Patents

Literature

47results about How to "Guaranteed exhaust effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic packaging mold

ActiveCN105729722ASlow down the flowReduce the chance of air bubblesCoatingsPlastic packagingSemiconductor

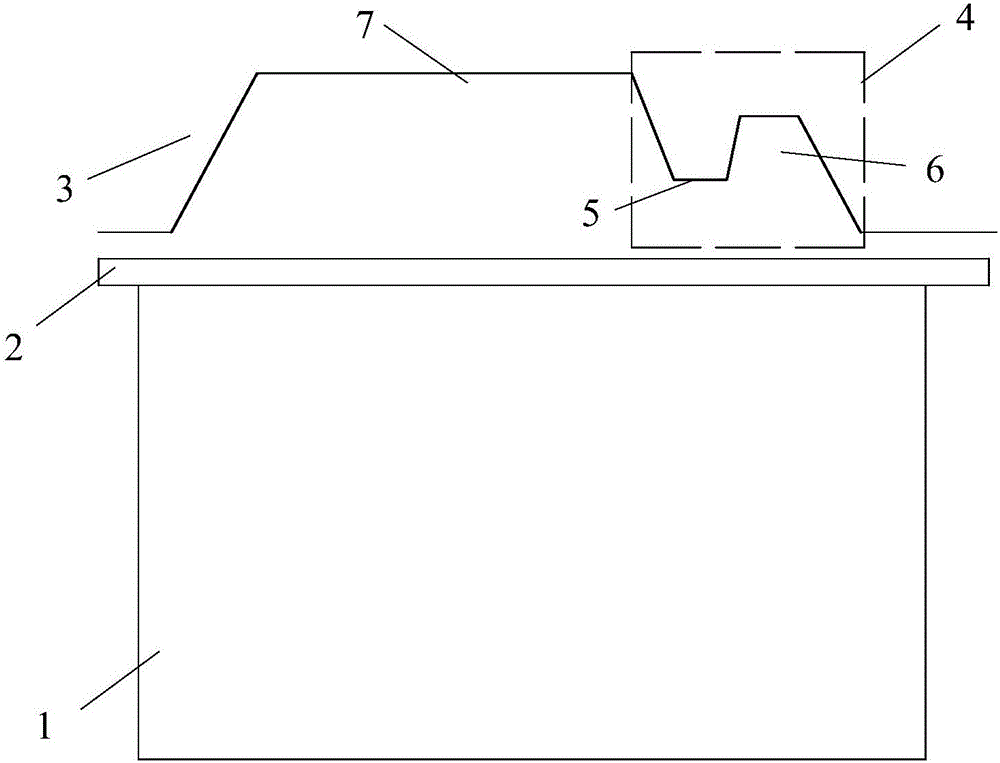

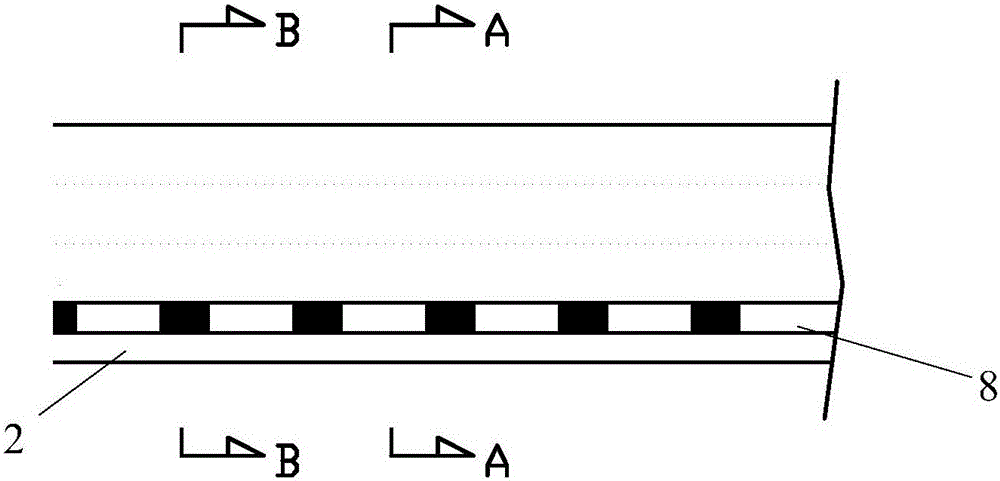

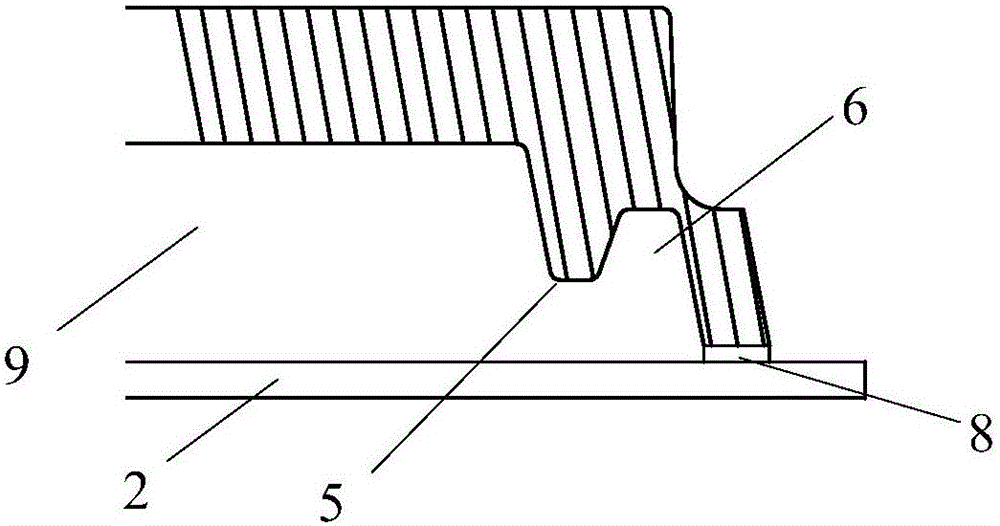

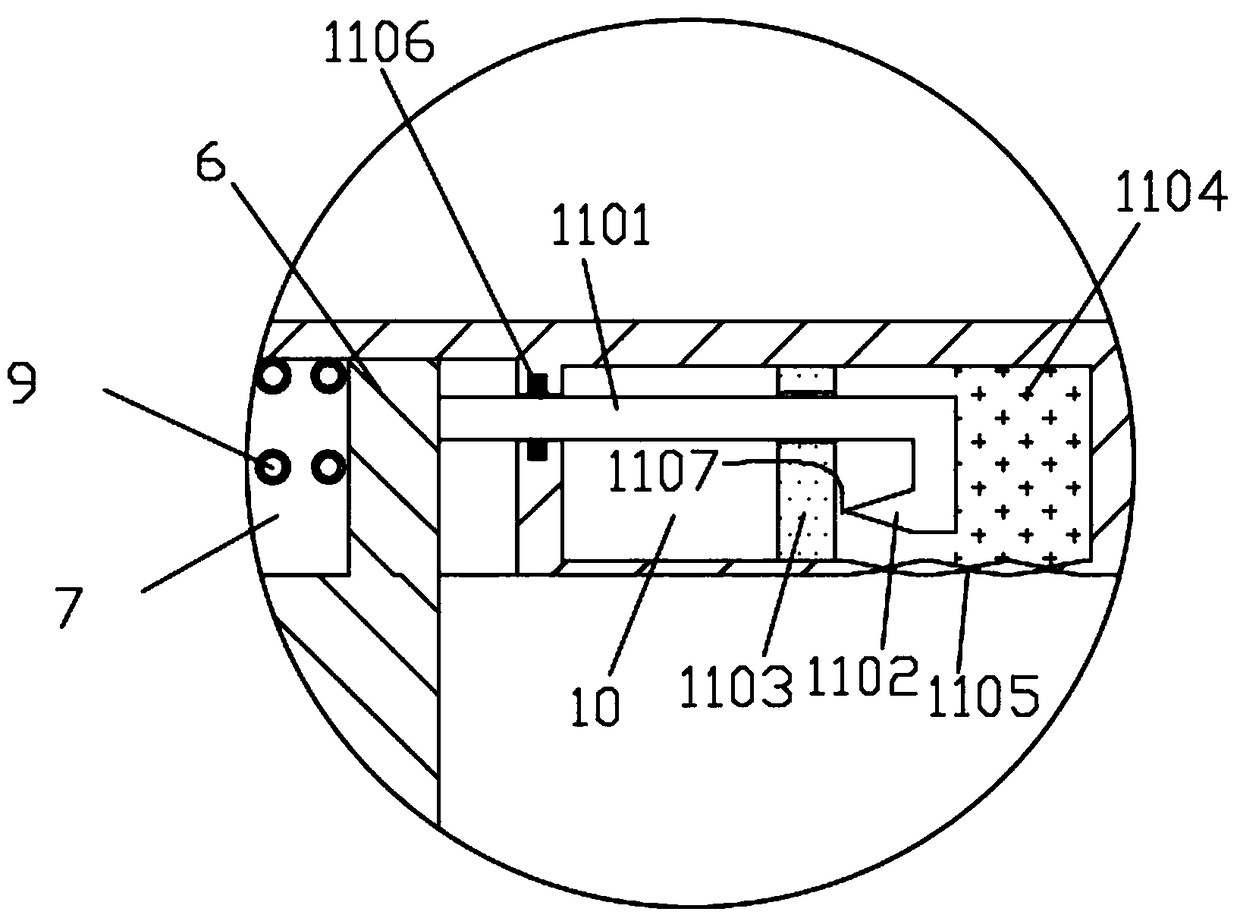

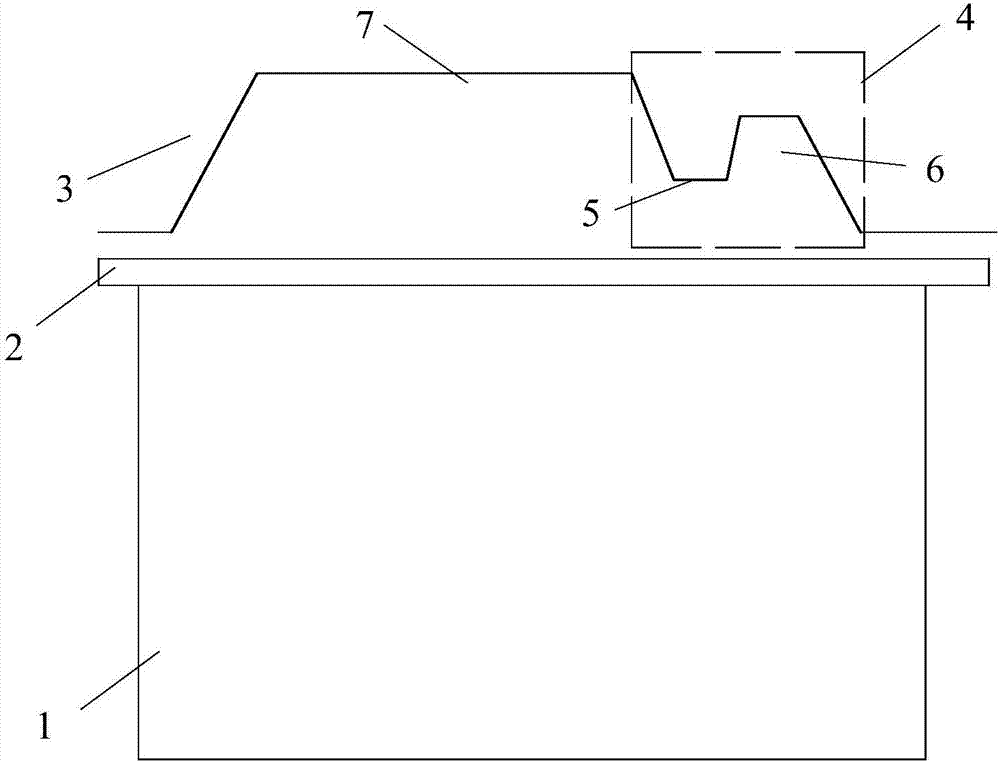

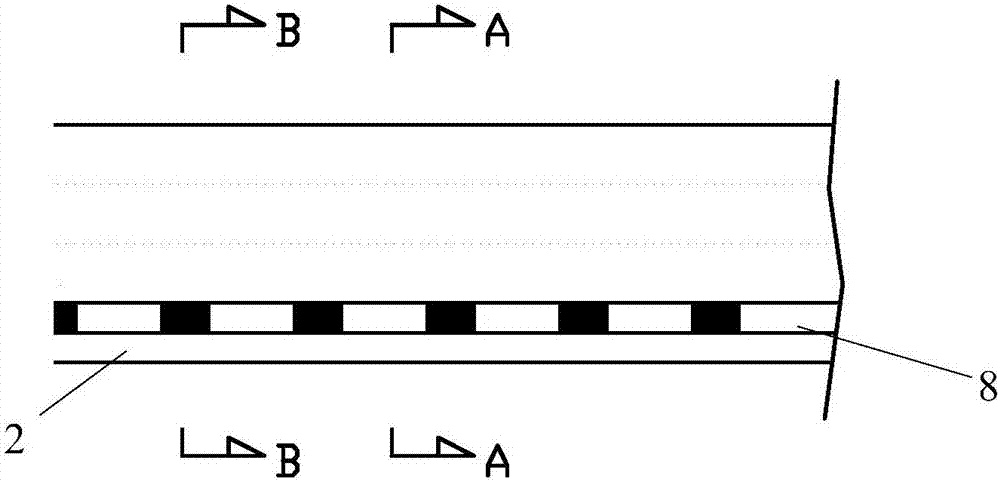

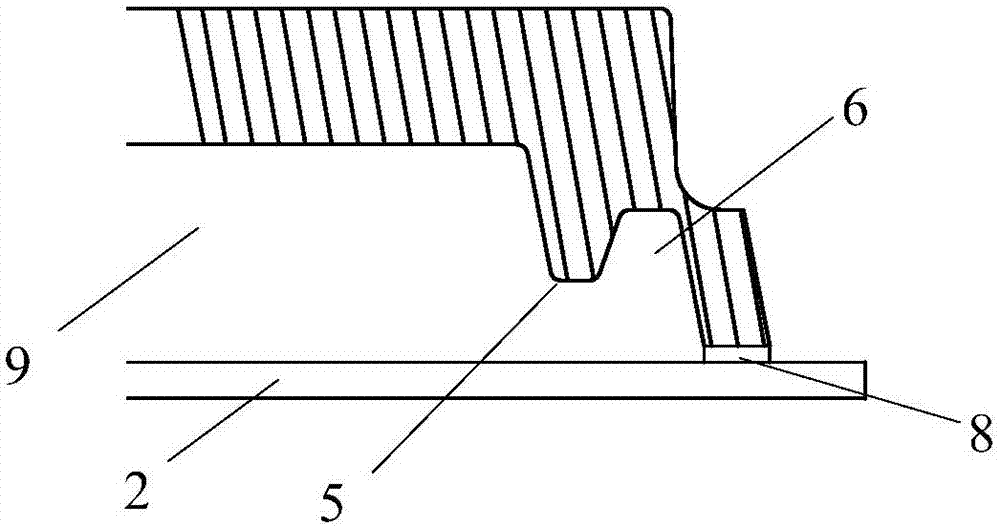

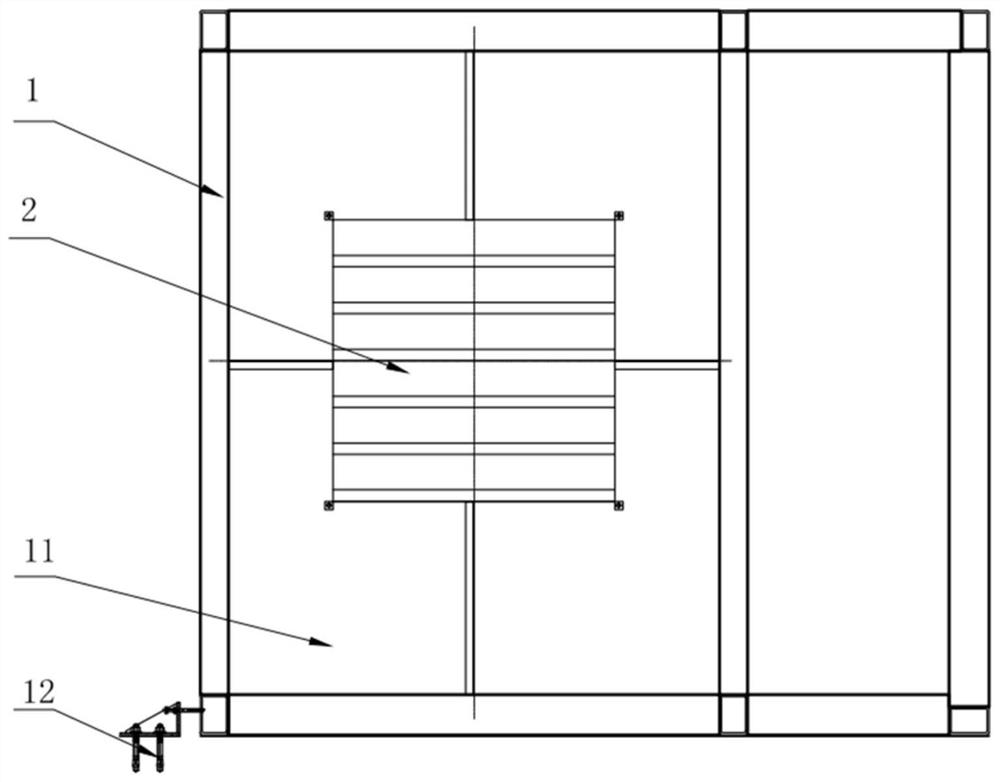

The invention discloses a plastic packaging mold and relates to the field of plastic packaging of semiconductors. The plastic packaging mold comprises an upper mold body and a lower mold body used for containing a PCB. The lower surface of the upper mold body is sunken towards the upper surface of the upper mold body to form a groove. When the upper mold body and the lower mold body are pressed and combined, a molding cavity is formed between the groove and the PCB. One end of the molding cavity communicates with an air discharge duct. The end, close to the air discharge duct, of the groove is provided with a buffer area used for balancing molding flow. The molding flow in the molding cavity is balanced through the buffer area. The discharge time of the air in the molding cavity is prolonged, and the product quality is improved.

