Patents

Literature

83results about How to "Improve casting pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hollow cast ceramic core and its preparation method

Disclosed is a hollow cast ceramic core, which comprises substrate material 80-85% and Mullite 20-15%, wherein the substrate material comprises quartz glass powder 60-80% and silica dioxide porous material 40-20%. Its manufacturing process consists of proportioning, mixing the core material with plasticity agent and right amount of oleinic acid, melting, mixing, press forming, sintering, and carrying out high temperature reinforcement and low temperature reinforcement treatment.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for increasing permeability of investment cast ceramic shell

ActiveCN104399885AGuaranteed surface qualityImprove casting pass rateFoundry mouldsFoundry coresFiberCarbon fibers

The invention provides a method for increasing the permeability of an investment cast ceramic shell, and belongs to the field of investment casting. The problem of easy formation of defects of the surface of a cast member in the cast member casting process in the prior art is solved. The method comprises the following steps: adding an adhesive, strengthening layer all-layer powder and carbon-containing fibers into a stirring barrel, adding an antifoaming agent and a wetting agent, and adjusting the viscosity of the obtained coating to a required range by using deionized water to obtain a strengthening layer coating with all layers having the carbon-containing fibers; coating a wax mold with the surface layer coating of the shell according to a routine shell making technology, completing a coating, sanding and drying process by using the all-layer strengthening layer coating, coating a sealing slurry layer without the carbon-containing fibers, and drying to obtain a shell; and dewaxing the shell, and roasting to obtain the net structured ceramic shell with exhaust channels. The method guarantees the strength of the shell, improves the permeability of the shell, eliminates the defects caused by unsmooth exhaust of the surface of the cast member, guarantees the quality of the surface of the cast member, and improves the qualified rate of the cast member.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

