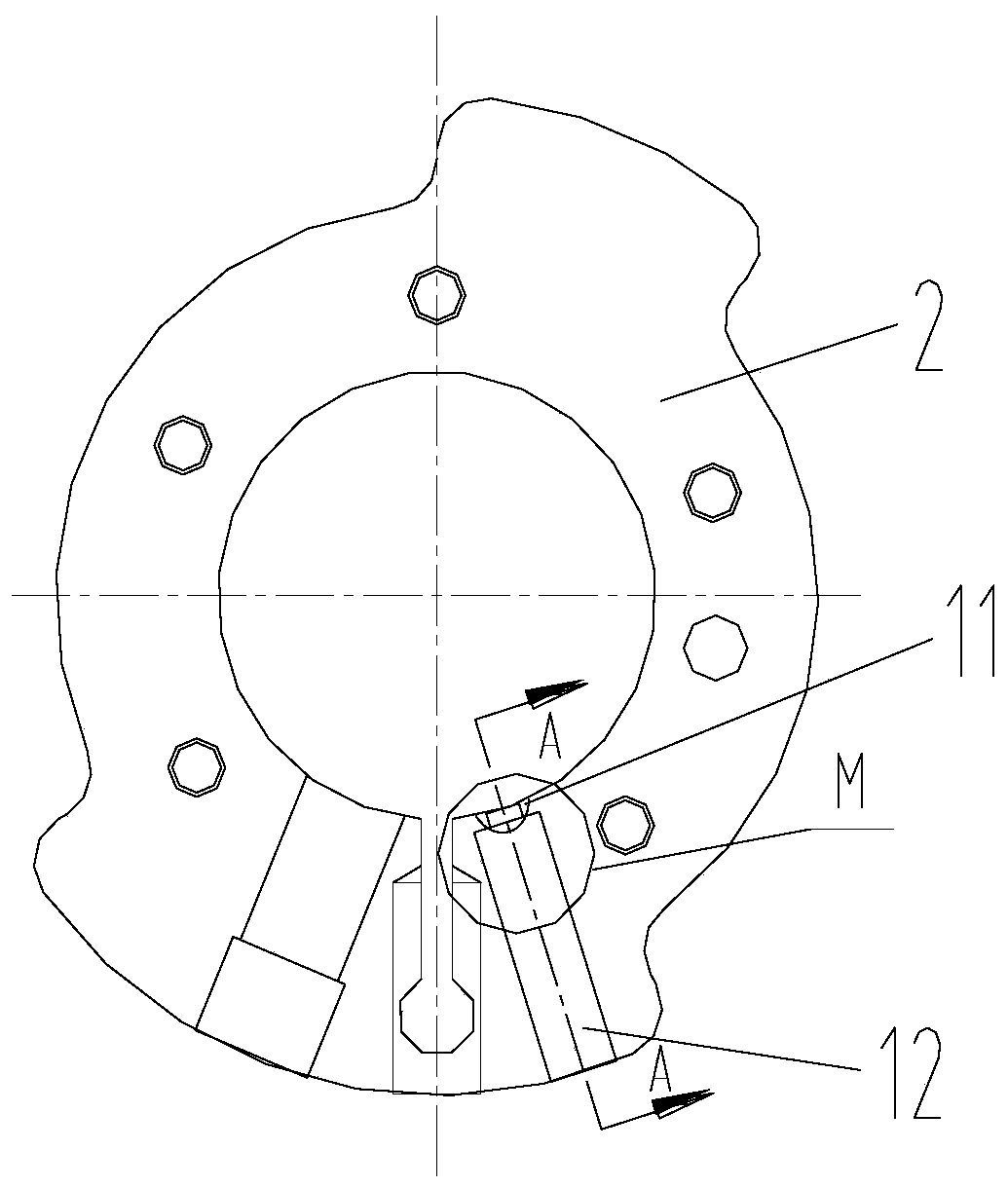

Pump body structure, compressor and air conditioner

ActiveCN110805555AReduce exhaust resistance and overcompression lossSmall torque fluctuationRotary piston pumpsRotary piston liquid enginesAutomotive engineeringMechanical engineering