Owner:HUANWEI ELECTRONICS SHANGHAI CO LTD

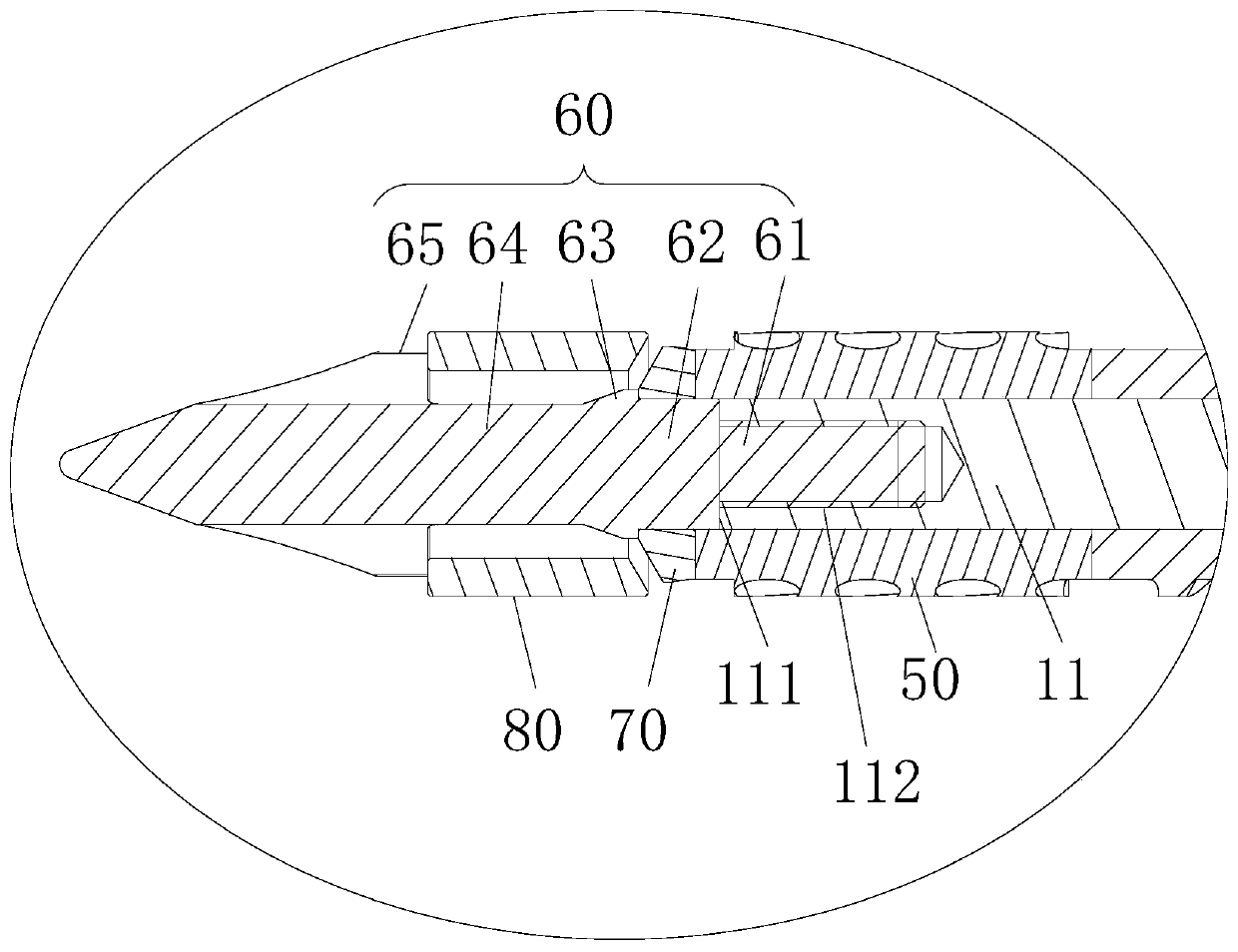

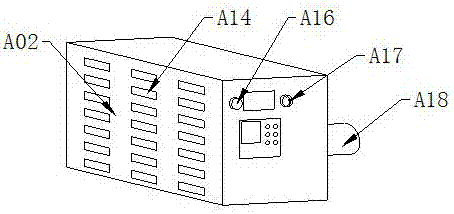

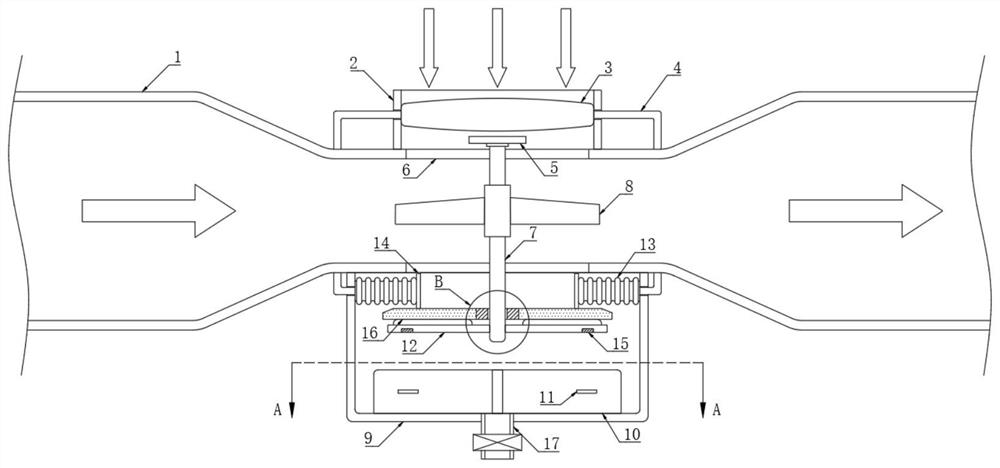

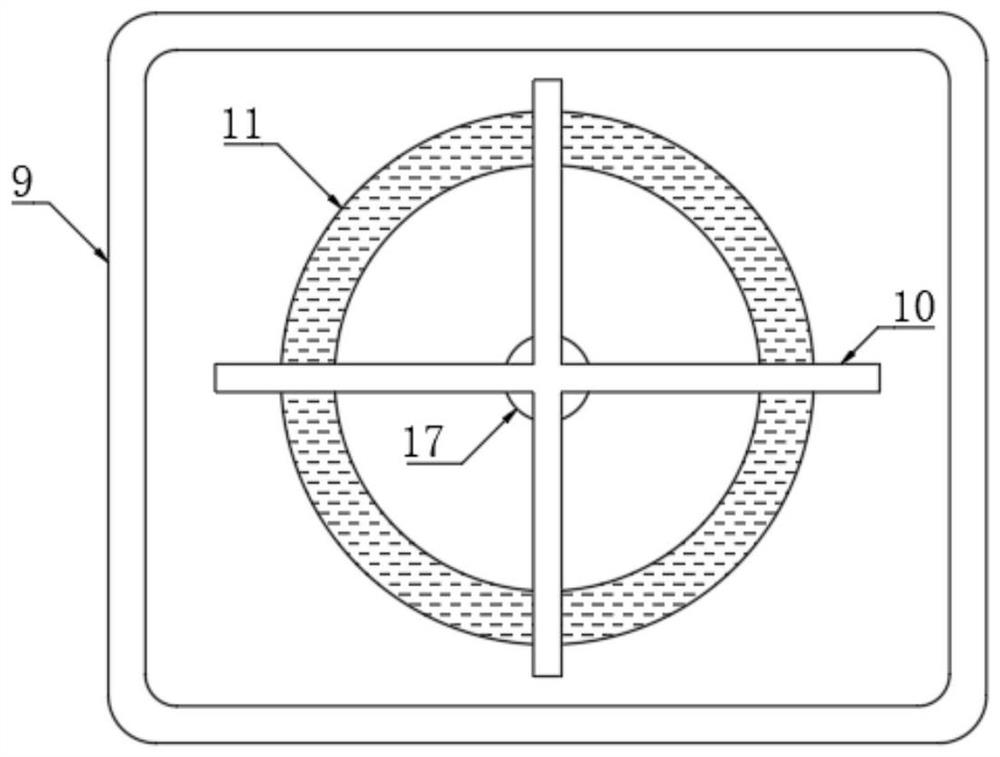

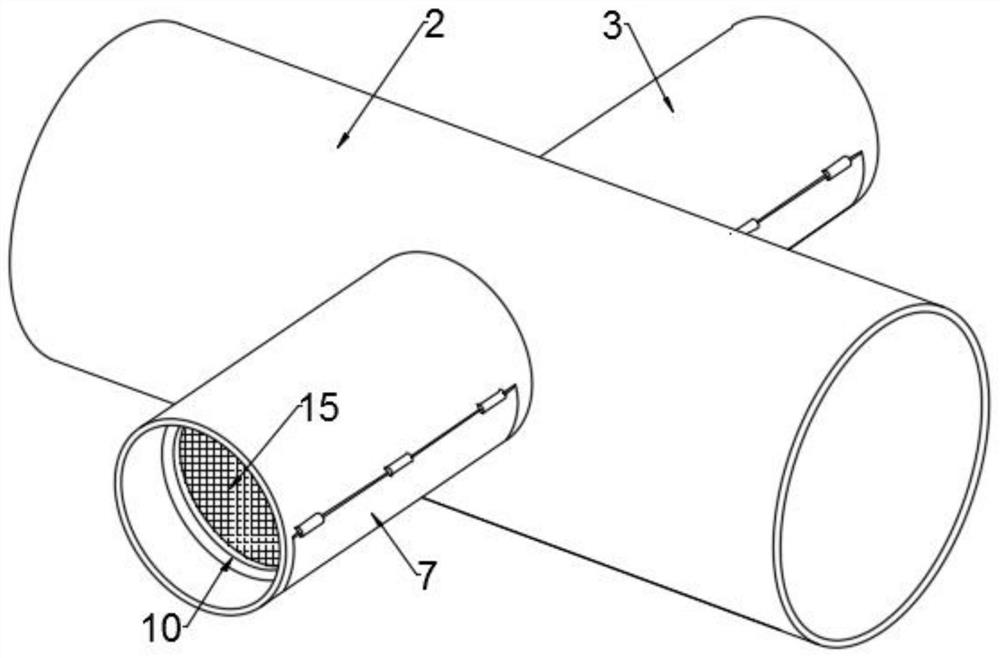

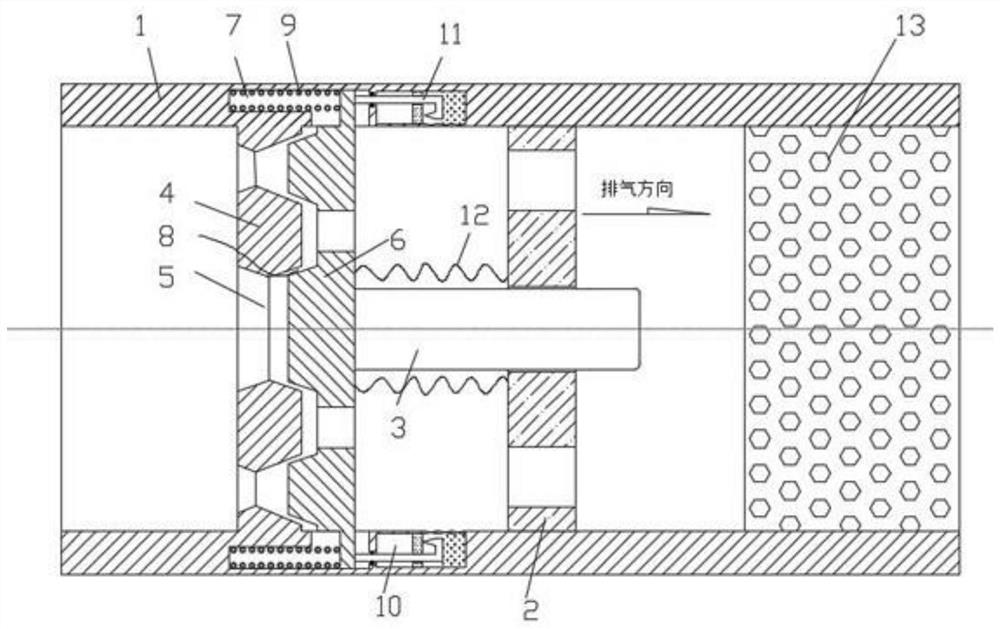

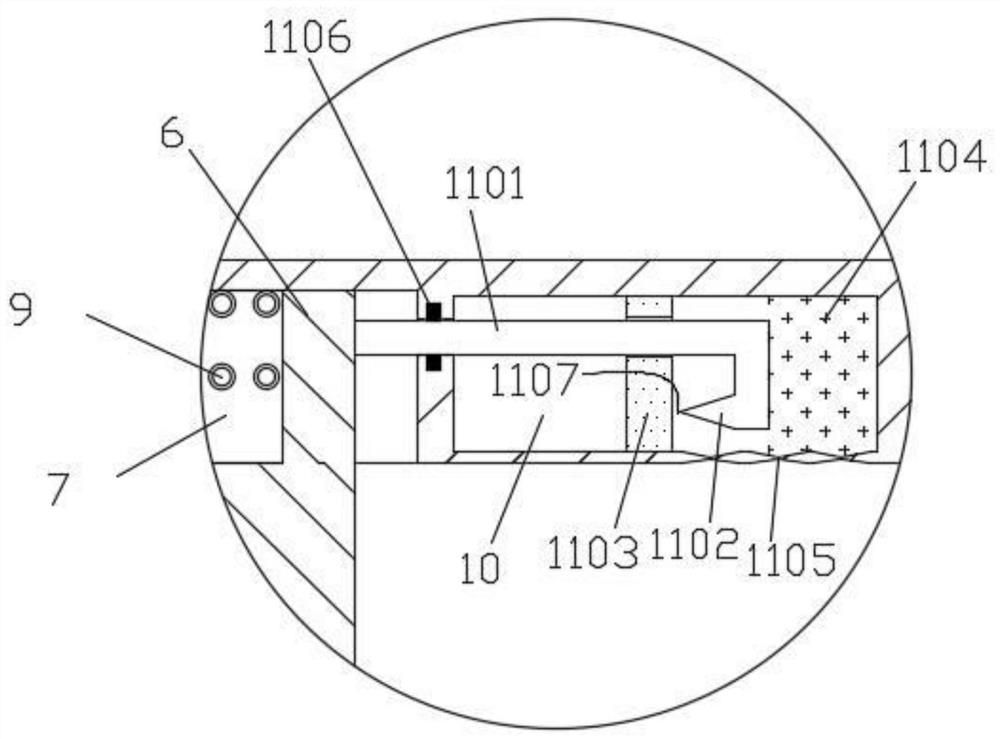

Automatic water-preventing device for automobile exhaust pipe

ActiveCN109372621AGood water release effectGuaranteed exhaust effectExhaust apparatusSilencing apparatusPiston ringExhaust pipe

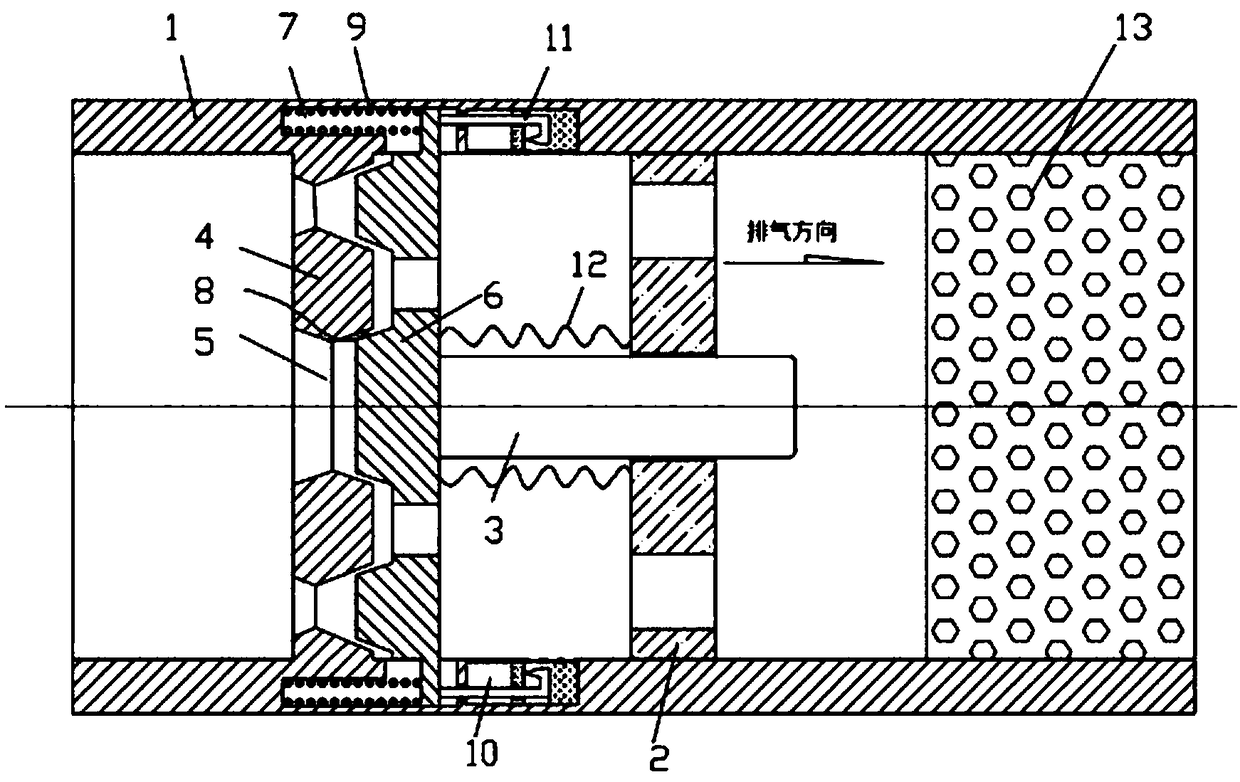

The invention provides an automatic water-preventing device for an automobile exhaust pipe. The device comprises a connecting pipe, a silencing plug, a tail end exhaust plate, a sliding rod, a slidingpiston, a front end exhaust plate, a front end exhaust hole, and a sealing piston; the silencing plug is arranged in the connecting pipe, the tail end exhaust plate is arranged in the connecting pipeand provided with a plurality of tail end exhaust holes, the sliding rod is inserted into the tail end exhaust plate, the sliding piston is fixedly connected with the sliding rod, the front end exhaust plate is arranged in the connecting pipe, the front end exhaust hole is formed in the front end exhaust plate, and the sealing piston is arranged on the sliding rod; a piston ring cavity used for containing the sealing piston is arranged in the connecting pipe, the piston ring cavity is internally provided with a lateral spring which acts on the sealing piston so as to enable the sealing pistonto be in clearance with the front end exhaust hole; and a sealing ring cavity is formed in the connecting pipe, and a rapid sealing mechanism is arranged in the piston ring cavity. According to the device, the water-preventing effect is good, the exhaust effect is ensured, and the abnormal sounds are avoided.

Owner:HANGZHOU POLYTECHNIC

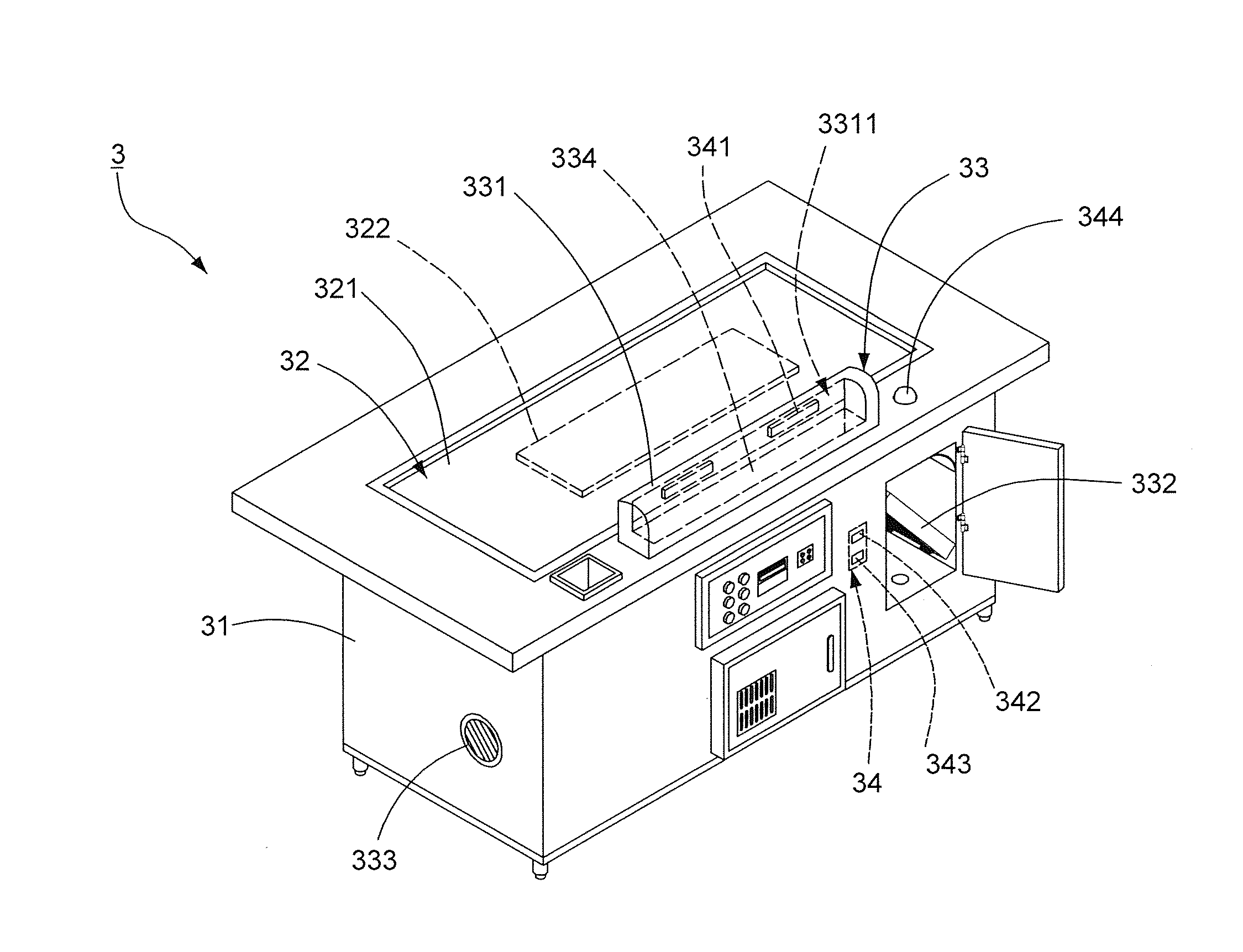

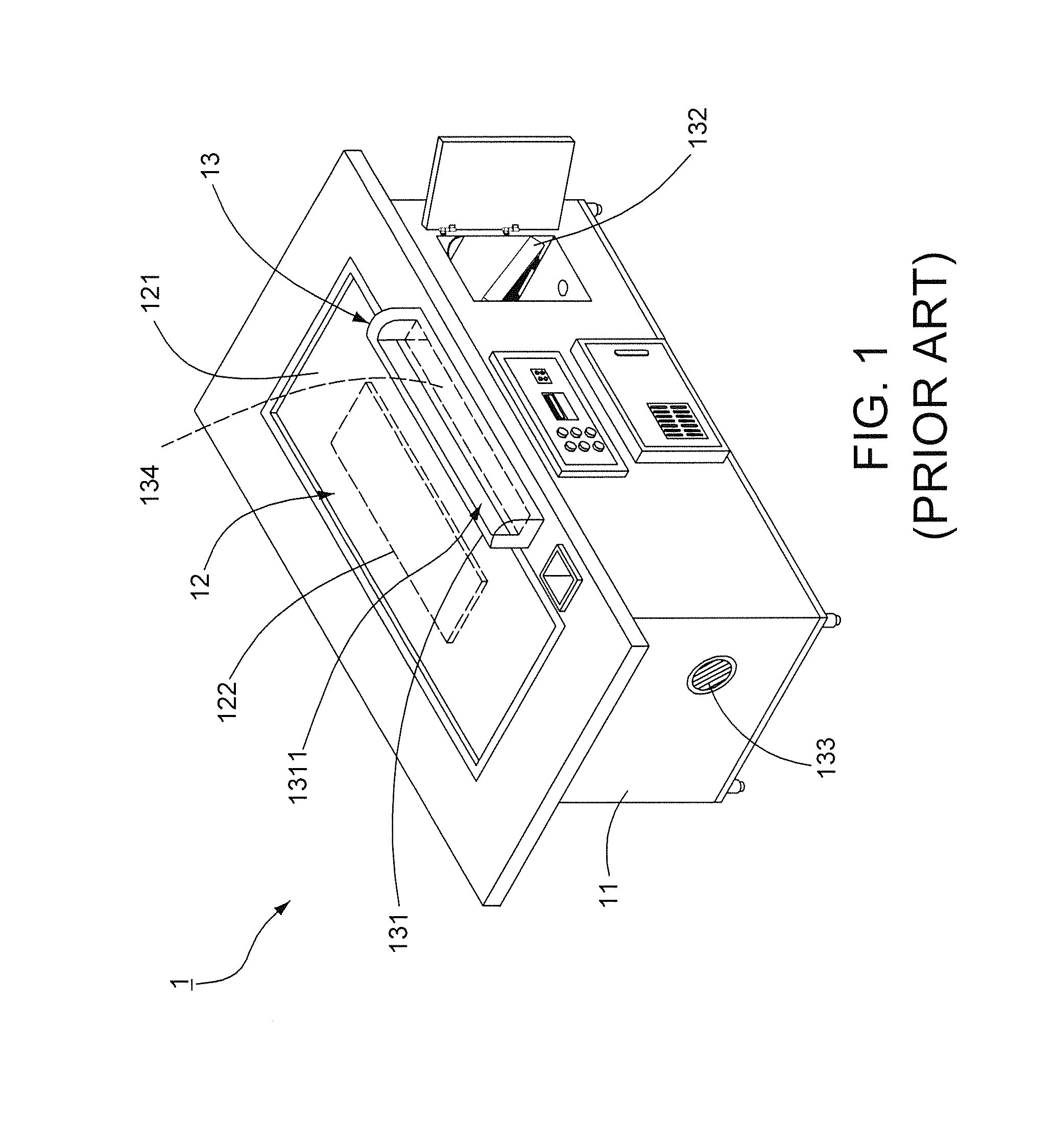

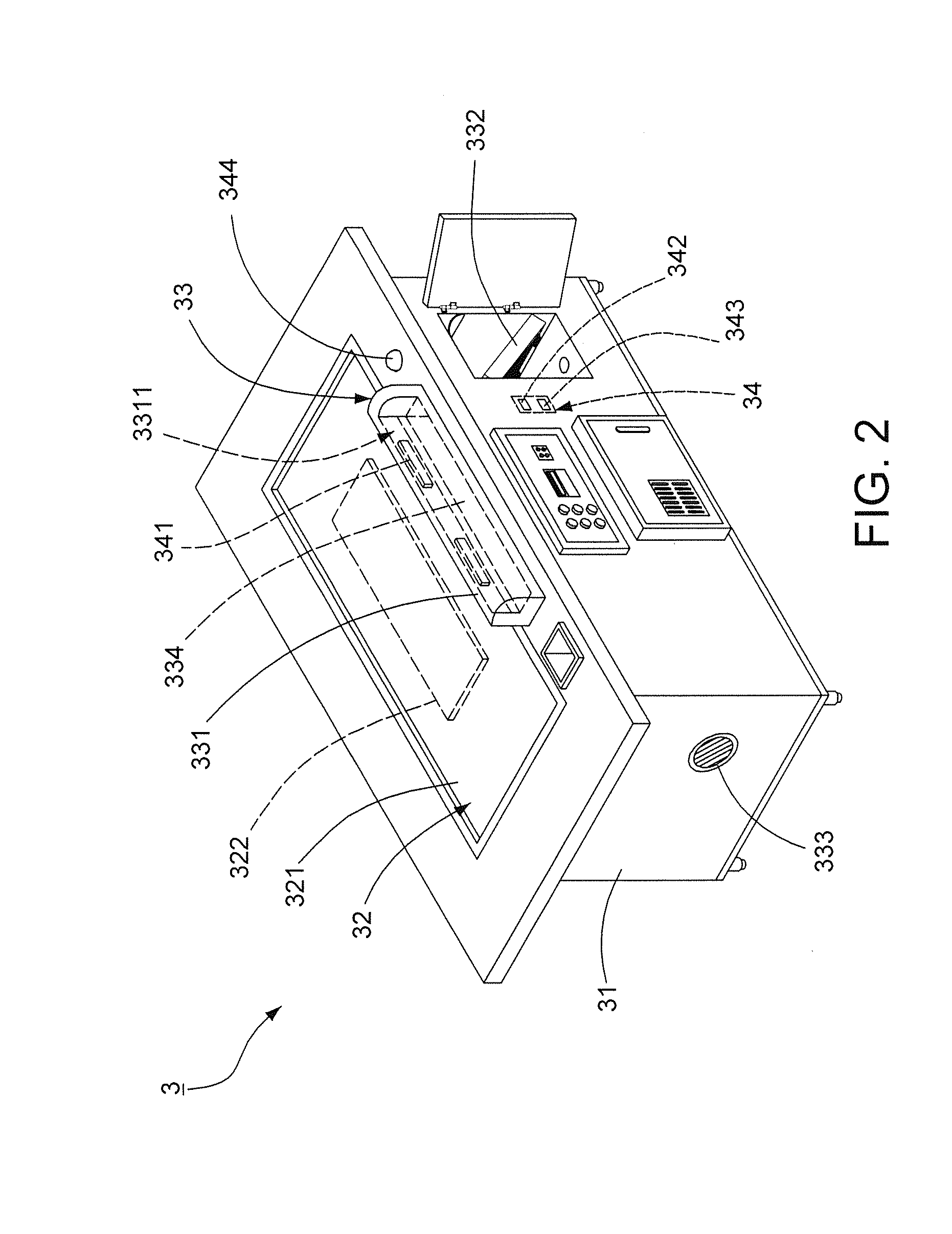

Assembly for cooking with a safety device

InactiveUS20130333686A1Increase rotation speedEfficiently inhaledDomestic stoves or rangesLighting and heating apparatusEngineeringStreamflow

An assembly for cooking has a safety device installed on an air guider. The safety device comprises a sensor detecting a wind flow from the air guider and a processing unit comparing a sensed flow value of the wind flow with a predetermined flow value and determining the flowing condition of the air guider and executing a controlling action. When oil sludge obstructs an opening of the air guider to cause the flow value of cooking fumes to be lower than the predetermined value, the processing unit stops an air pump of the air guider or activates an alarm unit to warn operators to clean the air guider, thereby maintaining an efficient inhaling effect of the air guider. The processing unit can concurrently promote a rotation speed of the air pump to keep inhaling an amount of cooking fumes for avoiding scattering the cooking fumes in dining spaces.

