Cooking exhaust structure with self-adaptive and adjustable exhaust speed and baking cooking device

An exhaust speed, self-adaptive technology, applied in applications, cooking utensils, roasters/barbecue grids, etc., can solve the problems of affecting the baking effect, unable to meet the requirements of humidity, constant exhaust speed, etc. The effect of the baking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

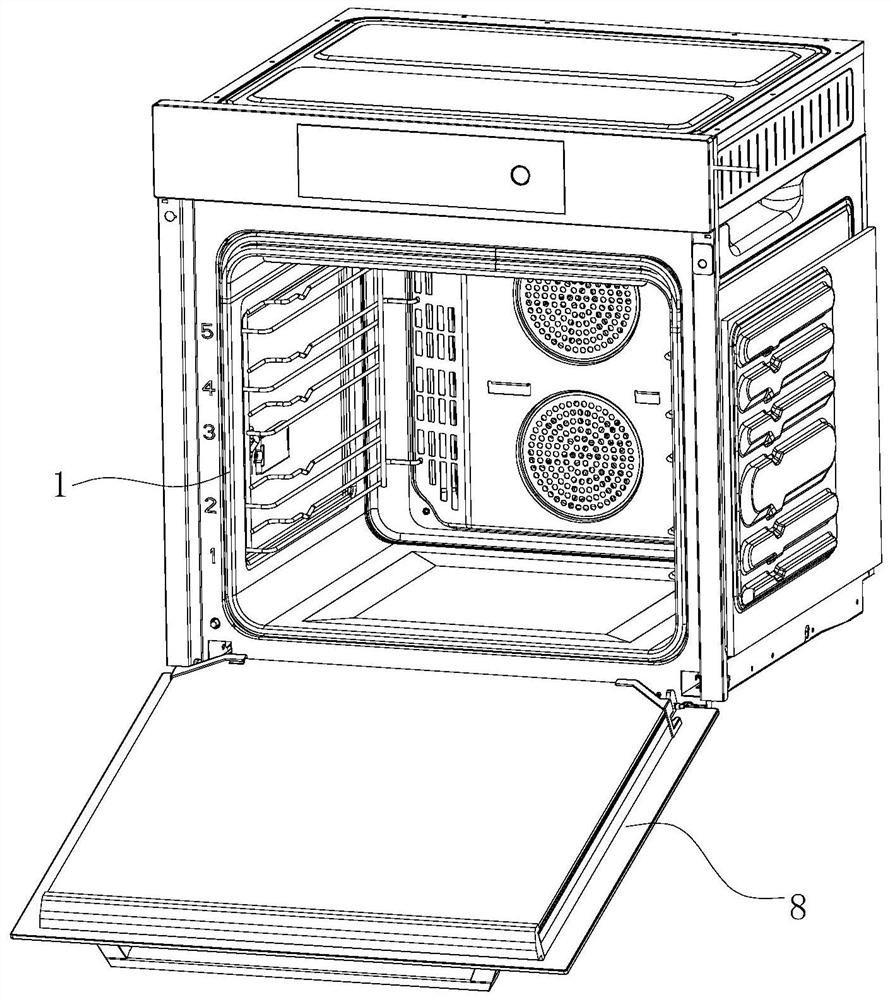

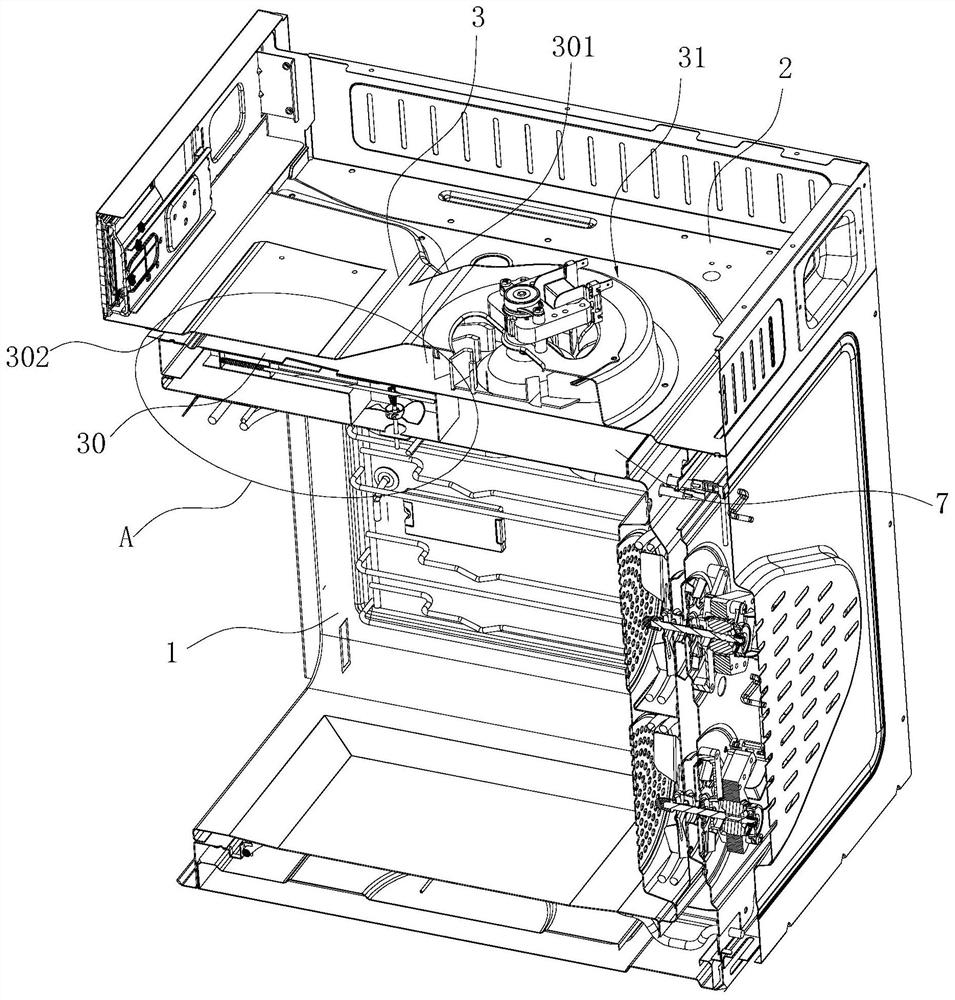

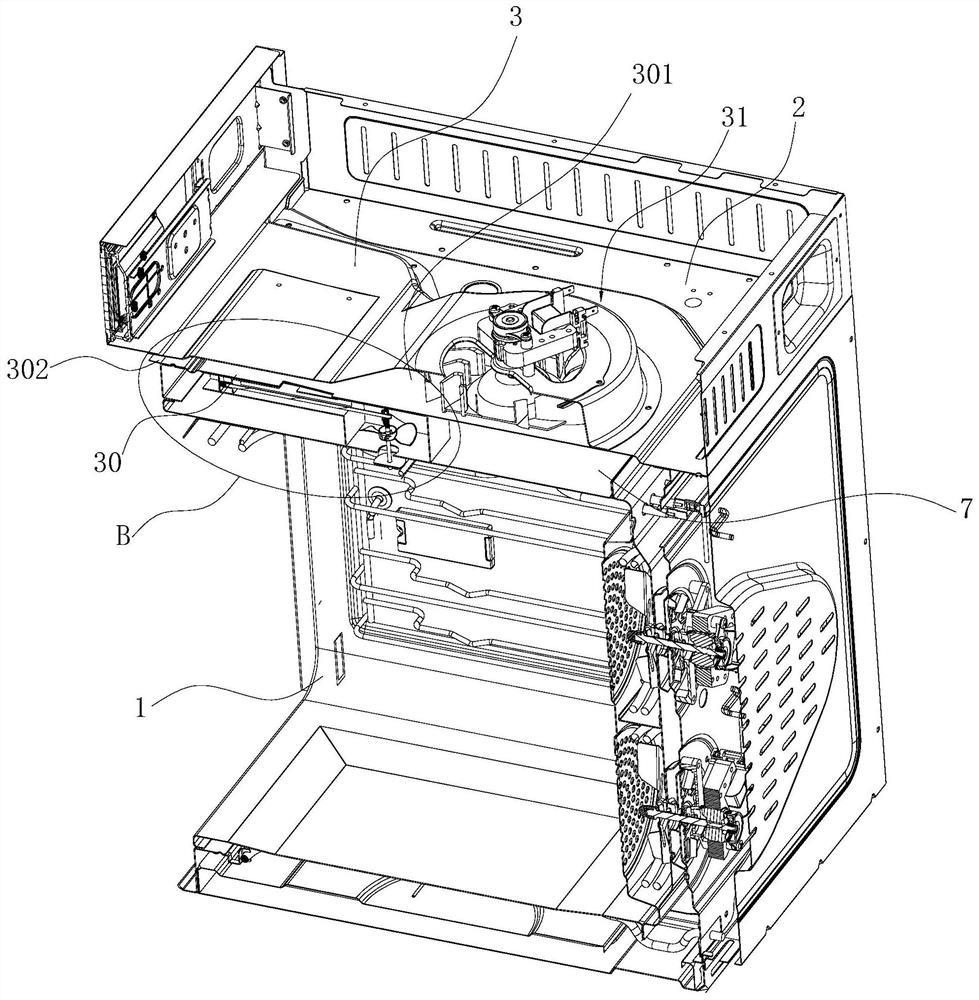

[0027] like Figure 1-7 As shown, a cooking device (such as an electric oven, a steaming and baking machine, etc.) includes a cooking exhaust structure, and the cooking exhaust structure includes an inner container 1 with an exhaust port 11 on the top wall. 1 is horizontally provided with an upper mounting plate 2, the upper mounting plate 2 is covered with an air deflector 3, the air deflector 3 and the upper surface of the upper mounting plate 2 enclose an exhaust channel 30 with an exhaust fan 31 , and there is an installation gap 7 between the lower surface of the upper mounting plate 2 and the top surface of the liner 1 . In this embodiment, the exhaust fan 31 is installed on the air inlet 301 of the exhaust channel 30 .

[0028] The above-mentioned upper mounting plate 2 is provided with a ventilation window 21 extending along the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com