Patents

Literature

118results about How to "Fast exhaust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

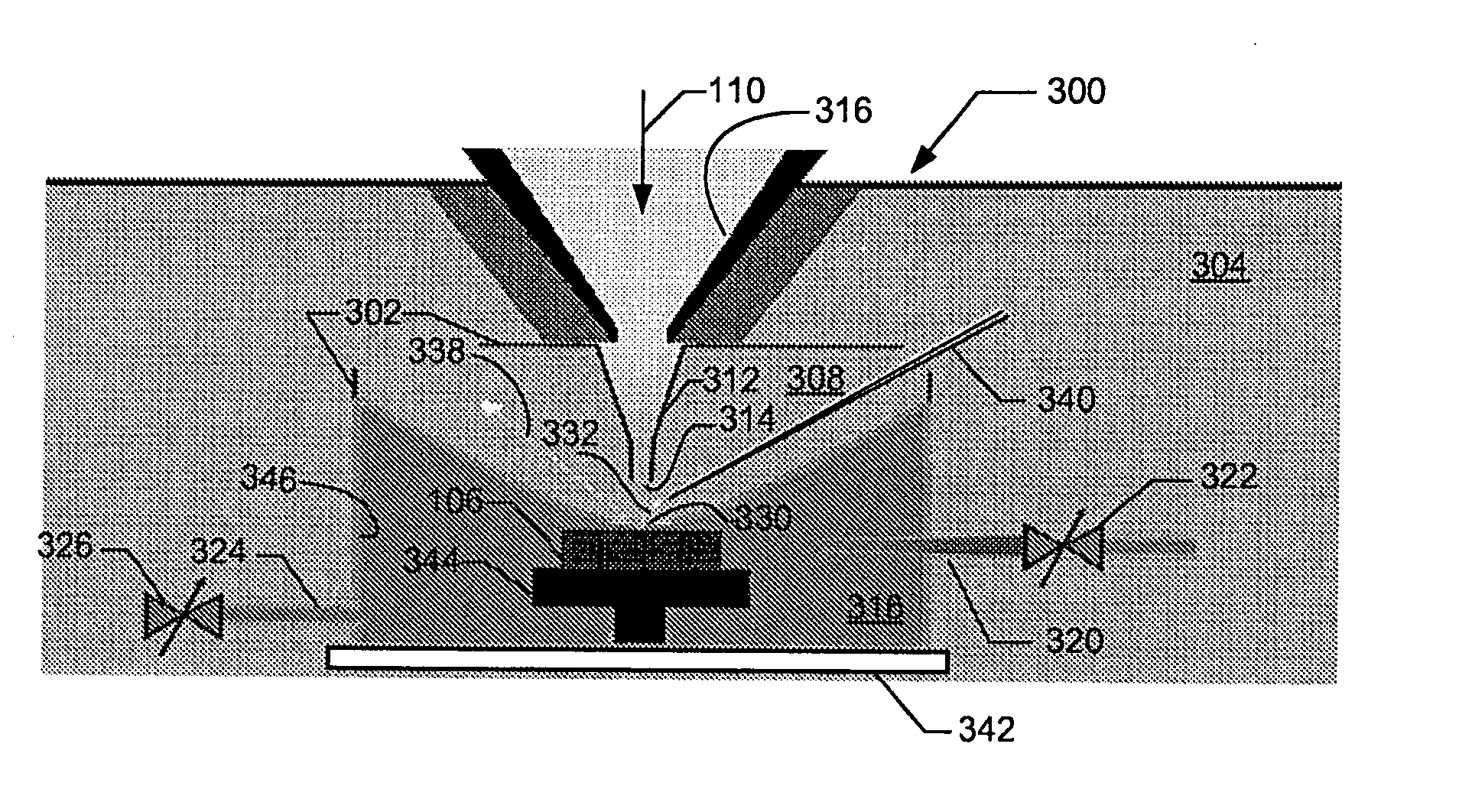

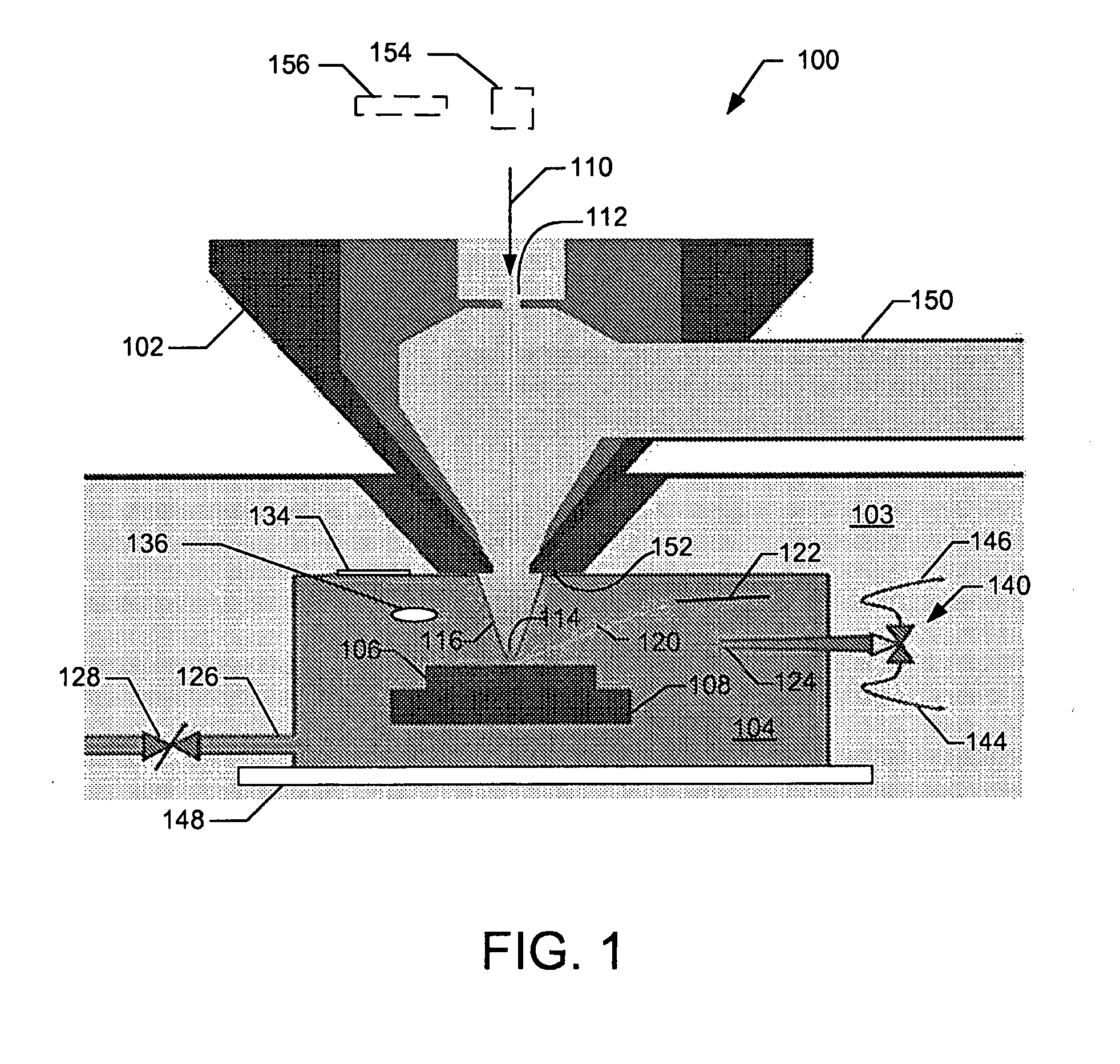

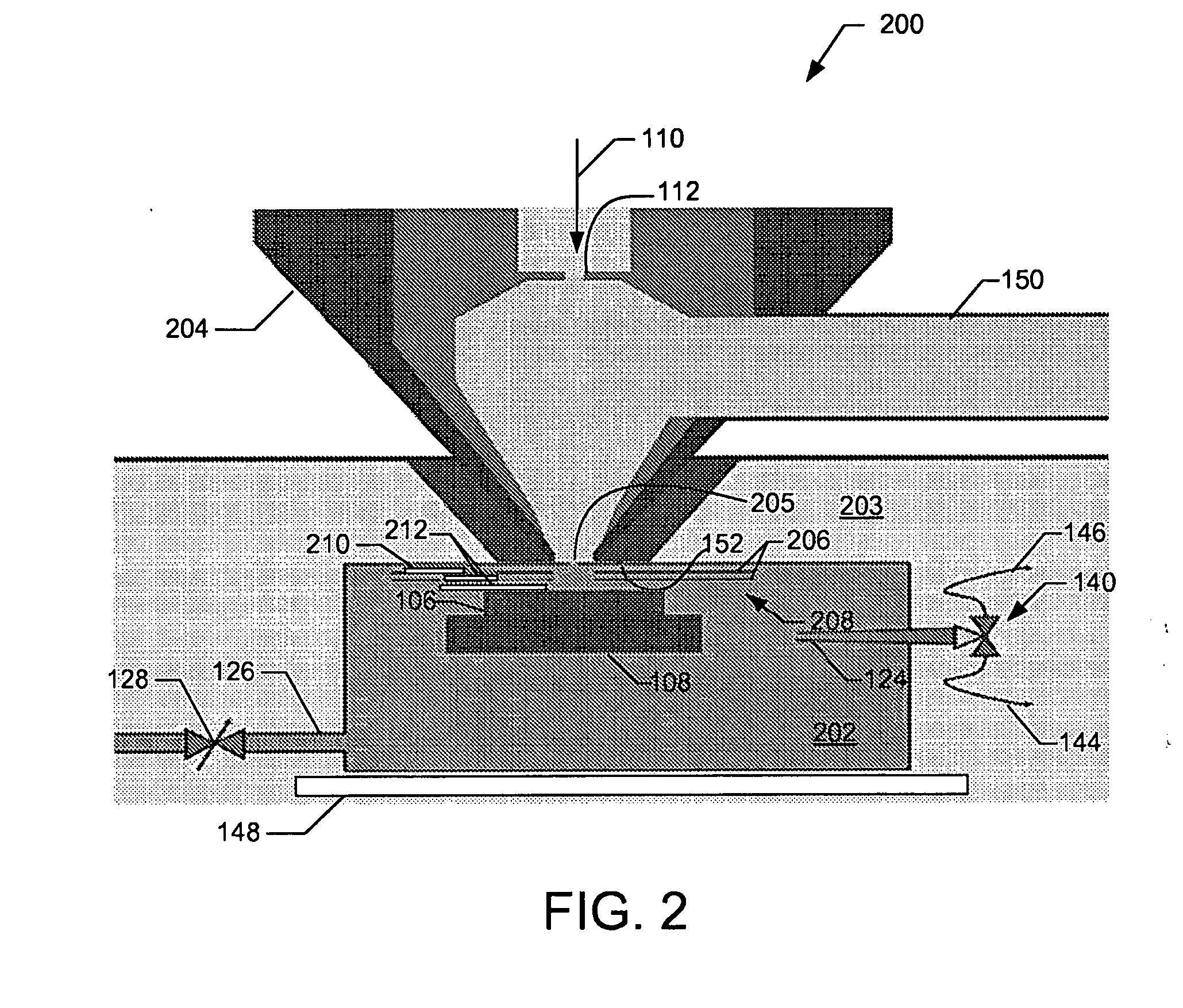

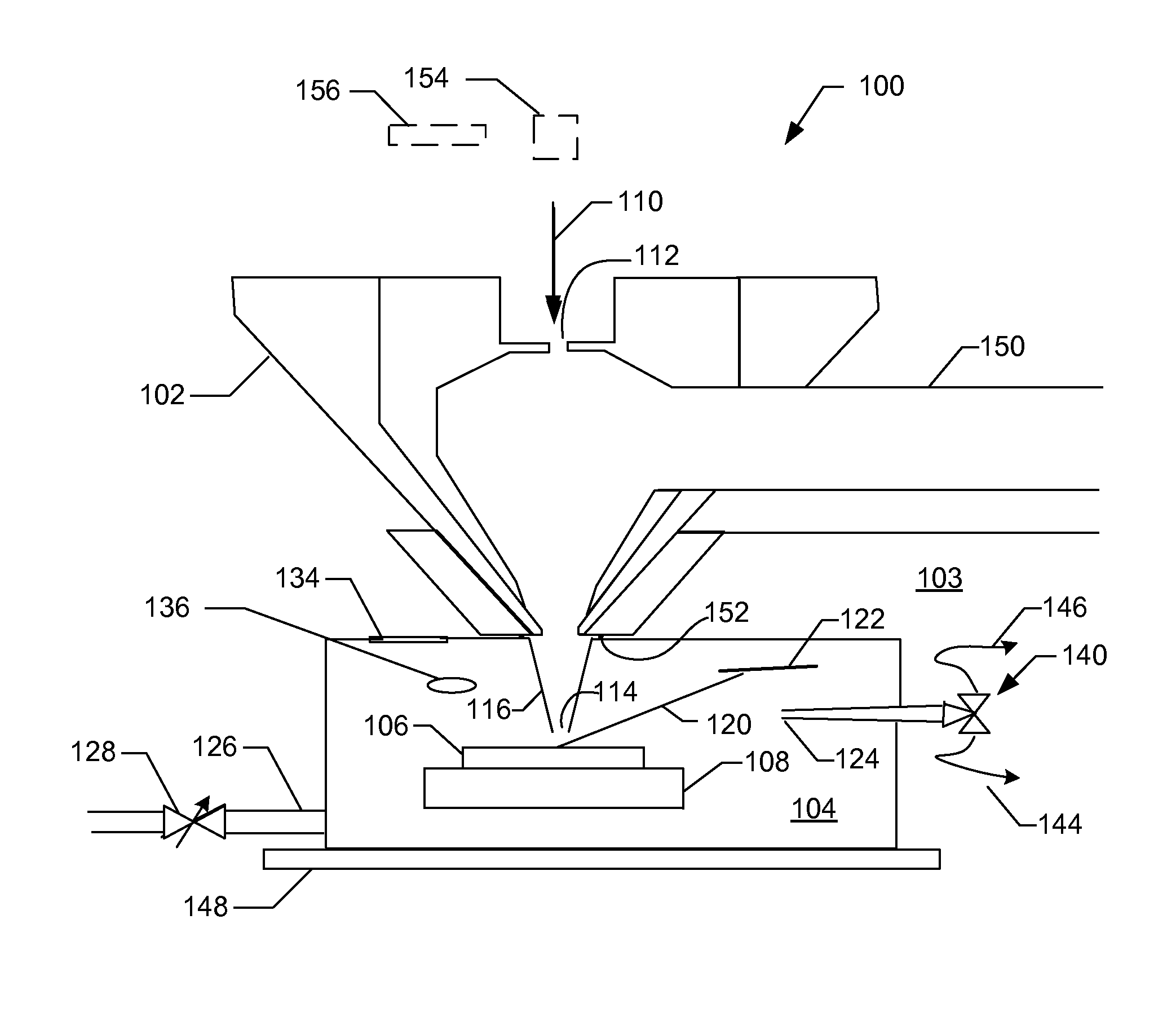

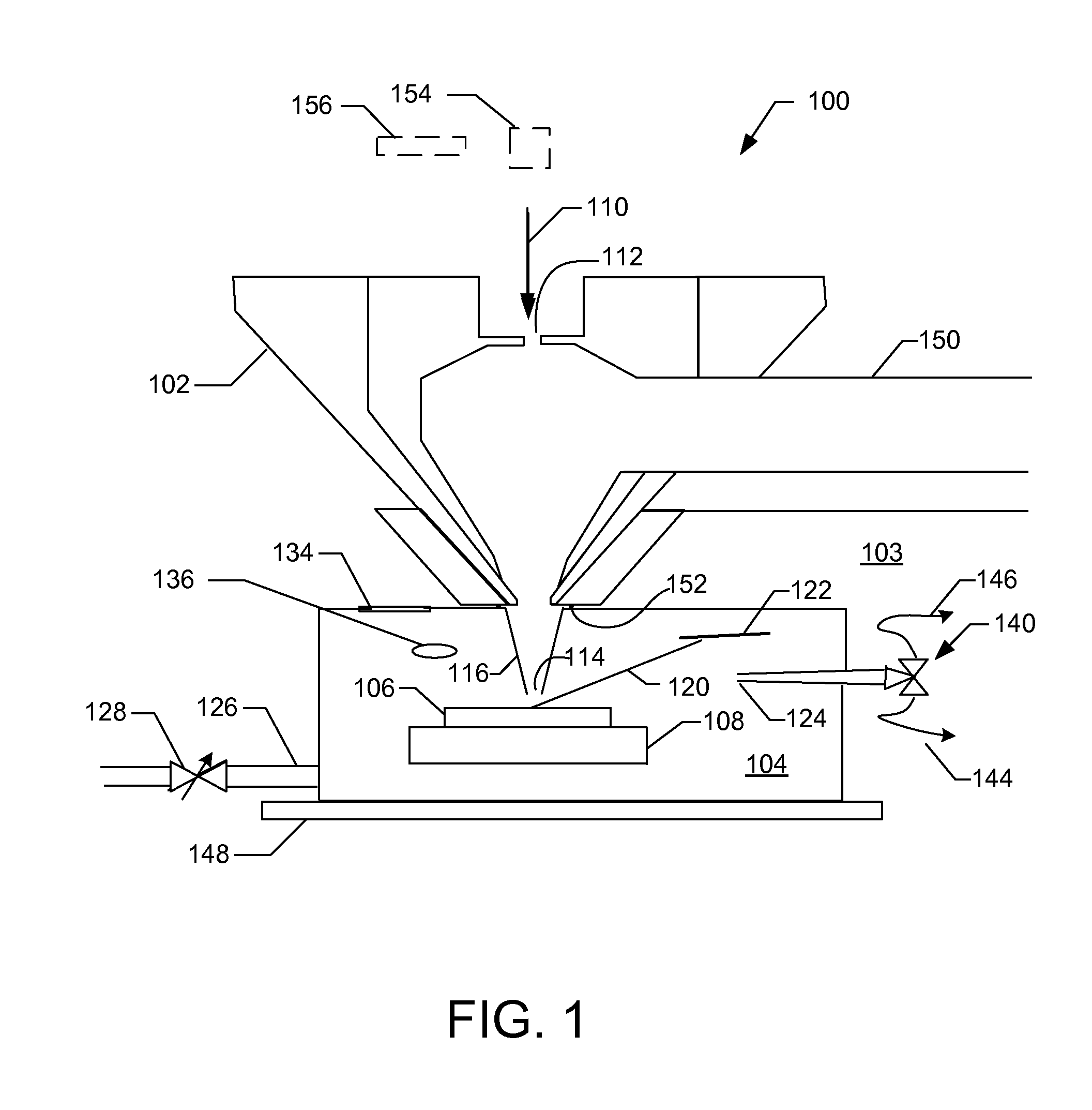

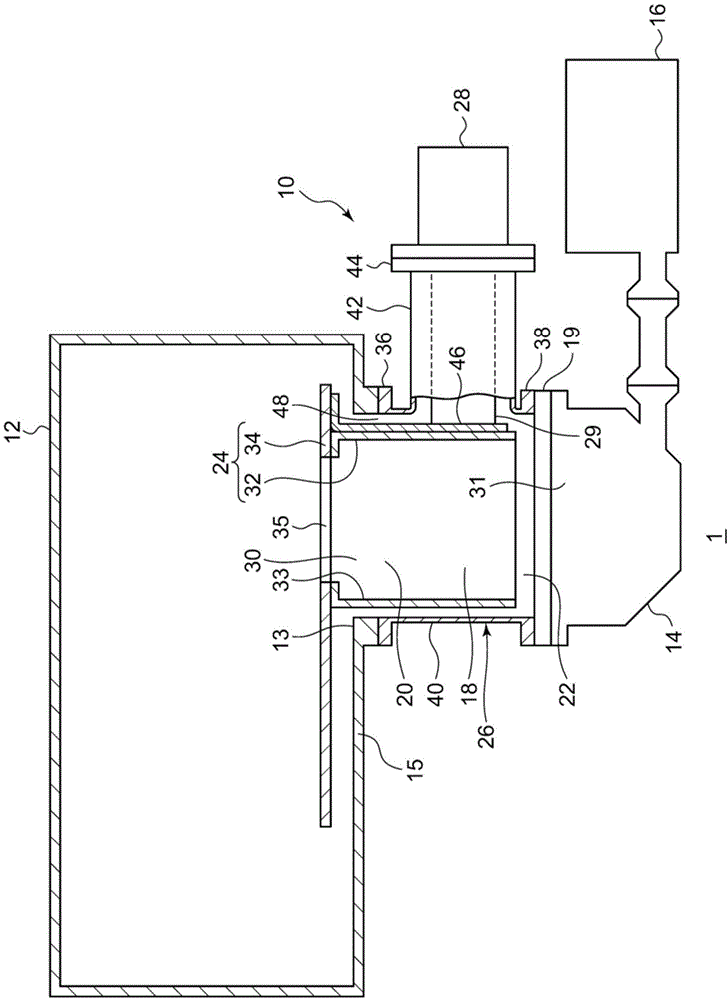

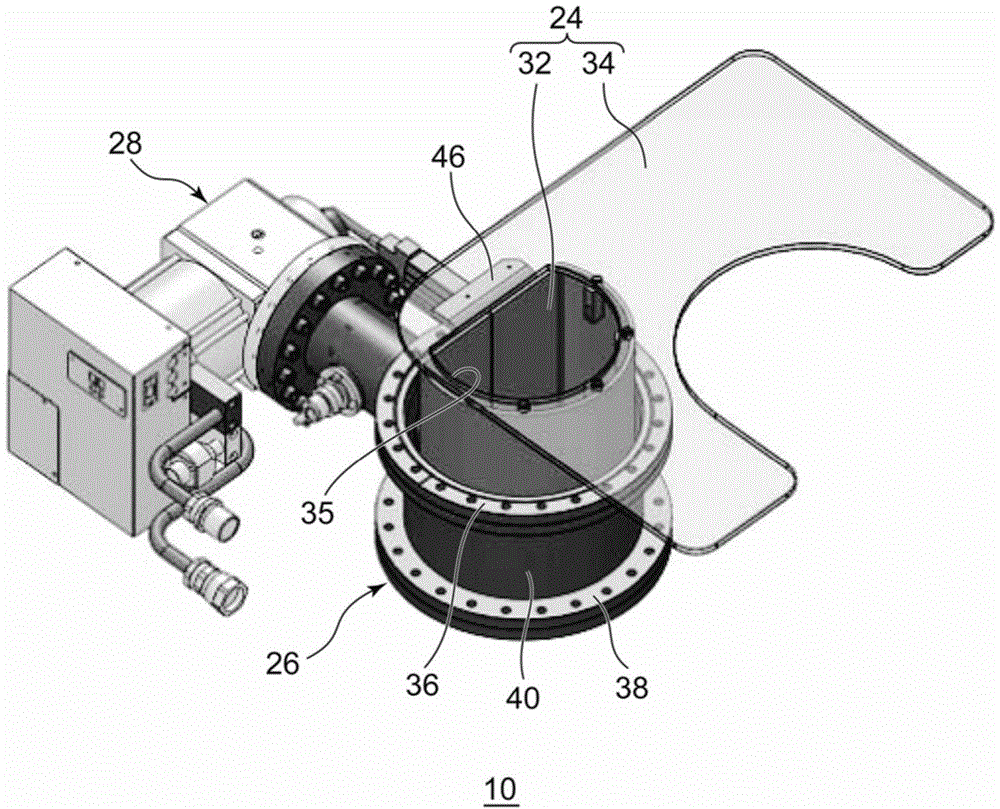

High pressure charged particle beam system

ActiveUS20110031394A1Reduce gas volumeFast exhaustMaterial analysis using wave/particle radiationElectric discharge tubesHigh pressureMolecular physics

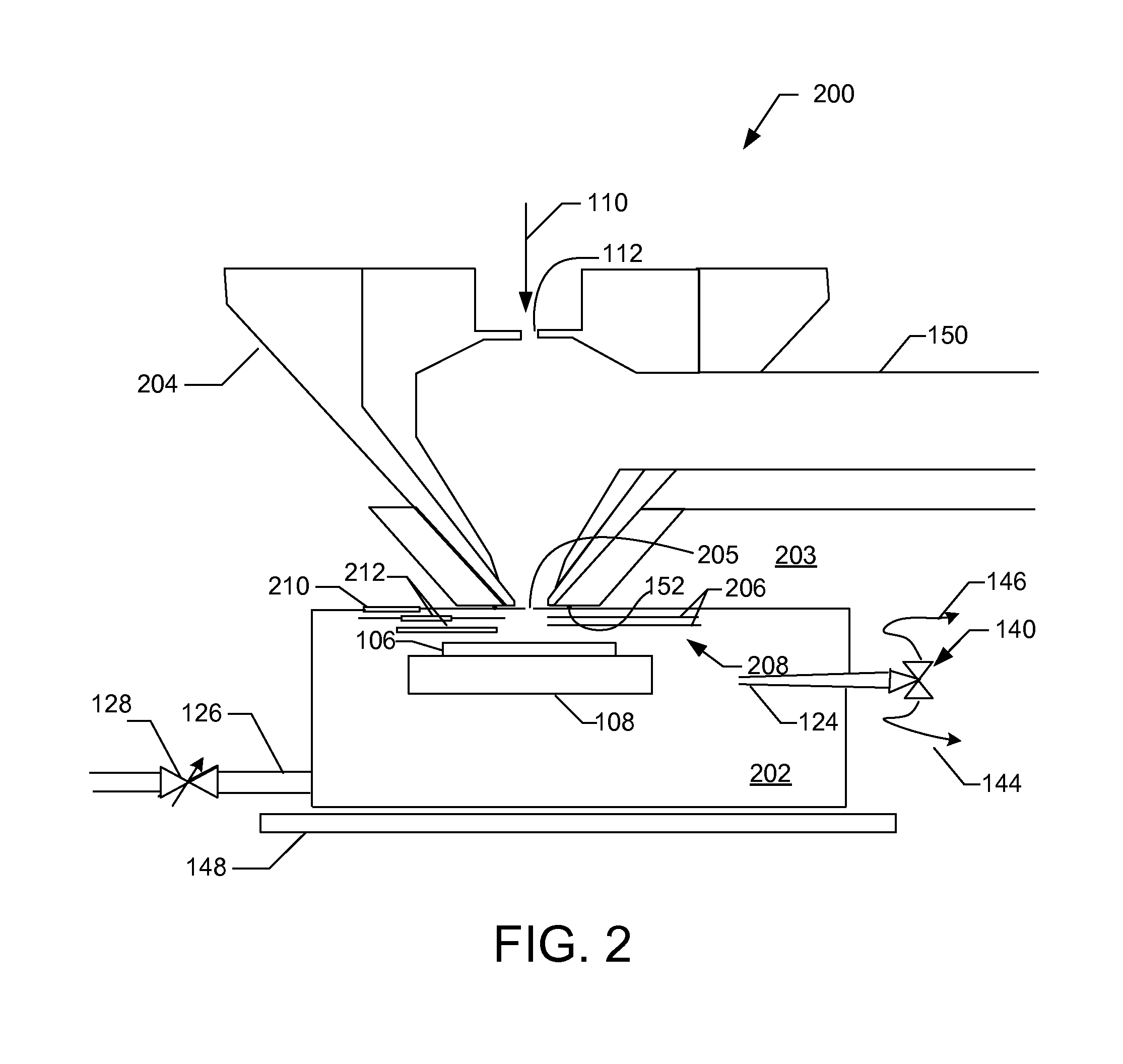

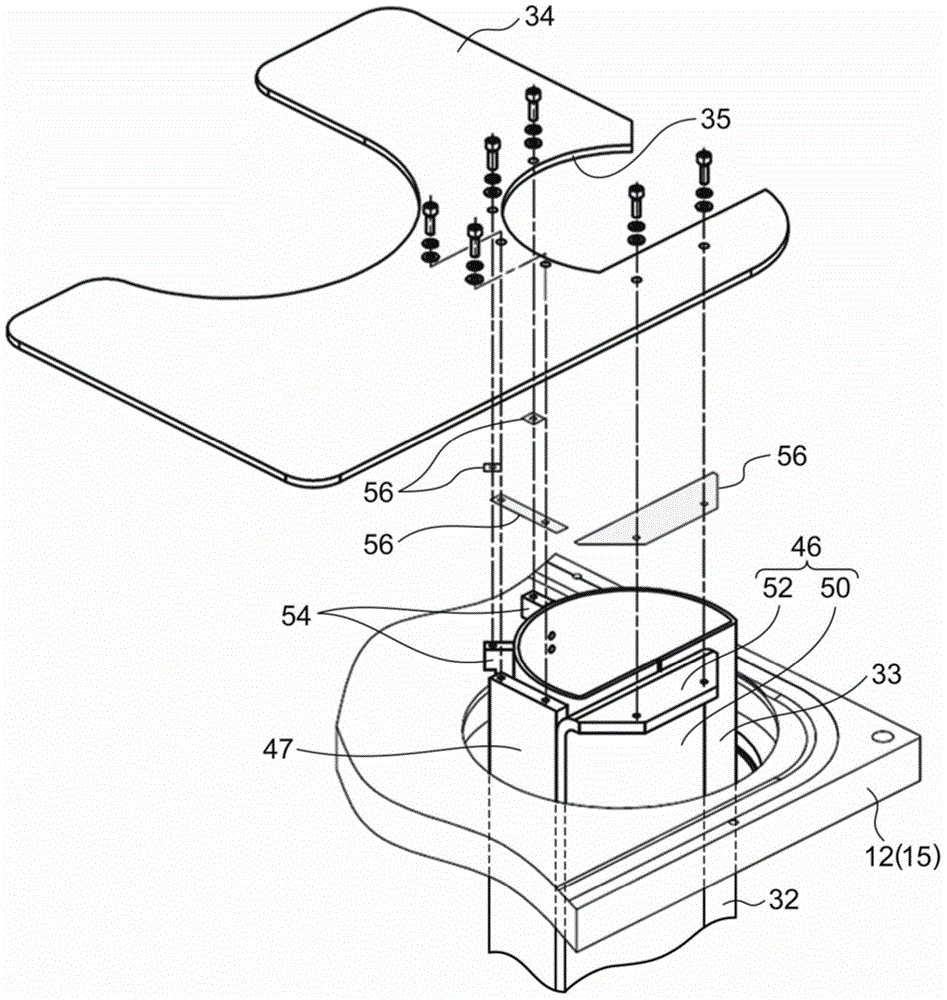

The current invention includes methods and apparatuses for processing, that is, altering and imaging, a sample in a high pressure charged particle beam system. Embodiments of the invention include a cell in which the sample is positioned during high pressure charged particle beam processing. The cell reduces the amount of gas required for processing, thereby allowing rapid introduction, exhaustion, and switching between gases and between processing and imaging modes. Maintaining the processes gases within the cell protects the sample chamber and column from contact with the gases. In some embodiments, the temperature of the cell walls and the sample can be controlled.

