Exhaust device of rotary compressor

A rotary compressor and exhaust device technology, applied in the field of refrigeration compressors, can solve the problems of small number of exhaust devices, large exhaust resistance, large clearance volume of exhaust devices, etc., to reduce clearance volume and improve efficiency , to avoid the effect of mechanical noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

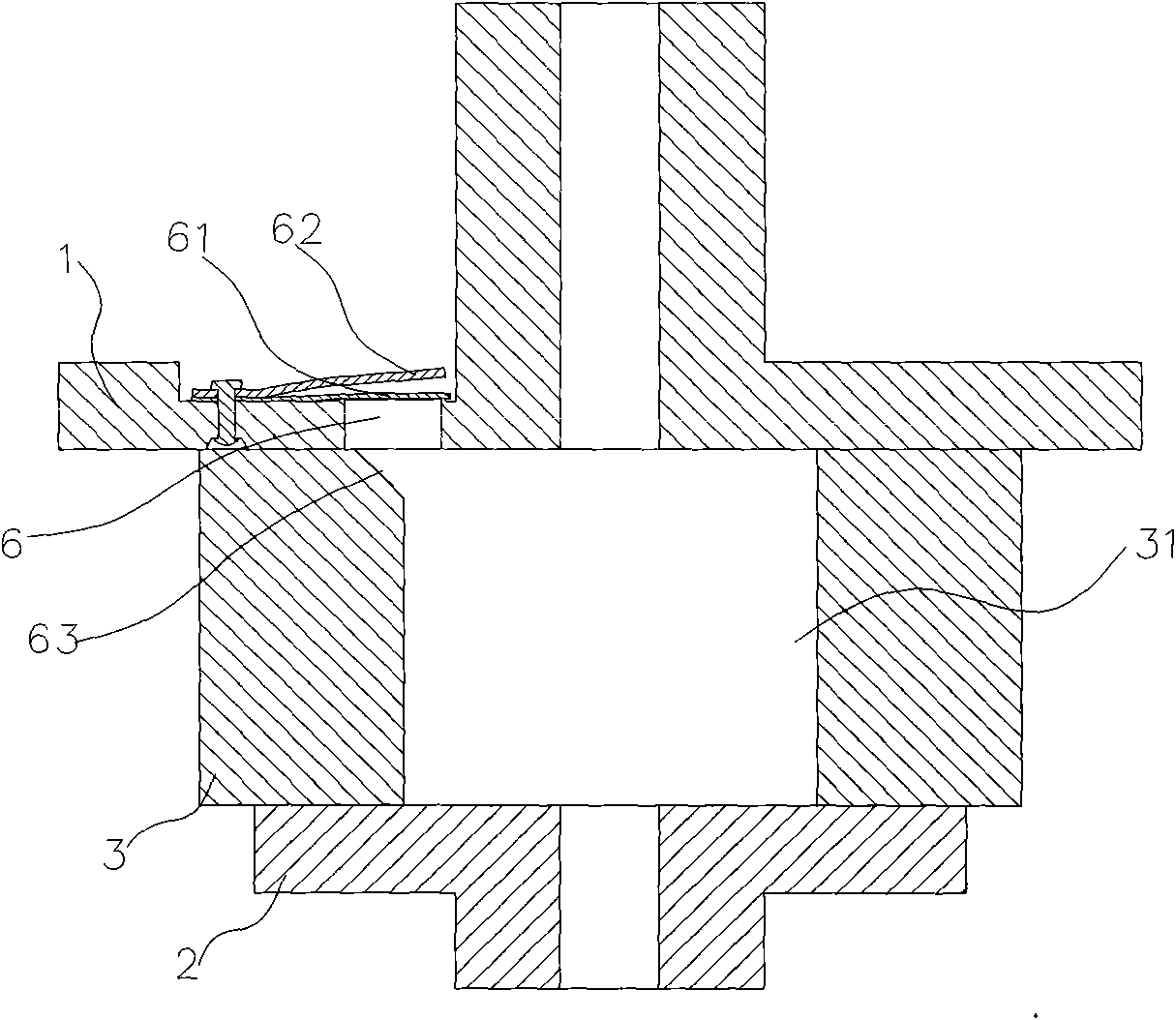

Embodiment 1

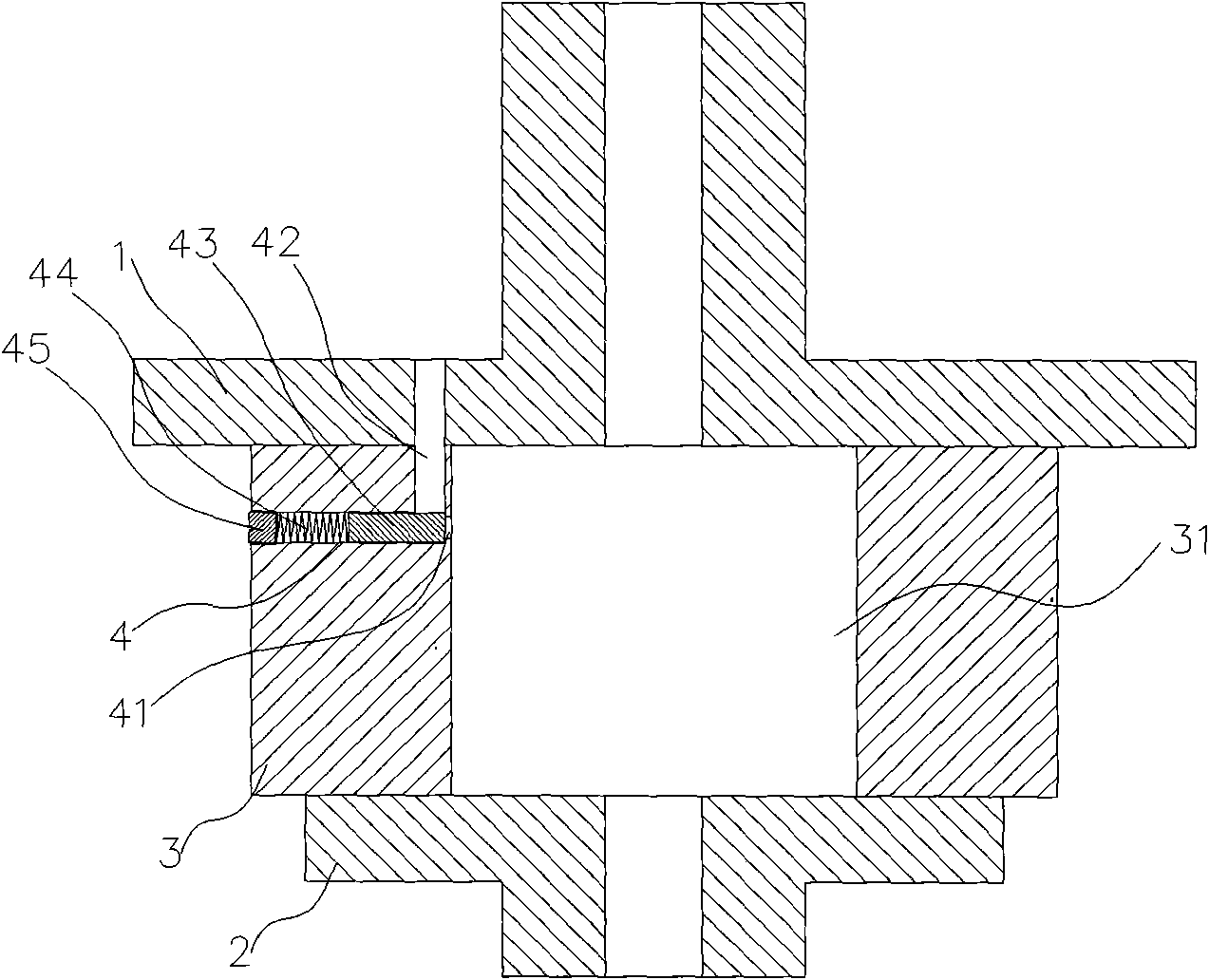

[0019] A rotary compressor exhaust device such as figure 2 As shown, the upper flange 1 and the lower flange 2 of the rotary compressor are arranged at both ends of the cylinder 3 to enclose a sealed cylinder cavity 31. At the exhaust position, a horizontal half-open piston is arranged on the cylinder wall of the cylinder 3. Channel 4, the opening of the piston channel 4 is located at the outer end of the cylinder 3, the bottom is adjacent to the cylinder cavity 31, and the bottom is provided with an exhaust port 41 connected to the cylinder cavity 31, and an upper flange 1 is arranged axially on the cylinder wall The flow path is connected to the bottom of the piston passage 4, thus forming the exhaust passage 42 of the exhaust device; a piston 43 is slidably arranged in the piston passage 4, and a thrust spring 44 is arranged at the outer end of the piston 43, and the thrust spring 44 Outer end is provided with supporting device 45, and supporting device 45 is a blockage be...