Owner:FANCY FOOD SERVICE EQUIP

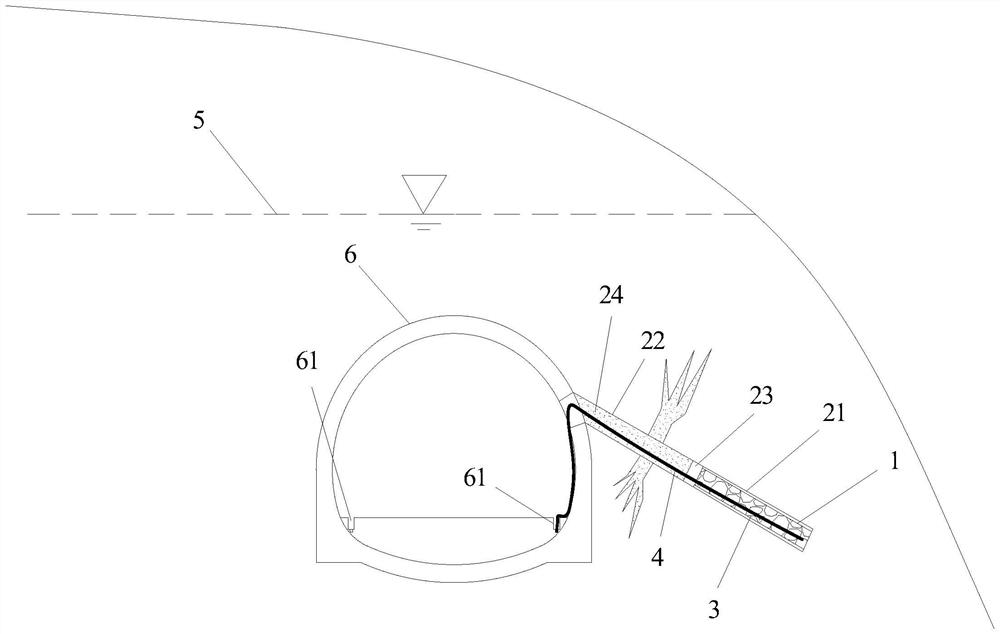

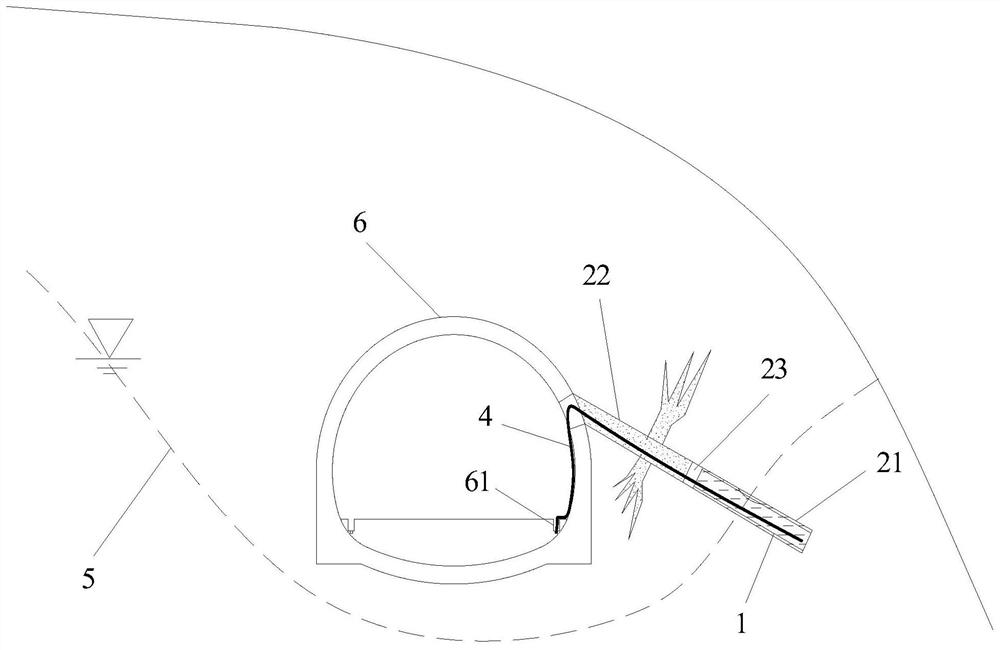

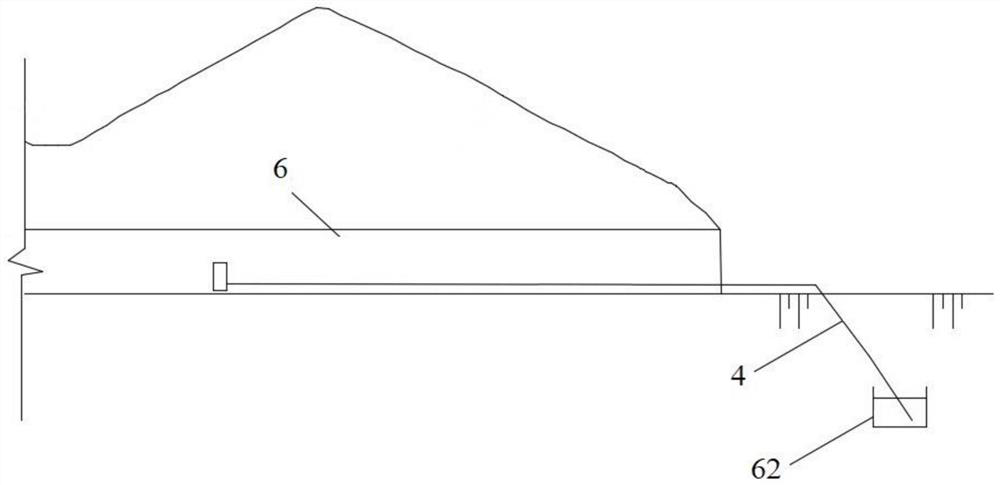

Tunnel water seepage and harmful gas discharge structure and semi-closed ice-filled drilling construction method

ActiveCN111810234AEfficient dischargePrevent escapeMining devicesUnderground chambersOutfallDrainage tubes

The invention discloses a tunnel water seepage and harmful gas discharge structure and a semi-closed ice-filled drilling construction method. The structure includes a permeable pipe arranged in a permeable section of a drilling hole. The drilling hole includes the permeable section and a grouting section, the drilling hole is drilled from the side wall of a tunnel, a water stop member is arrangedbetween the permeable section and the grouting section, the permeable pipe is filled with ice, and the permeable section is internally provided with an water inlet of a drainage pipe; and the elevation of the water inlet of the drainage pipe is higher than the elevation of a water outlet of the drainage pipe, and the lift of the drainage pipe is less than the height of a water column correspondingto the atmospheric pressure. According to the tunnel water seepage and harmful gas discharge structure, harmful gases in the surrounding rock in the drainage link can be effectively discharged, the situation that the harmful gas escapes or is greatly accumulated in the surrounding rock is reduced, the safety risk is reduced, and the water-stop member can be effectively supported during grouting,the structure is beneficial to increase the grouting pressure, the negative pressure effect of the permeable section improved, and the tunnel water seepage and harmful gas discharge structure is conducive to ensuring continuous drainage and exhaust effects and is of great significance to solving the problem of tunnel water seepage and gas leakage.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

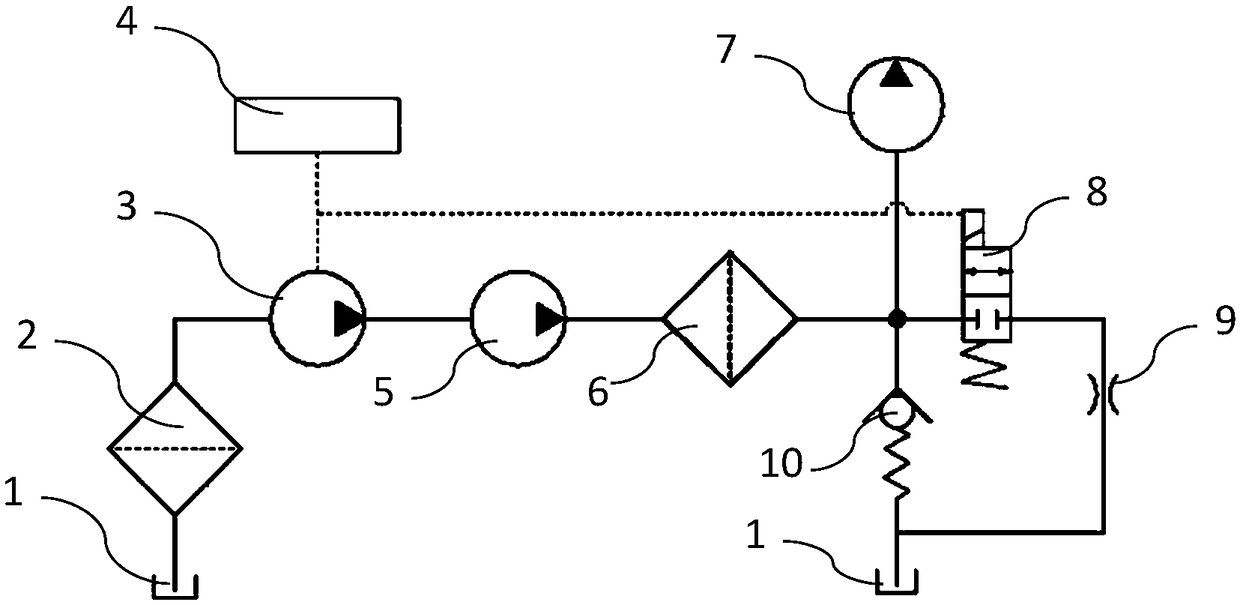

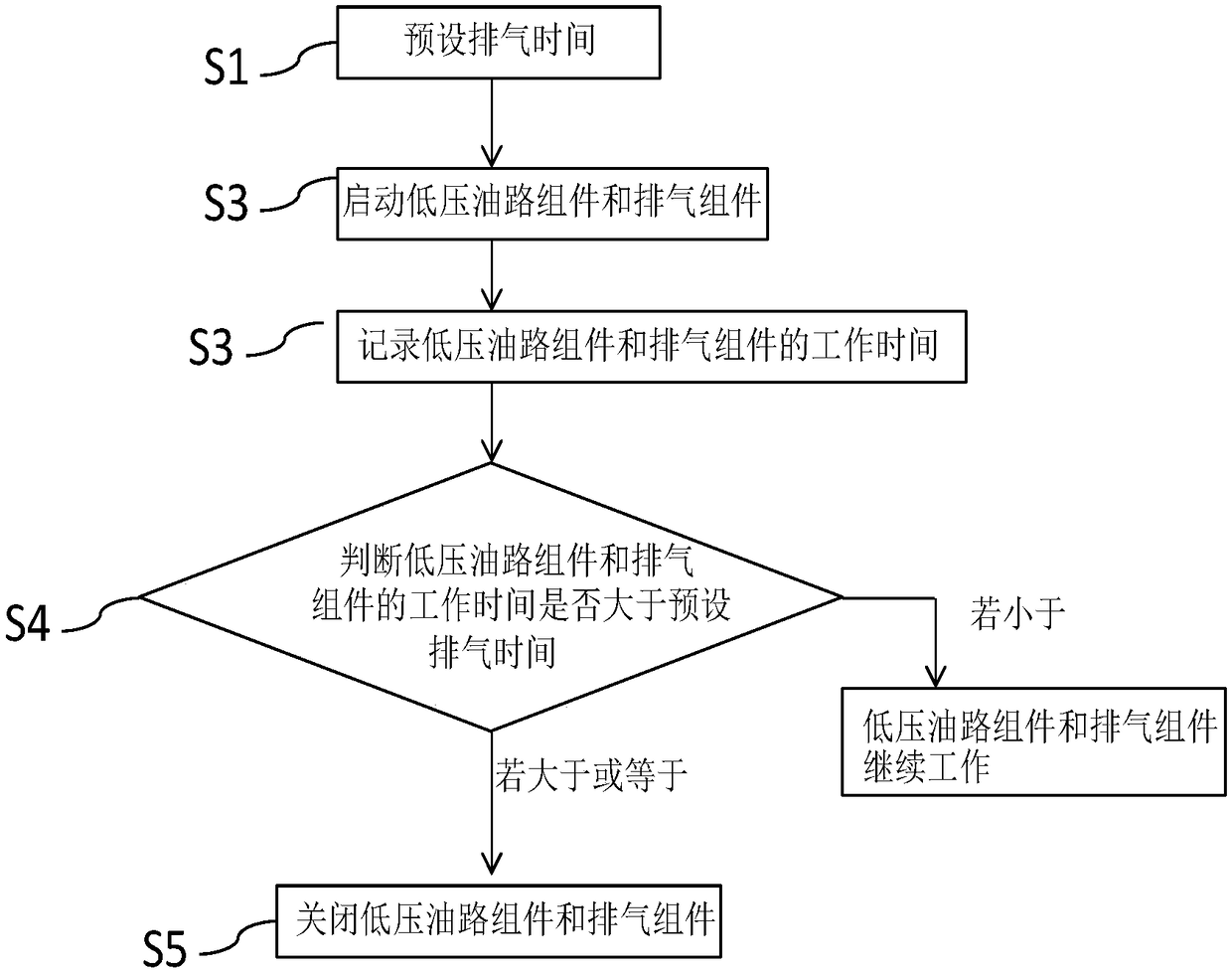

Exhaust system and method of low-pressure oil circuit

InactiveCN109441682ASimple structureMinor changesFuel injection apparatusMachines/enginesHigh pressureSystem structure

The invention discloses an exhaust system and method of a low-pressure oil circuit. The exhaust system comprises a one-way valve and a low-pressure oil circuit assembly communicating with a high-pressure pump. An oil inlet of the one-way valve communicates with an oil outlet of the low-pressure oil circuit assembly. An oil outlet of the one-way valve communicates with an oil tank. The oil outlet of the low-pressure oil circuit assembly further communicates with an exhaust assembly. An oil outlet of the exhaust assembly communicates with the oil tank. An exhaust pipeline is formed from the oiloutlet of the low-pressure oil circuit assembly to the oil tank through the one-way valve, another exhaust pipeline is formed from the exhaust assembly to an oil tank through the low-pressure oil circuit assembly, and the two exhaust pipelines are in parallel connection. The exhaust system is simple in structure, modification made to the structure of an original automobile is small, meanwhile, low-pressure oil circuit exhaust is automatic, the using comfort is improved, in addition, low-pressure oil circuit exhaust is high in efficiency and good in effect, and normal start of an engine can beguaranteed.

Owner:WEICHAI POWER CO LTD

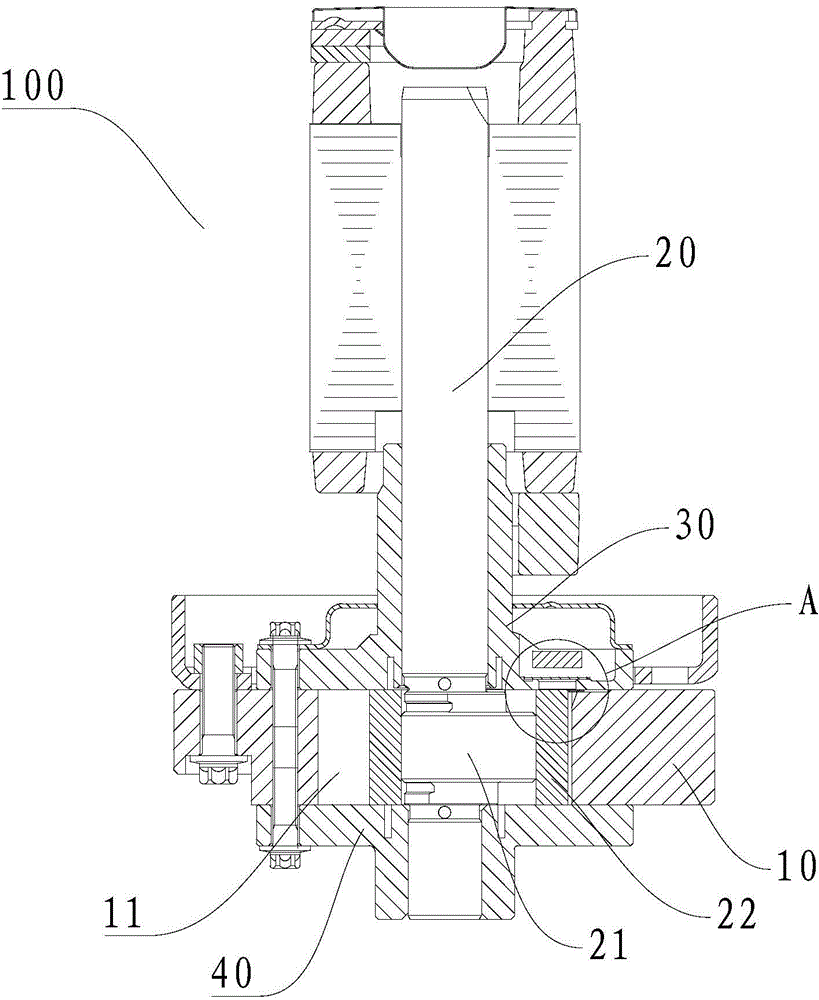

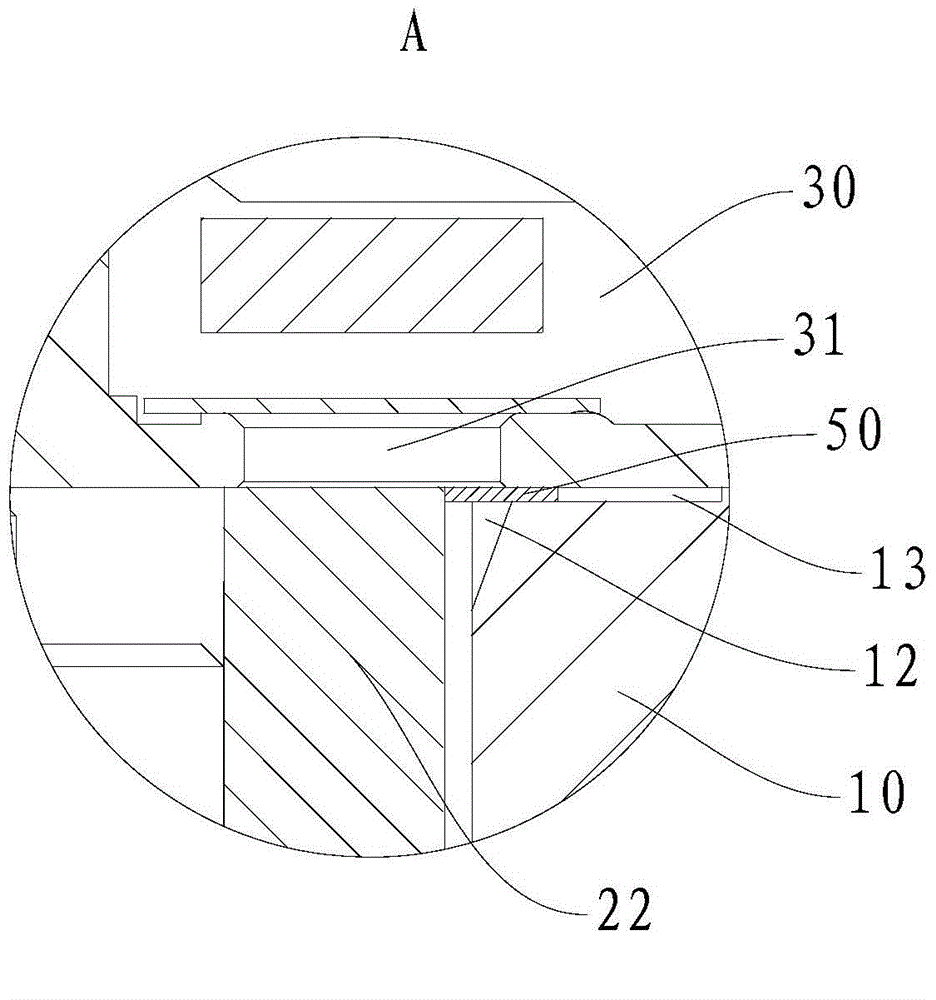

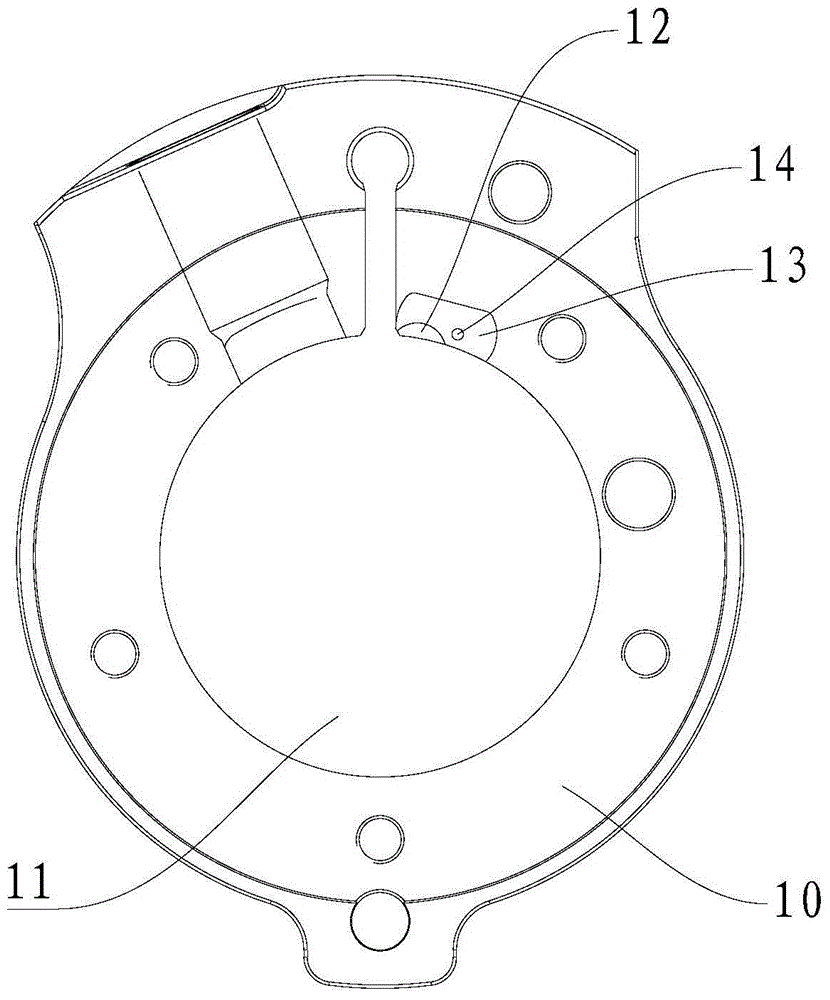

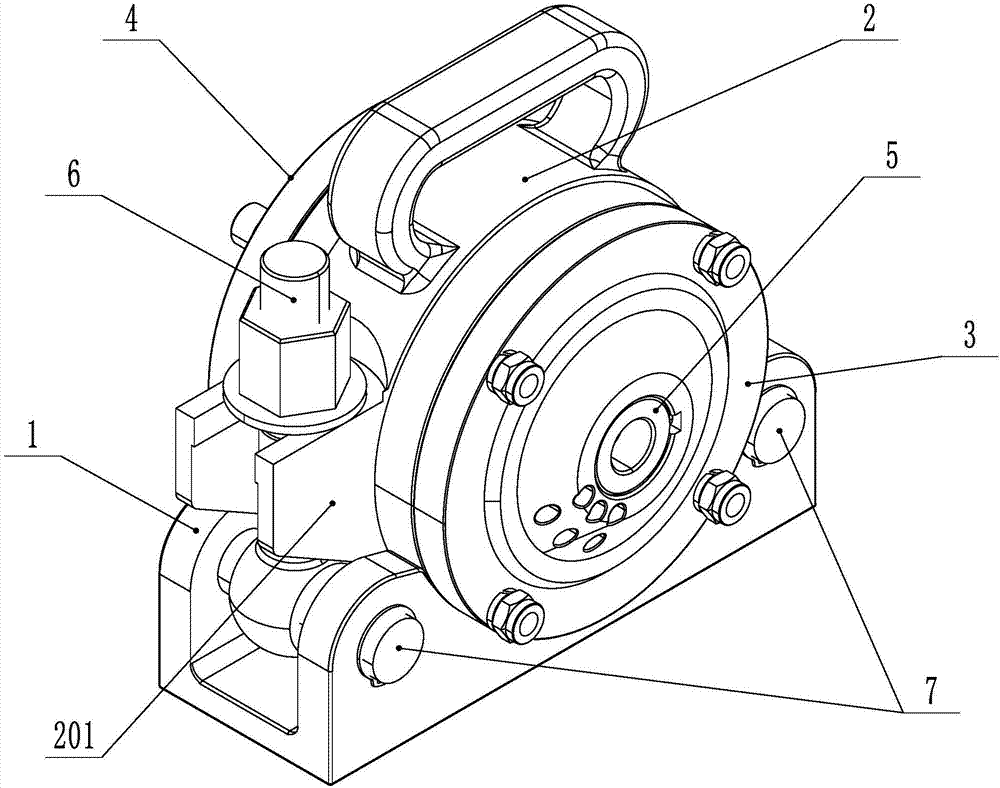

Compression mechanism and compressor provided with same

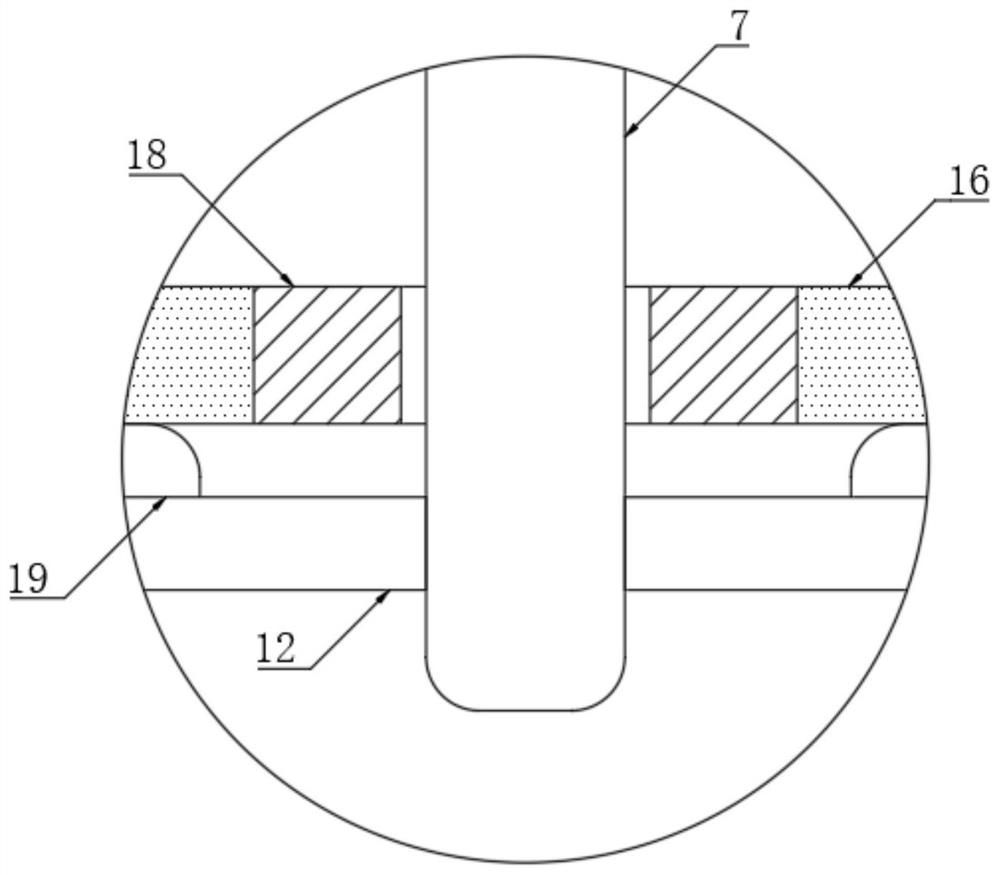

InactiveCN104564690AReduced clearance volumeGuaranteed exhaust effectRotary piston pumpsRotary piston liquid enginesPulp and paper industryCrankshaft

The invention discloses a compression mechanism and a compressor provided with the compression mechanism. The compression mechanism comprises a cylinder, a crankshaft, an upper bearing, a lower bearing and a switch valve plate, wherein a compression chamber is defined in the cylinder, and a tapered cut communicated with the compression chamber is formed in the upper end or the lower end of the inner wall surface of the cylinder; the crankshaft penetrates through the compression chamber along the axial direction of the cylinder and can rotate around the central axis of the crankshaft, the part, extending into the compression chamber, of the crankshaft is provided with an eccentric shaft, and a roller is arranged on the eccentric shaft; the upper bearing and the lower bearing are arranged at the upper end and the lower end of the cylinder respectively, and an exhaust hole corresponding to the tapered cut in position is formed in the upper bearing or the lower bearing and is connected with the tapered cut; and the switch valve plate is arranged between the upper end of the cylinder and the upper bearing or between the lower end of the cylinder and the lower bearing, and can move between a first position and a second position to connect or disconnect the tapered cut and the exhaust hole, the tapered cut is connected with the exhaust hole when the switch valve plate is at the first position, and the tapered cut is disconnected with the exhaust hole when the switch valve plate is at the second position.