Owner:FEI CO

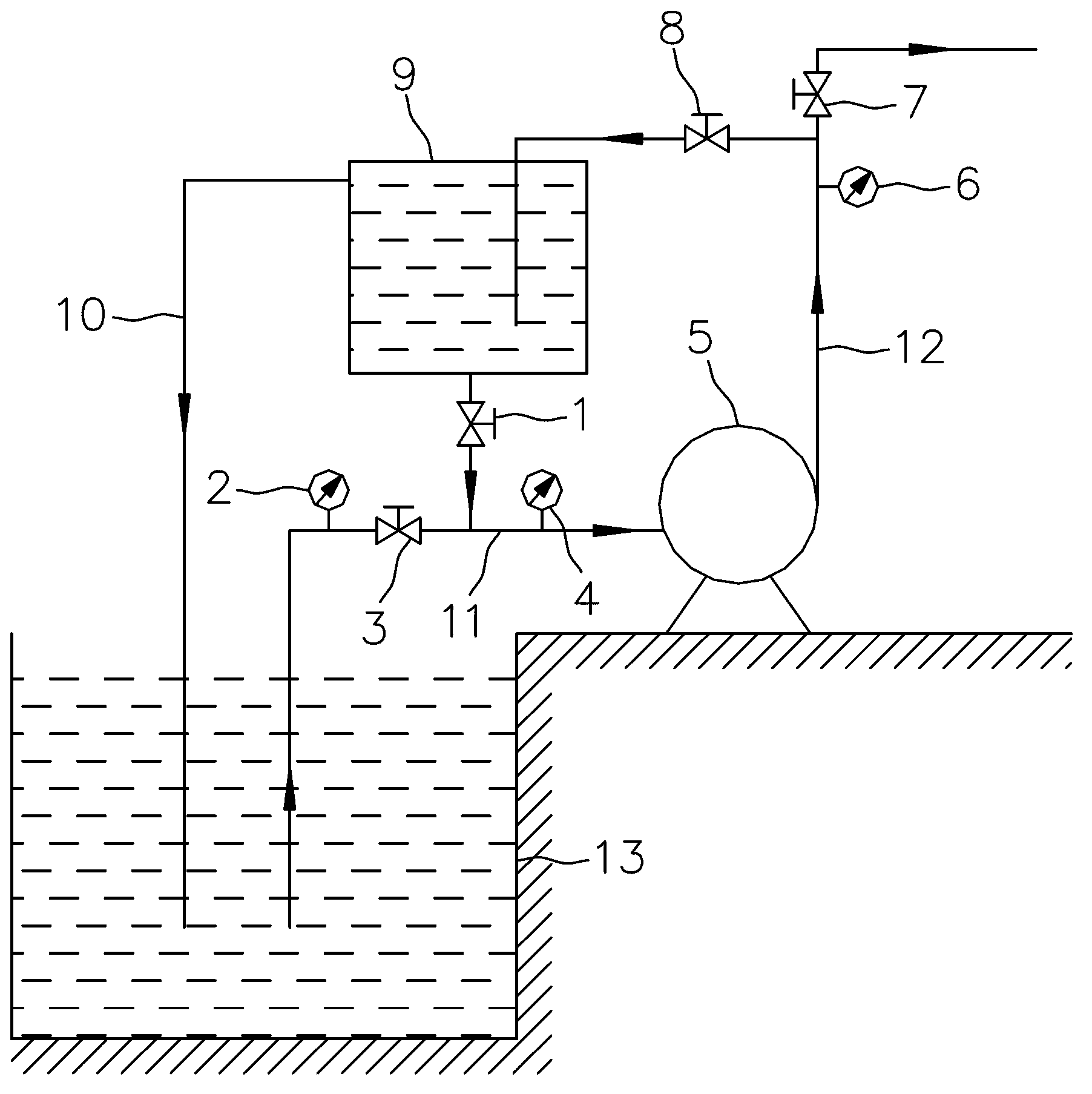

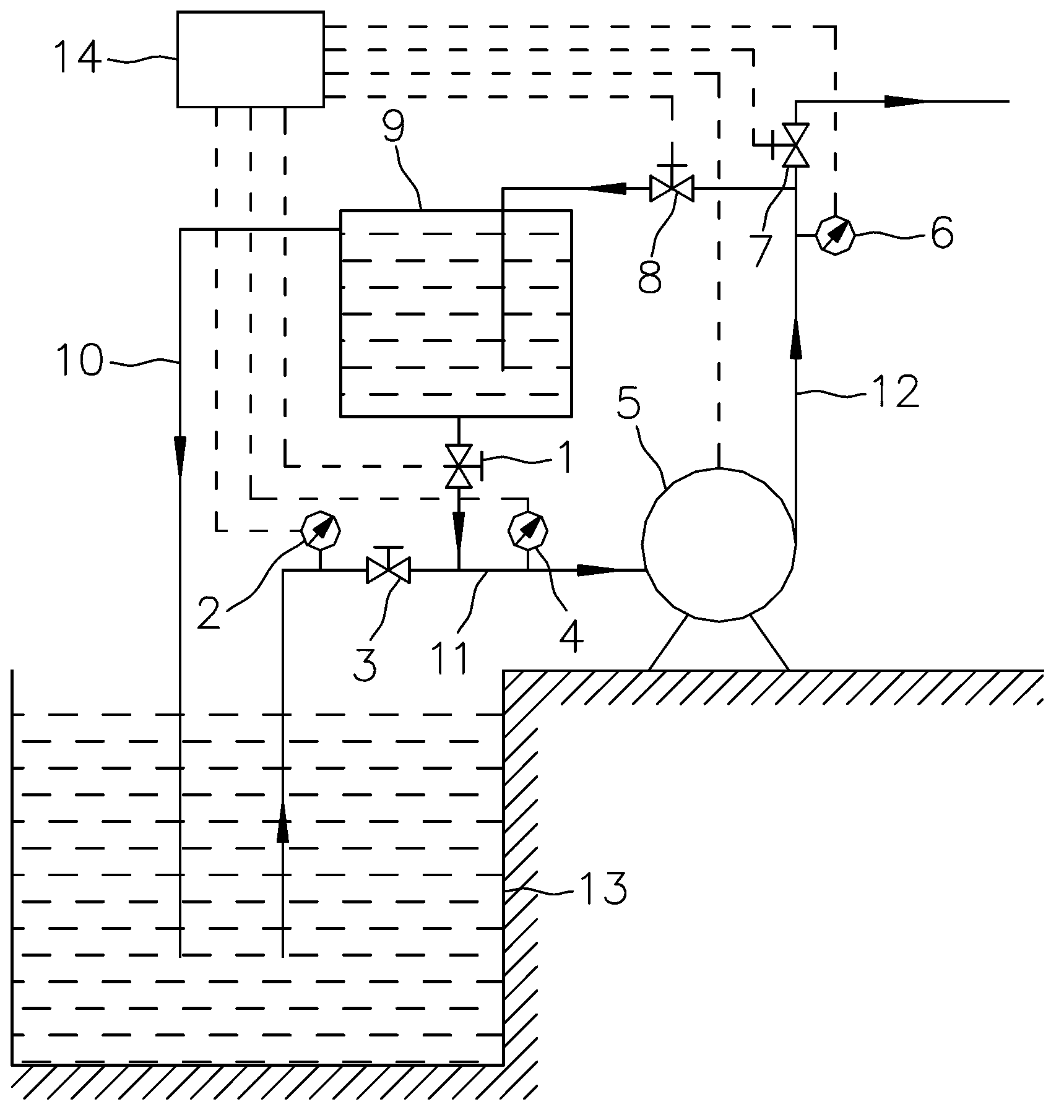

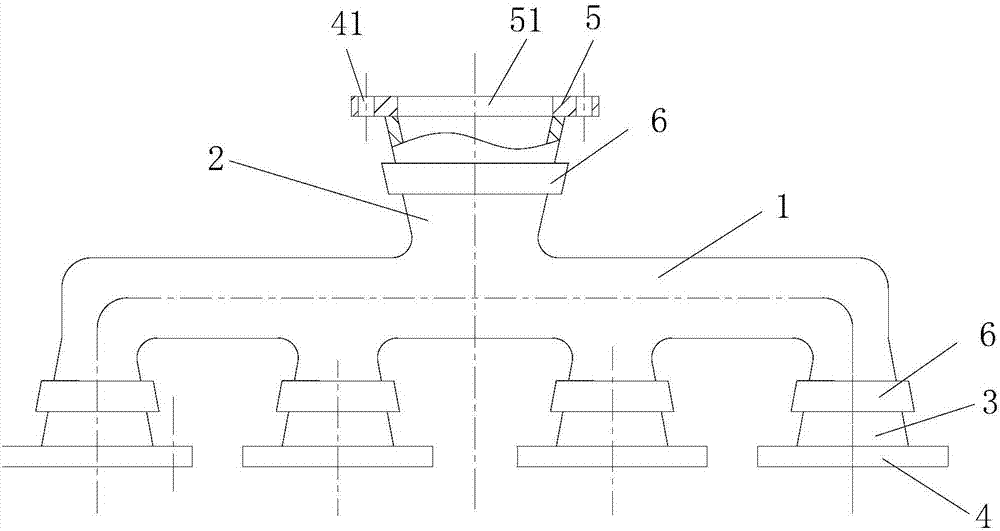

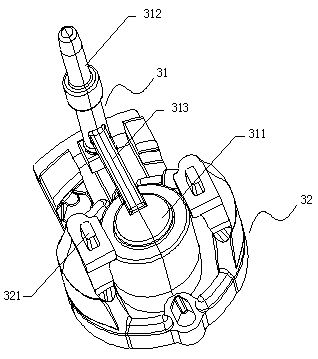

Outer ring type efficient start system for self-priming pump and start method thereof

ActiveCN102840140AImprove hydraulic efficiencyEasy to processPump componentsPriming pumpEngineeringMechanical engineering

The invention belongs to the technical field of a self-priming pump, and particularly relates to an outer ring type efficient start system for the self-priming pump and a start method thereof. The outer ring type efficient start system comprises a main pump which is communicated with a water pool, a pump inlet adjusting valve, a pump outlet adjusting valve, a gas-liquid separation device, a first pressure detecting device, a second pressure detecting device and a third pressure detecting device. All the parts of the invention form a vacuum adjusting system together. The vacuum adjusting system is used to facilitate circular flow of liquid in a circular pipeline outside the pump and enable a water inlet pipeline of the main pump to be in a vacuum state so that gas and liquid can be absorbed into the main pump, the gas absorbed into the main pump is exhausted in the gas-liquid separation device, and eventually the main pump achieves self-priming to complete start process. The outer ring type efficient start system for the self-priming pump and the start method thereof are simple in structure, quick in start, simple in main pump flow channel and convenient to process, flowability of the flow channel is greatly improved, the main pump needs no other auxiliary systems so that loss inside the pump is avoided, and accordingly operation efficiency of the main pump is greatly improved.

Owner:HEFEI GENERAL MACHINERY RES INST

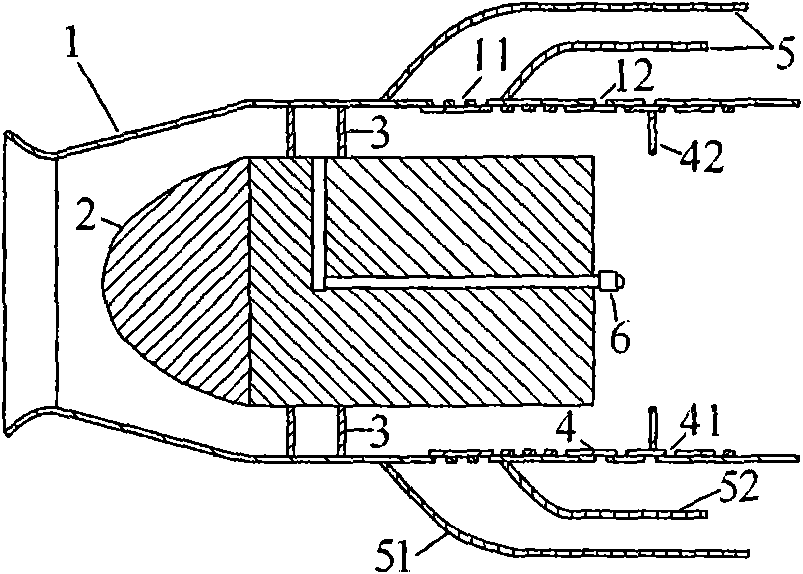

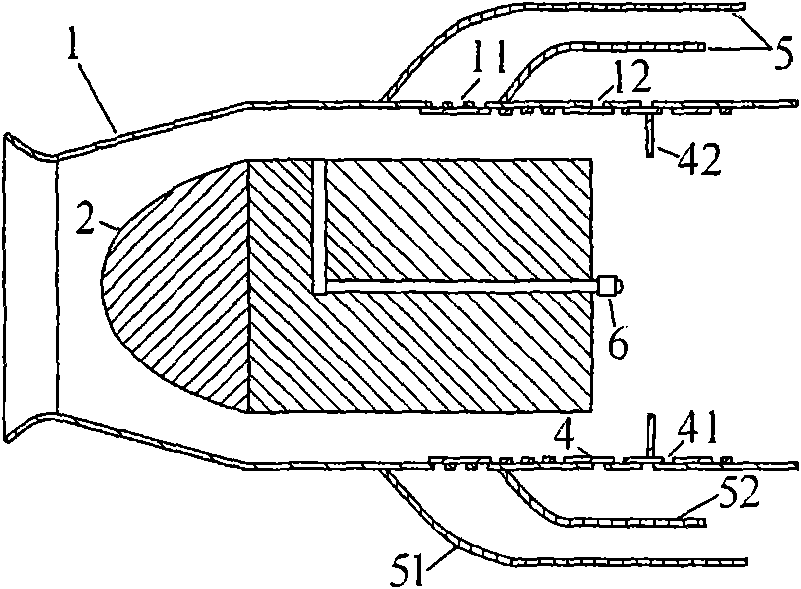

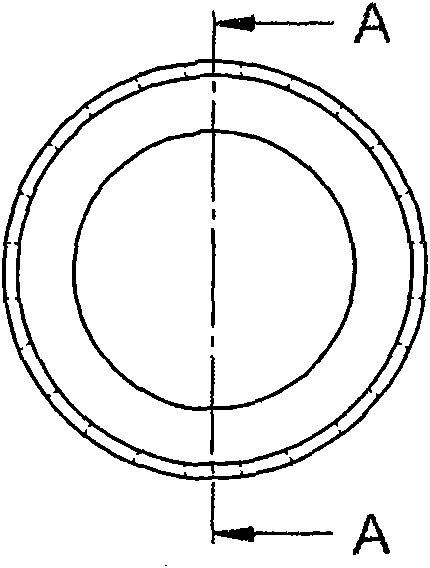

Air inlet channel of air-breathing type pulse detonation engine

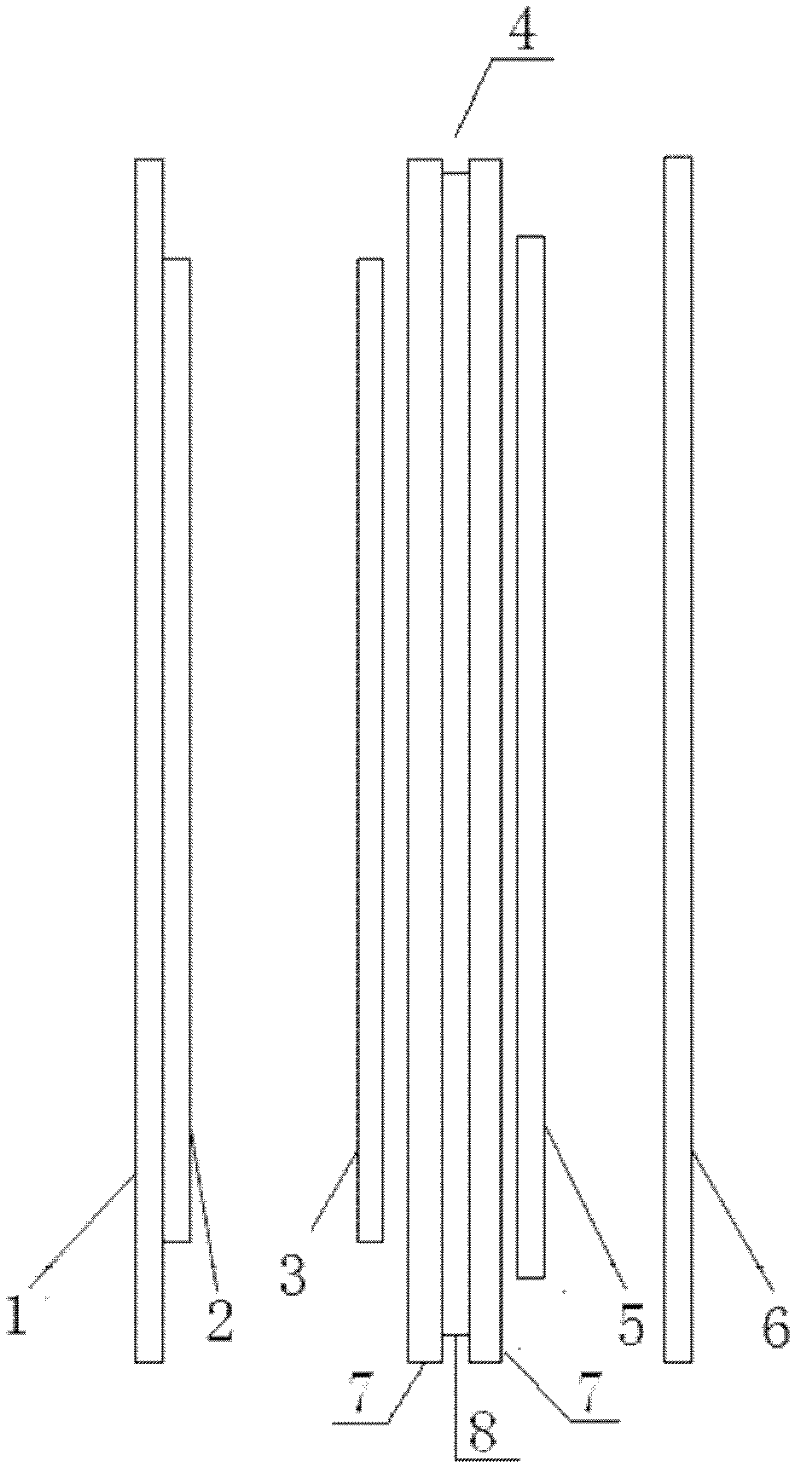

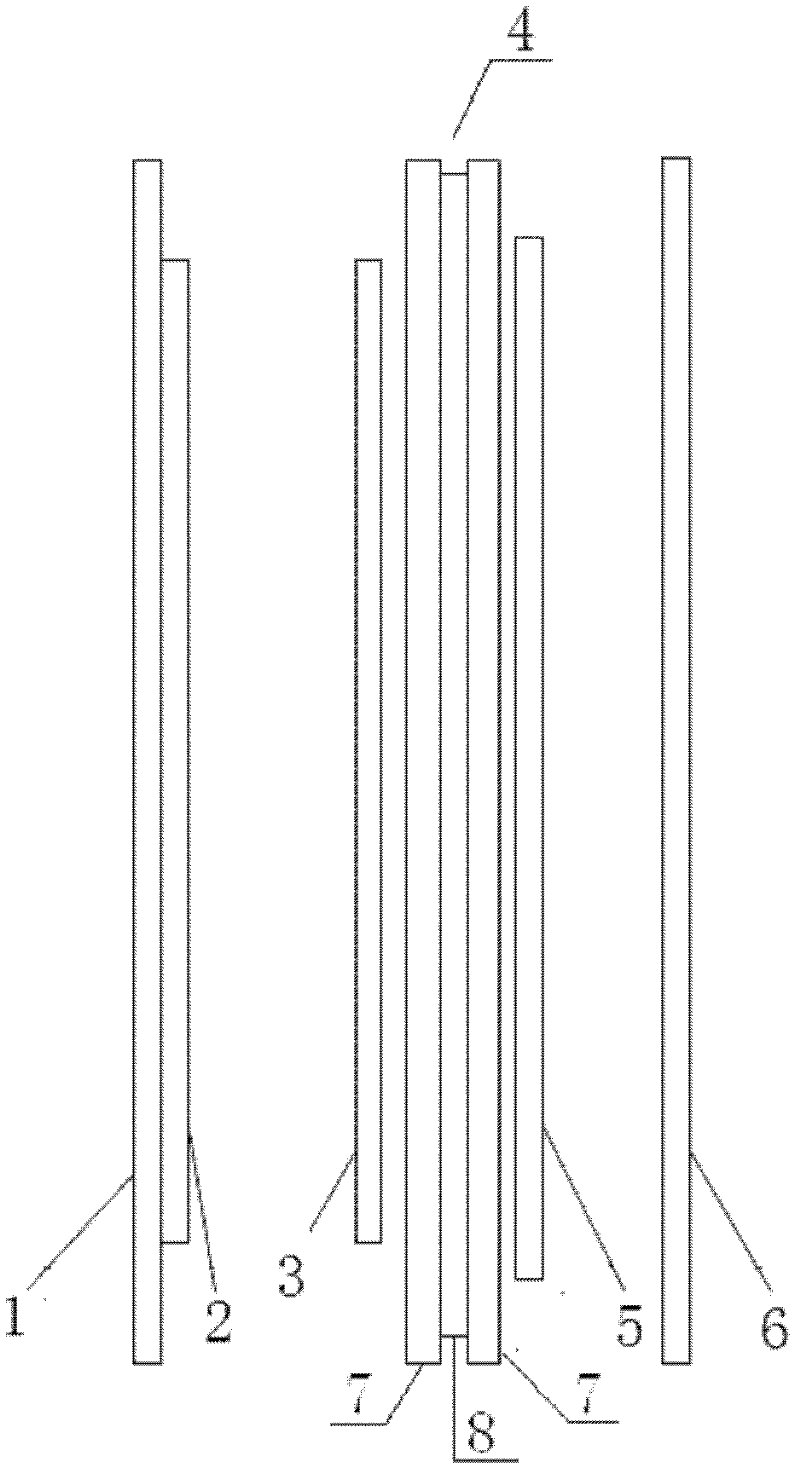

InactiveCN101956631AIncrease thrustIncrease working frequencyRam jet enginesComposite engine plantsInlet channelCounter flow

