Patents

Literature

232results about How to "Reduce exhaust resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Convex low-altitude glass welded by metal solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951814AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideAlloy

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper glass and the lower glass are respectively provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Preparation method of honeycomb ceramic net through Lu and N co-doped TiO2 photocatalysis

ActiveCN103406136AIncrease costGuaranteed costPhysical/chemical process catalystsDispersed particle separationRare-earth elementMass ratio

The invention relates to a preparation method of a honeycomb ceramic net through Lu and N co-doped TiO2 photocatalysis. The honeycomb ceramic net is regarded as a first carrier, and activity AL2O3 coating with specific surface area of 300 to 400m2 / g and doping with lanthanum, cerium and iron element is loaded on the first carrier and regarded as a second carrier; the mass ratio of AL2O3 to La to Ce to Fe is (100 to 110) to (90 to 115) to (50 to 70) to (5 to 15); the TiO2 photocatalyst films of rare earth element Lu and non-metallic element N are loaded on the second carrier; the mass ratio of Lu to N to TiO2 in the TiO2 photocatalyst film is (0.01 to 0.16) to (0.40 to 1.88) to (97.94 to 99.54). The removal rate of the honeycomb ceramic net prepared through photocatalysis to formaldehyde and toluene in the air is 98.7% and 92.2% respectively, and the removal rate to formaldehyde and toluene in the air is improved by 2.0 times and 1.9 time respectively compared with the application of the TiO2 photocatalyst film only.

Owner:JIANGSU GAOCHUN CERAMICS +1

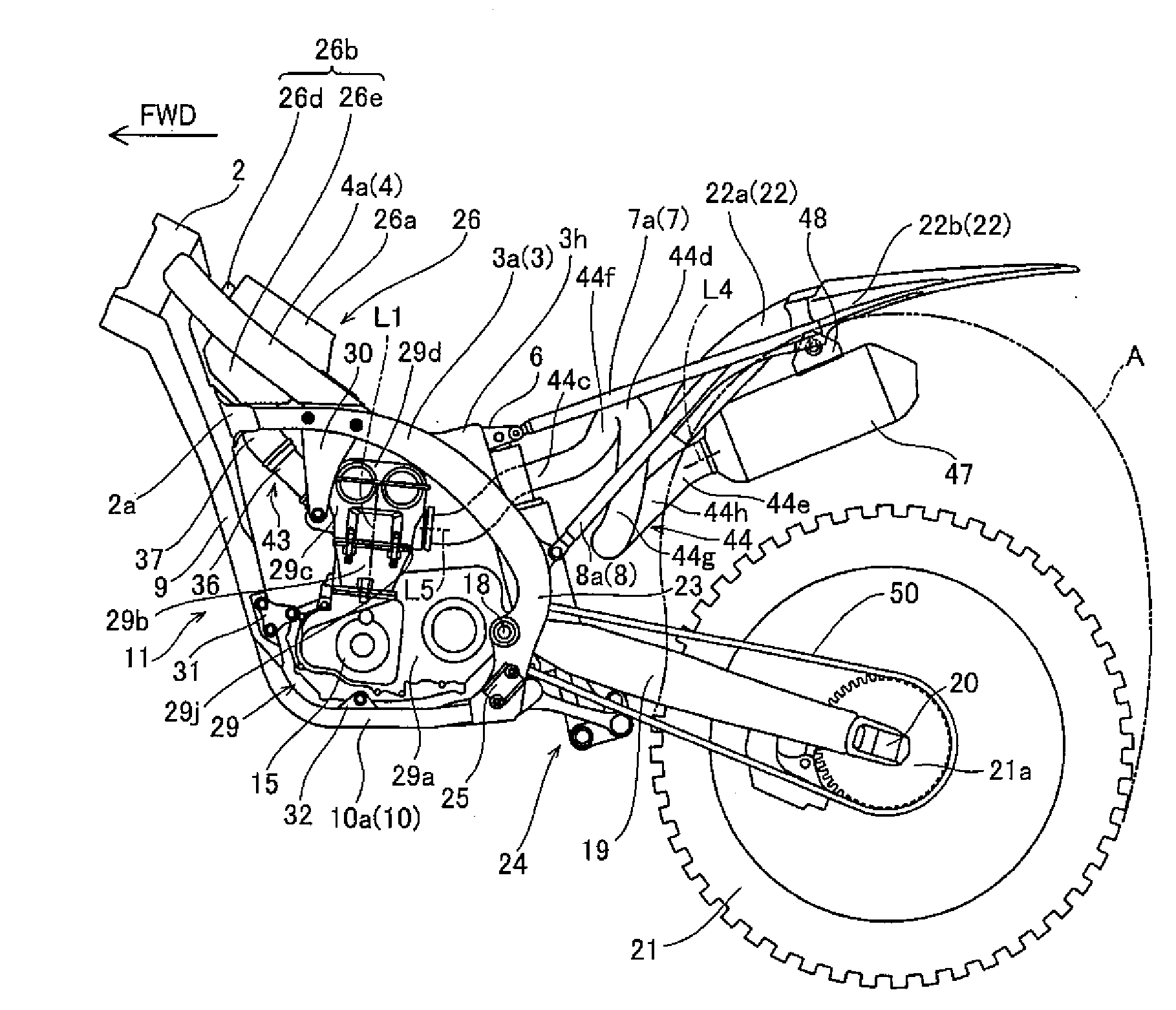

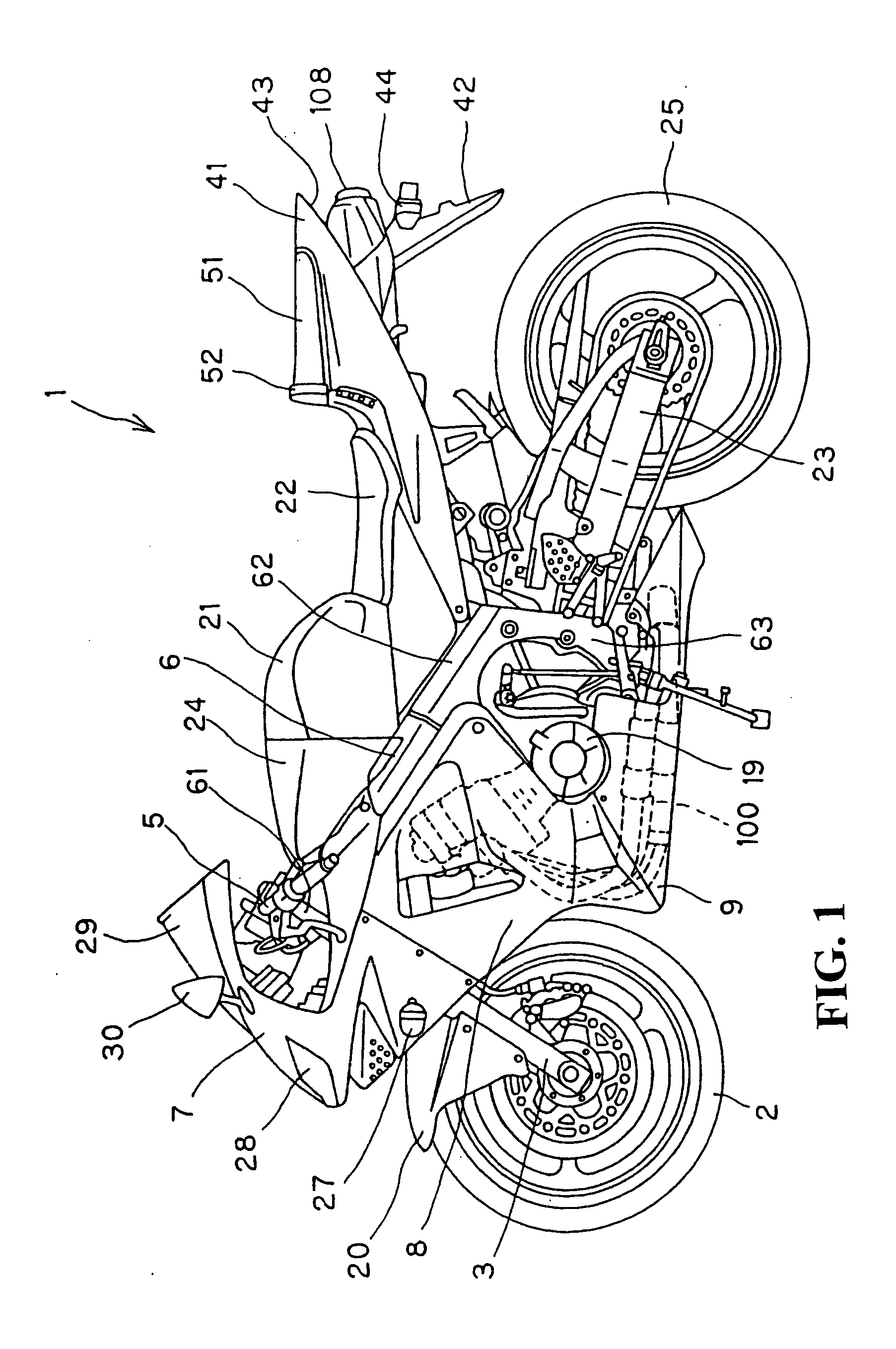

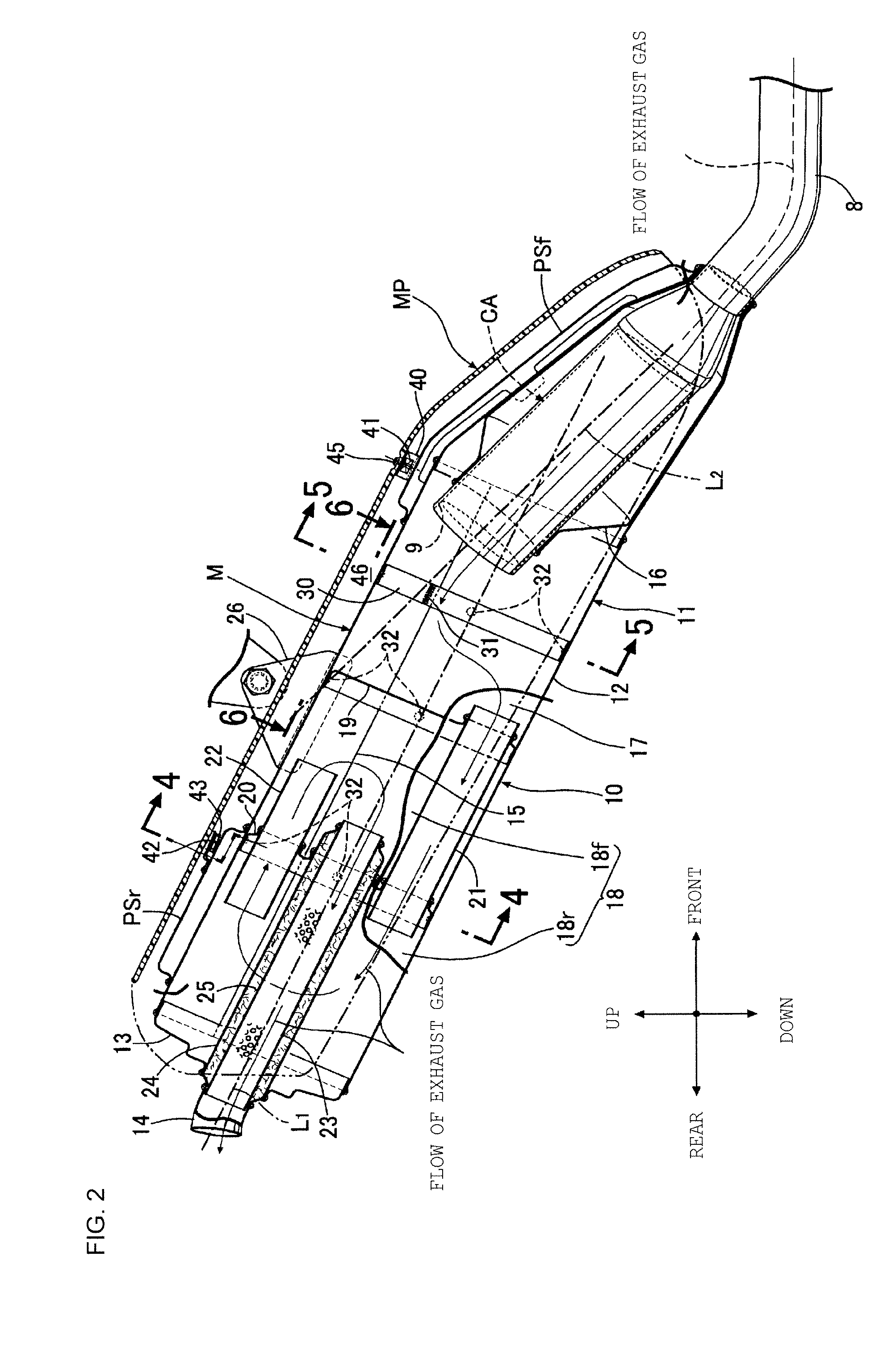

Vehicle

InactiveUS20080110687A1Sufficient lengthEnsures rigidityExhaust apparatusSilencing apparatusAutomotive engineeringExhaust pipe

A vehicle having a sufficient length of exhaust pipe and a member disposed above a rear suspension that is not too high. An exhaust pipe is connected to a rearward side of an engine. A rear suspension absorbs shocks generated when a rear wheel moves up and down. A coil-form part of the exhaust pipe is located between the rear suspension and a tire house of the rear wheel, within which the rear wheel moves up and down.

Owner:YAMAHA MOTOR CO LTD

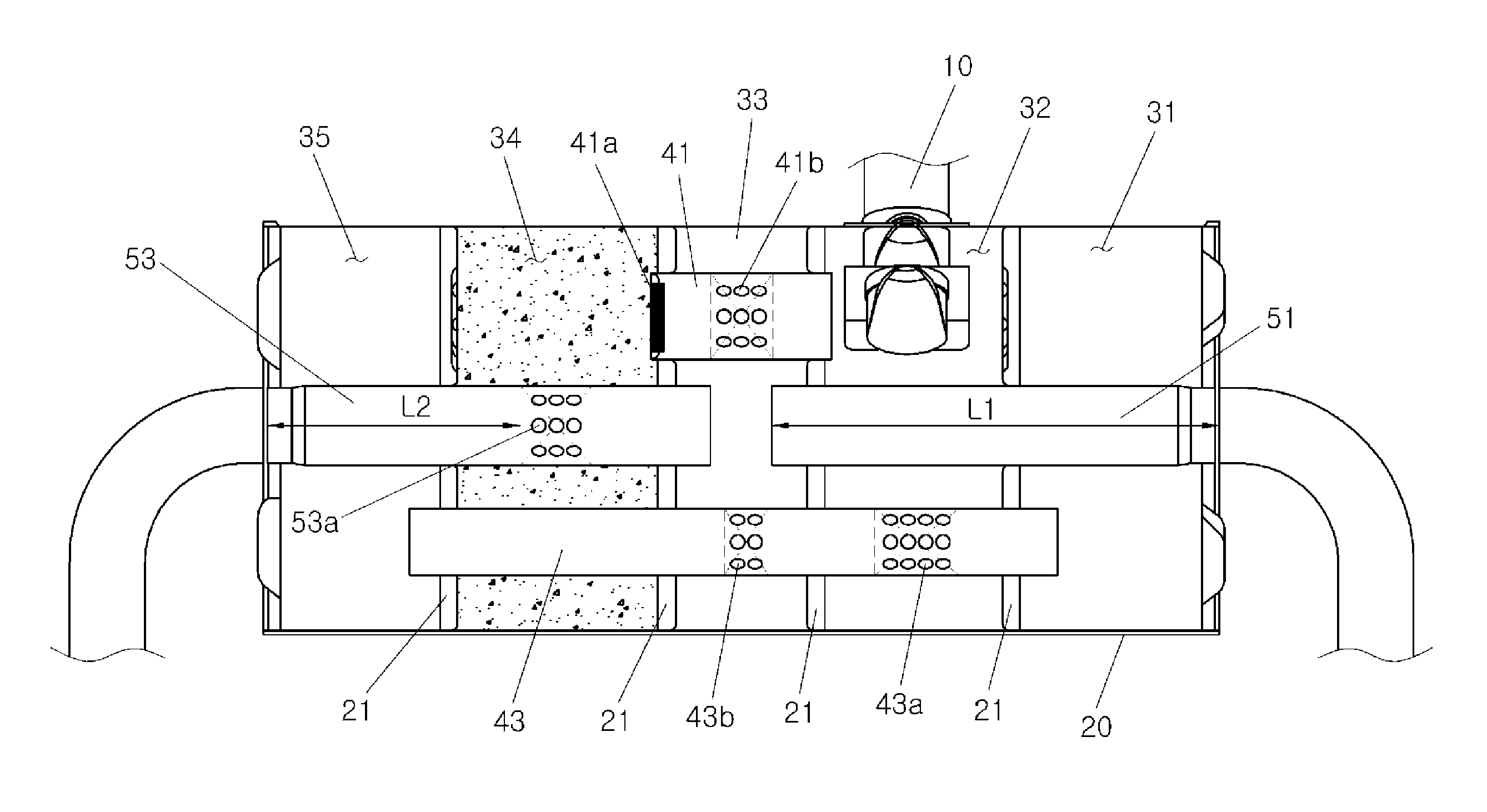

Horizontally installed muffler having sporty tone

InactiveUS20130213734A1Increase productionLower the volumeSilencing apparatusThermometers using physical/chemical changesExhaust pipeMuffler

A horizontally installed muffler may include a housing, first and second tail pipes installed to front and rear ends of the housing through the housing, an introduction chamber formed inside the housing and to which an outlet of the exhaust pipe is connected, a first intermediate pipe fluid-connected to the introduction chamber and having a first discharge hole, a discharge chamber fluid-connected to the introduction chamber through the first discharge hole of the first intermediate pipe, wherein each end of the first and second tail pipes and the first discharge hole are disposed inside the discharge chamber, first and second resonance chambers formed inside the housing, a second intermediate pipe fluid-connected to the first and second resonance chambers through the discharge chamber and the introduction chamber and having an introduction hole disposed inside the introduction chamber and a second discharge hole disposed inside the discharge chamber.

Owner:HYUNDAI MOTOR CO LTD

Exhaust device of fuel cell vehicle

ActiveUS9281533B2Smooth dischargeShorten the lengthFuel cells groupingFuel cell auxillariesFuel cellsAirflow

Owner:SUZUKI MOTOR CORP

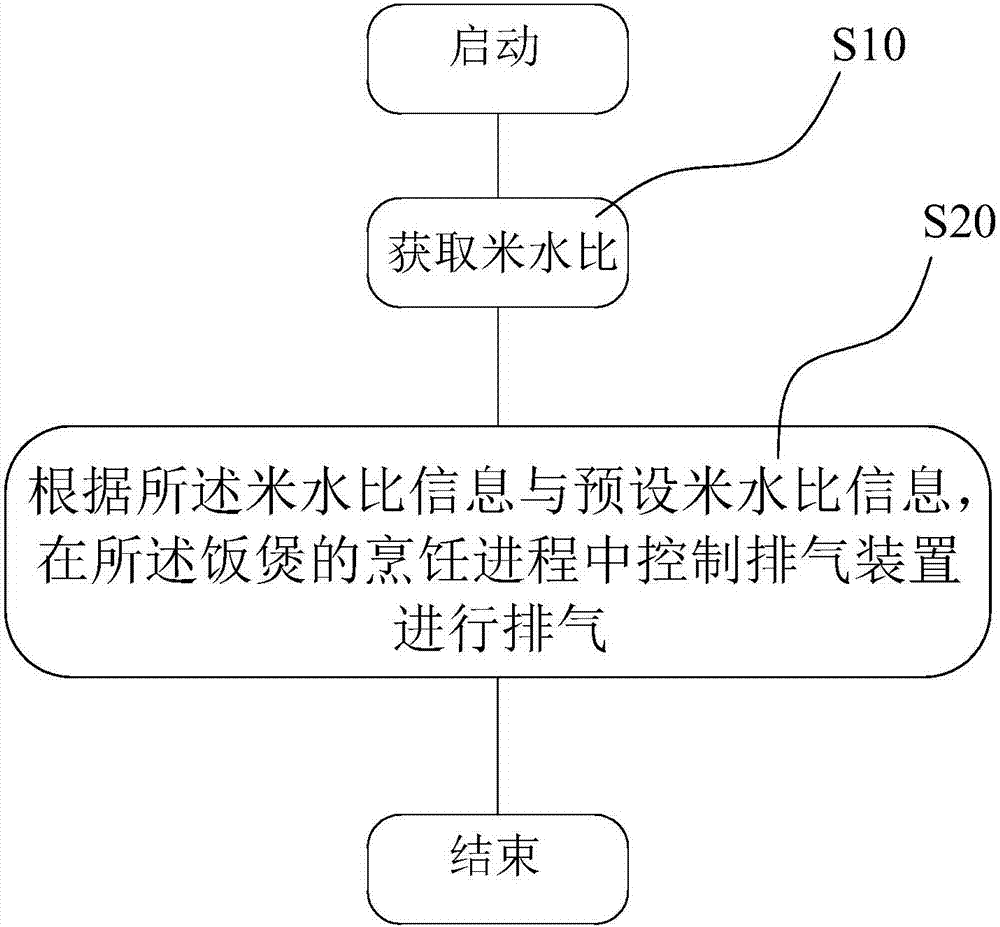

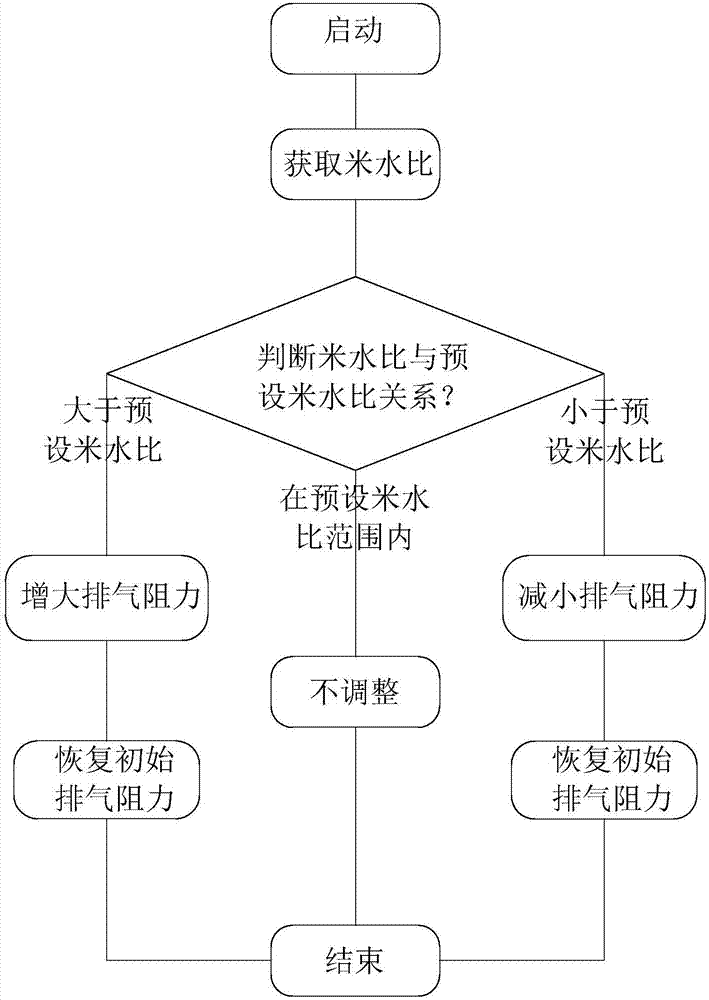

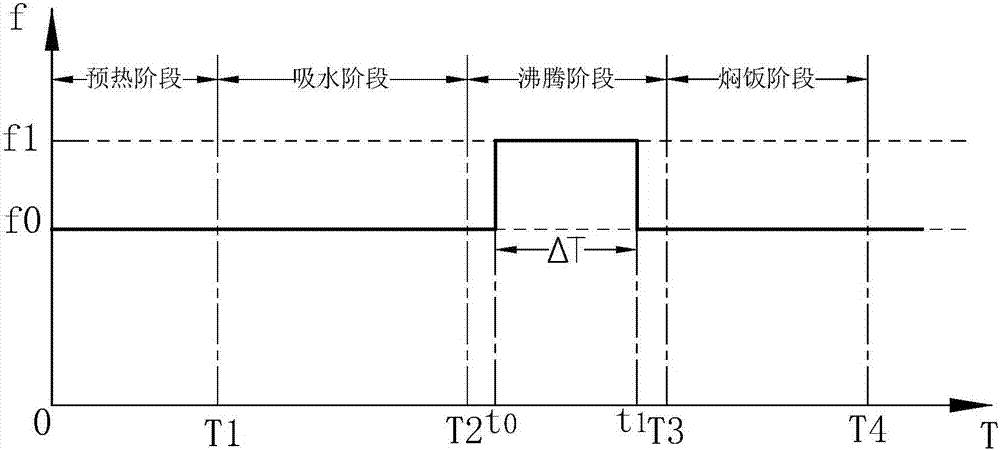

Cooking control method and rice cooker

ActiveCN107334357AEasy dischargeReduce exhaust resistanceSimultaneous control of multiple variablesVessels with intergral heatingEngineeringCooking process

The invention provides a cooking control method and a rice cooker realizing automatic adjustment and control on the air exhaust mode according to the rice-water ratio. The method comprises the following steps: acquiring the rice-water ratio information in an inner container of the rice cooker, and controlling an air exhaust device to exhaust air in the cooking process of the rice cooker according to the rice-water ratio information and the preset rice-water ratio information. In addition, the invention further provides the rice cooker adopting the method. With the adoption of the technical scheme provided by the invention, the cooking control method and the rice cooker have the advantages that even if the ratio of the rice and water added by a user does not meet the preset rice-water ratio requirement of the function selected by the user, the user does not need to manually adjust the rice and water, but water can be adjusted through air exhaust in the cooking process of the rice cooker, and finally, the rice which meets the requirements of the user is cooked.