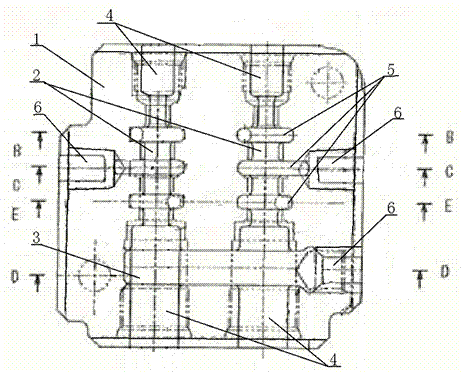

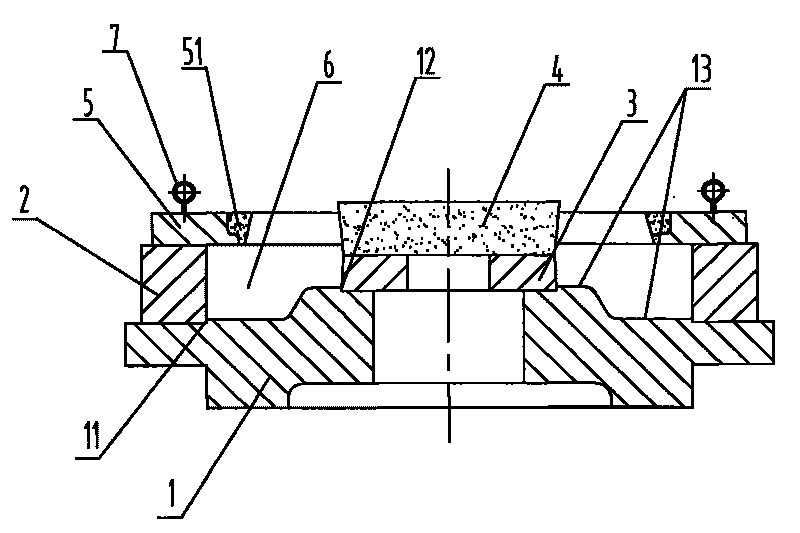

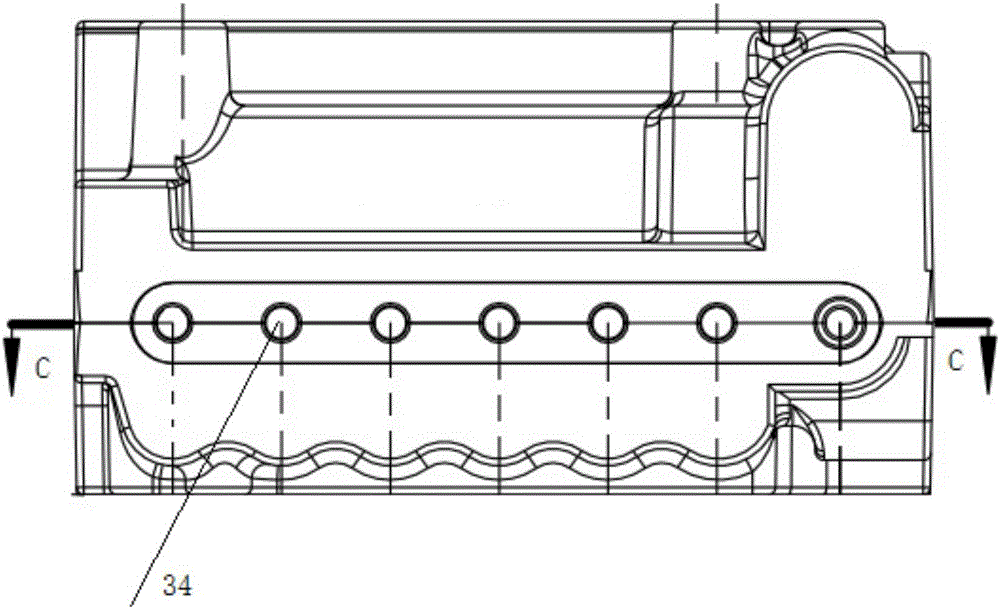

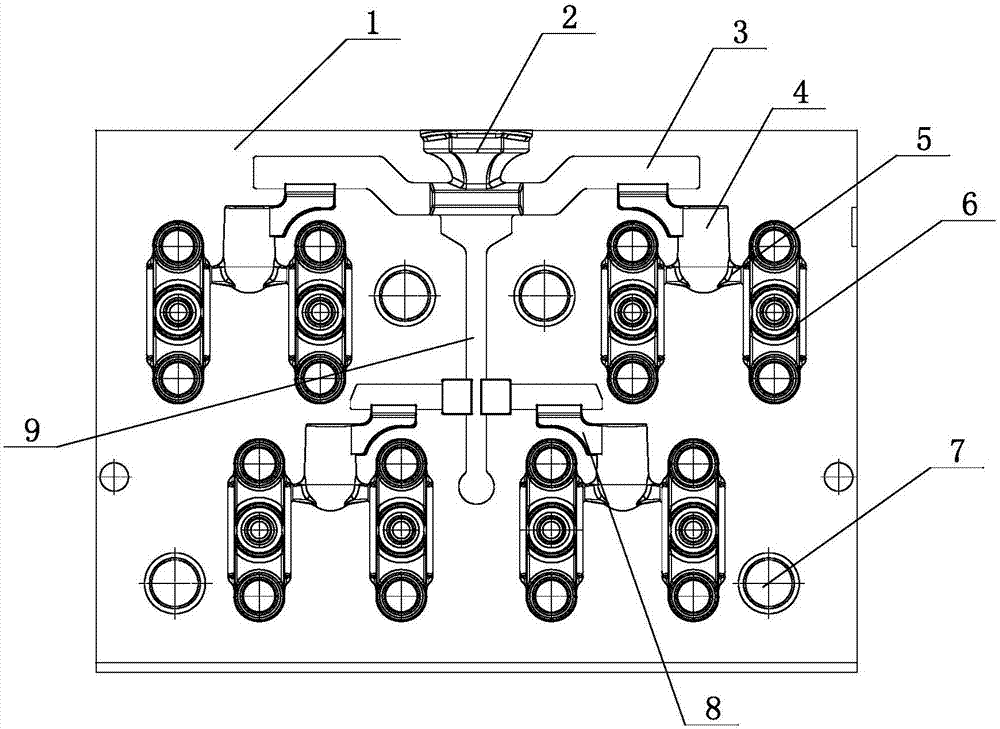

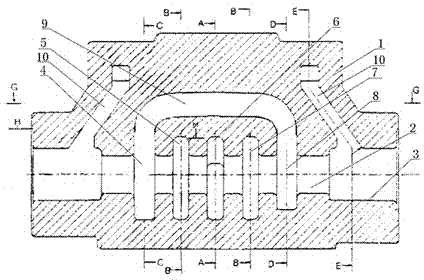

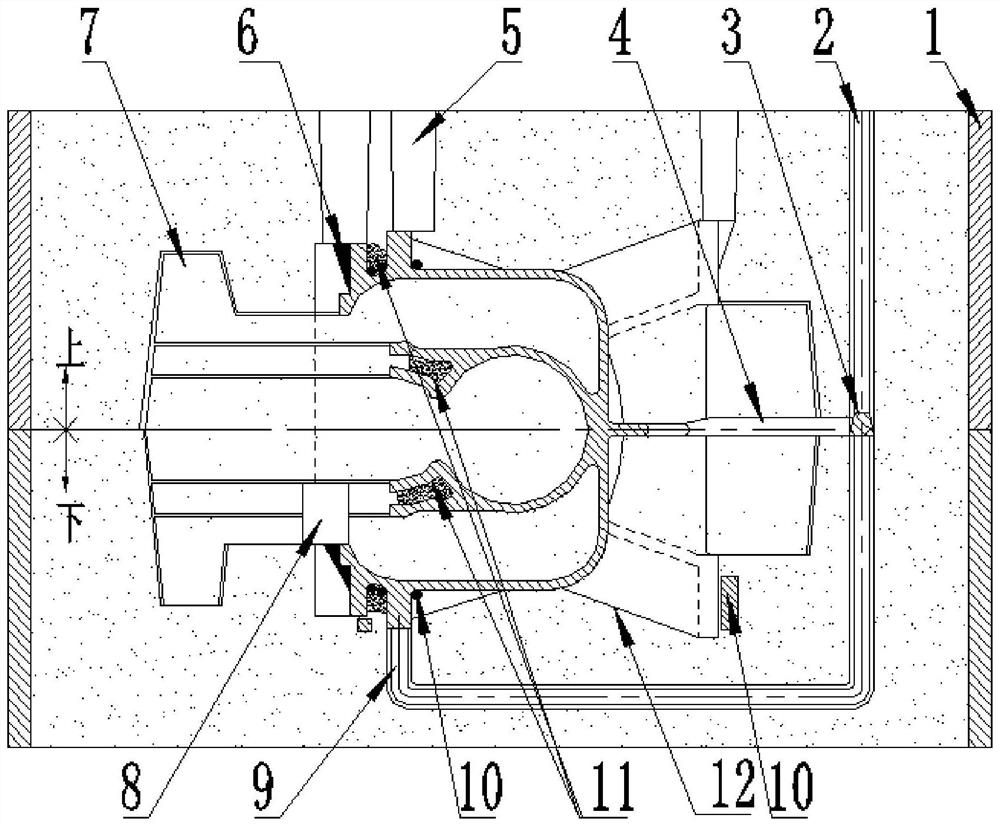

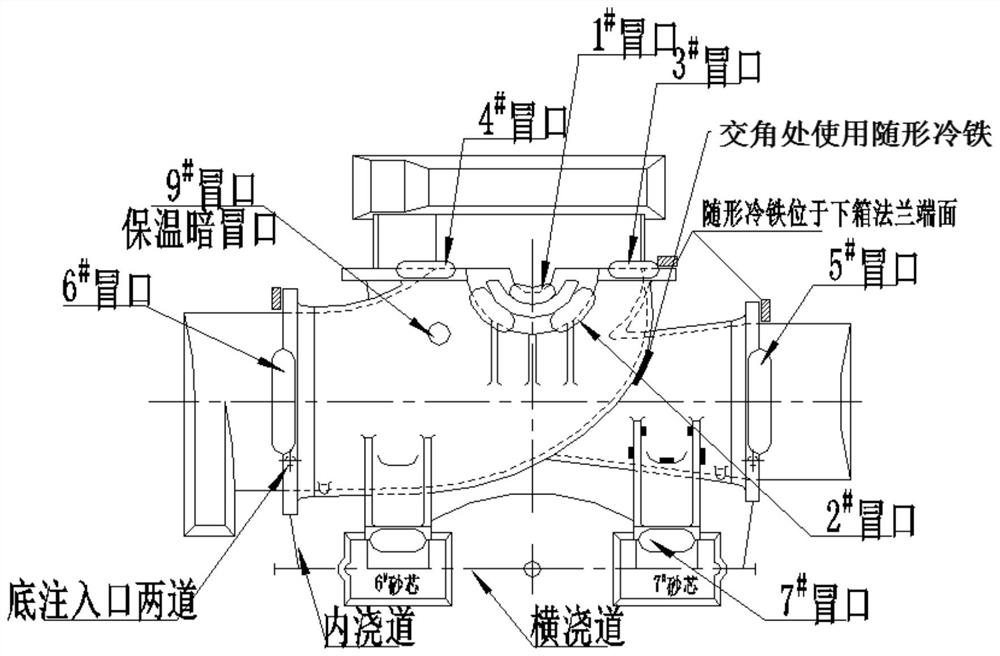

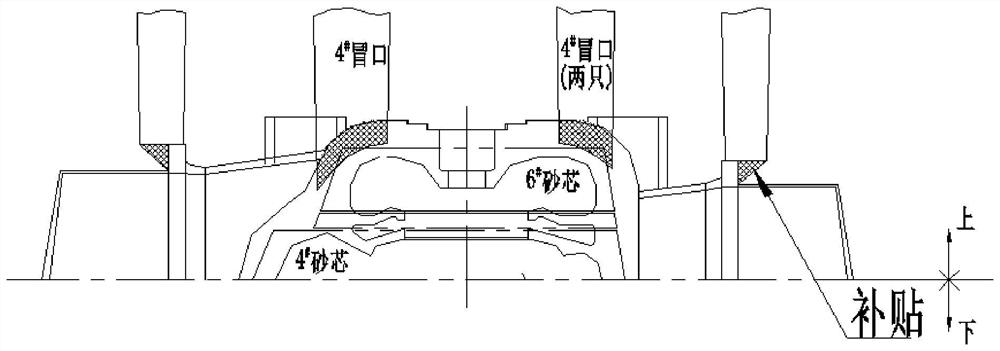

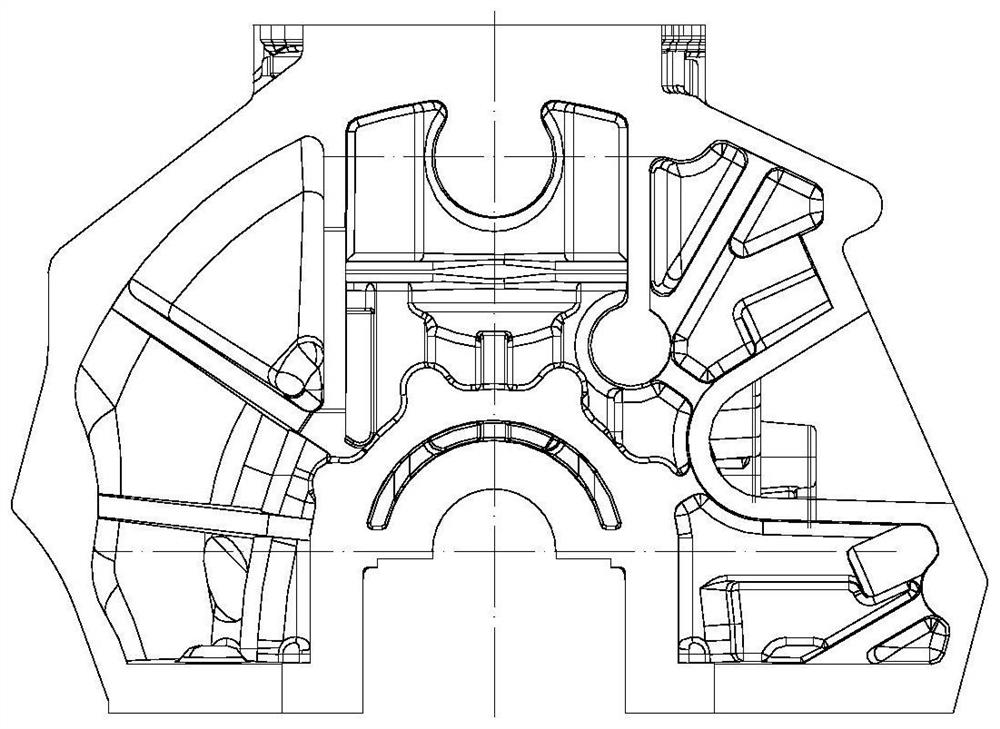

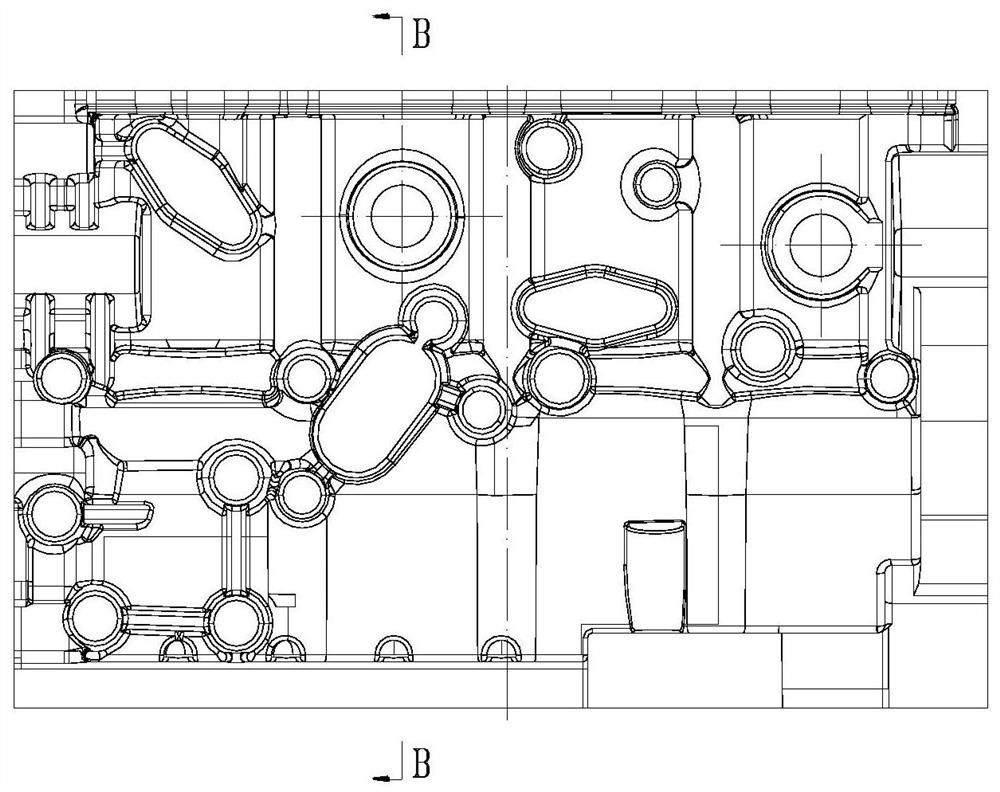

Large-duty loader hydraulic valve body casting mold and manufacturing method

ActiveCN105772646ACompact and reasonable structureStrong reliabilityFoundry mouldsFoundry coresCasting moldCasting defect

The invention discloses a large-duty loader hydraulic valve body casting mold. The large-duty loader hydraulic valve body casting mold comprises an upper shell mold body, a lower shell mold body, a sand core and a pouring and riser system. The sand core comprises a core head, a main core body and small core bodies. The main core body is composed of seven longitudinal arbors and four transverse arbors, and the longitudinal arbors and the transverse arbors are horizontally arranged in the same plane. The main core is provided with a plurality of convex blocks. Installation grooves are formed in the convex blocks. The small core bodies are fixed to the main core body through the installation grooves. The pouring and riser system comprises two exothermic and insulating risers with the diameter being 90 mm and the height being 120 mm. The large-duty loader hydraulic valve body casting mold has the advantages of being reasonable and compact in structure, high in reliability and convenient to assemble and cast, the straightness of a blank casted through a main valve hole is controlled to be smaller than 0.8 mm, assembly errors of a complex sand core are avoided, the casting defects of shrinkage cavities, shrinkage porosity, internal pores and the like of a casting piece are overcome, and the compactness of the internal structure is improved, so that leakage is avoided under a high-pressure working condition with the rated pressure being larger than or equal to 35 Mpa; and the casting qualified rate is improved greatly, and the casting cost is reduced.