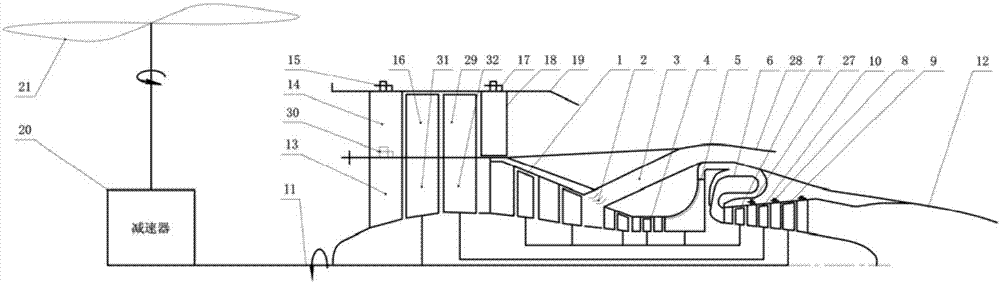

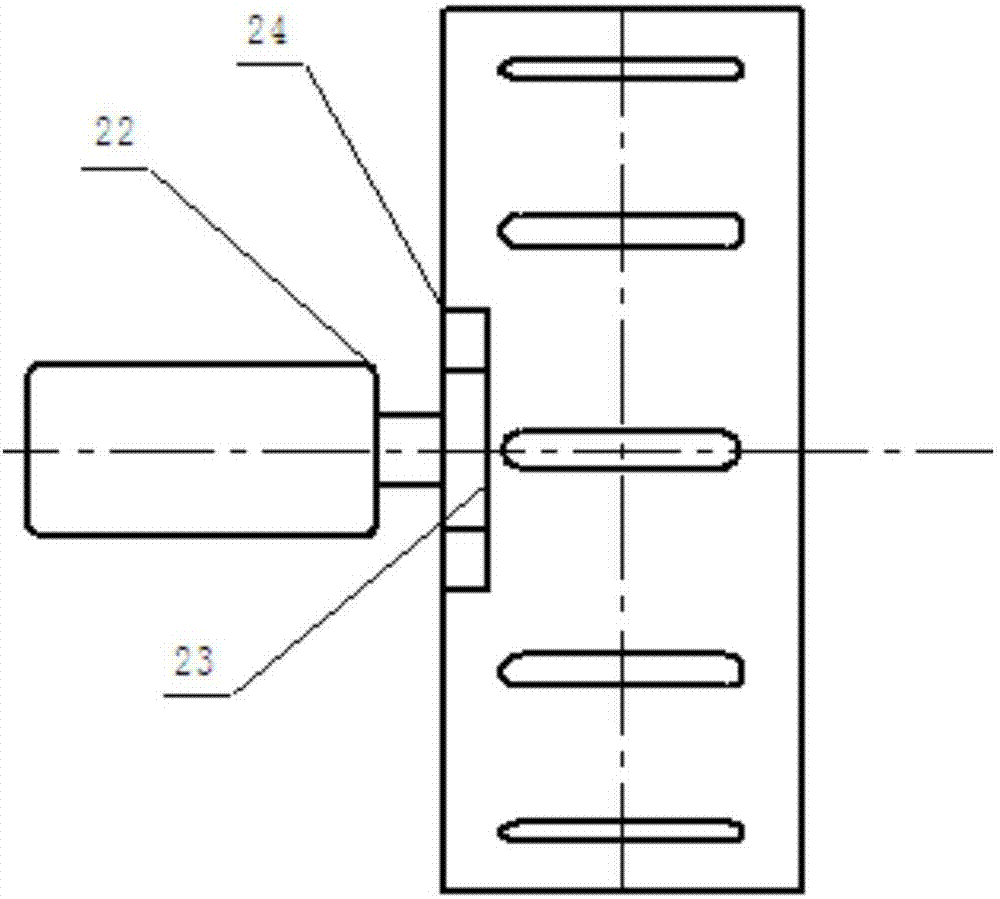

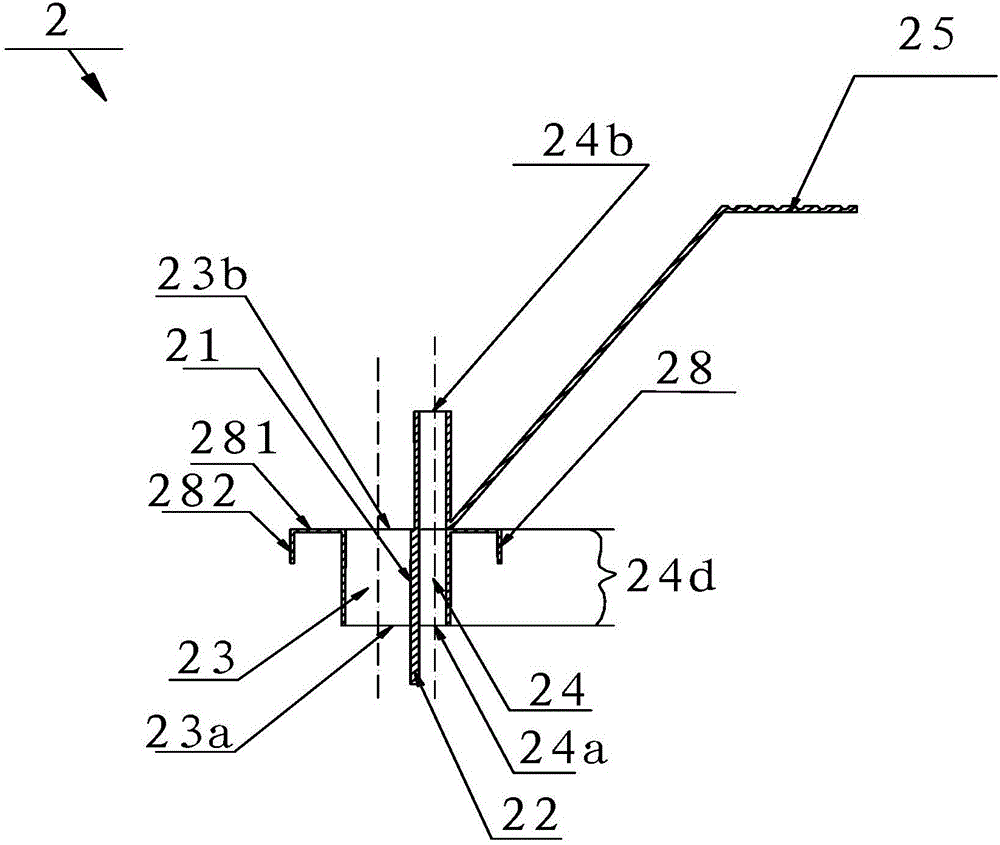

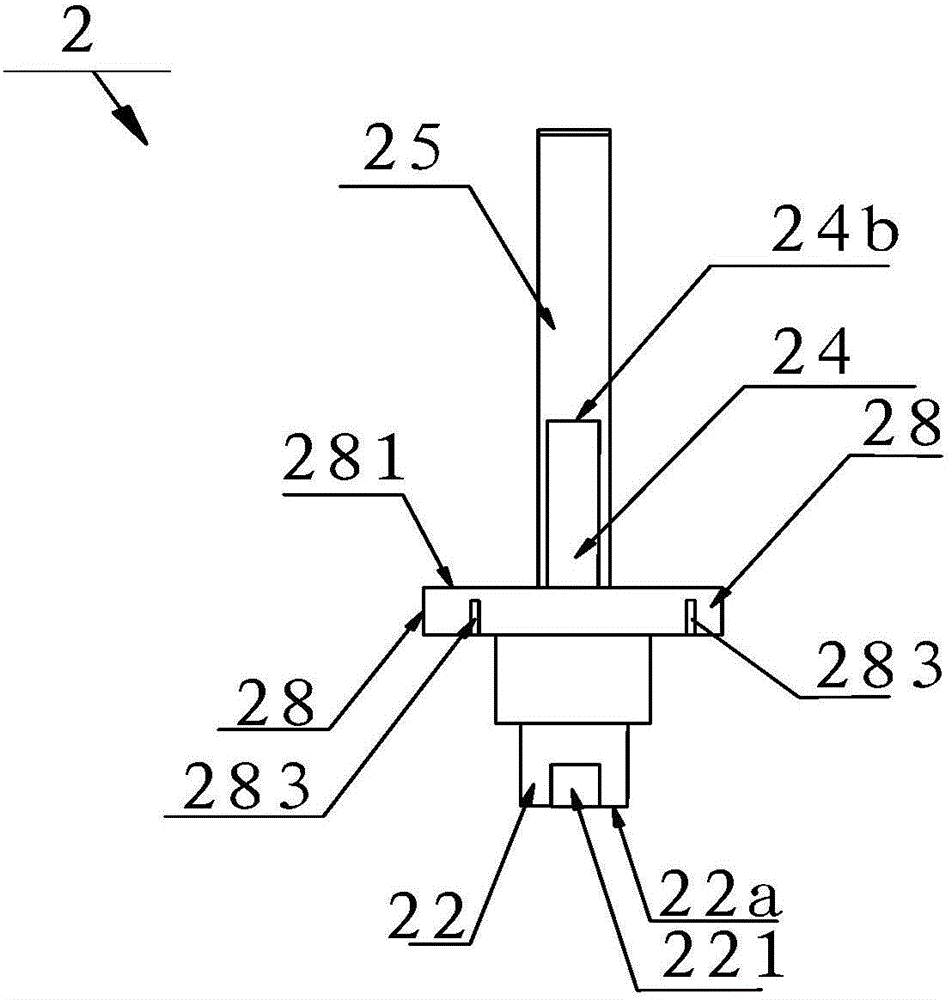

The invention discloses an air inlet channel of an air-breathing type pulse detonation engine. In the channel, an air inlet channel shell and a central body form an air inlet ring cavity; fuel oil is axially jetted from a nozzle of a rear end face of the central body to the air inlet channel; an air release hole groove is formed in an inlet of an air release tube facing the lower part of the air inlet channel on the air inlet channel shell; an actuating mechanism actuates back and forth along an axial direction in the air inlet channel; a plurality of rows of hole grooves are formed on the actuating mechanism; an actuating block is arranged on the actuating mechanism; and the hole grooves can be separately or simultaneously coincided with the air release hole grooves of the air inlet channel shell by axial actuation. The air inlet channel has the advantages of achieving smaller forward flow resistance under the condition of high-speed flight, simultaneously inhibiting and making use of a counter flow, improving the thrust force of the engine, increasing the air release speed, and improving the working frequency of the engine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

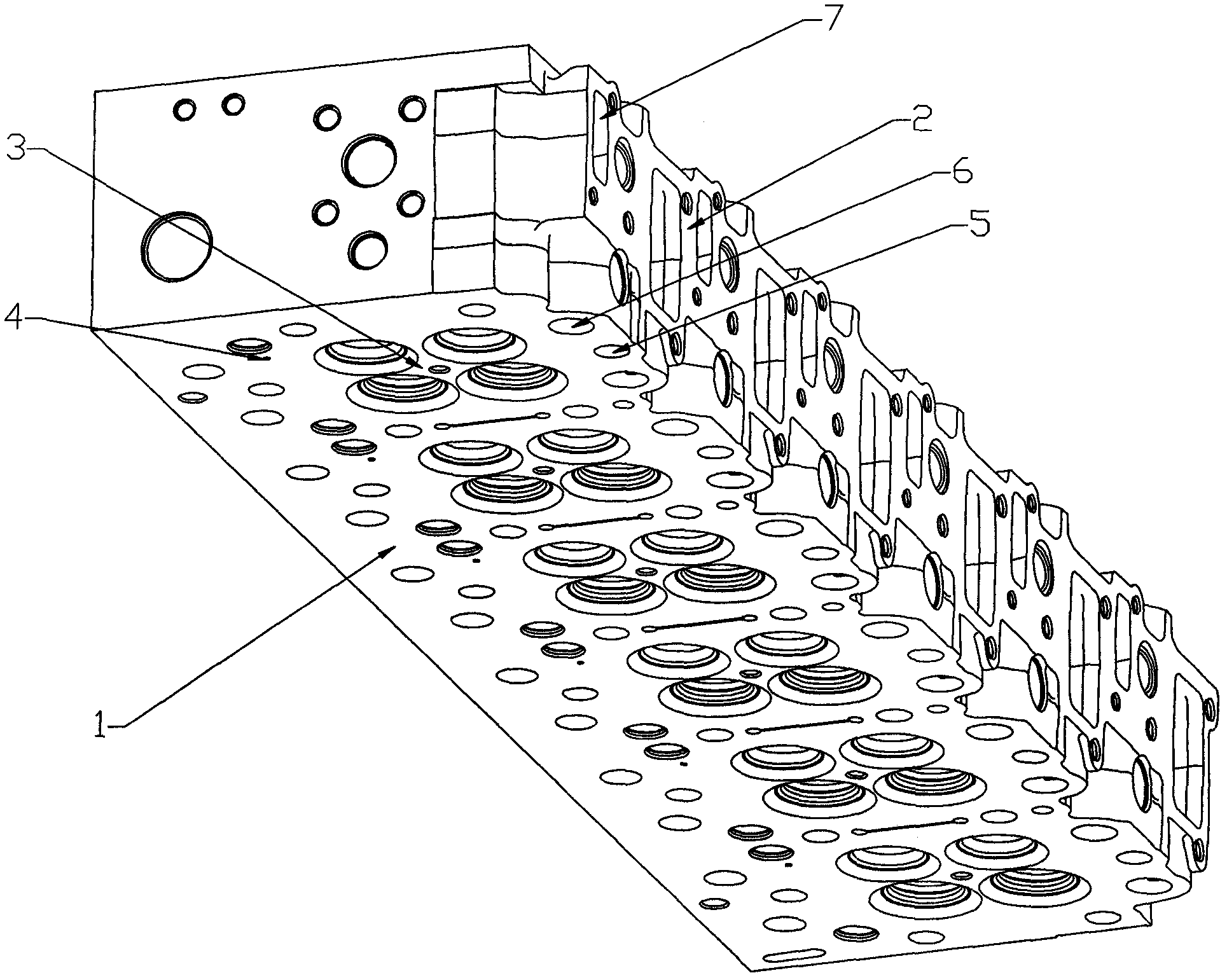

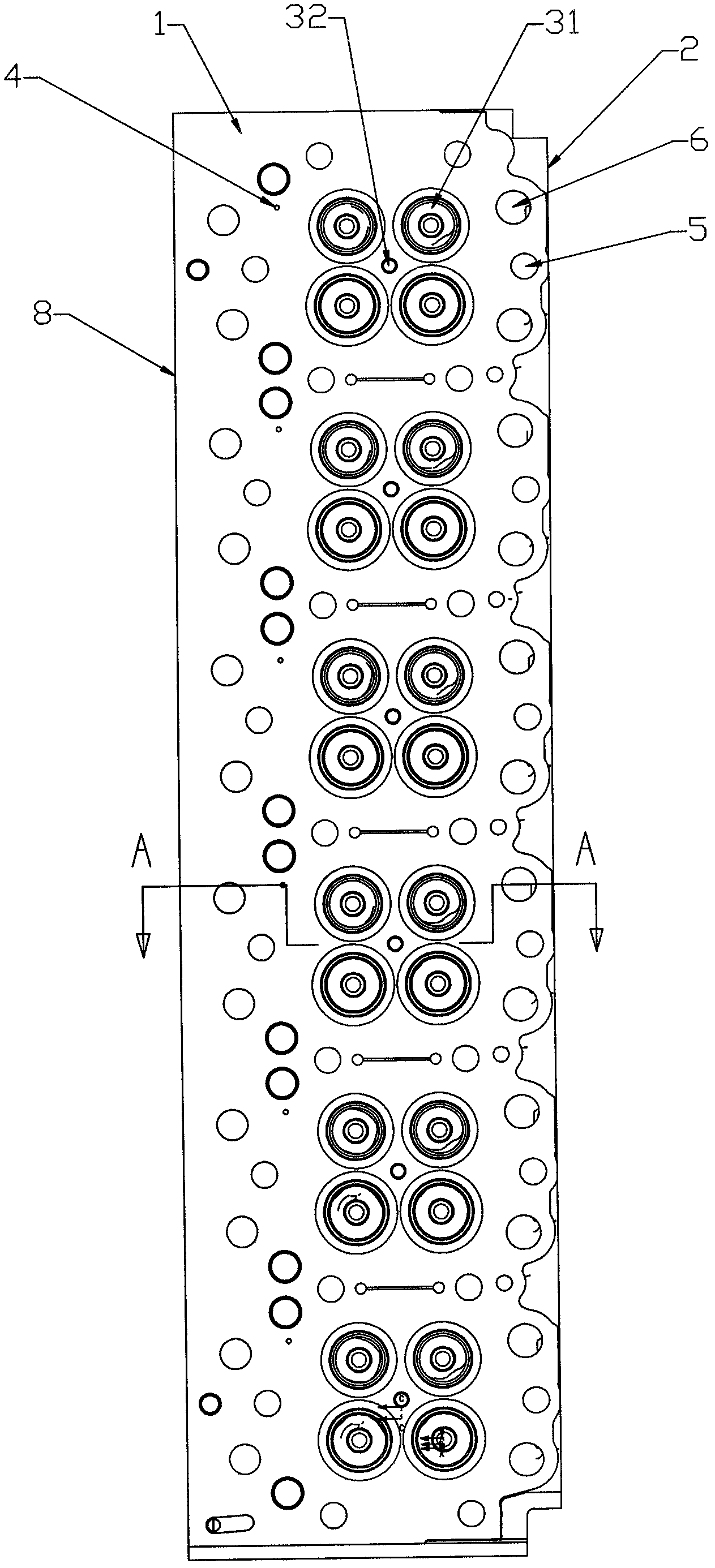

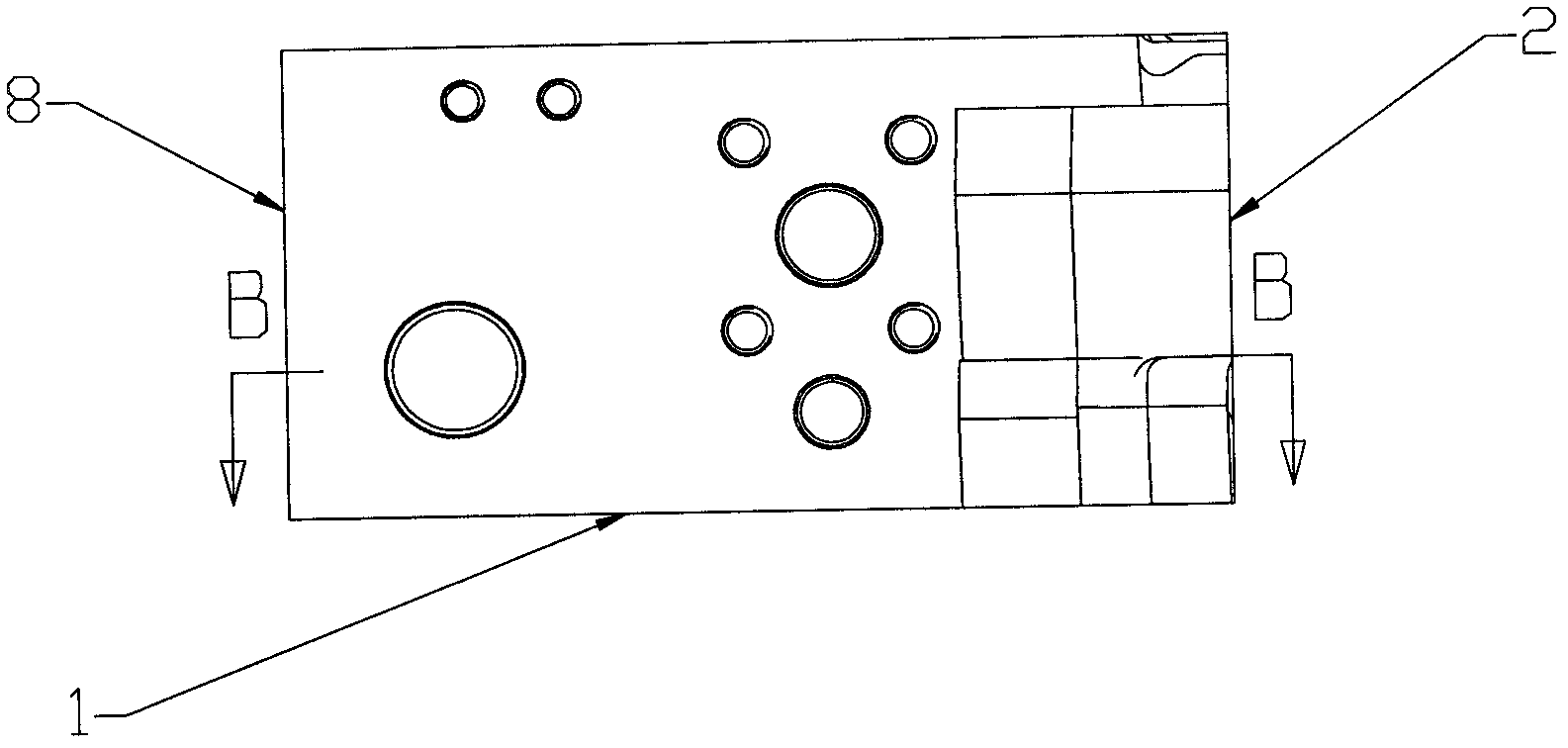

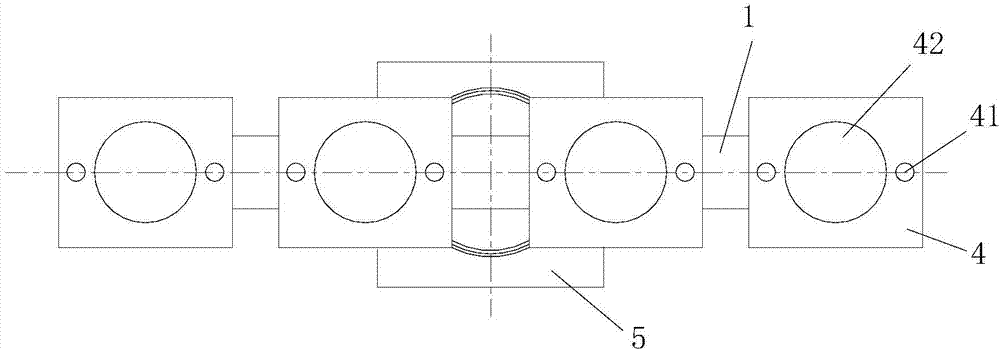

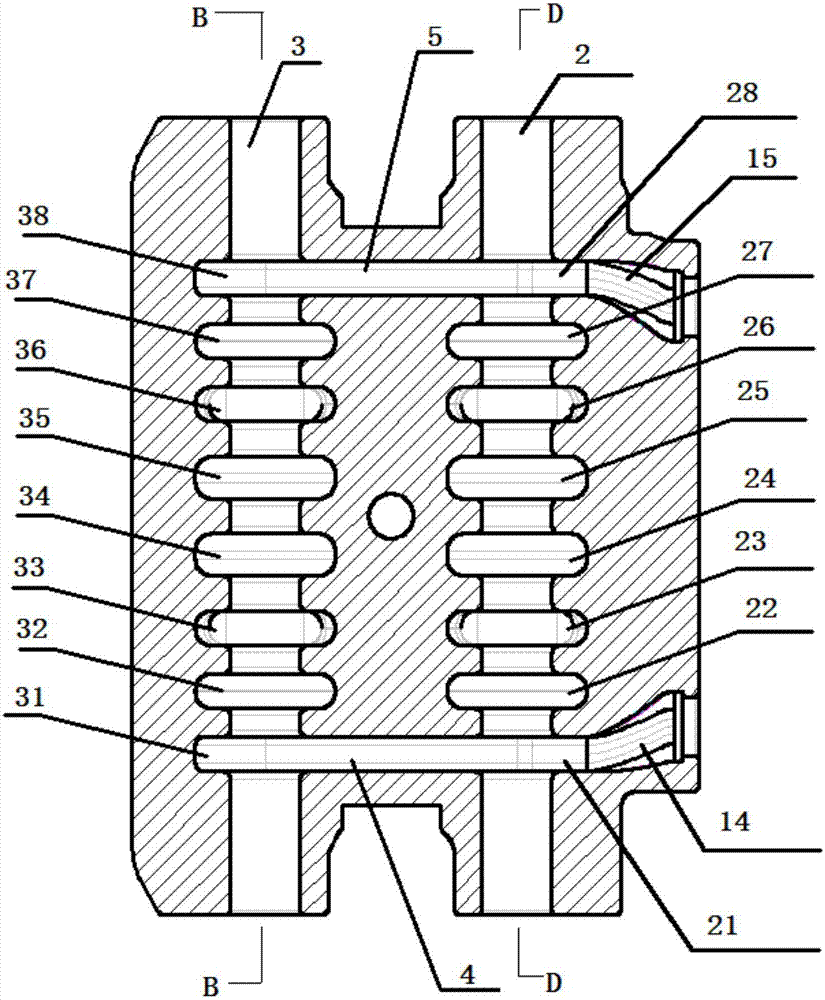

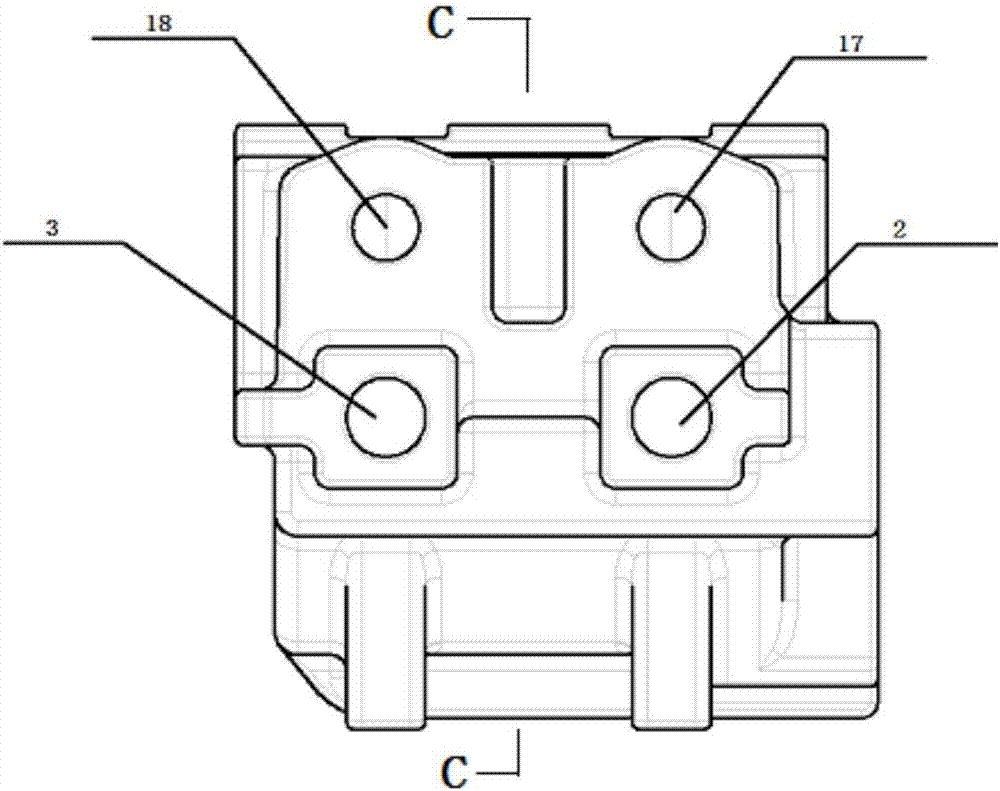

Integral cylinder cover of water-cooled four-valve diesel engine and corresponding diesel engine water cooling method

InactiveCN102758701ANo short circuitImprove cooling effectLiquid coolingCylinder headsCooling effectWater cooling

The invention discloses an integral cylinder cover of a water-cooled four-valve diesel engine and a corresponding diesel engine water cooling method based on the cylinder cover. According to the cylinder cover, a partition plate for partitioning a water cooling cavity into an upper cavity and a lower cavity is arranged in the water cooling cavity, wherein a water feeding passage for communicating the upper cavity and the lower cavity is formed on one side of the partition plate; a bottom plate is provided with an exhaust duct side exhaust hole corresponding to the water feeding passage; and a water inlet hole and an intake duct side exhaust hole which are communicated with the lower cavity are formed on the other side of the bottom plate. The diesel engine water cooling method comprises the following steps of: circulating water cooling outside a diesel engine cylinder from one side to the other side through a circulating water pump; and flowing the cooling water into the lower cavity from the water inlet hole on the bottom plate of the cylinder cover, then flowing to the upper cavity through the water feeding passage from the lower cavity and flowing out from the water outlet. By arranging the partition plate in the cylinder cover, forced cooling water passes through a nose bridge region so as to guarantee a cooling effect of the noise bridge region and the bottom plate of the cylinder cover; and bubbles produced on the outer wall of the cylinder can be quickly washed away and vapor can be discharged, so that cooling water of high water temperature does not easily occur in the diesel engine.