The invention provides a pump body structure, a compressor and an air conditioner. The pump body structure comprises an exhaust cavity. The exhaust cavity is provided with a first exhaust channel anda second exhaust channel, and the first exhaust channel and the second exhaust channel can communicate with the exhaust cavity or be separated from the exhaust cavity. The opening and penetrating pressure of the second exhaust channel is higher than the opening and penetrating pressure of the first exhaust channel. By means of the pump body structure, the compressor and the air conditioner, when the exhaust resistance is too large during running of the compressor or overcompression exists, the exhaust resistance and the overcompression losses of the compressor are reduced through opening and penetrating and the second exhaust channel, torque fluctuation caused by unsmooth exhausting when exhausting is over is reduced, and airflow pulsation is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

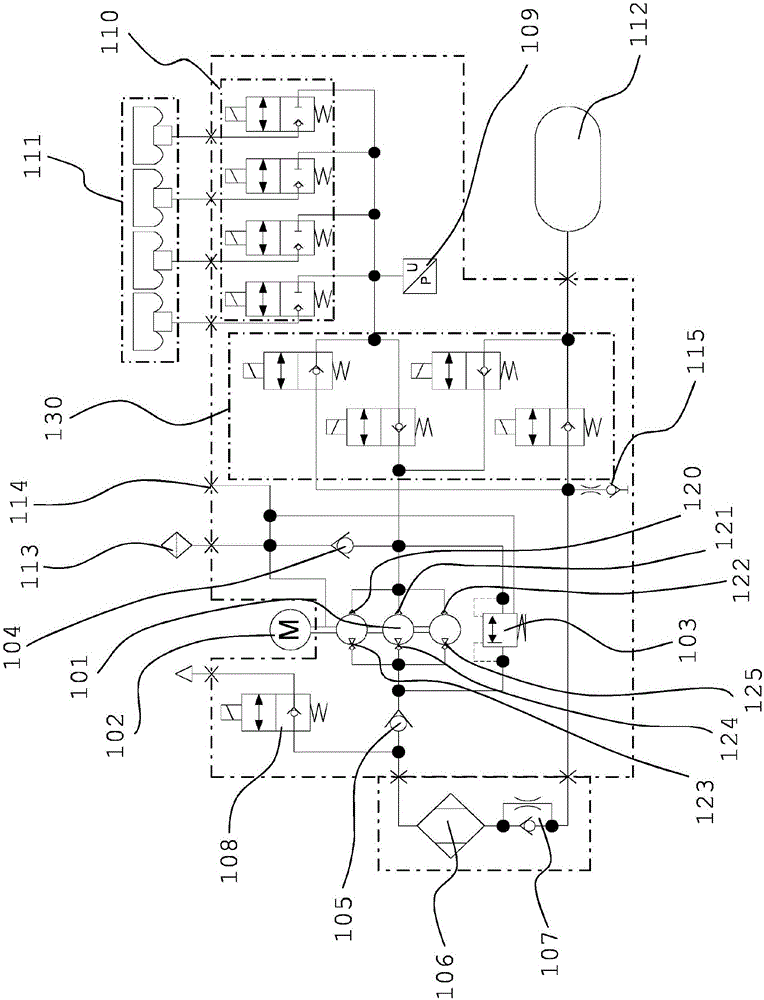

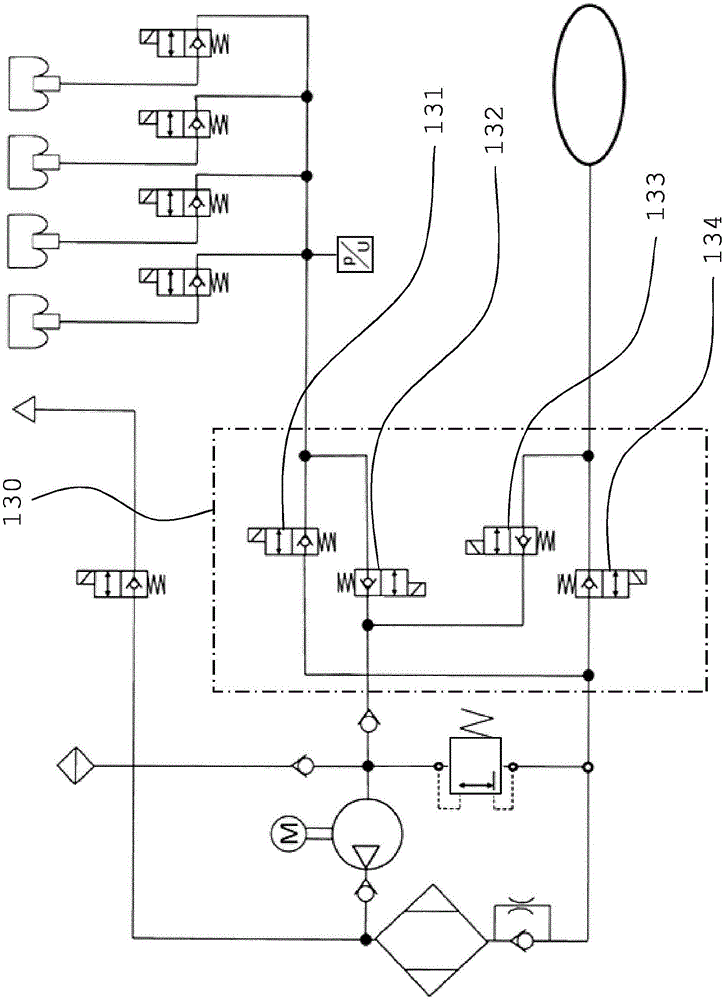

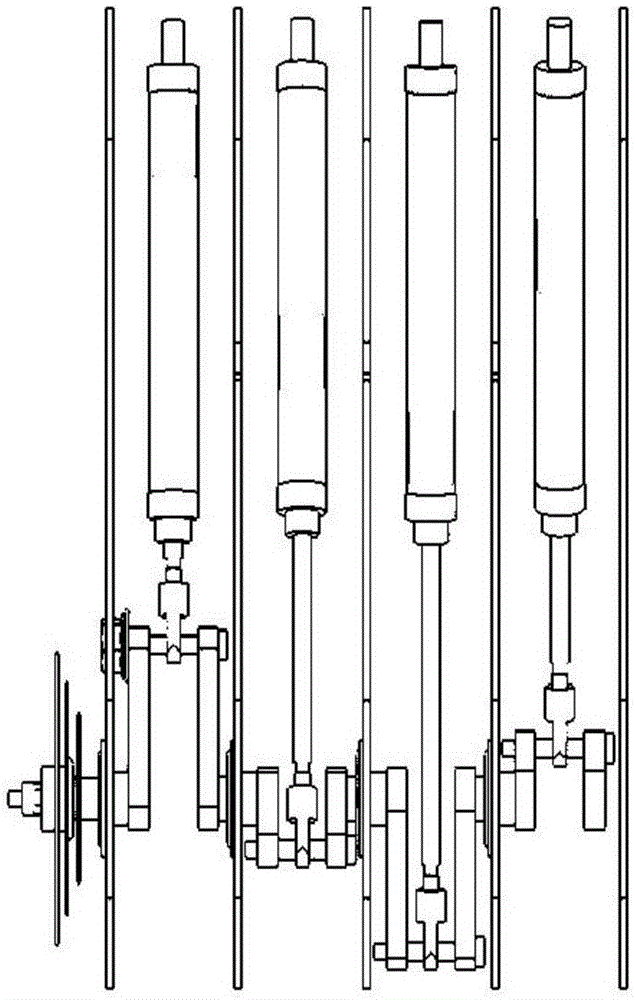

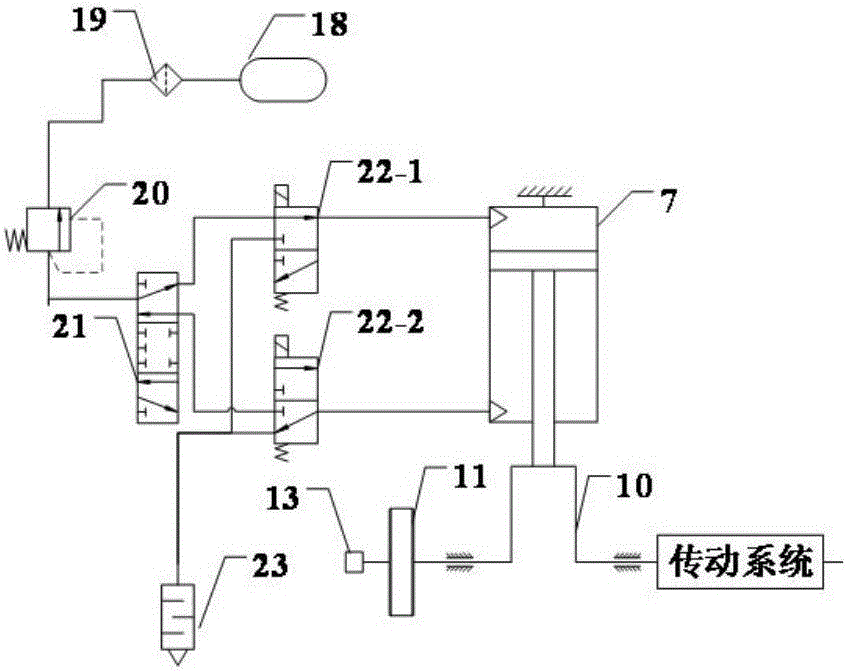

Crank type piston pneumatic engine apparatus

InactiveCN106762126AEnsure reliabilityGuarantee stabilityMachines/enginesEngine componentsLoop controlDual action