Embodiment 2

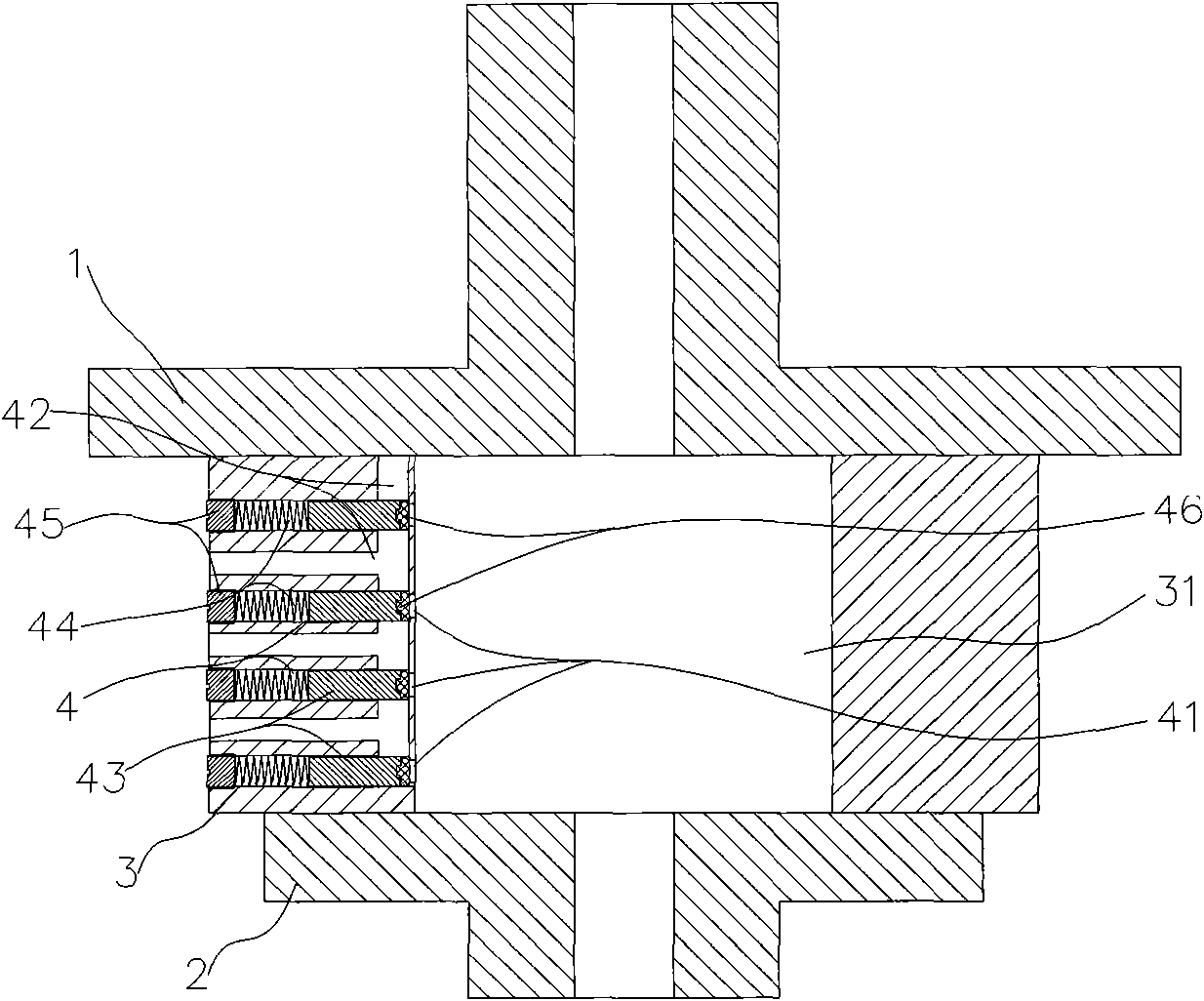

[0021] A rotary compressor exhaust device such as image 3 As shown, the upper flange 1 and the lower flange 2 of the rotary compressor are arranged at both ends of the cylinder 3 to enclose a sealed cylinder cavity 31. At the exhaust position, four transverse semi-open pistons are arranged on the cylinder wall of the cylinder 3. Channel 4, the opening of the piston channel 4 is located at the outer end of the cylinder 3, the bottom is adjacent to the cylinder cavity 31, the bottom is provided with an exhaust port 41 connected to the cylinder cavity 31, and a cylinder wall is axially provided with a hole extending through each piston. The flow channel at the bottom of the channel 4, the cylinder 3 is horizontally provided with a flow channel connecting the flow channel and the outside of the cylinder chamber 31, and the axial flow channel and the lateral flow channel form the exhaust channel 42 of the exhaust device; each piston channel 4 A piston 43 is slidingly arranged in t...

Embodiment 3

[0023] A rotary compressor exhaust device such as Figure 4 As shown, the upper flange 1 and the lower flange 2 of the rotary compressor are arranged at both ends of the cylinder 3 to enclose a sealed cylinder cavity 31. At the exhaust position, four transverse semi-open pistons are arranged on the cylinder wall of the cylinder 3. Channel 4, the opening of the piston channel 4 is at the outer end of the cylinder 3, the bottom is adjacent to the cylinder chamber 31, the bottom is provided with an exhaust port 41 connected to the cylinder chamber 31, and a cylinder wall is axially provided with a channel connecting each piston. 4 and runs through the upper flange 1 and the lower flange 2 flow passages, through which the upper flange 1 and lower flange 2 are connected to the flow passages outside the cylinder chamber 31 to form an exhaust passage 42; each piston passage 4 is slidingly set A piston 43, the outer end of the piston 43 is provided with a thrust spring 44, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com