Owner:JOYOUNG CO LTD

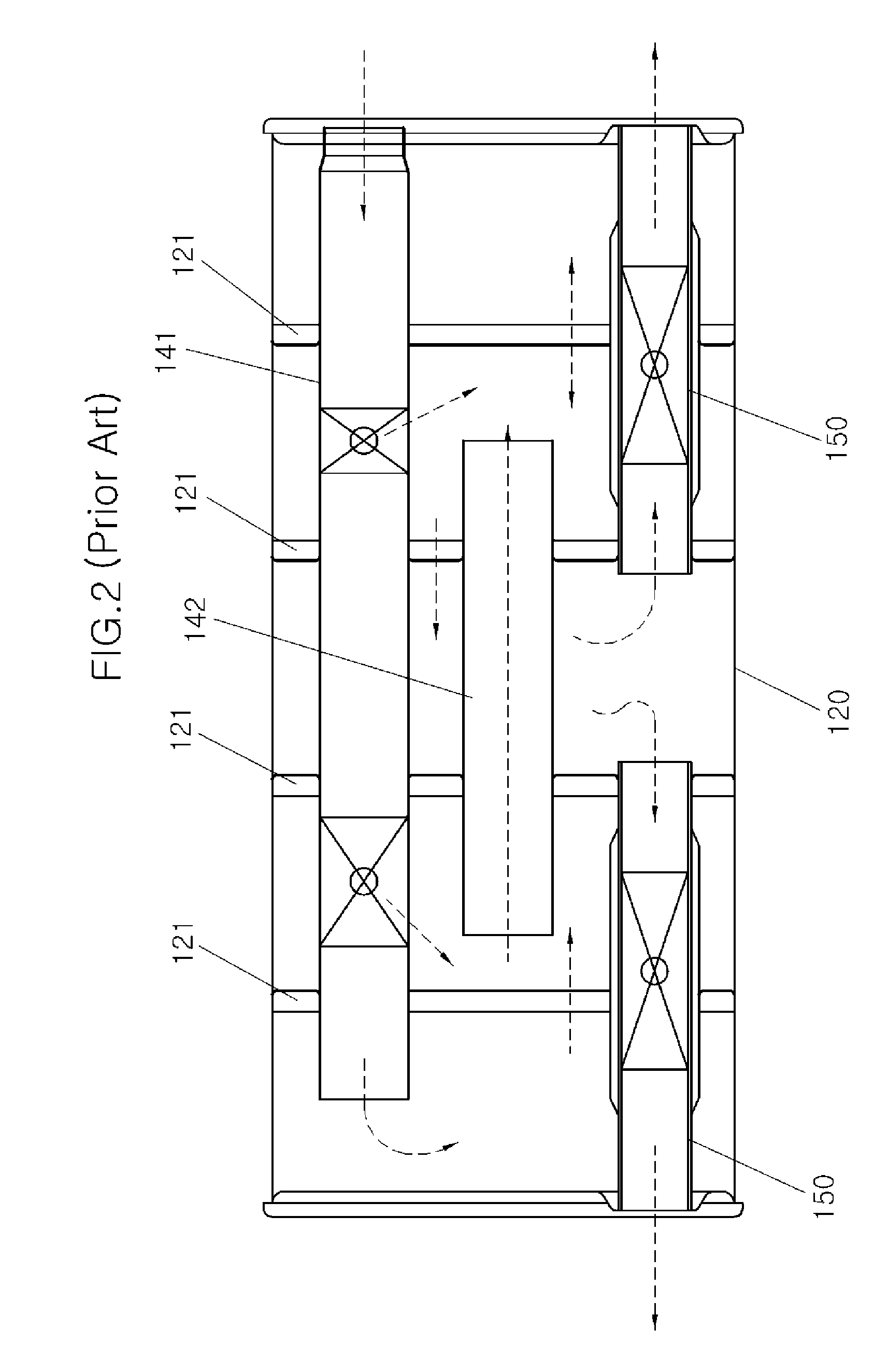

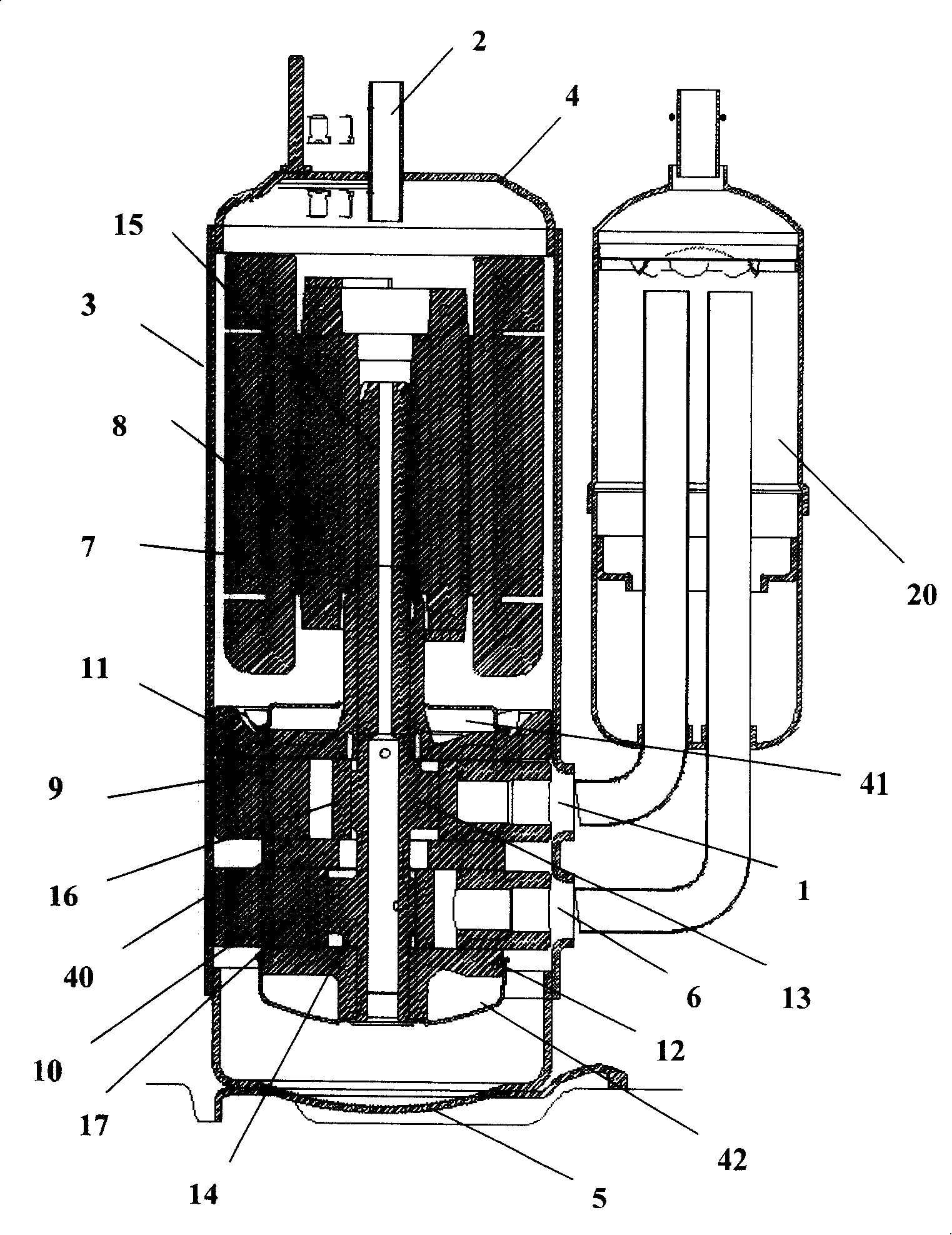

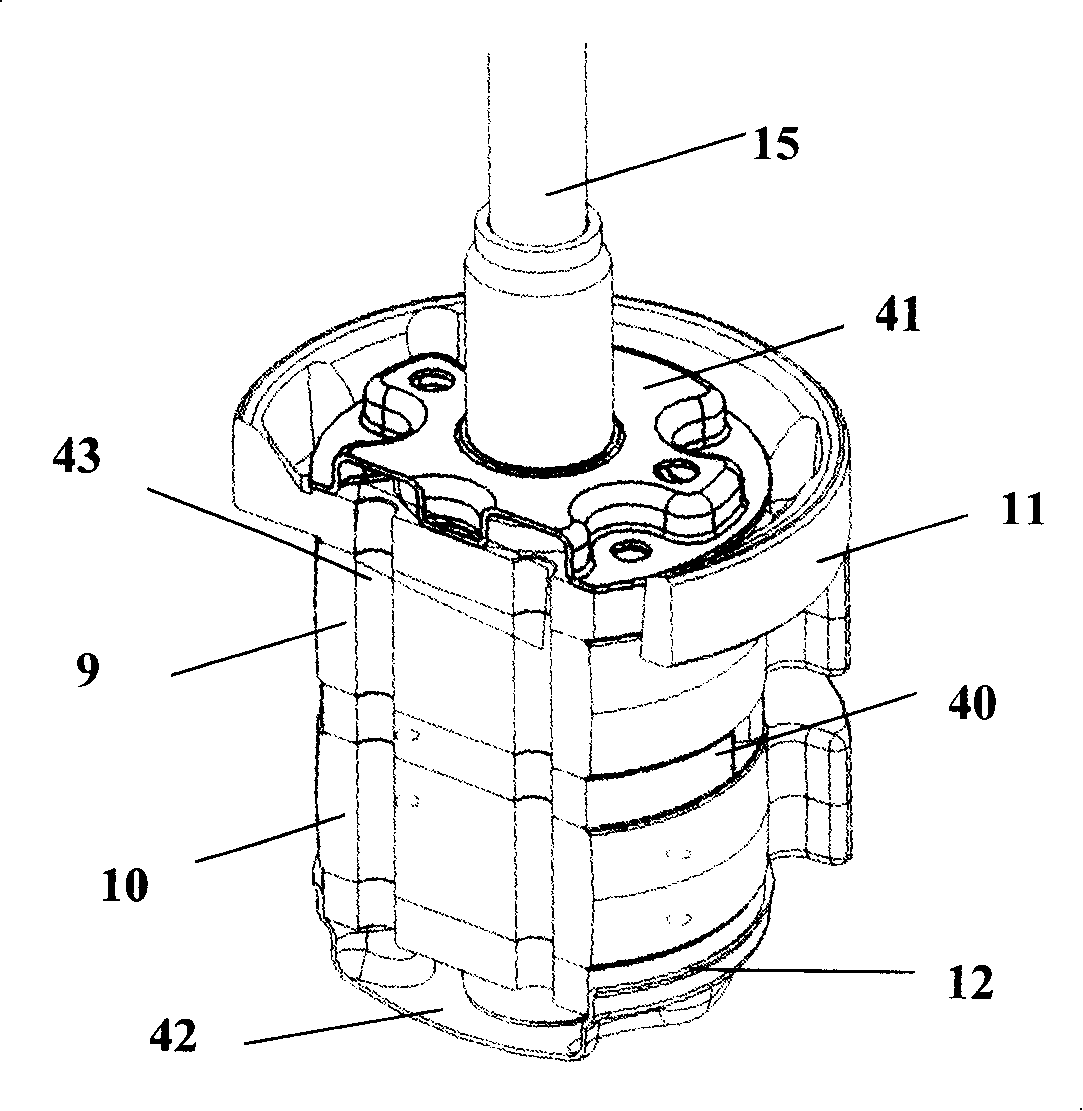

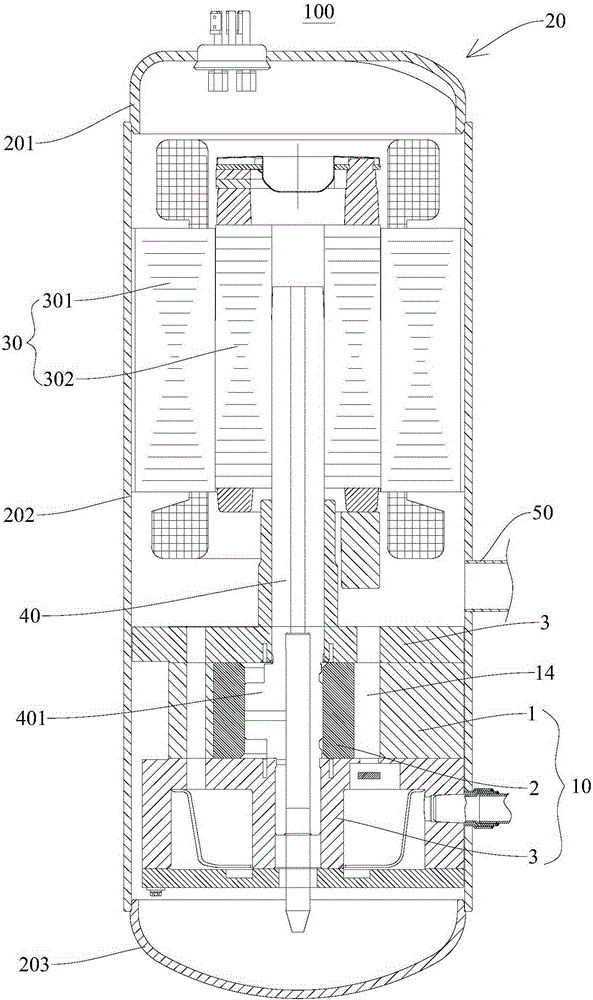

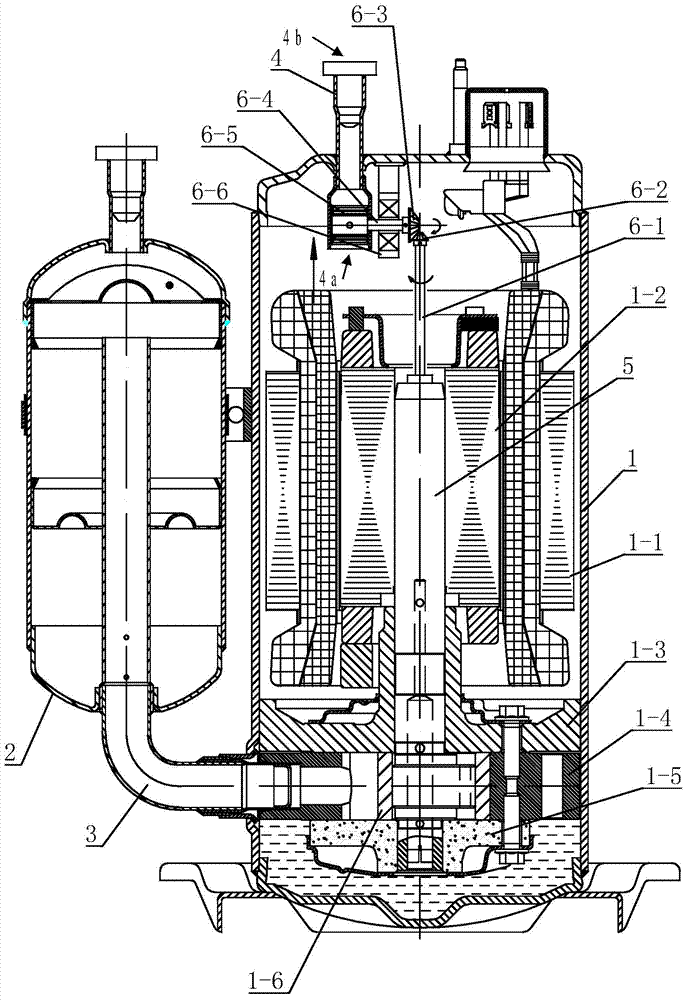

Dual-rotor rotary compressor

InactiveCN101210561AImprove performanceExtended service lifeRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsElectric machineryEngineering

Disclosed is a double-rotor rotary compressor which comprises a closed container, an electric machinery part and a compressing machinery part. A cooling medium outlet on a lower cylinder of the compressing machinery part is composed of a radial vent hole which extends outward along the radial direction from an upper end of an inner circumferential wall thereof, a vent groove which protrudes inward from an upper end of the lower cylinder and an axial vent hole which perforates downward from a rear end of the vent groove and whose bottom end is communicated with the rear end of the radial vent hole. The double-rotor rotary compressor changes the exhaust mode of the lower cylinder from downward exhaust mode to upward exhaust mode, thus a vent on a lower bearing is unnecessary to be processed, and a lower muffler can be removed, thereby the amount of parts, processing procedures, leakage of cooling medium and production cost can be reduced, and refrigeration performance of the cooling medium can be improved. In addition, since the cooling medium discharged from the lower cylinder can be directly discharged upward, exhaust resistance is weak, and stroke is comparatively shorter, thereby performance of the compressor can be improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

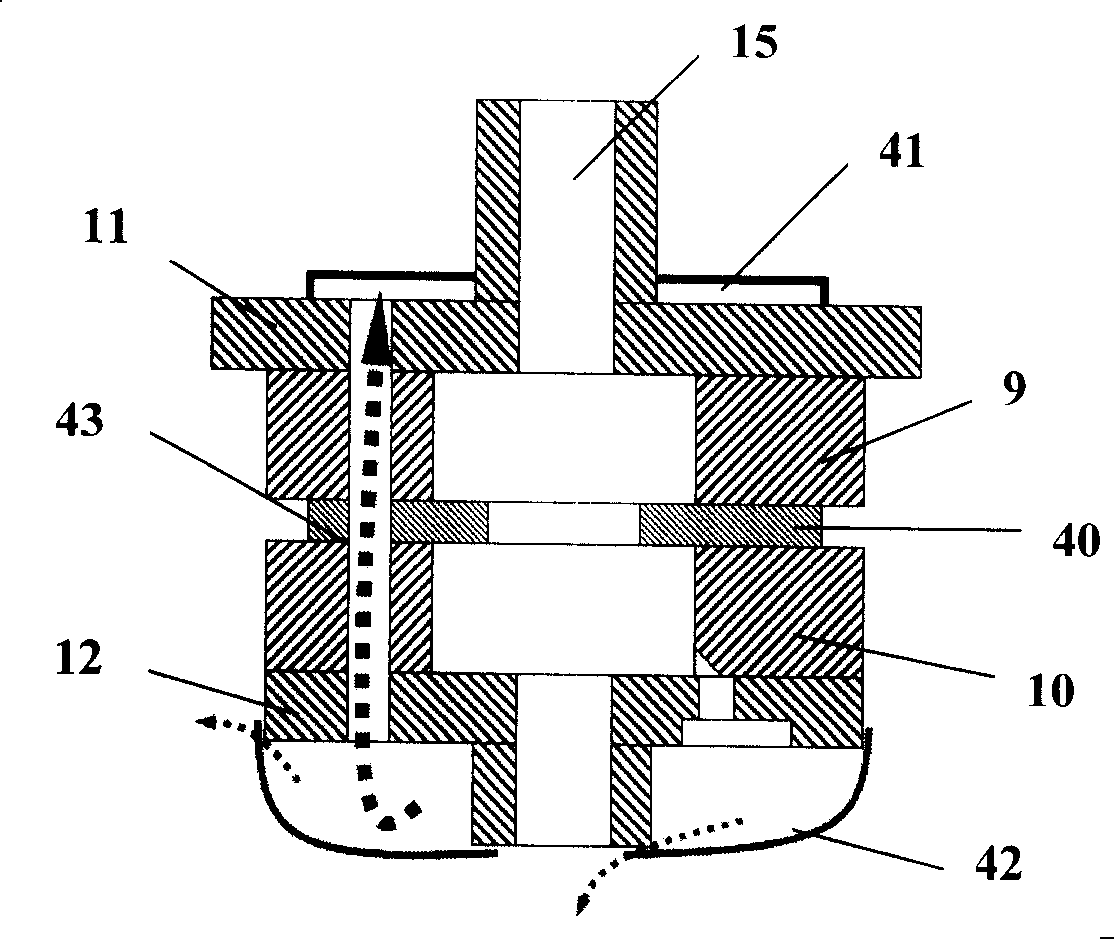

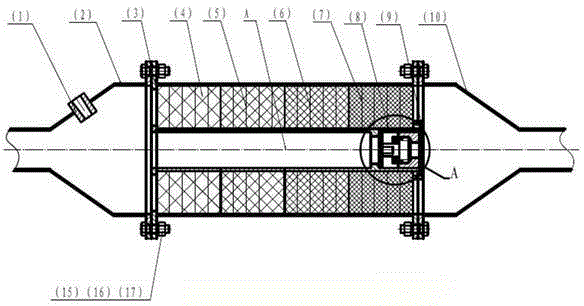

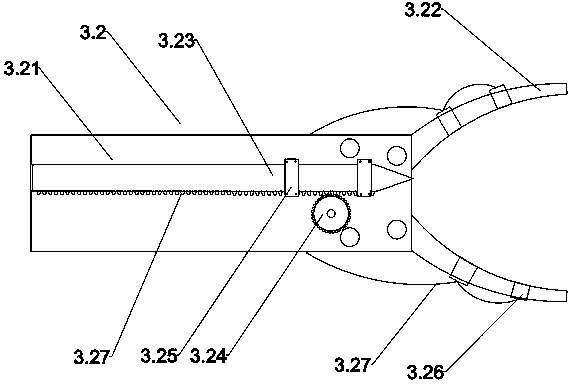

Efficient tail gas particle purification system of mining rubber-tyred vehicle

ActiveCN104594981ALow costImprove purification effectExhaust apparatusSilencing apparatusExhaust pipeMetal foam

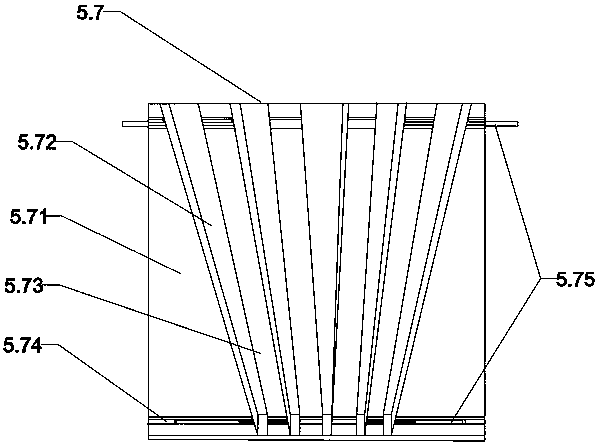

The invention belongs to the technical field of tail gas emission of transportation equipment of mining rubber-tyred vehicles for underground coal mines and particularly relates to an efficient tail gas particle purification system of a mining rubber-tyred vehicle. The efficient tail gas particle purification system solves the problem that in the running process of existing mining rubber-tyred vehicles for underground coal mines, tail gas particle emission performance exceeds standards seriously. The efficient tail gas particle purification system of the mining rubber-tyred vehicle comprises an exhaust pipe and an exhaust tail pipe and further comprises a tail gas particle purification device and a display and warning system, the tail gas particle purification device comprises an exhaust safety device and a tail gas particle catcher arranged between the exhaust pipe and the exhaust tail pipe, the tail gas particle catcher comprises multiple levels of catcher bodies arranged in a shell in sequence, the catcher body of each level is formed by stacking a plurality of metal foam sheets, the metal foam sheets are made of Fe-Cr-Al in a firing mode, have different hole diameters and have the thicknesses of 3 mm-5 mm, and the hole diameters of the metal foam sheets in the levels of catcher bodies gradually decrease.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

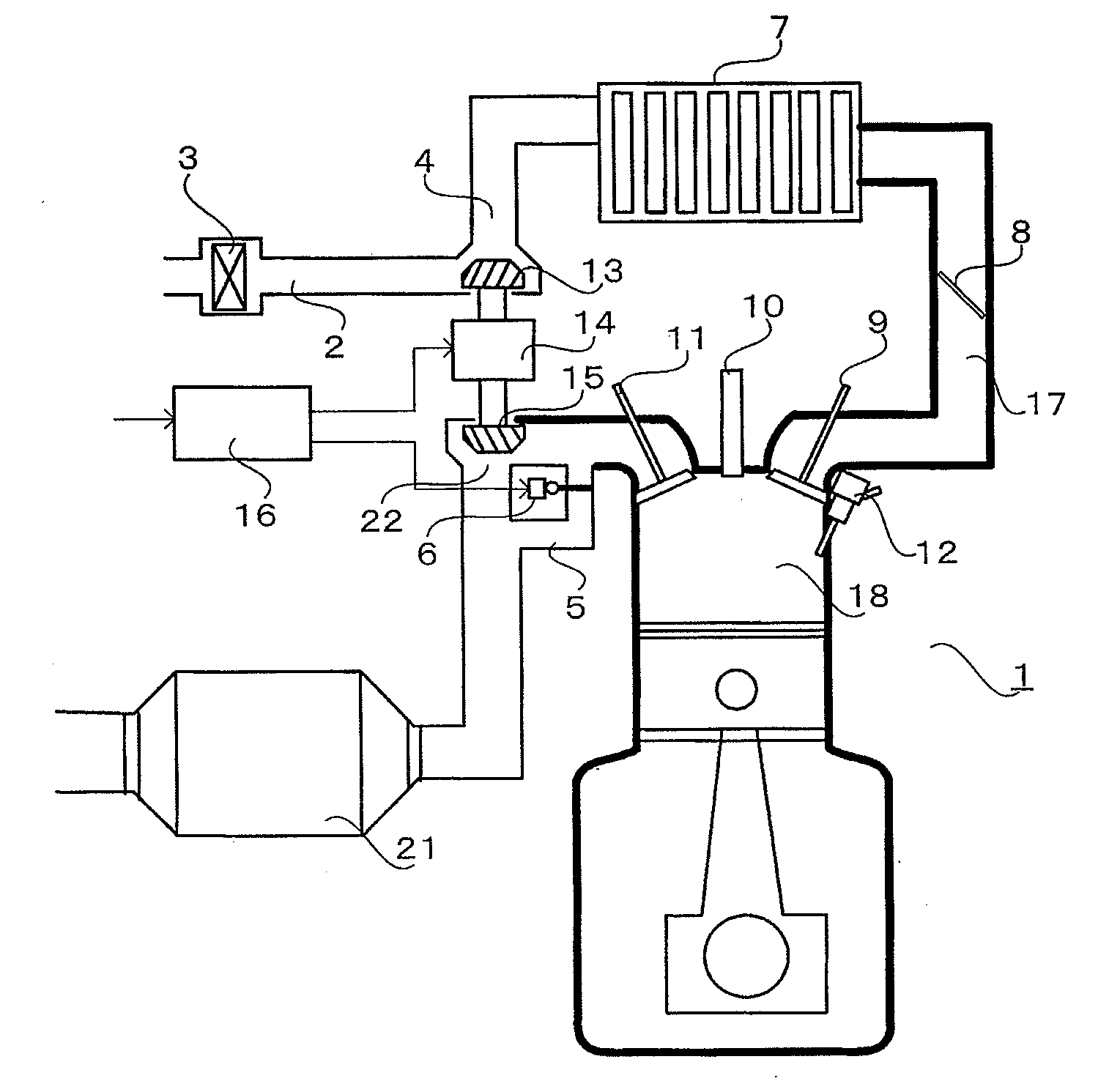

Exhaust emission control device

ActiveUS20110088376A1Good effectWell mixedInternal combustion piston enginesFlow mixersParticulatesExhaust fumes

An object of the invention is to provide an exhaust emission control device capable of favorably dispersing urea water for improved mixing with exhaust gas even if a flow rate of the exhaust gas is increased. An entry end of a mixing pipe is formed with a first opening at a position near an exit side of a particulate filter and is formed with a second opening at a position away from the exit side of the particulate filter and diametrically opposite to the first opening. Arranged in a downstream end of a gas gathering chamber are a first partition which guides all of the flow of exhaust gas from the particulate filter into a one-way swirling flow around the entry end of the mixing pipe, a second partition which divides the flow of the exhaust gas guided by the first partition into two to cause an inner one of the divided swirling flows to tangentially enter into the first opening and a third partition which causes the remaining outer swirling flow to tangentially enter into the second opening.

Owner:HINO MOTORS LTD

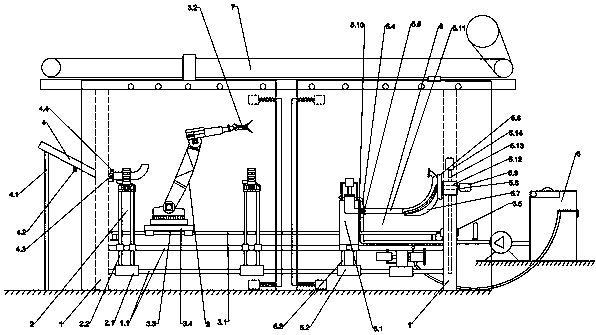

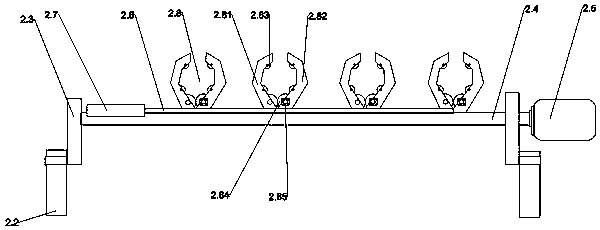

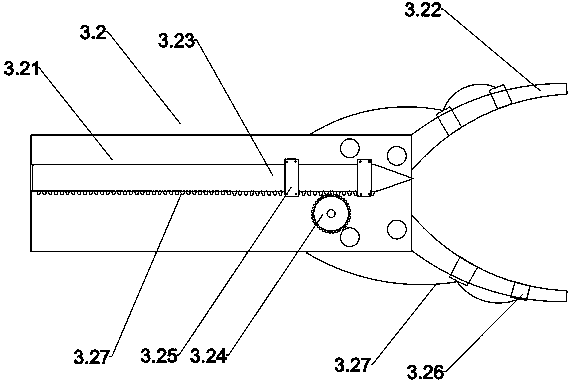

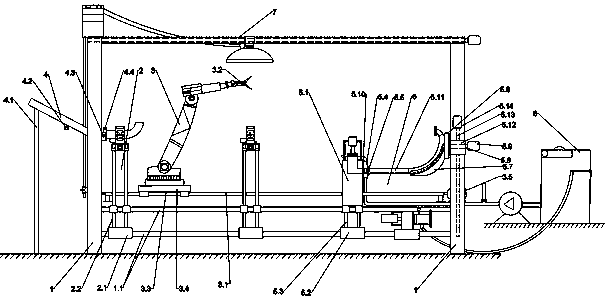

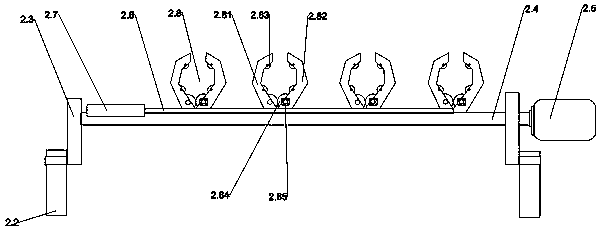

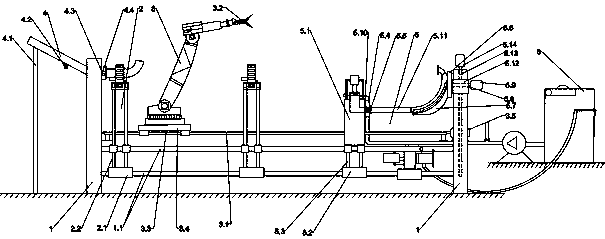

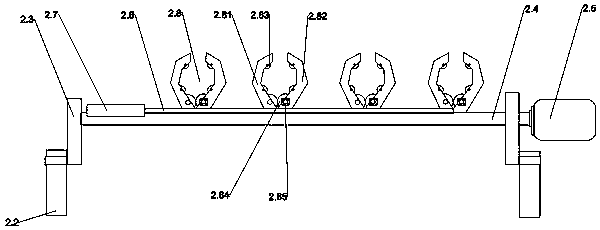

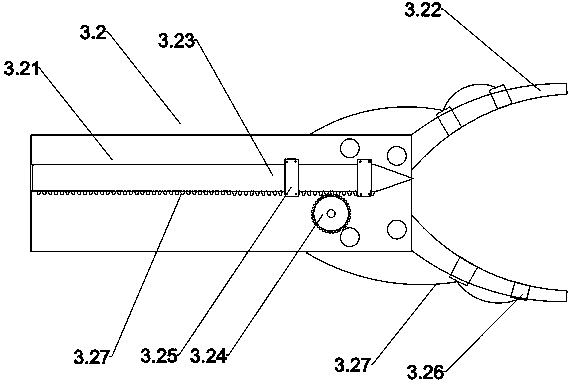

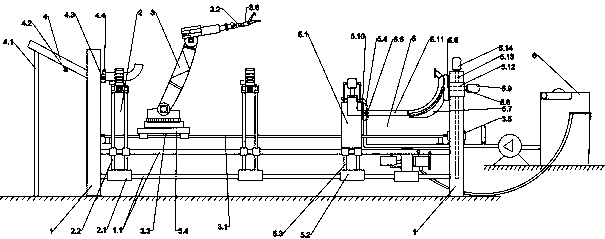

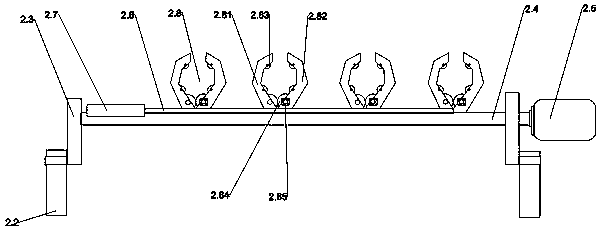

Safe automatic exhaust manifold welding device and working method thereof

InactiveCN109332935AAutomatically change working statusHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesManipulatorSingle section

The invention provides a safe automatic exhaust manifold welding device and a working method thereof. The safe automatic exhaust manifold welding device comprises a device rack, a single-section welding working table, a welding, carrying and detecting manipulator, a flange slideway, a combined welding working table, a polishing device and a safe protection device, wherein the single-section welding working table can move left and right and turn over for butt weld; an arranged clamping jaw can rotate a weld piece during welding; a clamping and welding device of the welding, carrying and detecting manipulator has welding, carrying and detecting functions; the combined welding working table can be used for combining and butt-jointing various sections of manifolds, and a polishing program canbe automatically started after an exhaust manifold is welded; and the safe protection device comprises a safe protection door and a filter coating. According to the safe automatic exhaust manifold welding device and the working method thereof provided by the invention, through arranging the safe protection device, the occurrence of the phenomenon that personnel enters the working area when the device works so as to cause mechanical injury is effectively prevented, and welding spatter is isolated; and the filter coating is arranged at the same time, so that harmful light rays produced during welding can be filtered, and the personnel can conveniently observe and spot-inspect the device.