Owner:GUANGXI YUCHAI MASCH CO LTD

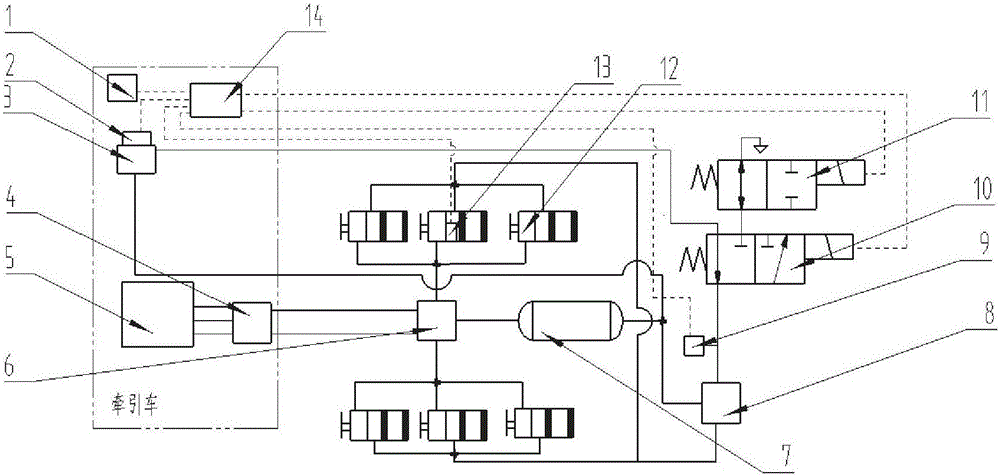

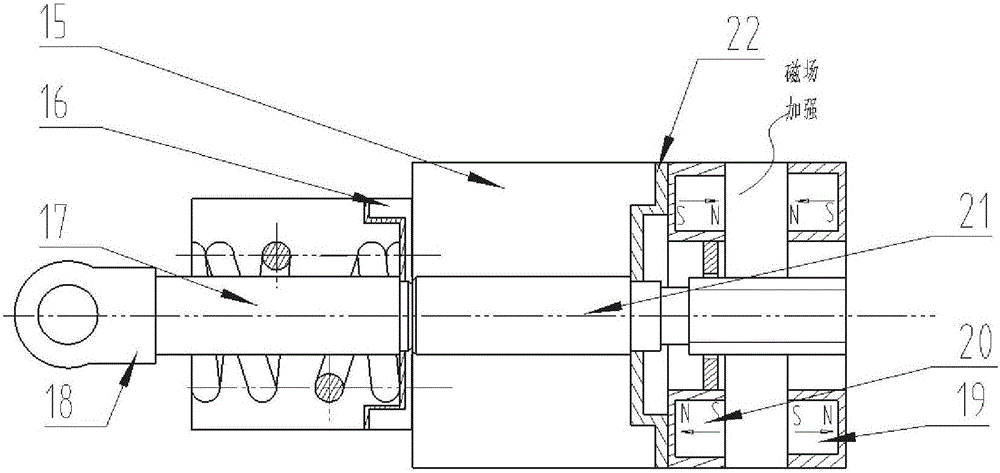

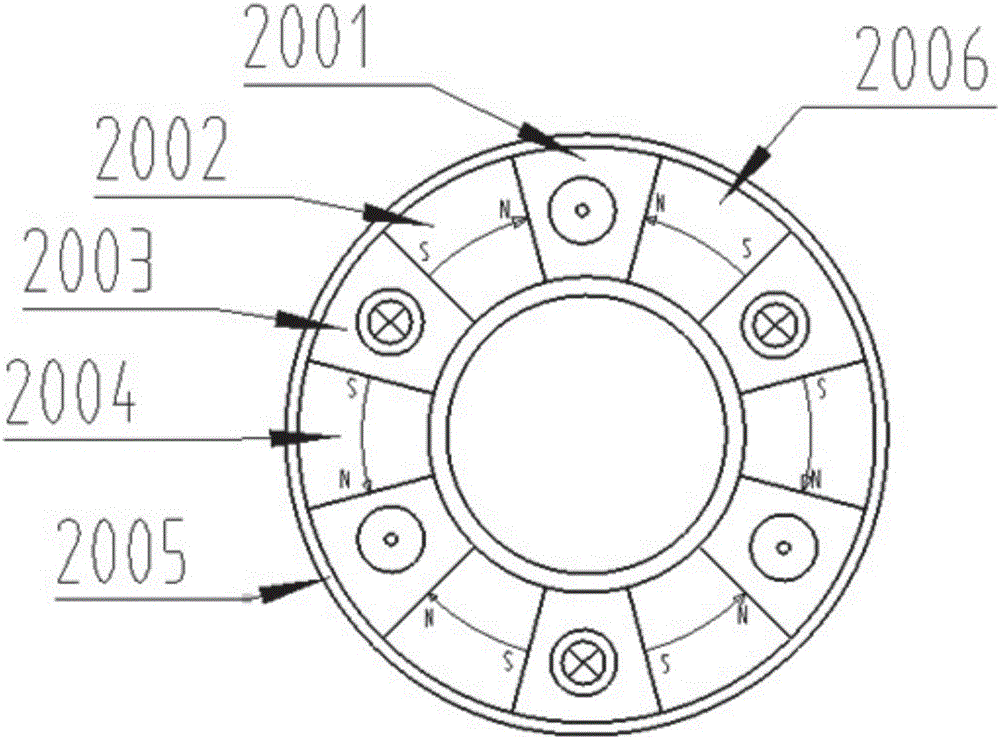

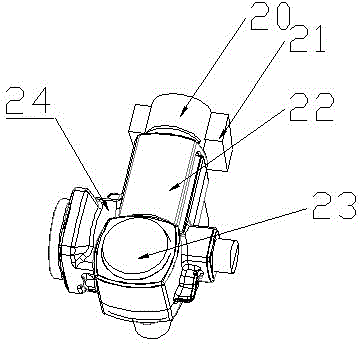

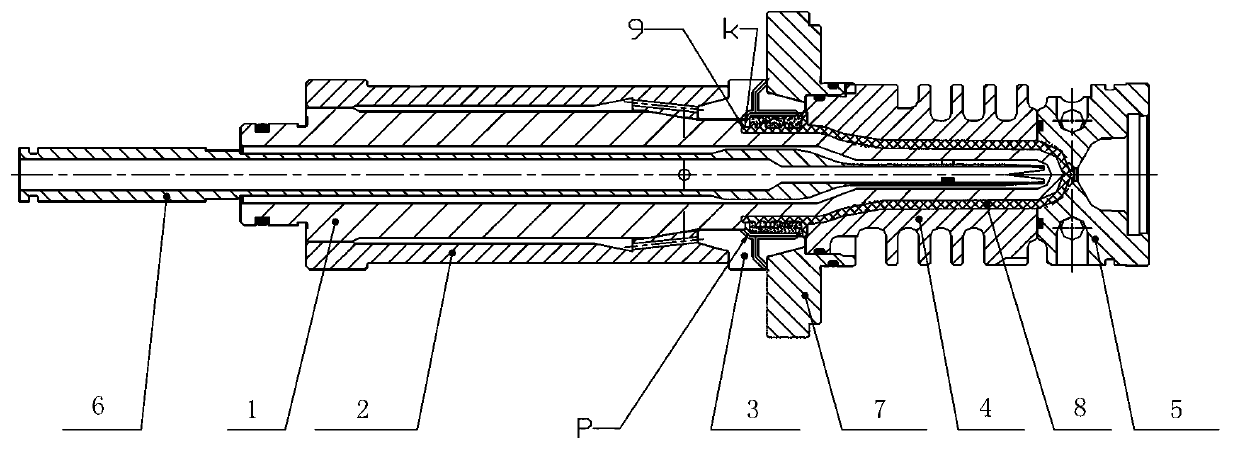

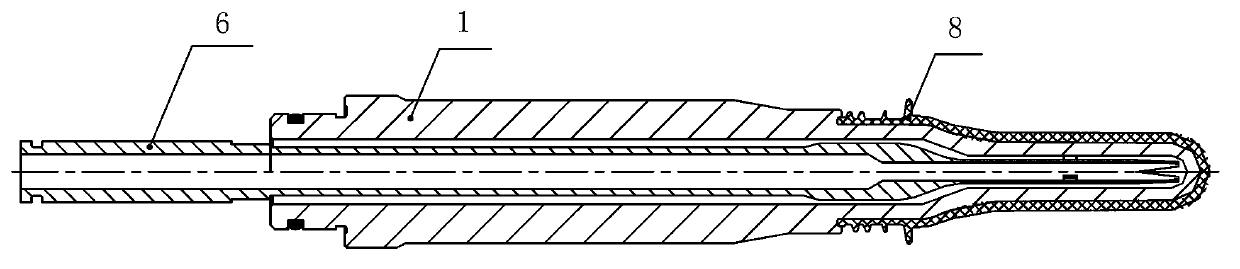

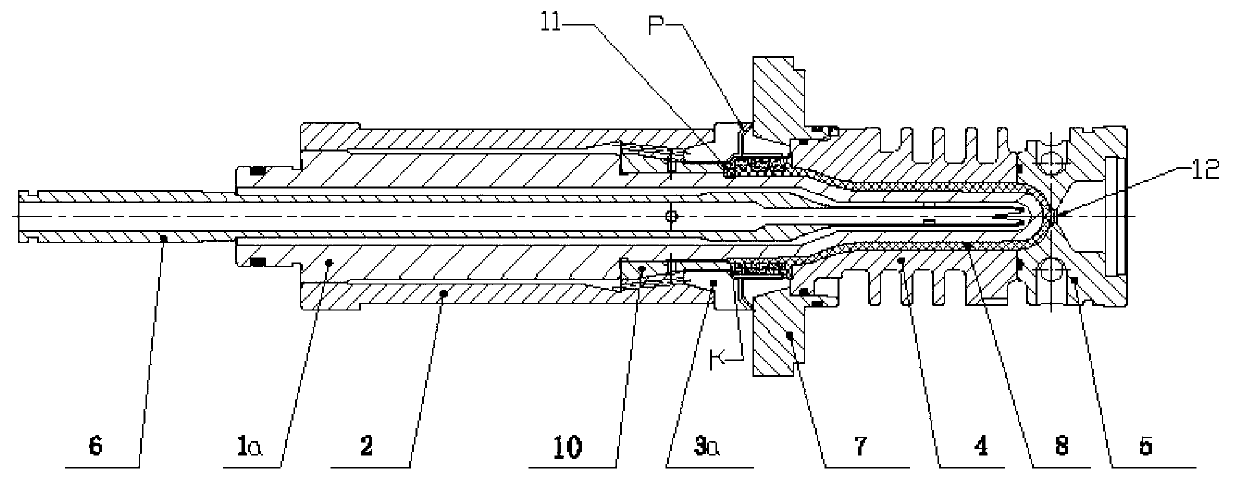

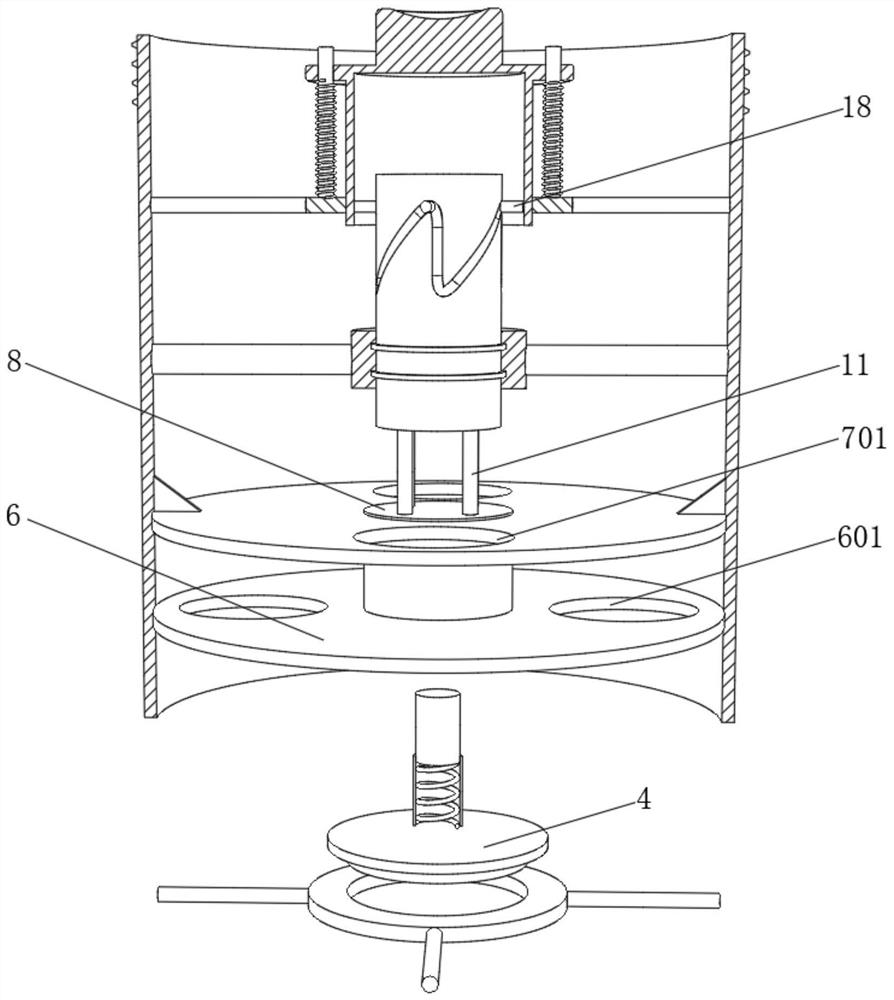

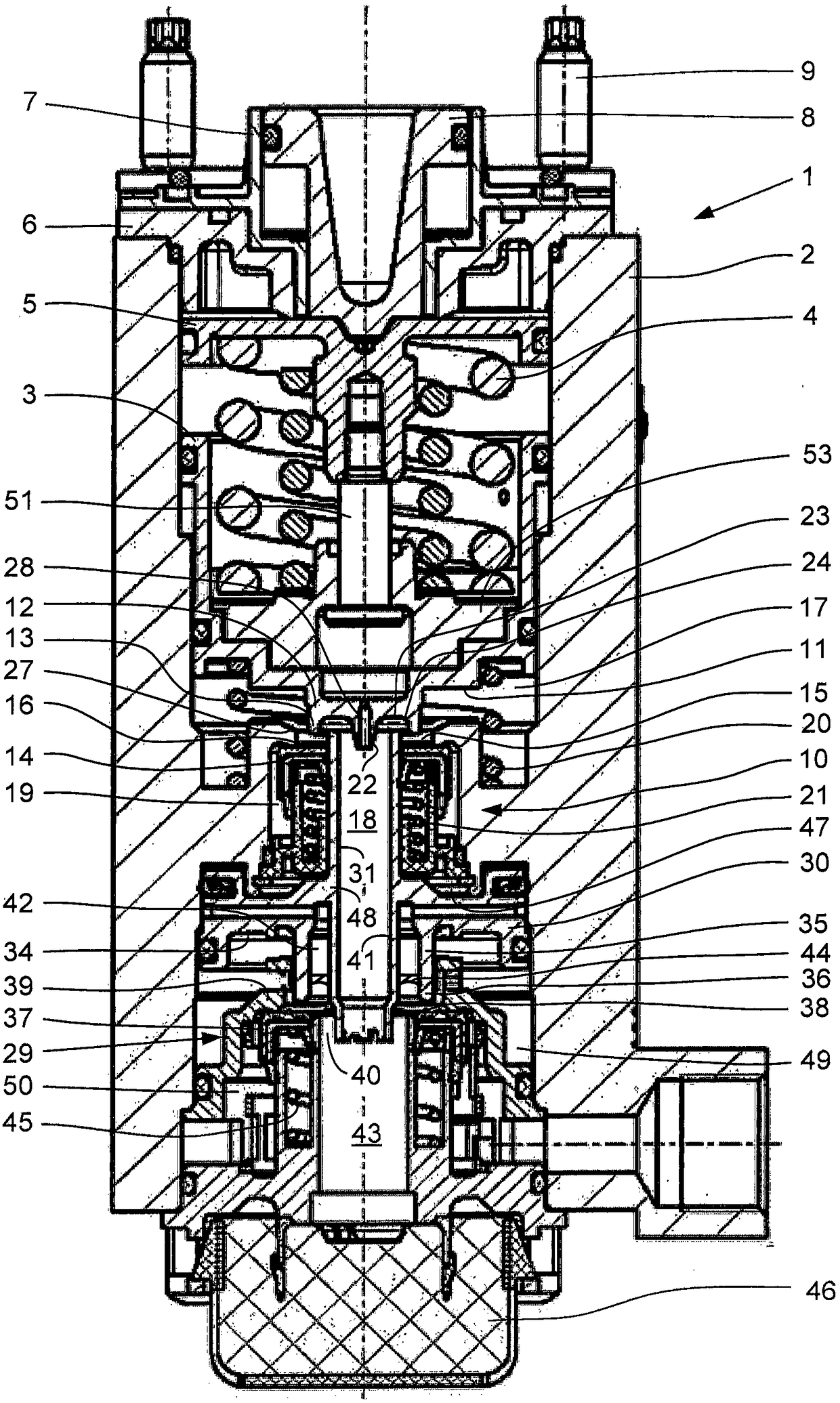

Permanent magnet composite type brake chamber capable of improving brake hysteresis characteristics of trailer and control method of brake chamber

InactiveCN105835859AFast exhaustReduce braking delay timeBraking action transmissionHysteresisParking brake

The invention discloses a permanent magnet composite type brake chamber capable of improving brake hysteresis characteristics of a trailer and a control method of the brake chamber. The permanent magnet composite type brake chamber mainly comprises a service braking chamber, a service braking chamber push rod, a parking braking chamber, a permanent magnet ring A, a permanent magnet ring B, a parking braking piston, a parking braking chamber push rod and a connecting fork; an electronic control system comprises a brake pedal displacement sensor, a handle displacement sensor, an air pressure sensor A, an air pressure sensor B, a two-position three-way reversing valve, a two-position two-way reversing valve and a microprocessor, the microprocessor controls air pressure signals of the chambers according to a brake pedal displacement signal, a hand control valve handle position signal, a parking braking chamber inner air pressure signal and a servo quick release valve and controls the on-off state of respective electromagnetic valves of the two-position three-way reversing valve and the two-position two-way reversing valve. The trailer braking delay time can be shortened, the braking delaying characteristic of a trailer air braking system is improved, and the braking stability of a combination vehicle is improved.

Owner:郑州宇通集团有限公司

High pressure charged particle beam system

ActiveUS8921811B2Reduce gas volumeFast exhaustMaterial analysis using wave/particle radiationElectric discharge tubesHigh pressureMolecular physics

The current invention includes methods and apparatuses for processing, that is, altering and imaging, a sample in a high pressure charged particle beam system. Embodiments of the invention include a cell in which the sample is positioned during high pressure charged particle beam processing. The cell reduces the amount of gas required for processing, thereby allowing rapid introduction, exhaustion, and switching between gases and between processing and imaging modes. Maintaining the processes gases within the cell protects the sample chamber and column from contact with the gases. In some embodiments, the temperature of the cell walls and the sample can be controlled.

Owner:FEI CO

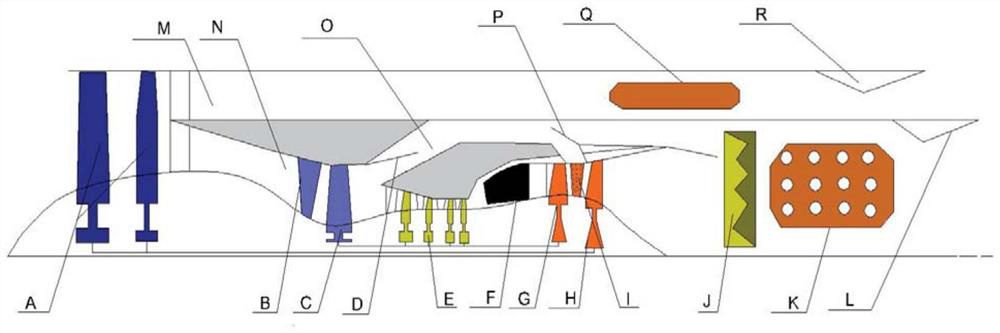

Turbo-shaft and turbo-fan combined cycle engine

ActiveCN106988926AImprove working abilityFast exhaustJet propulsion plantsGas generatorPower capability

The invention relates to the technical field of gas turbine engines, in particular to a turbo-shaft and turbo-fan combined cycle engine. The engine is characterized by comprising a core engine driving fan; an inner circular runner and an outer circular runner are arranged at the back part of the core engine driving fan; the inner circular runner communicates with a high-pressure gas compressor; the outer circular runner communicates with a first duct through a core engine driving fan gas bleed valve; a rotor of a gas generator turbine, the core engine driving fan, the high-pressure gas compressor and a rotor of a centrifugal gas compressor are coaxial; an intermediate-pressure turbine rotor, a rotor where second-stage Flade fan blades are located and a rotor where second-stage inner duct fan blades are located are coaxial; a power turbine / low-pressure turbine rotor is coaxial with rotors where first-stage Flade fan blades and first-stage inner duct fan blades are located and a power output shaft; and two rows of Flade fan rotors which rotate oppositely are arranged, so that the power capability of the fans to inflow air is enhanced, the exhaust speed of an outer duct in the turbo-fan mode of the engine is increased, and the better engine performance is acquired.

Owner:西安觉天动力科技有限责任公司

Flash scratchproof protection film and preparation method thereof

InactiveCN102390155ATransparent and brightStrong sense of fashionLiquid surface applicatorsSynthetic resin layered productsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a flash scratchproof protection film, which comprises a scratchproof layer protection film PET (polyethylene terephthalate) substrate, a protection film glue layer, a scratchproof layer, a composite main film PET substrate, an installing glue layer and an installing flue protection film PET substrate, wherein at least one of scratchproof layer, the composite main film PET substrate and the installing glue layer contains flash powder, or a color transparent material or a mixture containing the flash powder and the color transparent material. According to the protection film, because at least one of the scratchproof layer, the composite main film PET substrate or the installing flue layer is the flash layer or the color transparent layer or the color flash layer, the whole protection film has the characteristics of multiple colors and flashing, transparent brightness, strong fashion sense and the like; the flash scratchproof protection film can be widely used for various liquid crystal displays or automobile protection films and satisfies fashion pursuing trends of young people; and a preparation method of the flash scratchproof protection film is simple and easy to operate and is suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