Owner:NANTONG ENMAI PRECISION MACHINERY SCI & TECH CO LTD

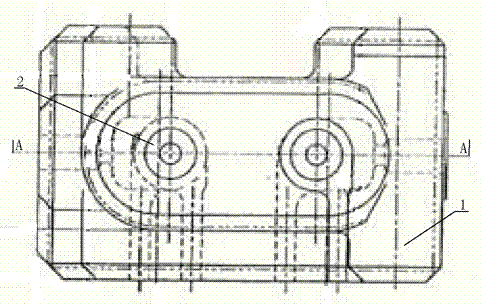

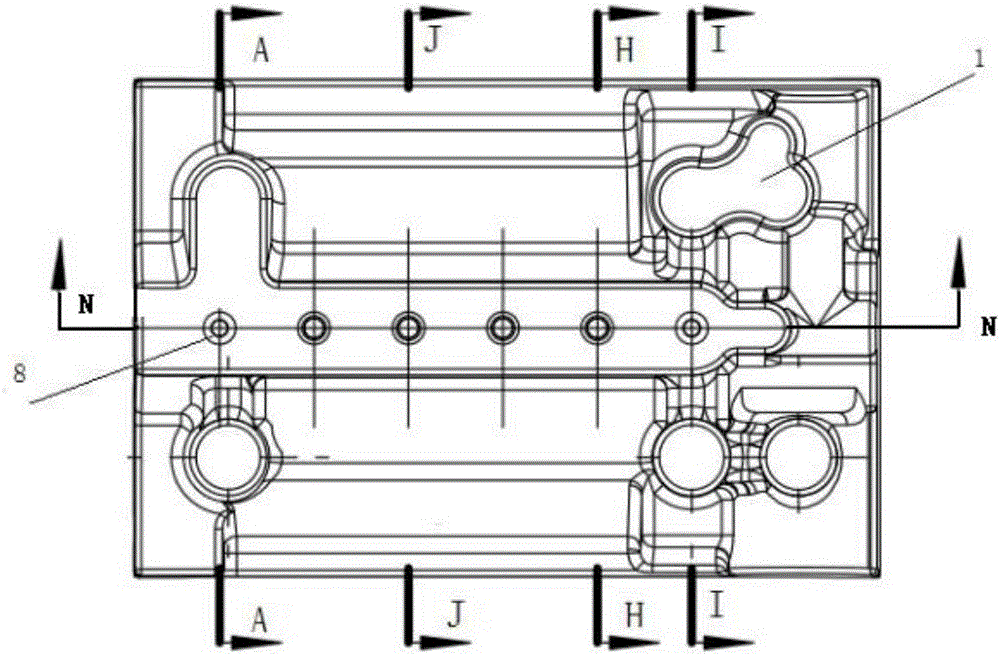

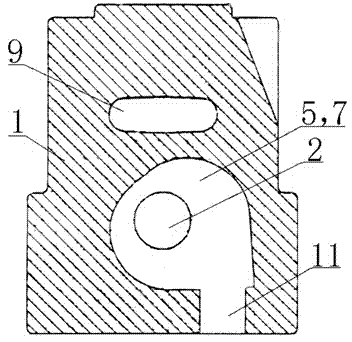

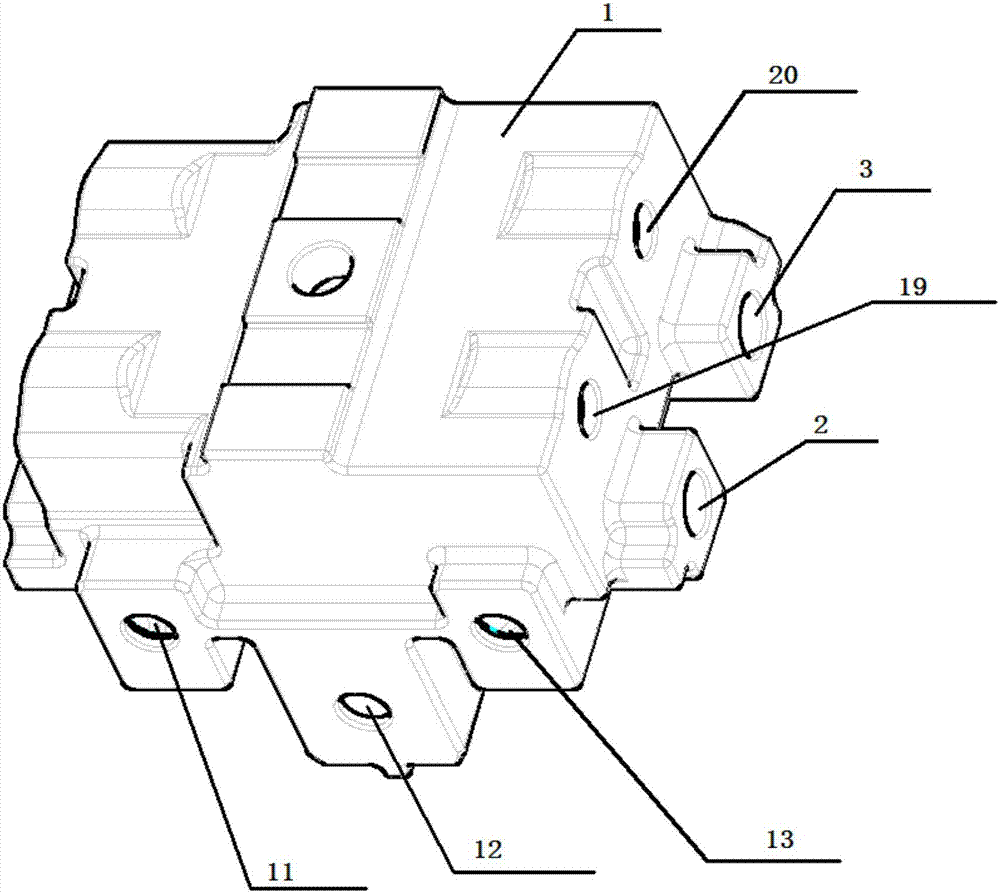

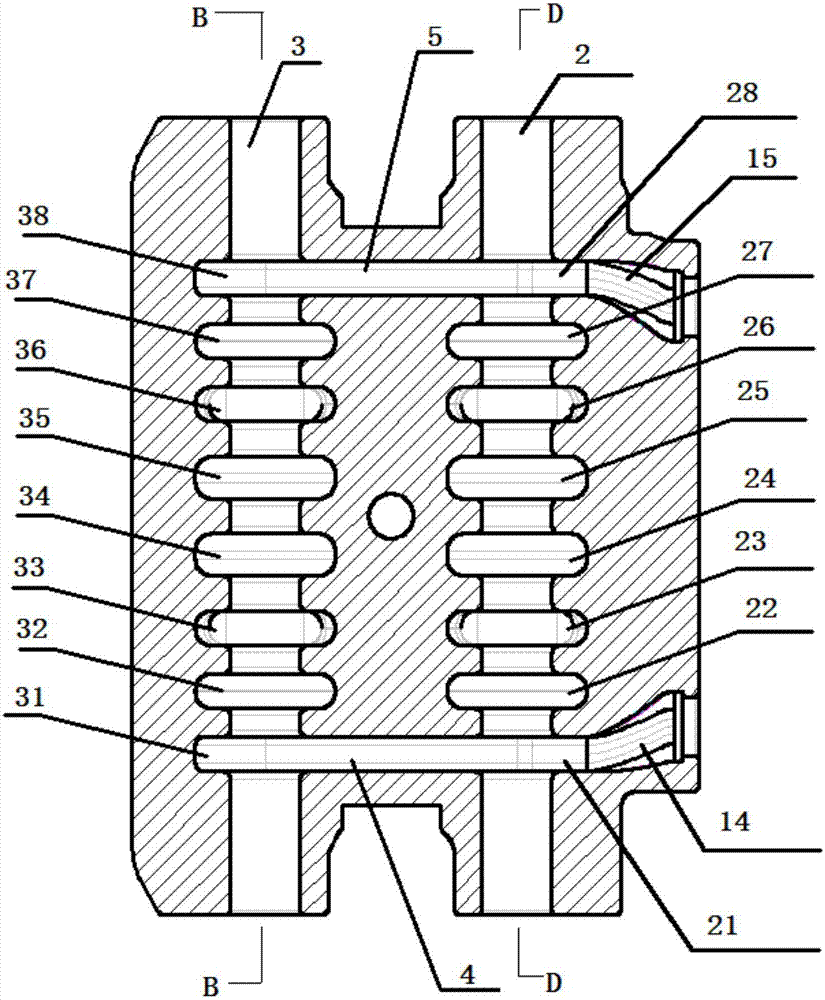

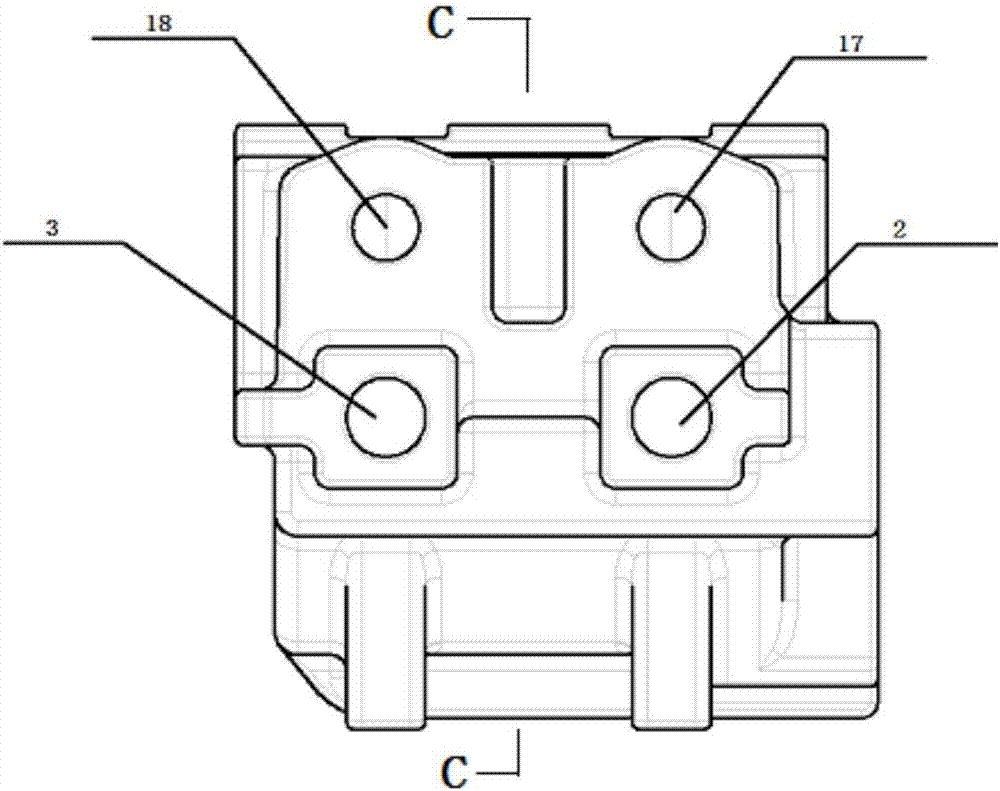

Multi-passage valve body casting

ActiveCN104776258ASimple designEasy to useFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention relates to a multi-passage valve body casting. The multi-passage valve body casting comprises a valve body, horizontal flow passages, a longitudinal flow passage and flow passage ports, the valve body is shaped like a cuboid, the two horizontal flow passages are arranged side by side in the valve body, the lower ends of the two horizontal flow passages communicate with each other via the longitudinal flow passage, the front and back of the valve body are respectively provided with two flow passage ports which communicate with the two horizontal flow passages, the middle parts of the two horizontal flow passages are respectively provided with three annular grooves, the upper ends of the annular grooves of the upper ends of the horizontal flow passages are provided with through holes, the openings of the through holes are located on the valve body, the left side of the middle annular groove of the left horizontal flow passage is provided with a through hole, the opening of the through hole is located at the left side of the valve body, the right side of the middle annular groove of the right horizontal flow passage is provided with a through hole, the upper ends of the annular grooves of the lower ends of the horizontal flow passages are provided with through holes, and the right side of the longitudinal flow passage is provided with a through hole. The multi-passage valve body casting has the following advantages: the design is simple, the multi-passage valve body casting is convenient to use and cast, and is ingenious and reasonable, the casting percent of pass is increased greatly, and the casting cost is reduced.