Owner:李春洪

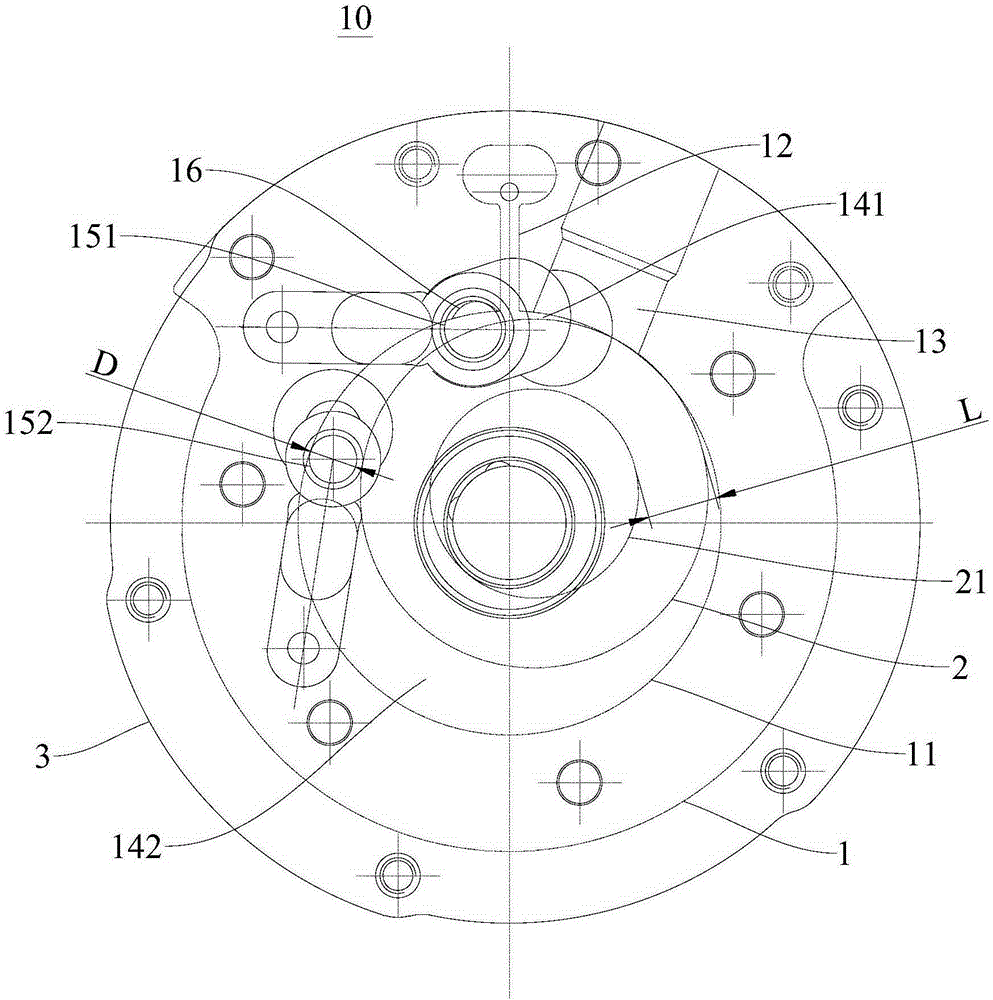

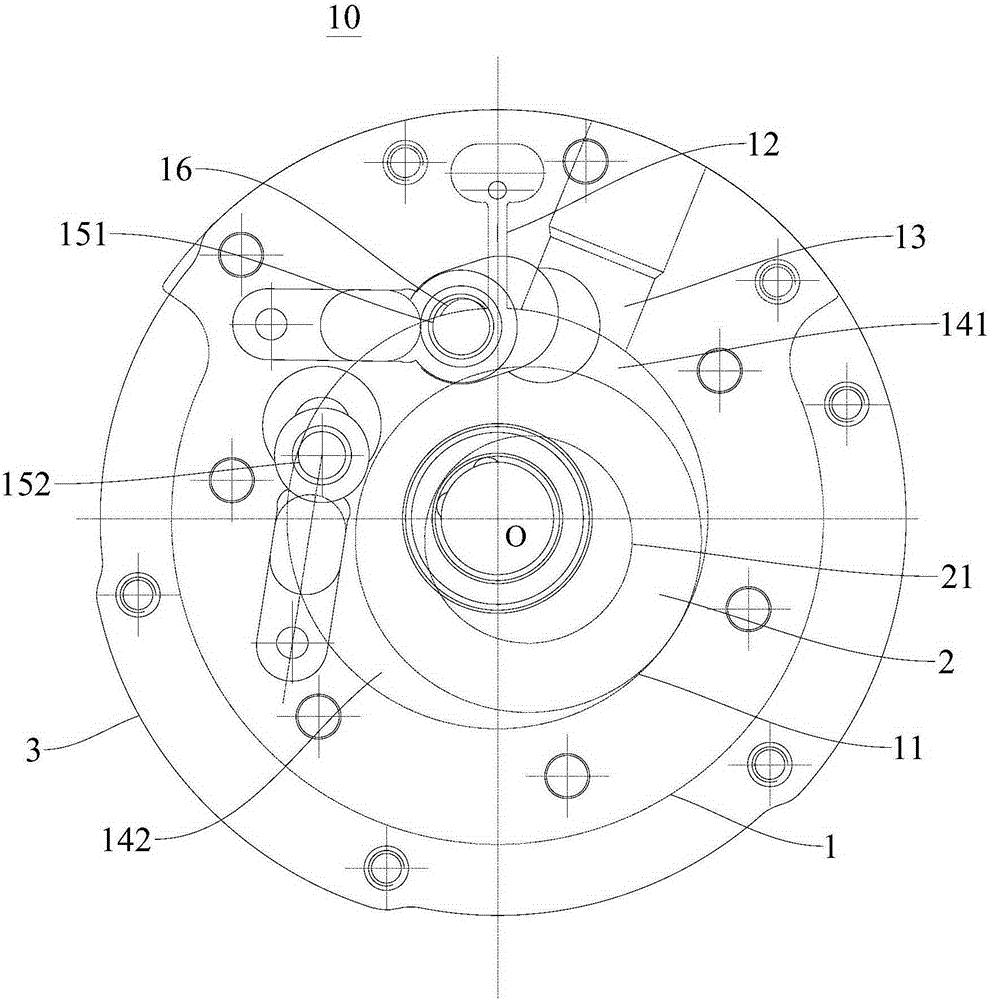

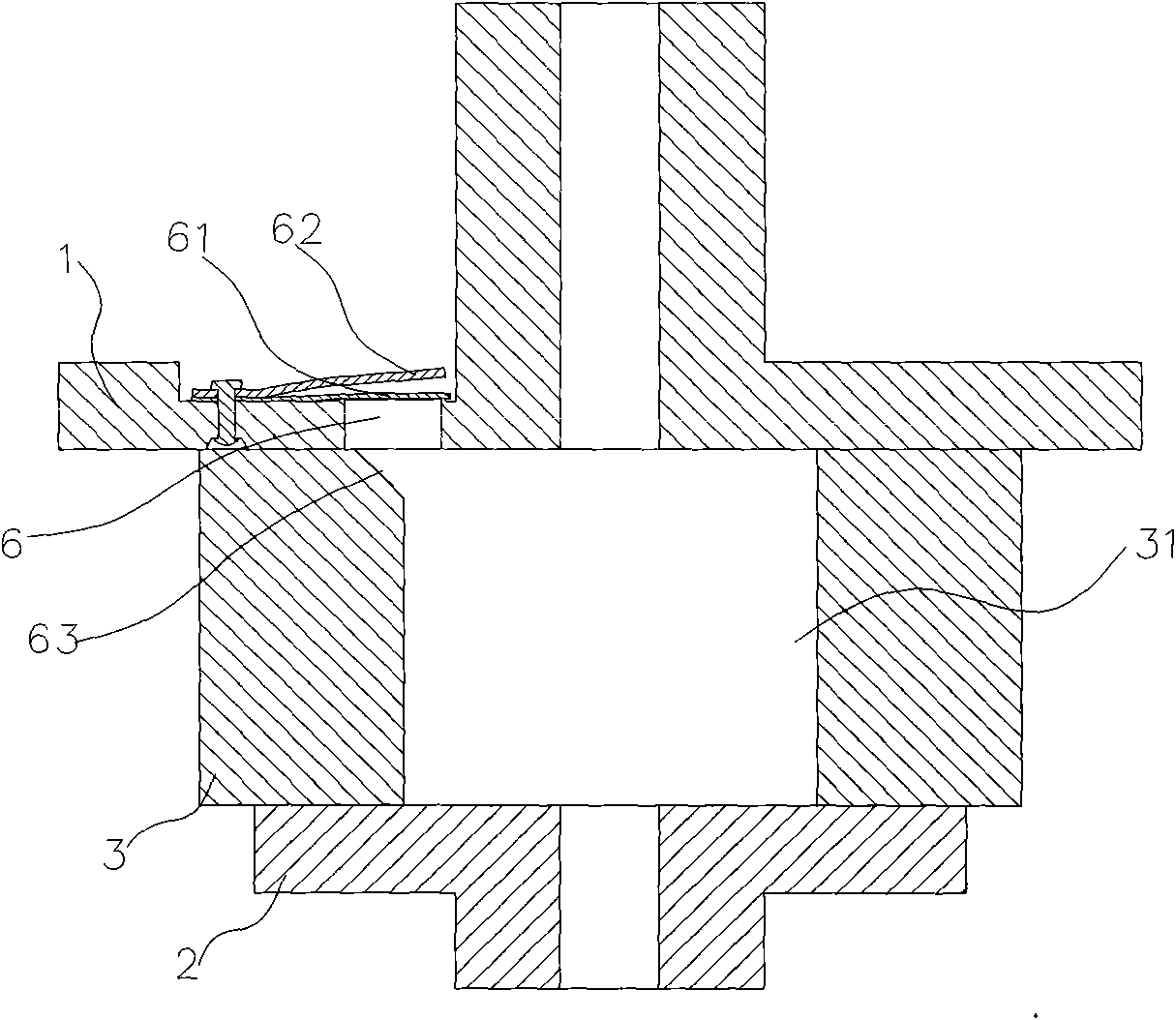

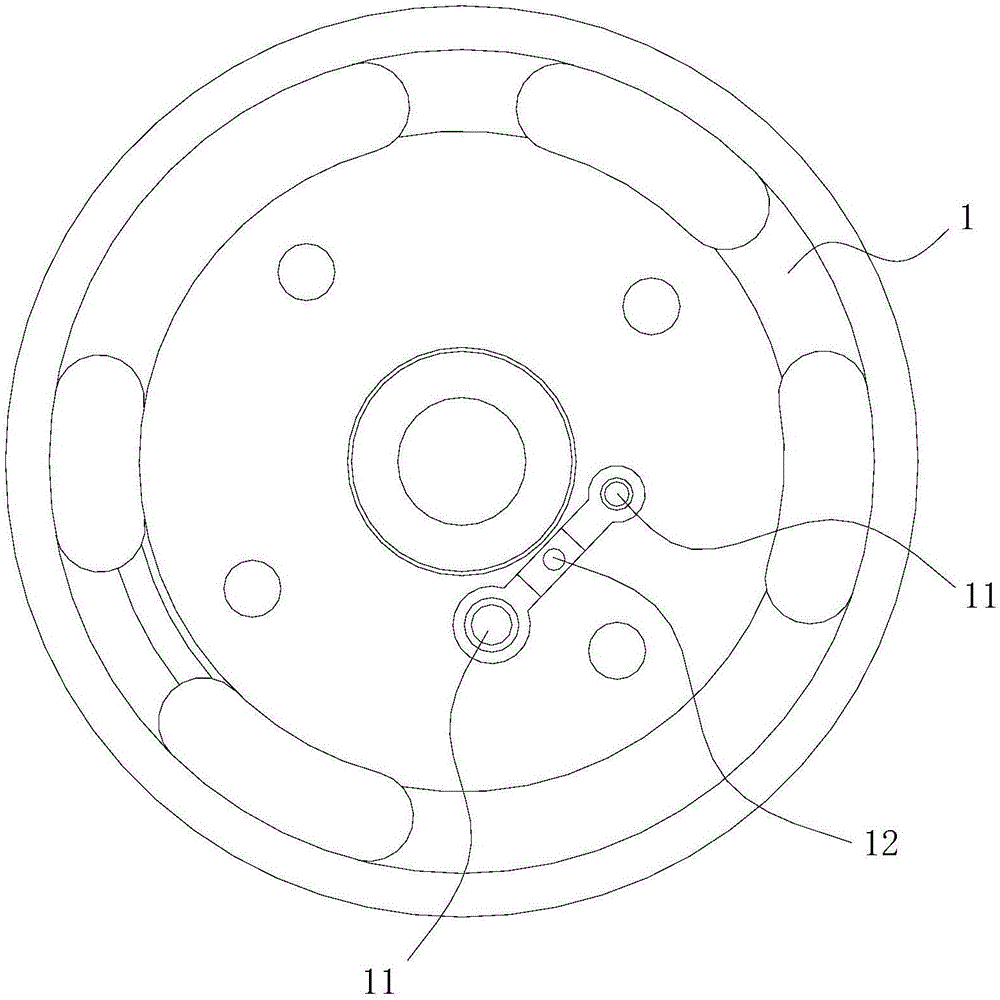

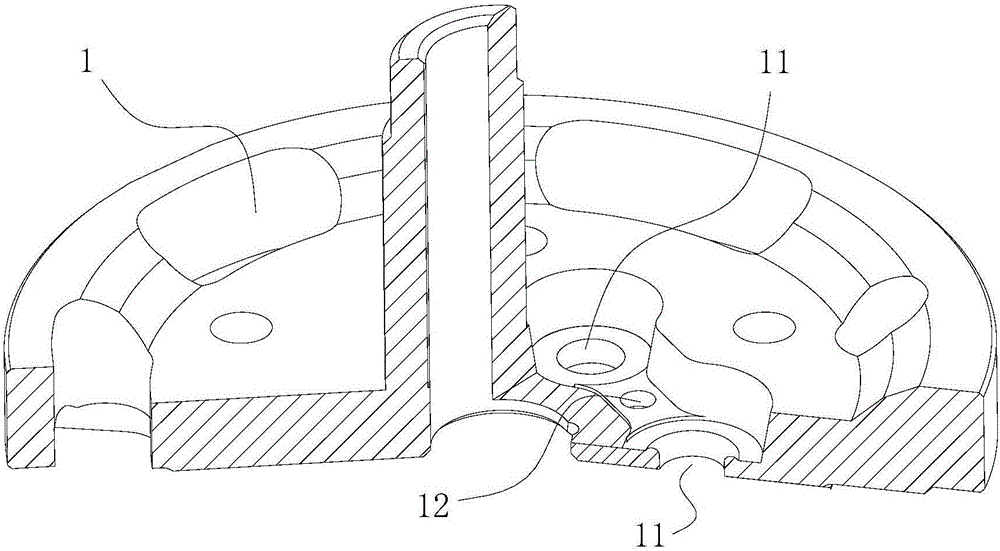

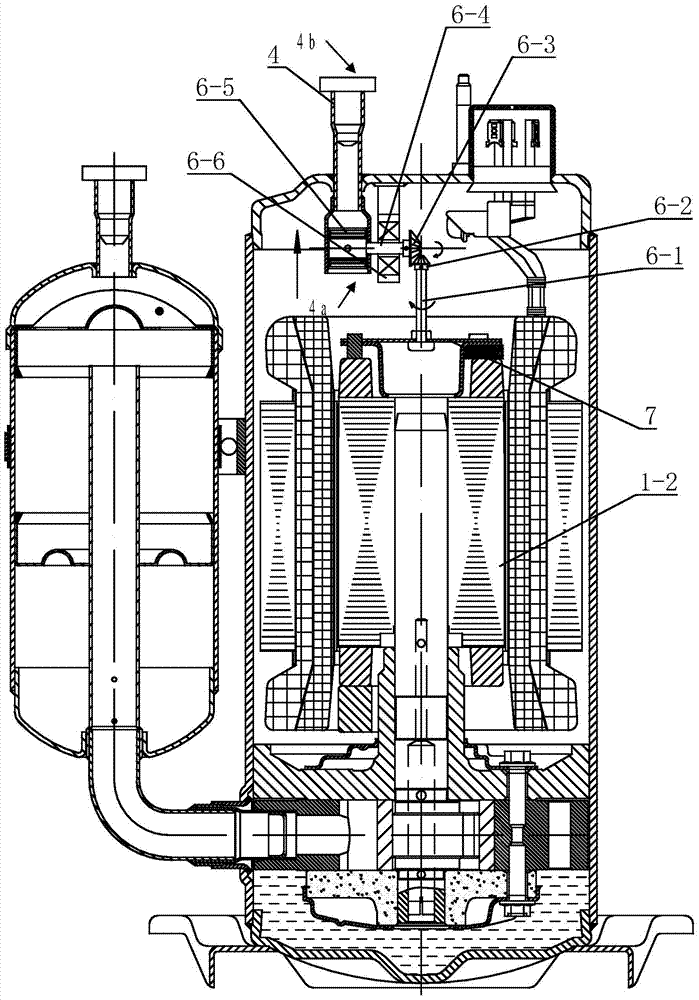

Rotary compressor and compression mechanism thereof

InactiveCN105201830AReduce exhaust resistanceReduce noiseRotary piston pumpsRotary piston liquid enginesSlide plateCrankshaft

The invention discloses a rotary compressor and a compression mechanism thereof. The compression mechanism comprises an air cylinder, a piston and a bearing, wherein an air cylinder hole and a slide plate groove are formed in the air cylinder; the piston is arranged on an eccentric part of a crankshaft in a sleeving manner and is stored in the air cylinder hole in a way of eccentrically rotating surrounding the center of the air cylinder hole; the bearing is arranged on the upper end or the lower end of the air cylinder, an air cylinder cavity is collectively formed between the end surface of the bearing and the air cylinder hole, a plurality of exhaustion holes which are communicated with the air cylinder cavity are formed in the bearing, and the plurality of exhaustion holes are arranged at intervals along a rotating path of the piston. The compression mechanism is small in ventilation resistance, low in noise, small in exhaustion clearance volume, simple in structure and low in cost.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

