Actuator box body casting process

A casting process and actuator technology, which is applied in the field of actuator box casting process, can solve the problems of shrinkage and shrinkage, low temperature of molten iron, and low production efficiency, and achieve the effect of not easily deformed, high strength, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

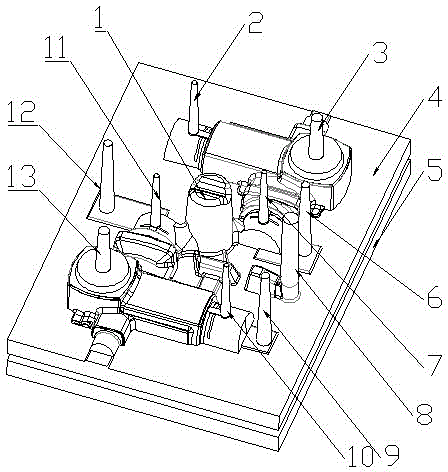

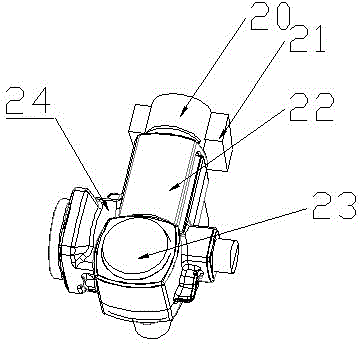

[0024] The actuator box in the present invention is composed of the output shaft installation end located in the center and the counter installation end and the motor connection end arranged at both ends of the output shaft installation end and distributed in the vertical direction. There is a The cross-shaped cavity has a horizontal cavity A that runs through the whole in the counter installation end, and a horizontal cavity B that runs through the whole in the motor connection end, and the horizontal cavity A and the horizontal cavity B are respectively connected with ten The two ends of the font cavity are connected.

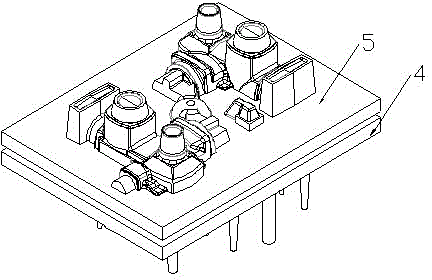

[0025] The description of the following structural drawings further explains the casting process of the actuator box of the present invention:

[0026] The first step is to use metal to make the metal formwork required to enter the actuator box.

[0027] In the second step, the metal template is heated to 180~280°C, and then the molding sand hardened by heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com