Owner:南通华东油压科技有限公司

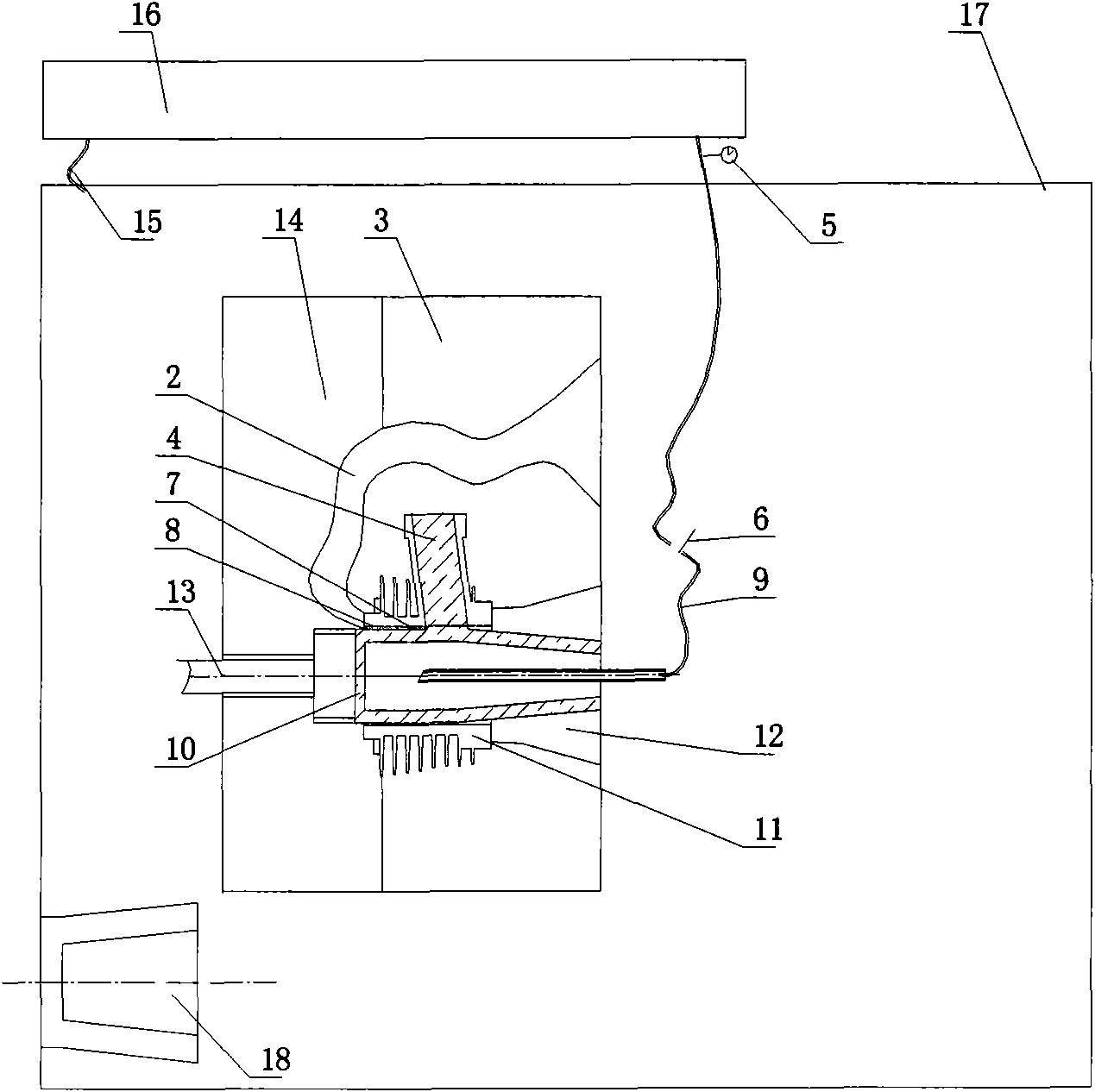

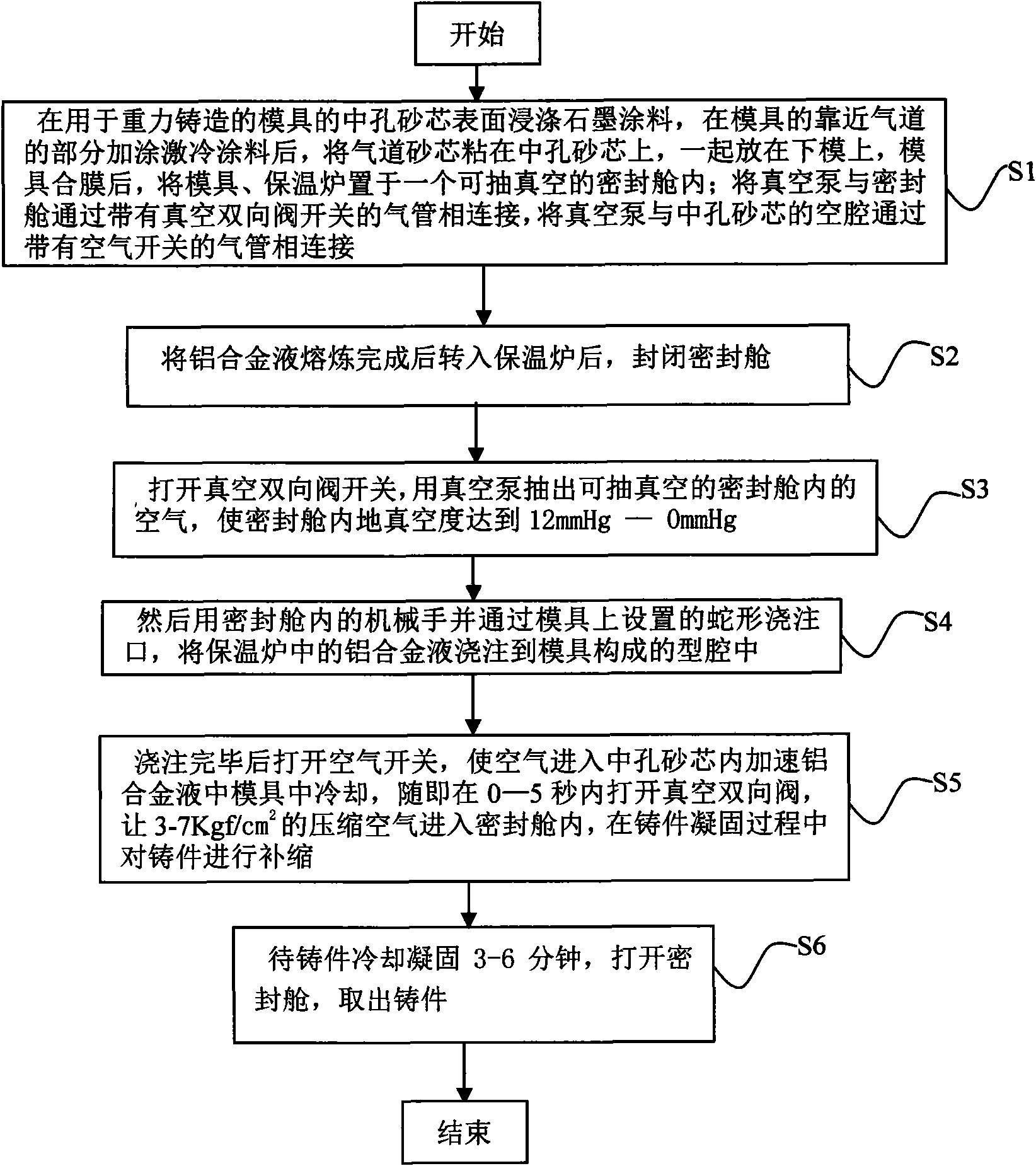

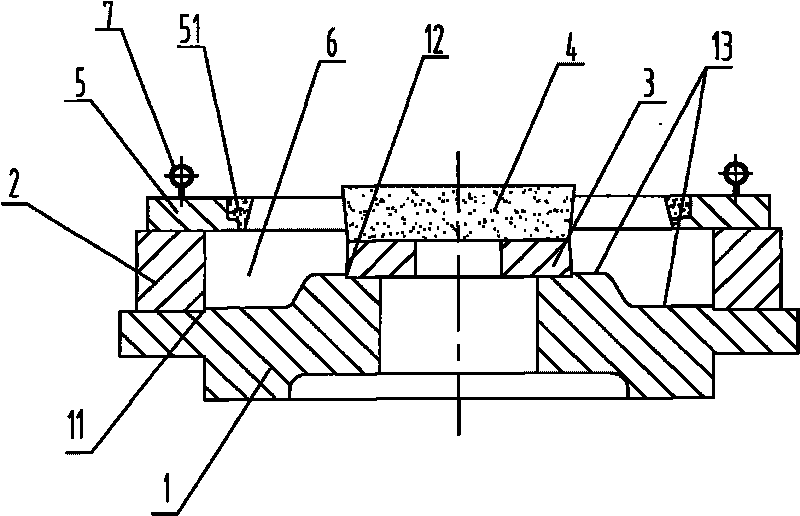

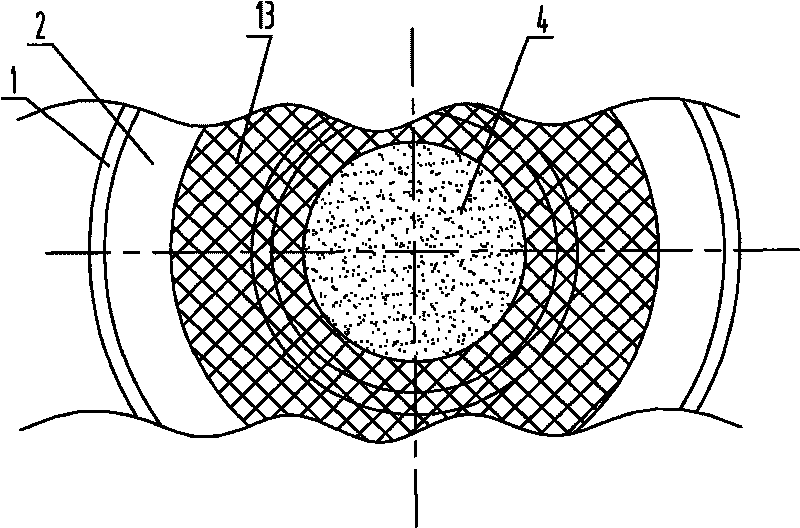

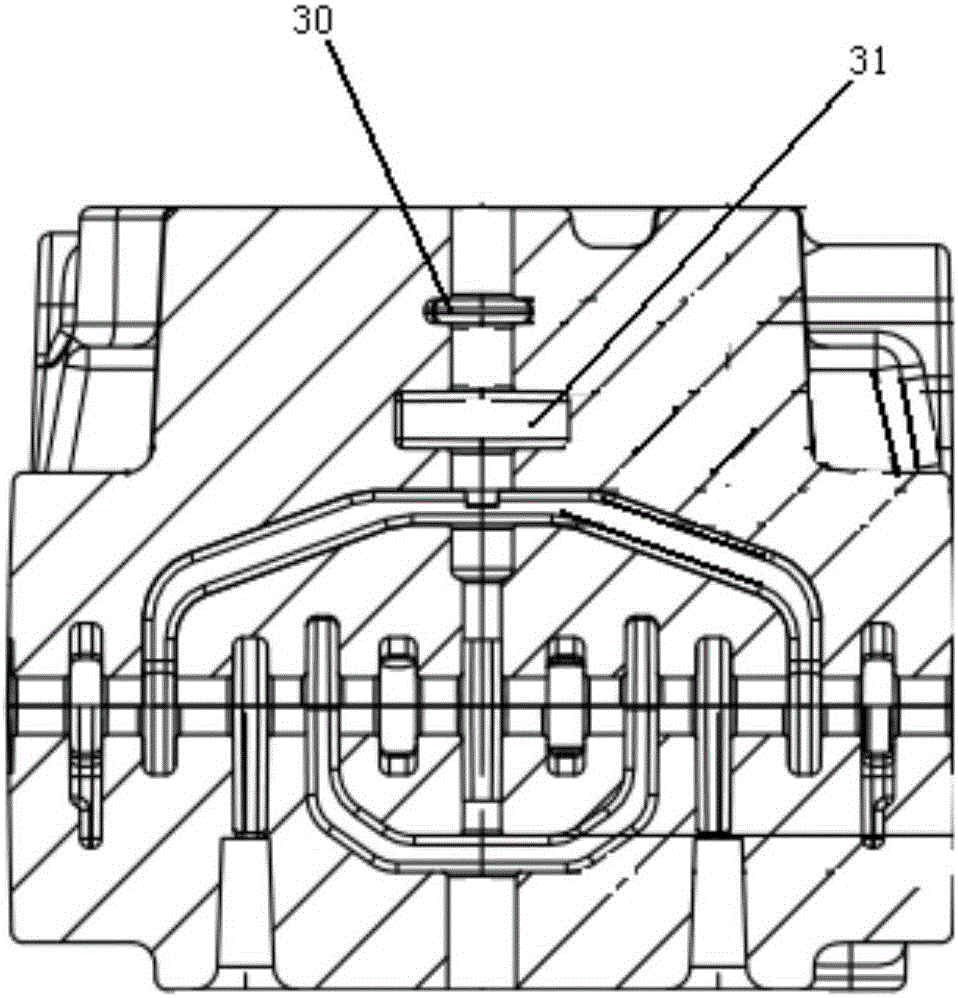

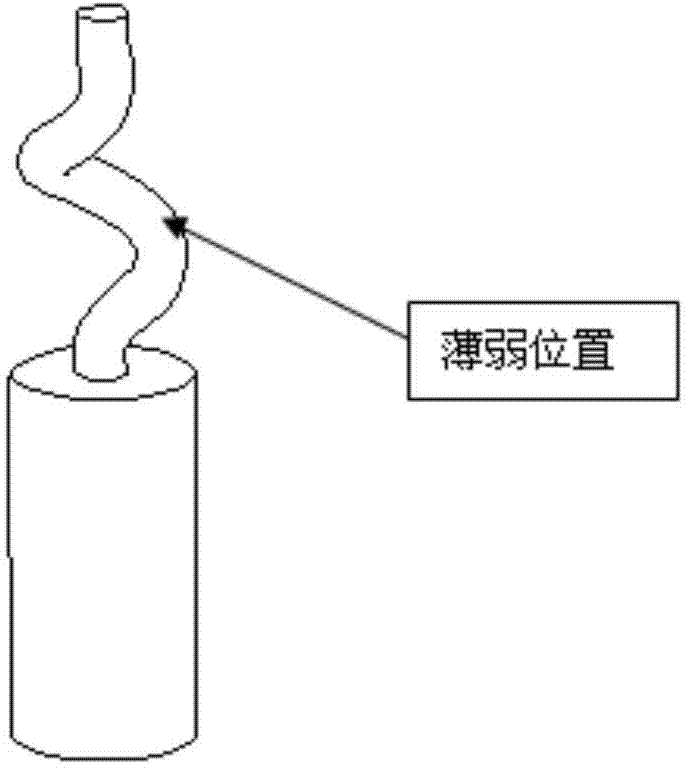

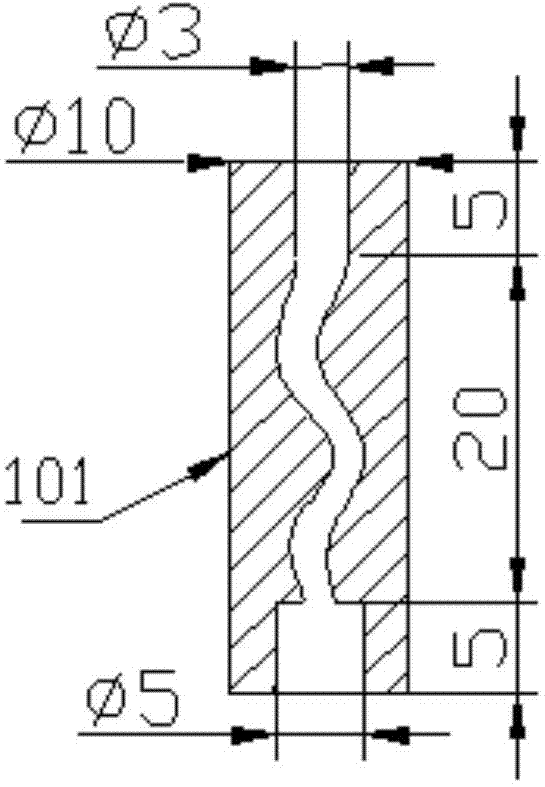

Vacuum gravity casting method of aircraft engine block

The invention relates to a vacuum gravity casting method of an aircraft engine block. The method comprises the following steps: graphite paint is dipped on the surface of a mesoporous sand core of a die used for gravity casting, chilling coating is coated at the part of the die used for gravity casting close to an air passage, a sealing cabin provided with the die is vacuumized before casting through a snake-shaped casting opening, and the mesoporous sand core and the sealing cabin are filled with compressed air after casting. Due to the adoption of the closed vacuum casting, the casting is performed through the snake-shaped casting opening, and as the graphite paint and the chilling coating are adopted, the compressed air is blown in the mesopore to carry the heat away, the shrinkage cavities in the casting part are greatly reduced, the qualification rate of the finished products of the casting part is improved to about 90 percent from 20 percent and the production cost is greatly reduced.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

Casting mold and casting method of high aluminum zinc alloy annular casting parts

The invention discloses a casting mold of high aluminum zinc alloy annular casting parts. A metal outer mold of the casting mold is positioned on a metal bottom plate, a metal core mold is positioned in the center of the metal bottom plate, a casting mold cavity with an annularly opened upper opening is formed by a cavity among the upper side of the metal bottom plate, the inner edge of the metal outer mold and the outer edge of the metal core mold, a casting mold sand core is fixed on the upper side of the metal core mold, a metal cover plate is covered on the upper side of the metal outer mold, and knurling is arranged on the bottom surface of the casting mold cavity. The invention also discloses a casting method for the high aluminum zinc alloy annular casting parts. The method includes 1) injecting liquid-state high aluminum zinc alloys into the casting mold cavity until the high temperature liquid level rises to the upper side of the metal outer mold; 2) lifting the metal cover plate to the upper side of the metal outer mold, continuing casting, compensating cooled the upper lateral surfaces of casting parts until the casting parts are formed finally. The casting mold and casting method reduces dendrite segregation and pinholes among dendrites, improves mechanical property of the casting parts and greatly increases qualified rate of the casting parts.