Owner:GUANGDONG MEIZHI COMPRESSOR

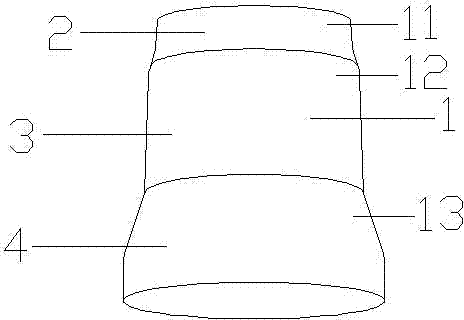

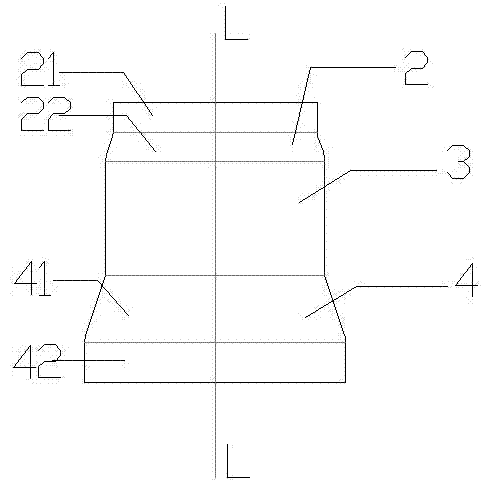

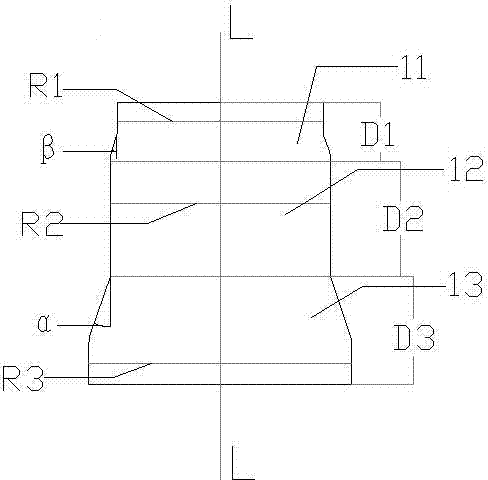

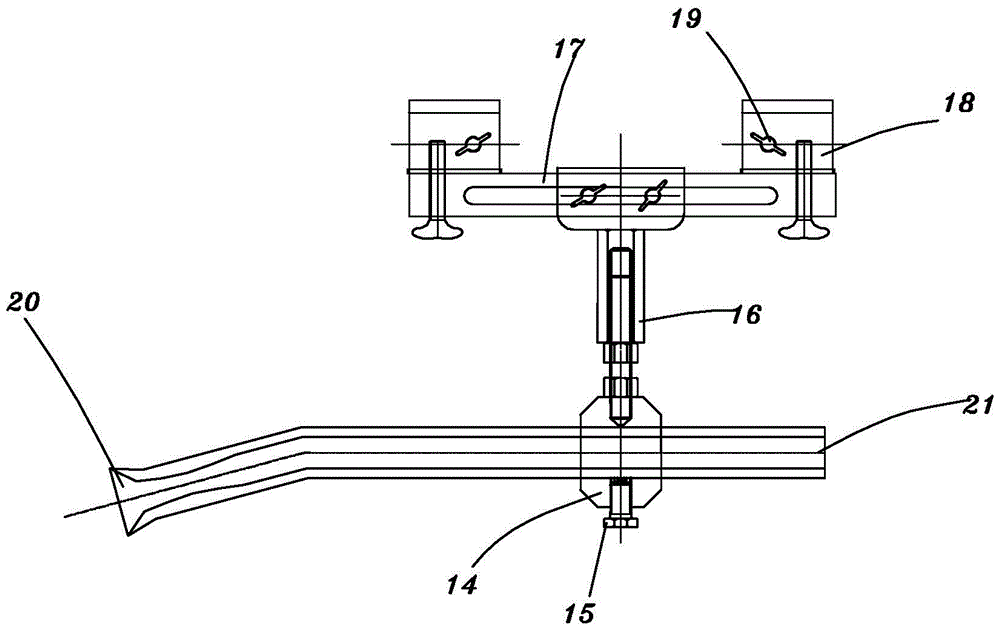

High-precision flared fitting forming tool

InactiveCN104492987AHigh precisionGuaranteed exhaust effectVehicle componentsPipe fittingMachining time

A high-precision flared fitting forming tool is characterized by comprising a pipe body; the pipe body is dived into an upper pipe body end, a middle pipe body end and a lower pipe body end; the upper pipe body end is a necking-down end; the middle pipe body end is a transition segment; the lower pipe body end is a flaring end; the necking-down end comprises a necking-down body and a necking-down circular arc; the flaring end comprises a flaring body and a flaring circular arc; when a pipe fitting is machined, the stamping necking manner is adopted; the machining time of the pipe fitting is greatly reduced, and the technical characteristics of stamping necking are combined; the necking precision is effectively improved, and the product quality is improved; meanwhile, the machining time is reduced, the machining speed and the efficiency of the pipe fitting are improved, and cost generated by purchasing of a plurality of necking-down devices is saved; and the manual cost is reduced, and meanwhile energy losses are reduced.

Owner:镇江利奥排气技术有限公司

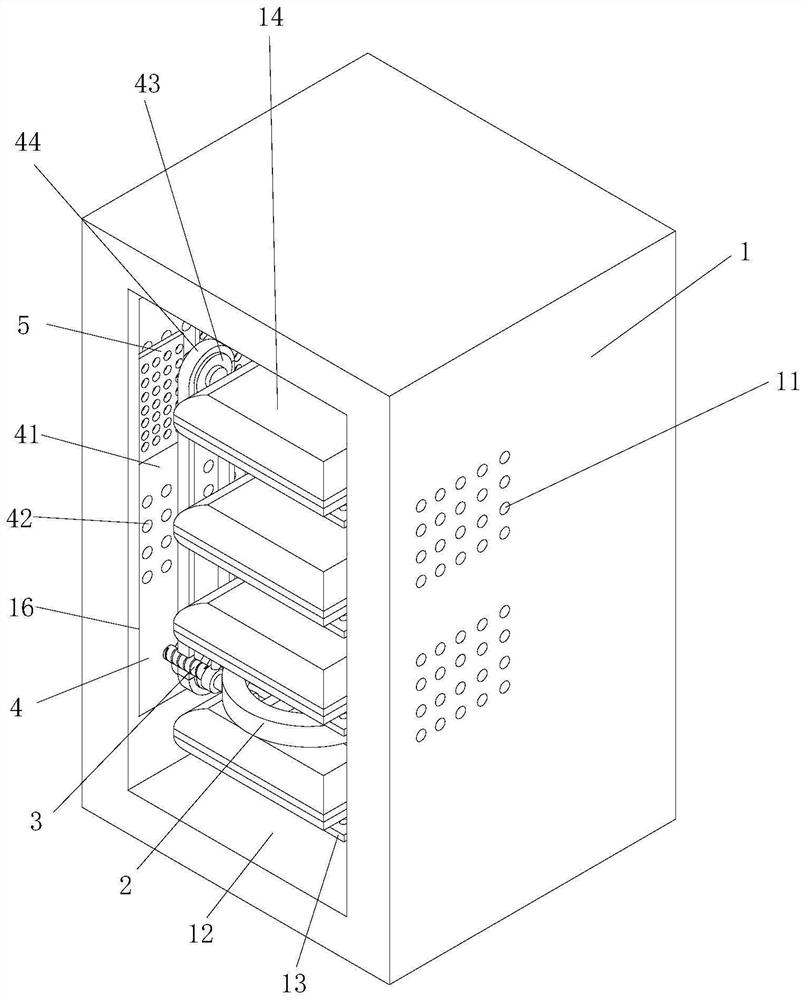

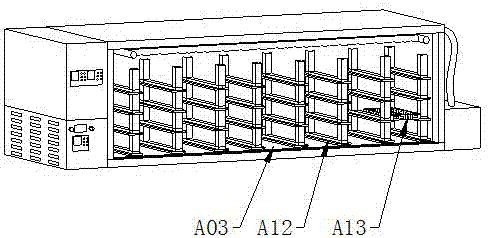

Block chain data storage device based on Internet of Things

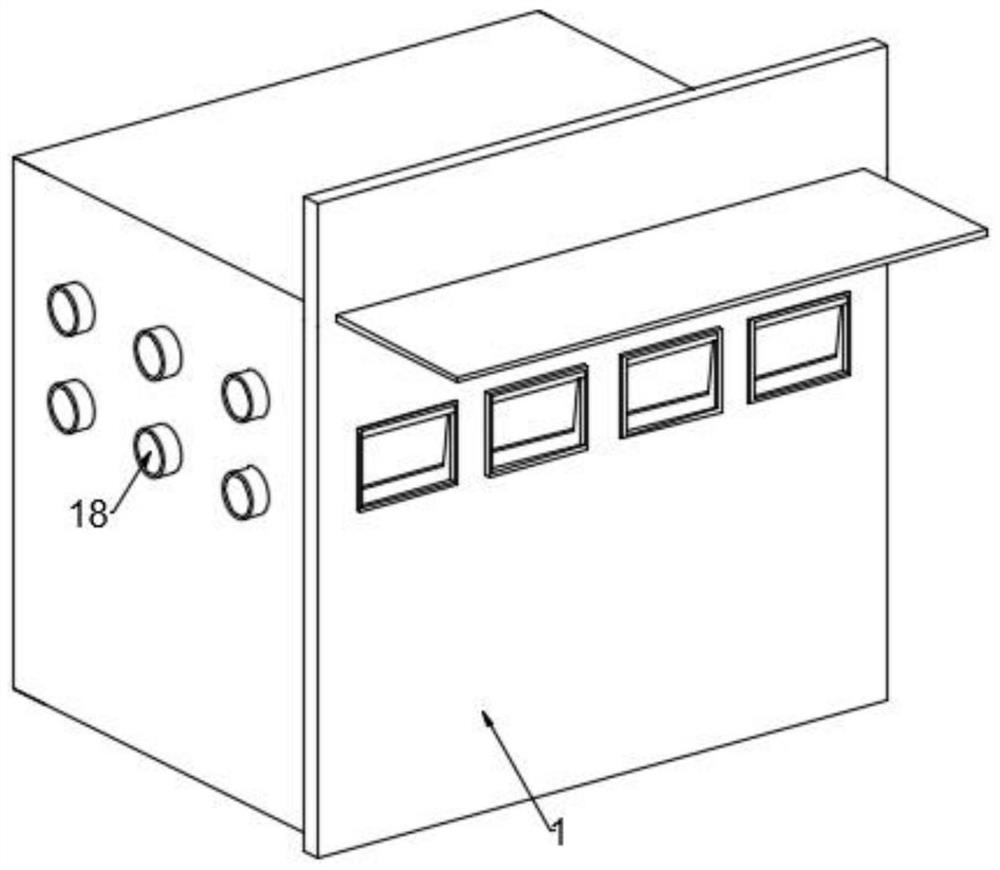

PendingCN113744771ASpeed up heat dissipationAffect the effect of heat dissipation and exhaustReducing temperature influence on carrierReducing carrier contaminationPhysicsBlockchain

The invention relates to the technical field of data storage devices, and discloses a block chain data storage device based on Internet of Things. The device comprises a machine body, an inner groove is formed in the machine body, ventilation openings are formed in two sides of the outer part of the machine body, four interfaces are fixedly connected in the machine body, a storage hard disk is movably connected to one side, far away from the inner wall of the inner groove, of each interface, a partition plate is arranged below each storage hard disk, holes are formed in the partition plates, a bottom air outlet fan is arranged above the lowest storage hard disk, air outlet mechanisms are arranged on the two sides, close to the inner wall of the inner groove, of the bottom air outlet fan, and a cleaning mechanism is arranged in each air outlet mechanism. The bottom air outlet fan is arranged to be matched with the air outlet mechanisms and the cleaning mechanism, so that a sponge plate is pulled downwards through a pull rope, an air outlet in a baffle is cleaned through the sponge plate, the situation that dust is accumulated at the air outlet to affect the heat dissipation and air exhaust effect in the machine body is avoided, and the normal heat dissipation effect of the device is guaranteed.

Owner:刘海钦

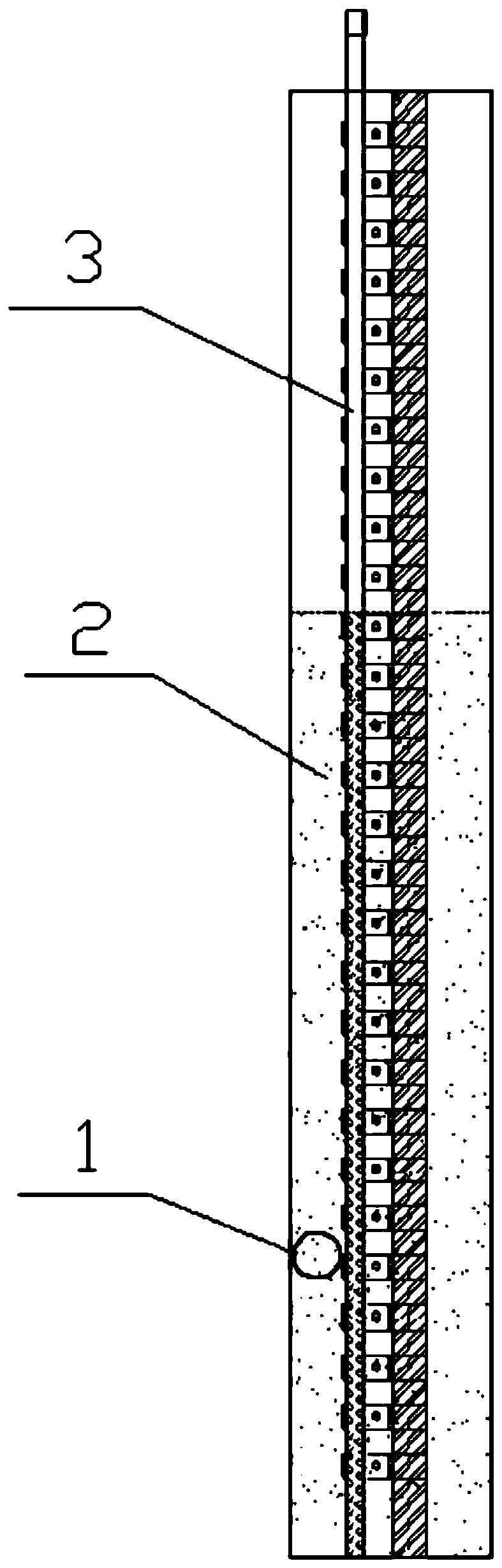

Coke mixture liquid of deep well type DC grounding electrode and filling method thereof

InactiveCN110600903AGuaranteed exhaust effectFilled tightlyConnection contact member materialEngineeringSlurry

The invention discloses a coke mixture liquid of a deep well type DC grounding electrode. The ratio of the weight of coke particles to the weight of water is not more than 1: 1 in the coke mixture liquid. The particle size of the coke particles is 0.1 mm-0.2 mm. The invention discloses a coke mixture liquid filling method of the deep well type DC grounding electrode. The coke mixture liquid is enabled to be effectively filled, and the exhaust performance of the exhaust system of the deep well type DC grounding electrode can also be guaranteed. The invention also discloses a filling method of the coke mixture liquid of the deep well type DC grounding electrode. The coke mixture liquid of the deep well type DC grounding electrode fills into the deep well through the hollow feed steel pipe extending to the underground by the way of hole bottom slurry pressing.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