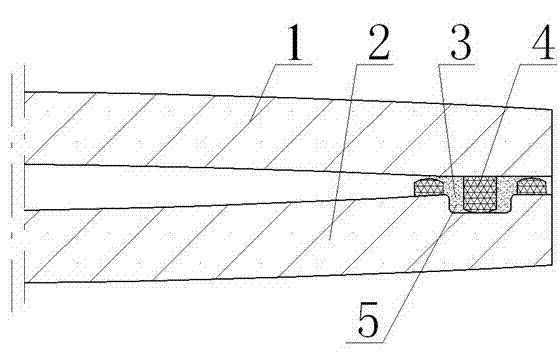

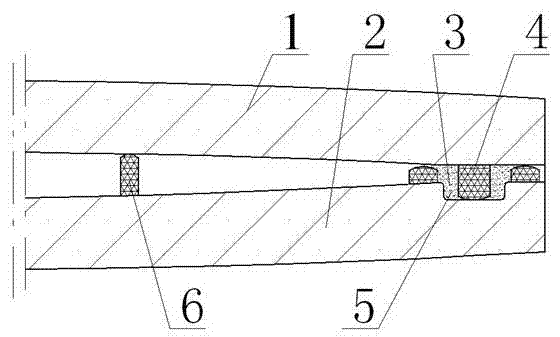

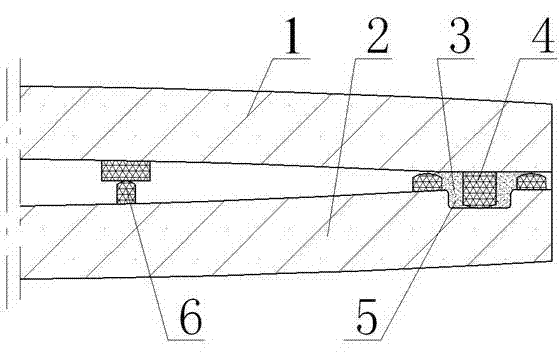

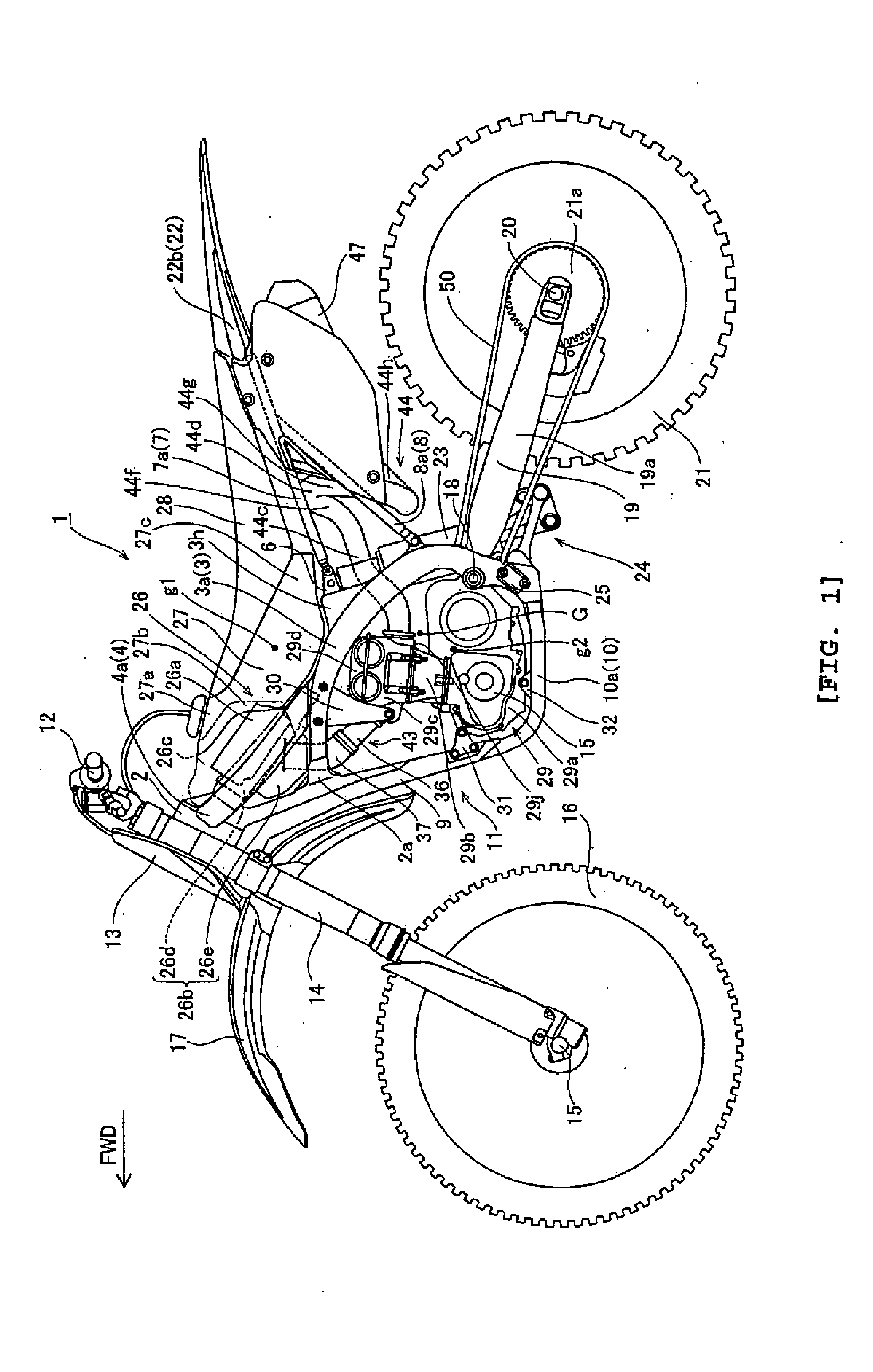

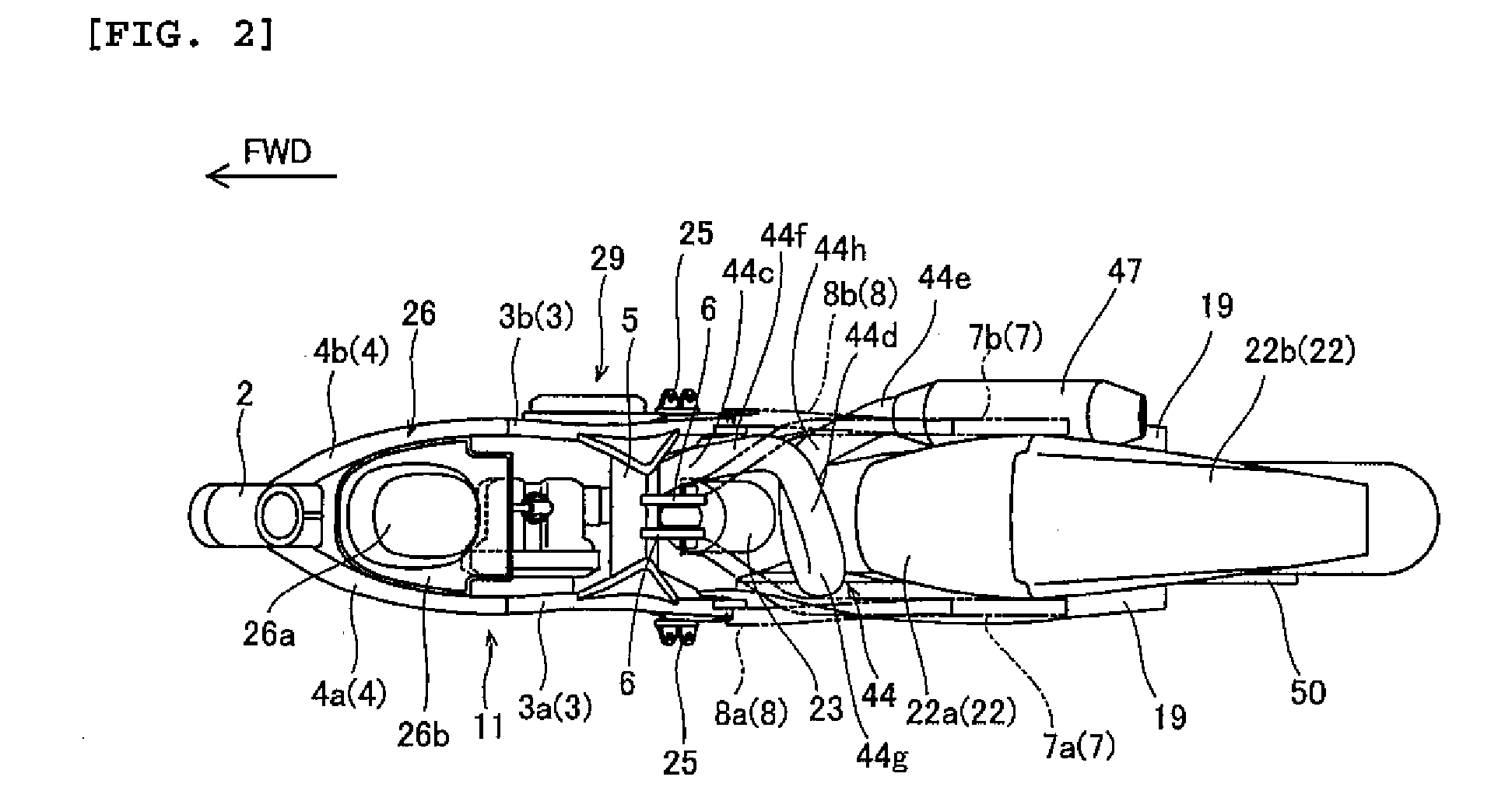

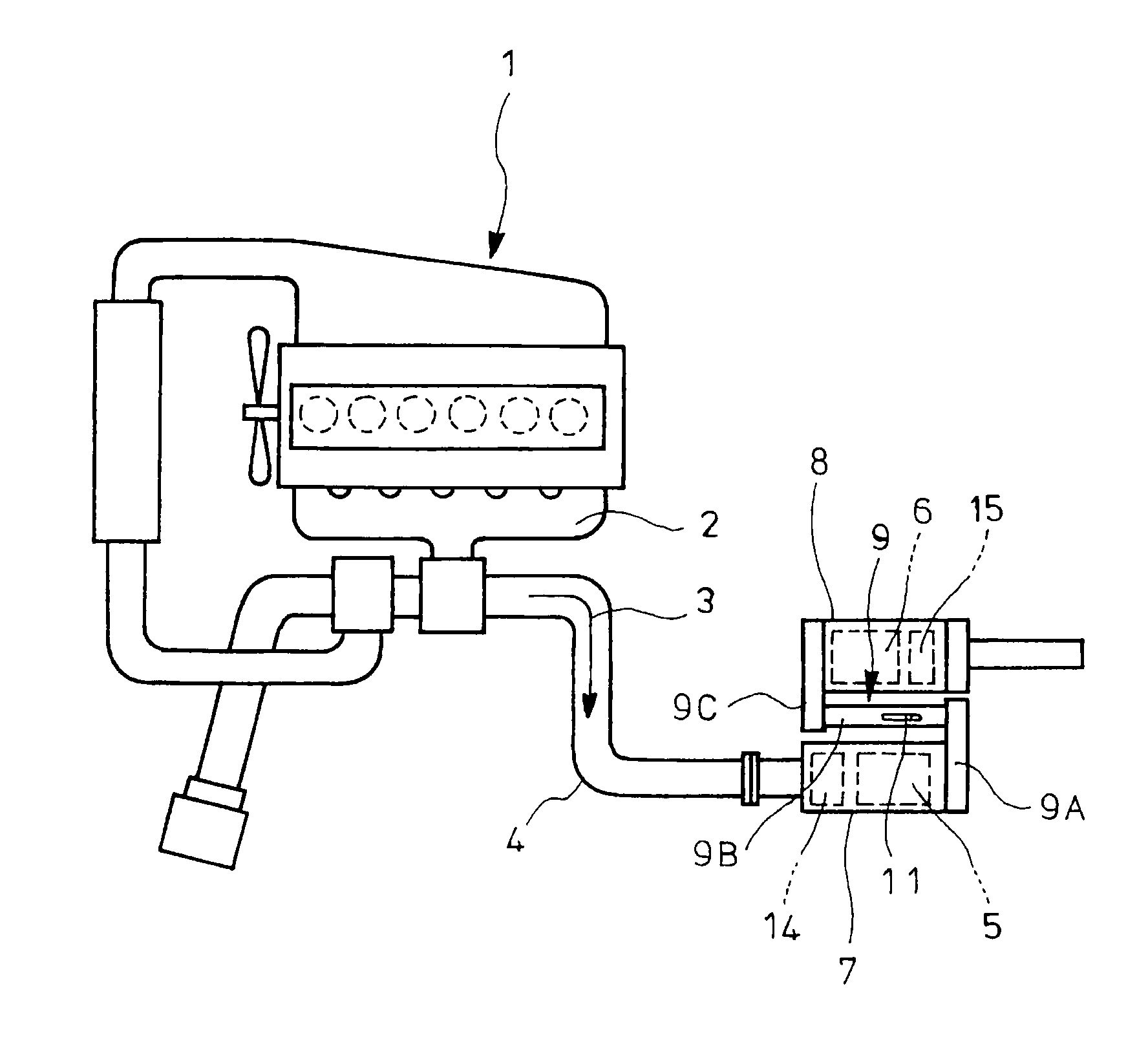

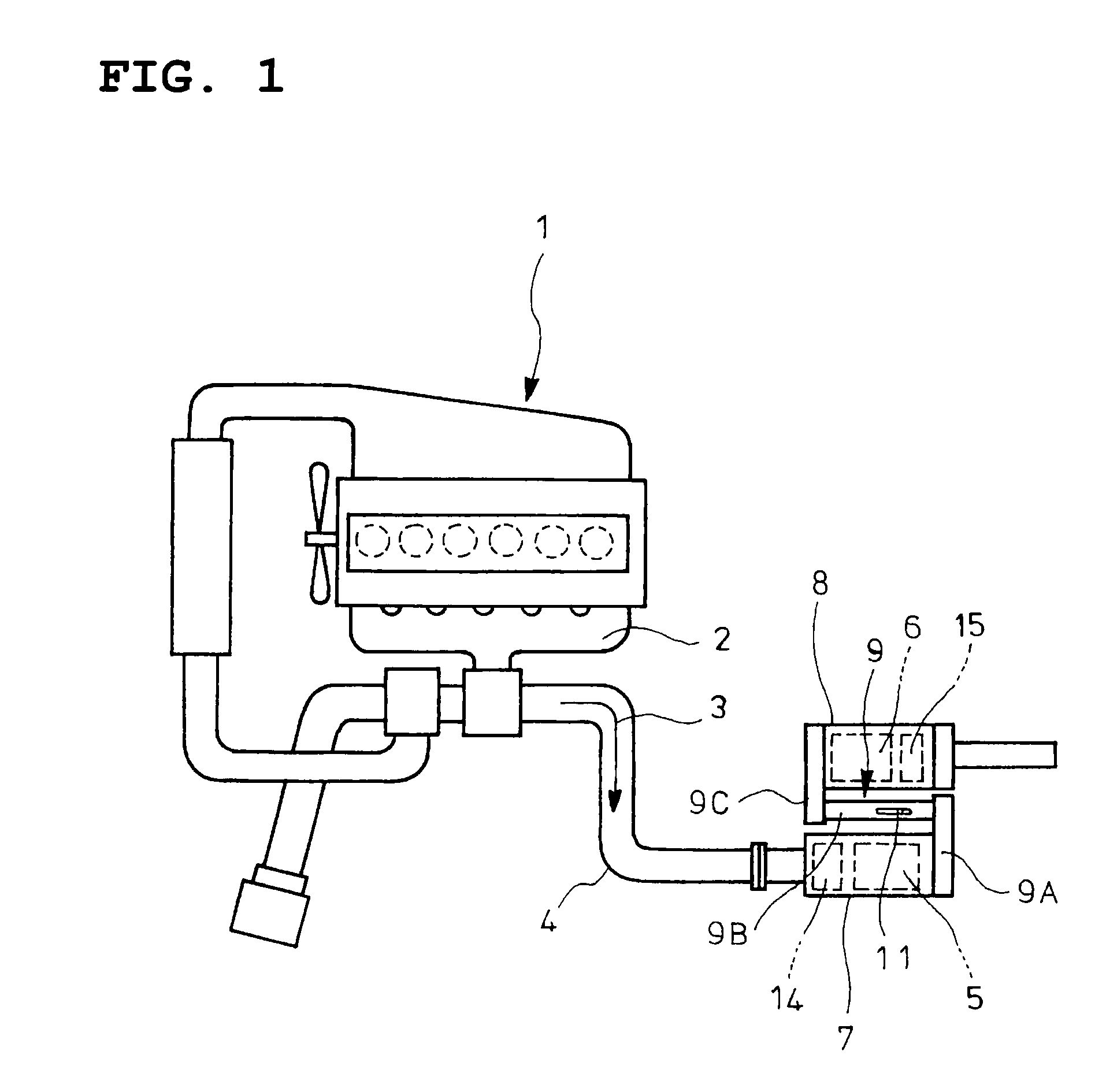

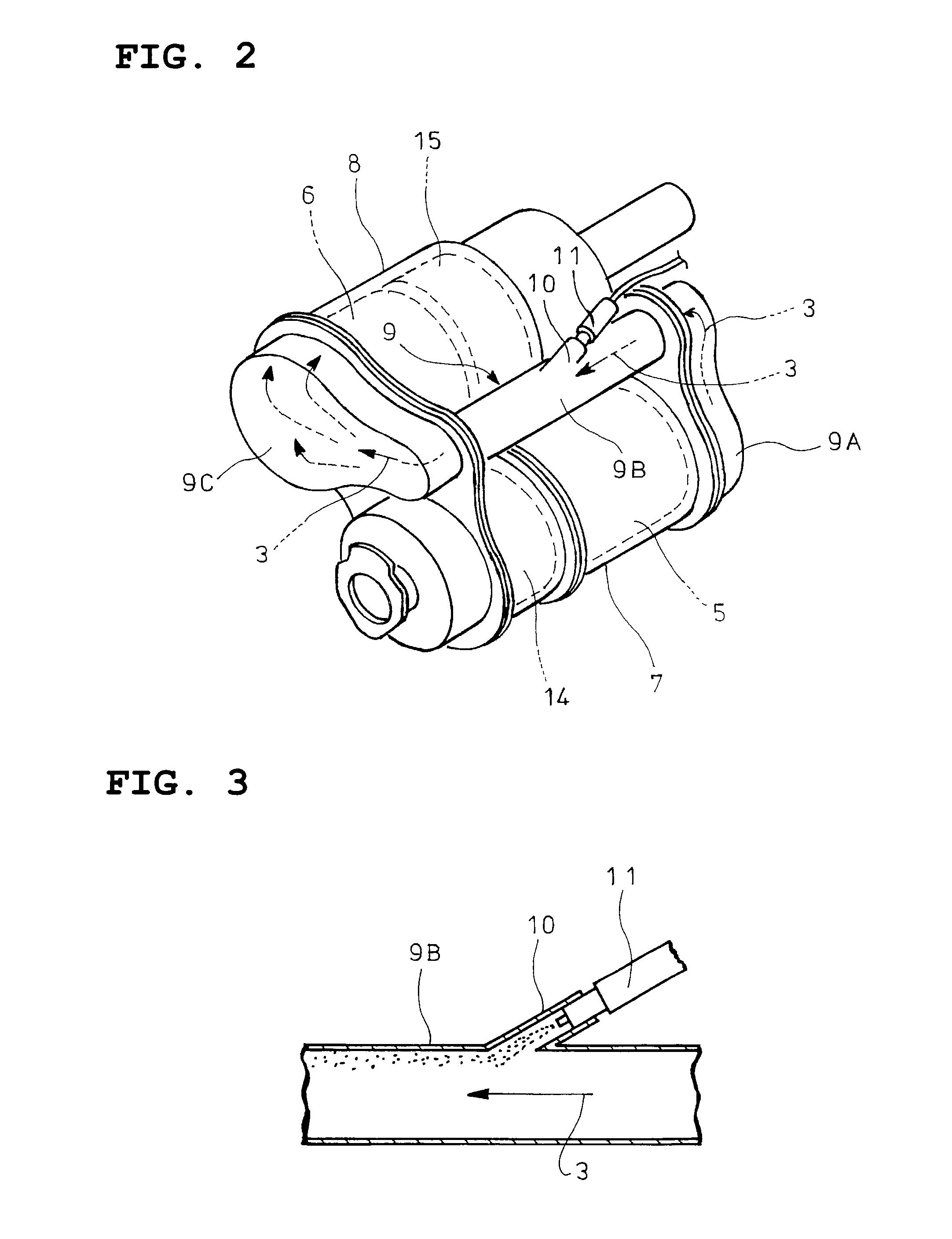

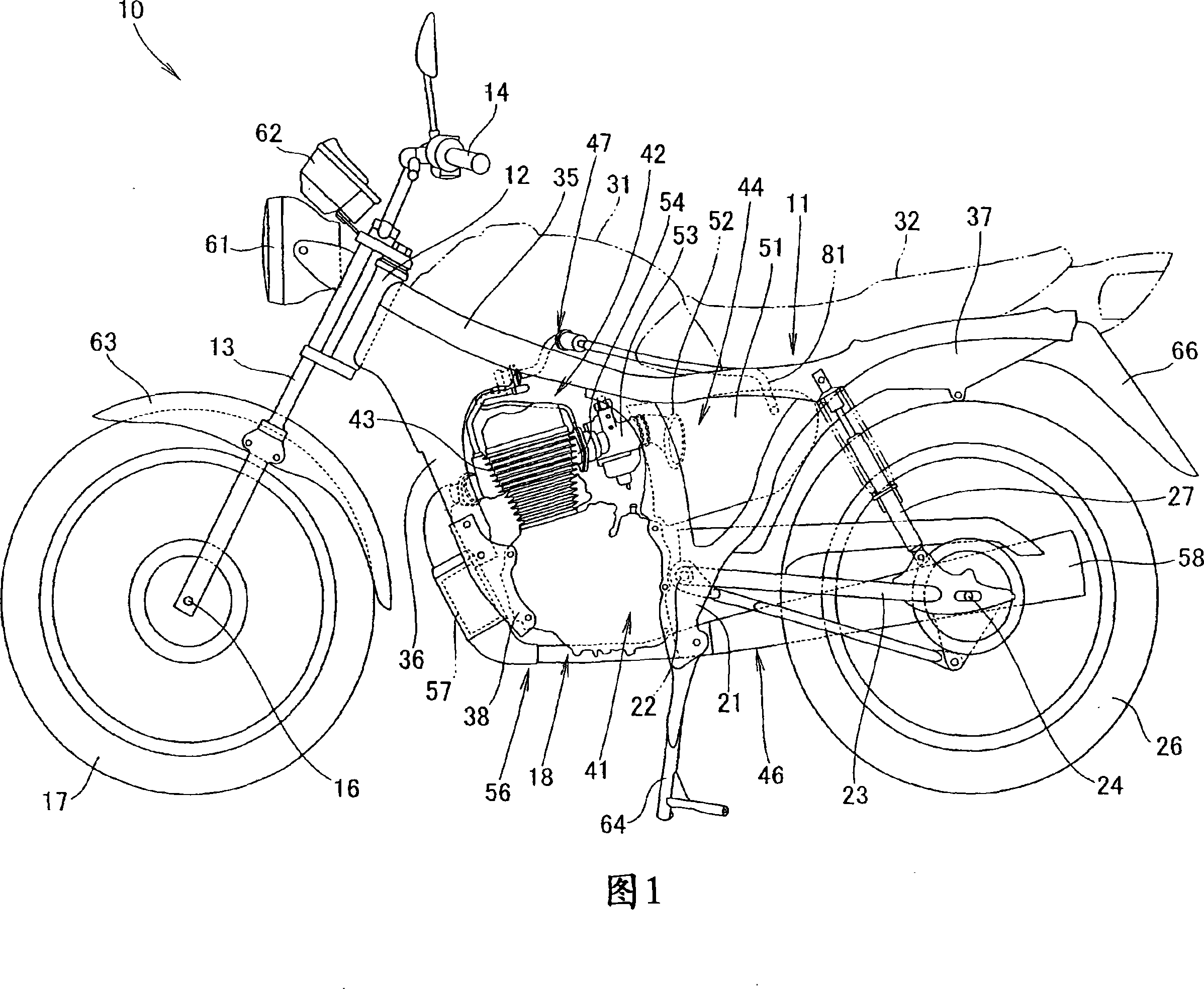

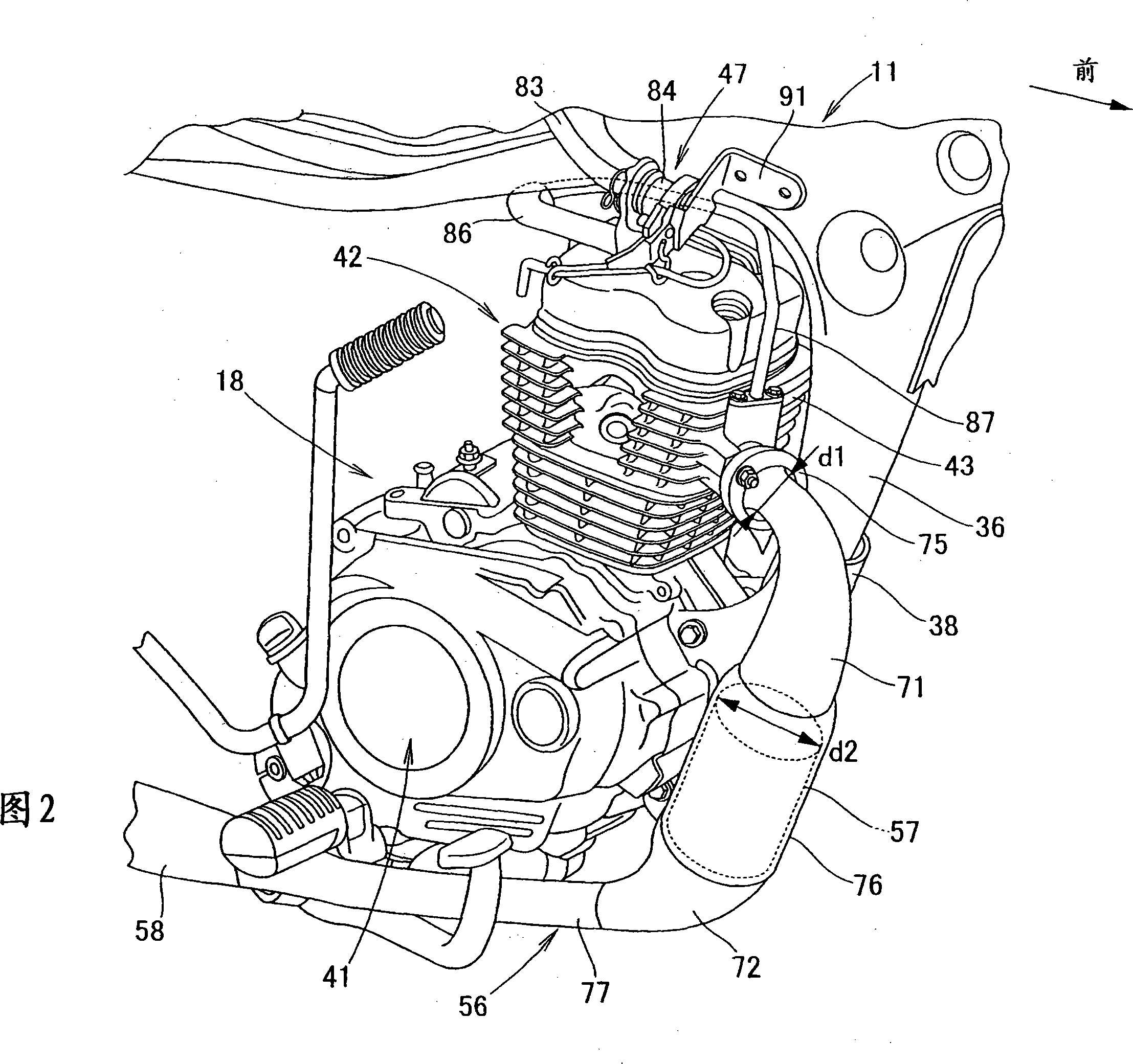

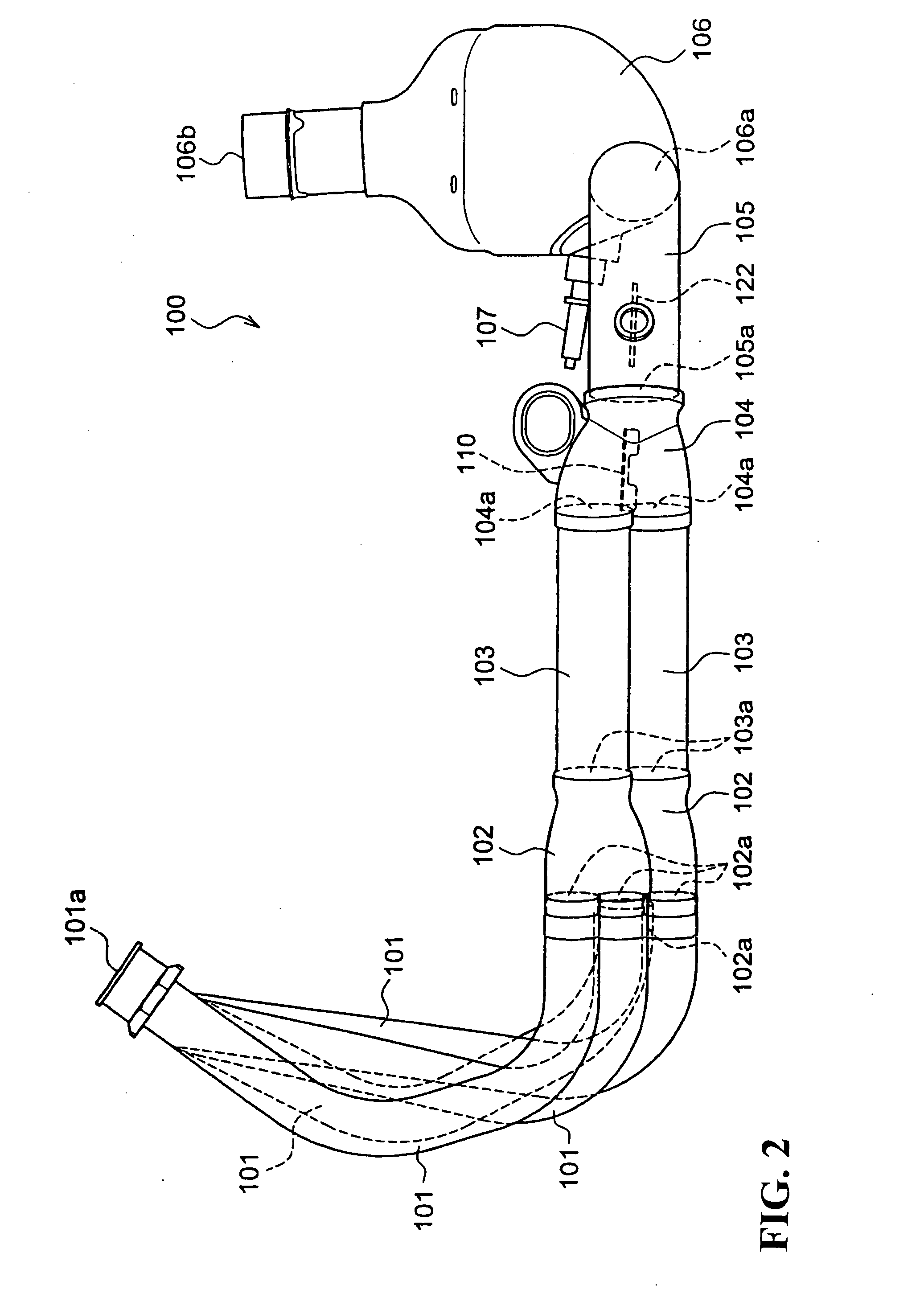

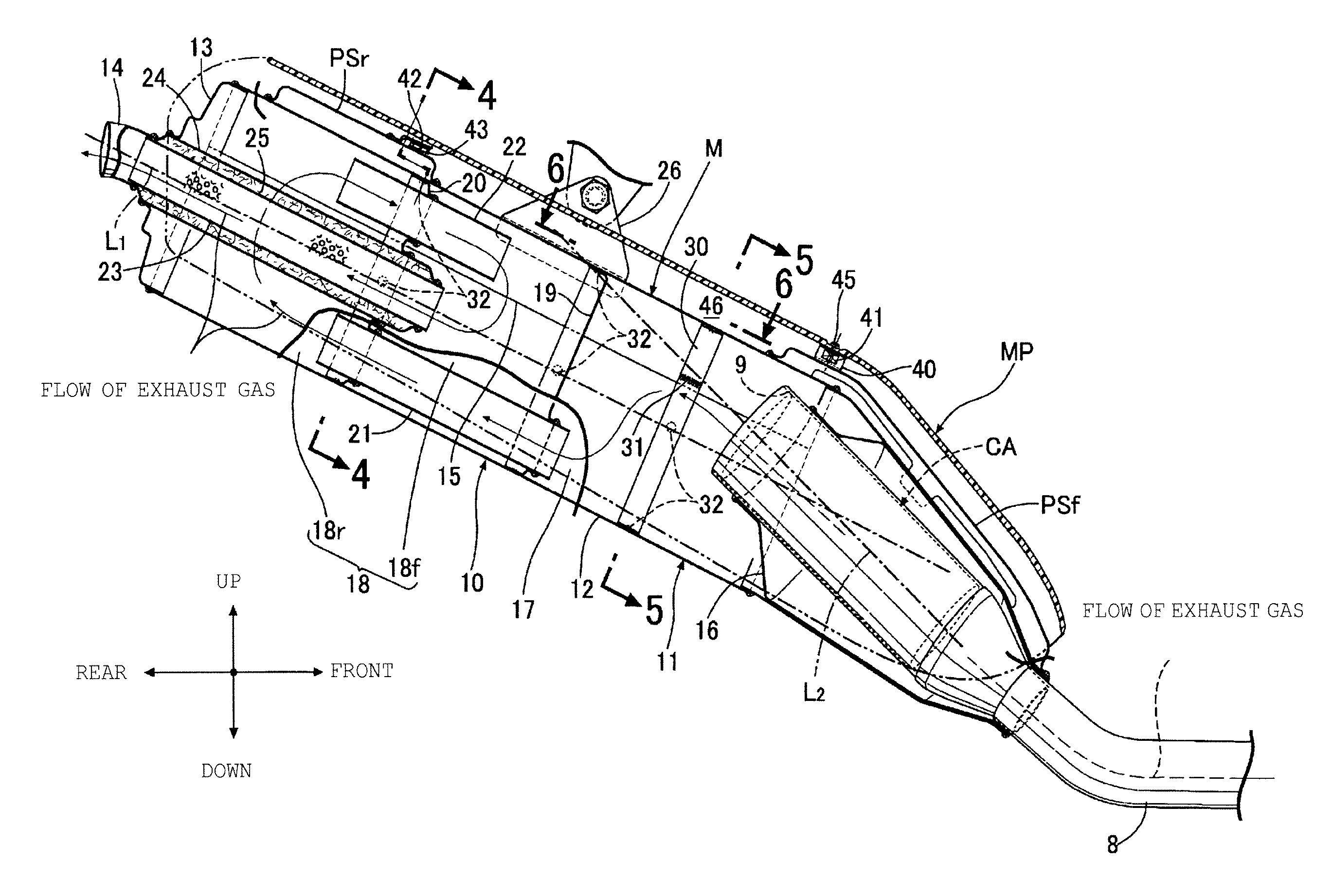

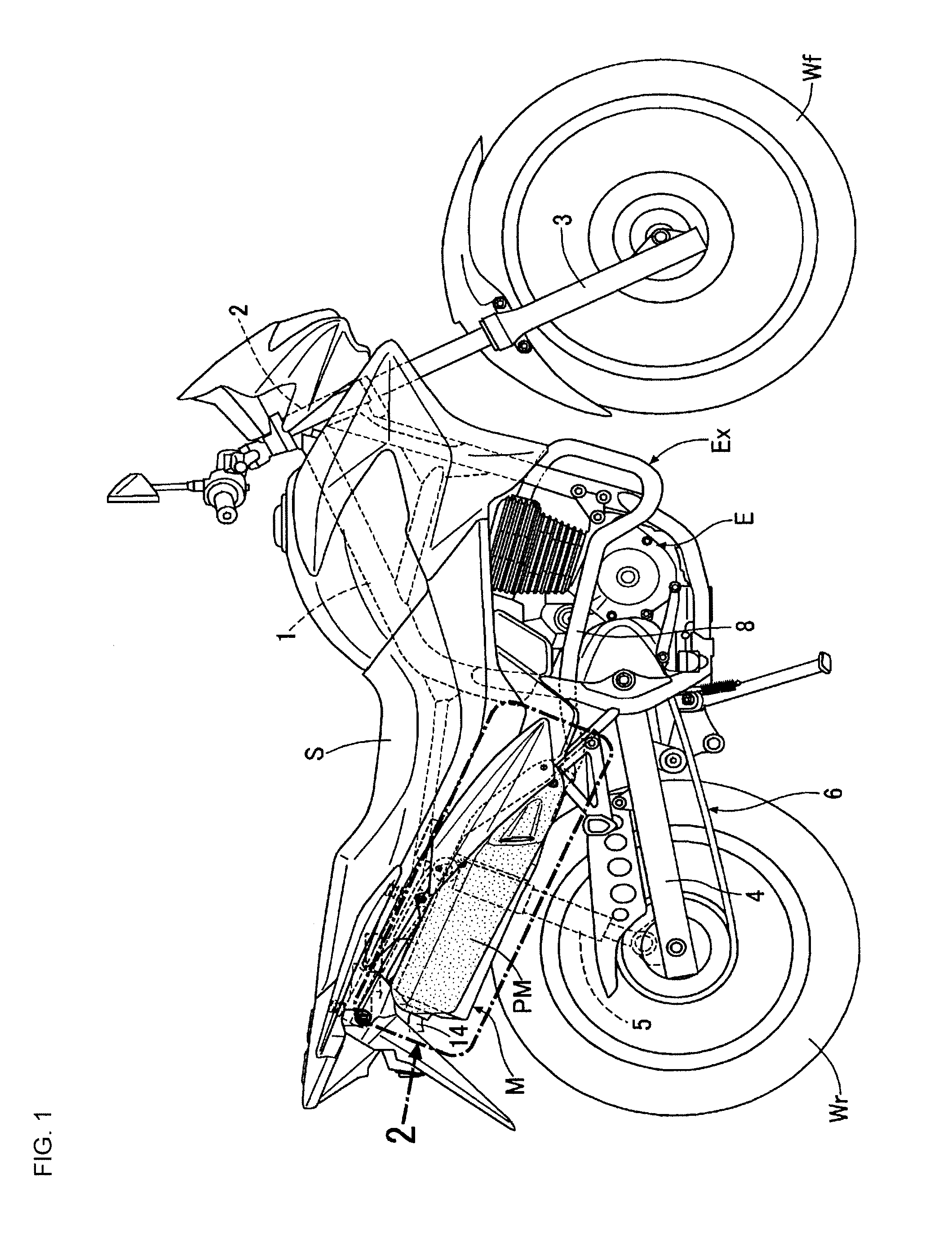

Catalyst arrangement construction of two-wheel motor vehicle

InactiveCN101240730AReduce exhaust resistanceMaintain active temperatureExhaust apparatusSilencing apparatusVehicle frameHoneycomb

The catalyst of the maneuvering two-wheeled vehicle of the invention is arranged and structured on a main frame extended from head towards rear of the vehicle frame and a lower extending frame extended from head tube towards to rear and lower inclination of the vehicle frame, the rear of the lower extending frame is arranged with an engine, the exhaust pipe extended from the engine firstly towards lower, then towards rear is arranged with a metal honeycomb type catalyst; wherein, the front and the back of the metal honeycomb type catalyst of the exhaust pipe forms a first conic section and a second conic section which are gradually expands towards the metal honeycomb type catalyst, the metal honeycomb type catalyst is arranged along the lower extending frame. Thus, while improving the purification efficiency of the metal honeycomb type catalyst, the engine output is improved at the same time, and the cost is reduced.