Owner:镇江汇通金属成型有限公司

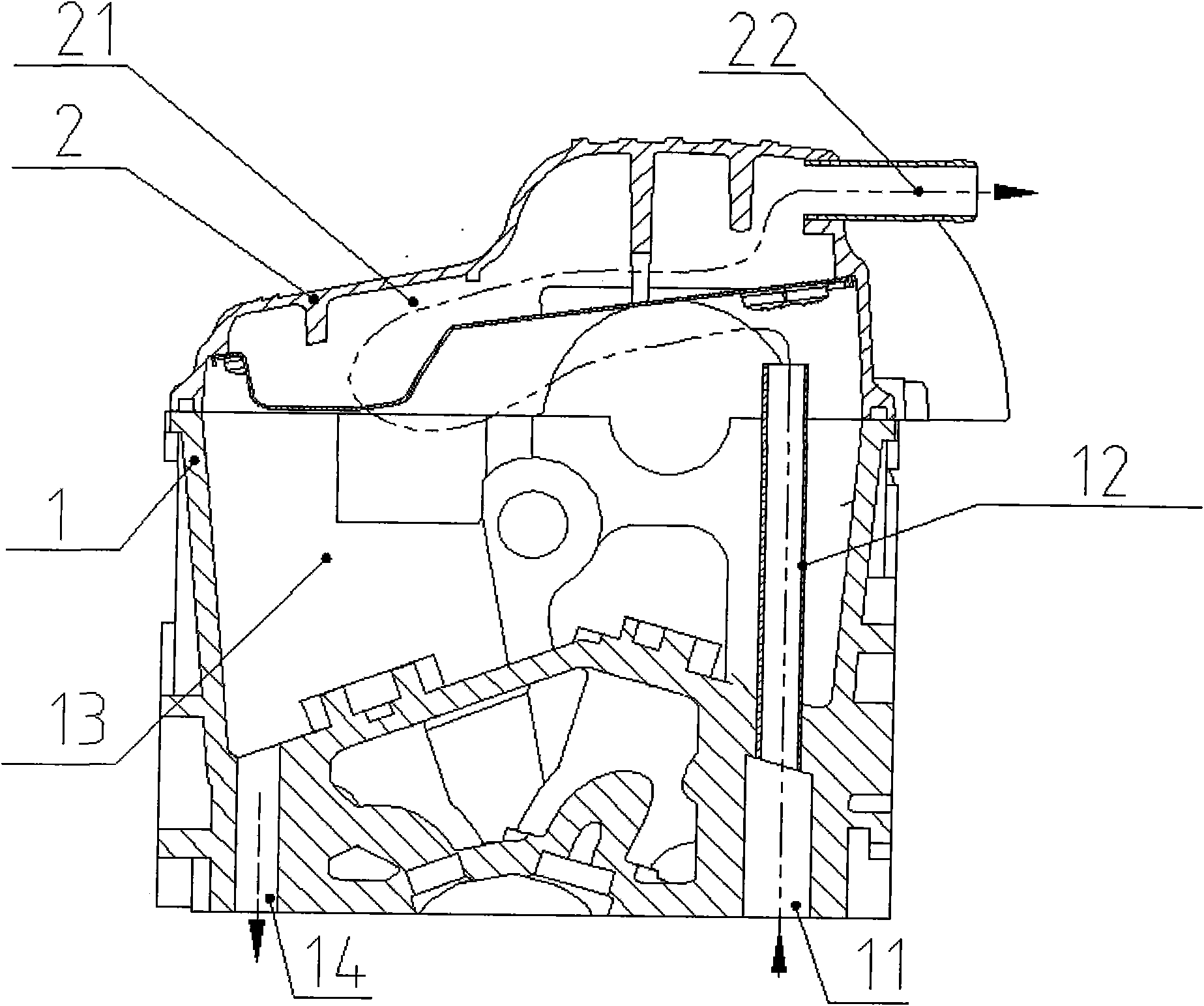

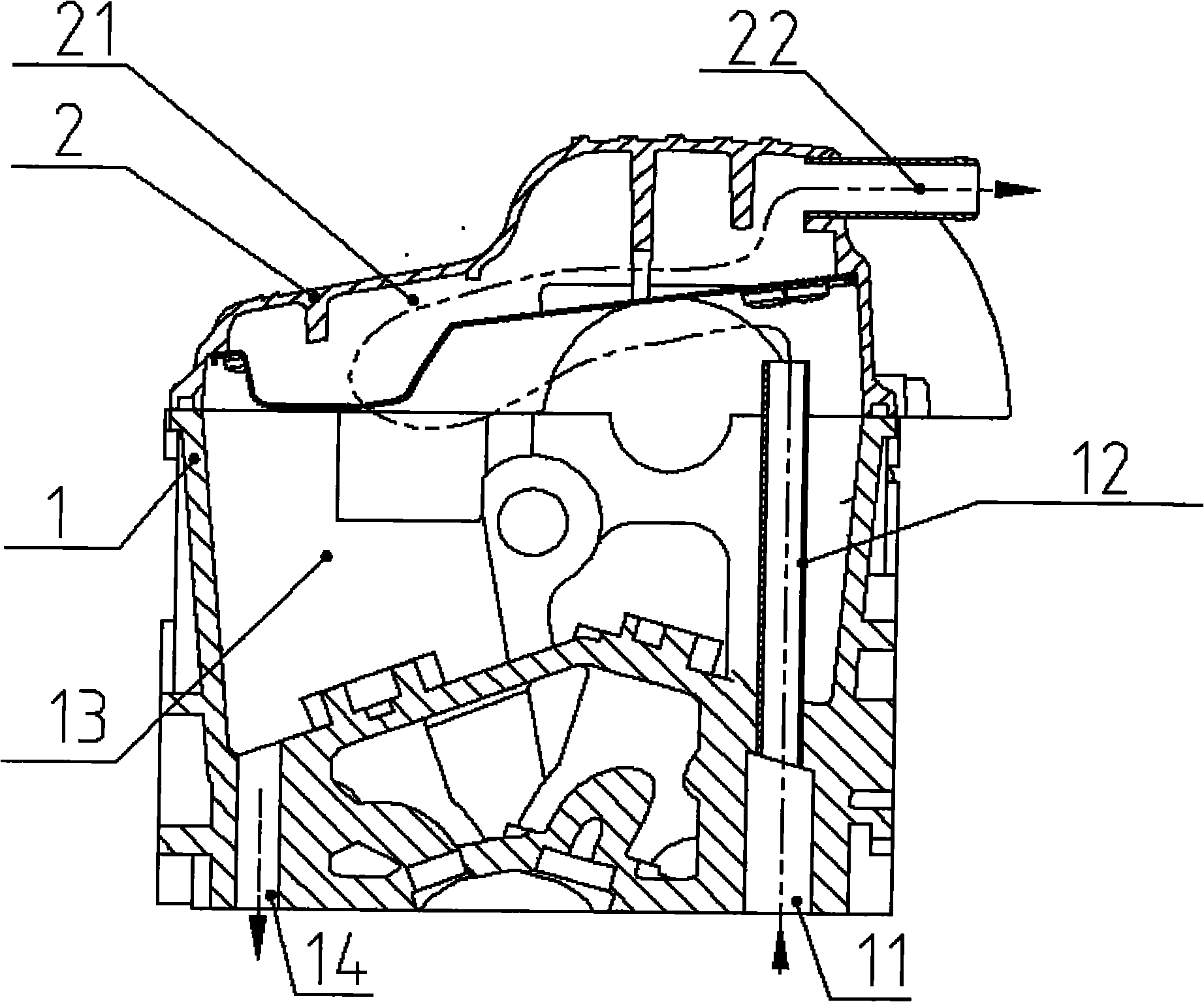

Cylinder head of internal combustion engine

InactiveCN101943078ASimple structureImprove casting pass rateCylinder headsCylindersCylinder headCrankcase

The invention provides a cylinder head of an internal combustion engine, which is provided with a mixed gas inlet and an oil return hole on the combination part of the cylinder head and a crank case, wherein the mixed gas inlet and the oil return hole are respectively communicated with the crank case; a cylinder head oil chamber is formed between the upper part of the cylinder head and a cylinder head cover and is communicated with the mixed gas inlet, the oil return hole and an oil-gas separation cavity on the cylinder head cover; and the mixed gas inlet of the cylinder head is pressed with a mixed gas inlet tube the outlet height of which is higher than the oil surface height of lubricating oil in the cylinder head oil chamber. The invention omits the original baffles arranged around the mixed gas inlet of the cylinder head so as to relatively simplify the structure of the cylinder head, simplify the casting die of the cylinder head and improve the casting qualification rate of the cylinder head; and by changing the installation height of the mixed gas inlet tube, the cylinder head can be suitable for various types of entire vehicle arrangements, and the cylinder head has high popularity.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

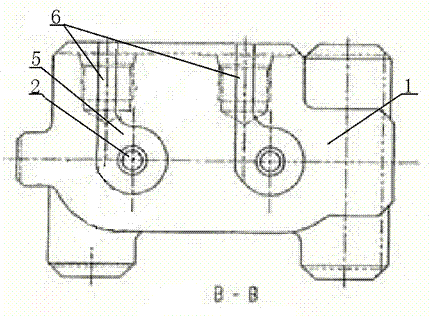

Large-duty loader hydraulic valve body casting

ActiveCN105782500AHighly integratedCompact and reasonable structureMultiple way valvesValve housingsEngineeringMechanical engineering

The invention discloses a large-duty loader hydraulic valve body casting. The large-duty loader hydraulic valve body casting comprises a valve body, perpendicular runners, horizontal runners, auxiliary runners and runner openings. The valve body is internally provided with the six perpendicular runners, the seven horizontal runners and four horizontal transverse runners. The perpendicular runners from the first one to the sixth one communicate with the four transverse runners, and the second transverse runner and the third transverse runner communicate with the seventh longitudinal runner; the first transverse runner communicates with the seventh longitudinal runner through an inclined runner, the fourth transverse runner does not communicate with the seventh longitudinal runner, and the six perpendicular runners communicate with the midpoint of the perpendicular runners from the first one to the sixth one; and the multiple auxiliary runners are formed between the horizontal runners and the perpendicular runners, and the seven horizontal longitudinal runners are provided with a plurality of oil grooves. The large-duty loader hydraulic valve body casting has the advantages of being high in integration level, reasonable and compact in structure, high in reliability, convenient to cast, use and maintain, safe, capable of saving energy, long in service life and wide in application range, the casting qualified rate is increased greatly, and the casting cost is reduced.