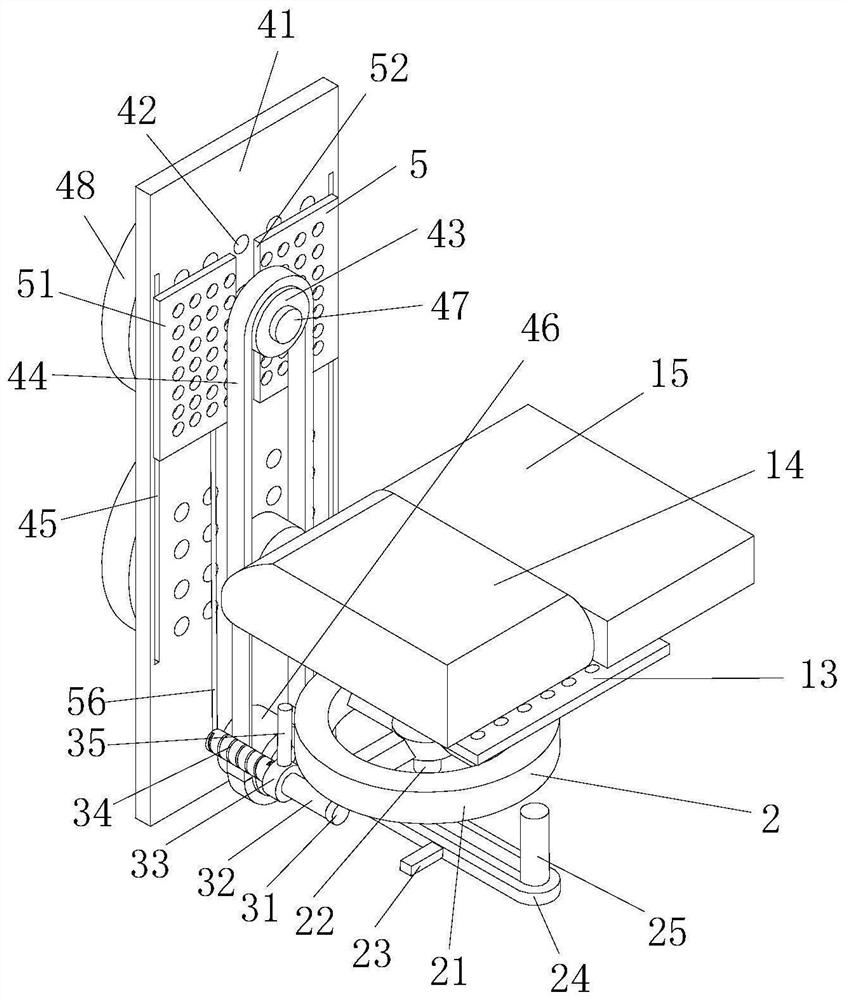

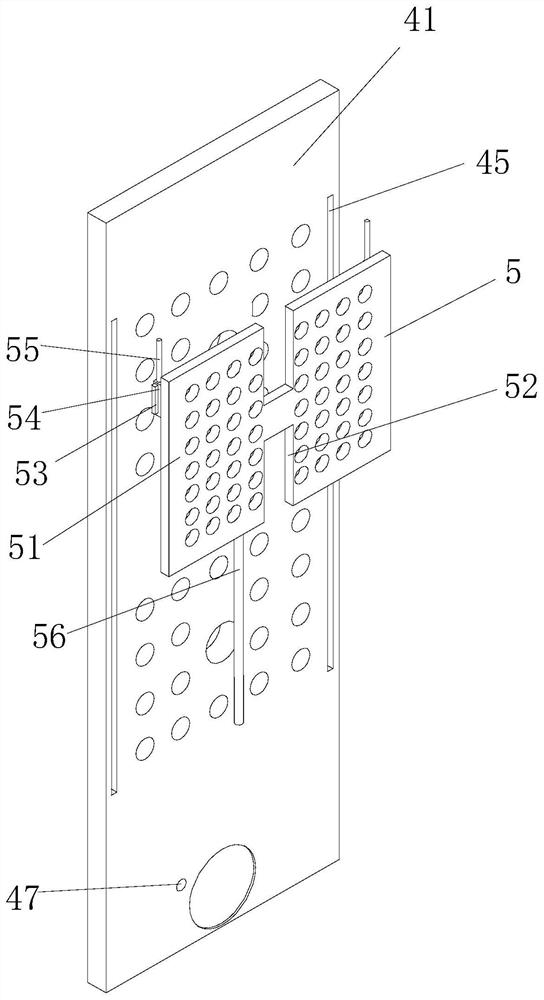

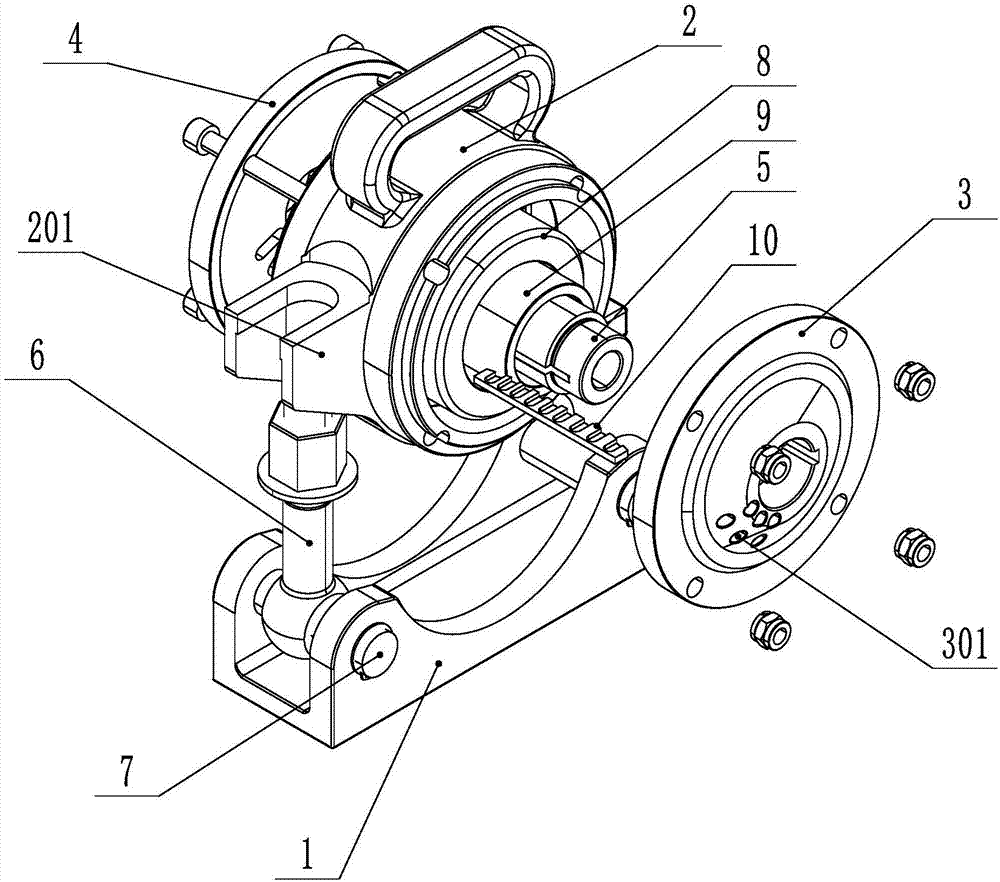

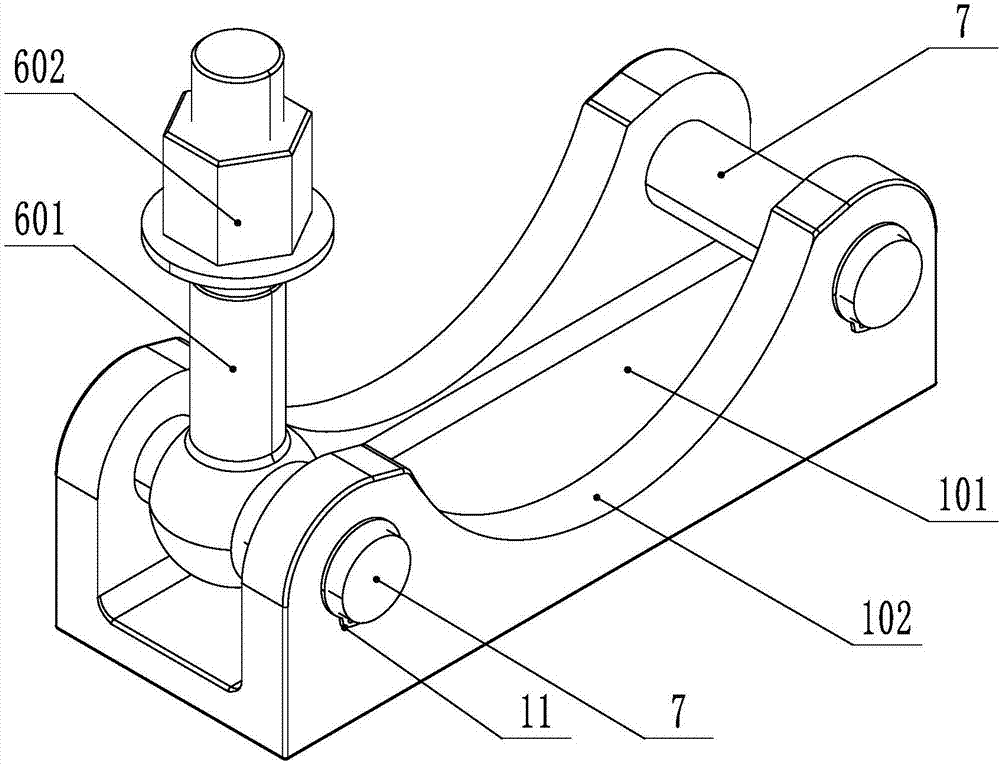

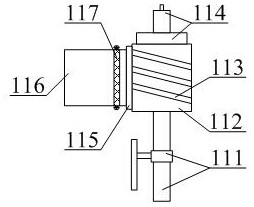

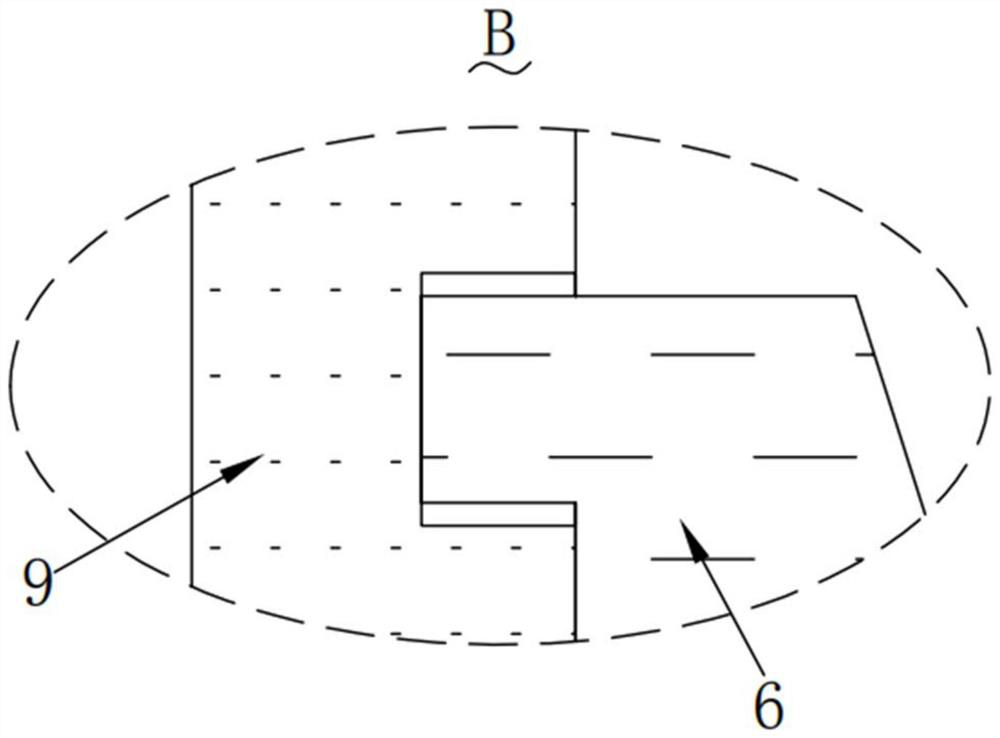

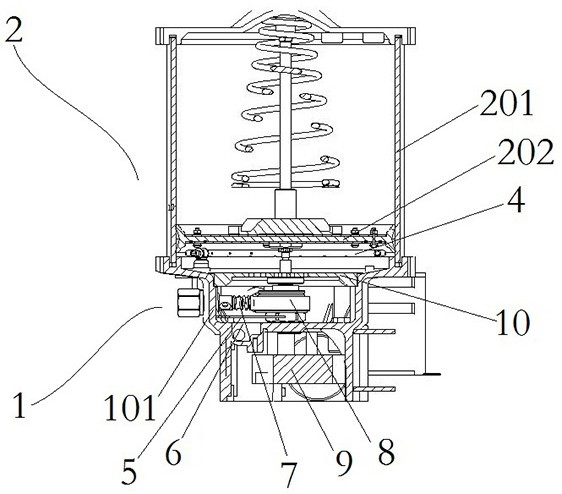

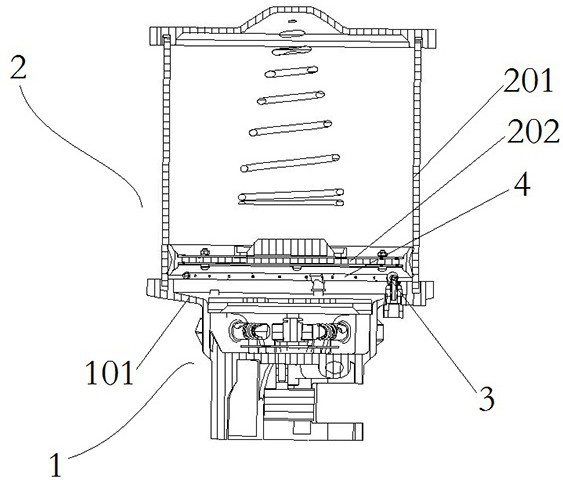

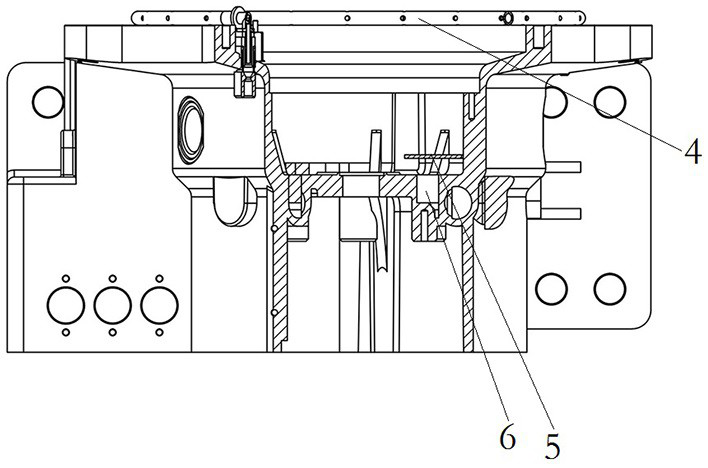

Novel rapid mounting pneumatic vibrator

PendingCN108000678AEasy to installEasy to operateCeramic shaping apparatusMechanical vibrations separationEngineeringSlide plate

The invention discloses a novel rapid mounting pneumatic vibrator, and relates to the field of pneumatic vibrators. At present, most pneumatic vibrators are trouble to mount, large in gas consumptionamount, small in exciting force, short in service life, easy to damage and the like. The pneumatic vibrator comprises a base, a machine base, a front end cover, a rear end cover, a middle shaft, an eccentric rotating inner casing pipe and an eccentric rotating outer casing pipe; an air chamber and a sliding groove are formed in the center and the outer side of the middle shaft, the side, located on the front end cover, of the middle shaft is provided with a connection port for connecting the air chamber and an air source, a side air outlet is formed in the air chamber and leads to the slidinggroove, a sliding plate capable of closing and opening the air outlet of the air chamber is arranged in the sliding groove, a rapid mounting structure is arranged between the machine base and the baseand can be detachably connected, the rapid mounting structure comprises a rapid positioning structure and a bolt type rapid fixing mechanism capable of turning over, and the bolt type rapid fixing mechanism can be rotatably connected to the base. According to the pneumatic vibrator, the gas consumption amount can be effectively reduced, the exciting force is improved, and starting and exhaust effect of the vibrator can be better ensured.

Owner:WOLONG ELECTRIC GRP CO LTD +1

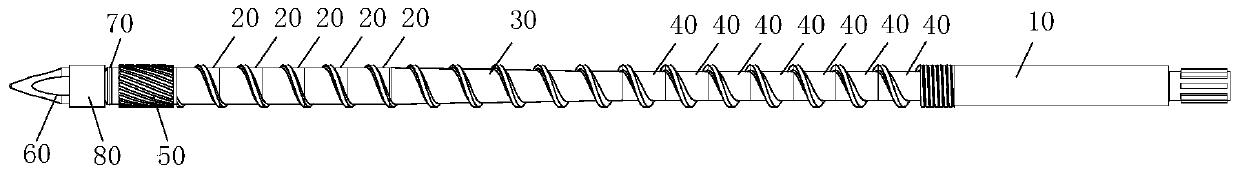

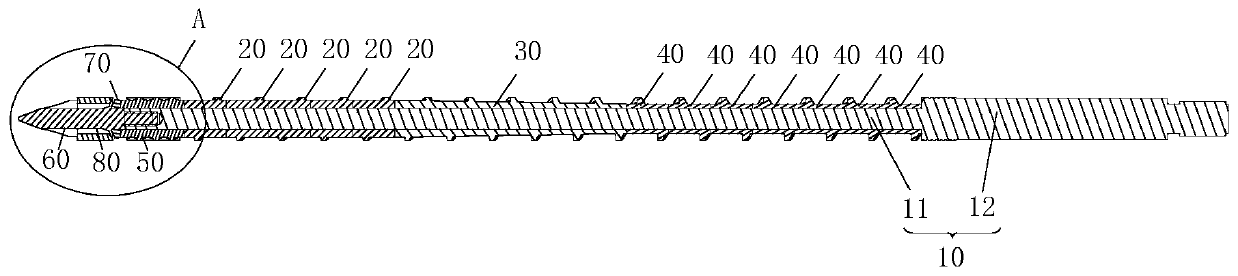

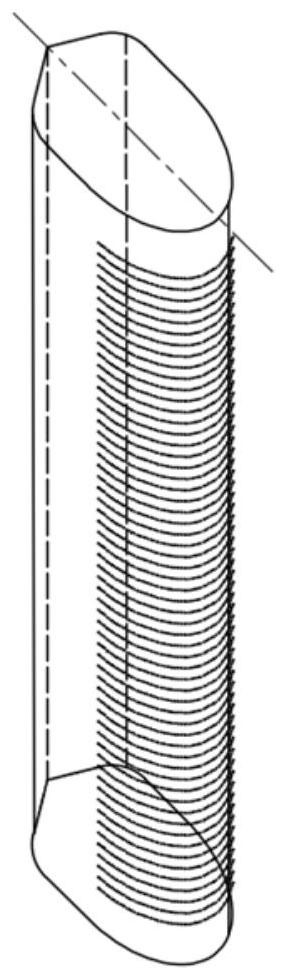

Screw and injection molding machine

The invention provides a screw and an injection molding machine. The screw comprises a connecting shaft, a homogenizing section, a compressing section and a feeding section. The homogenizing section,the compressing section and the feeding section are sequentially arranged on the connecting shaft in a sleeving manner. The homogenizing section and the feeding section are of equal-diameter structures, the diameter of the homogenizing section is larger than that of the feeding section, the diameter of the compressing section is gradually reduced from the homogenizing section to the feeding section, the diameter of the first end, close to the homogenizing section, of the compressing section and the diameter of the homogenizing section are equal, and the diameter of the second end, close to thehomogenizing section, of the compressing section and the diameter of the feeding section are equal. According to the technical scheme, the problem that when a screw of an injection molding machine inthe prior art is replaced, it is needed to replace the whole screw is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Telescopic ventilation system based on laboratory ventilation

The invention discloses a telescopic ventilation system based on laboratory ventilation. A telescopic exhaust assembly is installed at the bottom end of a ventilation pipe, a sliding plate is connected with a guide rail through a sliding connection assembly, a ventilation plate is installed at the bottom end of a connecting pipe, and rubber rings are embedded in the positions, corresponding to thin ropes, of a folding curtain. A precise ventilation assembly is installed at the position, corresponding to the bottom end of the connecting pipe, of the bottom end of the ventilation plate, rotating shaft pipes are installed at the joints of a top pipe, a middle pipe and a bottom pipe in a penetrating mode, and an emergency fire extinguishing assembly is installed at one end of the top face of the ventilation plate. Adjustment and splicing of the telescopic exhaust assembly are utilized to form a ventilation cabinet structure with an adjustable range, and an experiment is facilitated. The precise ventilation assembly further strengthens the small-range ventilation effect, large-range ventilation and small-range ventilation are switched, the sliding connection assembly is used in cooperation with the telescopic exhaust assembly, maintenance is facilitated while movement is smoother, the emergency fire extinguishing assembly effectively extinguishes fire and prevents harmful gas diffusion, and therefore safety is improved.

Owner:江苏万融系统集成有限公司

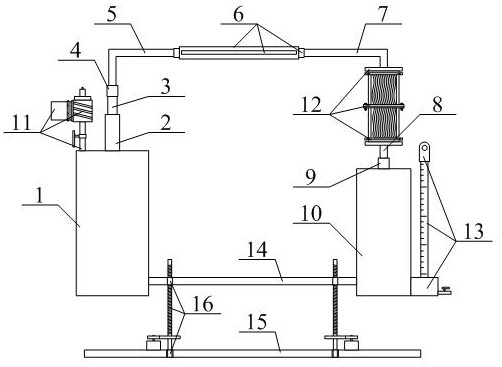

Multifunctional polyurethane reaction kettle condensation recovery device

InactiveCN112221300AEase of DisposalAvoid pollutionDispersed particle filtrationChemical/physical/physico-chemical processesThermodynamicsFiltration

The invention provides a multifunctional polyurethane reaction kettle condensation recovery device which comprises a reaction kettle body, a gas phase outlet pipe, an alcohol-water separator, a connecting pipe head, a gas guide pipe, a condenser, a condensate water guide pipe, a flow guide pipe, a butt joint and a buffer tank, and the upper outlet of the reaction kettle body is in threaded connection with the gas phase outlet pipe; and the upper end of the gas phase outlet pipe is in threaded connection with the alcohol-water separator. The arrangement of the gas phase valve, the antifouling adsorption box, the adsorption net, the exhaust fan, the dismounting cover, the exhaust pipe and the impurity filtering net is beneficial to exhaust treatment of waste gas, environmental pollution is avoided, gas in the reaction kettle body is exhausted by opening the gas phase valve, and deep adsorption and filtration are performed through the adsorption net in the antifouling adsorption box, thegas can be discharged after being filtered by the impurity filtering net in the exhaust pipe; the exhaust efficiency can be improved through the exhaust fan, the exhaust effect is guaranteed, cleaningcan be conducted by taking down the dismounting cover and the exhaust pipe, and maintenance is convenient.

Owner:王秀云

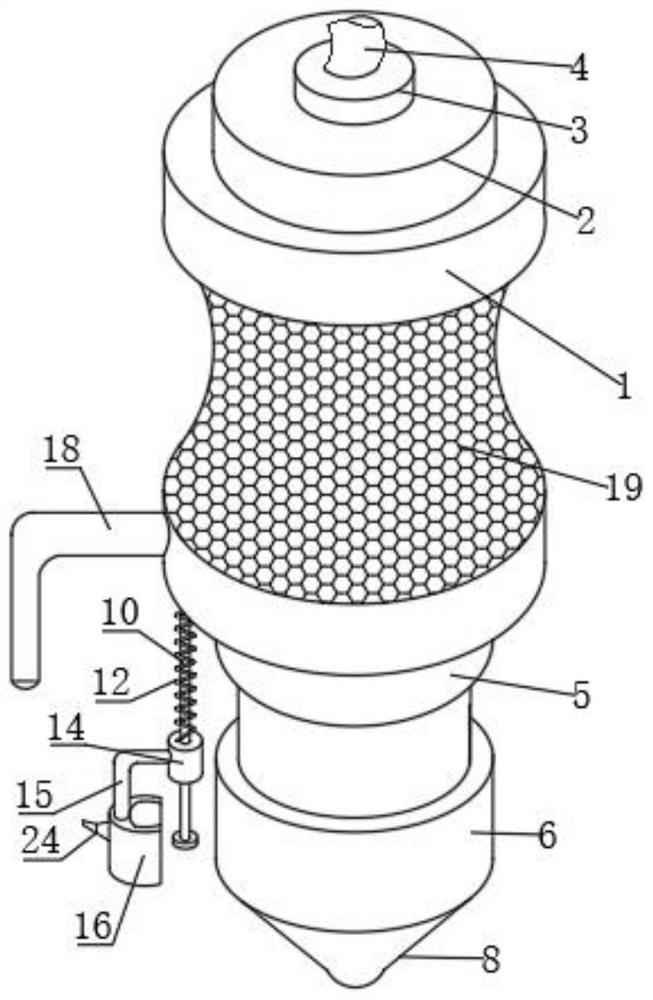

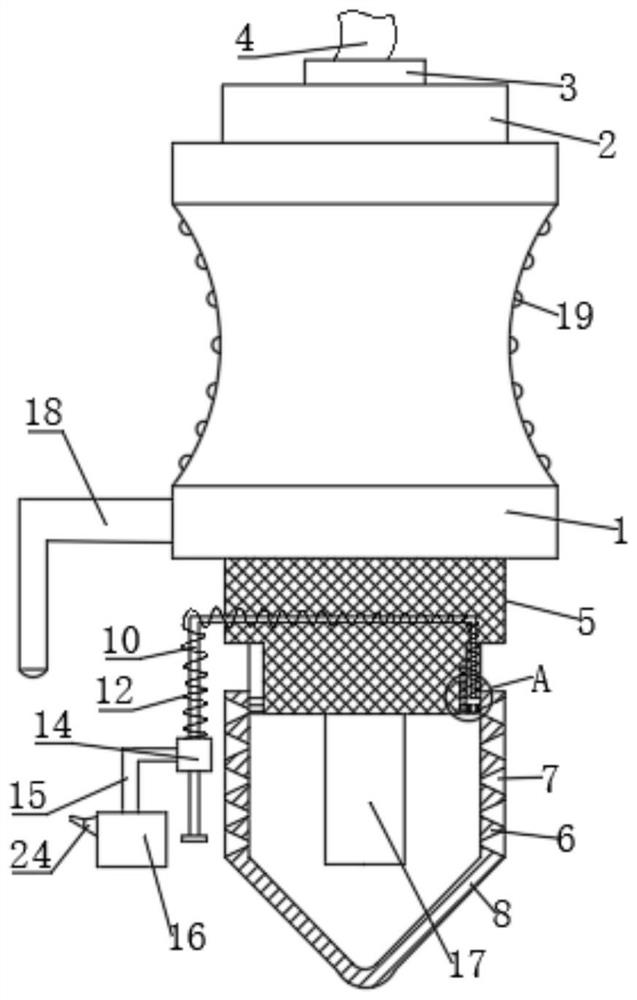

Novel seed germination accelerating machine and application method thereof

InactiveCN107996072ASolve disinfection problemsAutomate managementSeed immunisationGerminating apparatusEngineeringOzone Sterilization

The invention provides a novel seed germination accelerating machine and an application method thereof and relates to the field of germination accelerating machines. The germination accelerating machine comprises a germination accelerating machine body, wherein the germination accelerating machine body is mainly composed of a control machine case, an ozone sterilization machine, a culture cabin and a water supply mechanism; a control panel is arranged at the front end of the control machine case; the control panel is embedded into the control machine case. The germination accelerating machineprovided by the invention has the characteristics of a previous germination accelerating machine; the ozone sterilization machine is arranged and sterilization and disinfection are set in the ozone sterilization machine; a rotary adjusting button is turned to select the degree of producing ozone; after a starting button is clicked, the ozone sterilization machine detects the bacterium-containing degree in the culture cabin at any time; if bacteria reach a certain degree, the ozone sterilization machine is automatically started to produce the ozone, the ozone is discharged from an ozone exhausting opening and is used for sterilizing and disinfecting the culture cabin and the high-efficiency germination accelerating effect is realized; automatic management is realized; the problem in the prior art that a culture tray needs to be manually taken out and then seeds are disinfected is solved. The novel seed germination accelerating machine has a good development prospect.

Owner:丁年生

Tire mold vulcanizing device

The invention provides a tire mold vulcanizing device, and relates to the technical field of tire molds. A barrel-shaped valve body is inserted in an exhaust hole, the bottom of the valve body is provided with a limiting necking port, a barrel-shaped valve element is inserted in the valve body, and a plurality of strip-shaped through holes are evenly and annularly formed in the valve element. A limiting ring is inserted in the valve element and provided with a plurality of first limiting blocks, a first connection ring is coaxially arranged at the bottom end of the valve element, the outer edge of the first connection ring is provided with second limiting blocks, a push ring is coaxially inserted to the lower end of the valve element, third limiting blocks are arranged on the outer edge ofthe push ring, a second connection ring is coaxially arranged below the limiting necking port, a circular truncated cone-shaped sealing block is arranged at the top end of the valve element, the topend of the valve body is provided with a flaring, the valve element is provided with fourth limiting blocks, the valve element is sleeved with springs, the outer surface of the valve element is provided with vent holes, and the springs and the vent holes are arranged between the fourth limiting blocks and the first limiting blocks. An exhaust valve is additionally arranged in the exhaust hole, therefore, the exhaust effect is effectively ensured, and the exhaust valve is good in performance and convenient to use.

Owner:合肥大道模具有限责任公司

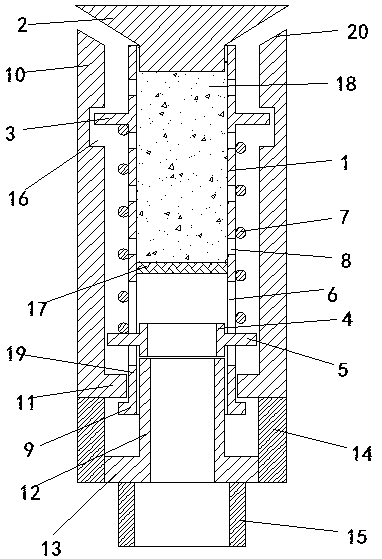

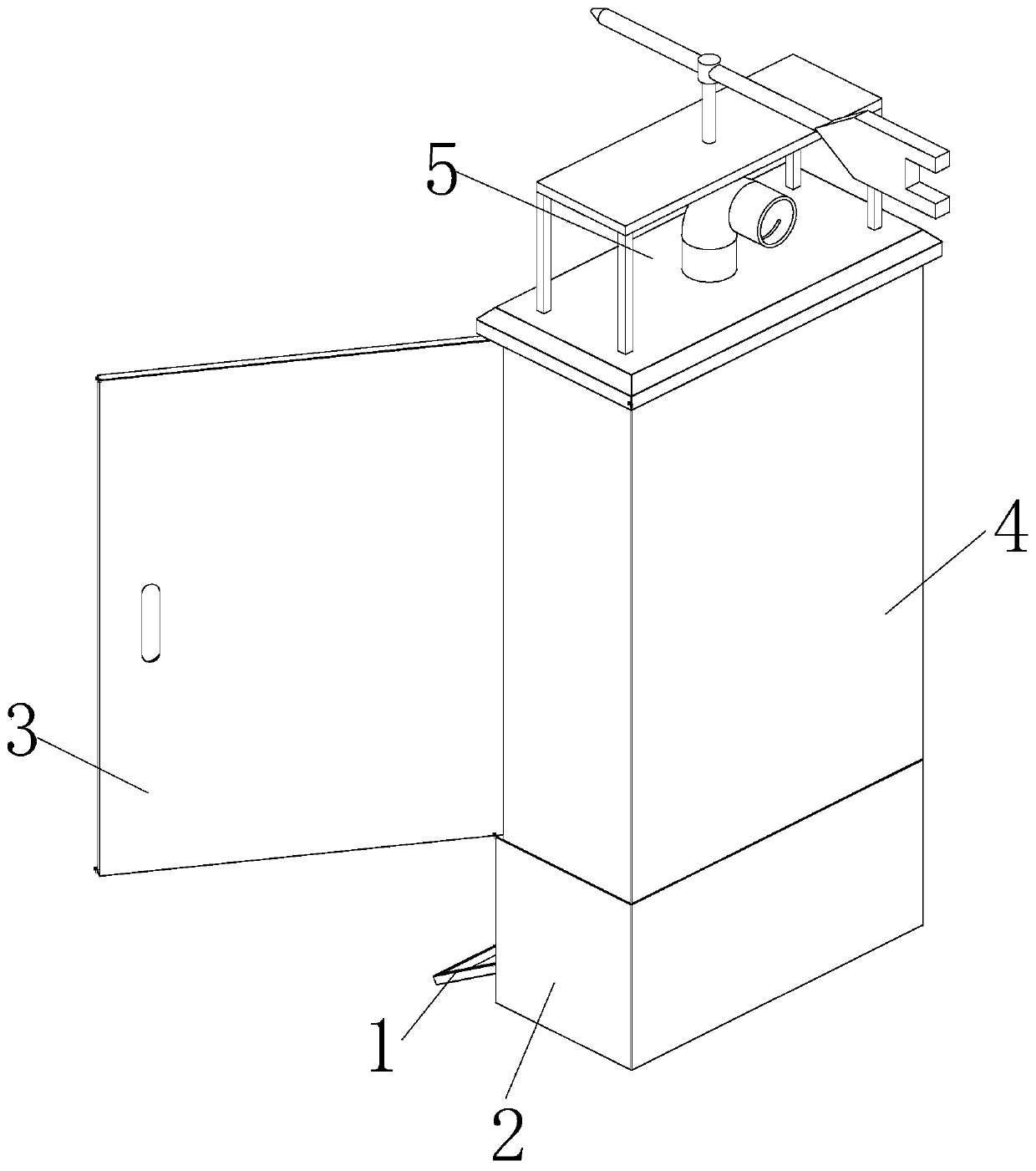

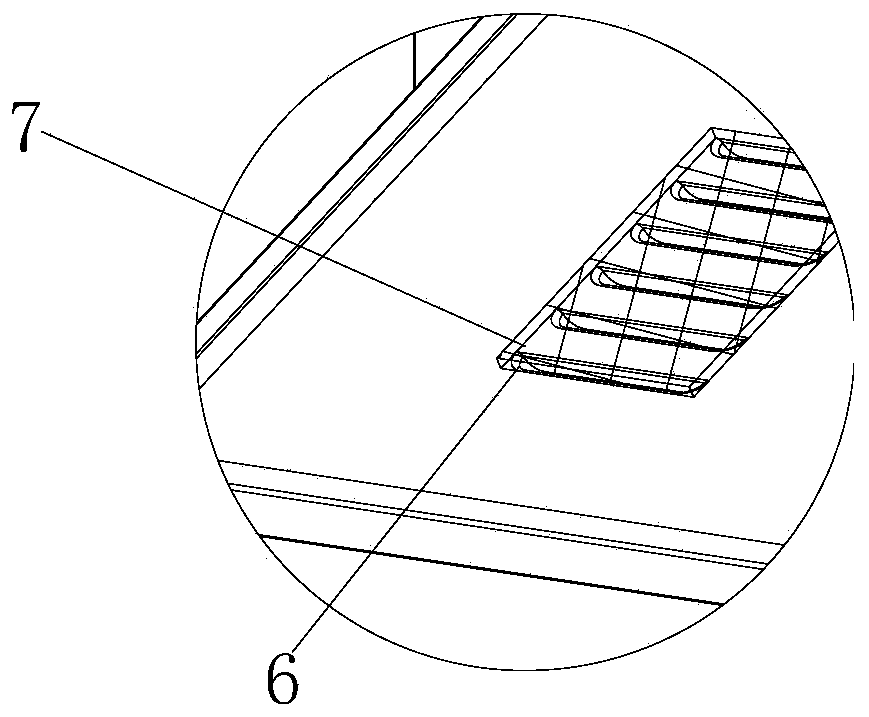

An optical cable transfer box with dust removal and heat dissipation functions

ActiveCN109856748BReduce frequency of useExtended service lifeFibre mechanical structuresInsect catchers and killersDust controlEngineering

The invention discloses an optical cable splice box with dust removal and heat dissipation functions. The optical cable splice box comprises a lower box body, a side turnover door and an upper box body, wherein the upper box body is welded to the upper part of the lower box body, and the side turnover door is rotatably connected to the front face of the upper box body through hinges. According tothe optical cable splice box, an air intake elbow pipe is driven to align with the wind intake direction through contacting of a paddle board and an external air flow, and the external air flow is ledinto the upper box body for heat dissipation, so that the use frequency of a draught fan is lowered, the service life of the draught fan is prolonged, and energy is saved. A rubber ball is driven toperiodically impact by a reverse air flow generated by driving the draught fan, and a first airbag pad and a second airbag pad have elasticity, so that dust is accelerated to be dropped from the upperpart of a purification mesh enclosure and the dust removal performance of the optical cable splice box is improved, an insulating cover is connected to the position, corresponding to window-shades, of the inner wall of a lower turnover door, and when a mosquito is killed, the body of the mosquito stuck in a high-voltage shock net can be discharged outward through conduction of the insulating cover to ensure the effects of mosquito prevention and exhausting.