The invention provides a crank type piston pneumatic engine apparatus comprising a plurality of dual-action air cylinders and a plurality of crank power output units connected with adjacent air cylinders, a variable platen, an inertia wheel, and a pressure control loop. Each crank power output unit has a piston rod connection head, a piston rod connection shaft, a first crank, a second crank, a crank output shaft and an inertia wheel shaft; one end of the piston rod connection head is fixedly connected with an air cylinder piston and the other end is fixedly connected with the middle part of the piston rod connection shaft; two ends of the piston rod connection shaft are respectively connected with the upper end of the first crank and the upper end of the second crank via bearings; the lower end of the first crank is connected with the crank output via a bearing; the lower end of the second crank is connected with the inertia wheel shaft via a bearing; the adjacent air cylinders are connected via the crank output shaft or the inertia wheel; the variable platen is arranged the outermost crank output shaft and fixed thereon; the inertia wheel is arranged on the outermost inertial wheel shaft and fixed thereon; and the pneumatic control loop controls the air cylinder to work.

Owner:NANJING UNIV OF SCI & TECH

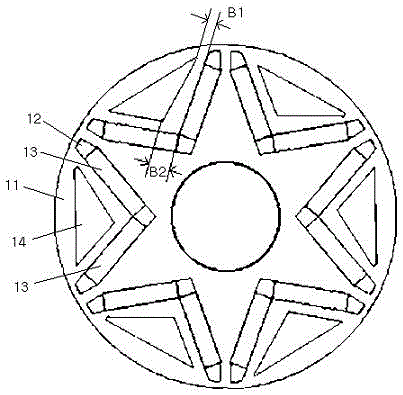

Low-fluctuation asymmetric type permanent magnetic rotor for electric vehicle motor

InactiveCN105871098ASmall fluctuationStable fluctuationMagnetic circuit rotating partsPermanent magnet rotorElectric machine

The invention relates to the technical field of motors, in particular to a low-fluctuation asymmetric type permanent magnetic rotor for an electric vehicle motor. The low-fluctuation asymmetric type permanent magnetic rotor solves the technical problem of difficulty in reducing motor moment fluctuation. A plurality of slotted permanent magnetic grooves are formed in the rotor, wherein a piece of slotted magnetic steel is embedded into each slotted permanent magnetic groove, the slotted permanent magnetic grooves are divided into a type A and a type B, the type A permanent magnetic grooves and the type B permanent magnetic grooves are alternatively distributed in the circumferential direction of the rotor, the radial inserting depths of the A type permanent magnetic grooves are the same, the radial inserting depths of the B type permanent magnetic grooves are the same, the radial inserting depths of the A type permanent magnetic grooves are larger than the radial inserting depths of the B type permanent magnetic grooves, and the radial inserting depths of the slotted permanent magnetic grooves are the minimum distance between the slotted permanent magnetic grooves and the axis of the rotor. The rotor is especially suitable for an electric vehicle.