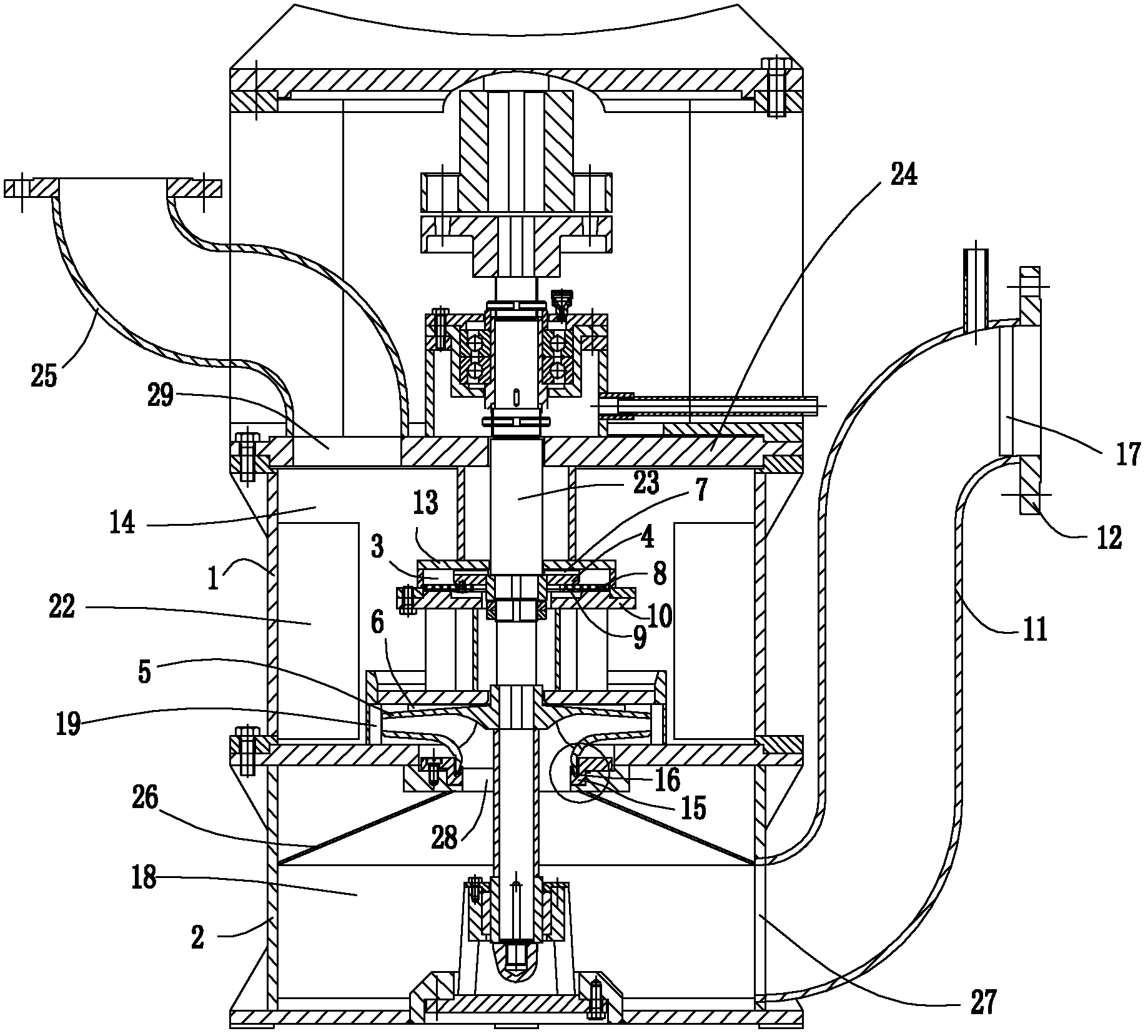

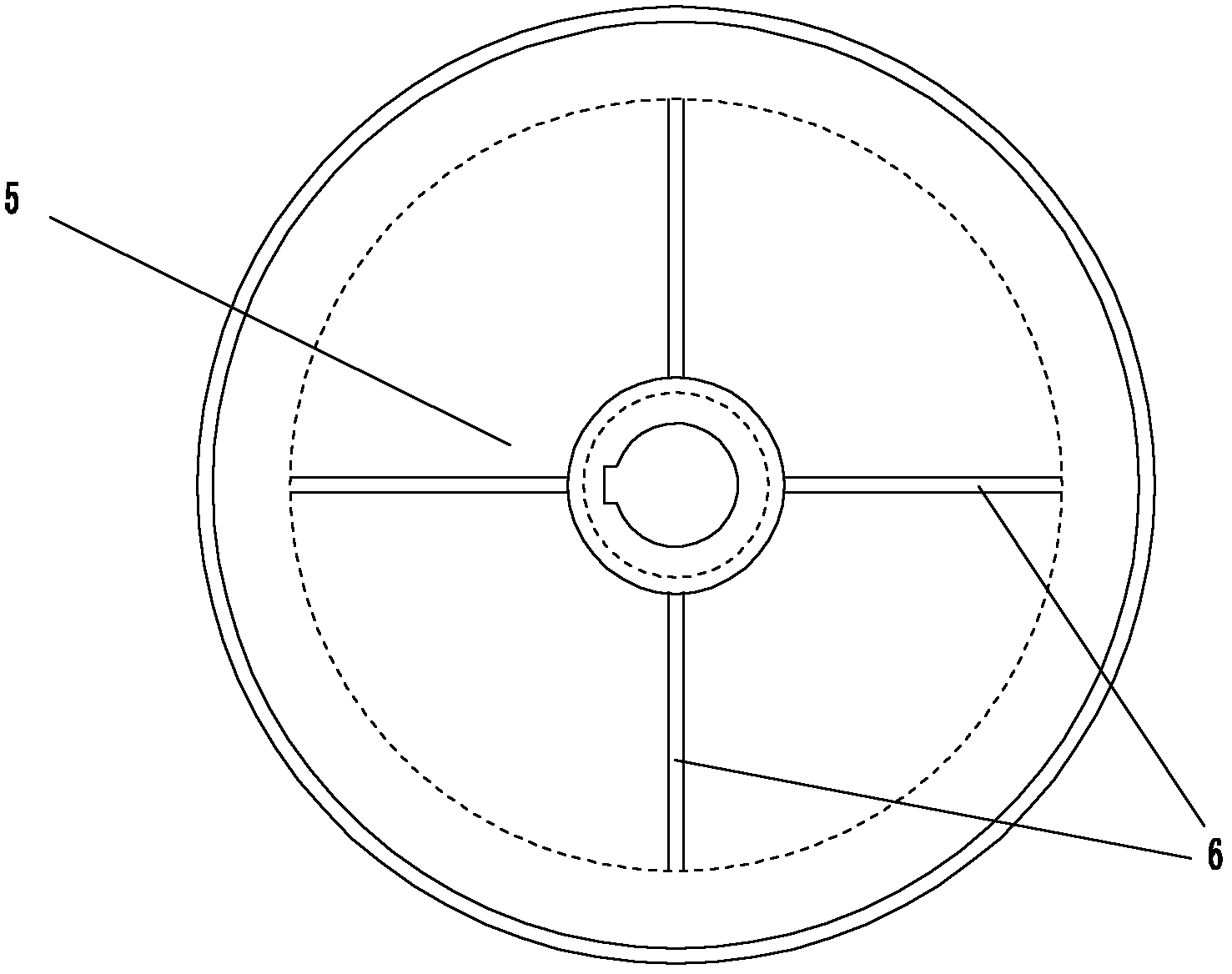

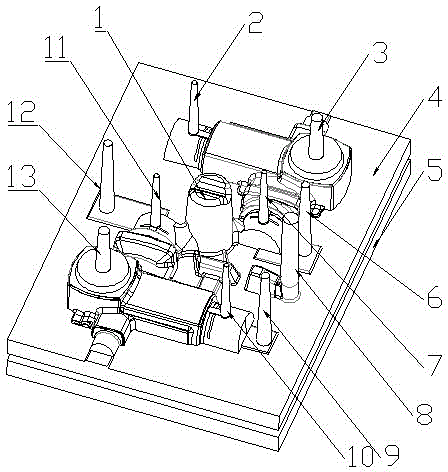

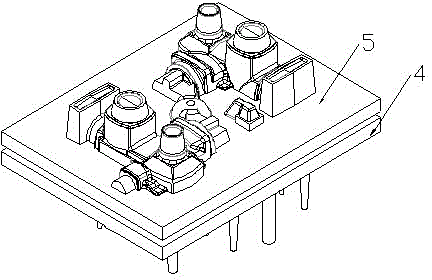

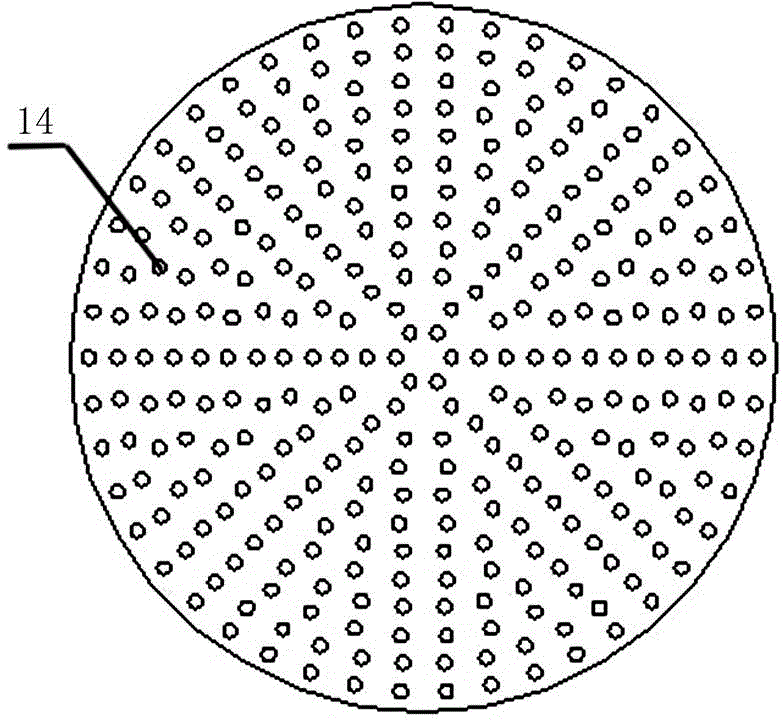

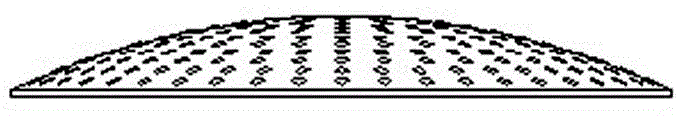

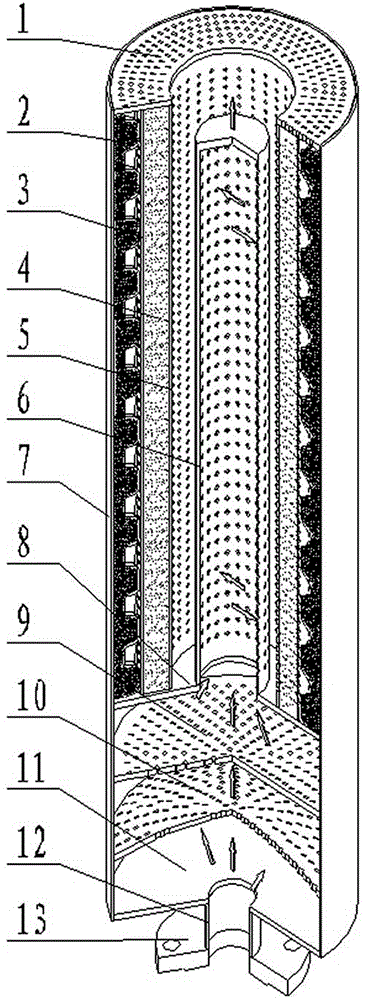

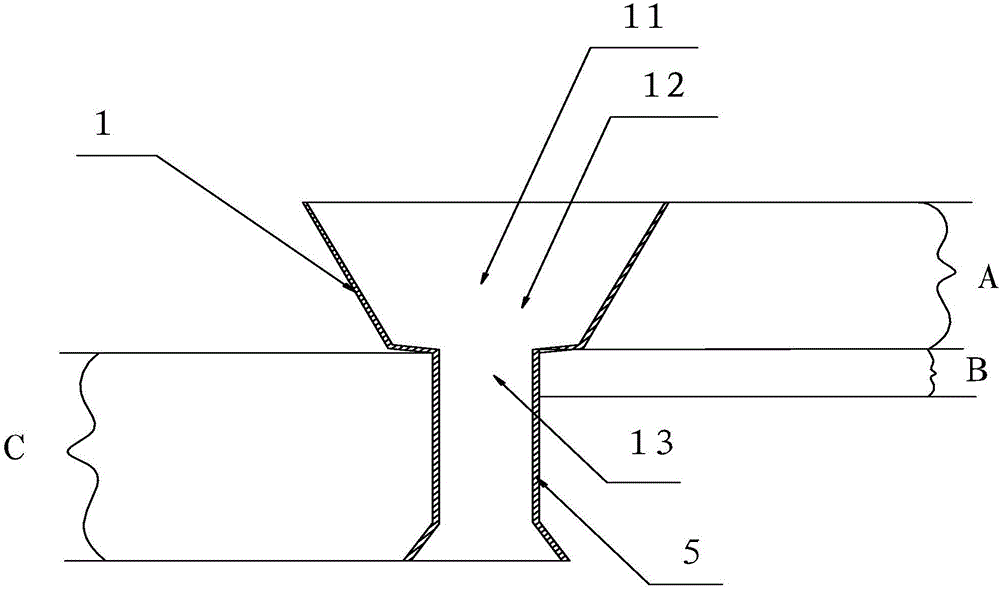

Vertical internal and external mixing shaft-seal-free self-sucking pump

ActiveCN102192157AFast separationImprove self-priming performancePump componentsPriming pumpImpellerEngineering

The invention discloses a vertical internal and external mixing shaft-seal-free self-sucking pump which comprises a pump body, a pump cover, a pump shaft, a main impellor, a main impellor seal chamber, an assistant impellor chamber, an assistant impellor, a water sucking chamber, a water outlet, a water inlet pipe, a water inlet pipe flange, a volute chamber and a gas-water separation chamber, wherein the top surface of the main impellor and the top surface of the assistant impellor are respectively provided with a radial main impellor balancing rib and a radial assistant impellor balancing rib; the outer edge at the bottom surface of the assistant impellor is fixedly provided with an annular seal pad; and the bottom surface of the assistant impellor chamber is provided with an annular supporting plate. Through the self-sucking pump provided by the invention, the issue of air intake of a shaft seal can be solved, high-vacuum continuous air exhaust can be kept all the time in the self-sucking process, the self-sucking capability is improved, and the self-sucking time is shortened.

Owner:GUANGZOU BAIYUN PUMP GROUP

Wide-speed-range variable-cycle engine for driving low-pressure turbine rotor based on interstage combustion chamber

ActiveCN114856855AChange thrustNo air leaksEfficient propulsion technologiesGas turbine plantsRamjetCombustion chamber

According to the wide-speed-range variable-cycle engine for driving the low-pressure turbine rotor based on the interstage combustion chamber, firstly, the interstage combustion chamber is opened, a turbofan interstage afterburning cycle mode is started, the thrust of the engine is greatly increased, meanwhile, all the first mode selection valves are opened, and the second mode selection valve is closed; therefore, more air flow with high oxygen content enters the internal duct afterburner, an internal duct afterburner mode is started, and Ma0-2.5 + flight is realized. When Ma reaches 2.5-6, a turbine engine core engine is closed, meanwhile, first modal selection valves are all opened, a duct second modal selection valve at an inlet of an interstage combustion chamber is gradually opened, a part of air pressurized by a fan enters the interstage combustion chamber I through the second modal selection valve, a low-pressure turbine is driven to drive a fan A to rotate and pressurize, and the fan A is driven to rotate and pressurize; after air flow pressurized by the engine fan A enters the outer duct, the dual-mode ramjet engine is started and enters a stamping mode, and Ma2.5-6 flight is achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Actuator box body casting process

The invention relates to an actuator box body casting process, which comprises the following steps: making a metal mold plate entering an actuator box body with metal, heating the metal mold plate to 180-280 C degree, coating molding sand on the metal mold plate, curing the molding sand, heating and curing the molding sand form a shell mold, wherein a pouring opening is formed in the central part of the shell mold, an overflow pipe and exhaust pins communicated with the cavity is arranged on the shell mold; forming three sets of actuator box body sand cores through chromite sand, combining the sand cores to form a sand core main body and horizontally arranging the sand core main body in a lower shell; making a sand box with sand, wherein upper and lower shells are embedded into the sand box, a sand layer is coated on the cavities among the inner side of the sand box and the outer surfaces of the upper and lower shells, and a pouring and rising system communicated with the shell mold is arranged in the sand layer; pouring towards the cavity through the pouring and rising system to form the actuator box body. The actuator box body casting process has the advantage that the exhaust is fast and the work efficiency is high.

Owner:江苏力源金河铸造有限公司

High-temperature sintering process for neodymium iron boron

The invention discloses a manufacture process of an iron-base alloy and particularly discloses a high-temperature sintering process for neodymium iron boron. The process includes the steps that (1) neodymium iron boron powder is compacted and placed in a furnace; (2) vacuum is pumped, a pump group of a rotary plunger vacuum pump and a roots pump is adopted, and a rough valve is opened to conduct pumping to enable the vacuum degree in a sintering device to be 1.0x10-1Pa; (3) temperature is raised and air is exhausted, the target temperature is 600 DEG C, after the temperature is kept for 0.5h, the temperature is raised to the final air exhaust temperature point of 950 DEG C, after the air exhaustion vacuum degree is 1.0x10-1Pa, the temperature is kept raised to 1080 DEG C, the temperature is kept for 4h, at this time, the pump group keeps working, and the vacuum degree is maintained to be 1.0x10-1Pa; (4) tempering is conducted, the temperature is reduced to 900 DEG C and kept for 2h, and then the temperature is reduced to 490 DEG C and kept for 4h; (5) the pump group is closed, a fan is turned on, and the neodymium iron boron is cooled to the room temperature and taken out from the furnace. The high-temperature sintering process solves the technical problem in the existing high-temperature sintering process for the neodymium iron boron that the sintering time is long and electric energy consumption is large and has the advantages of saving energy consumption and reducing cost and the like.

Owner:NINGBO HUAHUI MAGNETIC IND

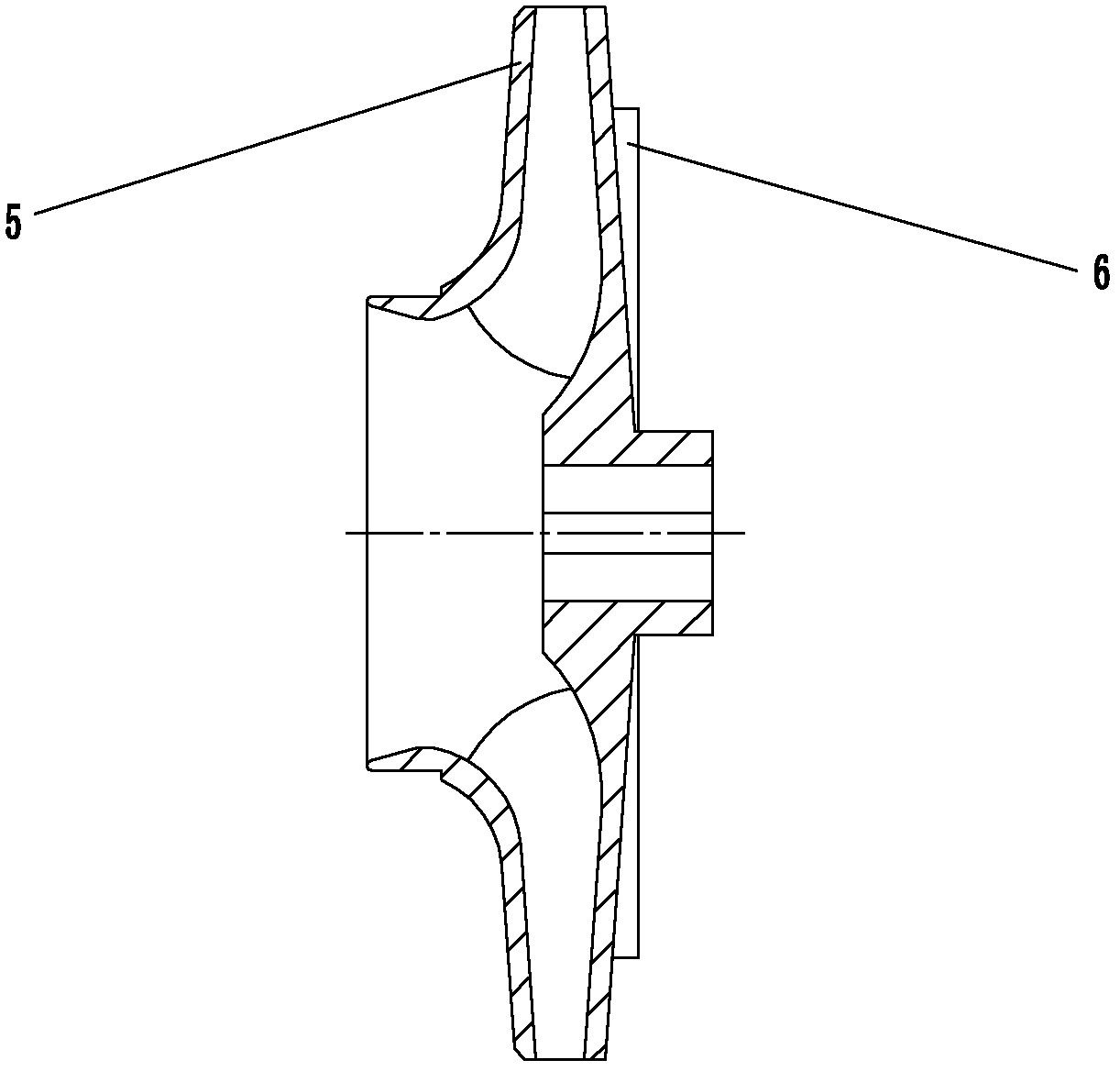

Bottle perform mold structure provided with bottle opening groove

The invention discloses a bottle perform mold structure provided with a bottle opening groove. A mold core mode-locking ring of the bottle perform mold structure is a hollow cone-column structure, the inside of the hollow cone-column structure is cylindrical, one peripheral end is a cone structure, one end is a cylindrical structure, a through hole is arranged on a wall at the combing position of the cone structure and the cylindrical structure, an annular groove is processed on the inner side cylindrical face at the end portion of the cylindrical structure of the mold core mode-locking ring, and an air vent groove is formed at the step transition position of the annular groove and the mold core outer cylindrical face. A mold lip consists of two split oppositely-opening pieces, and one piece is provided with the air vent groove on the contact face of the two pieces. The air vent groove is divided into two branches, one branch is parallel to the axial direction of the mold lip, one end of the one branch is led to the contact end face of the mold core mode-locking ring and the mold lip, and a distance from the contact end face to the mold lip is 0.025-1mm. The bottle perform mold structure achieves multiple-channel air venting and is high in air venting speed. A bonding line is close to a bottle opening. The required opening distance of the mold lip is short in demolding, and demolding and perform fetching are reliable.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

Straight pipe type silencer

InactiveCN104088689AImprove the noise reduction effectFast exhaustSilencing apparatusMachines/enginesGlass fiberEngineering

The invention relates to a straight pipe type silencer which comprises an outer cylinder, wherein an air inlet end plate is arranged at an air inlet end of the outer cylinder, a damping air outlet hole plate is arranged at the air outlet end of the outer cylinder, and a baffle with a through hole is arranged in the middle of the outer cylinder and divides the inside of the outer cylinder into an upper inner chamber and a lower inner chamber. The straight pipe type silencer is characterized in that a spherical damping hole plate and a planar damping hole plate are successively arranged in the lower inner chamber in the air flowing direction, an air guide pipe integrally positioned in the upper inner chamber is welded onto the baffle coaxially, one end of the air guide pipe is communicated with the lower inner chamber through the through hole in the baffle, the other end of the air guide pipe is closed, a group of silencing holes are formed in the lateral walls of the air guide pipe, and a silencing device is arranged outside the air guide pipe coaxially. The silencing device comprises an inner hole plate and an outer hole plate which are arranged between the air guide pipe and the outer cylinder coaxially, the space between the inner hole plate and the outer hole plate is filled with glass fiber cotton, and the space between the outer hole plate and the outer cylinder is filled with wave crest sound-absorbing sponge firmly adhering to the cylindrical surface on the inner side of the outer cylinder. The straight pipe type silencer has the advantages of being good in sound silencing and noise attenuation effect, high in exhaust speed and the like.

Owner:杭州鼎岳空分设备有限公司

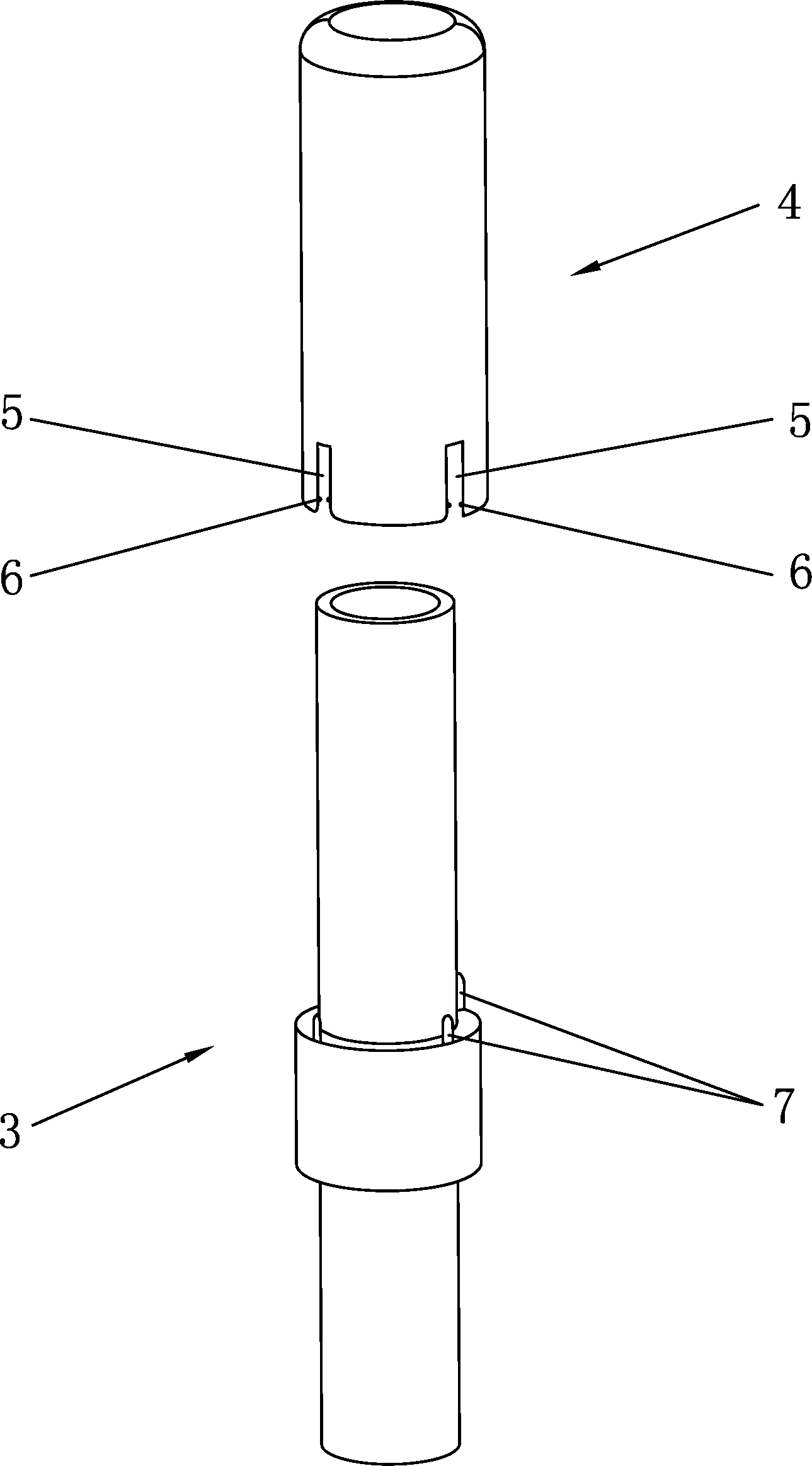

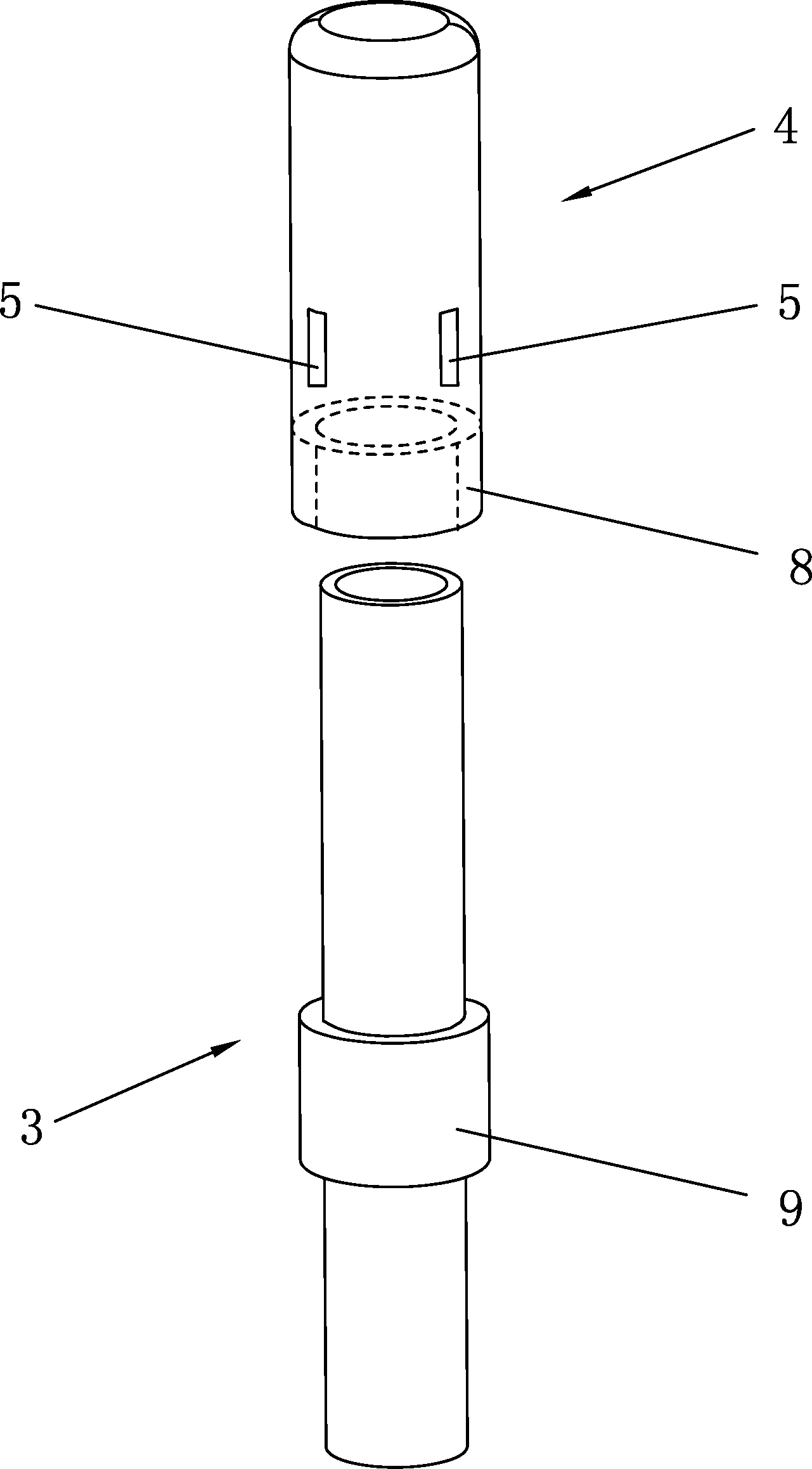

Fluid extractor for closed body fluid retention devices

ActiveCN106669869ALow costIncrease productivityFluid transfer labwareBody fluid retentionEngineering

The invention relates to the field of medical appliances, particularly a collecting device for collecting the body fluid. The fluid extractor for closed body fluid retention devices comprises an annular side wall and a channel assembly, wherein the annular side wall forms a channel; the channel assembly is arranged in the channel and positioned on the lower part of the channel; the channel assembly and annular side wall form a split fit; the channel assembly is provided with a through hole; the upper part of the channel is used for collecting the fluid; and the lower part of the channel is matched and connected with the channel assembly. The fluid extractor is capable of lowering the cost and enhancing the production efficiency; and when the excess fluid is poured out of the fluid extractor, the fluid in the test tube can be prevented from being poured out from the diversion channel or exhaust channel.

