Dual-rotor rotary compressor

A rotary compressor and double-rotor technology, applied to rotary piston/swing piston pump components, elastic fluid rotary piston/swing piston pump combinations, mechanical equipment, etc., can solve the problem of affecting the compressor Life, reduce compressor performance, increase exhaust resistance and other issues, to achieve the effect of reducing refrigerant leakage, improving refrigeration capacity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

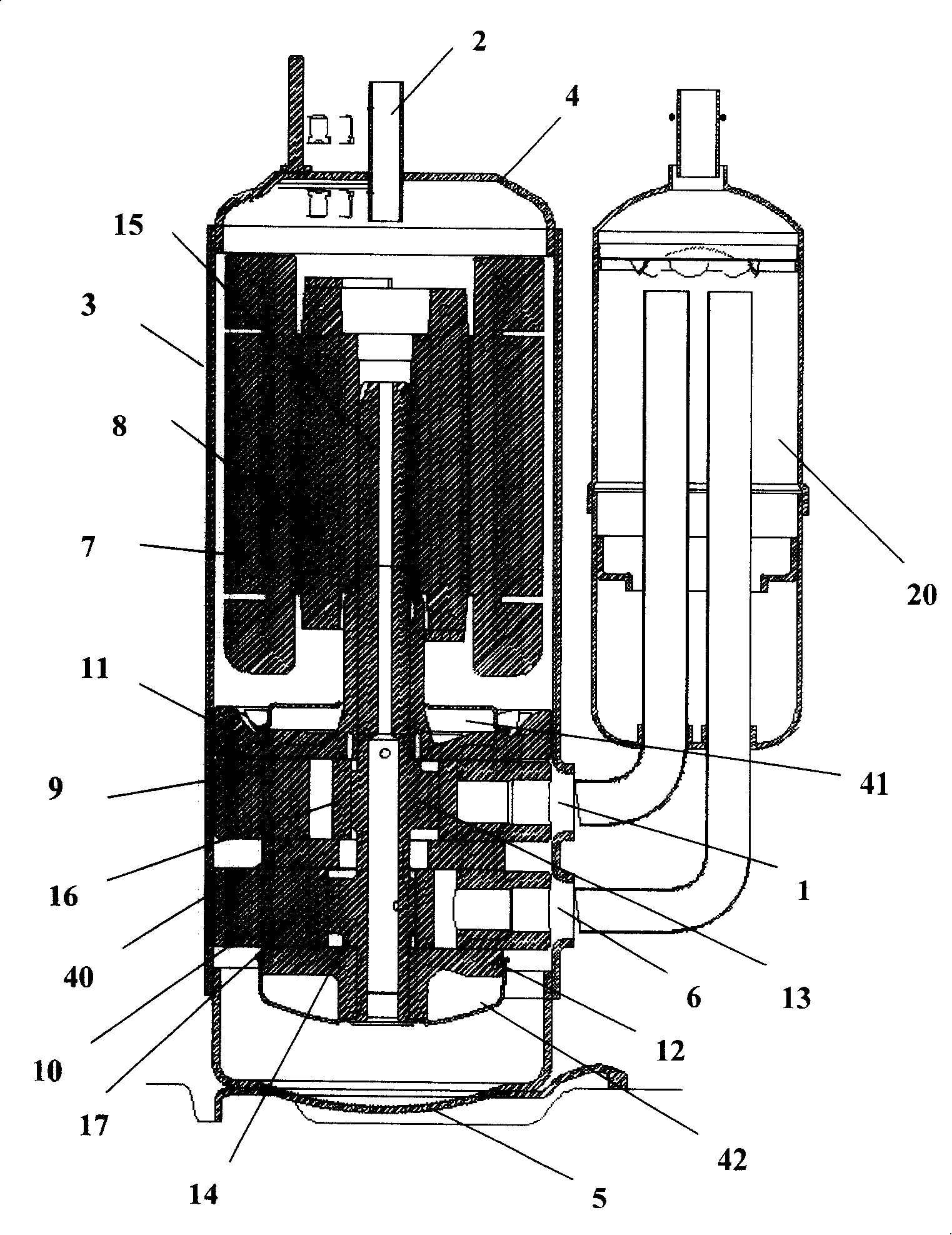