Owner:SHANGHAI TOP MOTOR

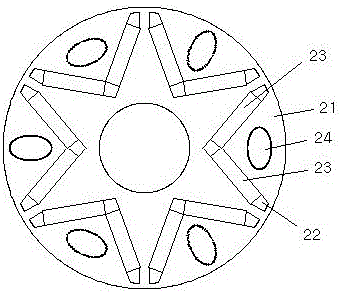

Low-fluctuation permanent magnetic rotor of electromobile motor

ActiveCN105871097ASmall fluctuationStable fluctuationMagnetic circuit rotating partsElectric machinesPermanent magnet rotorElectric machine

Owner:SHANGHAI CHUANYE ELECTRIC MACHINE

Amorphous alloy high-speed outer rotor permanent magnet motor

PendingCN112953059AReduce temperature riseLow iron loss at high frequencyMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic poles

The invention discloses an amorphous alloy high-speed outer rotor permanent magnet motor, which comprises a permanent magnet outer rotor, an amorphous alloy inner stator and an air gap, wherein the outer rotor adopts a three-section Halbach array+combined magnetic pole structure, the maximum magnetic energy product of magnetic steel in the middle of a magnetic pole is larger than that of the same type of magnetic steel which is symmetrical on two sides, and the thickness, the space angle, the magnetizing angle and the coercive force of the magnetic steel are all obtained through optimization so as to ensure that the harmonic distortion rate of no-load air gap flux density of the motor is minimum, and therefore torque fluctuation of the permanent magnet motor is restrained; an iron core of the inner stator is formed by iron-based amorphous alloy strips through overlying and linear cutting so as to reduce high-frequency iron loss; and the cross section of the stator slot wedge is of a special-shaped structure, and protrusions of the cross section in the axial direction of the slot wedge are 0.1-0.2 mm higher than a notch and the parts level with the notches alternately appear, so that the amorphous alloy stator iron core is prevented from being collided by the permanent magnet outer rotor when the motor is assembled or disassembled. The outer rotor high-speed permanent magnet motor is suitable for high-efficiency, high-speed and stable operation occasions.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