Owner:南通华东油压科技有限公司

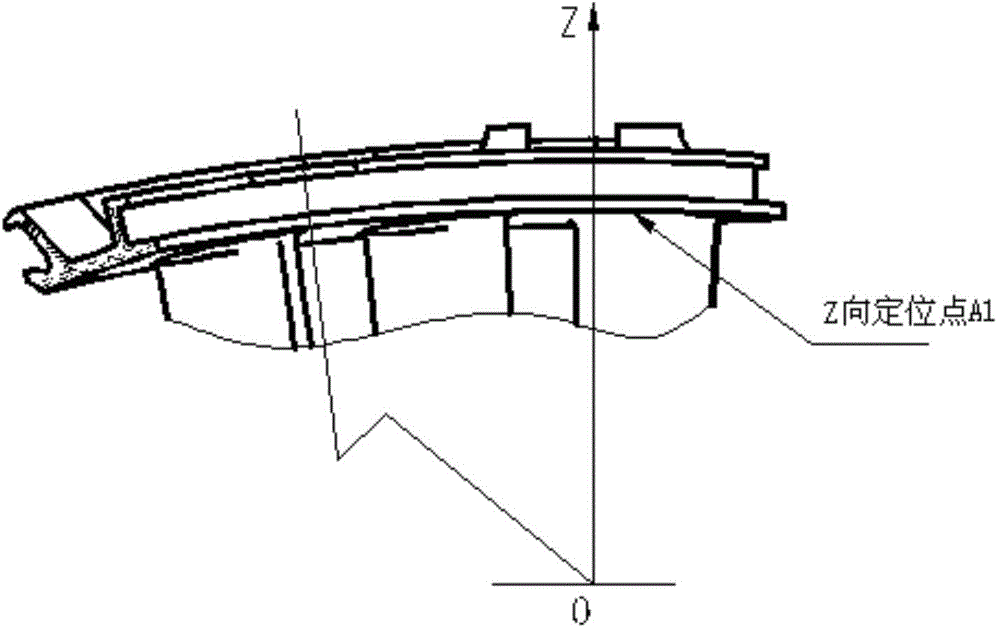

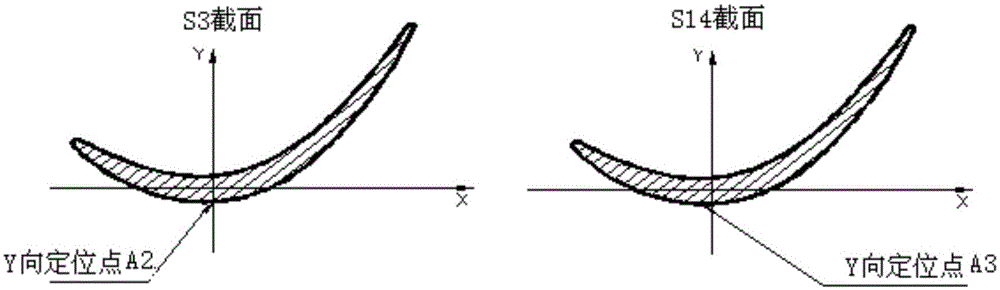

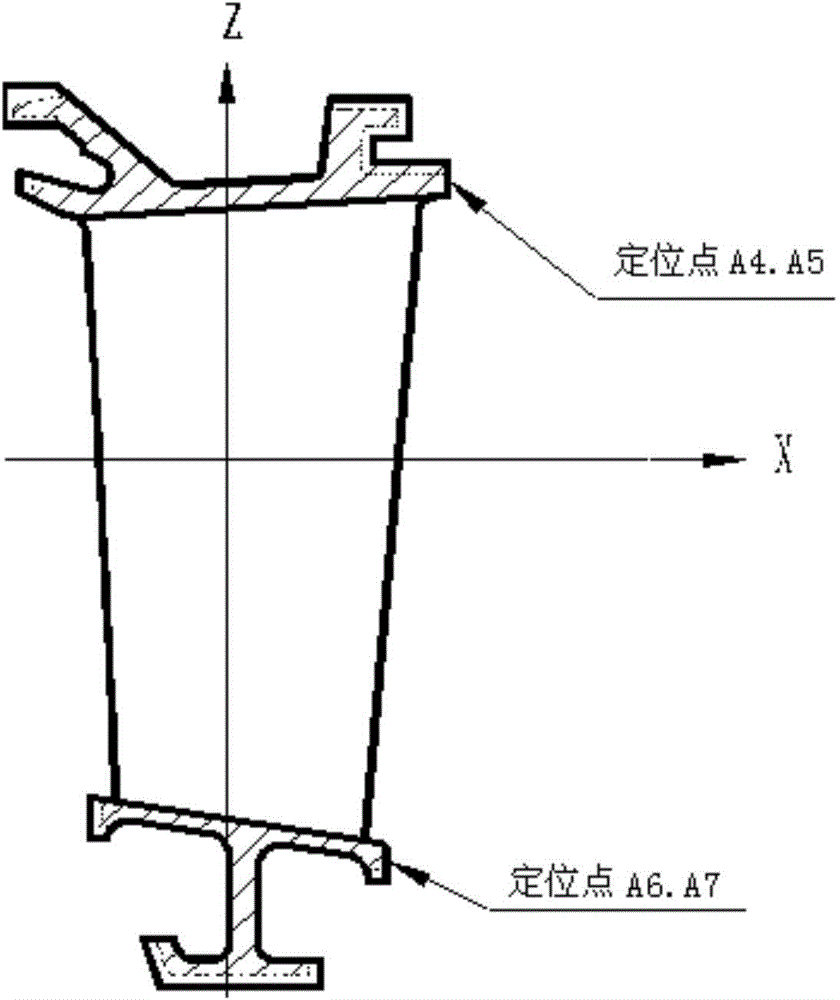

Positioning method for integrated guide vane

ActiveCN105583672AImprove casting pass rateShorten the development cycleWork holdersPositioning apparatusStable stateEngineering

The invention discloses a positioning method for an integrated guide vane. The integrated guide vane generally needs to be installed on a measurement tool or a tool clamp so as to be finished, measured and machined, and the effects that the vane is installed in the most stable state and meanwhile the position of the vane on the measurement tool or the tool clamp is proper are guaranteed by the adoption of the positioning method. The positioning method for the integrated guide vane is characterized by comprising the following steps that the coordinate point in the X-axis direction is selected and set, and four positioning points are set in the X-axis direction. According to a traditional positioning way, three positioning points are selected in the X-axis direction for determining a datum plane, positioning errors are caused due to the fact that the positioning datum in the X-axis direction does not coincide with the designed datum after the vane deforms, the longer the vane is, the larger the deformation is, and consequentially the deviation of the datum plane in the X-axis direction is larger. The positioning method for the integrated guide vane has the advantages that certain positive effects are achieved in the aspect of control over the size and the form and position accuracy of vane castings, the vane casting yield is increased, the model development cycle is shortened, and the development cost is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

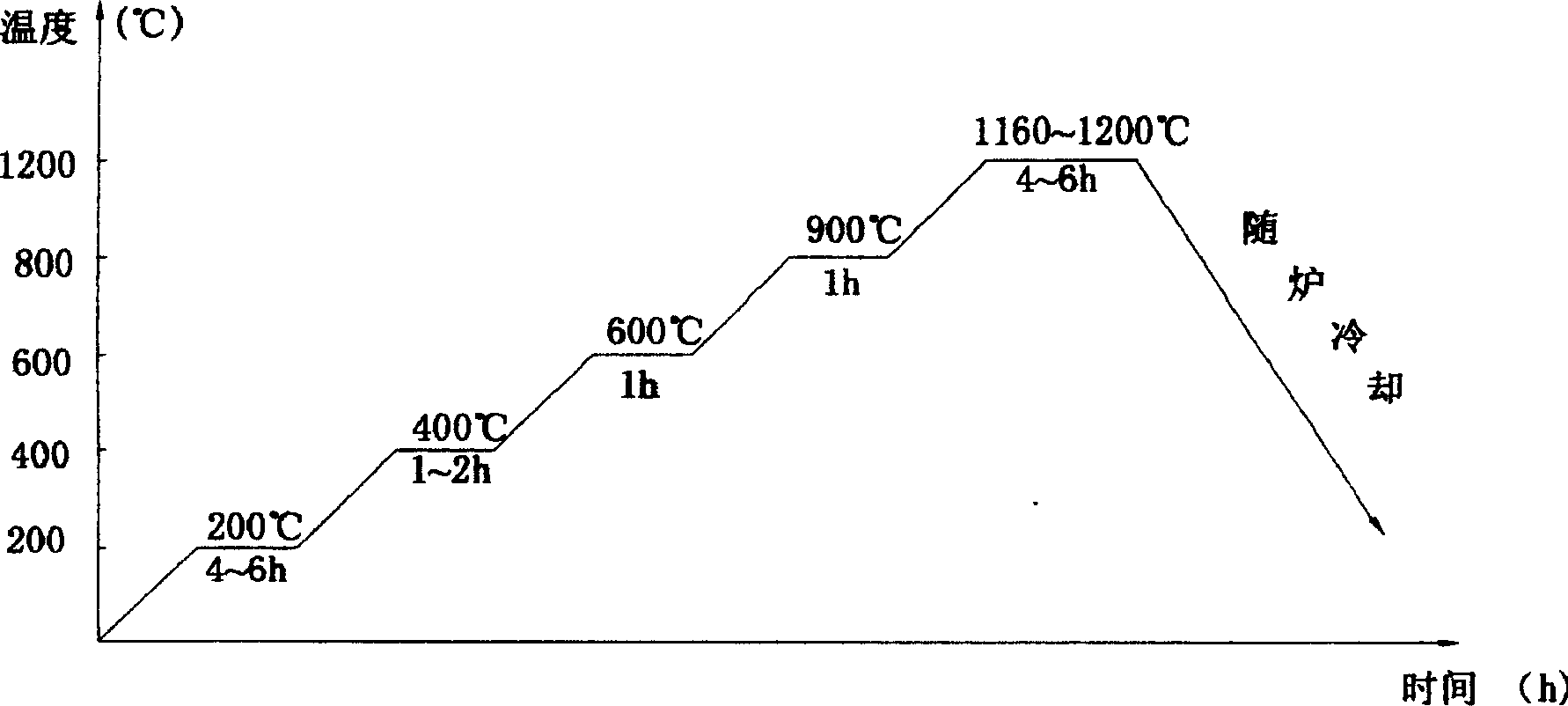

Method for improving poriness of alumina ceramic mold core

The invention relates to the technical field of preparation of ceramic, in particular to a method for improving the poriness of an alumina ceramic mold core. The technical scheme is as follows: feeding plasticizer which occupies 15 to 20 percent of core material by weight into a container with a stirrer and heating up to 100 to 120 DEG C; pressing mold core slurry into a mold core on an injection machine, insulating the mold core for 4 hours under the temperature of 200 DEG C, heating up to 400 DEG C and insulating for 2 hours, heating up to 600 DEG C and insulating for 2 hours, heating up to 900 DEG C and insulating for 2 hours, heating up to 1250 DEG C and insulating for 4 hours, and cooling down to 100 DEG C along with a furnace and taking out from the furnace; soaking the mold core in ethylsilicate digest with the viscosity of (3.6 to 8)*10<-6> Pa.s for 30 to 40 minutes, air drying for 24 hours and then ammonia drying for 30 minutes; placing the mold core which is strengthened for the first time in phenolic alcohol-soluble varnish, soaking for 2 to 3 hours under ambient temperature, and then air drying for 24 hours; and baking the strengthened mold core under the temperature of 150 DEG C for 2 hours to make the end product.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

