Valve body casting for vehicle-mounted pump

A vehicle-mounted pump and valve body technology, applied in pump components, variable-capacity pump components, casting molds, etc., can solve the problems of different wall thicknesses, low casting yields, sticky sand veins, etc., and achieve casting qualification rates. Improved, low casting cost, reasonably compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

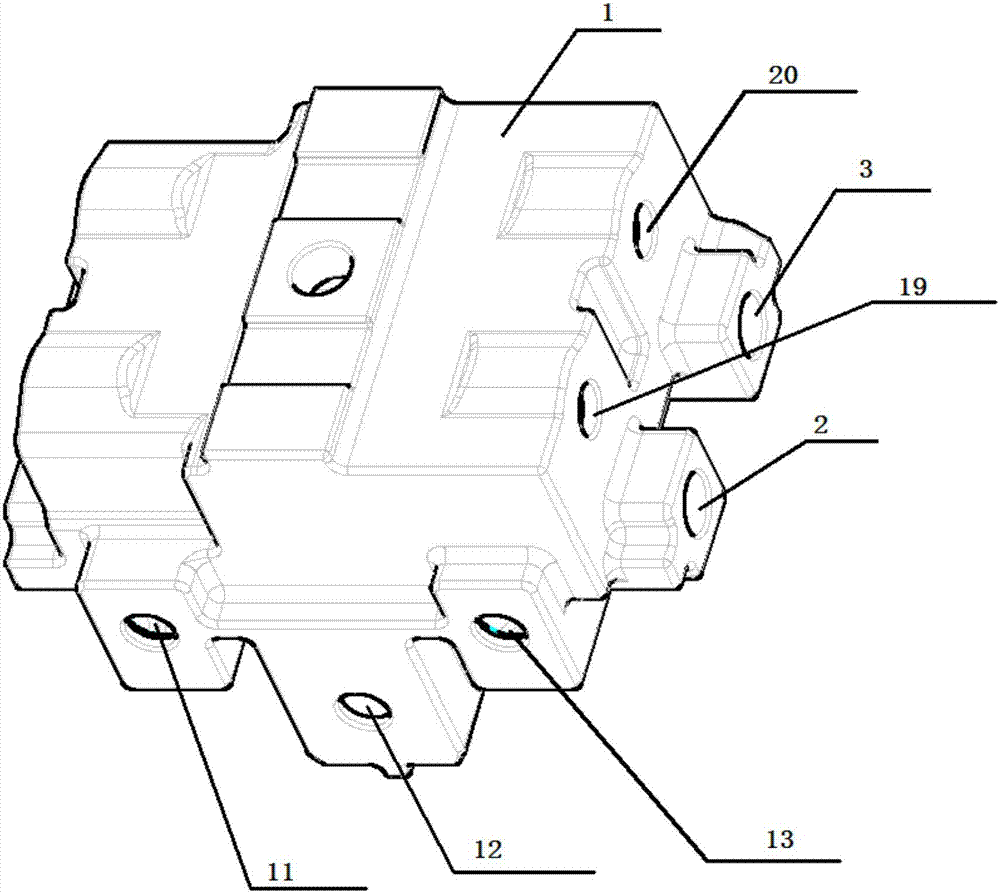

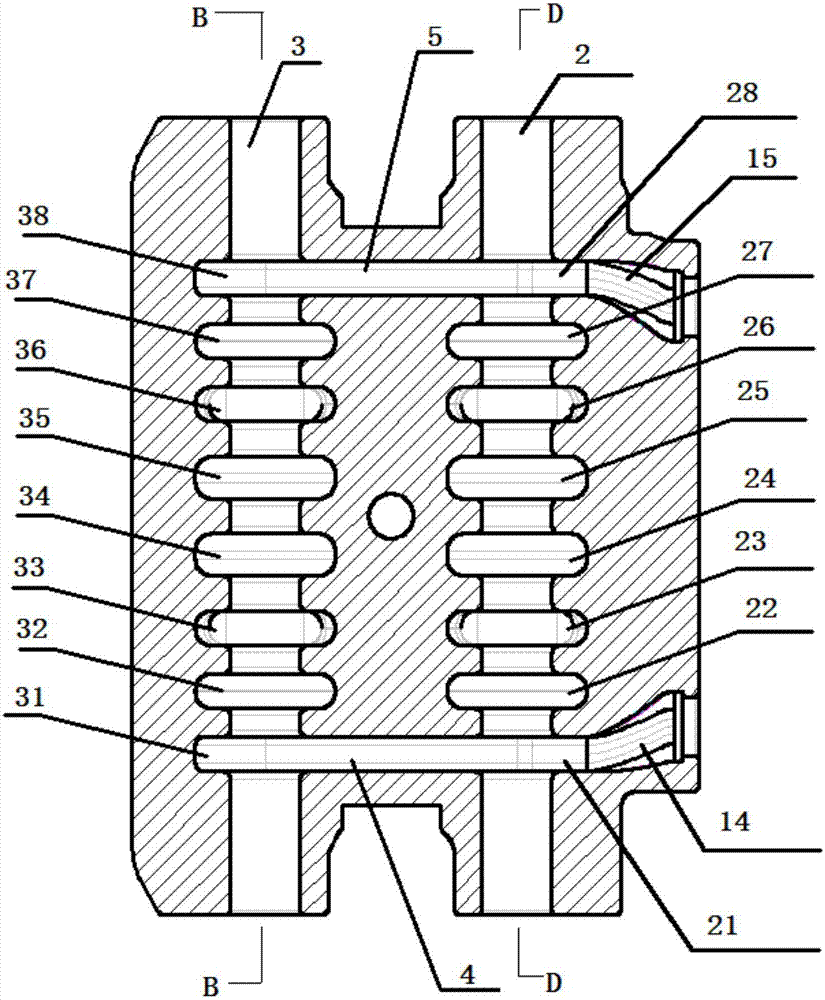

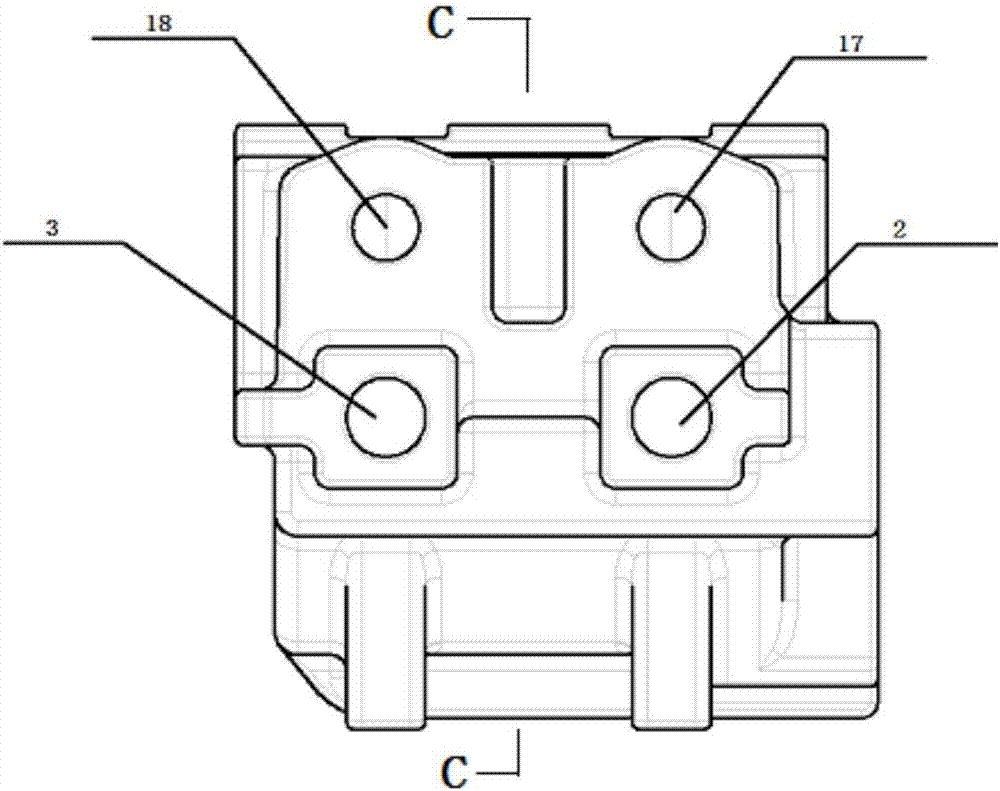

[0033] see figure 1 — Figure 6 , the present invention provides an integral vehicle-mounted pump valve body casting, the vehicle-mounted pump valve body casting includes a valve body (1), the valve body (1) is square, and the valve body (1) is provided with a valve Core through hole, annular oil groove, straight flow channel, inclined flow channel, flow channel opening and auxiliary flow channel, the valve body (1) contains two valve core through holes, namely the valve core through hole (2) and the valve core The through hole (3), the flow channel opening is located on each surface of the valve body (1), corresponding to the through hole of the spool inside the valve body (1), the annular oil groove, the straight flow channel, the inclined flow channel and the auxiliary flow channel And connected, the straight flow channel and the oblique flow channel are used to connect the flow channel port and the corresponding oil groove or flow channel in the valve body (1), and there ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com