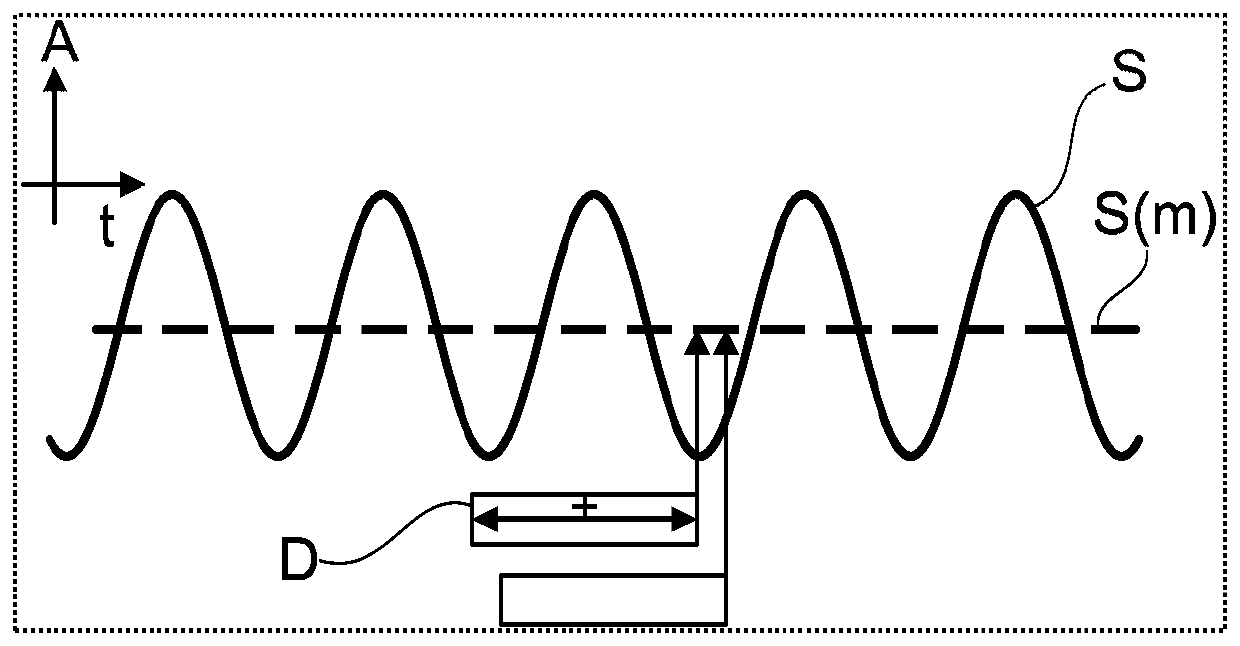

Method for filtering a position signal of a position sensor of a clutch actuation device

ActiveCN109891113AReduce the amplitudeFor high demands in terms of signal noise suppressionFriction clutchesCouplingsMoving averageHysteresis

The invention relates to a method for filtering a position signal (S) of a positions sensor of a clutch actuation device of a friction clutch in a drive train of a motor vehicle. In order to eliminatevibrations occurring in an in particular hydrostatically designed clutch actuation device due to a non-linear arrangement, the position signal (S) is filtered by means of a low pass filter (12), theposition signal (S) is additionally filtered in a first filter element (13) having a sliding average and in a second filter element (14) as a hysteresis filter (15), wherein both filtered position signals (S(m), (S(h)) are weighted in a decision module (16) in order to minimize deviations of the filtered position signal (S(s)) from the actual position.

