Low-fluctuation asymmetric type permanent magnetic rotor for electric vehicle motor

A technology for electric vehicles and permanent magnet rotors, applied in electric components, magnetic circuits, electrical components, etc., can solve the problems of reducing the area of the stator slot, increasing the manufacturing cost of the motor, and reducing the output, so as to reduce the core loss and torque fluctuation. , The effect of reducing mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention. All similar structures and similar changes of the present invention should be included in the scope of protection of the present invention. The commas in all indicate the relationship between and.

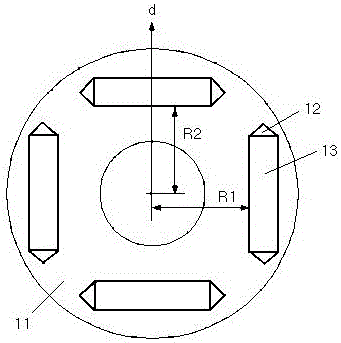

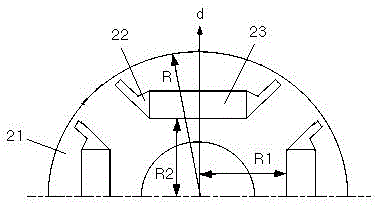

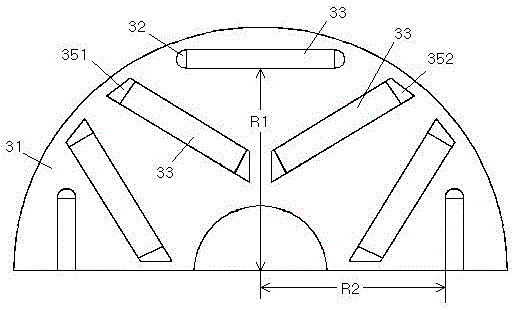

[0024] like figure 1 As shown, in the low-fluctuation asymmetric permanent magnet rotor of an electric vehicle motor provided by the first embodiment of the present invention, a plurality of inline permanent magnet slots 12 are opened on the rotor 11, and each inline permanent magnet There is a font magnetic steel 13 embedded in the groove, which is characterized in that:

[0025] Each inline permanent magnet slot 12 is equally divided into two categories, one of which is a class A permanent magnet slot, and the other is a class B permanent magnet slot, and each class A perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com