Owner:WUXI KAISHUN MEDICAL DEVICE MFG CO LTD

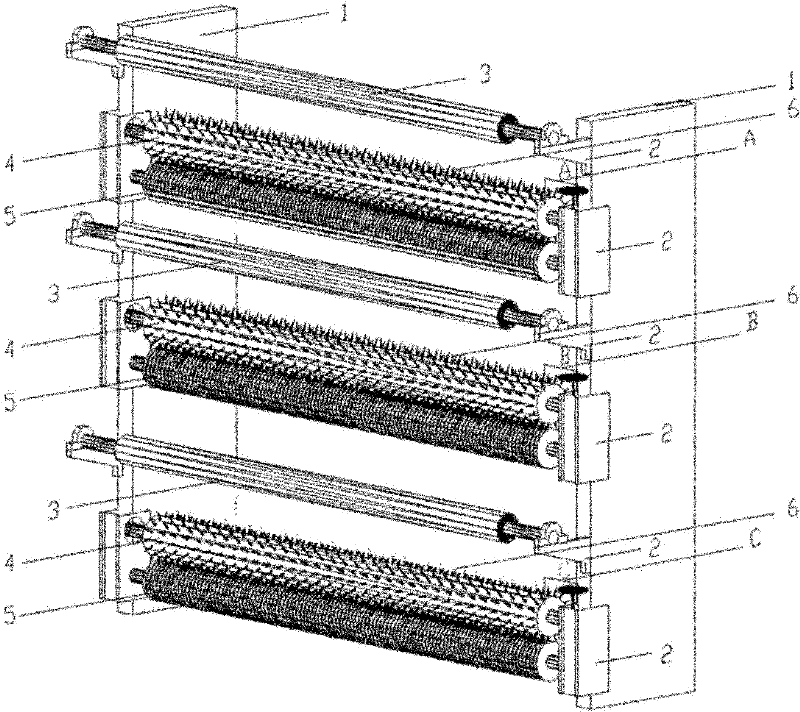

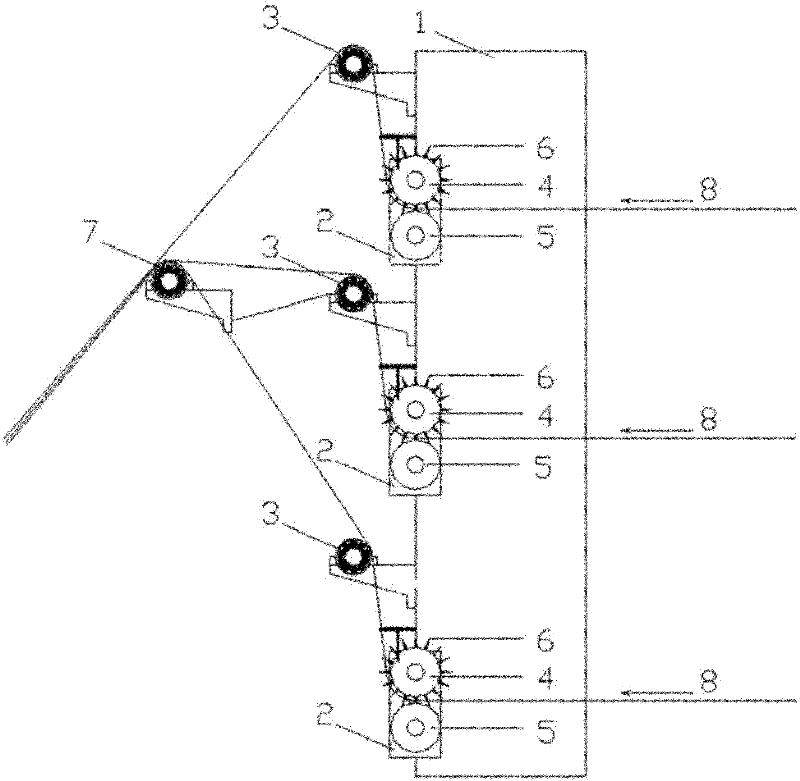

Multilayer dislocation punching device

The invention discloses a multilayer dislocation punching device, comprising a stand wall board, a bearing mounting base, paper passing rollers, needle rollers, rubber supporting rollers and a punching needle, wherein the bearing mounting base is mounted on the stand wall board; the rubber supporting roller is mounted on the bearing mounting base; the needle roller is further mounted on the bearing mounting base; the rubber supporting roller matched with the needle roller is mounted on the bearing mounting base by being matched with the needle roller; the punching needle is mounted on the needle roller; and three groups of punching mechanisms for individually working are respectively formed by the three needle rollers, the three rubber supporting rollers and the three paper passing rollers for guiding paper in pairs. Each layer of the paper sheet is punched by the multilayer dislocation punching device in a bag making process, so that holes are not flat and parallel to pass through. Therefore, filled materials are left in a body of a paper bag when a venting speed is greatly improved, so that not only can the filling speed be improved, but also the materials are saved; and the dust pollution problem in a filling field is solved.

Owner:广东盈通纸业有限公司

A plunger type lubricating grease pump

InactiveCN102261553AGuaranteed to workEliminate "air lock" phenomenonLubricating pumpsCompressibilityEngineering

The invention discloses a plunger-type lubricating grease pump. The plunger-type lubricating grease pump comprise a pump body and a plunger, wherein an oil outlet and an oil sucking hole are formed in the front end and the middle part of the pump body; the plunger is provided with an oil pumping end; the plunger is arranged at the back end of the pump body and the oil pumping end is put into a pump cavity of the pump body; a pump body vent is formed in the back end of the pump body; a plunger cavity and a one-way valve which is used for controlling fluid to flow from the pump cavity to the plunger cavity are arranged in the plunger; and a first plunger vent for communicating the plunger cavity and the pump body vent when the oil pumping end moves to a position between the oil sucking hole and an oil outlet and is a certain distance away from the oil sucking hole is arranged on the plunger. By using pressure difference and combining the compressibility of gas, the plunger-type lubricating grease pump can automatically exhaust the gas accumulated in the pump cavity under a certain condition, so that a gas blockage phenomenon is effectively eliminated, the normal work of a lubricating oil pump is ensured, the working efficiency is obviously improved, and manpower and materials are saved.

Owner:TALY AVIATION TECH SHENZHEN

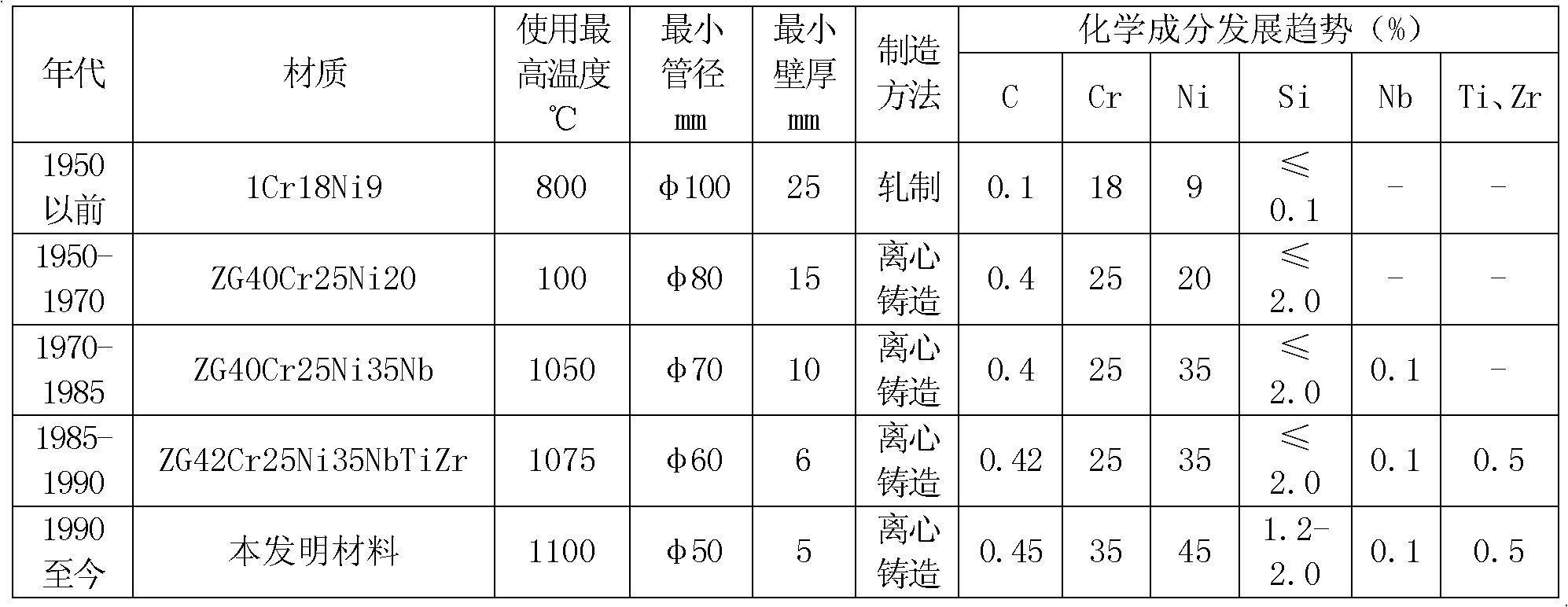

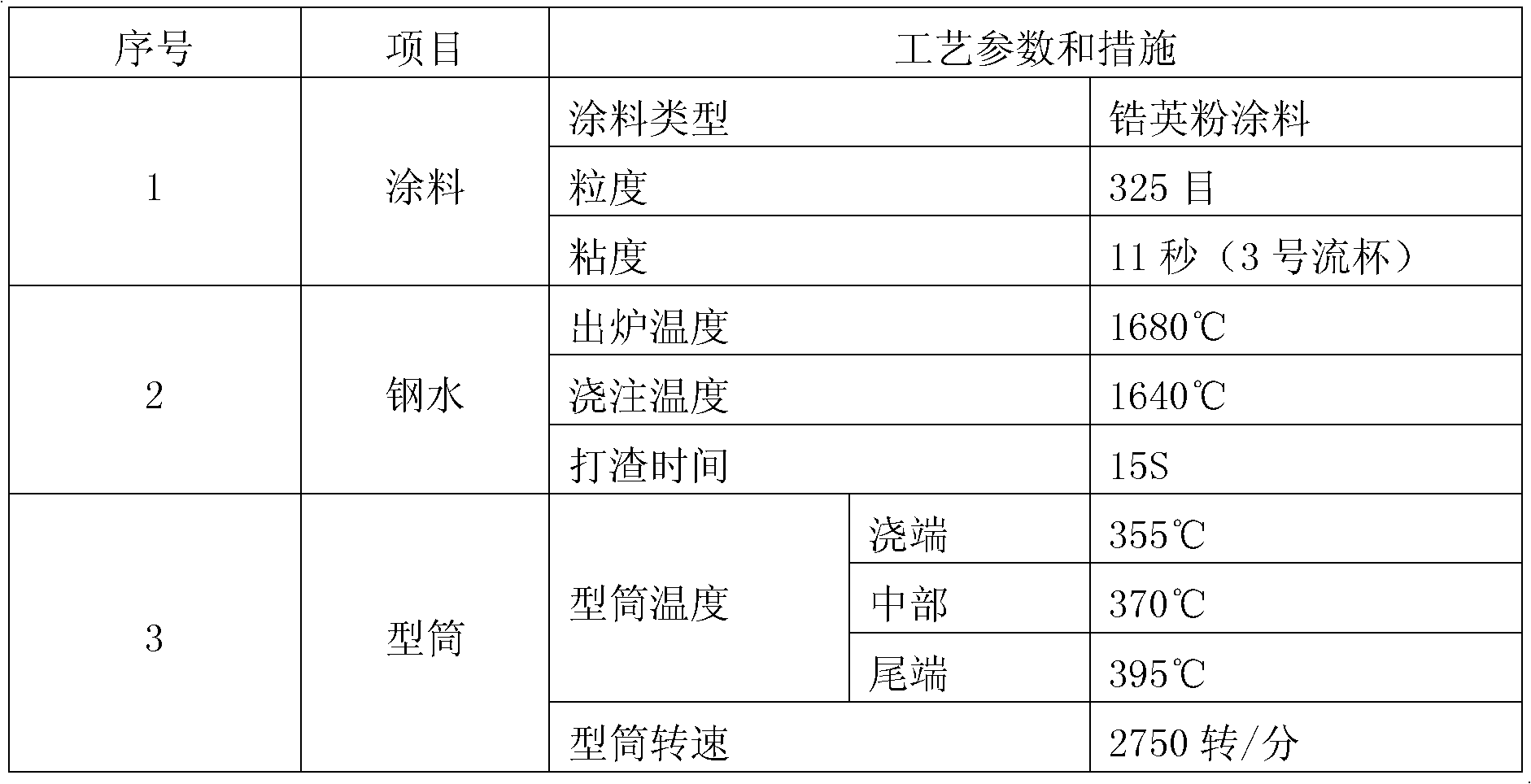

Centrifugal casting process for minor-caliber ultra-thin-wall microalloy furnace tube

The invention discloses a centrifugal casting process for a minor-caliber ultra-thin-wall microalloy furnace tube. The tapping temperature and the casting temperature of the casting molten steel, the temperature of a mould cylinder and the like are strictly controlled, so that the cast minor-caliber ultra-thin-wall microalloy furnace tube meets the design requirements and increases the yield thereof greatly. The centrifugal casting process can further reduce the wall thickness and the tube diameter of the furnace tube and reduce the manufacturing cost of the furnace tube, wherein the minimum wall thickness is 5 mm and the minimum tube diameter is 50 mm. The outer surface of the mould cylinder is divided into three segments for carrying out temperature control, so that on one hand, the drying speed of the coating is increased, the exhaust amount of the coating is reduced and the exhaust speed of the coating in the mould cylinder can be increased, and on the other hand, the temperature difference between the cast segment and the tail segment of the mould cylinder is reduced, thus the stress and deformation of the furnace tube during the casting cooling are reduced.

Owner:浦杰

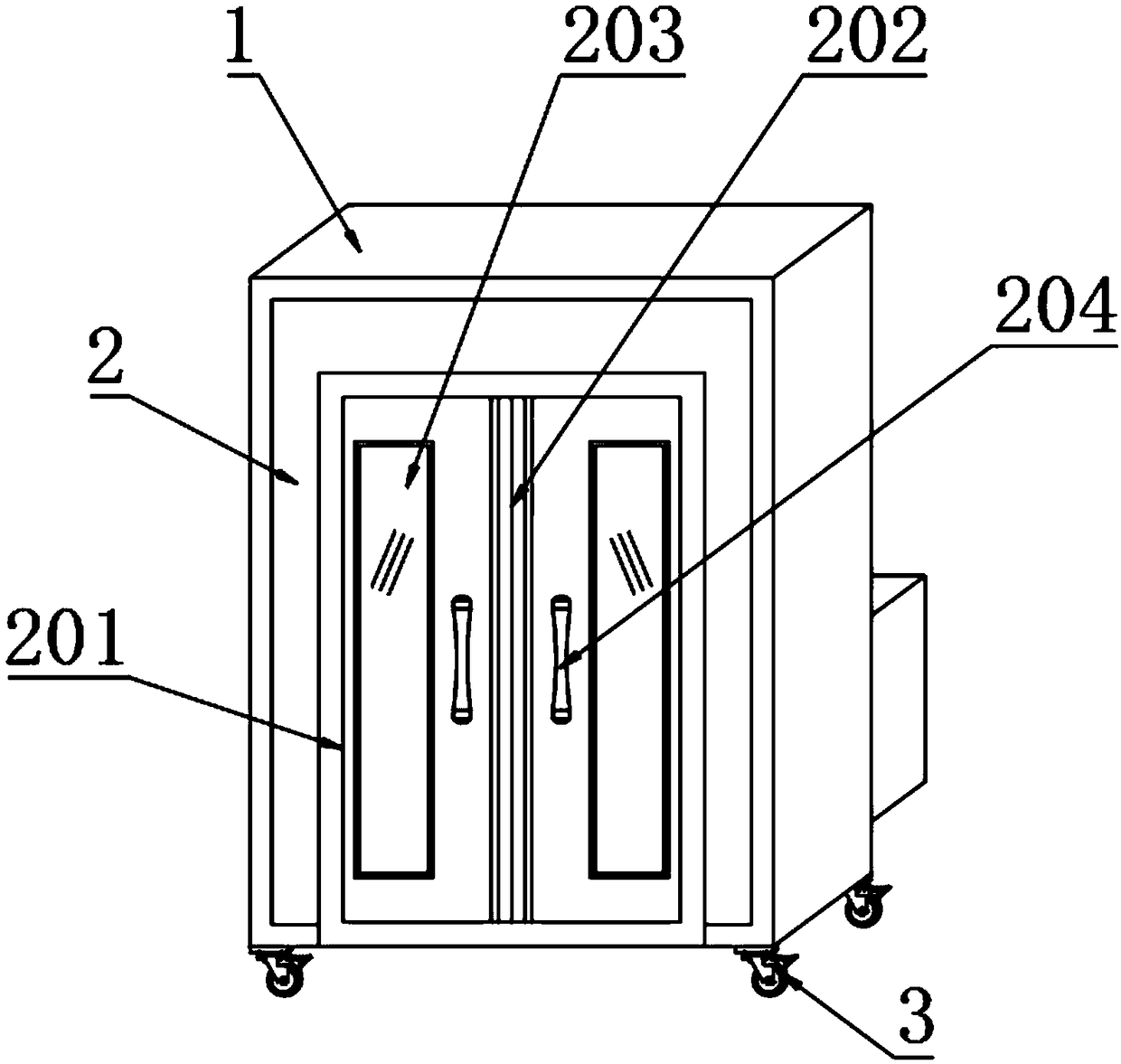

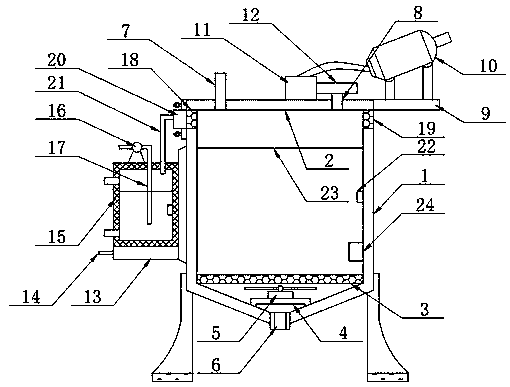

Multifunctional household tableware disinfection cabinet

The invention discloses a multifunctional household tableware disinfection cabinet. The multifunctional household tableware disinfection cabinet comprises a housing body, a suction case is fixedly arranged at a back of the housing body through screws, a suction fan is fixedly arranged at an edge of the inner side of the suction case through a soleplate, an air inlet channel is connected with the lower part of the bottom of the suction case in a sealing mode, and a cooling component is fixedly arranged at the lower part of the bottom of the air inlet channel. The multifunctional household tableware disinfection cabinet has the advantages of scientific and reasonable structure, and safe and convenient usage, the suction case and the internal suction fan are convenient for rapidly removing hot gas and steam after the disinfection of the disinfection cabinet is completed, secondary pollution of tableware due to water stain of liquefied accumulated gas in the tableware disinfection cabinetcan be prevented, a cooling box and an internal semiconductor refrigeration sheet can timely cool the gas absorbed by the suction fan to the water stain, the water stain can be collected in a water collection chamber, and local temperature increase in the chamber due to external diffusion of hot gas and steam can be prevented.

Owner:李成锦

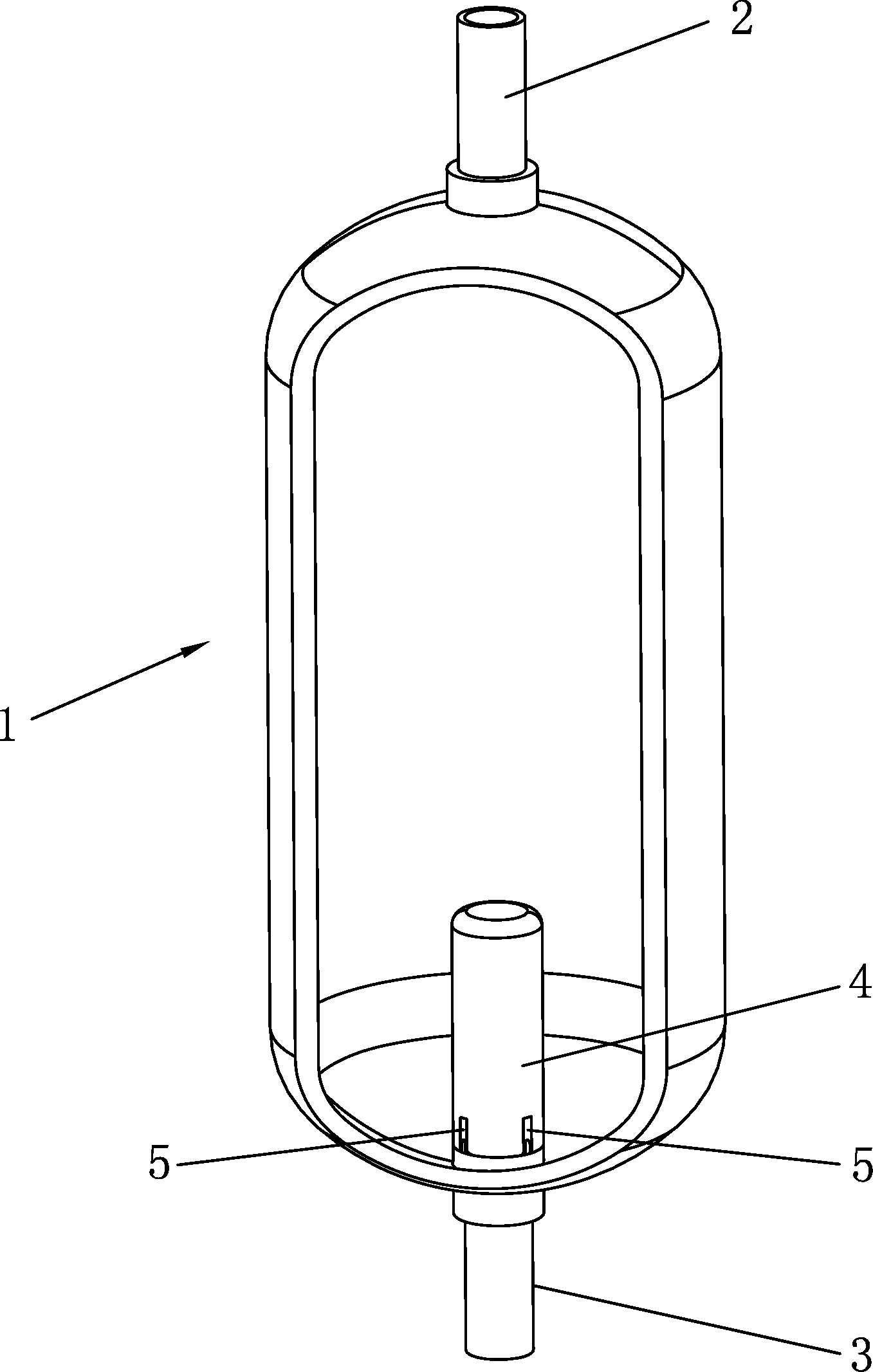

Cold trap

ActiveCN104667565AReduce conductivityFast exhaustSolidificationLiquefactionVacuum pumpVacuum chamber

A cold trap is provided between a vacuum chamber and a vacuum pump. The cold trap includes a cold panel and a cold panel chamber that surrounds the cold panel in an exhaust passage. The cold panel includes an expansion panel outside the cold panel chamber. The expansion panel is located in the vacuum chamber.