Owner:HANGZHOU ZHONGKAI TELECOMM EQUIP

Environment-friendly boiler tail gas emission pipeline dust removal system

InactiveCN112007756AAvoid pollutionReduce economic costsLighting and heating apparatusElectrodes cleaningDust controlEngineering

The invention discloses an environment-friendly boiler tail gas emission pipeline dust removal system, which comprises an exhaust pipe, wherein two openings are formed in the side wall of the exhaustpipe in a penetrating mode, a fixing frame is fixedly connected to the upper side wall of the exhaust pipe, a mounting box is fixedly connected to the lower side wall of the exhaust pipe, a water outlet pipe is arranged at the bottom in the mounting box in a communicating mode, a water valve is arranged on the water outlet pipe, a dust collection mechanism is arranged on the exhaust pipe, and comprises a fixed plate fixedly connected to the inner wall of the fixing frame, a rotating rod is rotatably connected to the lower side wall of the fixed plate through a bearing, a plurality of axial flow fan blades are fixedly connected to the side wall, located in the exhaust pipe, of the rotating rod, an auxiliary plate is fixedly connected to the inner wall of the mounting box, and dust collection plates are fixedly connected to the two side walls of the auxiliary plate. According to the invention, dust in tail gas can be prevented from polluting the atmospheric environment, the economic costis low, the occupied space of equipment is small, installation is easy, the exhaust effect of the exhaust pipe can be guaranteed, and then the combustion efficiency of the boiler is improved.

Owner:陈辉辉

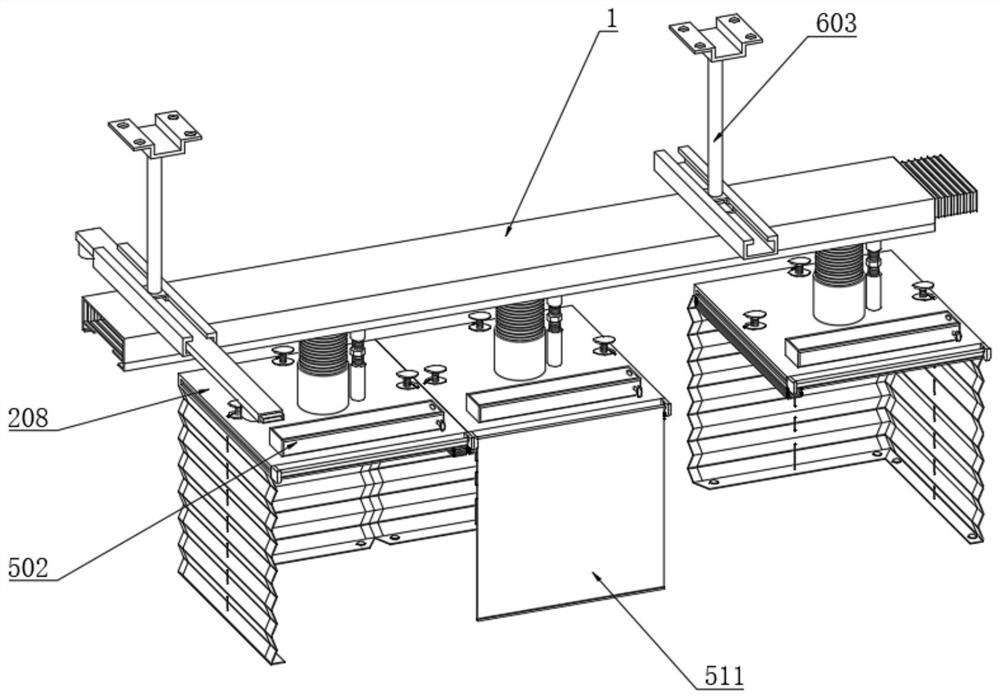

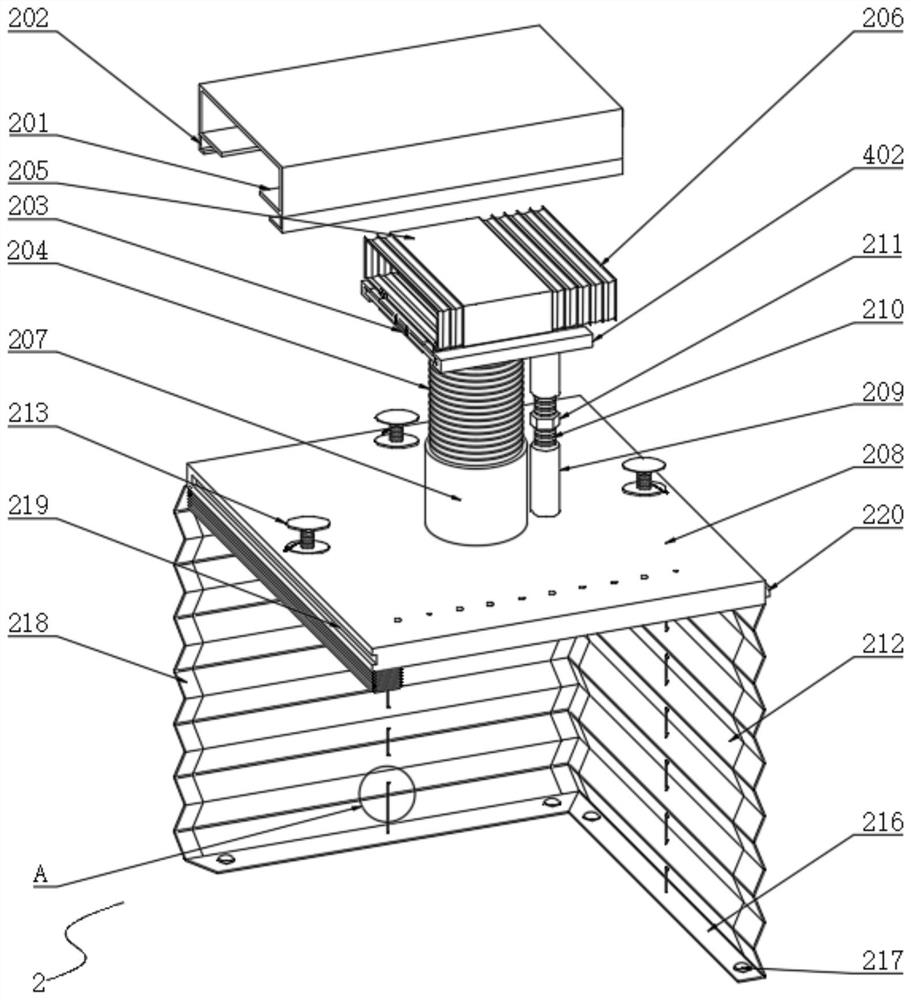

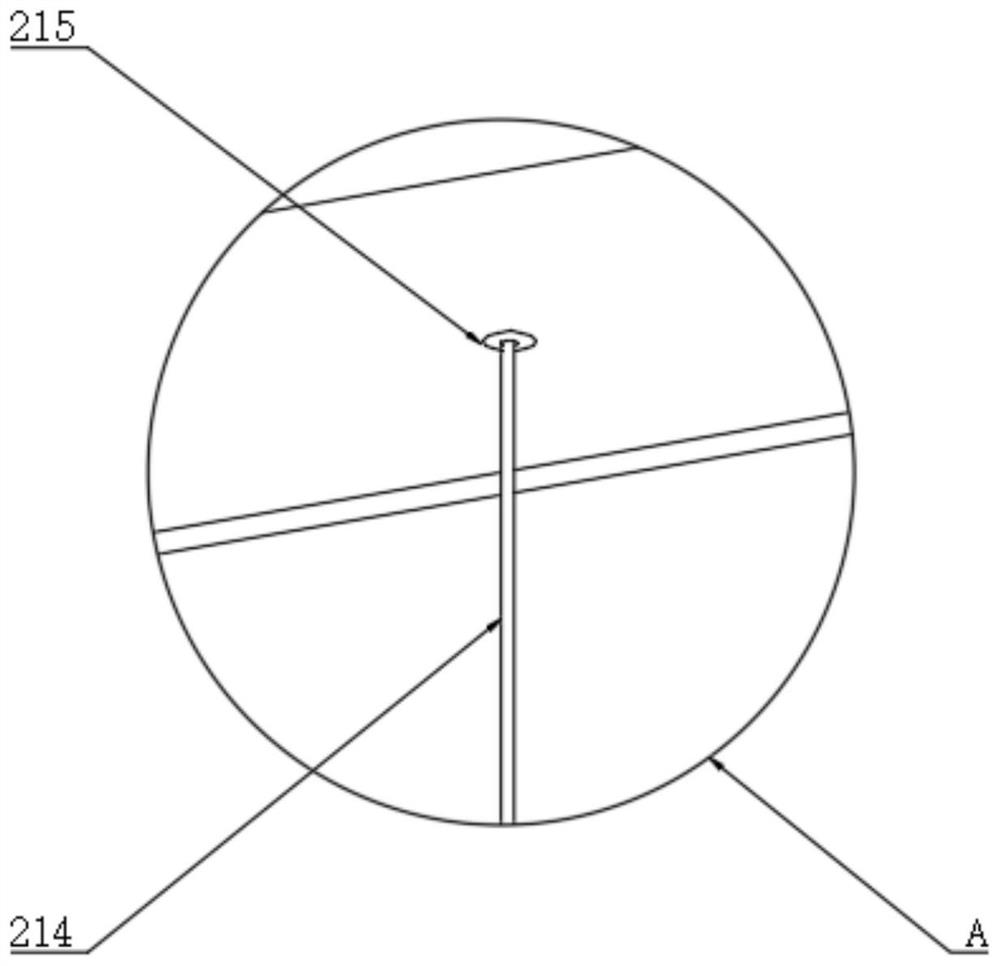

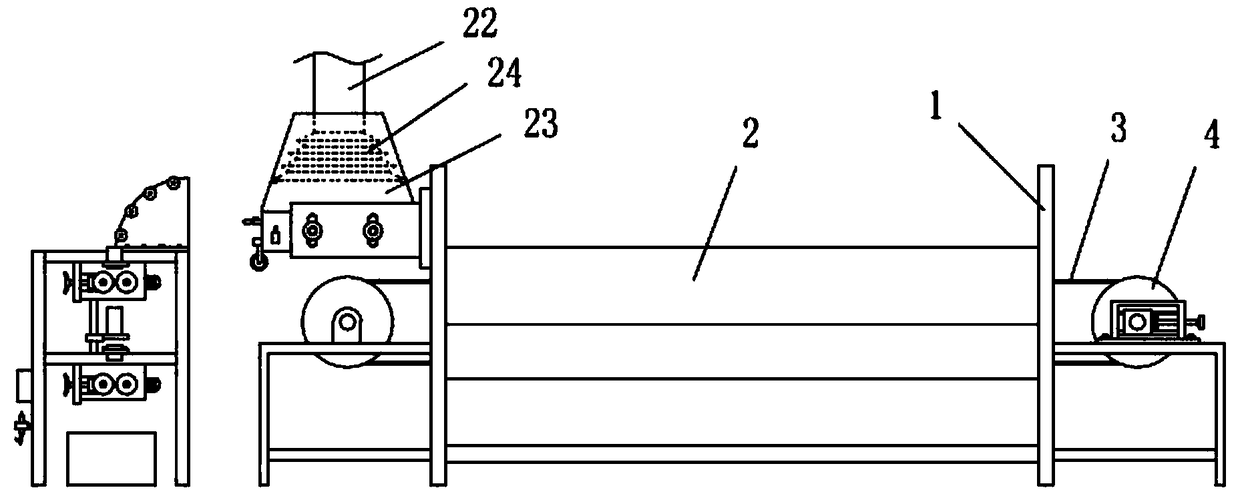

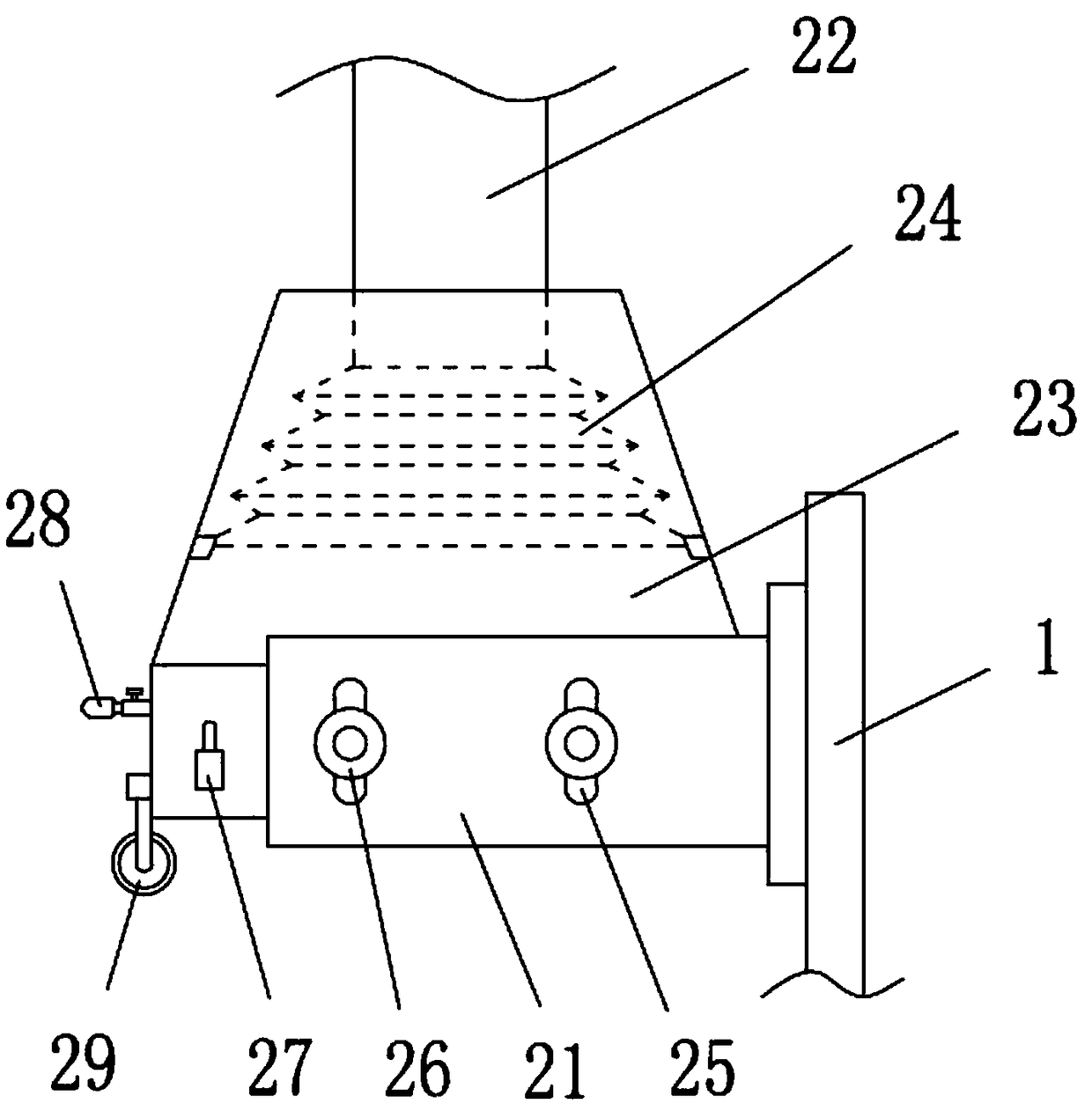

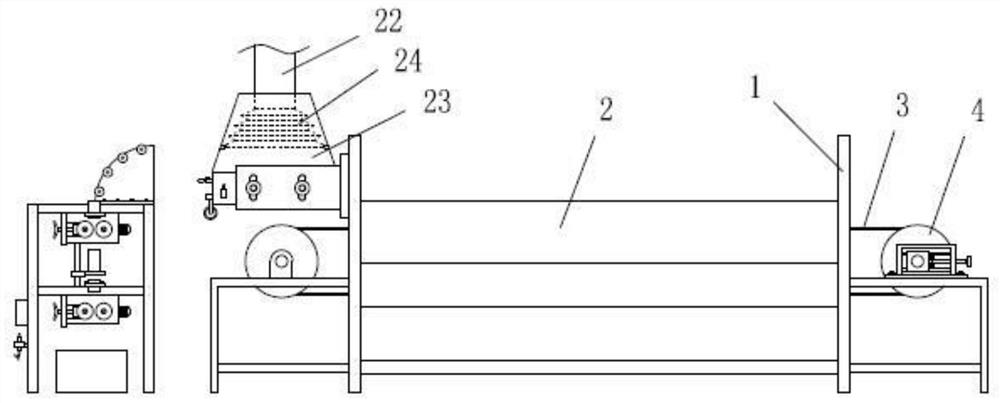

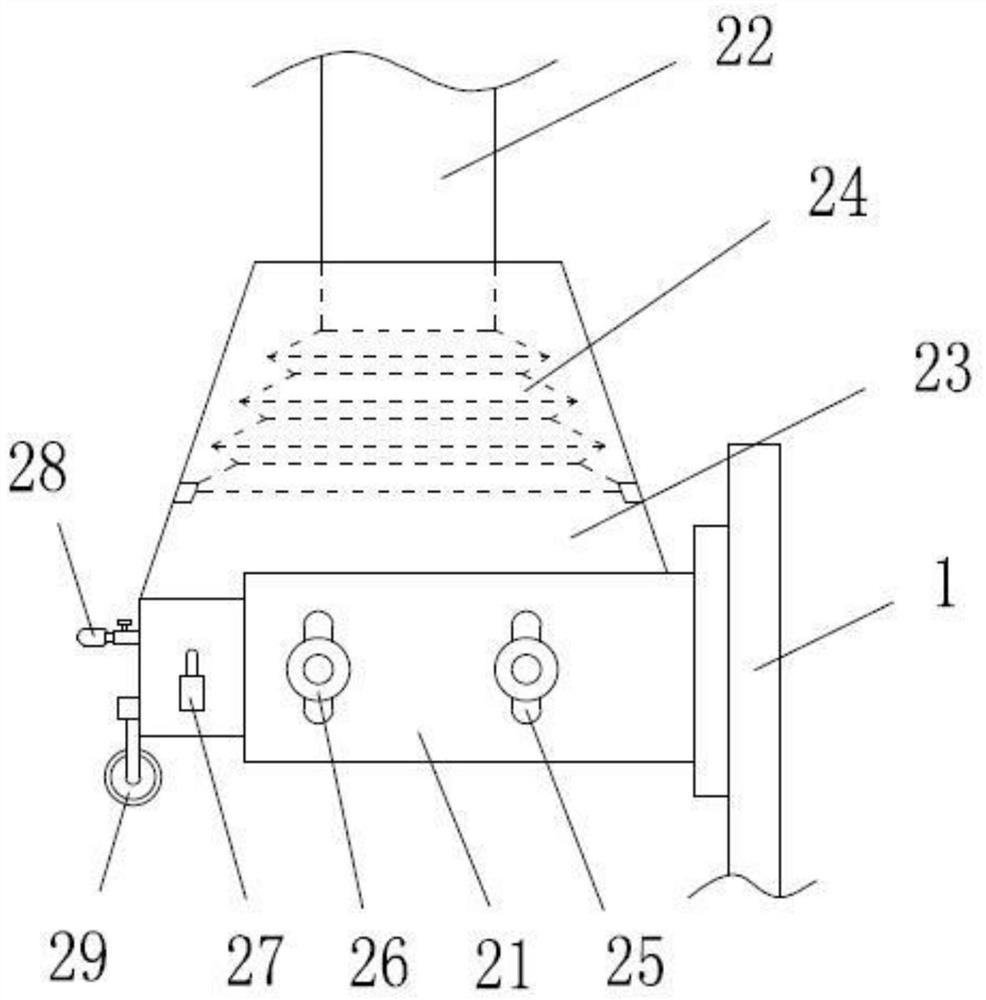

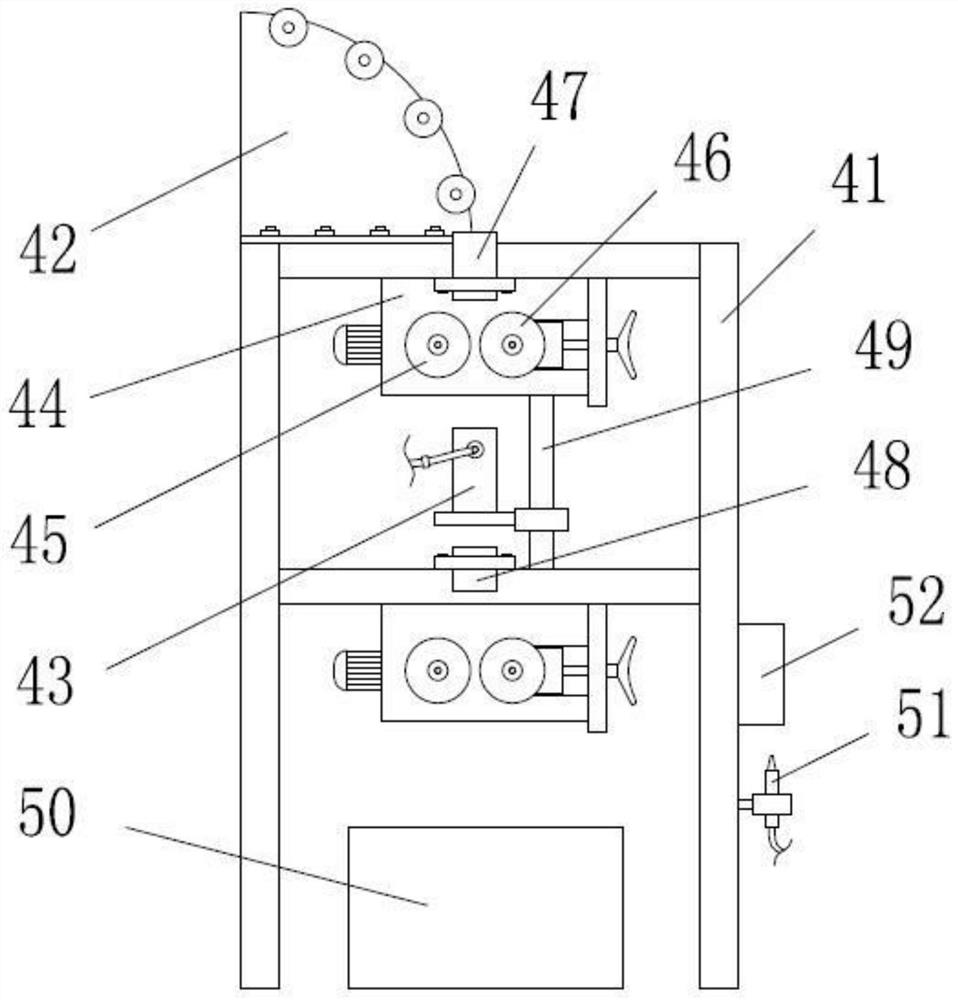

Vulcanizing machine with exhaust and expansion mechanism

ActiveCN108859085APrevent overflowGuaranteed exhaust effectDirt cleaningEngineeringMechanical engineering

The invention discloses a vulcanizing machine with an exhaust and expansion mechanism. An exhaust mechanism is arranged at the discharging end, wherein an exhaust hood can be adjusted in a lifting mode according to the height of a product to ensure the exhaust effect. The exhaust hood is matched with an exhaust passage through an organ hood to prevent exhaust gas from overflowing while the liftingadjustment is realized. An expansion part seals both ends of the expansion position of a heat-shrinkable tube workpiece through two sets of clamping transmission assemblies, so that the expansion gasis always left at the expansion position, and the heat-shrinkable tube workpiece does not need to be ventilated at all times, so that the wall thickness of each position of a heat-shrinkable tube after expansion is ensured to be consistent, the stability of the expansion process is improved, the expansion effect is ensured, and the production efficiency is improved.

Owner:苏州沃尔兴电子科技有限公司

A vulcanizer with exhaust and expansion mechanism

The invention discloses a vulcanizing machine with an exhaust and expansion mechanism. An exhaust mechanism is arranged at the discharging end, wherein an exhaust hood can be adjusted in a lifting mode according to the height of a product to ensure the exhaust effect. The exhaust hood is matched with an exhaust passage through an organ hood to prevent exhaust gas from overflowing while the liftingadjustment is realized. An expansion part seals both ends of the expansion position of a heat-shrinkable tube workpiece through two sets of clamping transmission assemblies, so that the expansion gasis always left at the expansion position, and the heat-shrinkable tube workpiece does not need to be ventilated at all times, so that the wall thickness of each position of a heat-shrinkable tube after expansion is ensured to be consistent, the stability of the expansion process is improved, the expansion effect is ensured, and the production efficiency is improved.

