Tin soldering device for electronic product production

A technology for electronic products and soldering, applied in auxiliary devices, welding equipment, metal processing, etc., can solve the problems of waste of electric energy and untargeted gas absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

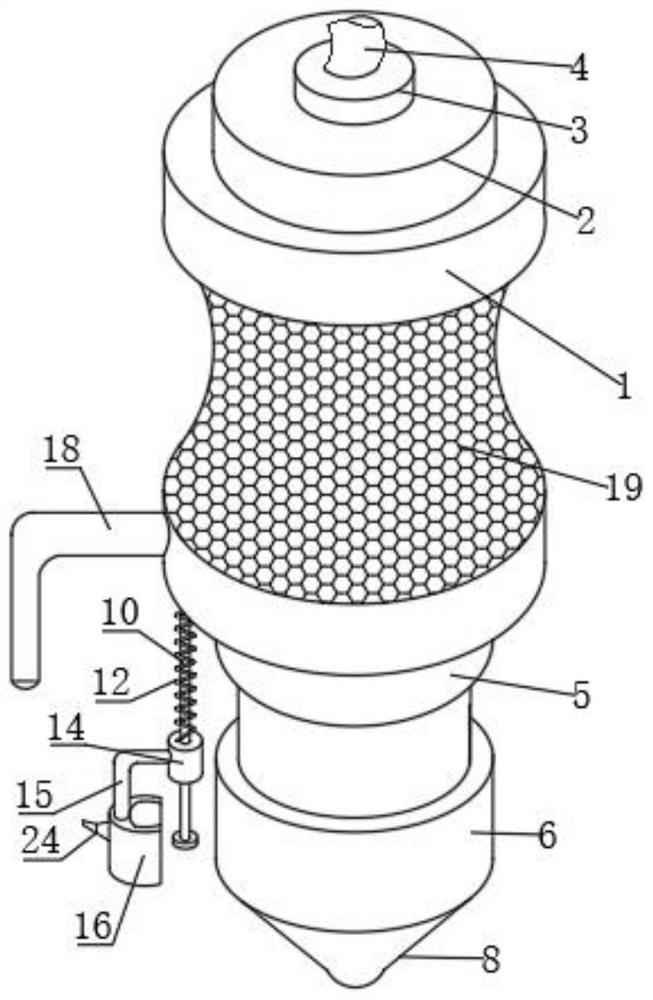

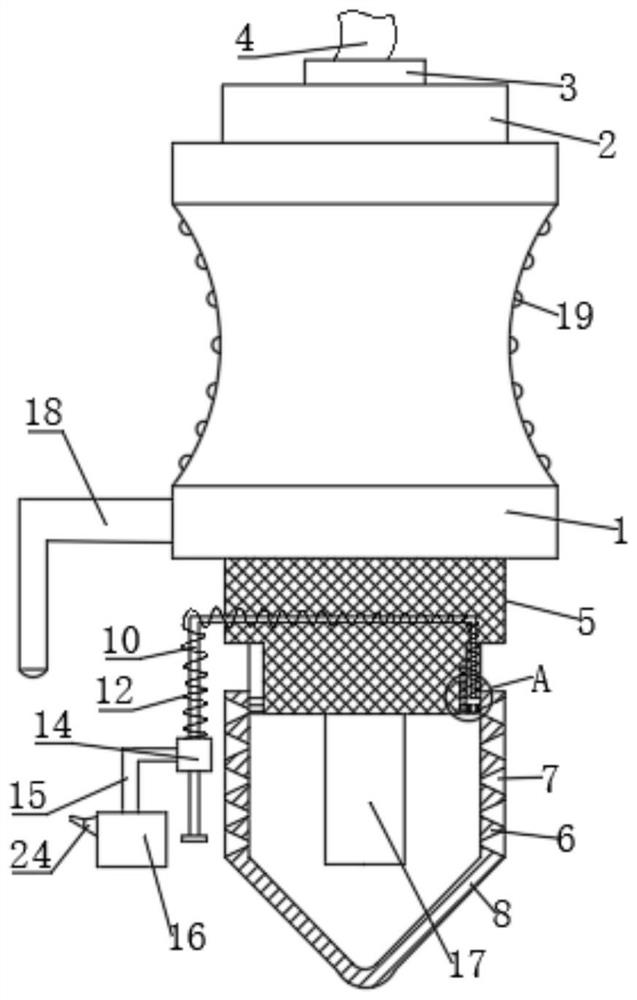

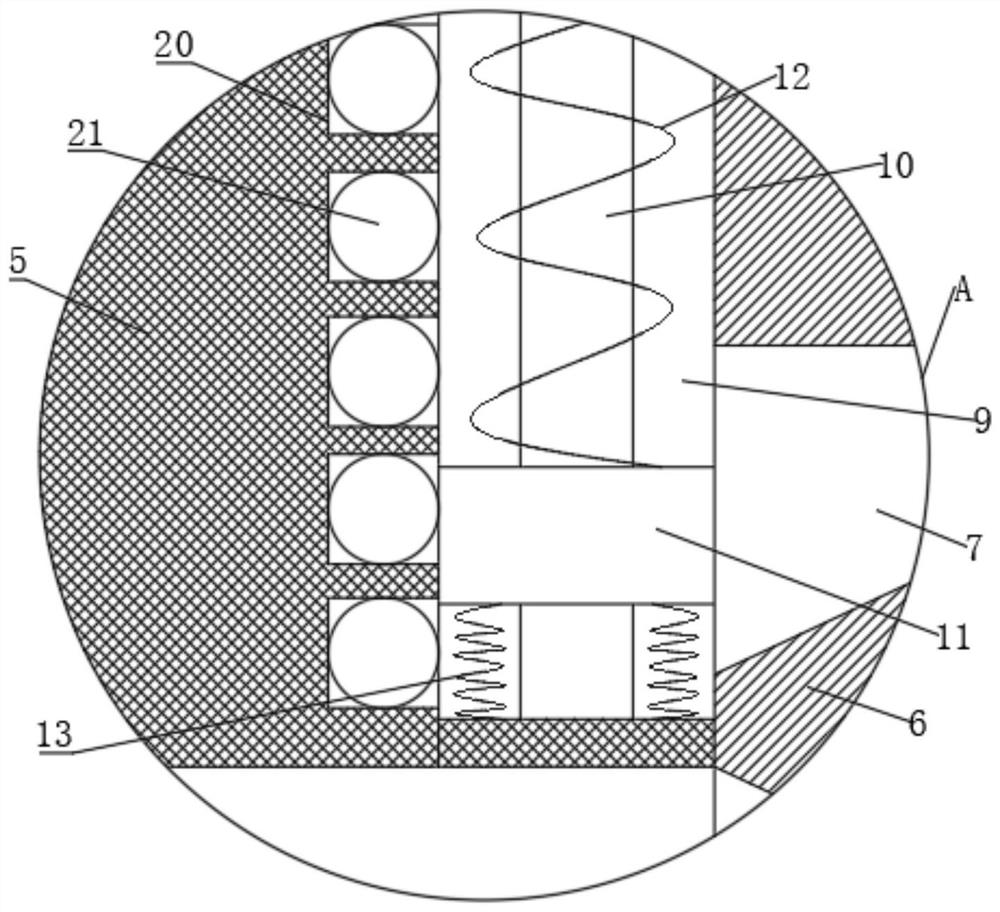

[0026] refer to Figure 1-3 , a soldering device for the production of electronic products, comprising a hand-held tube 1, a support column 2 is welded on the top of the hand-held tube 1, a wire harness ring 3 is welded on the top of the support column 2, and a wire 4 is threaded inside the wire harness ring 3, The bottom of the hand tube 1 is welded with a connecting rod 5, the bottom of the connecting rod 5 is nested and slidably connected to a heat pipe 6, the bottom of the heat pipe 6 is welded with a soldering tip 8, the connecting rod 5 is pierced with a guide rod 10, and the cross section of the guide rod 10 is Set to U-shape, two chutes 9 are provided symmetrically on both sides of the connecting rod 5, the bottom of the guide rod 10 and the bottom of the inner wall of the chute 9 are fixed by bolts, and the guide rod 10 is connected with a sliding block 11 through sliding, the outer side of the sliding block 11 and the inner wall bottom of the chute 9 are fixed by bolt...

Embodiment 2

[0030] refer to Figure 1-5 , a soldering device for the production of electronic products, the cross section of the exhaust box 16 is arranged in an arc shape, the inner surface of the exhaust box 16 is provided with a plurality of protrusions 22, the cross section of the protrusions 22 is arranged in an arc shape, and the protrusions 22 are provided with Fine air extraction holes 23, the exhaust mechanism is fixed with a support rod 25 by bolts inside the exhaust box 16, a motor 26 is fixed on the inside of the support rod 25 by bolts, the output shaft of the motor 26 is connected with an exhaust fan 27, and the exhaust box 16 is away from One side of the air extraction hole 23 is fixed with an exhaust pipe 24 by bolts, and the exhaust pipe 24 is arranged to be bent and narrowed from the inside out.

[0031] During use, start the motor 26, and the motor 26 drives the exhaust fan 27 to rotate and exhaust. The exhaust box 16 cross-sections are arranged in an arc shape, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com