Pump body structure, compressor and air conditioner

A compressor and pump body technology, applied in the direction of machine/engine, liquid fuel engine, pump, etc., can solve problems such as excessive instantaneous torque fluctuation, increase in pump exhaust resistance, abnormal compressor shutdown, etc. The effect of airflow pulsation, reducing torque fluctuation and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

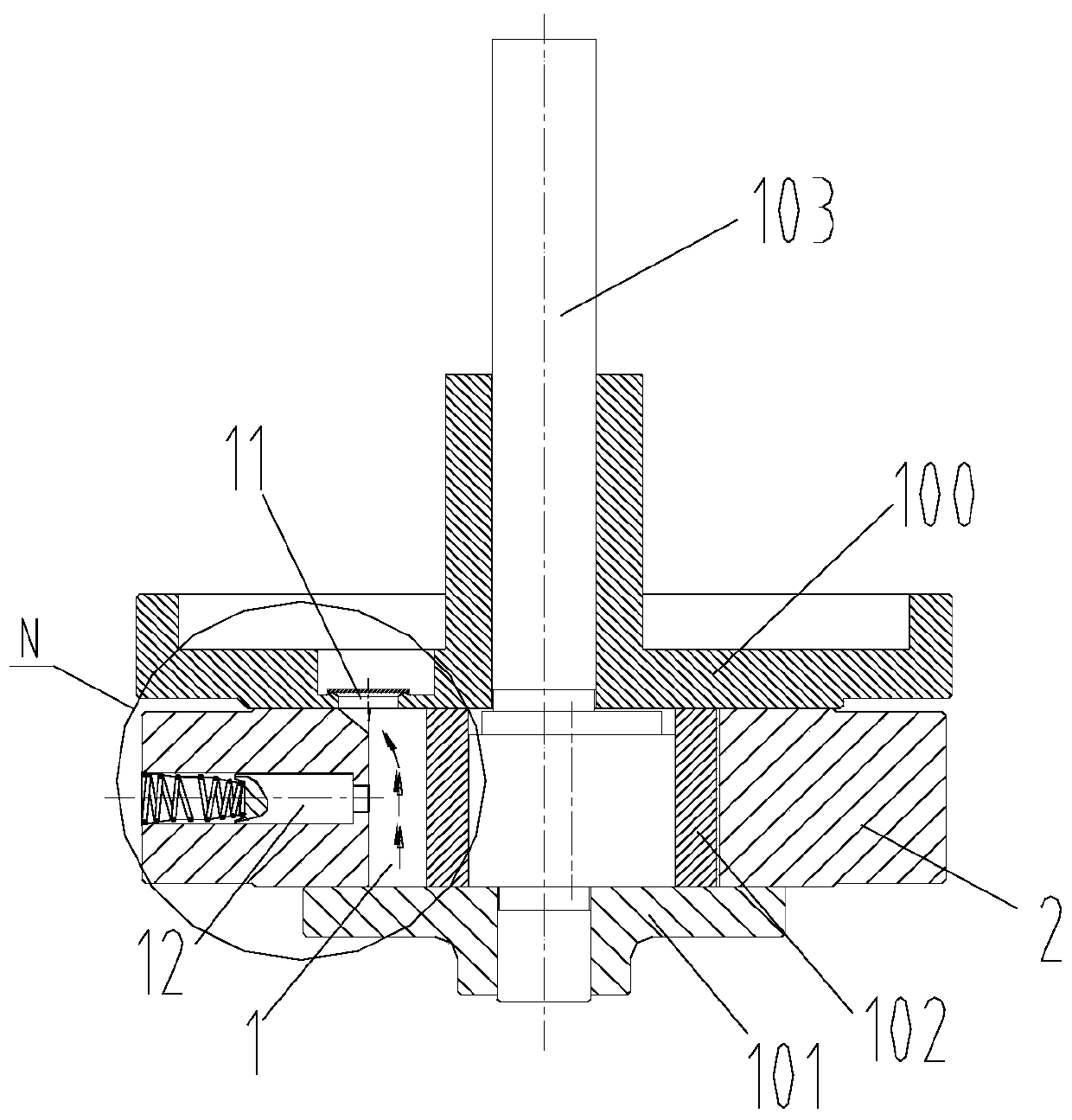

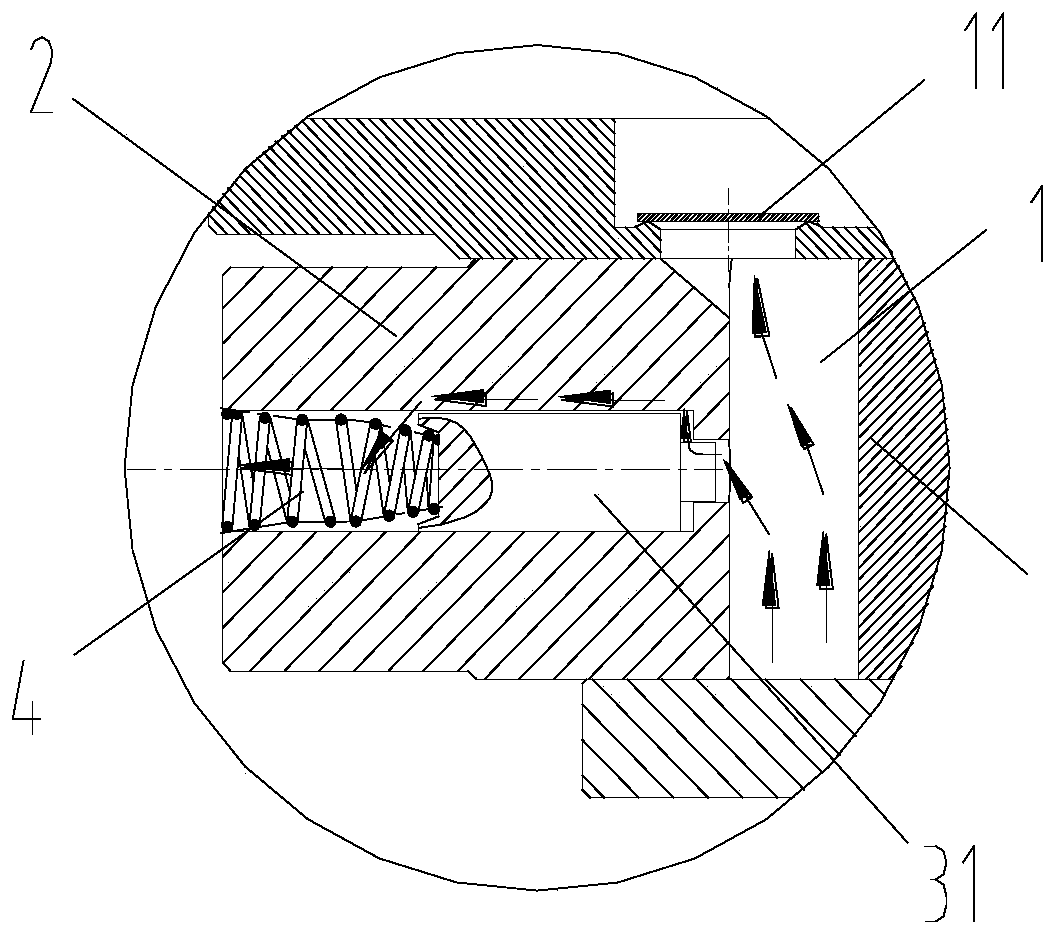