Owner:苏州沃尔兴电子科技有限公司

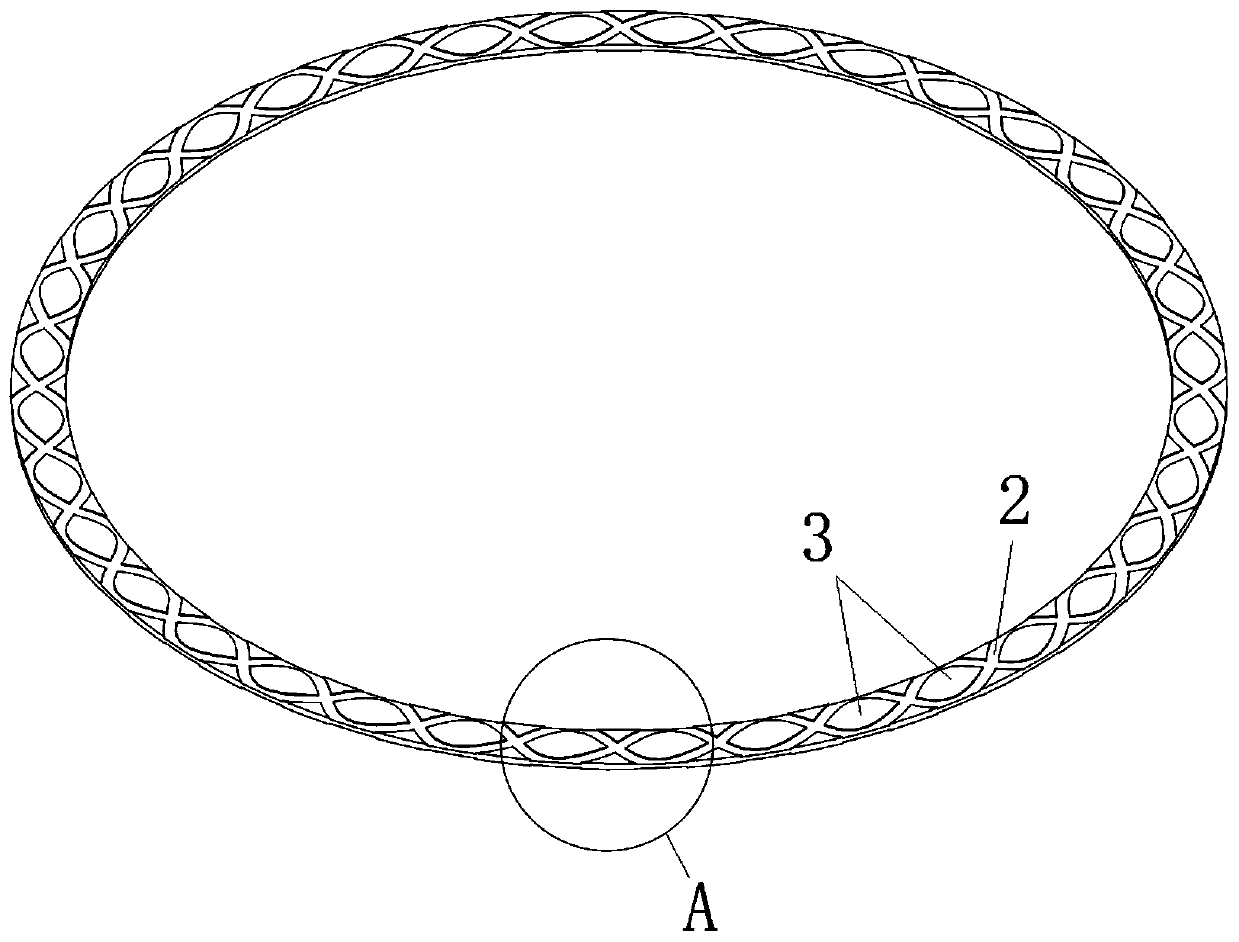

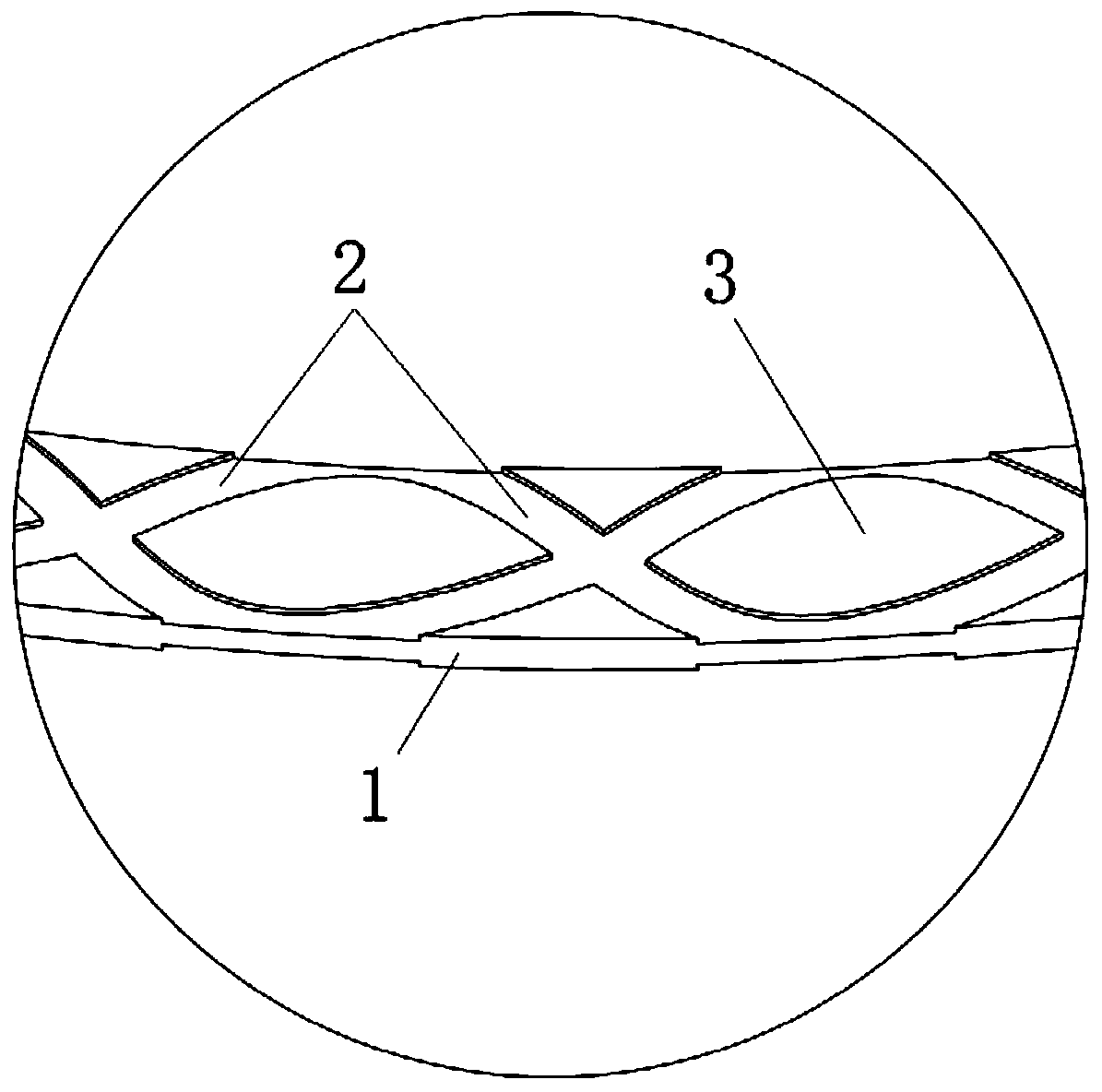

Air guide gasket and manufacturing method thereof

PendingCN110411613AImprove exhaust efficiency and exhaust effectGuaranteed exhaust effectForce measurementPressure difference measurement between multiple valvesEngineeringMechanical engineering

The invention provides an air guide gasket and a manufacturing method thereof, and belongs to the technical field of equipment specially used for manufacturing sensors. The air guide gasket is of an annular structure and comprises a gasket body and air guide grooves, wherein the gasket body is of an annular structure and is provided with an upper junction surface and a lower junction surface, andthe air guide grooves are formed in at least one junction surface of the gasket body and communicated with the inner and outer sides of the gasket body. When the air guide gasket is in use, through the air guide grooves, the inner and outer sides of the gasket body are communicated with each other, on the premise that the original thickness of the gasket body is unchanged, air in an inner ring ofthe gasket body can be quickly and efficiently exhausted during vacuumizing, thus the situation that the air is caught in the annular gasket is avoided, and the exhaust efficiency and exhaust effect of a sensor during ultrahigh vacuum exhaust are improved.

Owner:CHUANBEI VACUUM TECH BEIJING +1

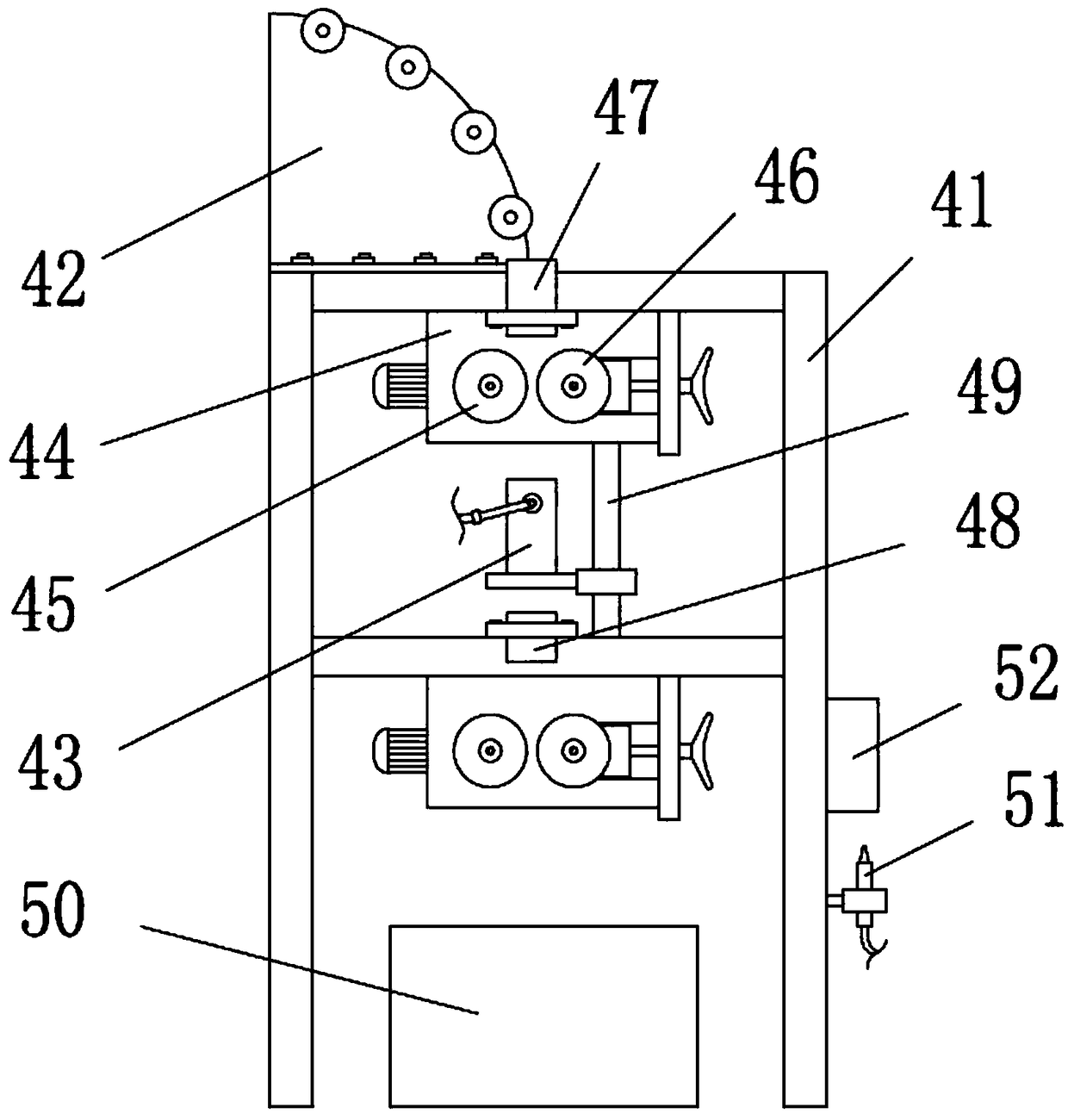

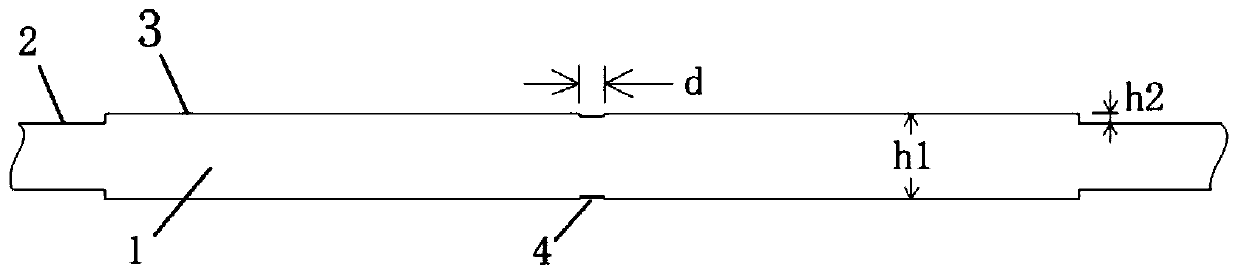

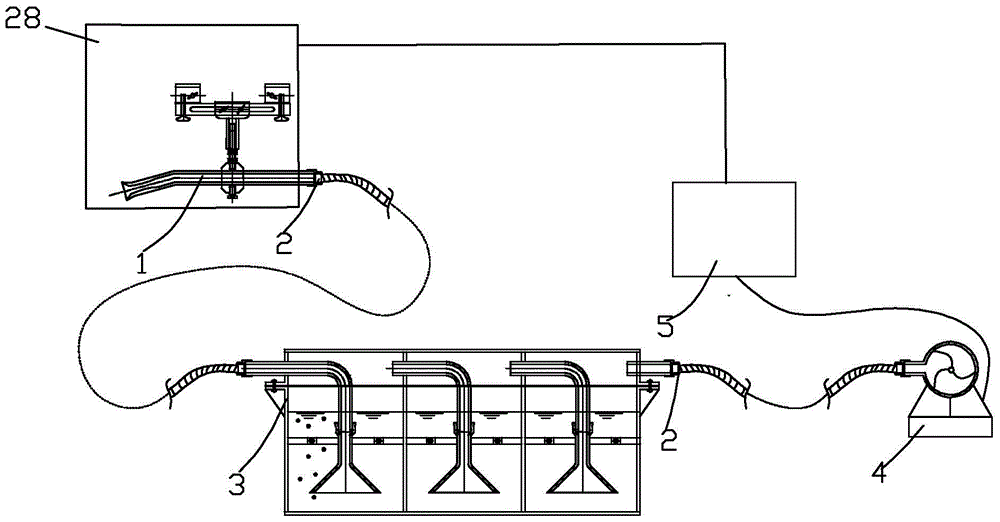

A kind of smoke and dust direct discharge type environment-friendly welding auxiliary device

ActiveCN104923996BEasy to installGuaranteed exhaust effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoot

The invention provides a smoke directly-discharging type environment-friendly auxiliary welding device. The device comprises a welder, a suction nozzle, a conveying pipe, a smoke filter, an exhaust fan and an energy converter and is characterized in that the energy converter is connected with the welder and the exhaust fan in a controlling mode, fixed to the welder through the suction nozzle, and connected with the suction nozzle and the smoke filter through the conveying pipe, the exhaust fan is directly connected with the smoke filter, the energy converter is an electromagnetic conversion type energy converter, the energy converter and the welder are connected to a power supply in parallel, and the magnetic fielded generated by the power supply of the welder is converted through the energy converter to drive the exhaust fan to work. According to the device, harmful gas and smoke generated by welding are directly discharged through a working point, magnetic field energy generated when the welder works can be utilized to provide exhaust power, extra electric energy does not need to be provided, and therefore exhaust power is obtained and waste energy reutilization is achieved.

Owner:陈建平

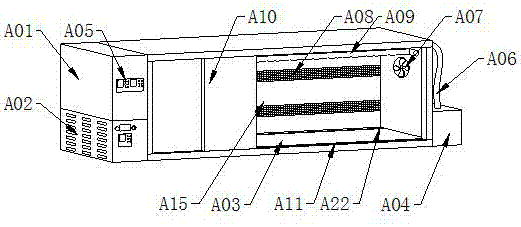

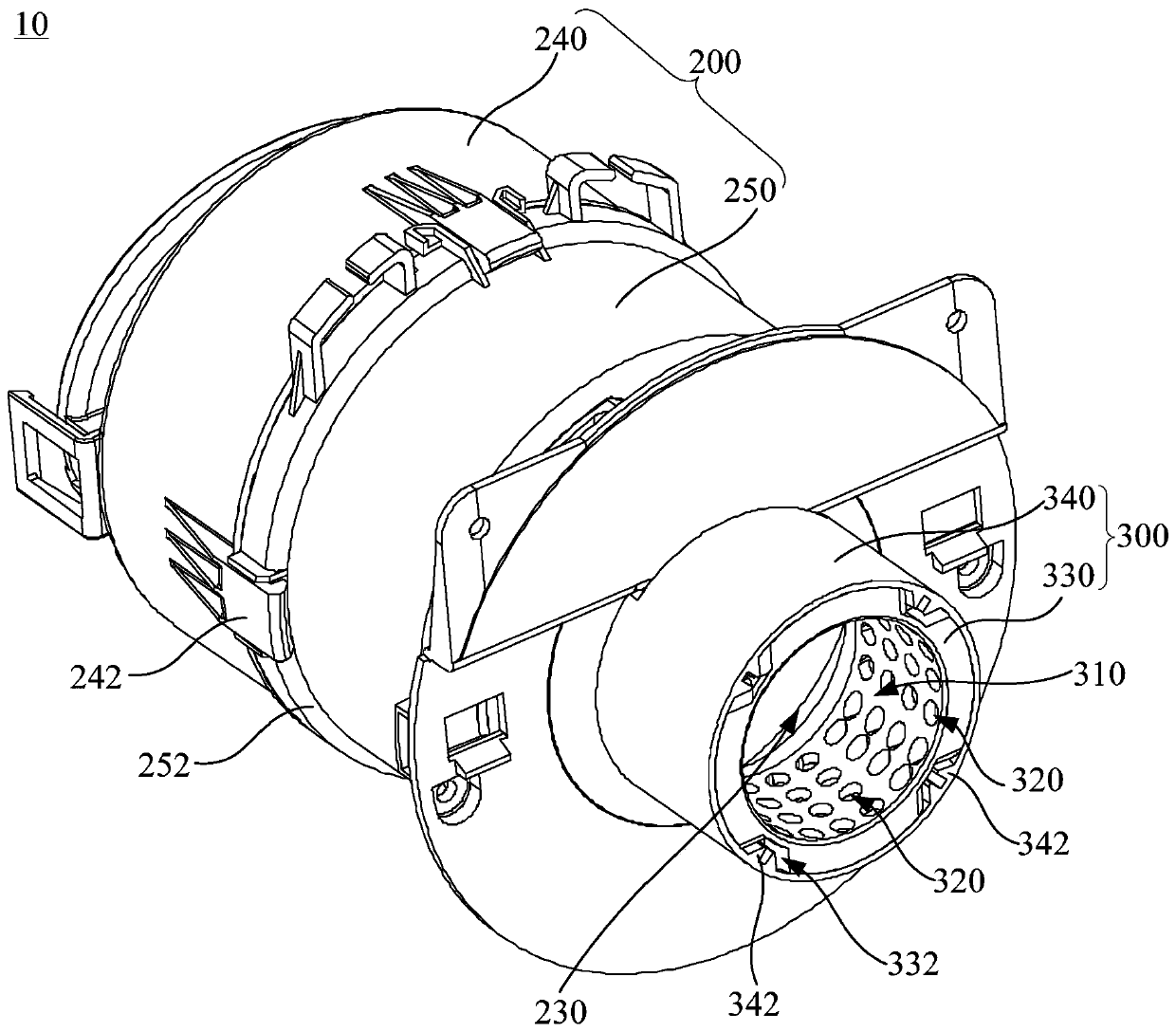

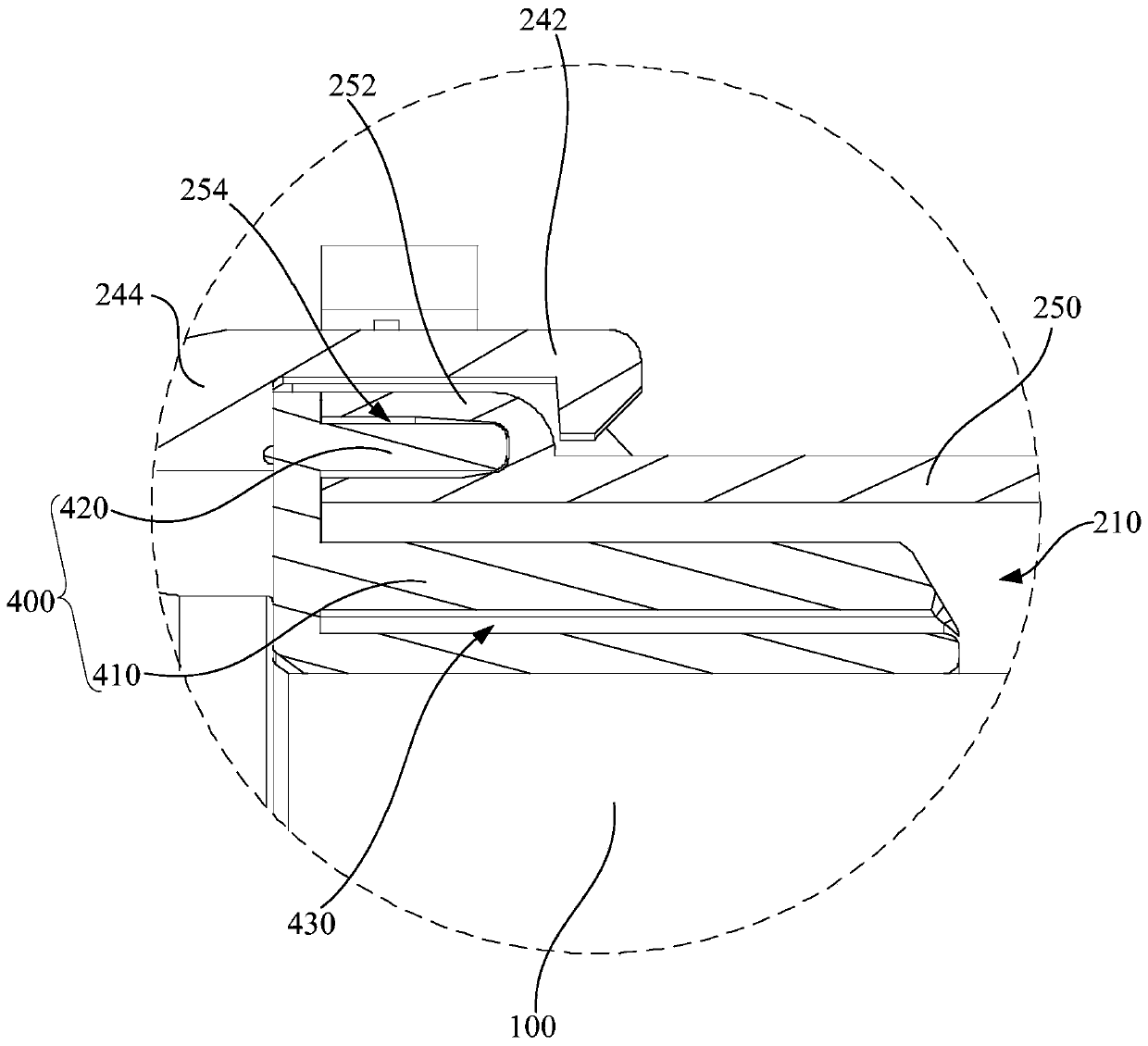

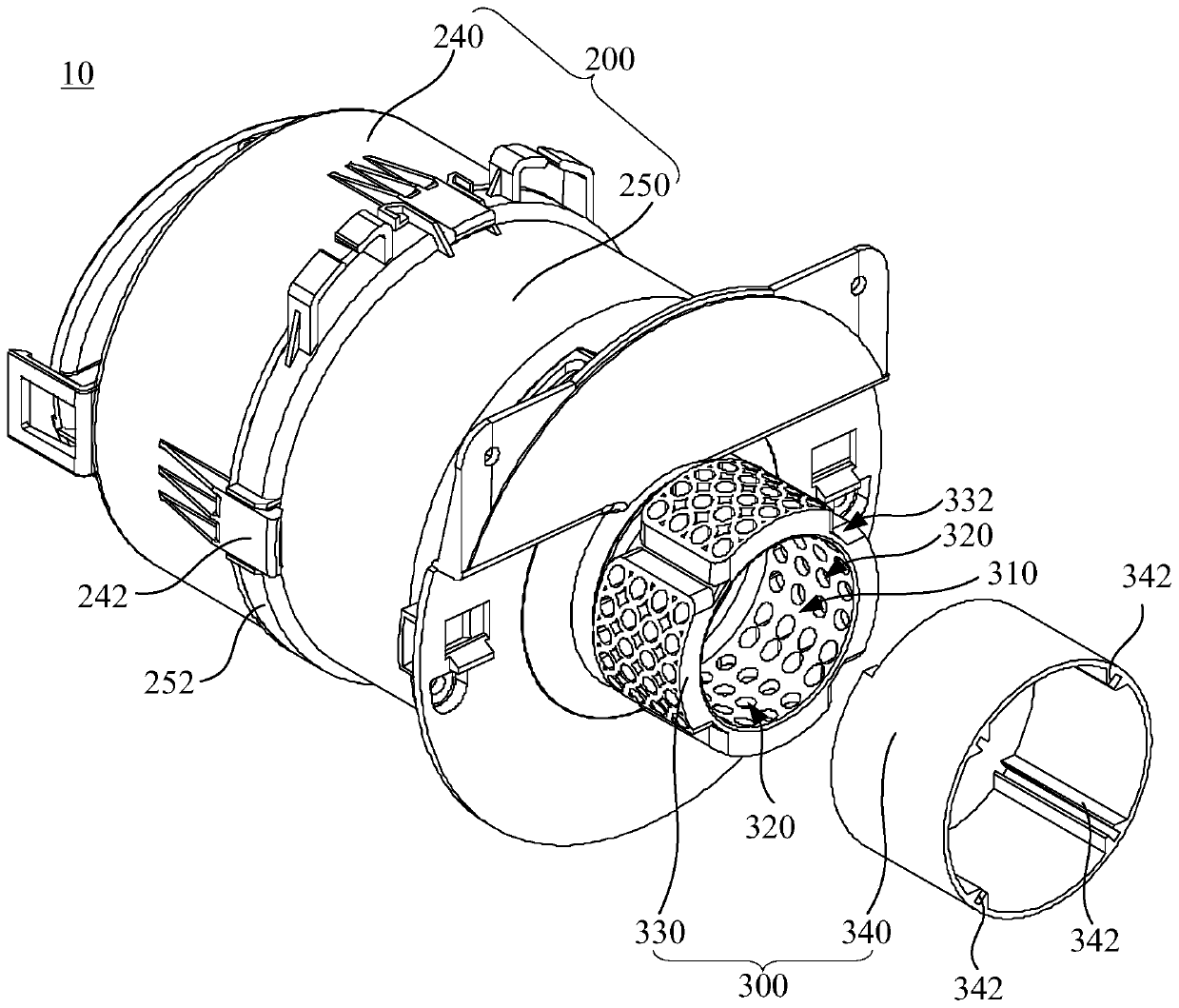

Dust collector, motor assembly and shell structure thereof

PendingCN110664308AIncrease the lengthGuaranteed exhaust effectExhaust-air diffusionSupports/enclosures/casingsElectric machineryEngineering

The invention relates to a dust collector, a motor assembly and a shell structure thereof. The motor assembly comprises a motor and the shell structure, wherein the shell structure comprises a machineshell and an exhaust assembly; the motor is arranged in an accommodating cavity of the machine shell; and air is sucked from a machine shell air suction port and is discharged into an exhaust channelof the exhaust assembly through an exhaust port. Due to the fact that a plurality of silencing cavities which are arranged at intervals are formed in the inner wall of the exhaust channel, noise in the exhaust process is absorbed by the silencing cavities arranged at intervals, and then exhaust noise is reduced. By arranging the silencing cavities, prolonging of the length of the exhaust channelcan be avoided, the size of the shell structure is further reduced, the size of the motor assembly is further reduced, the size of the dust collector is reduced, and the structure of the dust collector is more compact. Meanwhile, due to the fact that prolonging of the length of the exhaust channel is avoided, increasing of the exhaust air resistance can be avoided, and the exhaust performance of the dust collector can be effectively guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

A plastic mold

ActiveCN105729722BSlow down the flowReduce the chance of air bubblesCoatingsPlastic packagingSemiconductor

The invention discloses a plastic packaging mold and relates to the field of plastic packaging of semiconductors. The plastic packaging mold comprises an upper mold body and a lower mold body used for containing a PCB. The lower surface of the upper mold body is sunken towards the upper surface of the upper mold body to form a groove. When the upper mold body and the lower mold body are pressed and combined, a molding cavity is formed between the groove and the PCB. One end of the molding cavity communicates with an air discharge duct. The end, close to the air discharge duct, of the groove is provided with a buffer area used for balancing molding flow. The molding flow in the molding cavity is balanced through the buffer area. The discharge time of the air in the molding cavity is prolonged, and the product quality is improved.