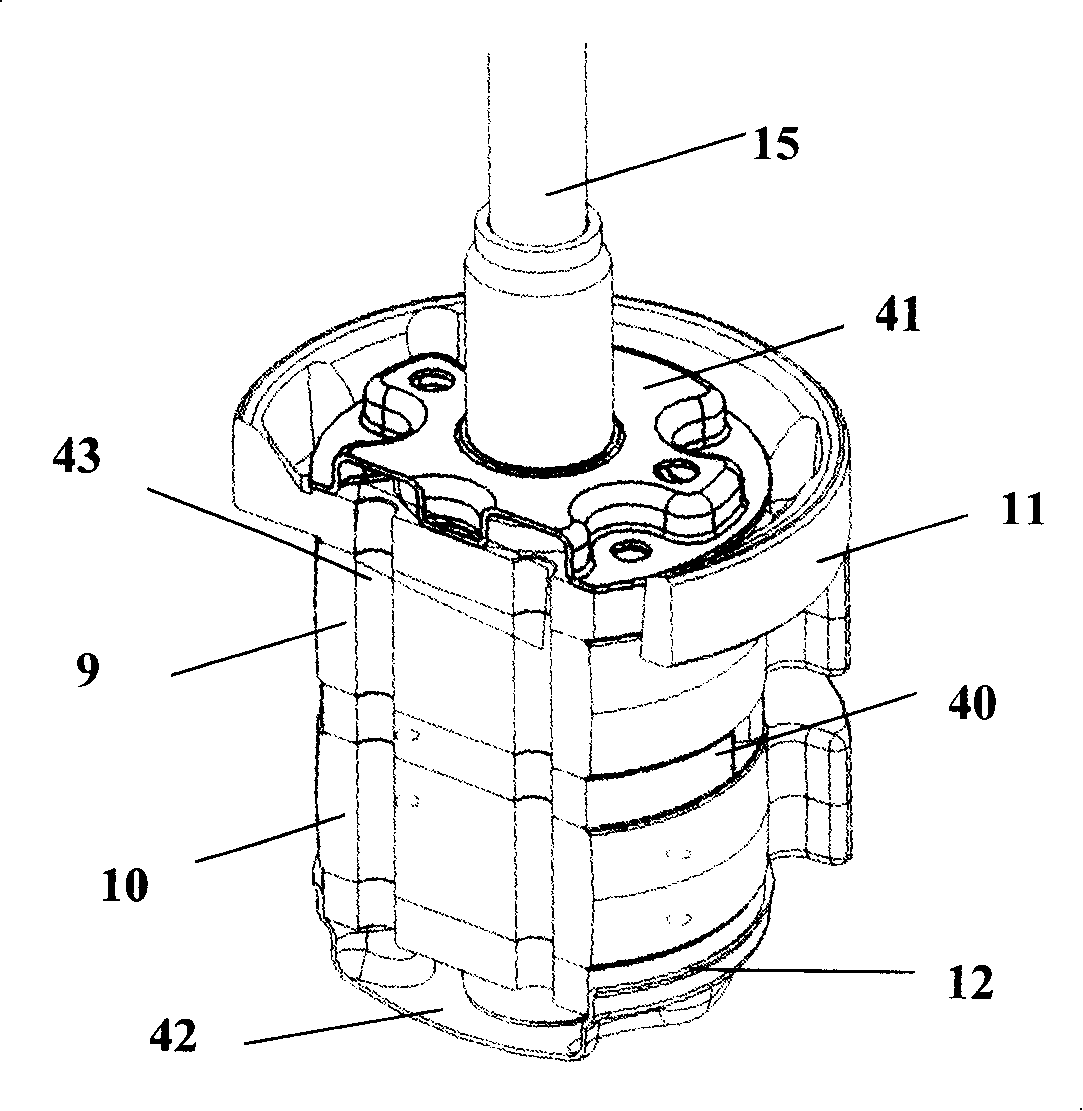

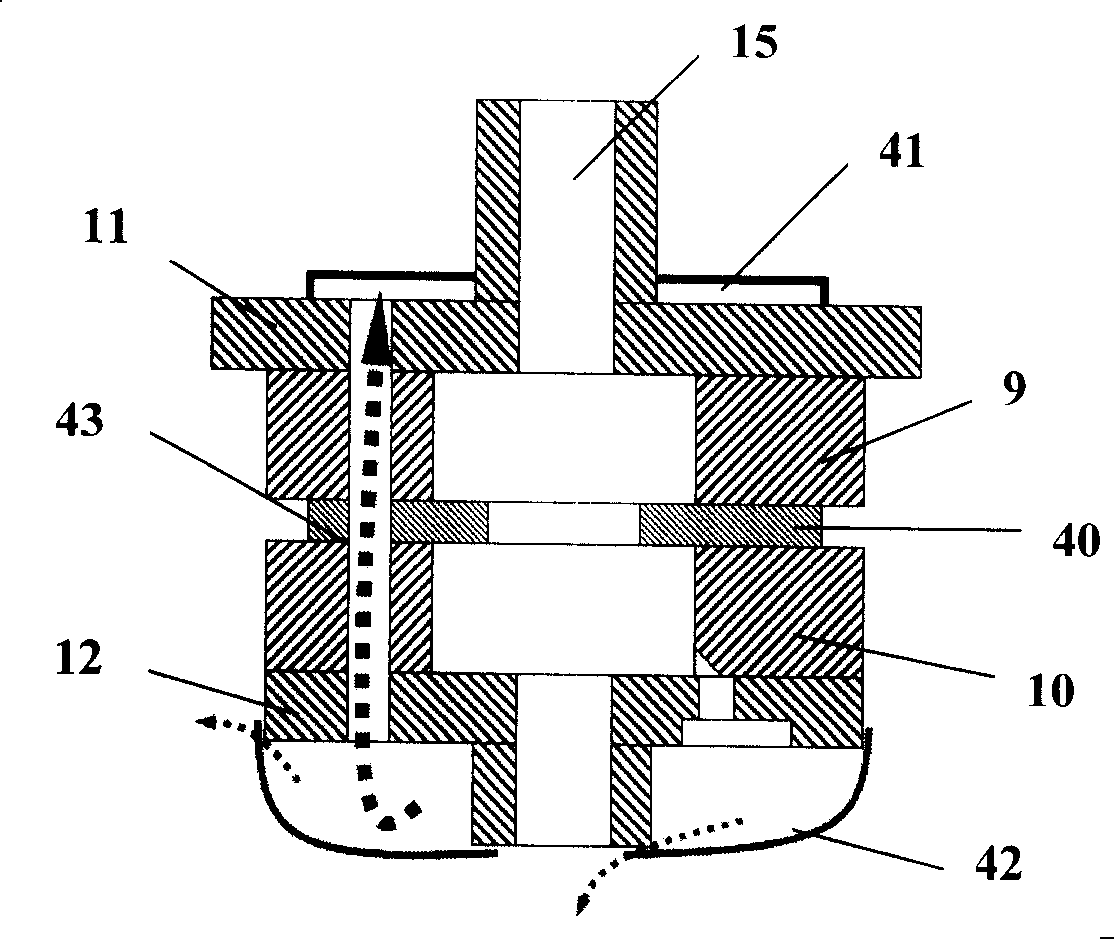

[0016] like Figure 4 ~ Figure 7 and figure 1As shown, the double-rotor rotary compressor provided by the present invention includes an airtight container, an electric mechanical part and a compression mechanical part; wherein the airtight container is provided with two refrigerant input pipes connected to the refrigerant inlet pipeline on the liquid storage tank 20 on one side. 1, 6, and a cylindrical shell 3 filled with lubricating oil at the bottom, an upper cover 4 and a lower cover 5 with a refrigerant discharge port 2 in the center; the electromechanical part located on the upper part of the airtight container is mainly fixed on the cylinder The stator 7 on the inner wall of the shaped housing 3 and the rotor 8 which is located at the center of the stator 7 and can rotate through the electromagnetic interaction with the stator 7; The cylinder refrigerant inlet of the cylinder is connected with the refrigerant input port 1 on the shell 3, and the upper cylinder 9 with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com