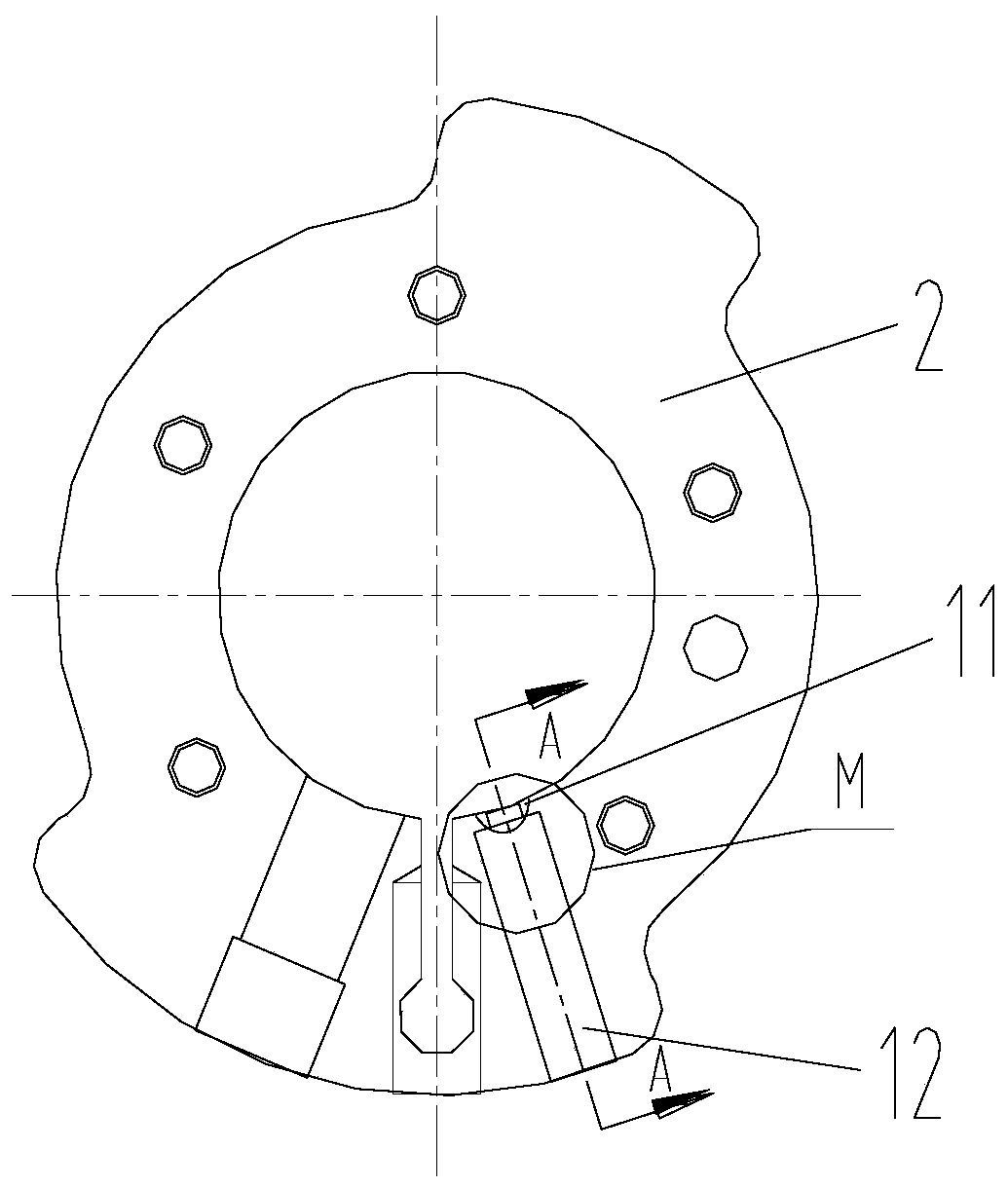

[0033] see in conjunction Figure 1 to Figure 8 As shown, according to an embodiment of the present invention, a pump body structure is provided, including a cylinder block 2, an upper flange 100, a lower flange 101, a roller 102, a crankshaft 103, and a slide (not shown in the figure), The cylinder block 2 has a hollow cavity, the upper flange 100 and the lower flange 101 are located at both ends of the cylinder block 2 in the axial direction, the roller 102 is sleeved on the eccentric portion of the crankshaft 103, and Located in the hollow cavity, the crankshaft 103 passes through the shaft holes of the upper flange 100 and the lower flange 101 in sequence, and the slide plate is reciprocatingly arranged in the chute of the cylinder block 2, The head of the sliding plate abuts against the roller to divide the hollow cavity of the cylinder block into an air suction chamber and an exhaust chamber 1, and the exhaust chamber 1 has a first exhaust passage 11 and a second exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com