Owner:HONDA MOTOR CO LTD

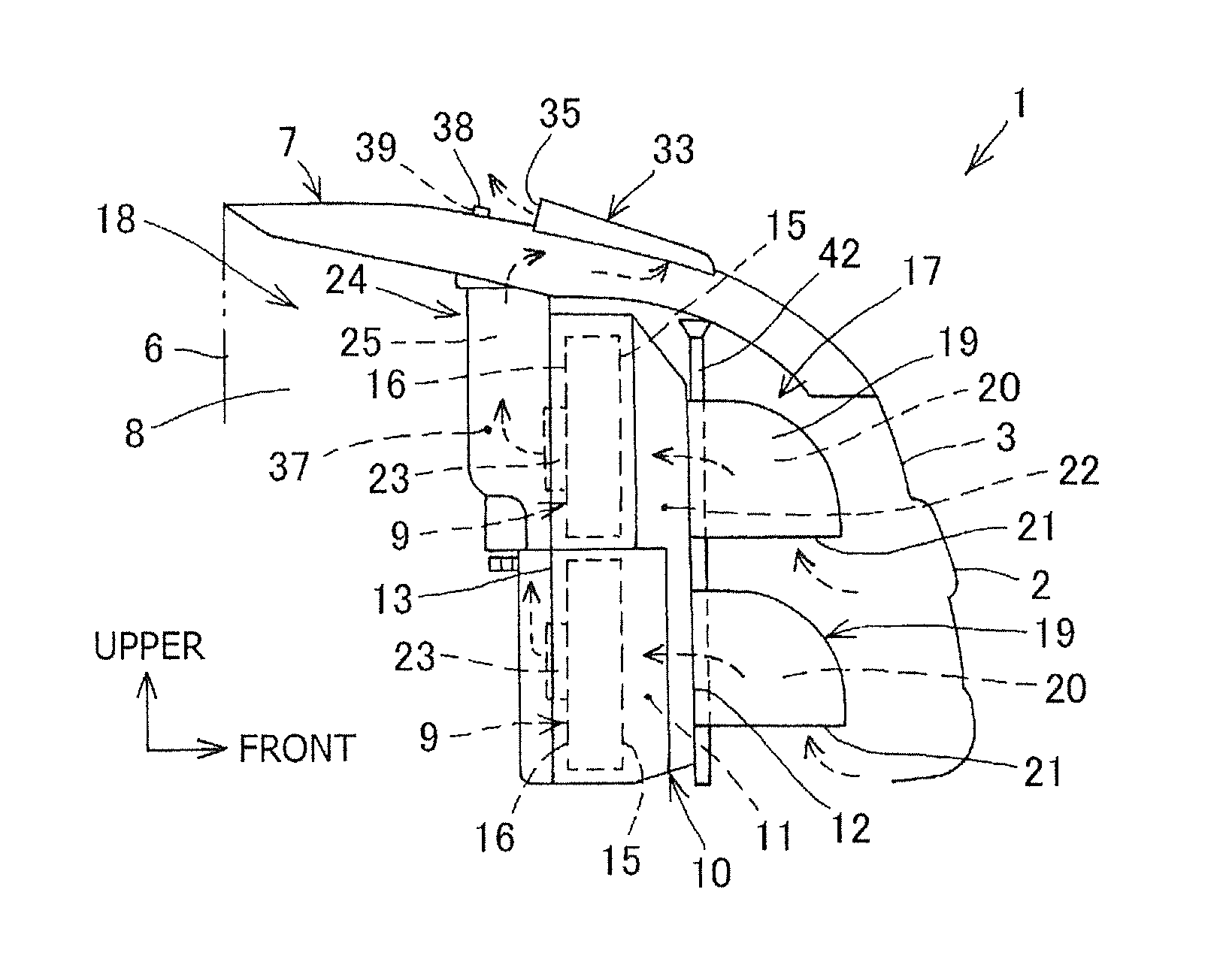

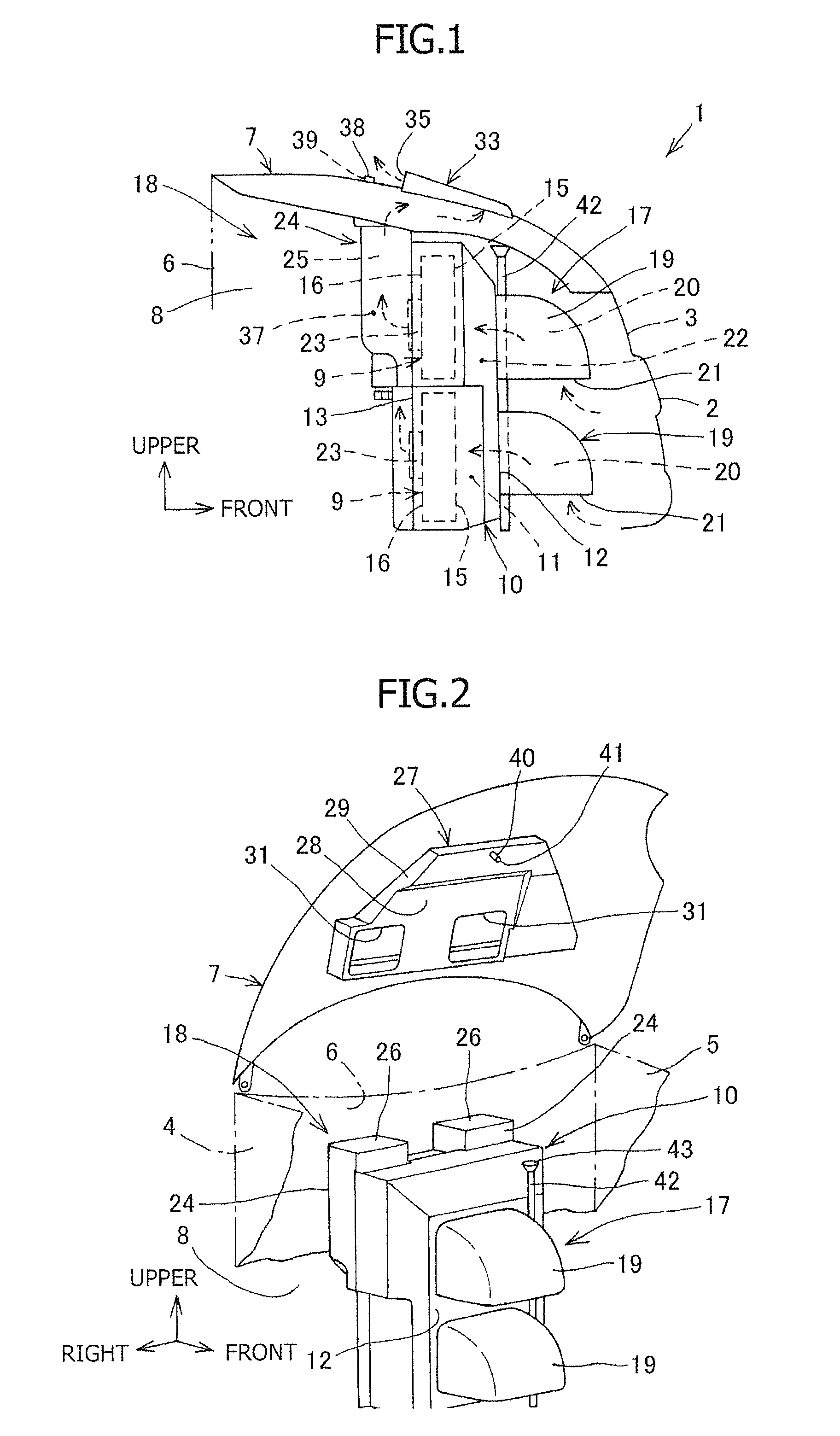

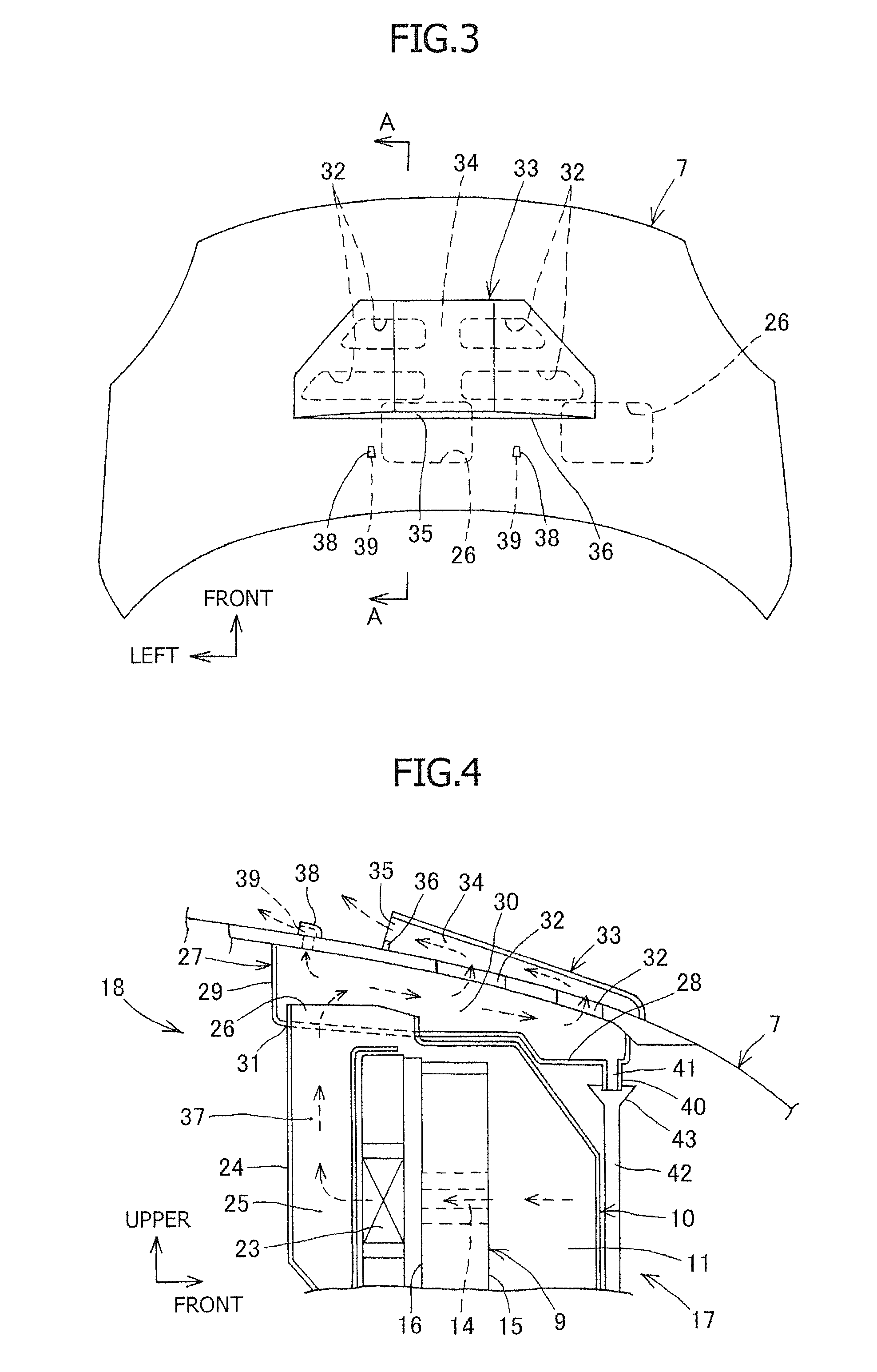

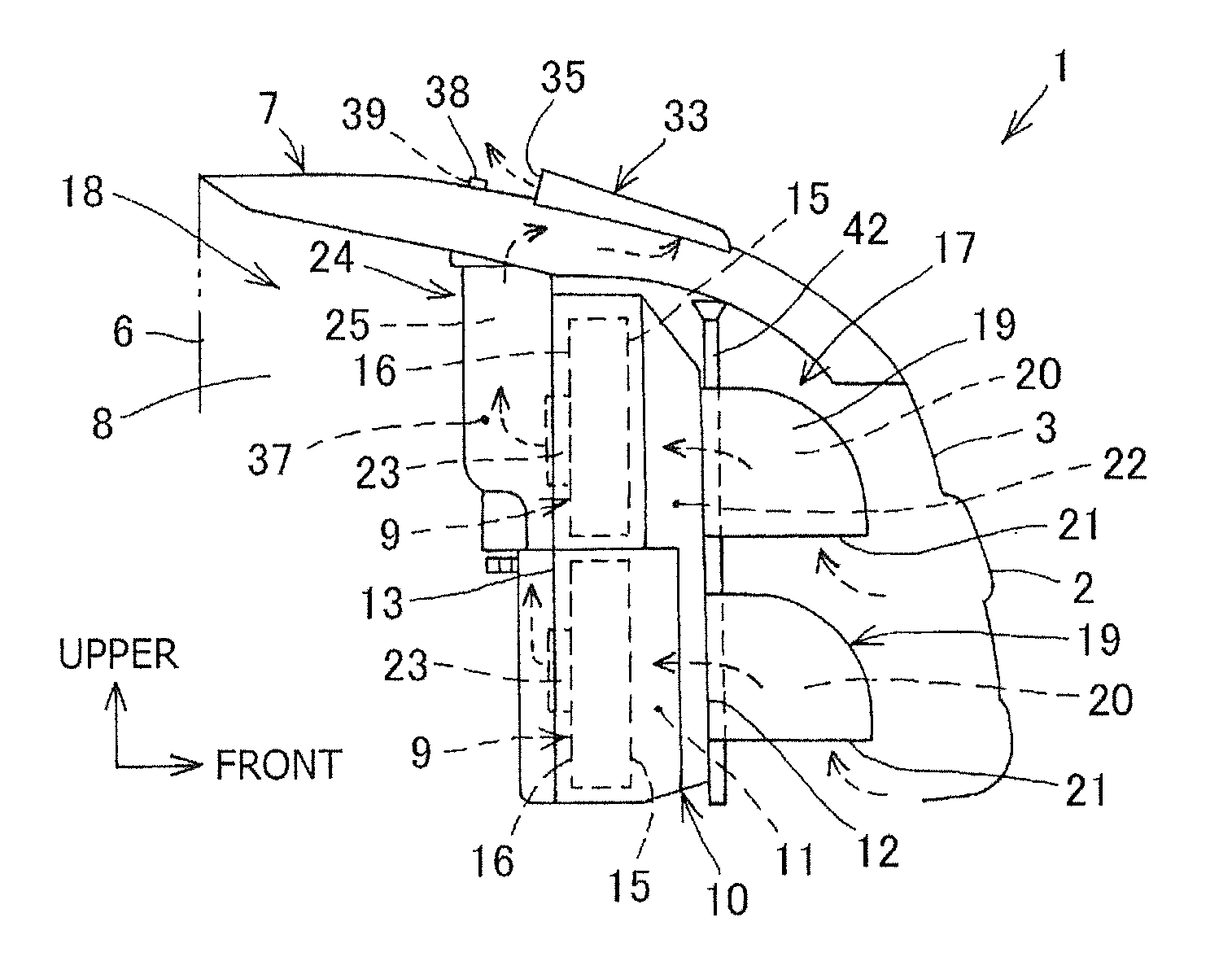

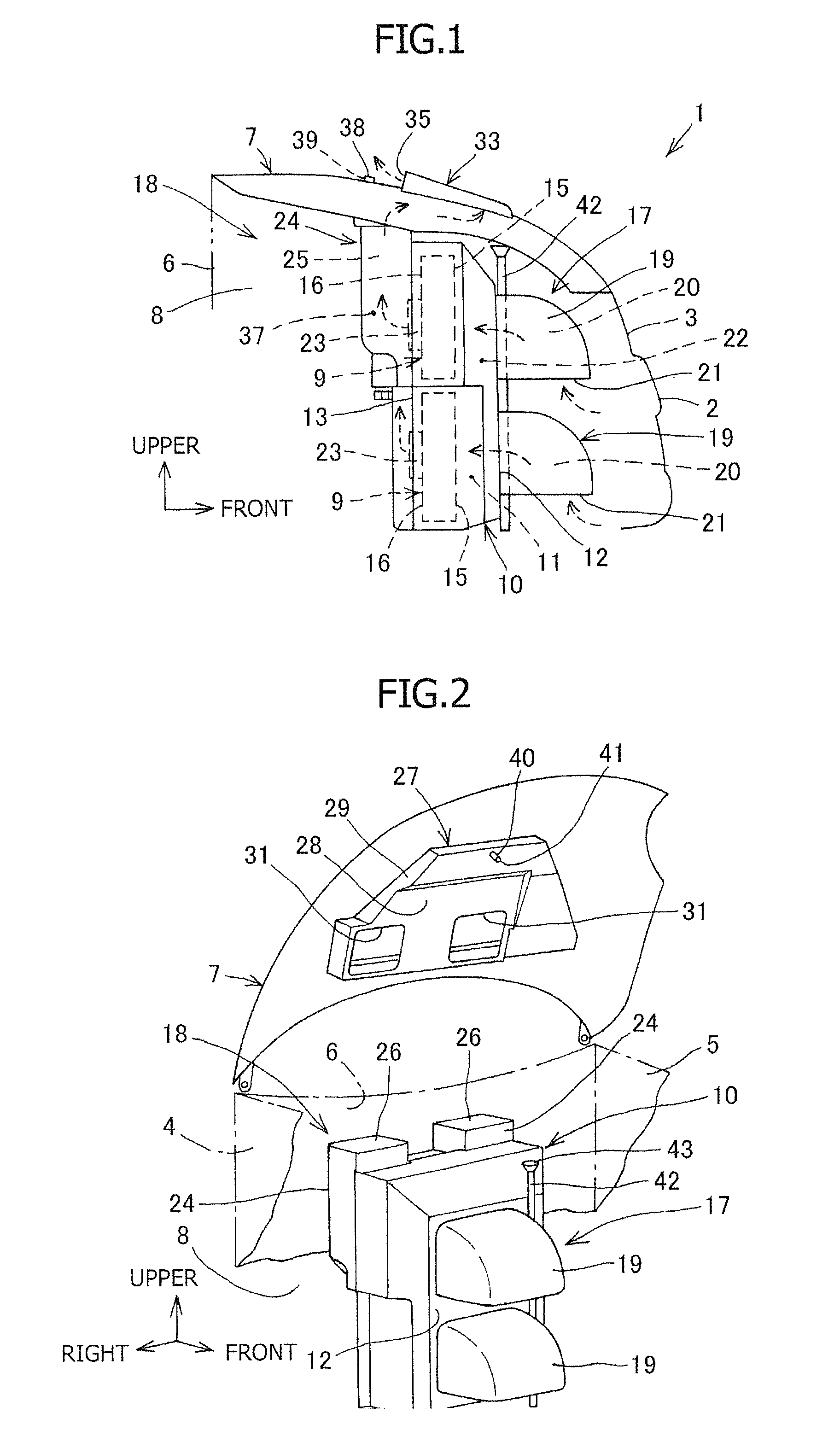

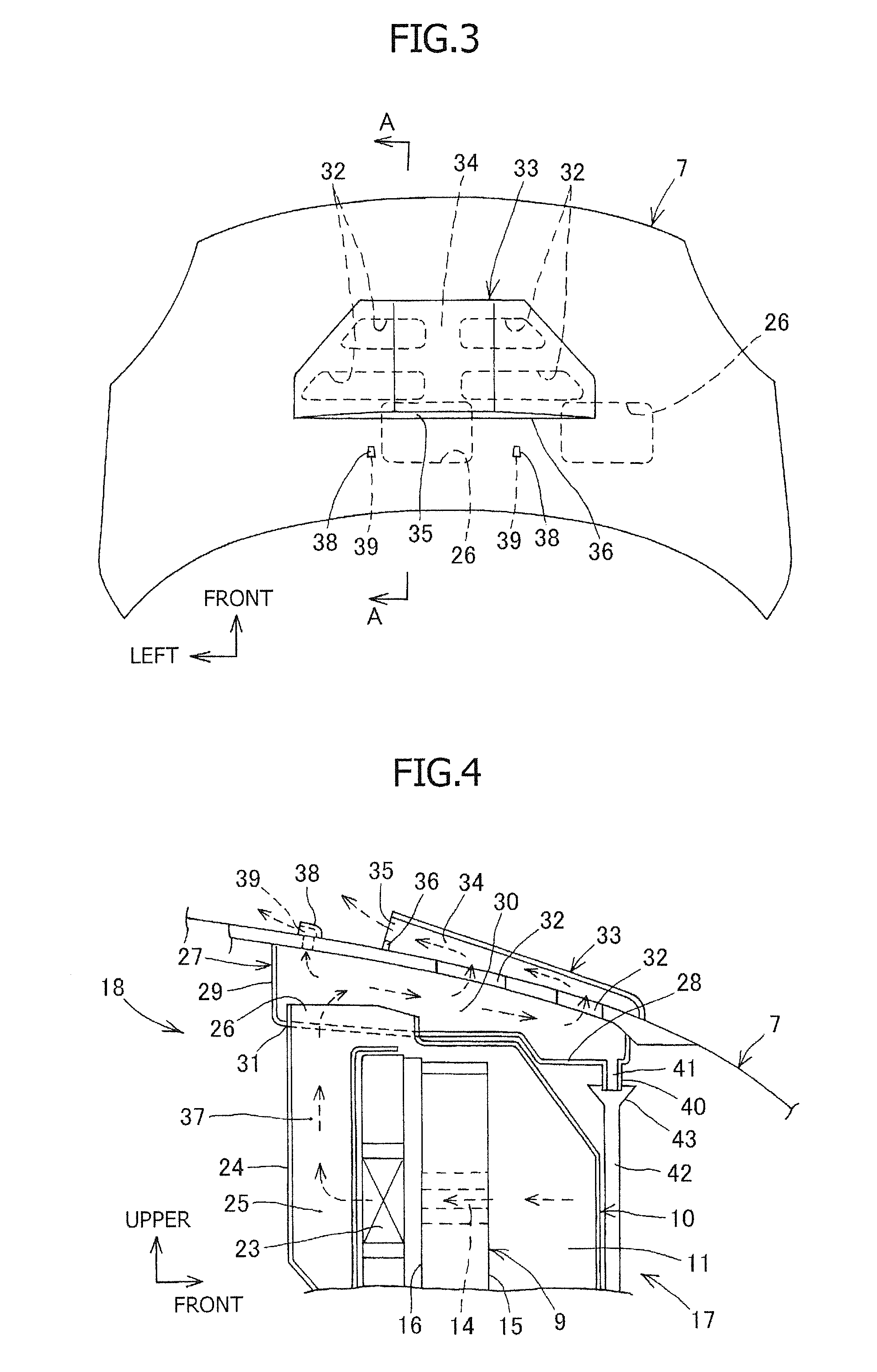

Exhaust device of fuel cell vehicle

ActiveUS20130302720A1Smooth dischargeShorten the lengthElectric propulsion mountingFuel cell auxillariesFuel cellsAirflow

To achieve smooth drawing of air into a fuel cell, the air-flow resistance of an exhaust passage is reduced and intrusion of water into an exhaust duct is prevented. In the present invention, in an exhaust device of a fuel cell vehicle, an exhaust chamber is attached to a lower surface of the front hood, the exhaust duct extends upward in a vertical direction from a rear portion of a fuel cell case, an exhaust port at an upper end of the exhaust duct opens to an interior of the exhaust chamber, a penetrating hole through which the inside of the exhaust chamber communicates with the outside space, is formed in the front hood in a portion in front of the exhaust port in a vehicle front and rear direction, the penetrating hole is covered with a cover, and an opening portion opening toward a rear side of the vehicle and being positioned above and away from an upper surface of the front hood, is formed in the cover.

Owner:SUZUKI MOTOR CORP

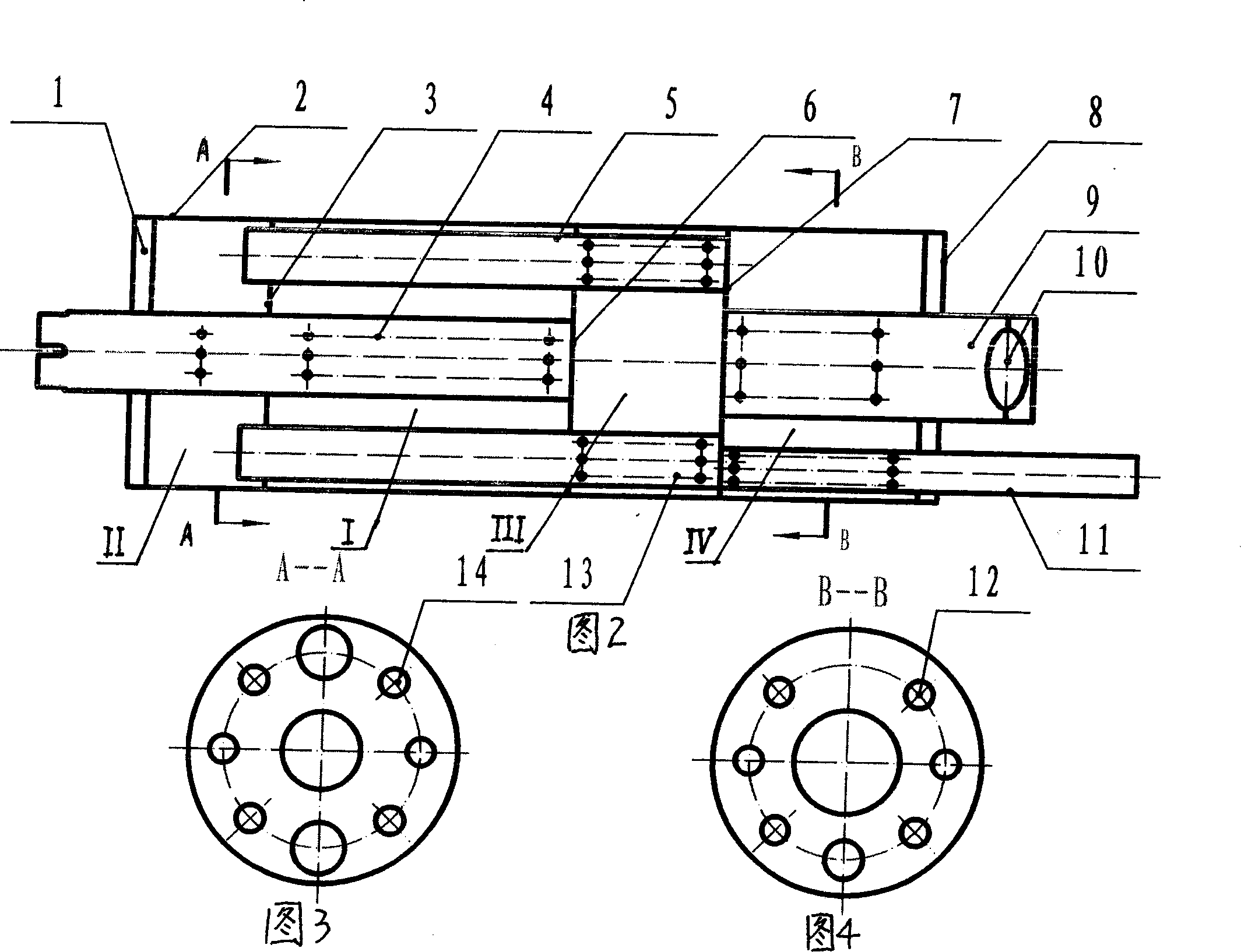

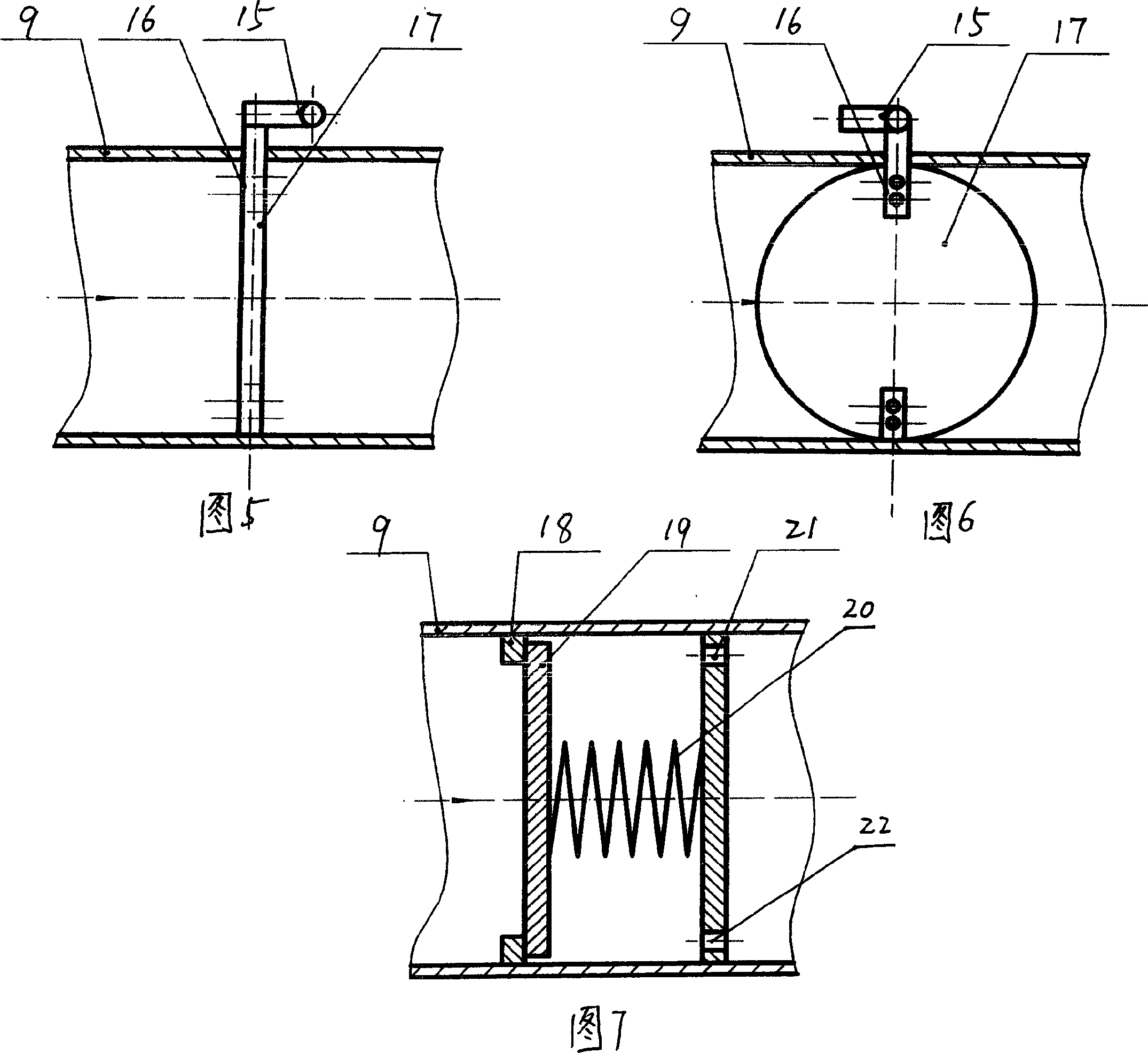

Exhaust device of rotary compressor

ActiveCN101644266AReduced clearance volumeImprove efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorEngineering

The invention relates to the technical field of refrigeration compressors, in particular to an exhaust device of a rotary compressor; in the exhaust device of the rotary compressor, a piston channel is arranged on a wall of an air cylinder, the bottom part of the air cylinder is provided with an exhaust port communicated with an air cylinder cavity, the inner end of a piston is tightly close to and blocks the exhaust port under the action of spring thrust; when the compressor exhausts air in the working process, the piston slides outwards in a piston channel, so as to remove blocking to the exhaust port, at the moment, high-pressure air in the air cylinder cavity is exhausted outside a compressing cavity through the exhaust port and an exhaust pipeline; the exhaust device in the inventioncan reduce clearance volume of the compressor in the exhaust process, and the efficiency of the compressor is improved; the mechanical noise generated by repeat beating is avoided when the traditionalcompressor is exhausted; in addition, a plurality of exhaust devices are arranged on the air cylinder wall according to needs, so as to bear the exhaust pressure respectively, reduce the exhaust resistance and reduce energy loss.

Owner:GREE ELECTRIC APPLIANCES INC +1

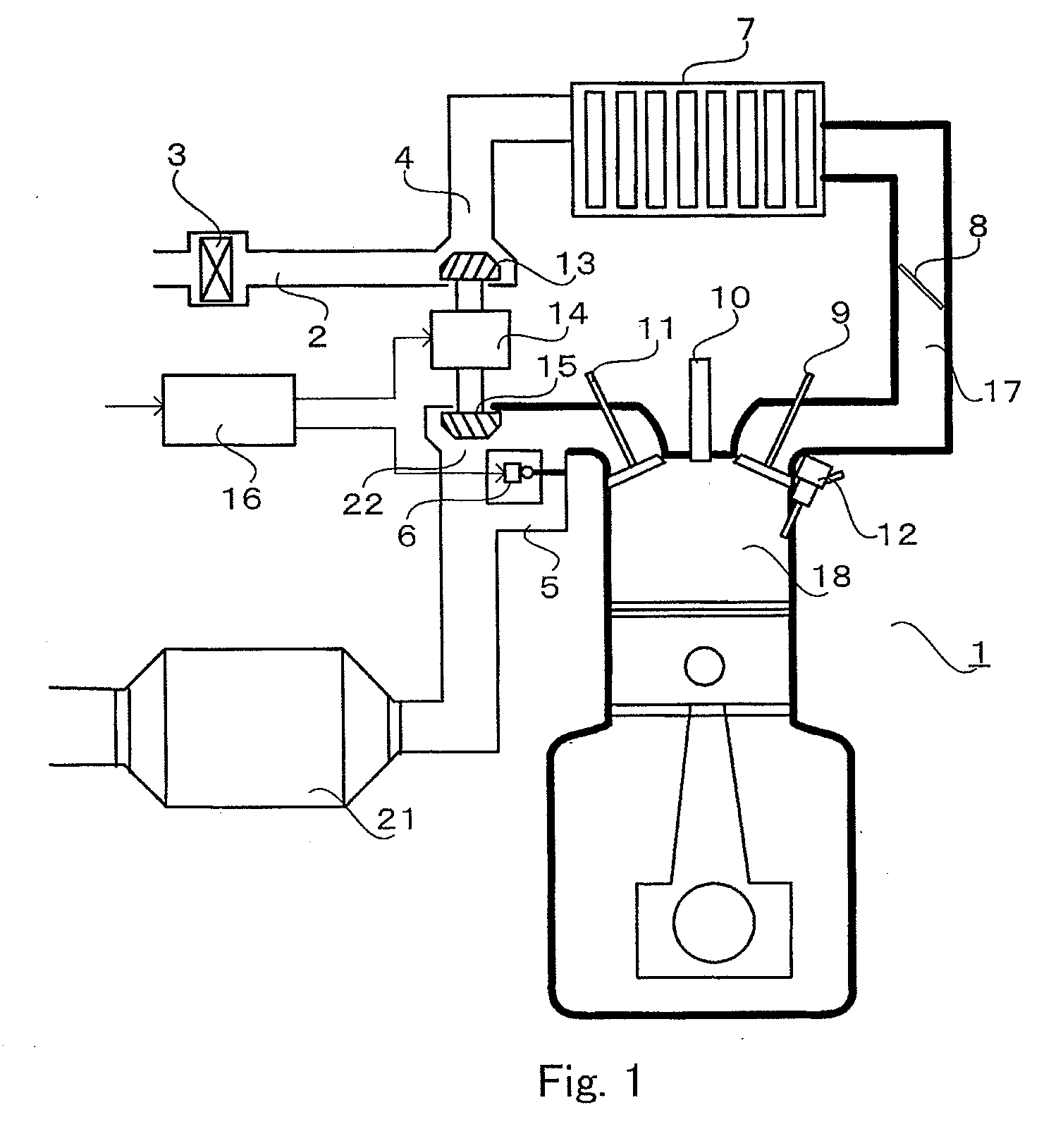

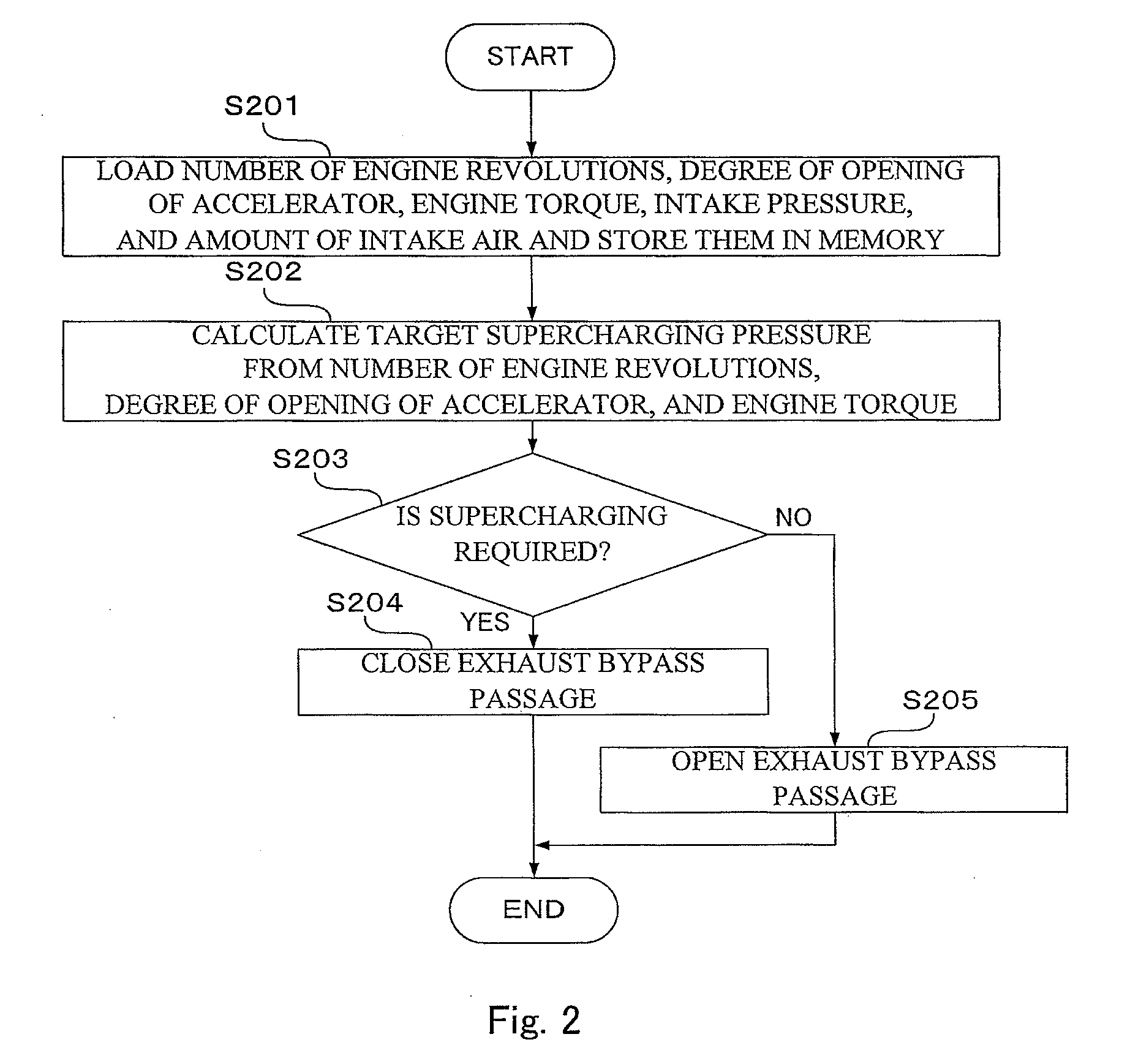

Internal combustion engine

InactiveUS20100263374A1Improve fuel economy performanceImprove performanceInternal combustion piston enginesGas turbine plantsExhaust gasForced induction

Provided is an internal combustion engine for improving fuel-economy performance in any of the case where supercharging performed by an electric supercharger is required and the case where the supercharging is not required. The internal combustion engine includes: an electric supercharger; a supercharger; an electric motor; and a controller, the electric supercharger being for compressing an intake air by rotation of the supercharger caused with rotation of the exhaust turbine by an exhaust gas energy to perform supercharging and for rotationally driving the supercharger with electric-motor assistance by the electric motor; an exhaust bypass passage provided to bypass the exhaust turbine; and an opening and closing the exhaust bypass passage unit. In the internal combustion engine, the opening and closing the exhaust bypass passage unit opens the exhaust bypass passage until the supercharging is started by the electric supercharger.