Owner:HUANWEI ELECTRONICS SHANGHAI CO LTD

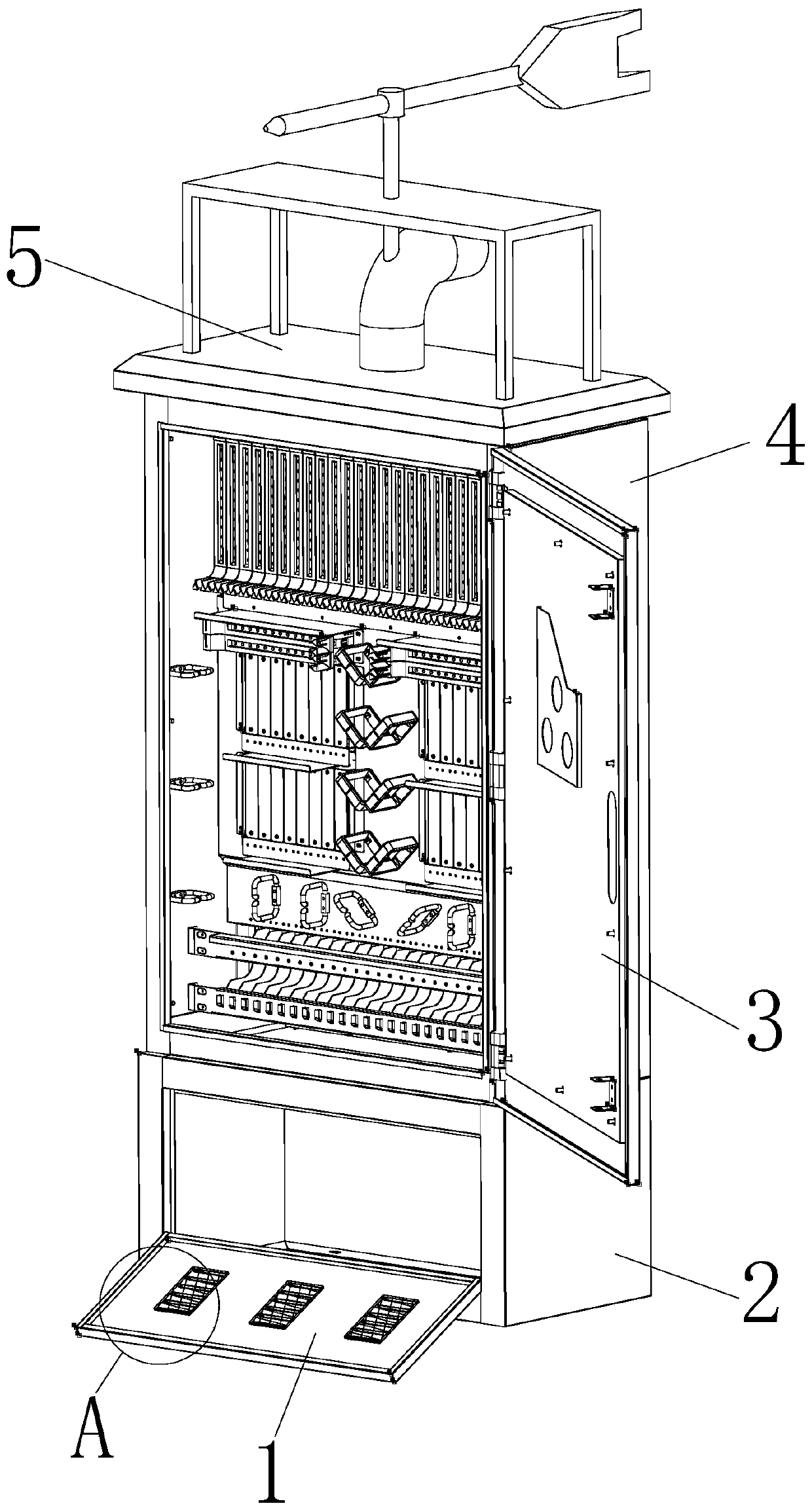

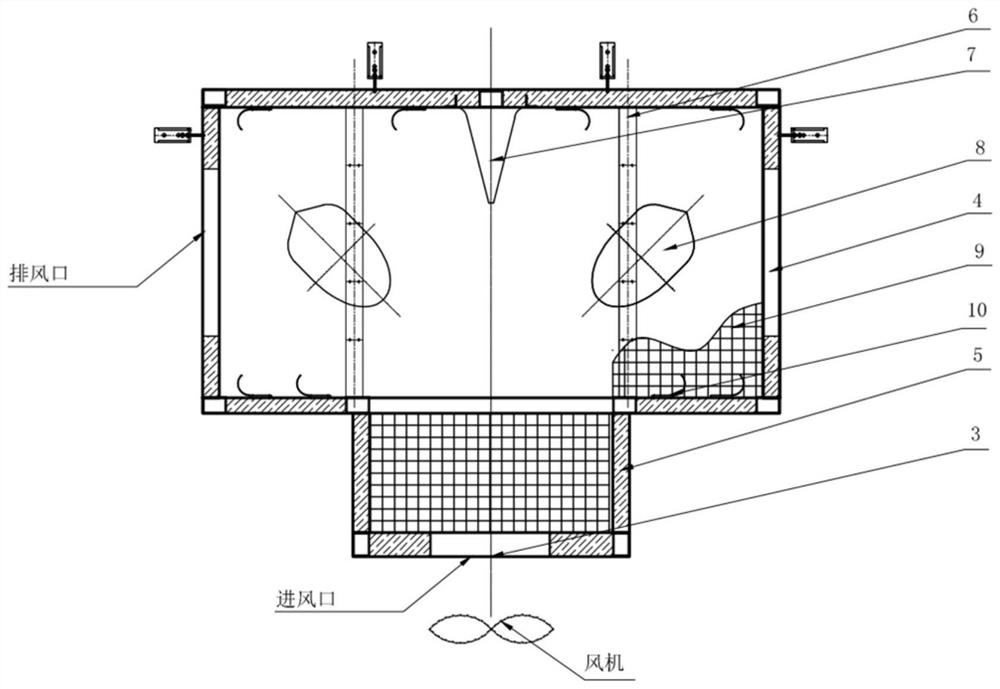

Ventilation system of garbage classification station

PendingCN113666033AReduce odorImprove the overall environmentRefuse receptaclesRefuse cleaningVentilation ductProcess engineering

The invention discloses a ventilation system of a garbage classification station. The ventilation system comprises a first ventilation pipeline, second ventilation pipelines and a storage cavity which are arranged in the garbage classification station, and further comprises an exhaust assembly which is arranged outside the garbage classification station and communicated with the storage cavity. The first ventilation pipeline, the second ventilation pipelines and the storage cavity are sequentially arranged in a communicated mode. A collecting assembly is arranged in the first ventilation pipeline, and deodorization assemblies are arranged in the second ventilation pipelines and are detachably fixed to the second ventilation pipelines. A gas exhaust path in the garbage classification station is formed by the first ventilation pipeline, the second ventilation pipelines, the storage cavity and the exhaust assembly in sequence. Gas in the garbage classification station can be rapidly discharged through the path, and the exhaust effect in the garbage classification station is guaranteed; and the gas is treated by the deodorization assemblies, so that the peculiar smell of the discharged gas is reduced, and the overall environment of the garbage classification station is improved.

Owner:安徽世绿环保科技有限公司

Automatic waterproof device for automobile exhaust pipe

ActiveCN109372621BGood water release effectGuaranteed exhaust effectExhaust apparatusSilencing apparatusPiston ringEngineering

The invention provides an automatic water-preventing device for an automobile exhaust pipe. The device comprises a connecting pipe, a silencing plug, a tail end exhaust plate, a sliding rod, a slidingpiston, a front end exhaust plate, a front end exhaust hole, and a sealing piston; the silencing plug is arranged in the connecting pipe, the tail end exhaust plate is arranged in the connecting pipeand provided with a plurality of tail end exhaust holes, the sliding rod is inserted into the tail end exhaust plate, the sliding piston is fixedly connected with the sliding rod, the front end exhaust plate is arranged in the connecting pipe, the front end exhaust hole is formed in the front end exhaust plate, and the sealing piston is arranged on the sliding rod; a piston ring cavity used for containing the sealing piston is arranged in the connecting pipe, the piston ring cavity is internally provided with a lateral spring which acts on the sealing piston so as to enable the sealing pistonto be in clearance with the front end exhaust hole; and a sealing ring cavity is formed in the connecting pipe, and a rapid sealing mechanism is arranged in the piston ring cavity. According to the device, the water-preventing effect is good, the exhaust effect is ensured, and the abnormal sounds are avoided.

Owner:HANGZHOU POLYTECHNIC

Tin soldering device for electronic product production

InactiveCN111822809AGuaranteed exhaust effectSave electricityMetal working apparatusSoldering auxillary devicesToxic gasHeat conducting

The invention belongs to the technical field of electronic products, and particularly relates to a tin soldering device for electronic product production. A scheme is presented with regard to the problem of a tin soldering device wasting electrical energy. According to the scheme, the tin soldering device comprises a handheld pipe; the bottom of a connecting rod is in embedding sliding connectionwith a heat conducting pipe; a tin soldering tip is welded to the bottom of the heat conducting pipe; a guiding rod is mounted in the connecting rod in a penetrating mode; a sliding block is slidablyconnected to the guiding rod; a first spring is welded to the top of the sliding block; a fixing ring sleeves the guiding rod; the other side of the first spring is fixed to the top of the fixing ring; a supporting rod is fixed to the outer side of the fixing ring; an exhausting box is fixed to the bottom of the supporting rod; and an exhausting mechanism is mounted in the exhausting box. According to the tin soldering device for electronic product production, during spot welding, the tin soldering tip drives the heat conducting pipe and the sliding block to move upwards, and the first springis stressed to sequentially drive the fixing ring, the supporting rod and the exhausting box to move downwards, so that the exhausting mechanism is close to an electric welding position to exhaust poisonous gases, the tin soldering device is used for exhausting pertinently, and electric energy is saved on the premise of ensuring the exhausting effect.

Owner:SUZHOU YUQIAN INFORMATION TECH CO LTD

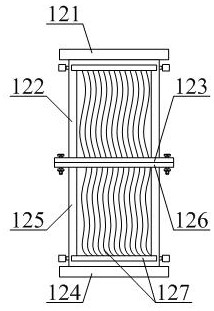

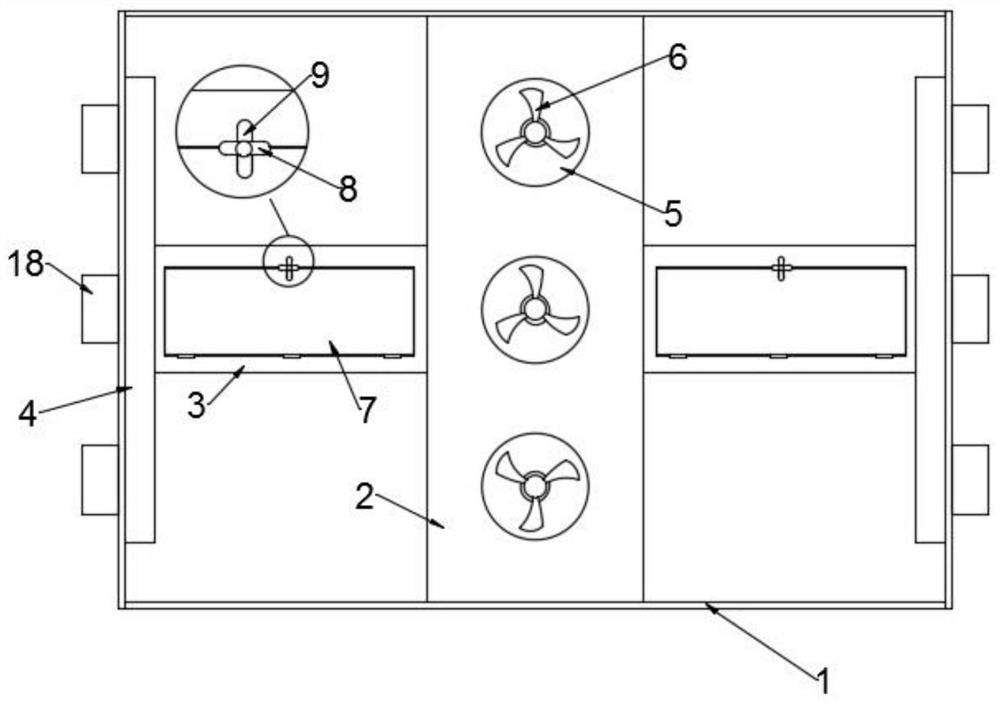

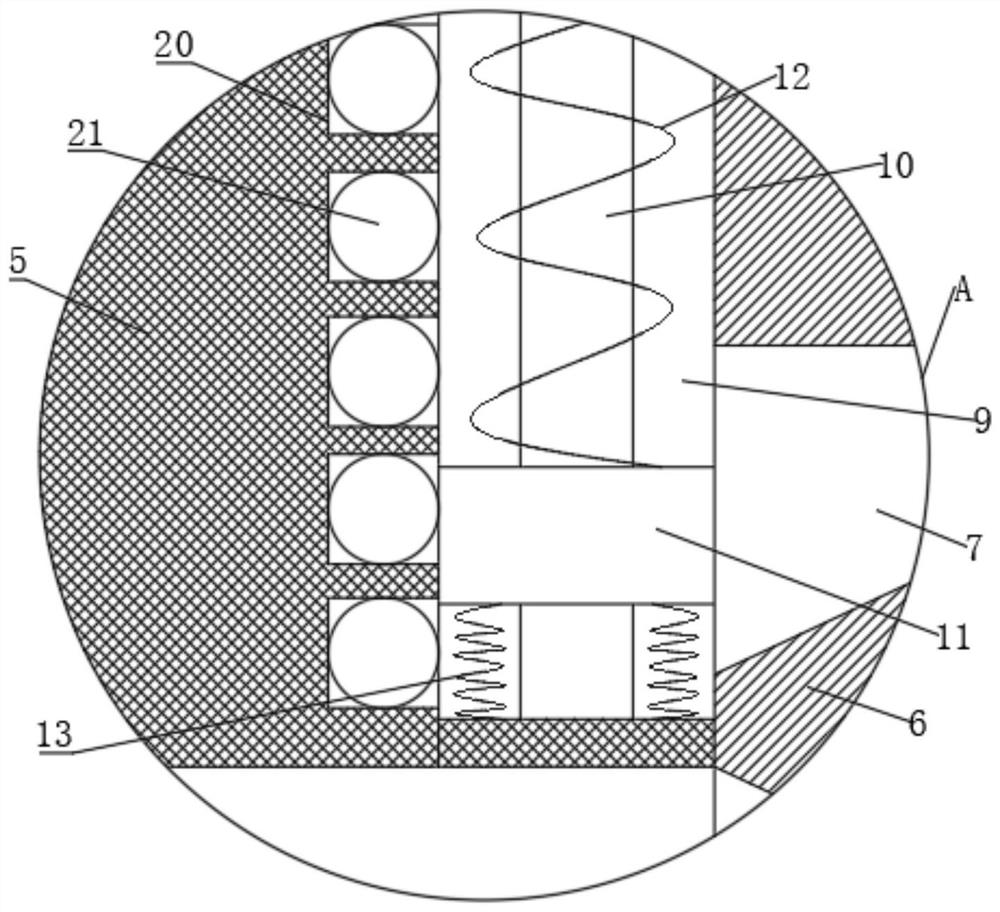

T-shaped impedance micropore multi-combination exhaust silencing device

ActiveCN111946670AGuaranteed exhaust effectImprove noise reductionPump componentsPumpsStructural engineeringAir velocity

The invention discloses a T-shaped impedance micropore multi-combination exhaust silencing device. The T-shaped impedance micropore multi-combination exhaust silencing device comprises a metal frame,wherein a stainless steel skin wraps the surface of the metal frame, the whole metal frame is T-shaped, an air inlet is formed in the tail end of the T-shaped metal frame, exhaust outlets are formed in the left end and the right end of the T-shaped metal frame, resonance boxes cover the side walls and the top face of the interior of the stainless steel skin, a tight box wall is formed, and a second sealing layer is formed. In the device, a metal flow guide wedge faces the air inlet, the left side and the right side of the metal flow guide wedge are provided with a sliding rail and a bullet flow guide column respectively, and the bullet flow guide column is arranged on the sliding rail and can slide along the sliding rail. The resonance boxes, the metal flow guide wedge and the bullet flowguide column are filled with sound absorption materials, and holes are formed in the surfaces of the resonance boxes, the metal flow guide wedge and the bullet flow guide column. According to the device, an expansion type impedance silencing principle is adopted, air can enter the device and can be rapidly expanded by 10 times or above in the channel space of the device, and the air speed is rapidly reduced; and meanwhile, sound waves are refracted along a 90-degree elbow, sound energy is consumed, and noises can be reduced by 45 dB or above.

Owner:绍兴华放新材料有限公司

Sheet welding preventing method

ActiveCN102026495BImprove printing qualityImprove plug hole effectNon-metallic protective coating applicationCooking & bakingScreen printing

The invention relates to a sheet welding preventing method, which comprises the following operation flow: (1) performing copper plate pre-treatment on a circuit board; (2) screen printing a first face by using a gas-guide base plate, standing, pre-baking the first face and cooling; (3) screen printing a second face by using a waste film as a cushion, standing and pre-baking the second face; and (4) aligning, developing and post-baking. Compared with the conventional sheet welding preventing method, the sheet welding preventing method has the innovation that: the first face is screen printed by adopting the gas-guide base plate and the second face is screen printed by using the waste film as the cushion, so that working staff can better control the hole-pass inking amount in a production process and control hole blockage to be at a rational level of approximate 80 percent; the method is simple in operation, high in efficiency and high in operability; when used for manufacturing a sheet, the method can obviously improve the hole blockage effect and can effectively improve the gas exhaust effect of hole passing when blocking and printing are carried out at the same time during singleface manufacturing and avoid the phenomenon that copper is exposed from a circuit; and the traditional time-wasting nail bed screen printing is obviated, so that the printing quality of the circuit board is greatly improved and the production efficiency of sheets is improved.

Owner:AOSHIKANG TECH CO LTD

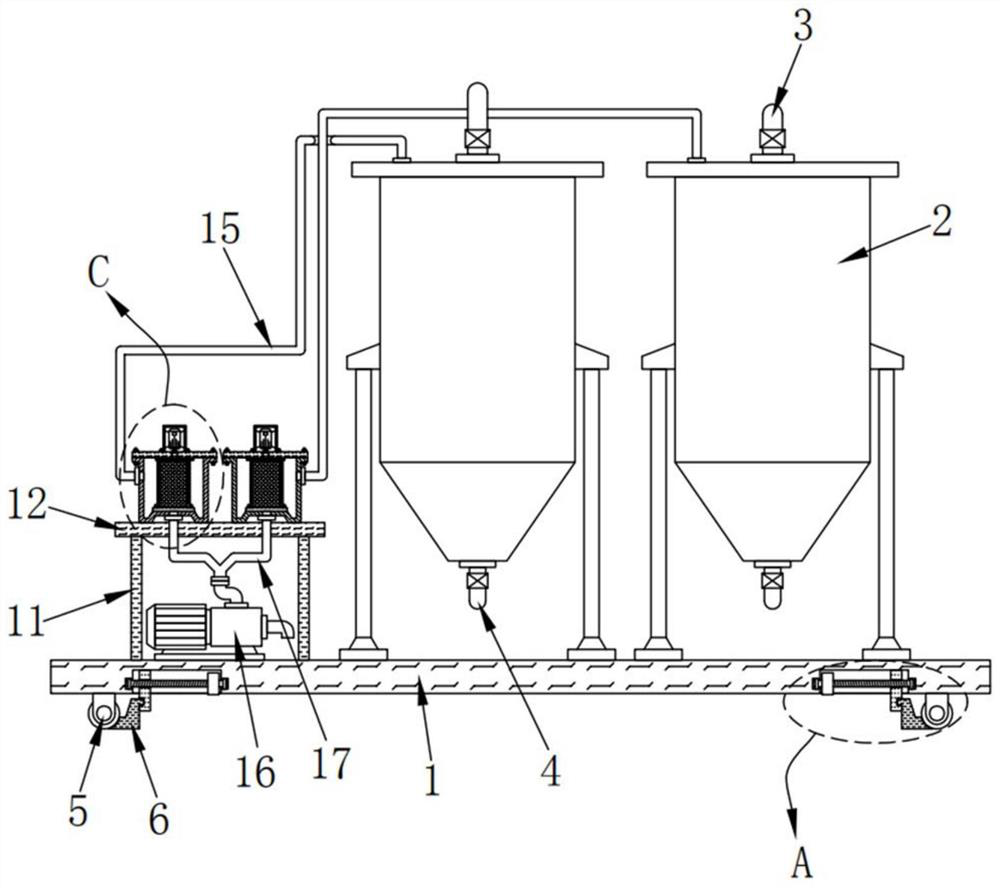

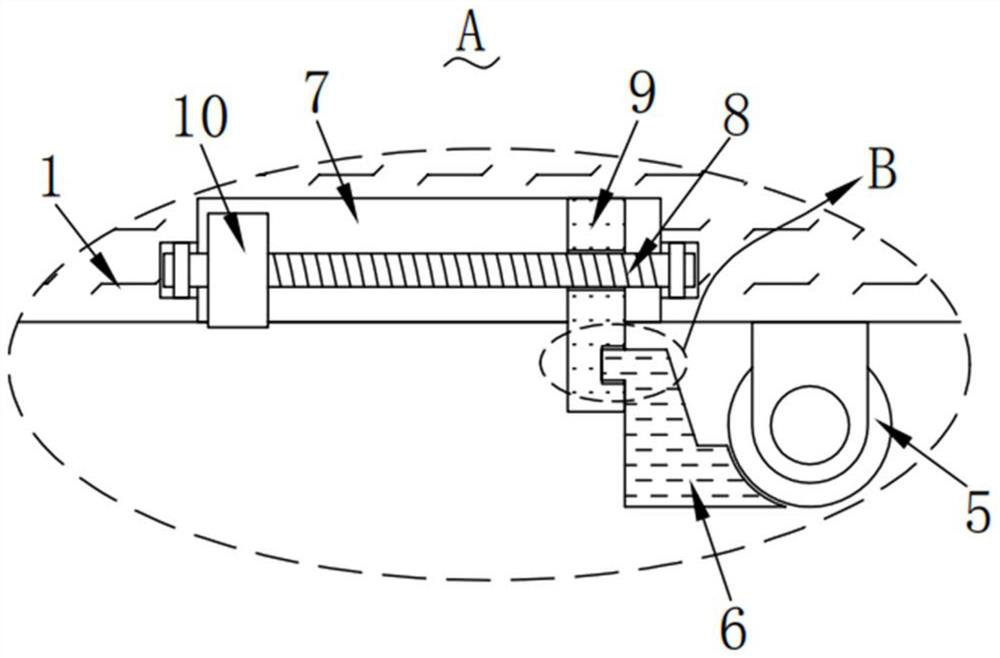

A kind of progesterone raw material classification and preservation device

ActiveCN113023140BEasy to moveFacilitate subsequent collection and processingDispersed particle filtrationLarge containersAnimal scienceEngineering

Owner:河北今水生物科技有限公司

Pump base of lubricating pump and lubricating pump

PendingCN111720721AReduce air contentEasy to driveLubricating pumpsLubrication elementsOil and greaseThermodynamics

The invention relates to the technical field of lubricating equipment, and in particular relates to a pump base of a lubricating pump and the lubricating pump. The lubricating pump comprises the pumpbase and an oil tank, wherein the pump base comprises a base body, a sealed oil cavity is defined by the base body and the oil tank, an oil filling orifice is formed in the bottom of the base body, the oil filling orifice has the upward opening and is eccentrically arranged, an exhaust channel is arranged in the oil tank or the base body, and a flow guide plate is arranged in the base body. When oil is injected into the lubricating pump, after the grease enters the oil cavity in the upper portion of the base body from the oil filling orifice, the grease first moves to the position far away from the oil filling orifice in the horizontal direction under pressing of the flow guide plate so as to horizontally spread, then the grease in the oil cavity is wholly lifted, therefore, the grease inthe oil cavity can better drive air in the base body upwards in the accumulation and rising process, and the air is exhausted to the outside through the exhaust channel. In this way, the air content in the grease entering the oil tank is effectively reduced, and then the lubricating effect of the lubricating pump is improved.

Owner:AUTOL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com