Owner:SUMITOMO HEAVY IND LTD

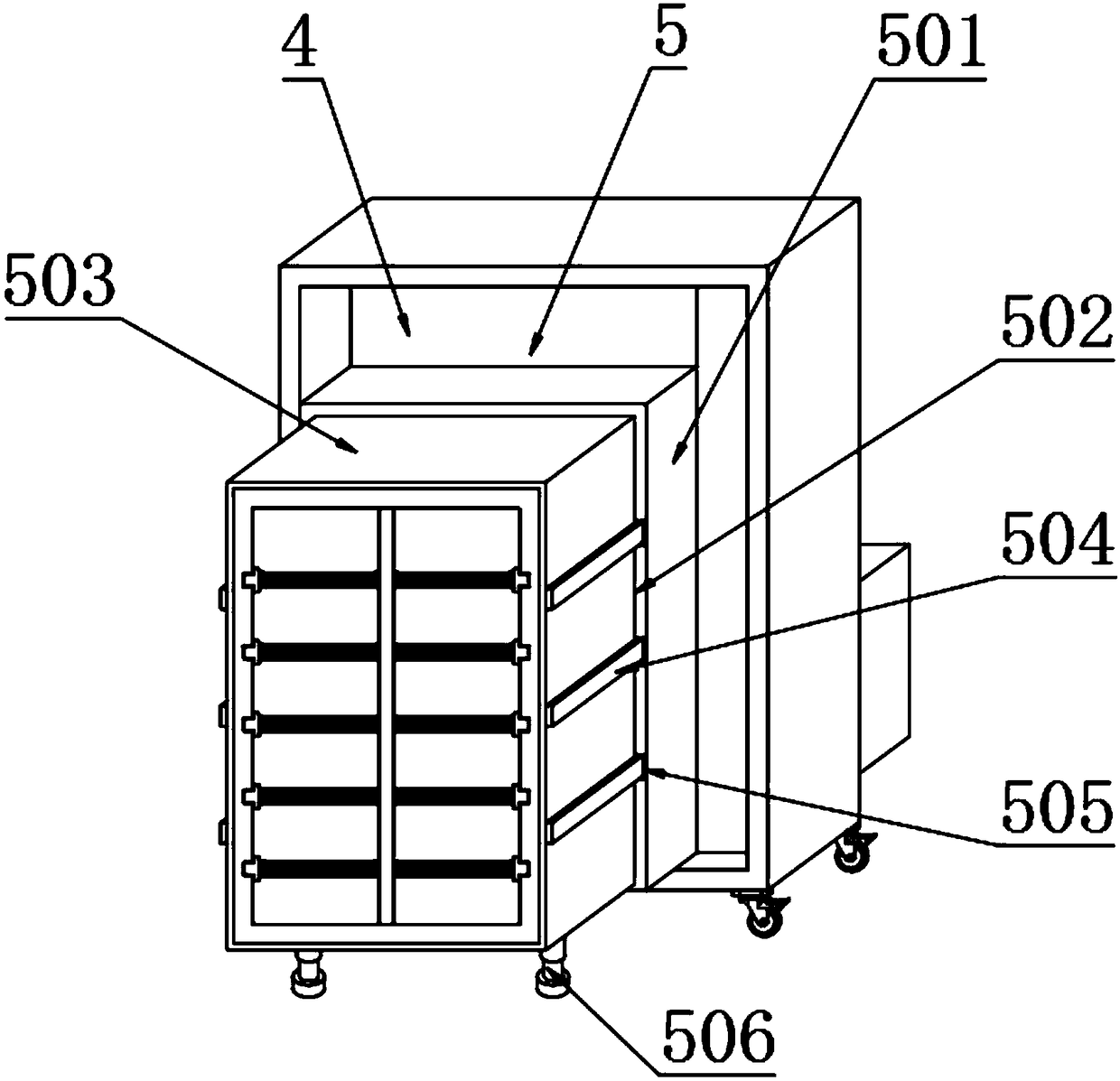

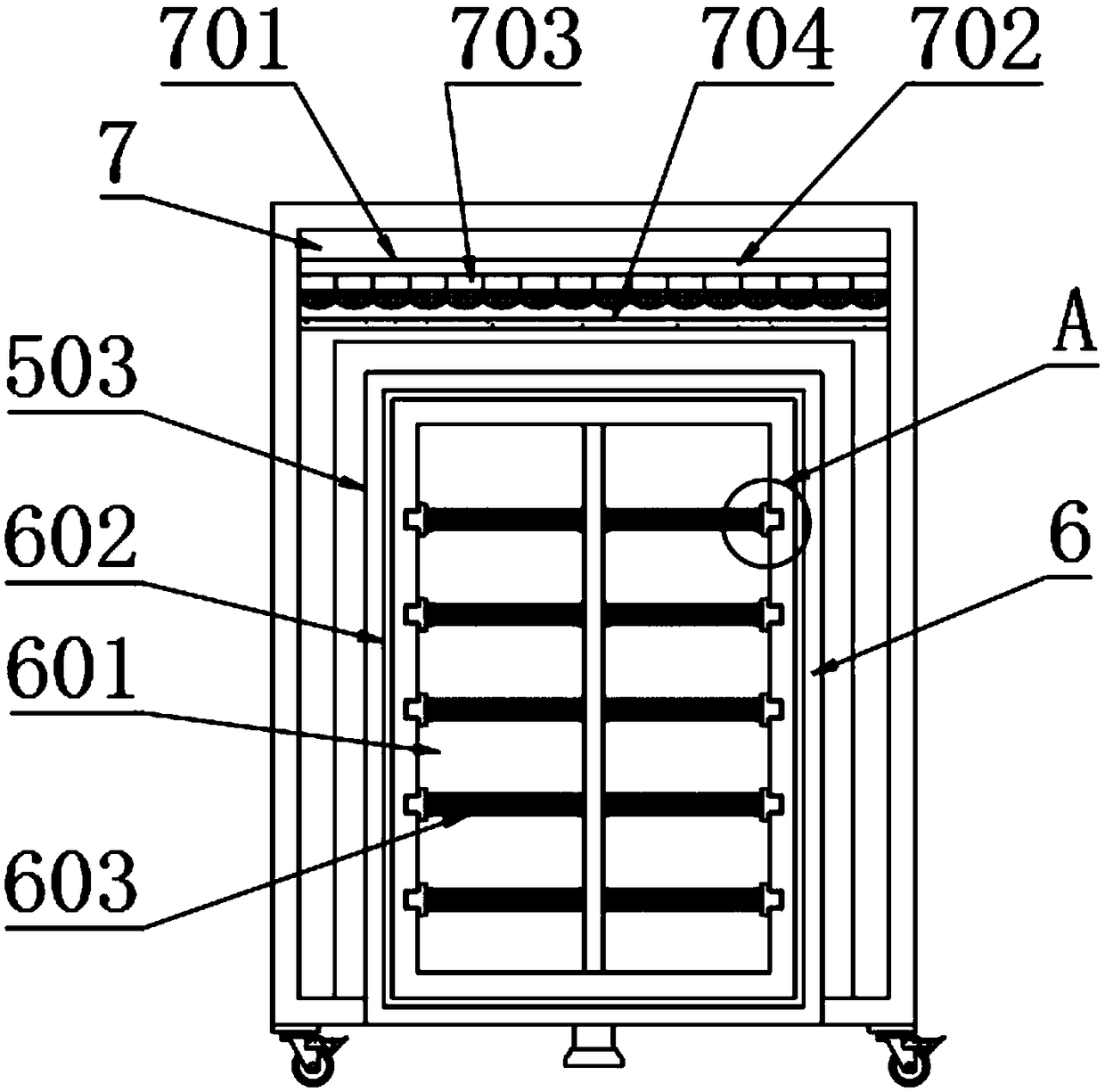

Numerical-control chronic intermittent anoxic box

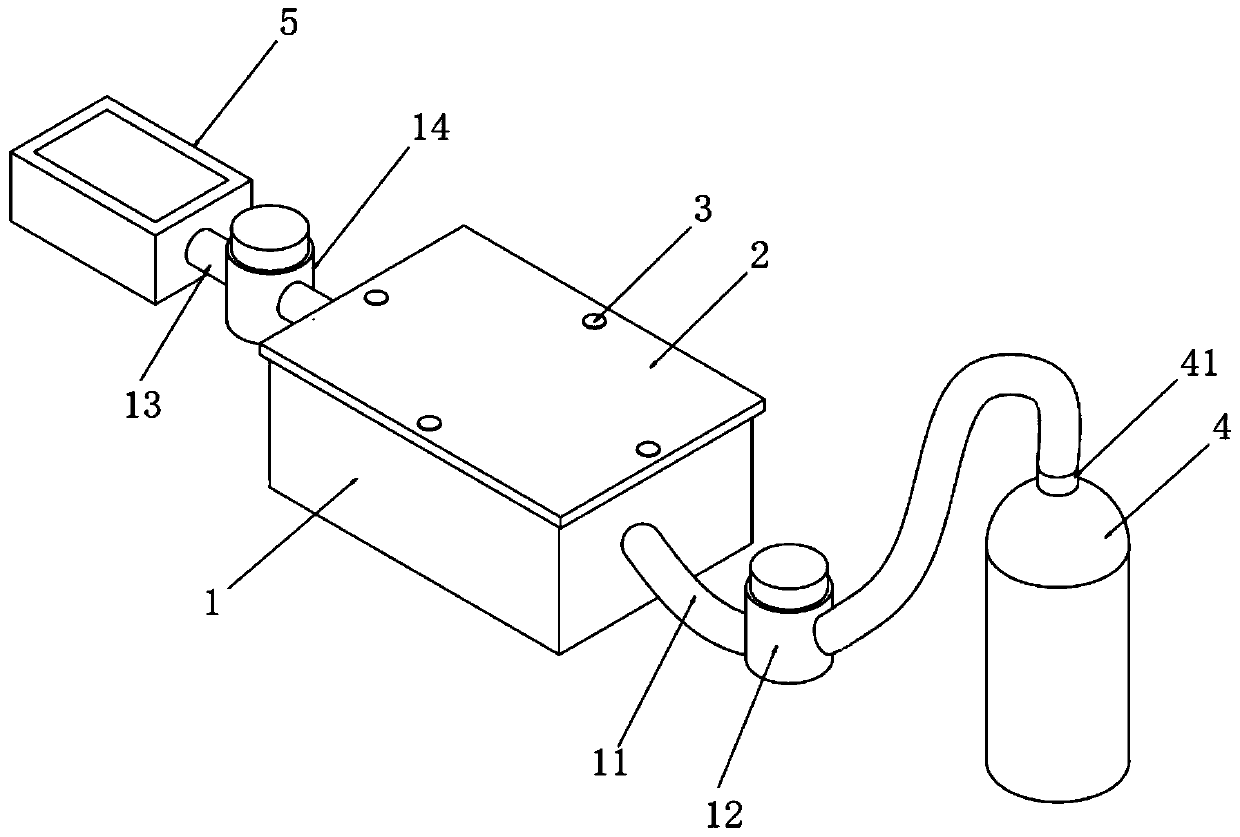

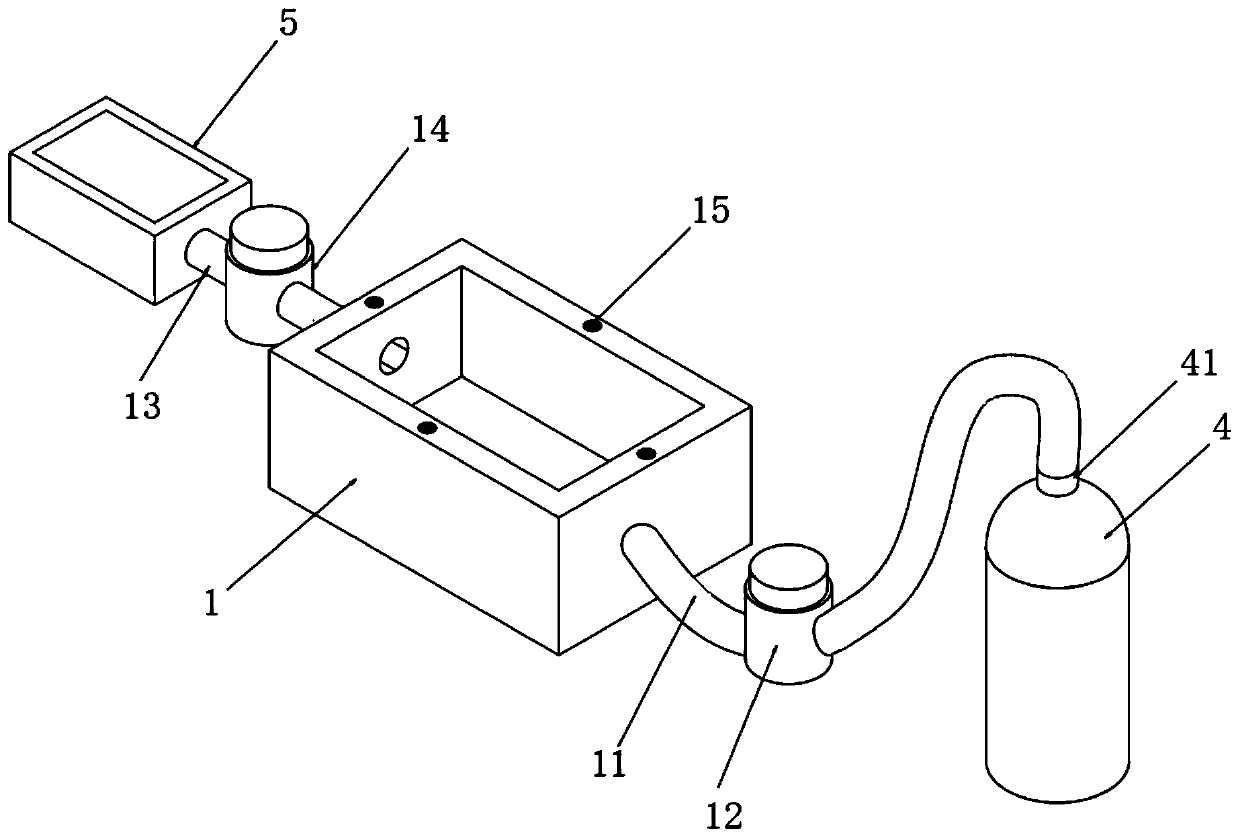

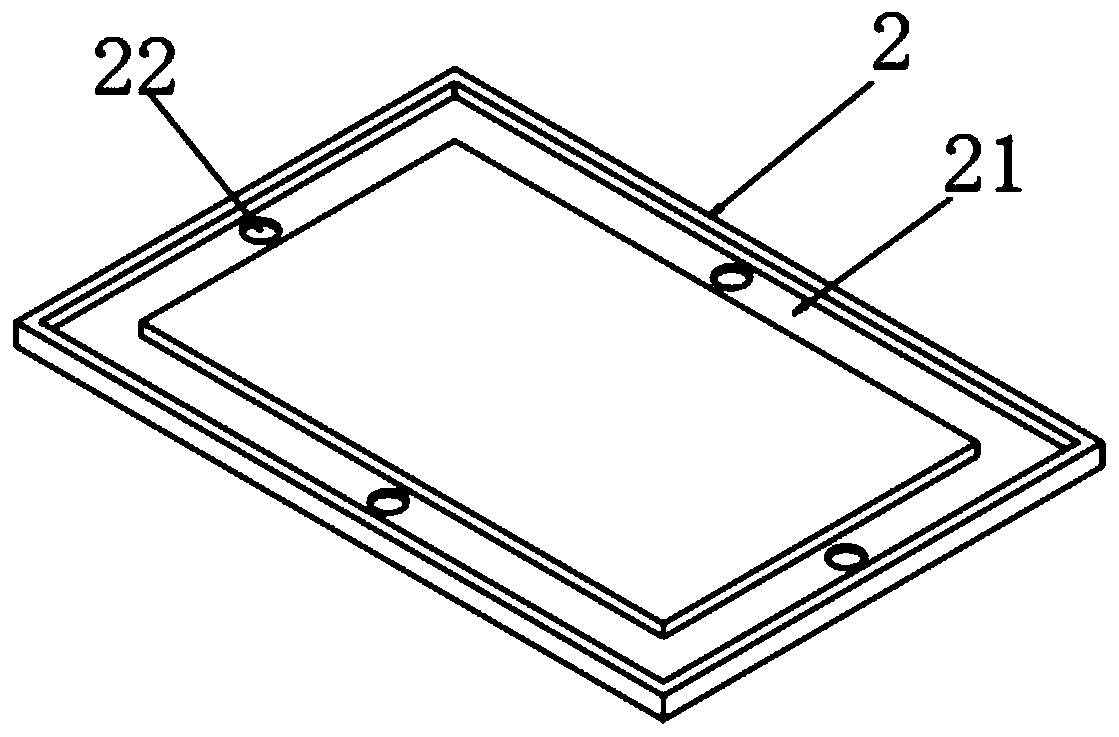

InactiveCN110742760AImprove test speedImprove test efficiencyBreathing protectionTreatment roomsHuman bodyAnimal science

The invention relates to the technical field of animal test equipment, in particular to a transparent observable box for generating a chronic intermittent hypoxic state by applying a numerical controltechnology. According to the equipment, a nitrogen conveying pipe and an exhaust pipe which are communicated with the interior of a test box are connected to the two end parts of the closed test boxrespectively; the flow of an air inlet valve and an exhaust valve are designed and controlled through a computer application program, and a nitrogen conveying pipe is connected to a nitrogen conveyingbottle; and nitrogen is added into the closed test box, so that air in the closed test box is exhausted from the exhaust pipe, oxygen in a box is rapidly exhausted, the content of the oxygen in the box is reduced, an experimental animal placed in the box body is in an intermittent hypoxia state, and a chronic intermittent hypoxia animal model is established. The device enables the oxygen contentin the test box to automatically simulate the state of chronic intermittent oxygen deficiency in the human body according to experimental requirements.

Owner:谭东

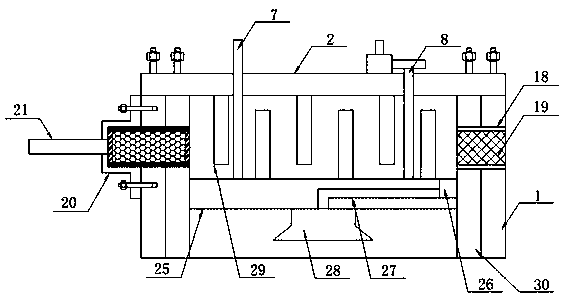

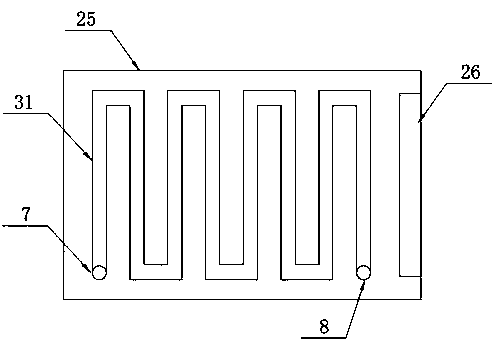

High-low voltage power distribution cabinet with temperature regulation and control intelligent system

InactiveCN111092388ASlow down the flowImprove cooling effectBoards/switchyards circuit arrangementsSubstation/switching arrangement cooling/ventilationLow voltageCirculator pump

The invention discloses a high-low voltage power distribution cabinet with a temperature regulation and control intelligent system, which belongs to the technical field of power distribution cabinets.The high-low voltage power distribution cabinet comprises a cabinet body, an air cooling box is arranged at the top of the inner cavity of the cabinet body, the air cooling box comprises a mounting frame sleeved in the inner cavity of the cabinet body, a partition plate is arranged in the middle of an inner cavity of the mounting frame, a snakelike groove is formed in the outer wall of the top ofthe partition plate, and a snakelike pipe is clamped in the snakelike groove. In the case of cooling, condensed liquid is sucked by a circulating pump; then the condensed liquid is fed into the snakelike pipe through a condensed liquid inlet pipe; condensate in the inner cavity of the snakelike pipe can cool air on the top of the partition plate. The cooling box is matched with the circulating pump and the connecting pipe, low-temperature condensate circularly flows through an inner cavity, and water in the inner cavity of the water cooling box can be cooled. The air pump sends external air below the liquid level through the air pipe, the air enters the shell cover through the air supply pipe after being cooled by low-temperature water, the low-temperature air in the inner cavity of the shell cover enters the top of the partition plate, and the cooled air at the top of the partition plate enters the inner cavity of the cabinet body through the groove, the channel and the air outlet cover.

Owner:安徽华明电气设备有限公司

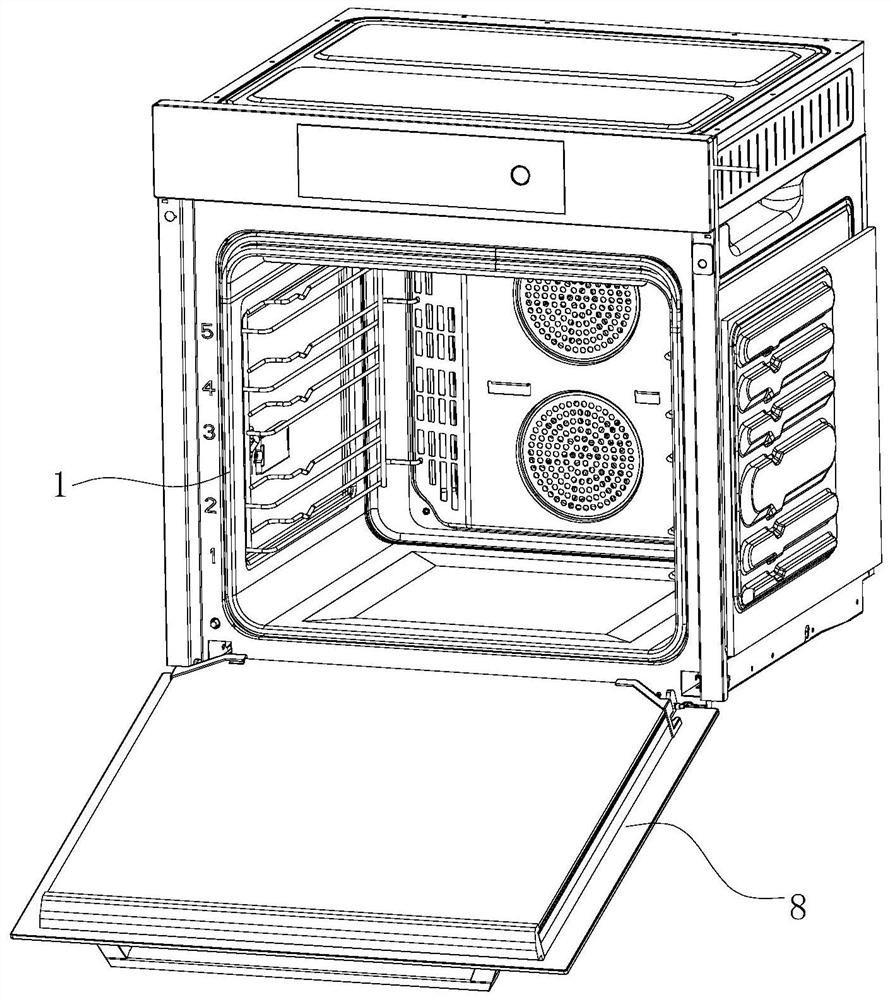

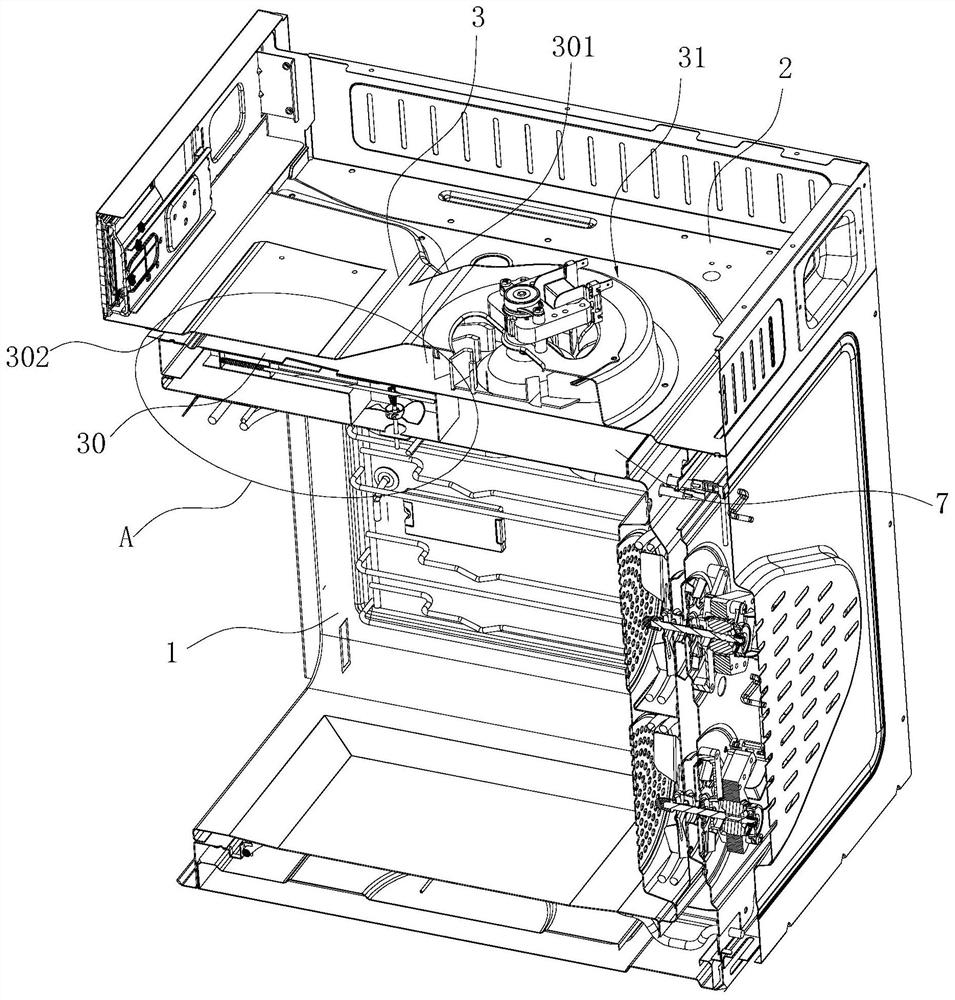

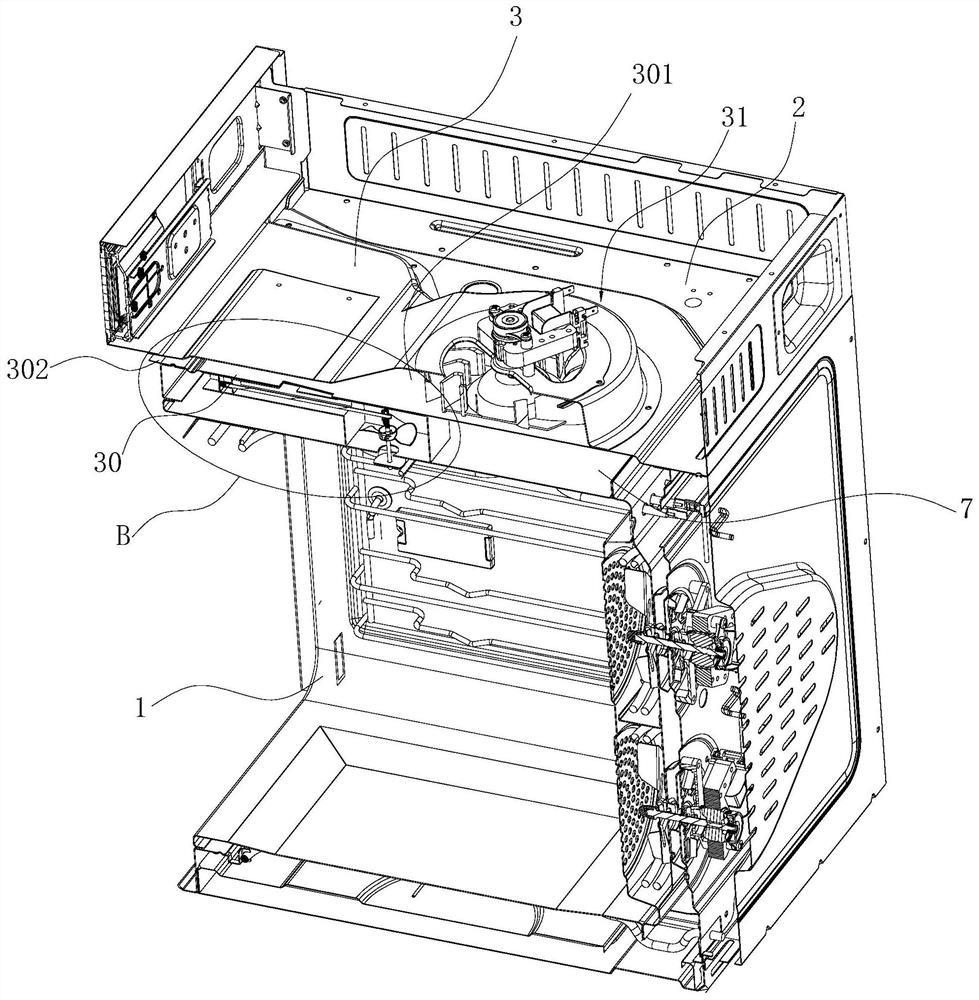

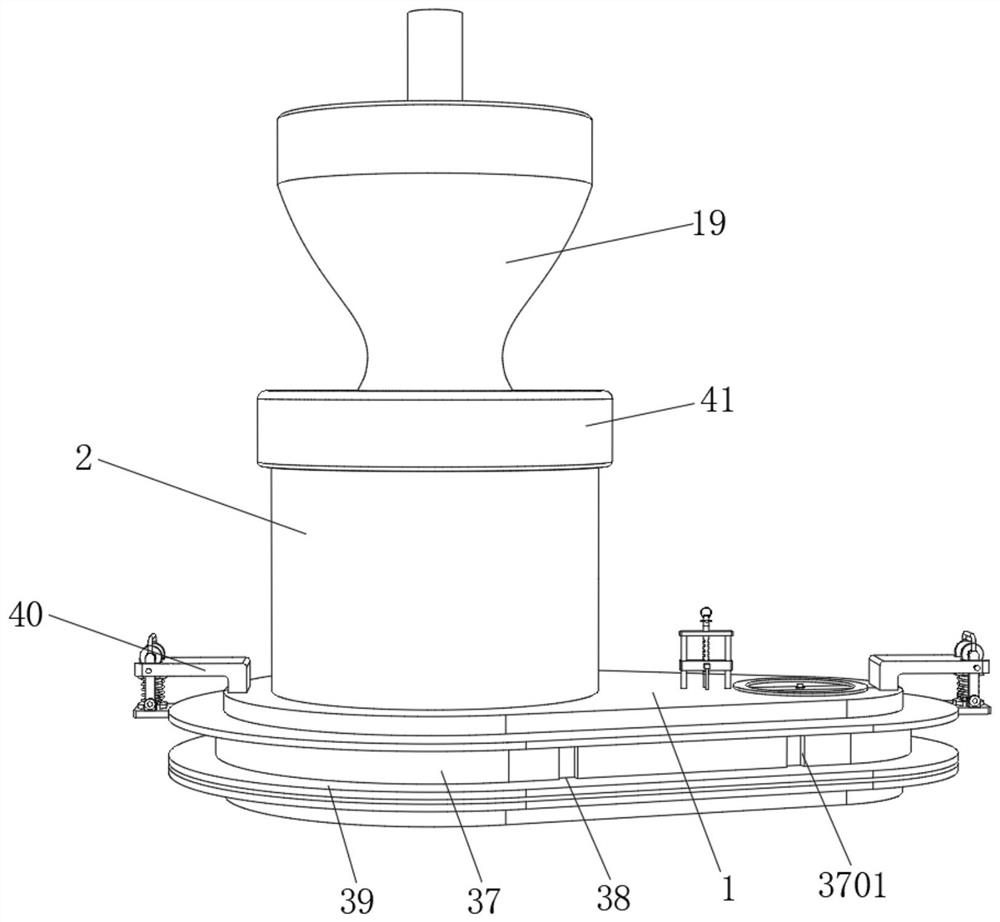

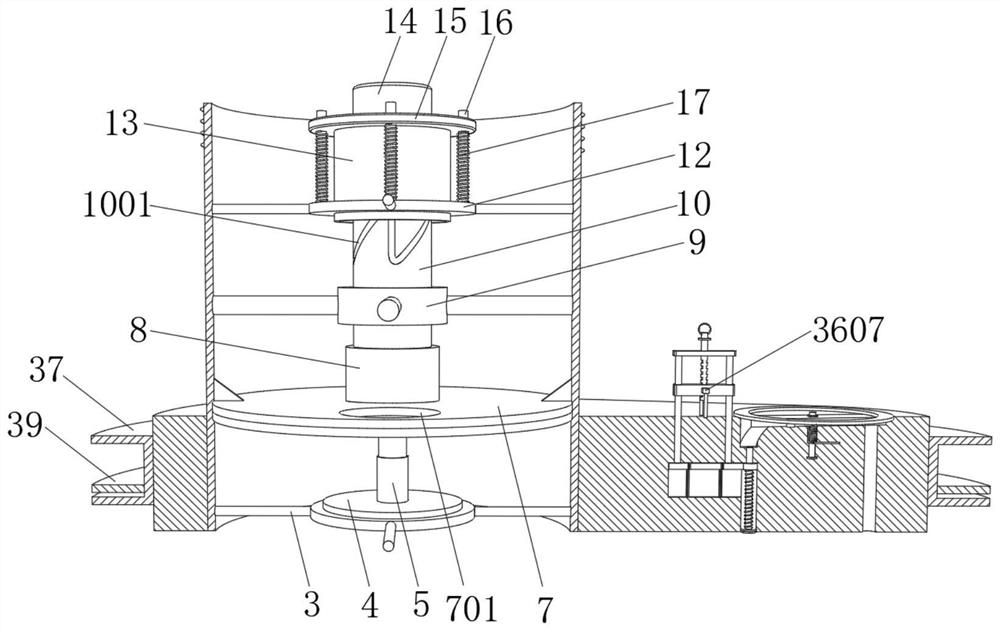

Cooking exhaust structure with self-adaptive and adjustable exhaust speed and baking cooking device

ActiveCN112716313AFast exhaustExhaust speed controlFood processingCooking vesselsThermodynamicsEngineering

The invention relates to a cooking exhaust structure with a self-adaptive and adjustable exhaust speed and a baking cooking device. The first side and the second side of a piston are subjected to the action of the outside atmospheric pressure and the inner pressure of an inner container correspondingly. When the pressure borne by the first side of the piston is larger than that borne by the second side, a vent hole of a first baffle moves backwards relative to a ventilation window, and the exposed part of the ventilation window moves backwards relative to the air outlet of an exhaust channel, so that the exhaust speed of the liner is reduced; and when the pressure borne by the first side of the piston is smaller than that borne by the second side, the vent hole of the first baffle moves forwards relative to the ventilation window, and the exposed part of the ventilation window moves forwards relative to the air outlet of the exhaust channel, so that the exhaust speed of the inner container is increased. Therefore, the exhaust speed of the inner container is controlled by controlling the distance between the exposed part of the ventilation window and the air outlet of the exhaust channel, and then the baking effect is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Rubber dinghy inflation air valve structure

The invention relates to the technical field of inflation supplies, and discloses a rubber dinghy inflation air valve structure. The rubber dinghy inflation air valve structure comprises a valve seat,a valve body is inserted into the left side of the upper surface of the valve seat, a first supporting frame is fixedly connected to the bottom of the inner wall of the valve body, a supporting plateis rotatably connected to the middle of the upper surface of the first supporting frame, and a telescopic rod is fixedly connected to the upper surface of the supporting plate. According to the rubber dinghy inflation air valve structure, a lower air baffle, an upper air baffle, a rotating column, a first sliding rod, an adjusting block, an adjusting groove, an adjusting sleeve, a button and an adjusting pin are used in cooperation, so that a user can rotate the lower air baffle by pressing the button, the inflation and deflation modes of the device are determined by the placement angle of the lower air baffle, therefore, the user can further conveniently switch the inflation state and the deflation state of the air valve, air in a rubber dinghy can be fully exhausted through an upper vent hole and a lower vent hole, and the exhaust speed of the device is further increased.