Owner:MITSUBISHI ELECTRIC CORP

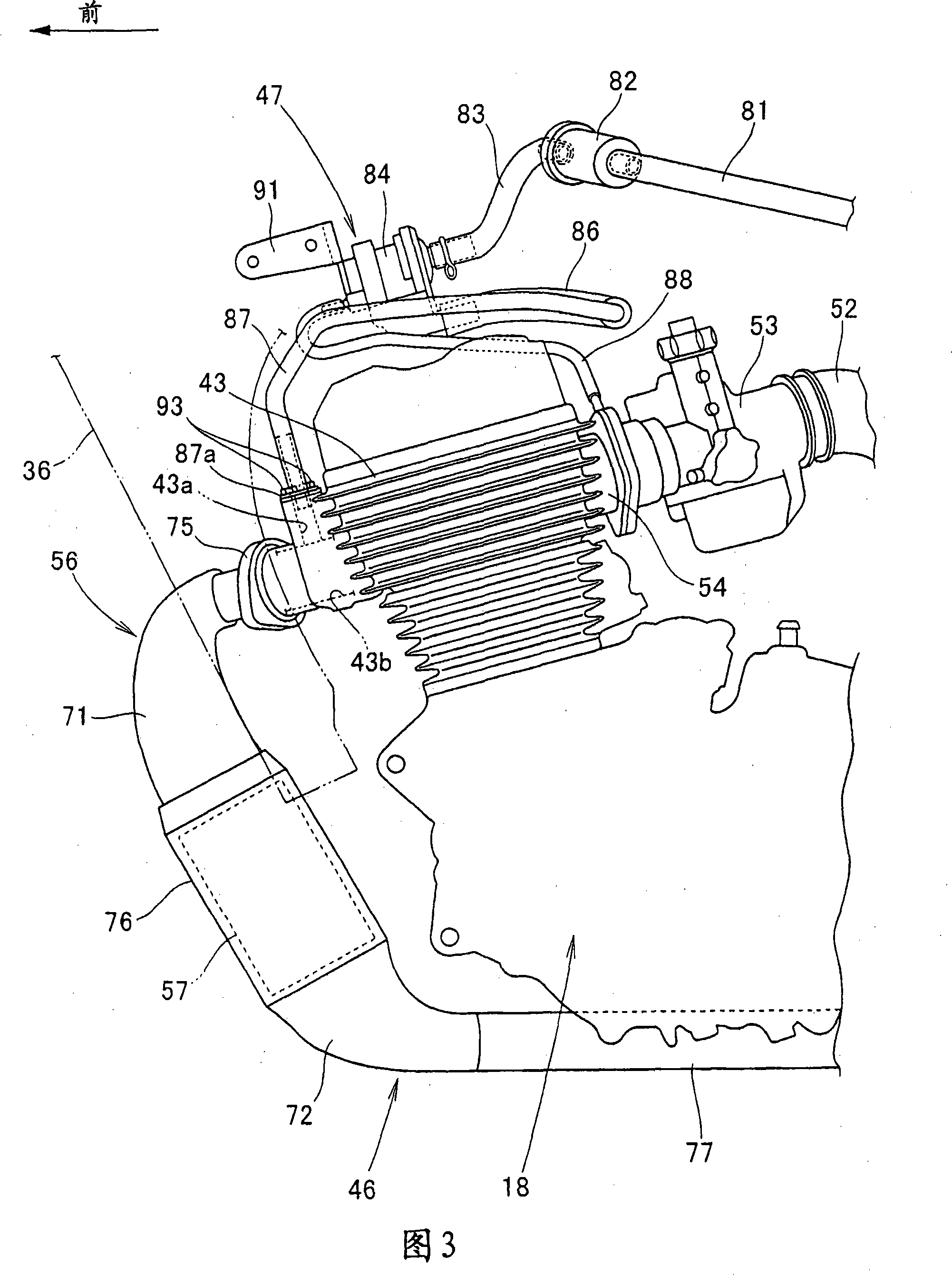

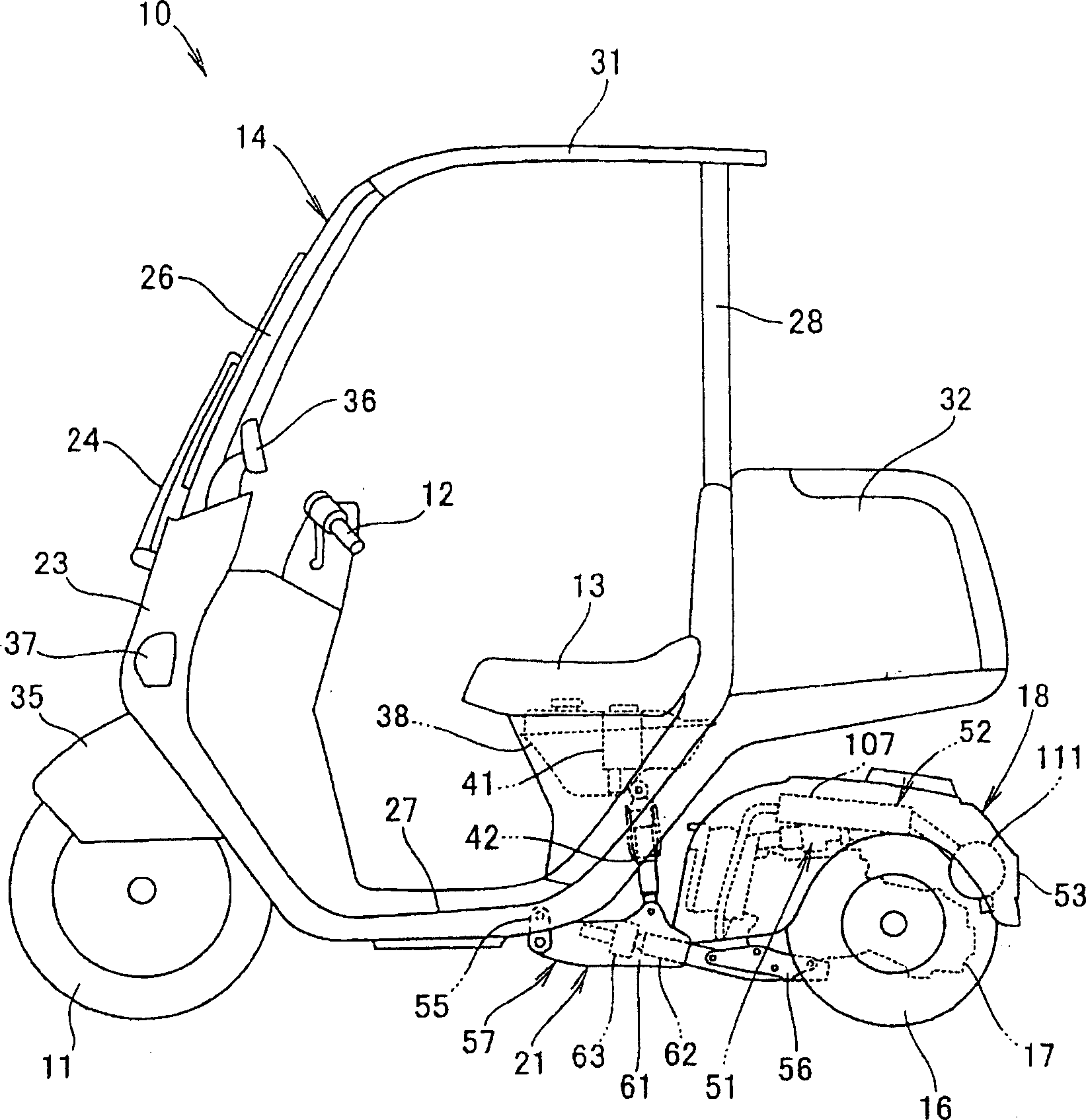

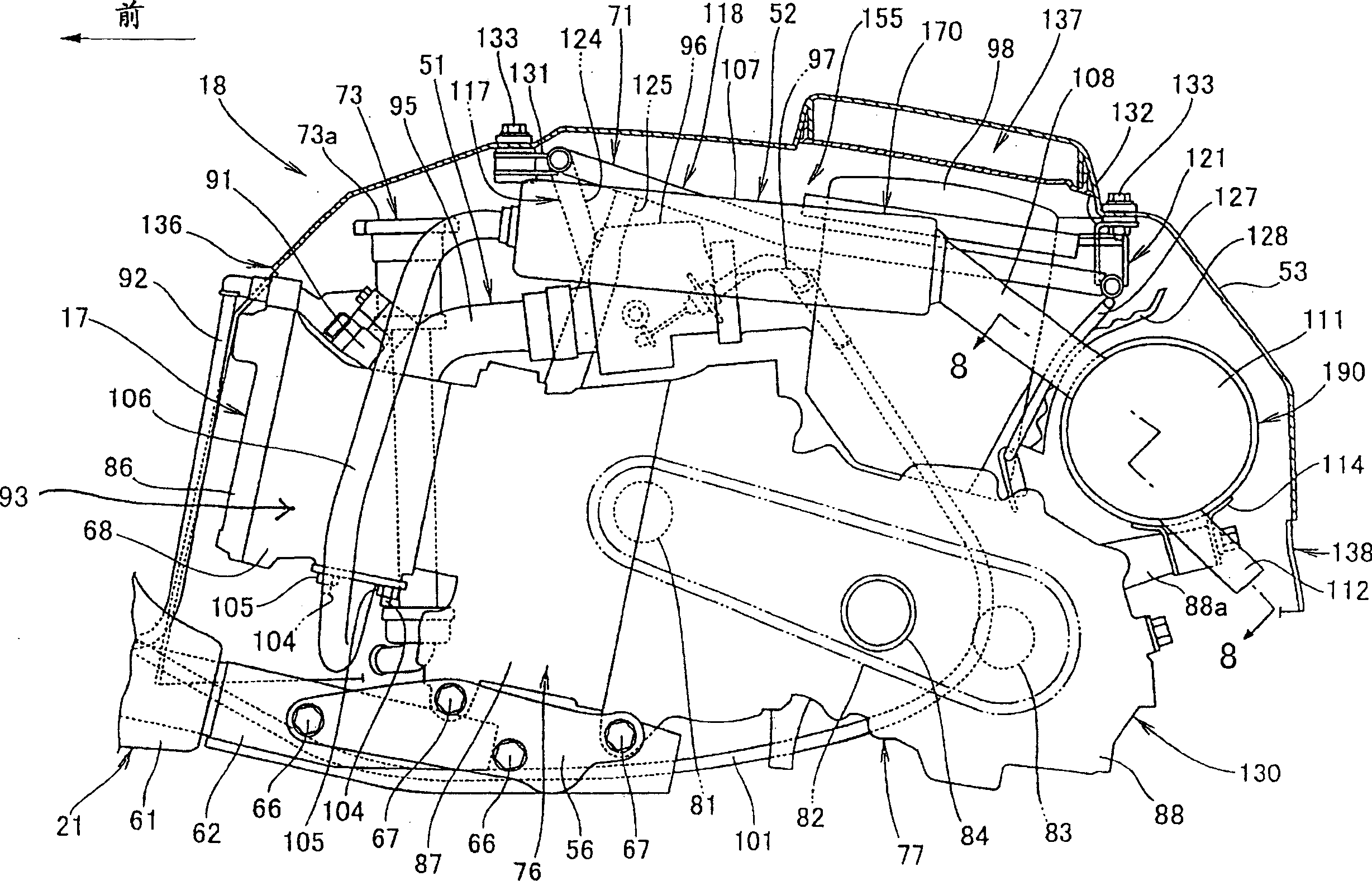

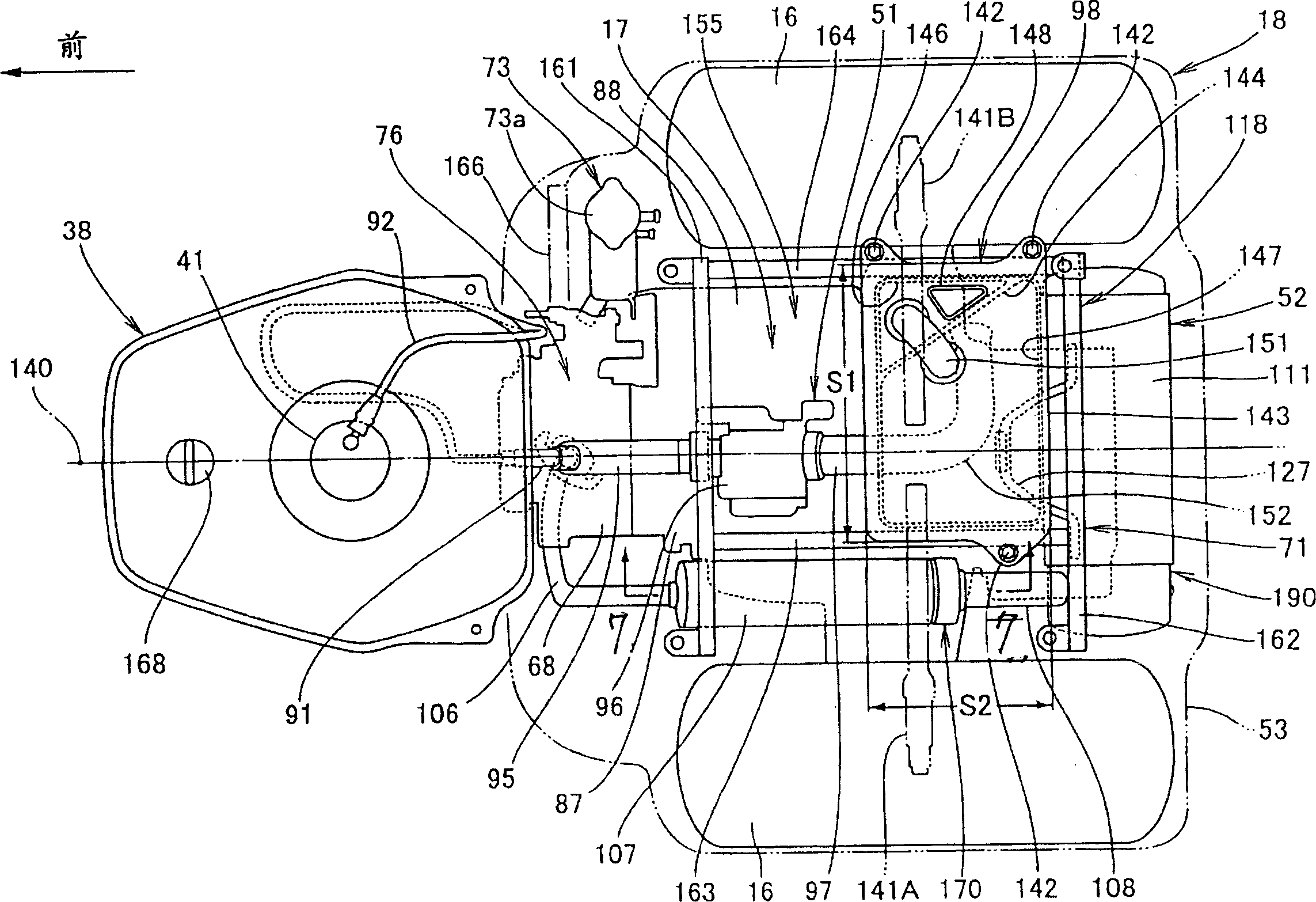

Rocking three-wheels vehicle

InactiveCN1903639AEffective centralized protectionEfficient use ofInternal combustion piston enginesExhaust apparatusEngineeringThrottle

The utility model relates to a tricycle, which effectively arranges and supports various functional parts of the rear body, makes the rear body further compact and miniaturized, and is environmentally friendly at the same time. The rear car body (18) is connected with the rear portion of the front car body, and the rear car body is connected so that it can swing freely relative to the front car body, and the rear car body (18) is covered by an integral casing (53) , the engine (76), the rear wheels (16, 16) driven by the engine (76), and the exhaust system (52) of the engine (76) are arranged in the casing (53). The cylinder part (93) of the engine (76) is arranged in the casing (53) inclined forward. In the exhaust system (52), a catalyst pipe (107) and a muffler (111) for purifying exhaust gas are arranged, and a fuel injection valve (91) and a throttle body (107) for supplying fuel to the engine (76) are arranged. Arranged in the casing (53).

Owner:HONDA MOTOR CO LTD

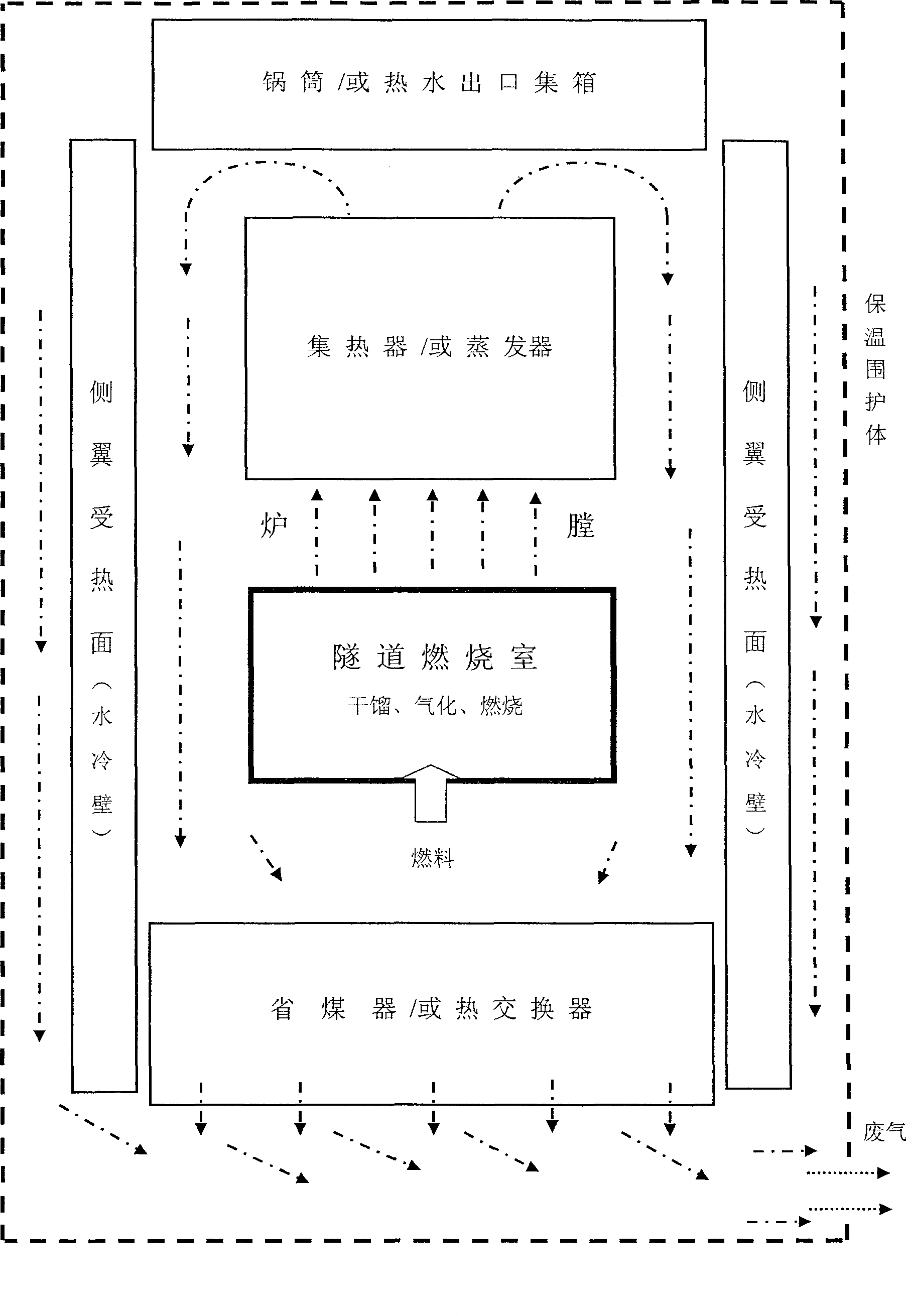

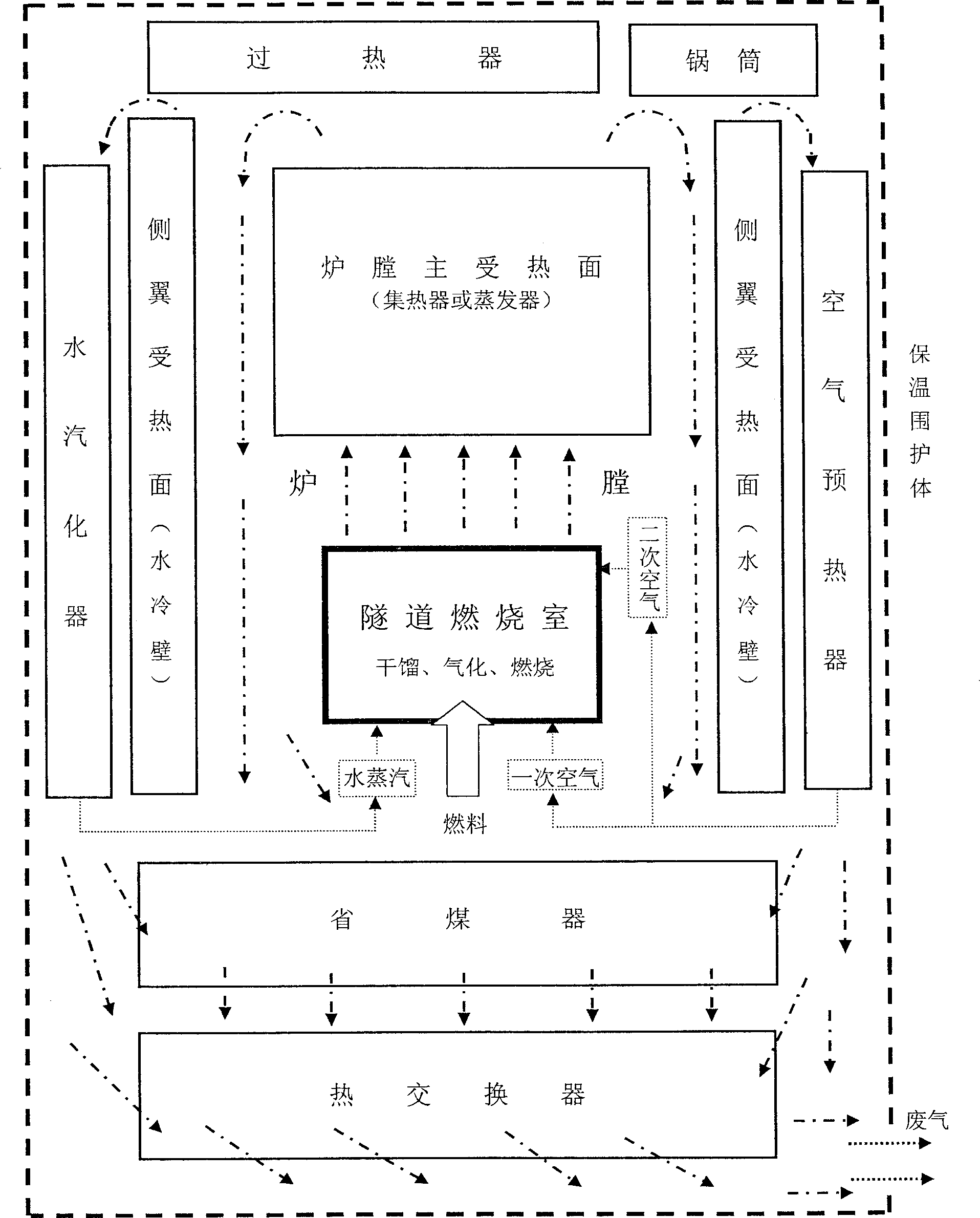

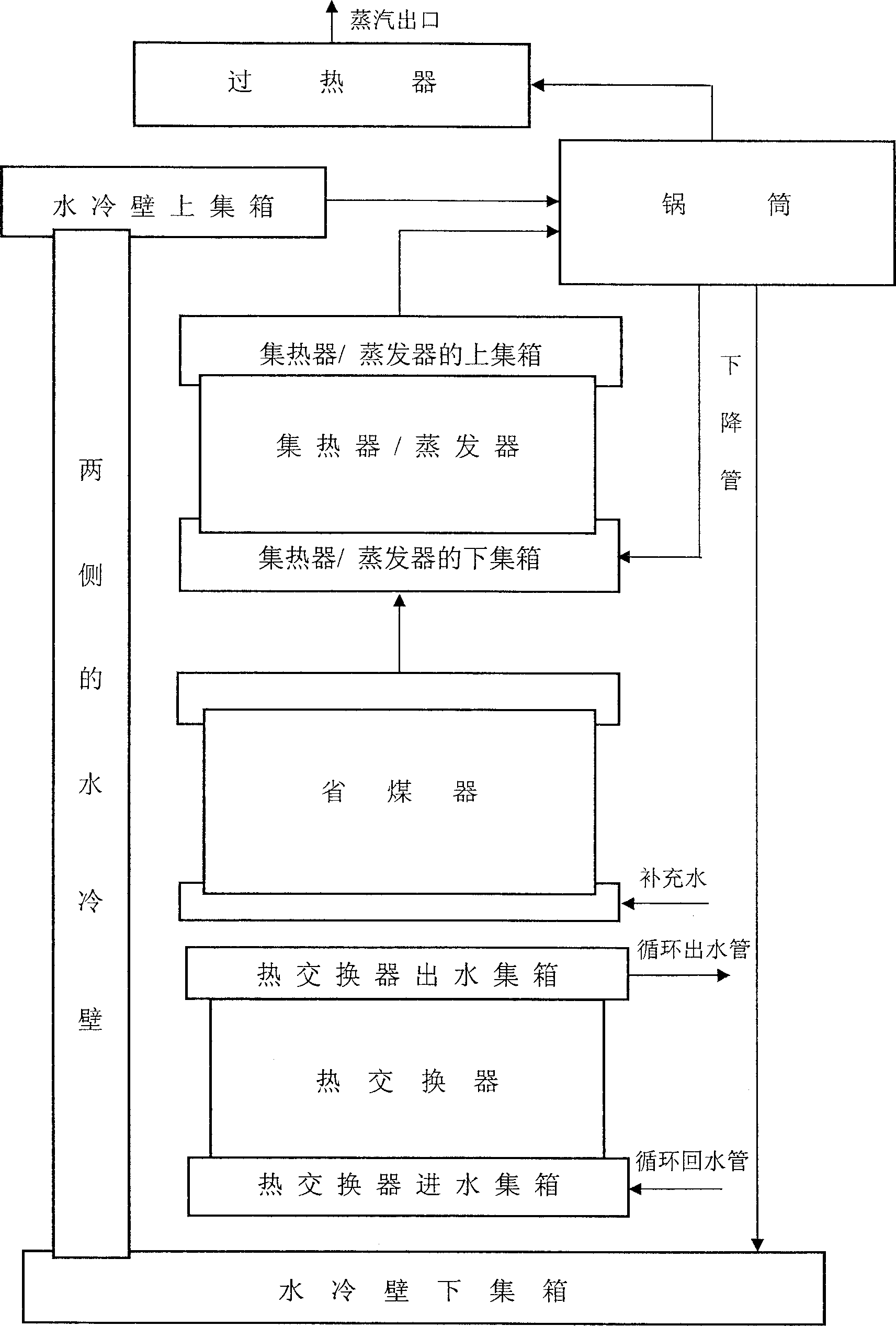

Tunnel combustion chamber and its constructed smoke dust less fuel coal and biomass equipment

InactiveCN1904479ARaise the gradePrevent escapeCasings/liningsNon-combustible gases/liquids supplyResource depletionCombustion chamber

The tunnel combustion chamber and its constitute of burning coal and organism without smoke and dust relate to boiler, furnace and aerify equipment whose fuel is coal and organism. The tunnel combustion chamber has wide fuel scope. It can carry out the cleanness combustion of the smoke raw coal, the spread coal, the organism, the type coal and the biologic coal. It applies the biologic fuels reasonably and has high thermal efficiency. It realizes the large-scale and mechanical burning. The invention resolves the problem of pollution atmosphere environment by coal burning device. It makes the equipments the cleanness combustion when burning the coals. The small equipment doesn't need air blast and induced air and it can burn. And it doesn't need the ash handling equipment to protect the environment. The invention sends the vapour to the tunnel combustion chamber. It is used to restrain the smoke and translate to the gas fuel. It carries out cleanness combustion when realizes the increase the combustion value of the fuels. It lowers the resources depletion and relief the energy strain. It creates a condition for pushing economy social overall coordination sustained developing.

Owner:周开根

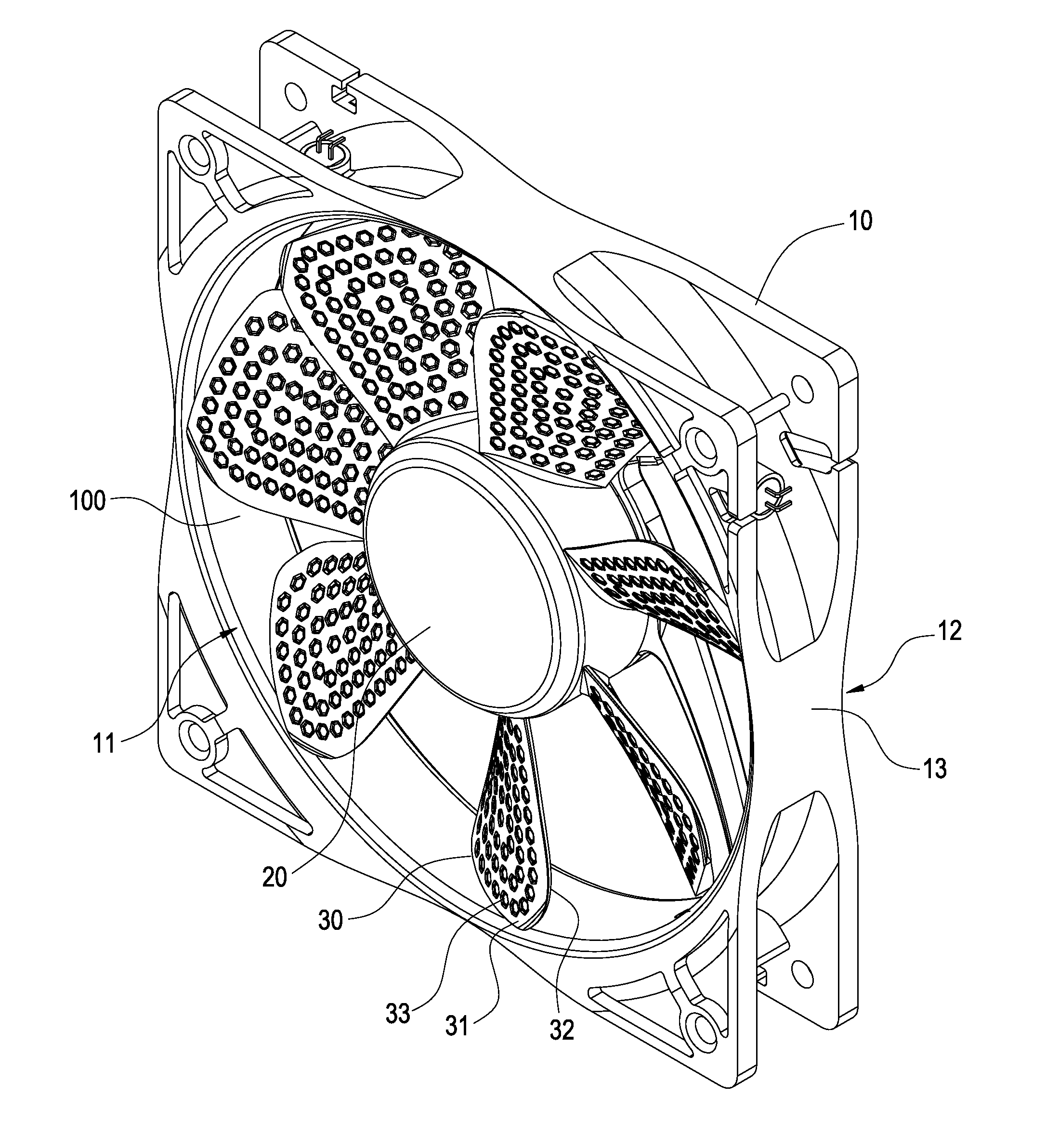

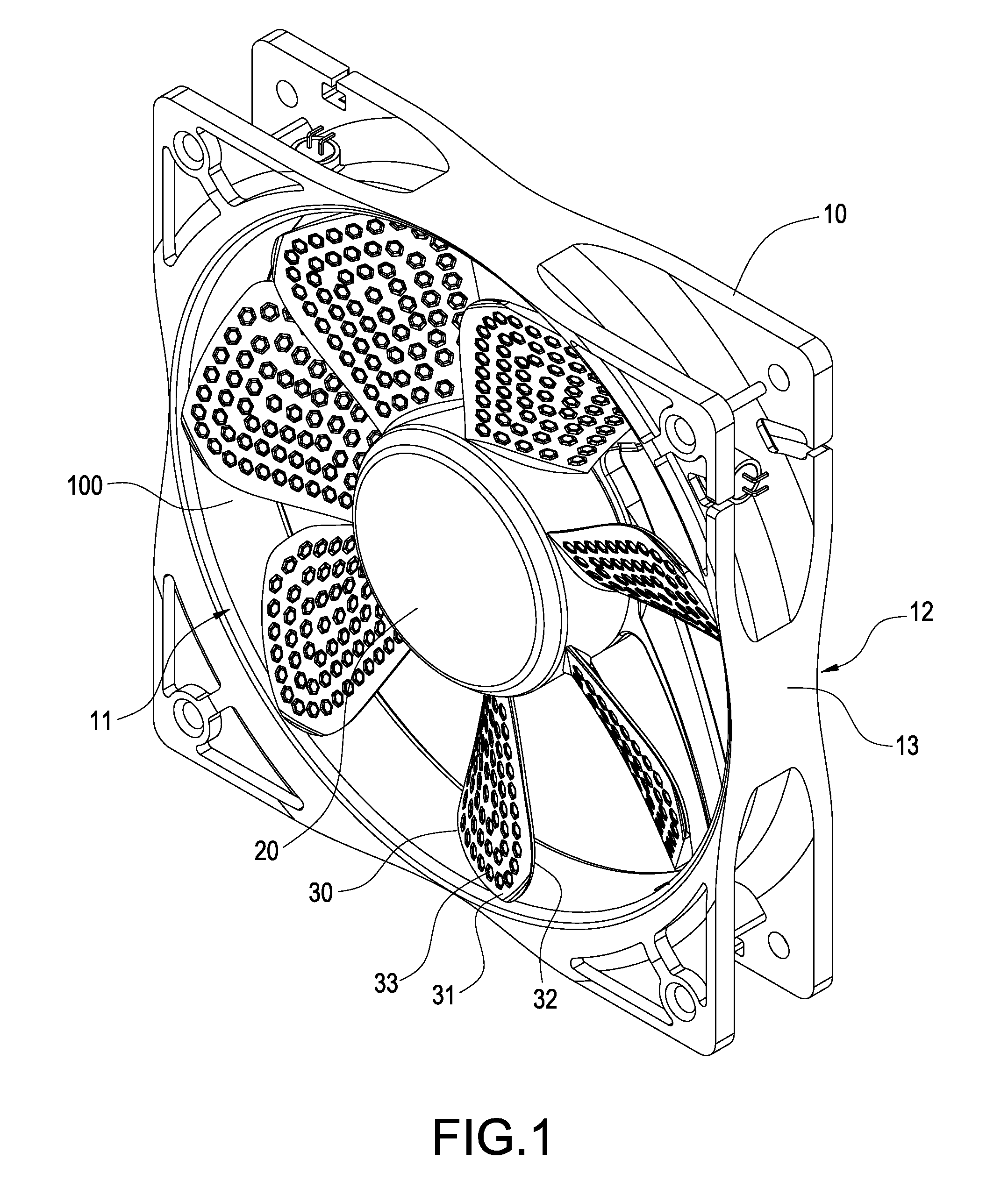

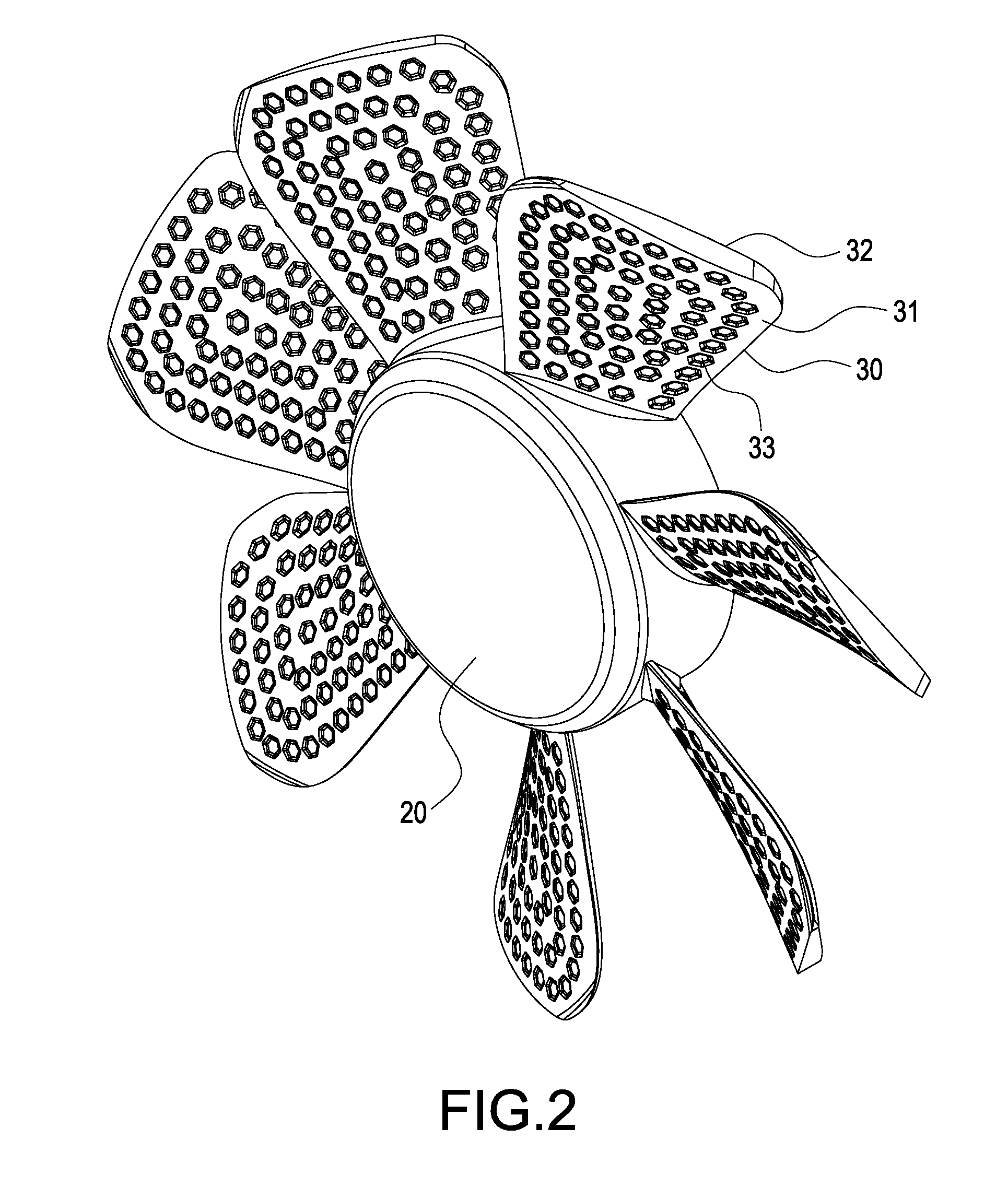

Fan structure

A fan structure includes a hub and a plurality of blades extending from the periphery of the hub. The airflow generated by the fan forms a boundary layer on the surface of each blade. The present invention is characterized in that: each of the blades is provided with a plurality of polygonal dents, a turbulent flow is generated in each dent when the airflow passes through the dent, a plurality of the turbulent flows collect together to form an air film between the surface of blade and the boundary layer. By this structure, the distance of separating points from the boundary layer is extended, and the frictional force and noise caused by the rotation of the blades are reduced.