Owner:SCHAEFFLER TECH AG & CO KG

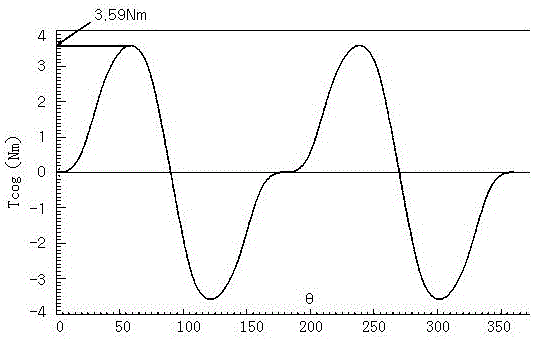

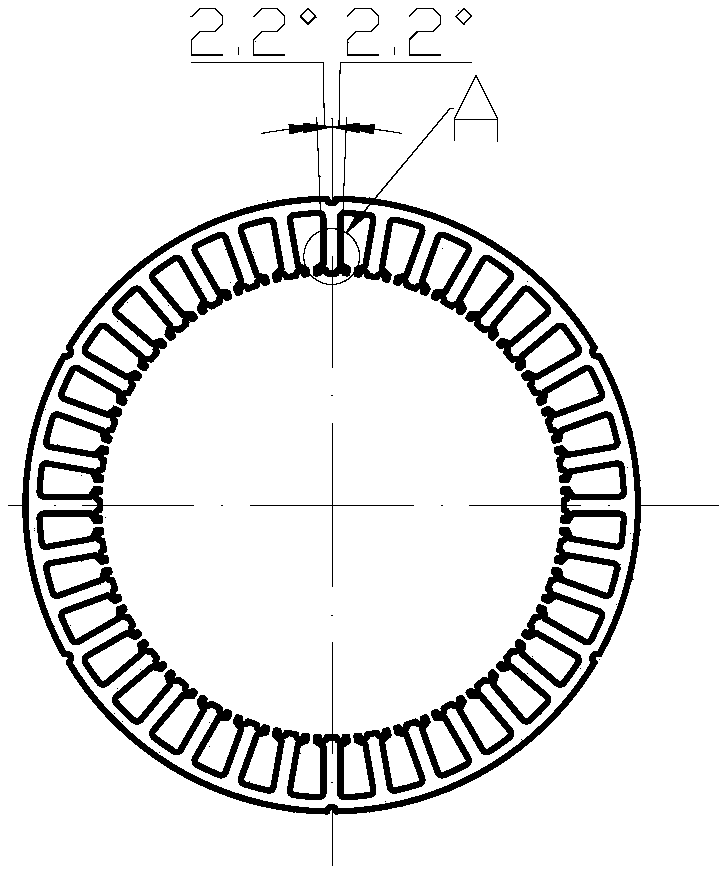

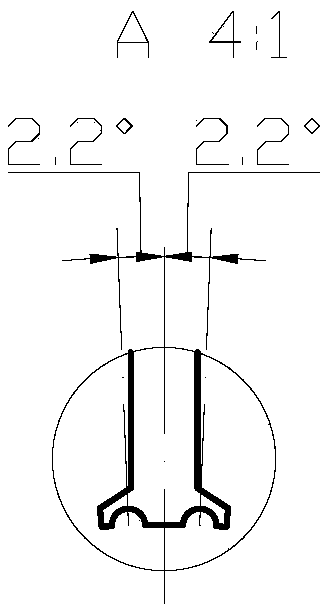

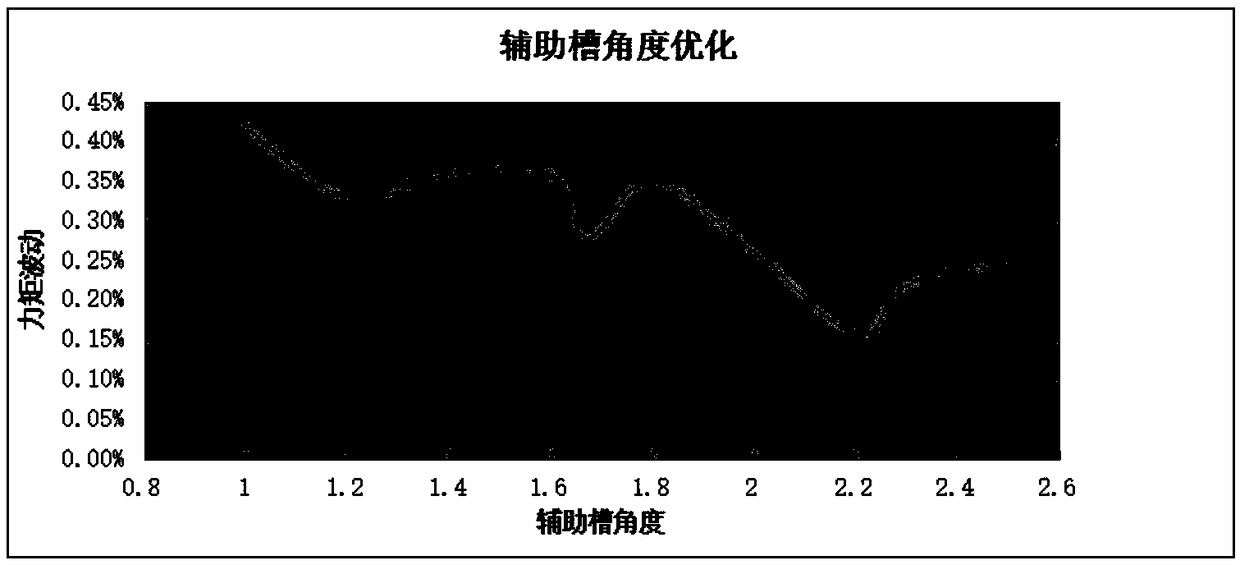

Structure design method of torque motor with low torque fluctuation

InactiveCN109391098ASmall torque fluctuationSmall torqueManufacturing stator/rotor bodiesTorque motorControl theory

The invention provides a structure design method of a torque motor with low torque fluctuation, which comprises the following steps: determining the number of auxiliary grooves, the groove type and the grooving angle, wherein the number Nn of auxiliary grooves in a single crown part is the smallest integer value satisfying the condition that Nn+1 is not equal to Np / k, the auxiliary grooves are semicircular grooves, and the grooving angle is obtained from the set range by using the simulation calculation method when the torque fluctuation is minimum. The structure designed by the invention reduces the cogging torque of the motor and is very effective in reducing the torque fluctuation of the motor. Moreover, the scheme is simple in structure, good in manufacturability and easy to implement.

Owner:XIAN AEROSPACE PROPULSION TESTING TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com