Owner:常德山河游乐设备制造有限公司

Engine exhaust pipe

InactiveCN107100708AFast exhaustGood exhaust effectExhaust apparatusSilencing apparatusAerospace engineeringFlange

The invention discloses an engine exhaust pipe which comprises an exhaust manifold and a plurality of exhaust branch pipes; the exhaust branch pipes communicate with the exhaust manifold; an outlet pipe is arranged on the exhaust manifold; the air inlet ends of the exhaust branch pipes are connected with first connecting flanges correspondingly; the air outlet end of the outlet pipe is connected with a second connecting flange; connecting holes are formed in the first connecting flanges and the second connecting flange; the outlet pipe and the exhaust branch pipes are tapered pipes; one end, having the small diameter, of each tapered pipe is welded with the exhaust manifold; the outer walls of the tapered pipes are correspondingly sleeved with heat dissipation rings which are tapered rings; and the tapered rings and the tapered pipes have the same taper. The engine exhaust pipe is high in exhaust velocity and good in exhaust effect, and has a better heat dissipation effect, the outer surface temperature of the engine exhaust pipe can be lowered effectively, and normal operation of an engine can be guaranteed.

Owner:CHANGZHOU LIANGJIU MACHINERY MFG

Bubble-prevention fast exhaust transfusion device with improved structure

The invention belongs to the technical field of medical transfusion devices and particularly relates to a bubble-prevention fast exhaust transfusion device with an improved structure, which comprises a dripping chamber, wherein the upper end part of the dripping chamber is connected with an upper liquid dripping pipe, the lower end part of the dripping chamber is connected with the lower liquid dripping pipe, the bubble-prevention fast exhaust transfusion device also comprises an air isolation cover body, the air isolation cover body is matched with the lower liquid dripping pipe, and the airisolation cover body or the lower liquid dripping pipe is provided with a bubble-prevention liquid outlet groove for making liquid flow into the lower liquid dripping pipe from bottom to top. The bubble-prevention fast exhaust transfusion device has the advantages that the structure is simple, the production cost is low, the goal of automatically, fast and thoroughly exhausting the air in the transfusion device can be realized, the exhaust operation by medical personnel is not needed, the exhaust speed is high, and safety and reliability are realized.

Owner:魏颖德

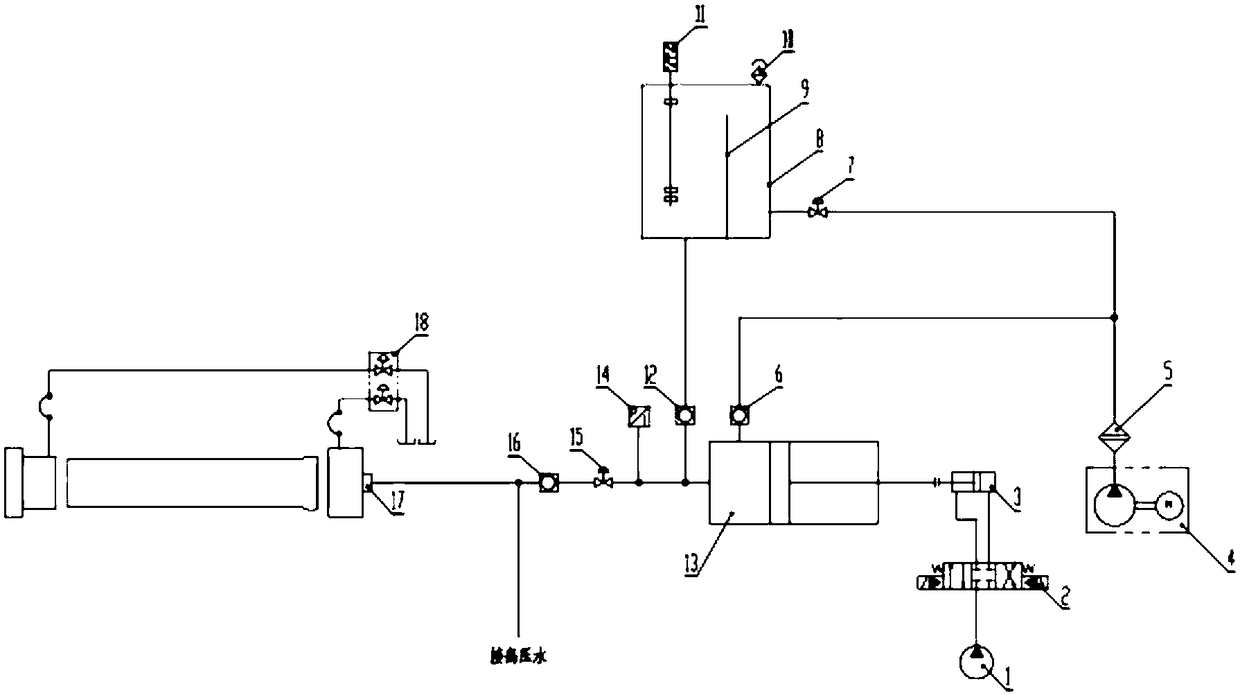

Rapid water filling system for hydraulic press and control method thereof

PendingCN108827789ALarge amount of waterFast exhaustMaterial strength using tensile/compressive forcesSimultaneous control of multiple variablesAutomatic controlCheck valve

The invention discloses a rapid water filling system for a hydraulic press. The rapid water filling system comprises a hydraulic driving system, a water supplementing system and a water-filling and air-exhausting system, wherein the hydraulic driving system comprises a hydraulic oil source, a hydraulic control valve and a hydraulic cylinder; the water supplementing system comprises a water pump, afilter, a first check valve, a first pneumatic control valve, a high-level water tank and a second check valve; and the water-filling and air-exhausting system comprises a water filling tank, a pressure relay, a second pneumatic control valve, a third check valve, a water column dispersion plate and a third pneumatic control valve. In addition, the invention also discloses a control method for the rapid water filling system of the hydraulic press. The rapid water filling system provided by the invention has large water filling capacity and rapid air exhausting speed, greatly shortens the timeof water filling, and greatly improves the production rhythm of the hydraulic press; the rapid water filling system provided by the invention is driven by the hydraulic cylinder for water filling, soparameters like the flow rate and pressure of water filling are more stable and controllable; and the rapid water filling system provided by the invention adopts a PLC fully-automatic control hydraulic press to complete the process of rapid water filling, is simple in operation and convenient in maintenance, reduces the labor intensity of a worker, and increases production efficiency.

Owner:XINXING HEBEI ENG & RES INC

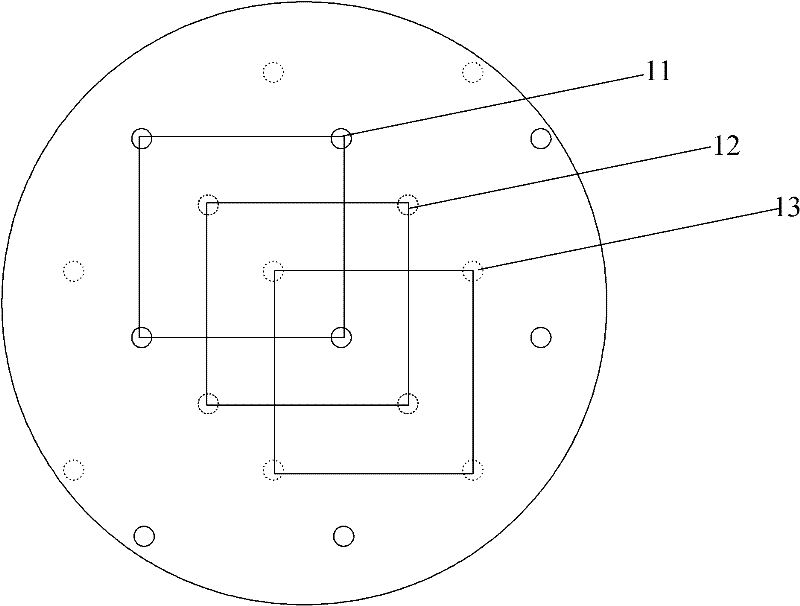

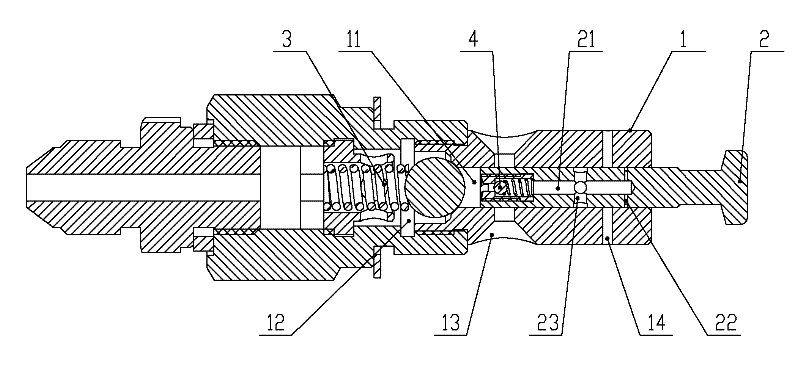

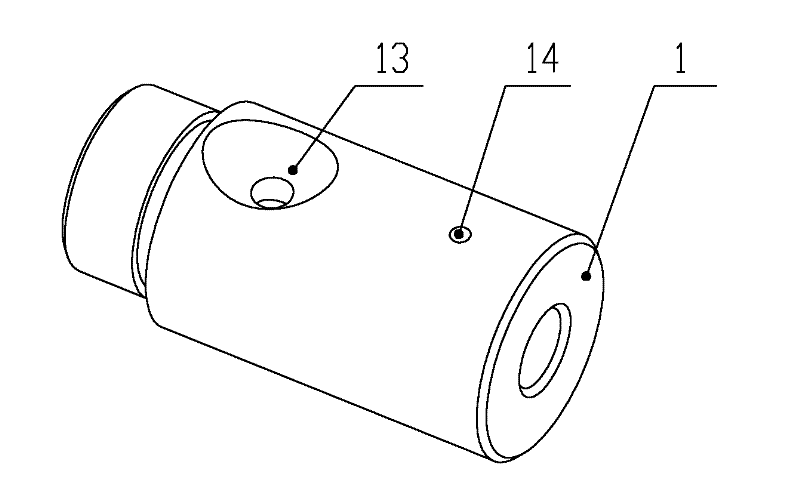

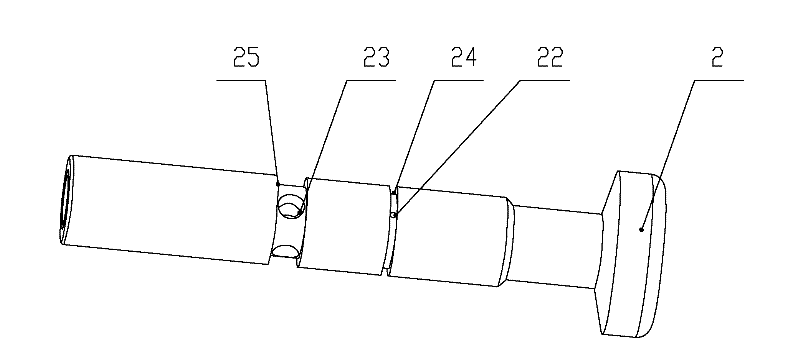

Device for increasing the bleeding rate of a pneumatic control valve

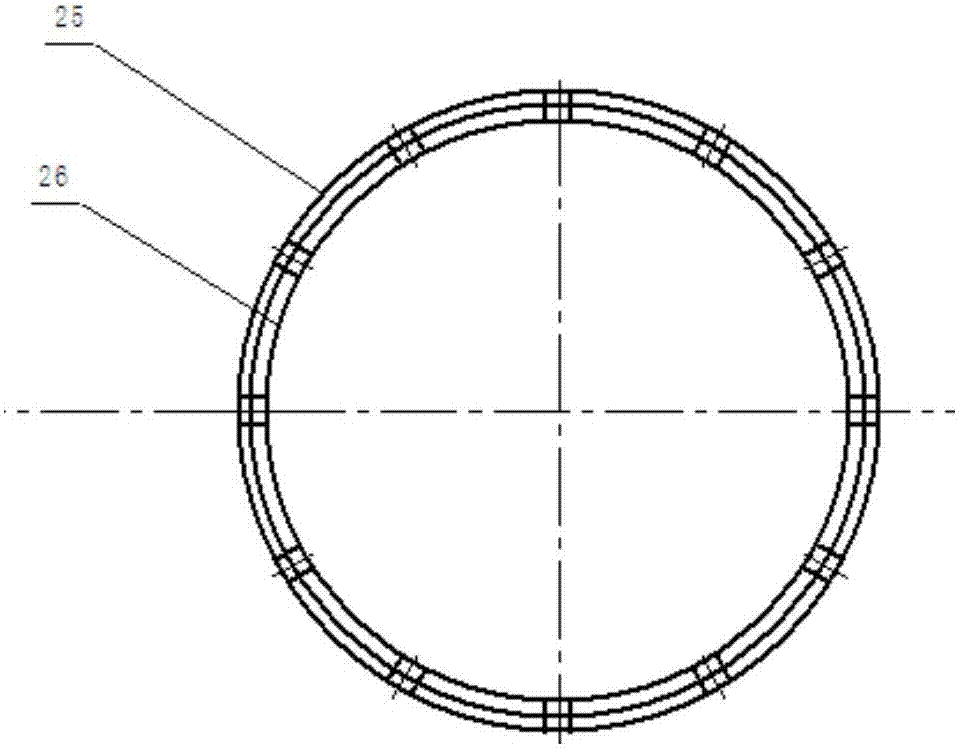

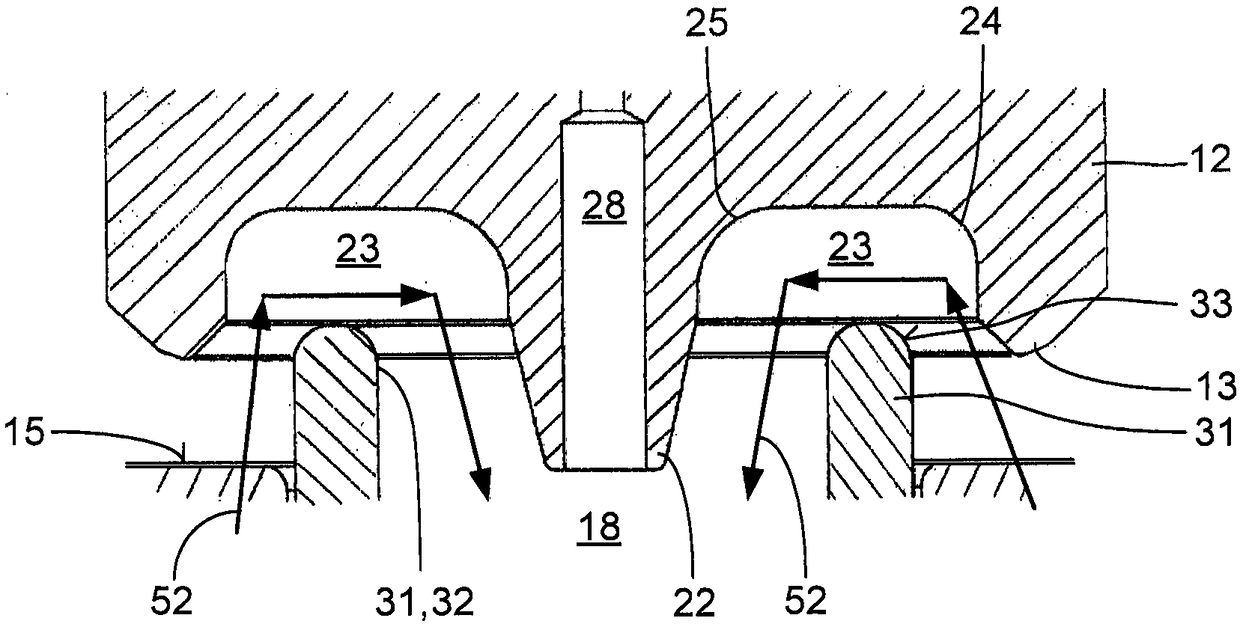

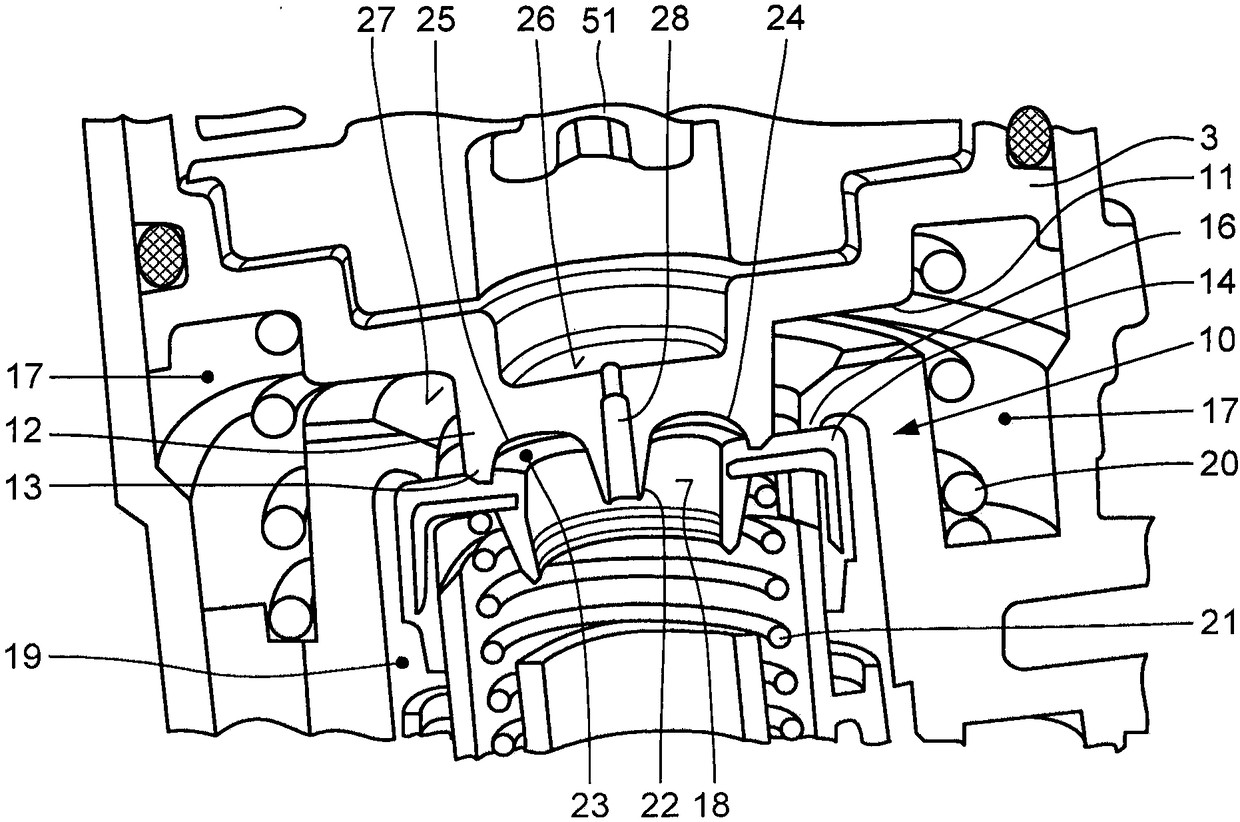

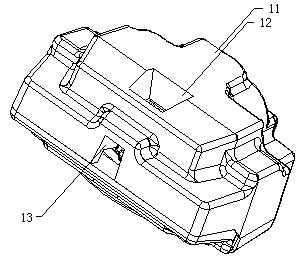

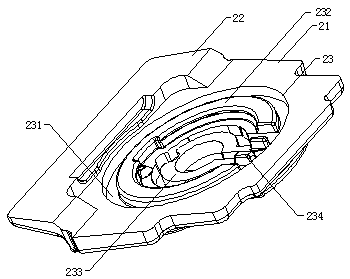

ActiveCN108137026AFast exhaustEasy to guideOperating means/releasing devices for valvesApplication and release valvesBleed airBrake pressure

The invention relates to a device in a control valve designed as a braking value indicator for a single-circuit or dual-circuit pneumatic brake system in a vehicle for adjusting a brake pressure corresponding to a desired braking effect, said control valve (1) comprising at least a first pneumatic valve system (10). In order to increase the bleeding rate, rounded transitions (24, 25) for conducting the bleeding air stream (52) in a flow-optimized manner are arranged at least in the region of a bleeding passage (18) of the at least first pneumatic valve system (10).

Owner:采埃孚商用车系统欧洲有限公司

A casting method based on a new type of oil pump shell mold

ActiveCN107321919BEasy to polishGuarantee casting qualityFoundry mouldsFoundry coresChromiteMolding sand

The invention relates to a casting method based on a novel oil pump body shell mould. The casting method comprises the following steps that (1) heating and solidifying are conducted on molding sand to form the shell mould, the shell mould consists of an upper shell body and a lower shell body, and after mould clamping is conducted on the upper shell body and the lower shell body, an oil pump body mould cavity is formed; (2) a set of sand cores of an oil pump body is formed through chromite sand, the sand cores are correspondingly an inner sand core and an outer sand core, the sand cores are combined to form a sand core main body, and the sand core main body is horizontally arranged in the lower shell body; (3) a sand box is manufactured through sand, the upper shell body and the lower shell body are embedded in the sand box, a sand layer covers a cavity between the outer surfaces of the upper shell body and the lower shell body and the inner side of the sand box , and the sand layer is internally provided with a gating and risering system which communicates with the shell mould; and (4) casting is conducted on the interior of the mould cavity through the gating and risering system, and the oil pump body is formed. The casting method has the advantages that through the casting method, burrs of parting mould surfaces of the oil pump body are easy to polish, and sand core fracture in the casting process is not easily caused.

Owner:江苏力源金河铸造有限公司

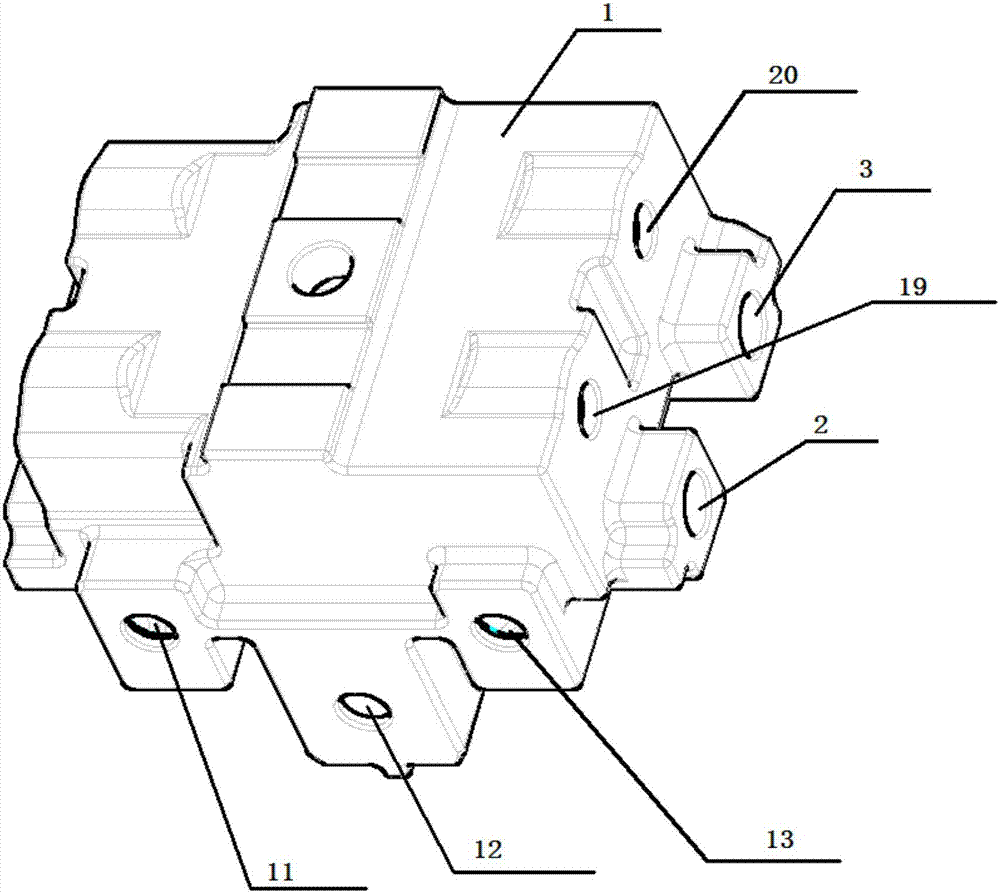

Valve body casting for vehicle-mounted pump

InactiveCN107035679AHighly integratedCompact and reasonable structurePositive displacement pump componentsFoundry mouldsIn vehicleHigh lift

The invention discloses a valve body casting for a vehicle-mounted pump and particularly discloses a large-tonnage and high-lift valve body casting for a concrete vehicle-mounted pump. The casting comprises a main valve body, valve core through holes, a straight runner, an inclined runner, runner ports and a plurality of auxiliary runners; the two valve core through holes are designed in the valve body; the runner ports are located in various surfaces of the valve body and correspond to and communicate with the valve core through holes, a circular oil groove, the straight runner, the inclined runner and the auxiliary runners in the valve body; and the plurality of auxiliary runners are used for connecting the runners in the valve body to enable the runners to communicate with one another. The valve body has the advantages of being reasonable and compact in structure, reliable in action, multiple in function and long in service life.

Owner:南通华东油压科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com