Owner:ZAWARD CORP

Internal combustion engine exhaust silencer with variable exhaust pipe cross section

InactiveCN1858412AReduce exhaust noiseMeet the requirements for noise reductionSilencing apparatusMachines/enginesEngineeringInternal combustion engine

The exhaust silencer with variable exhaust pipe cross section of internal combustion engine includes one casing, one air inlet silencing pipe and one exhaust silencing pipe inside the casing cavity, three partition boards set inside the cavity to separate the cavity into four chambers and one intermediate silencing pipe. The air inlet silencing pipe has its closed end penetrating the front end cap, the first partition board and two chambers and combining with the second partition board. The exhaust silencing pipe includes two pipes of different lengths and sizes, their closed ends penetrate the back end cap and the last chamber and combine with the third partition board, and the large and short pipe has one exhaust control valve in the opened end. The intermediate silencing pipe has its opened end located inside the second chamber and the closed end inside the third chamber.

Owner:河南天瑞环保新材料有限公司

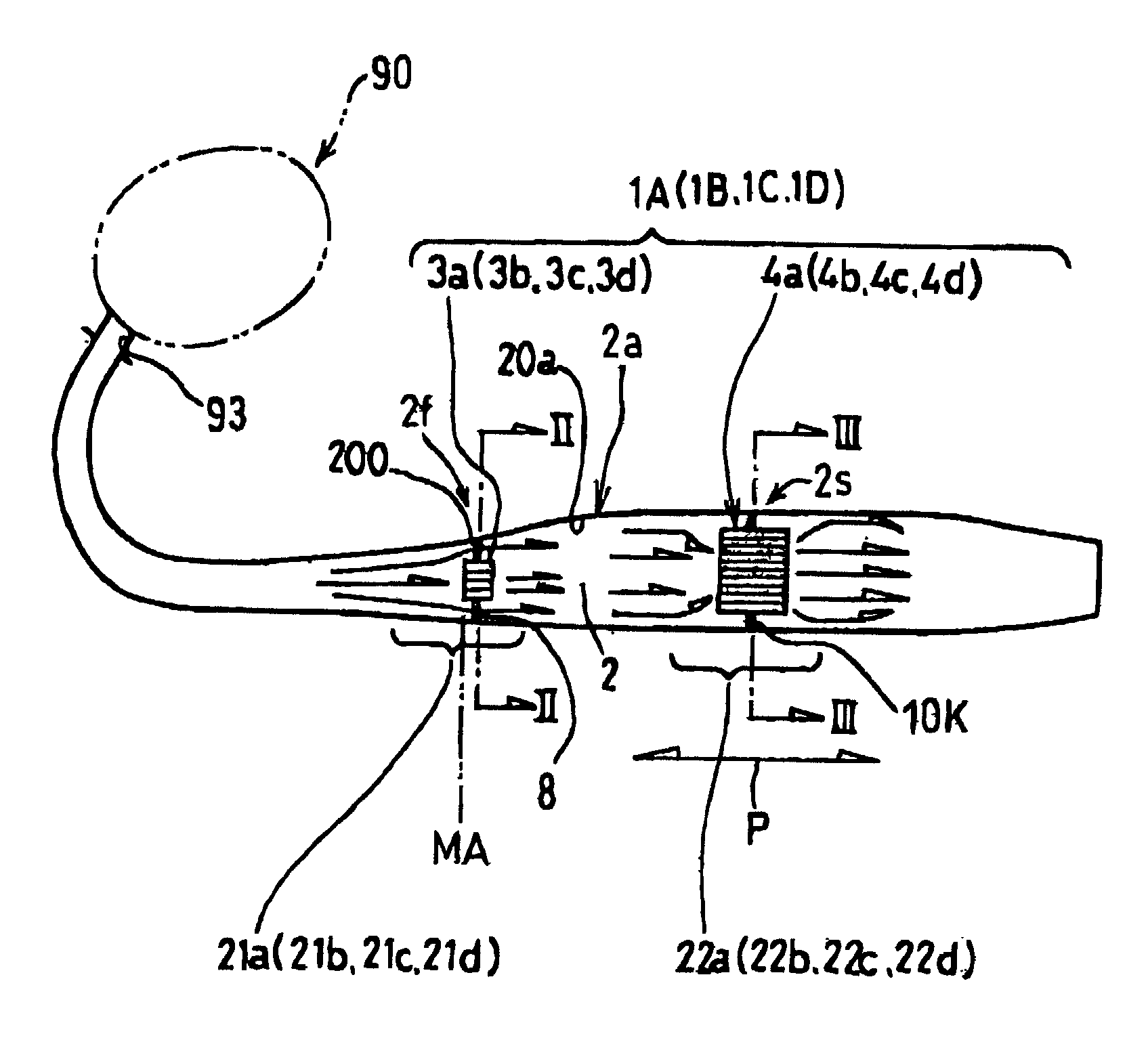

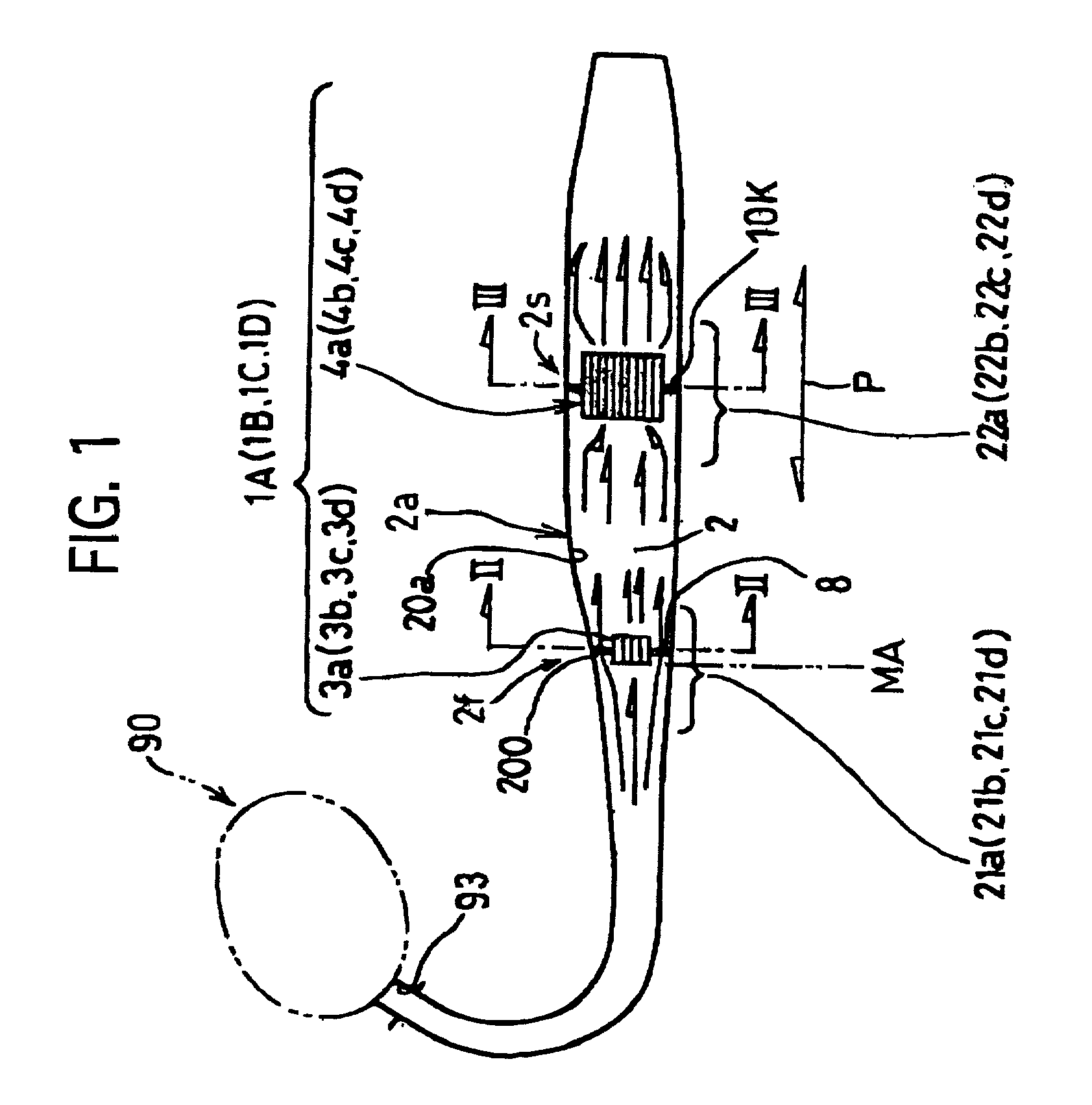

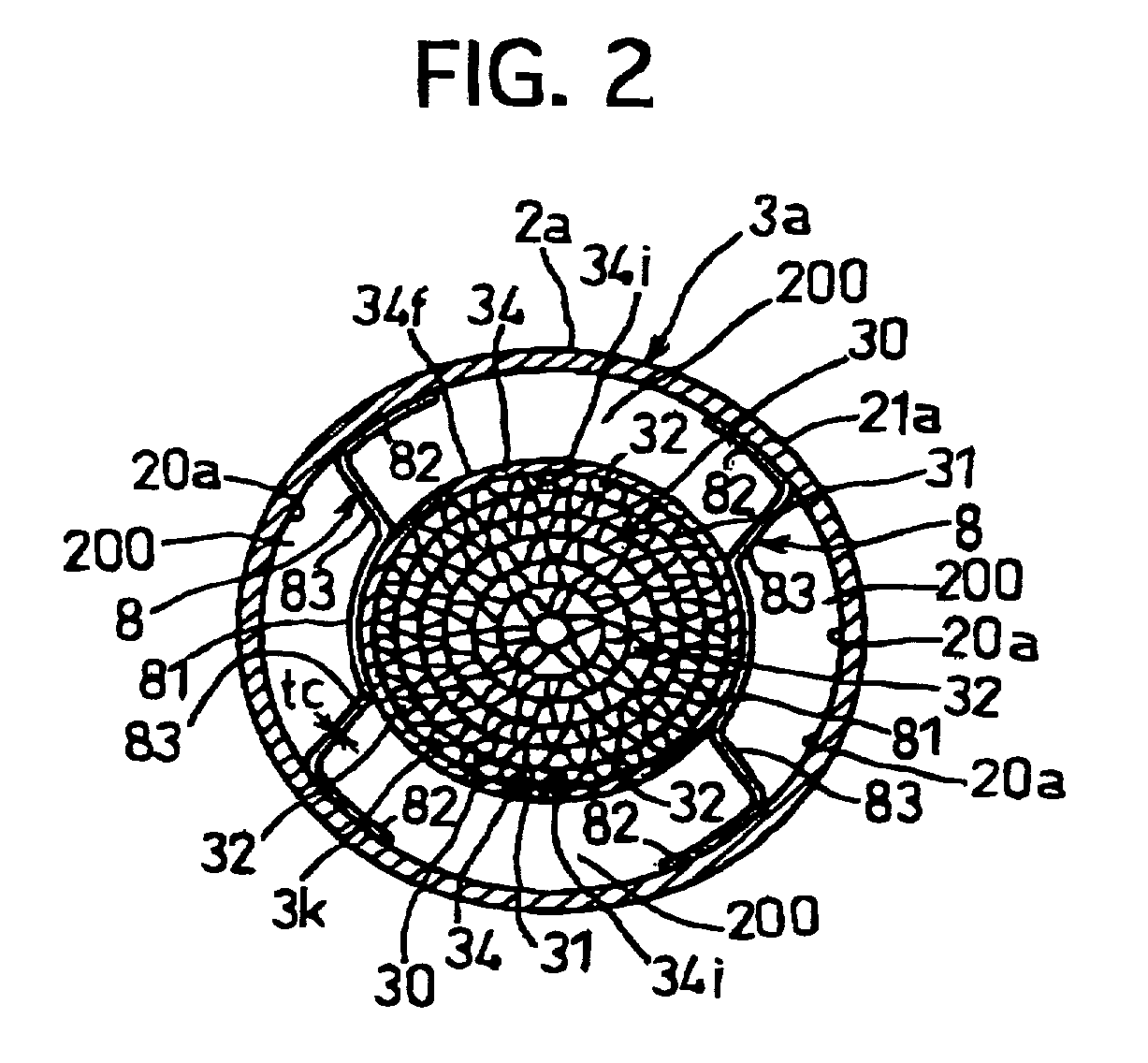

Exhaust gas purifying apparatus

InactiveUS7048895B2Improve purification effectSuppressing decrease of engine outputCombination devicesExhaust apparatusHoneycombEngineering

An exhaust gas purifying apparatus includes an exhaust pipe 2a for forming an exhaust way 2, and a catalyst disposed in the exhaust way 2 for purifying an exhaust gas. The catalyst includes the first honeycomb catalyst portion 3a and the second honeycomb catalyst portion 4a. The first honeycomb catalyst portion 3a has an outer circumferrencial surface for forming a blowing passage 200 with an inner circumferrencial surface of the exhaust pipe 2a. The radial cross sectional area in the catalyst region of the first honeycomb catalyst portion 3a is set in the 1 / 5–2 / 3 range with respect to the radial cross sectional area of a flowing way defined by the inwall surface of the first mounting position 3a placed in the exhaust way 2, with the first honeycomb catalyst portion 3a being removed.

Owner:CATALER CORP

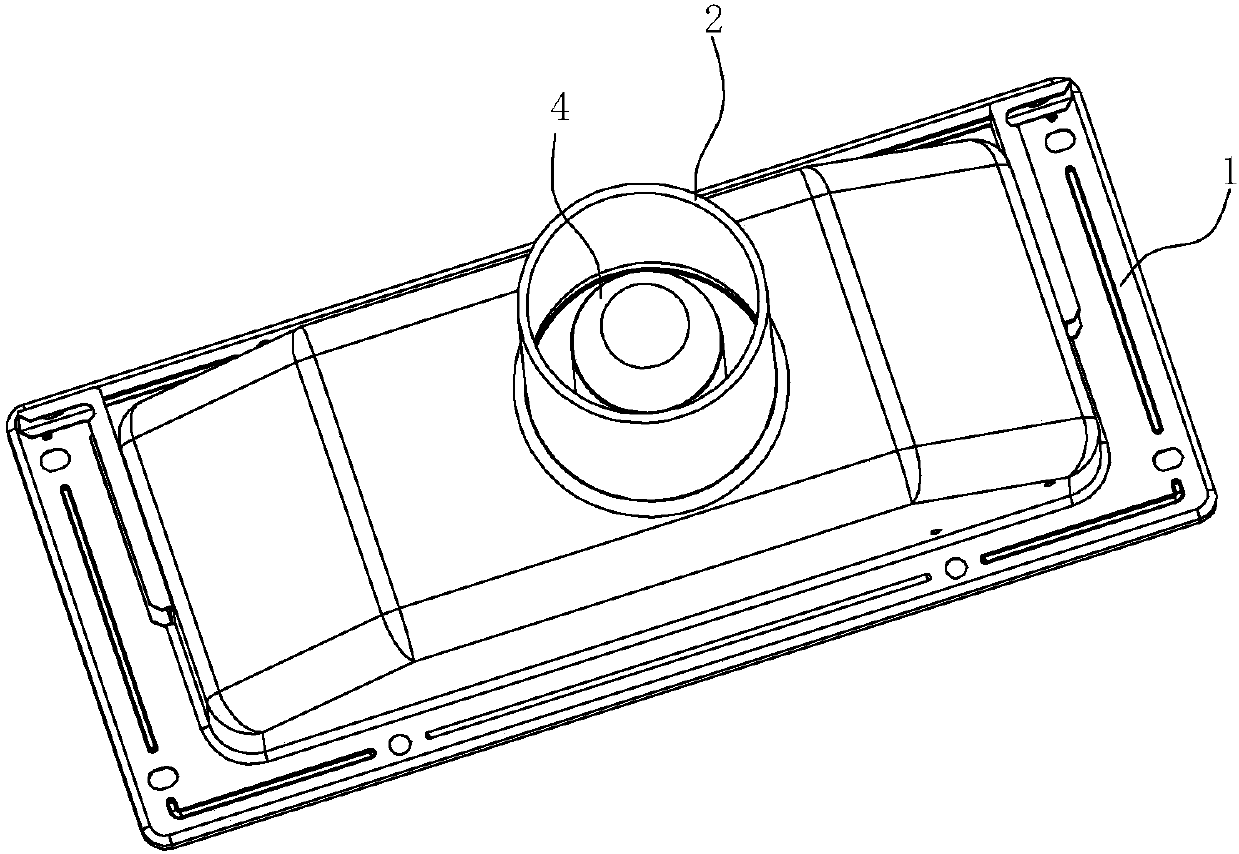

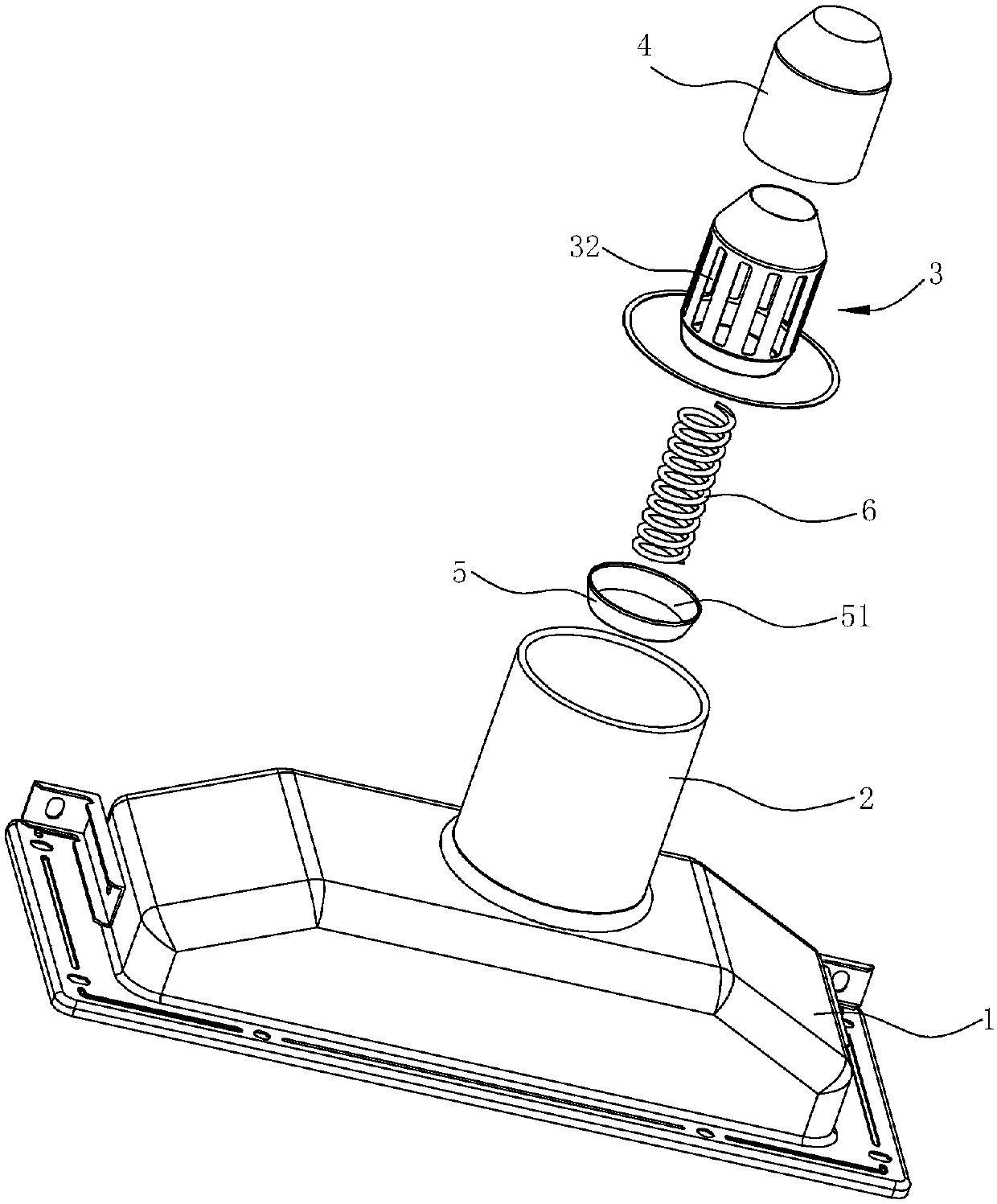

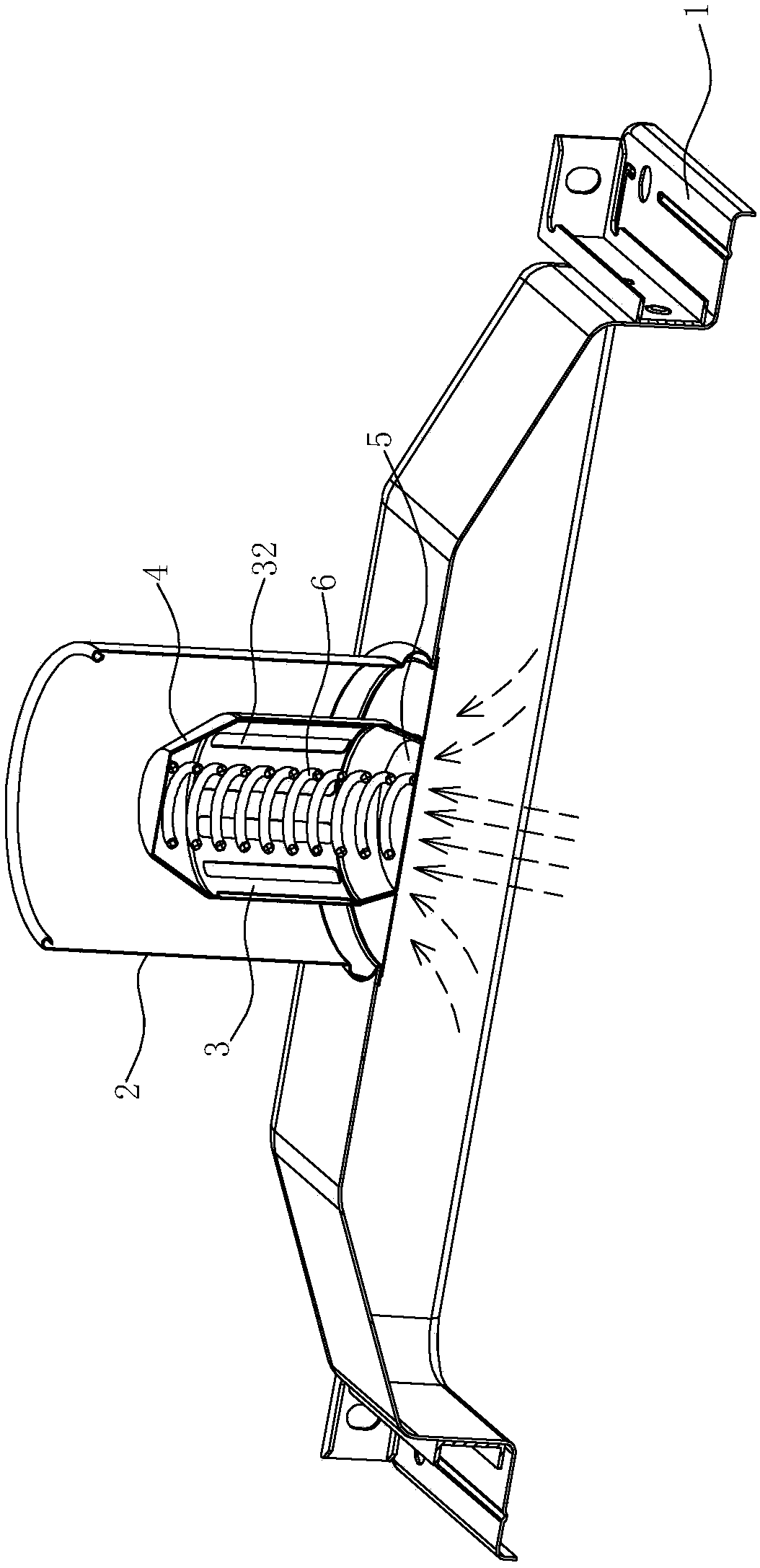

Gas-collecting hood for gas water heater and gas water heater using gas-collecting hood

The invention relates to a gas-collecting hood for a gas water heater. The gas-collecting hood comprises a hood body and a vertical gas-exhausting pipe arranged at the top of the hood body and is characterized in that: a gas guide drum is arranged in the gas-exhausting pipe; a gas inlet formed in the lower end of the gas guide drum is communicated with an inner chamber of the hood body; at least one gas-exhausting hole is formed in the side wall of the gas guide drum; a sleeve, of which the bottom is opened and the top is closed, is arranged on the outer side of the gas guide drum in a sleeving manner; and the sleeve can move up and down relative to the gas guide drum, and can move downward to fully cover the gas-exhausting hole and upward to expose at least part of the gas-exhausting hole. Compared with a manner of vertical fume exhausting, fume exhausting from the side wall of the gas guide drum can alleviate the impact of external wind force, reduces the resistance to the fume pressure, and allows fume to be exhausted easily.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

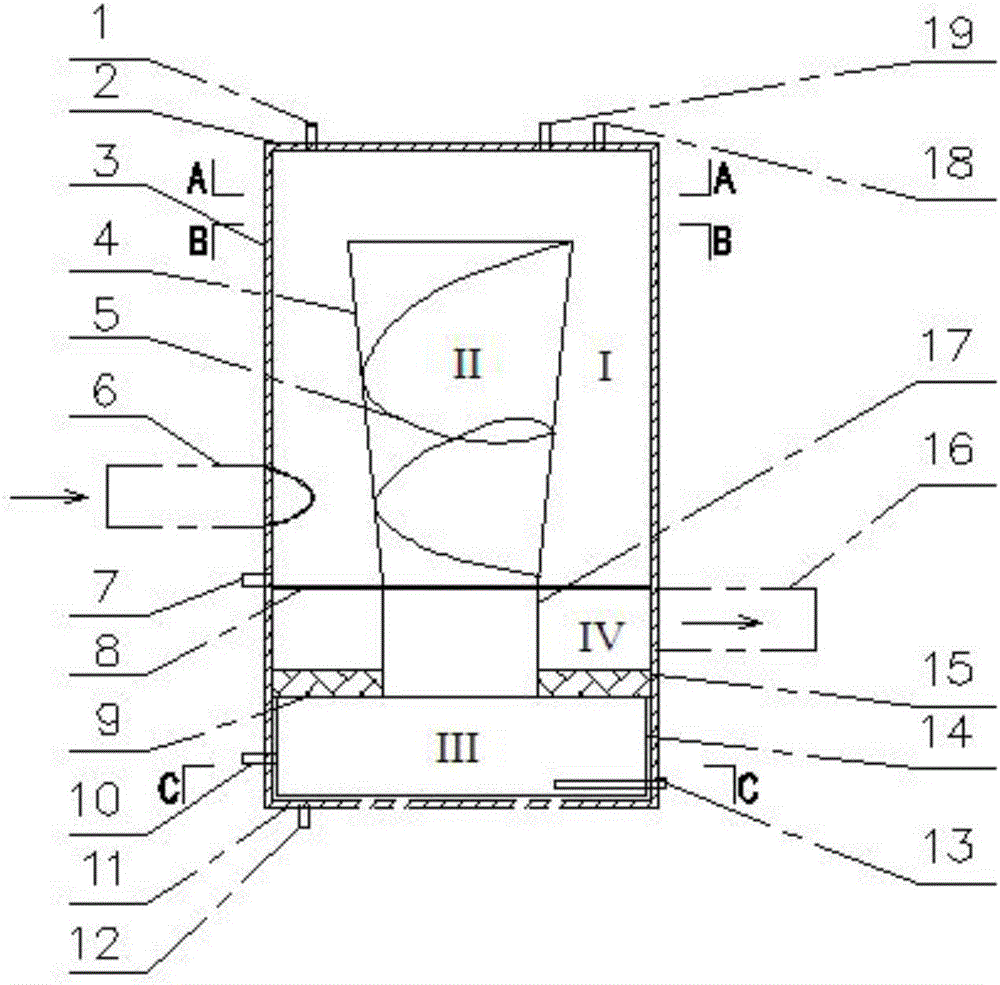

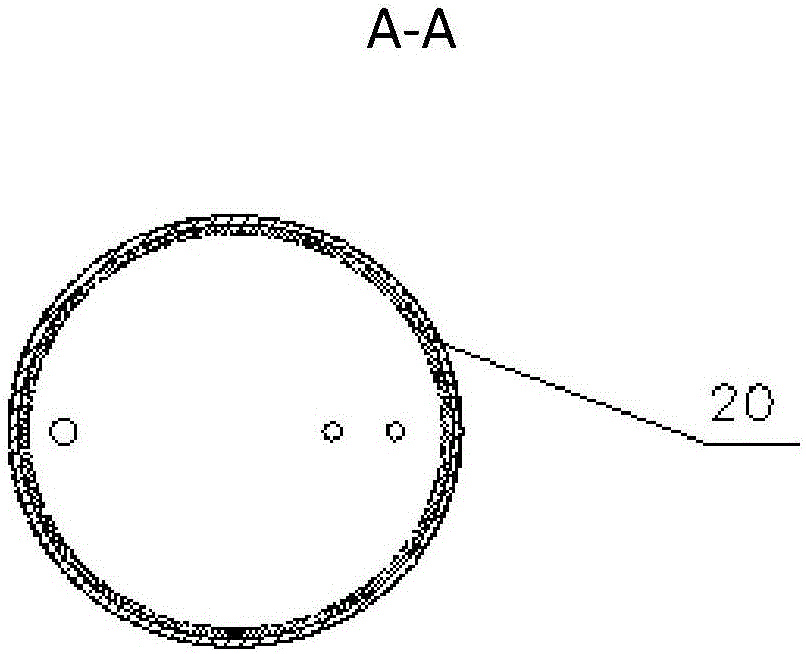

Oil separator

The invention relates to an oil separator. The oil separator comprises an outer barrel, a baffle arranged in the outer barrel and a filter screen layer. An inner circular truncated cone cavity is formed in the position, above the baffle, in the outer barrel. A first area chamber is formed between the inner circular truncated cone cavity and the outer barrel. A second area chamber communicating with the first area chamber is formed by the inner circular truncated cone cavity. A third area chamber is formed below the filter screen layer. An inner barrel enabling the second area chamber to communicate with the third area chamber is arranged between the baffle and the filter screen layer. A fourth area chamber is formed between the inner barrel and the outer barrel. The third area chamber communicates with the fourth area chamber through the filter screen layer. An air inlet is located in the first area chamber, and an exhaust opening is located in the fourth area chamber. According to the oil separator, dual-travel cyclone centrifugal separation and filter screen filtering separation are set, the four chambers are formed, the air flow direction is changed many times, the number of paths separated by the oil separator is increased, and the separation effect is enhanced; and the exhaust opening is formed in the lower middle portion of the oil separator, and therefore the distance of an exhaust pipe is shortened, exhaust resistance and vibration are reduced, and the energy efficiency of a unit can be improved easily.

Owner:TRANE AIR CONDITIONING SYST (CHINA) CO LTD

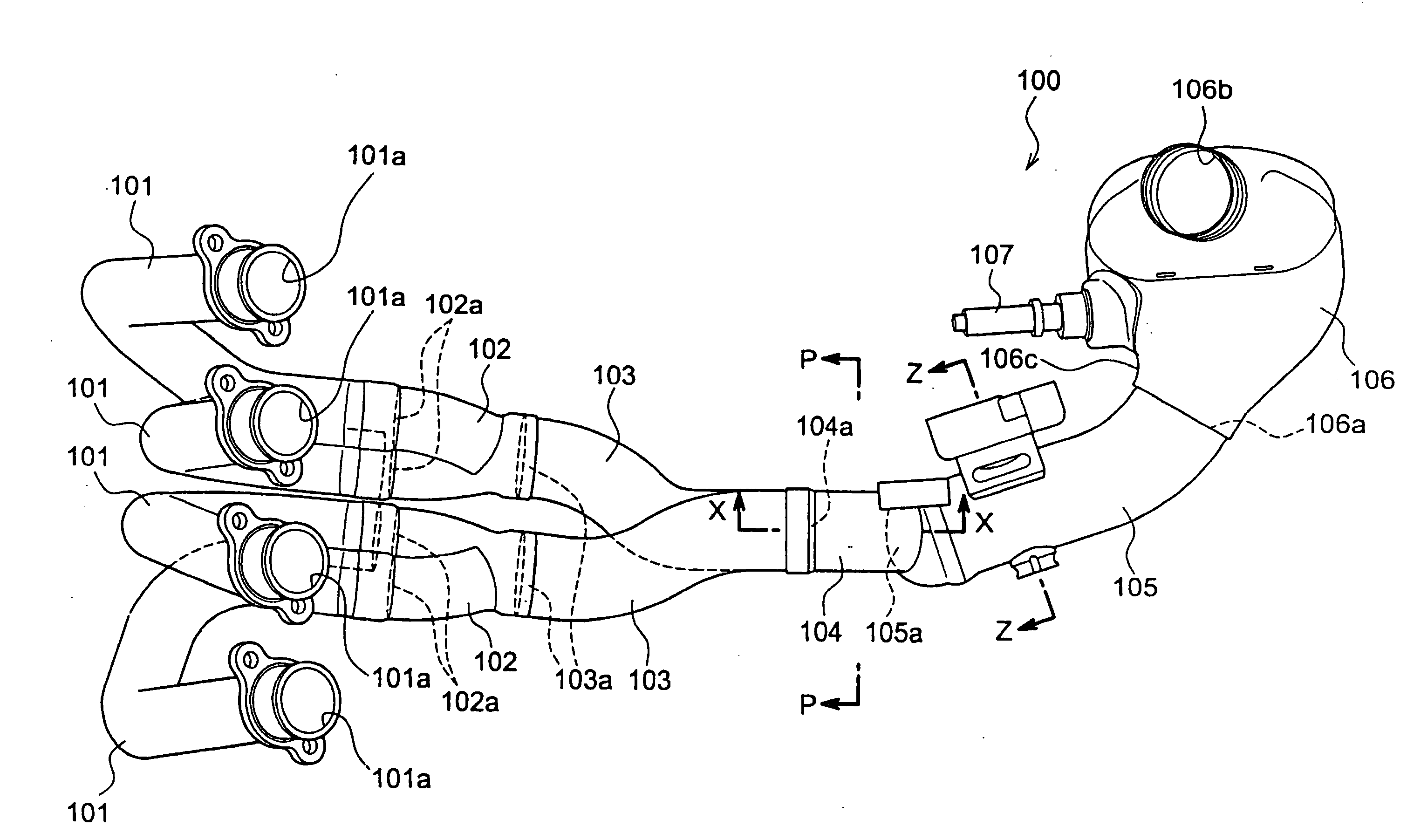

Exhaust device for motorcycle

ActiveUS20080053066A1Suppress exhaust resistanceSuppression resistanceCombustion enginesSilencing apparatusEngineeringControl valves

To provide an exhaust device for a motorcycle for suppressing an exhaust resistance due to the thickness of an exhaust control valve. An exhaust device for a motorcycle is provided for an engine having a plurality of cylinders. A plurality of upstream exhaust pipes are respectively connected to exhaust ports for the cylinders with an exhaust control valve provided in the downstream exhaust pipe. A separator is provided in the exhaust manifold portion for separating the flows of exhaust gas. The exhaust control valve is located on the downstream side of the separator so that a main surface of the exhaust control valve in its fully open condition becomes substantially parallel to a main surface of the separator.

Owner:HONDA MOTOR CO LTD

Environment-friendly exhaust manifold automatic welding equipment and work method thereof

InactiveCN109332934AAutomatically change working statusHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringManipulator

The invention provides environment-friendly exhaust manifold automatic welding equipment and a work method thereof. The automatic welding equipment comprises an equipment rack, single-segment weldingworktables, a welding carrying detection mechanical arm, a flange sliding way, a combined welding worktable, a polishing device and a welding fume treatment device; the single-segment welding worktables can move and turn over abut-joint welding lines left and right, a clamping jaw can rotate a welding part during welding, a clamping welding device of the welding carrying detection mechanical arm has welding, carrying and detection functions, the combined welding worktable enables all segments of manifolds to be combined and in abut joint, after an exhaust main pipe is welded, the polishing program can be automatically started, and the welding fume treatment device is arranged on the top of the equipment, and can be automatically moved to the position above the welding part to extract welding fume. The welding treatment device is arranged, the welding fume generated by welding can be automatically collected and treated and then exhausted, harmful gas in a welding workshop can be effectively reduced, and the equipment can quite meet the modern environment-friendly production needs.

Owner:李春洪

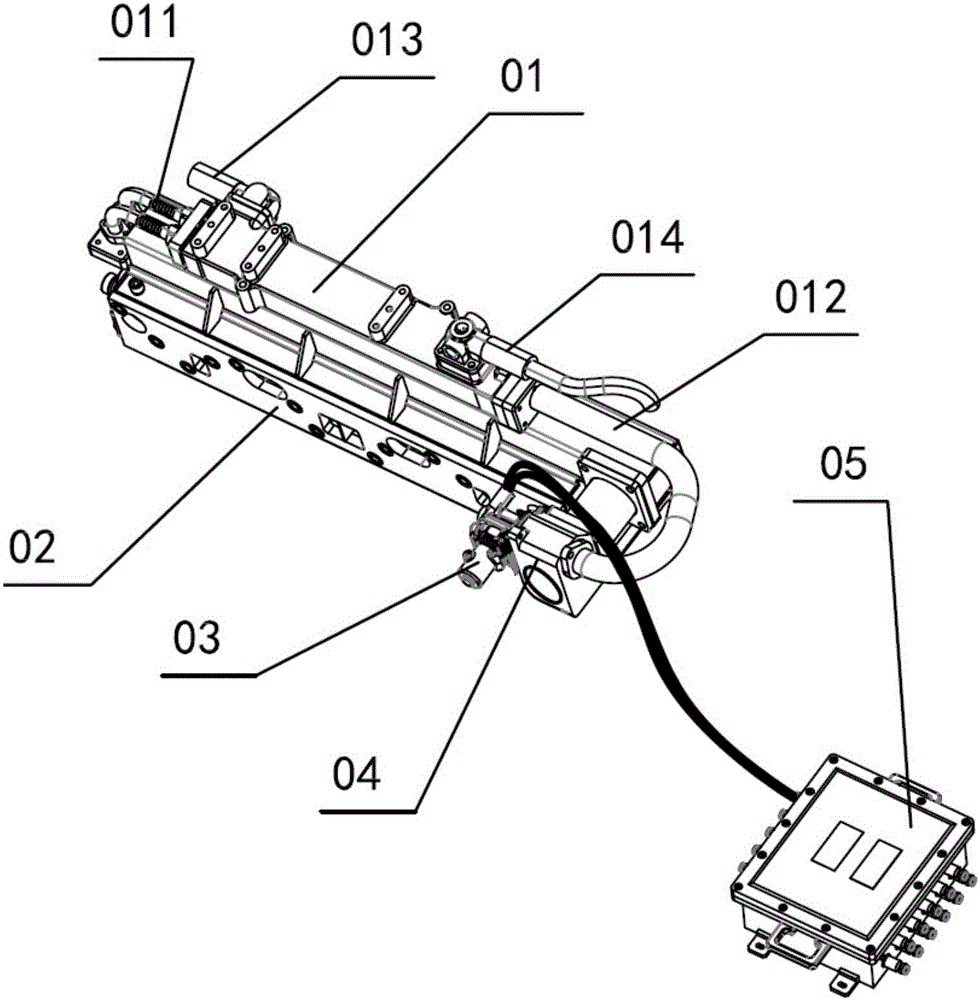

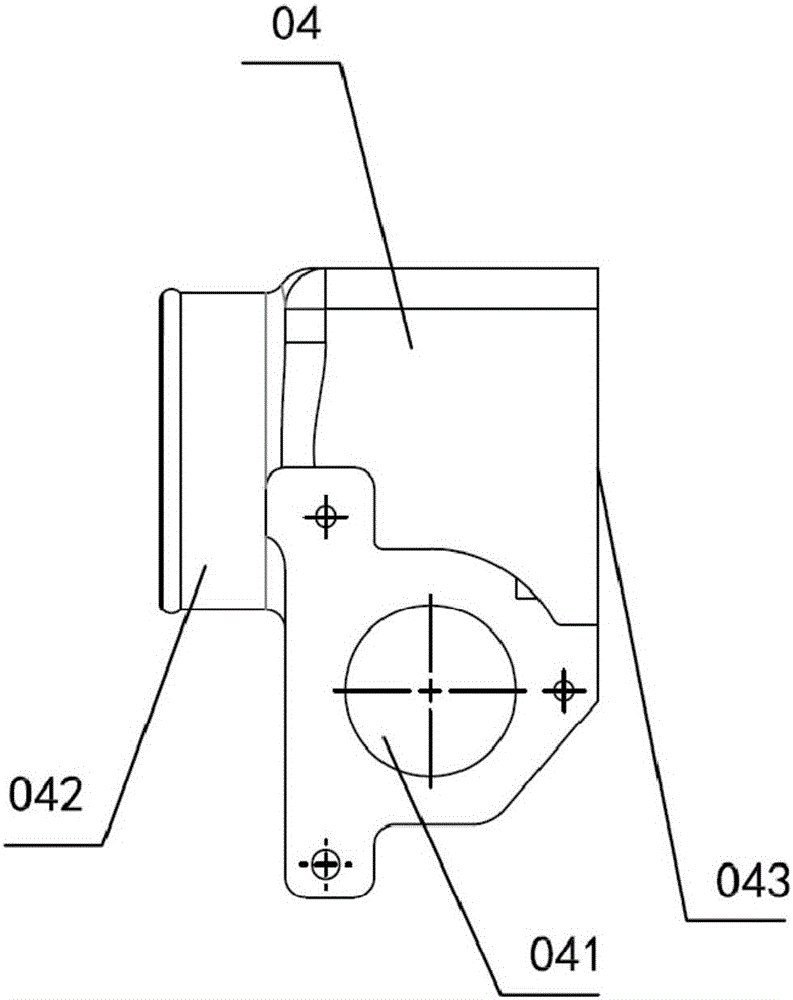

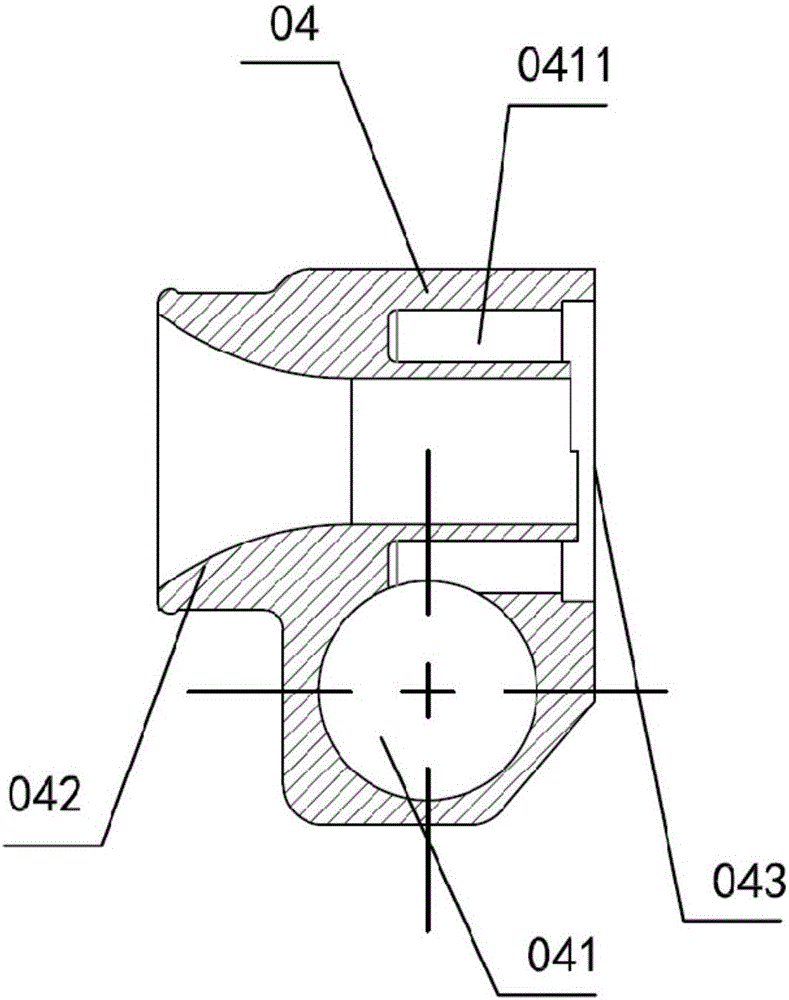

Explosion-proof electrically controlled EGR system for mine

ActiveCN105156235AEmission reductionGood explosion-proofNon-fuel substance addition to fuelInternal combustion piston enginesElectrical controlEngineering

The invention relates to an explosion-proof electrically controlled EGR system for a mine. The EGR system comprises an EGR cooler, an intake and exhaust manifold, an EGR mixing device and an explosion-proof EGR valve, wherein an EGR intake pipe and an EGR exhaust pipe are arranged at the two ends of the EGR cooler respectively; the EGR intake pipe is connected with an exhaust port of the intake and exhaust manifold; the EGR cooler is provided with a water inlet and a water outlet; a waste gas intake port of the EGR mixing device is connected with the EGR exhaust pipe; a mixing gas outlet port of the EGR mixing device is connected with a gas intake port of the intake and exhaust manifold; an explosion-proof EGR valve is connected with the EGR mixing device; the EGR valve is connected with an EGR control unit by a harness; the opening and closing of the explosion-proof EGR valve is controlled by an ECU to control the flow amount of the EGR waste gas; and the EGR control unit is arranged in an explosion-proof electrical control device. The EGR system has good explosion-proof effects, so that the EGR system can be used under the mine, and the exhaust of NOx of an explosion-proof diesel engine can be effectively reduced.

Owner:成都天地直方发动机有限公司 +2

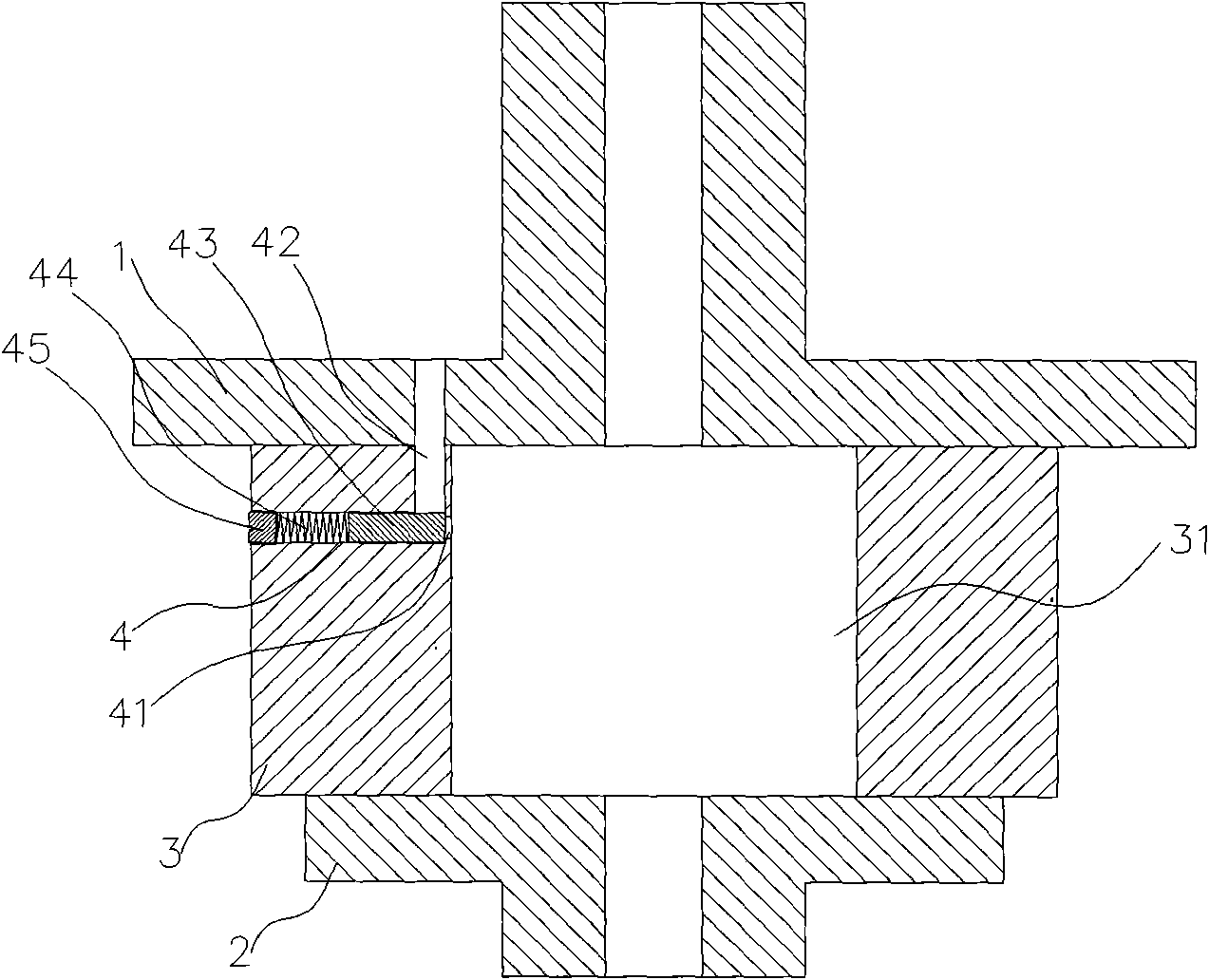

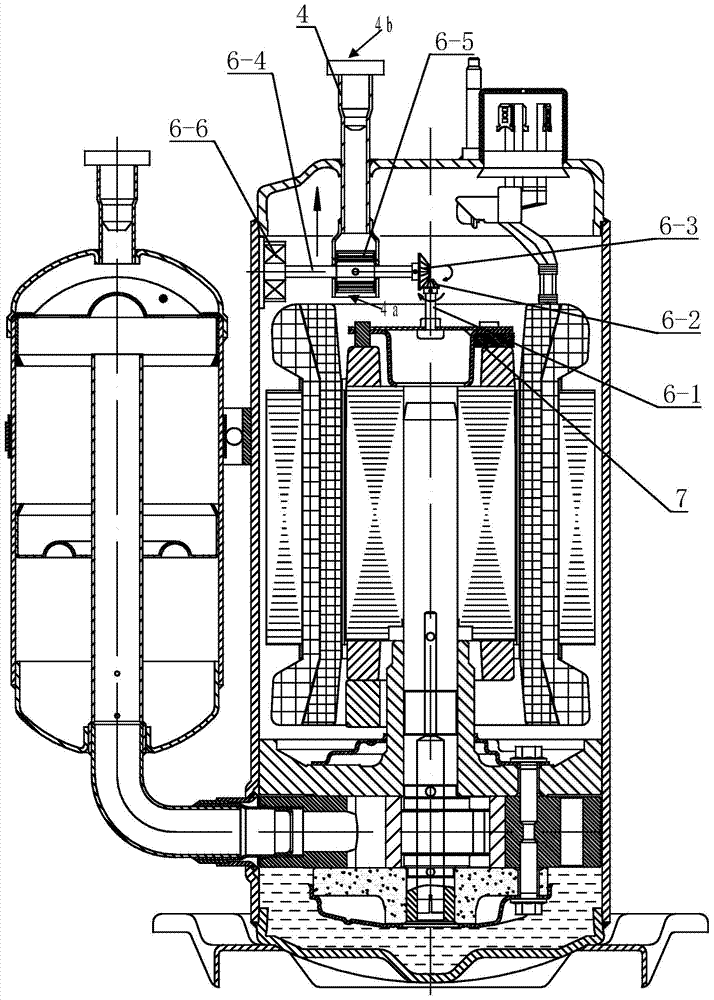

Upper flange of compressor and compressor comprising upper flange

InactiveCN105927543AReduce power consumptionReduce exhaust resistanceRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringRefrigerant

The invention discloses an upper flange of a compressor and the compressor comprising the upper flange and belongs to the technical field of compressors. The upper flange of the compressor and the compressor comprising the upper flange are designed to solve the problem that the exhaust resistance of an existing device is large. The upper flange of the compressor comprises a valve body. Two exhaust ports are formed in the valve body. One exhaust port is located in the stop position of an exhaust cavity of a compressing cavity, and the other exhaust port is located in the initial position of the exhaust cavity of the compressing cavity, or located between the initial position and the stop position. The two exhaust ports are covered with a valve block. The valve block is installed on the valve body through a valve block baffle. The compressor comprises an air cylinder and a lower flange and further comprises the upper flange of the compressor. By the adoption of the upper flange of the compressor and the compressor comprising the upper flange, compressed gas can be exhausted in advance, the exhaust resistance is reduced, over-compression of refrigerants is avoided, the power consumption of the compressor is reduced, and the energy efficiency is improved.

Owner:ZHUHAI LANDA COMPRESSOR +1

Exhaust manifold automatic welding device and working method thereof

InactiveCN109332932AAutomatically change working statusHigh degree of automationEdge grinding machinesPolishing machinesManipulatorFlange

The invention provides an exhaust manifold automatic welding device and a working method thereof. The exhaust manifold automatic welding device comprises an equipment frame, a single-segment welding workbench, a welding and carrying inspection mechanical arm, a flange slideway, a combined welding worktable and a polishing device; the single-segment welding workbench can move a butt weld left and right and overturn the butt weld, an arranged clamping jaw can rotate a welding piece during welding, a clamping and welding device of the welding and carrying inspection mechanical arm has the functions of welding, carrying and detecting, the flange slideway can automatically slide down a flange and a manifold head segment butt weld, the combined welding worktable can combine and joint all manifold segments together, and a polishing process can be automatically started after welding of an exhaust manifold. By means of the exhaust manifold automatic welding device and the working method, a segment welding working mode is adopted, the head segment flange and a curved segment pipe are respectively welded, and then overall welding of the butt weld is carried out in the combined worktable; andfluid abrasive particles are used for polishing the inner surface of the pipe, the mechanical arm conducts weld detection after welding is completed, and the exhaust manifold automatic welding deviceand the working method are very suitable for meeting the exhaust manifold welding process requirement.

Owner:李春洪

Muffler for small-sized vehicle

ActiveUS8701824B2Improve engine performanceReduce exhaust resistanceExhaust apparatusSilencing apparatusEngineeringExpansion chamber

Owner:HONDA MOTOR CO LTD

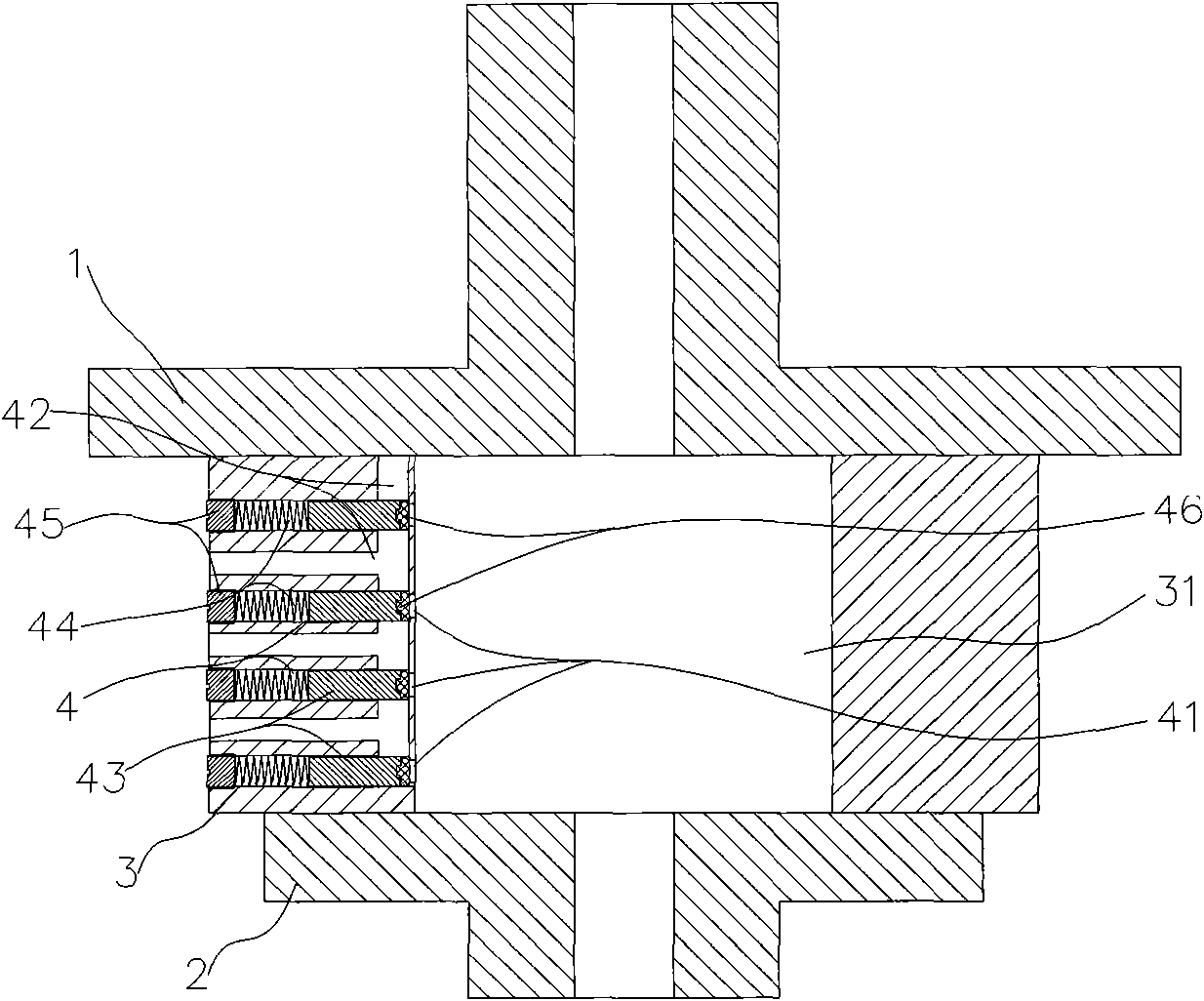

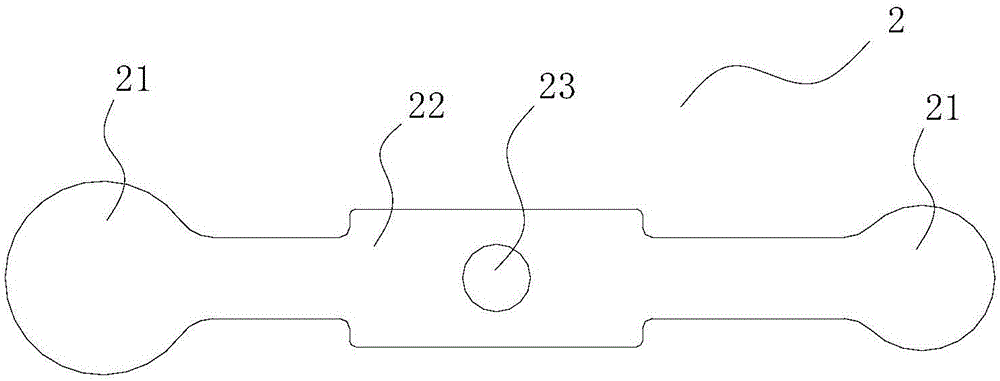

Rotary type compressor capable of being turbocharged

ActiveCN103486047AIncrease exhaust pressureReduce exhaust resistanceRotary/oscillating piston pump componentsLiquid fuel engine componentsCompression PumpStator

The invention provides a rotary type compressor capable of being turbocharged. The rotary type compressor comprises a closed shell, a gas-liquid separator, an exhausting pipe and a turbocharging mechanism, wherein the closed shell is internally provided with a motor assembly and a compression pump body assembly; the gas-liquid separator is communicated with a compression pump body by an air inlet elbow; the exhausting pipe is arranged at the upper end of the closed shell; the motor assembly comprises a stator and a rotor; a rotary shaft of the compressor is driven by the rotor; the compression pump body assembly comprises an upper flange, an air cylinder, a lower flange and a roller, which are mounted along the rotary shaft of the compressor in sequence; the turbocharging mechanism comprises a first transmission rod, a first transmission gear, a second transmission rod, a second transmission gear and a turbine fan blade; the first transmission rod and the rotor rotate synchronously; the first transmission gear is arranged on the first transmission rod; the second transmission rod is arranged in the closed shell by a bearing assembly; the second transmission gear and the turbine fan blade are arranged on the second transmission rod; the turbine fan blade is arranged at the air inlet end of the exhausting pipe; the first transmission gear and the second transmission gear are engaged with each other; the first transmission rod and the second transmission rod are arranged orthogonally. According to the rotary type compressor capable of being turbocharged, the flowing speed of a cold medium in circulating unit time is increased, the exhausting resistance is reduced and the performance of the compressor is improved.

Owner:ZHUHAI LANDA COMPRESSOR

New automatic welding equipment for exhaust manifold and working method of new automatic welding equipment

InactiveCN109332933AAutomatically change working statusHigh degree of automationPolishing machinesWelding/cutting auxillary devicesManipulatorSingle section

The invention provides new automatic welding equipment for an exhaust manifold and a working method of the new automatic welding equipment. The new automatic welding equipment comprises equipment racks, single-section welding worktables, a multifunctional manipulator, a flange slideway, a combined welding worktable and a polishing device; the single-section welding worktables can move butt weld leftwards and rightwards and overturn the butt weld, a weldment can be rotated through arranged clamping claws during welding, all sections of manifolds can be combined and butted together through the combined welding worktable, and after an exhaust main pipe is welded, polishing can be automatically conducted; and the multifunctional manipulator is provided with an automatic clamping structure, andworking heads can be automatically replaced and clamped through the automatic clamping mechanism. According to the new automatic welding equipment for the exhaust manifold and the working method of the new automatic welding equipment, segmented welding is conducted first, then overall welding is conducted, polishing is conducted after welding, the working heads of the equipment can be automatically replaced, thus the functions of welding, carrying, detecting and stress removing are achieved, and the new automatic welding equipment is quite suitable for welding of the exhaust manifold.

Owner:李春洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com