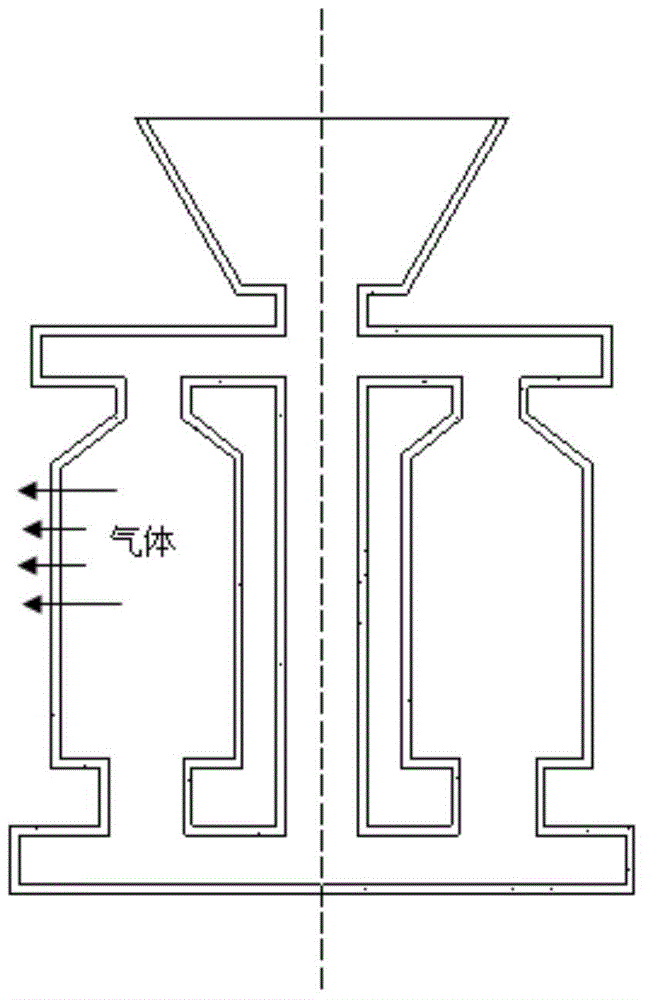

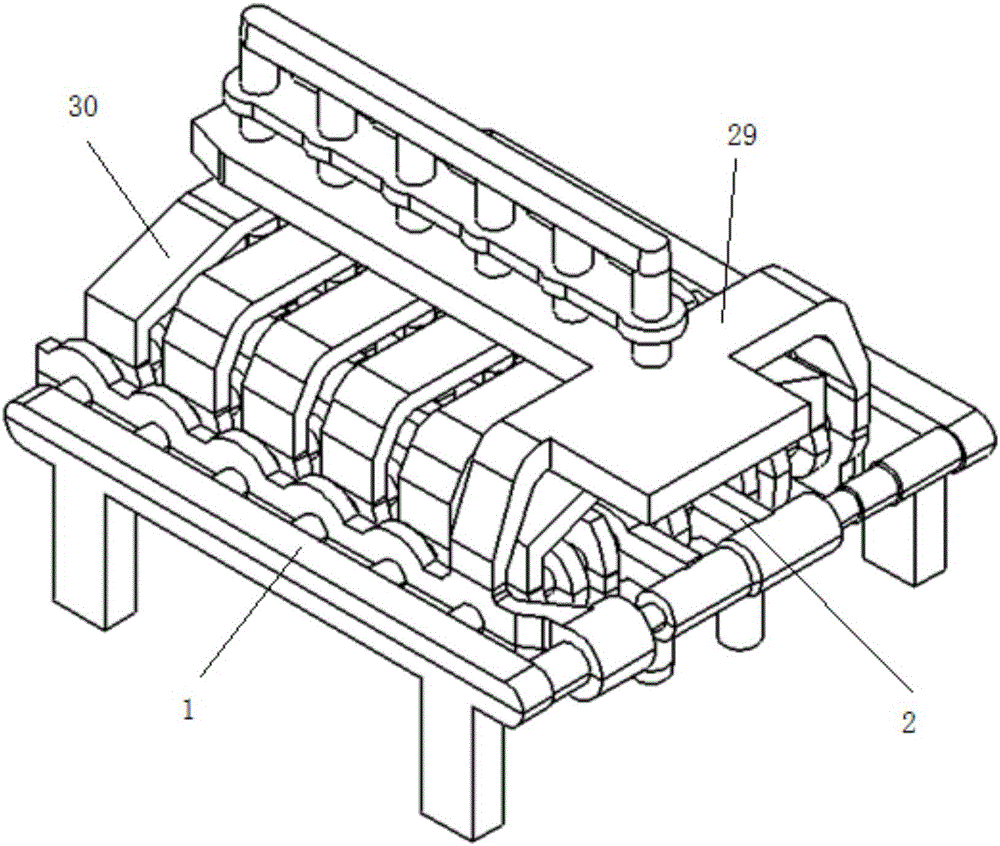

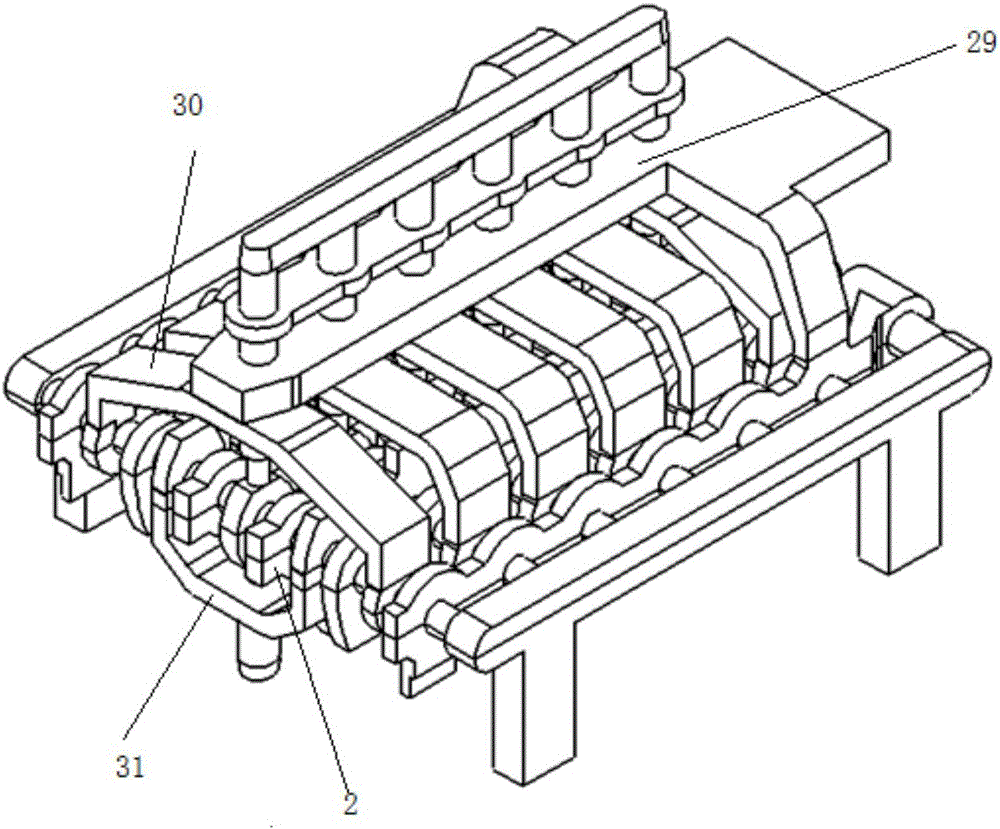

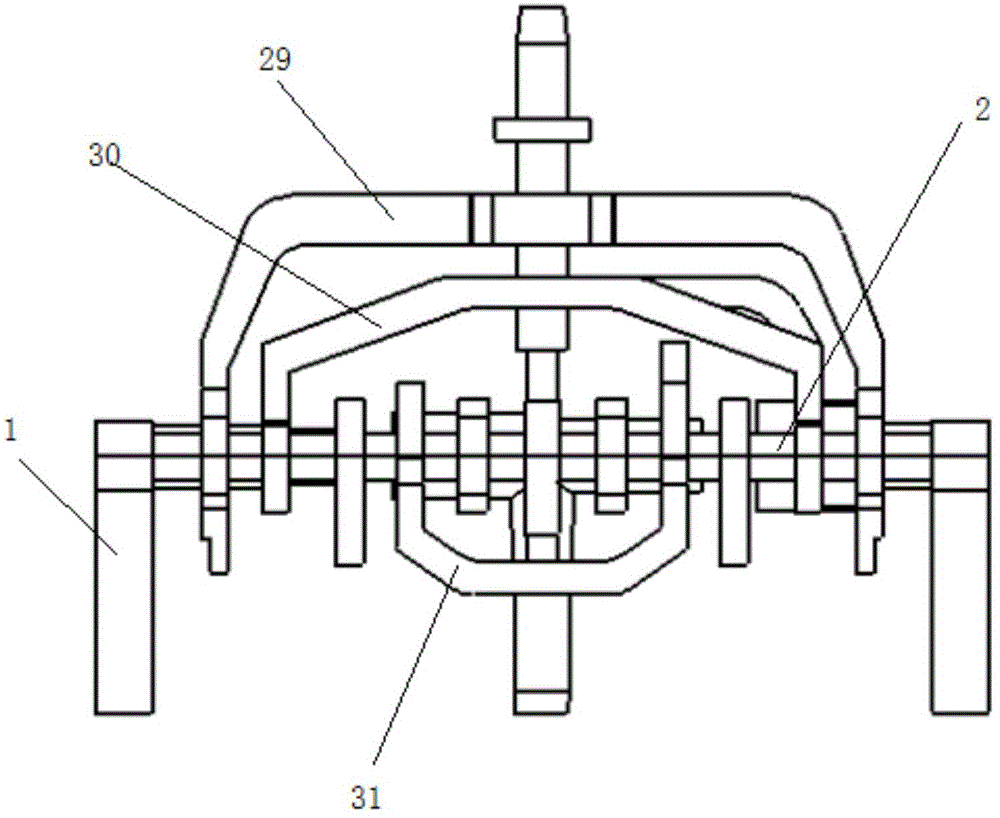

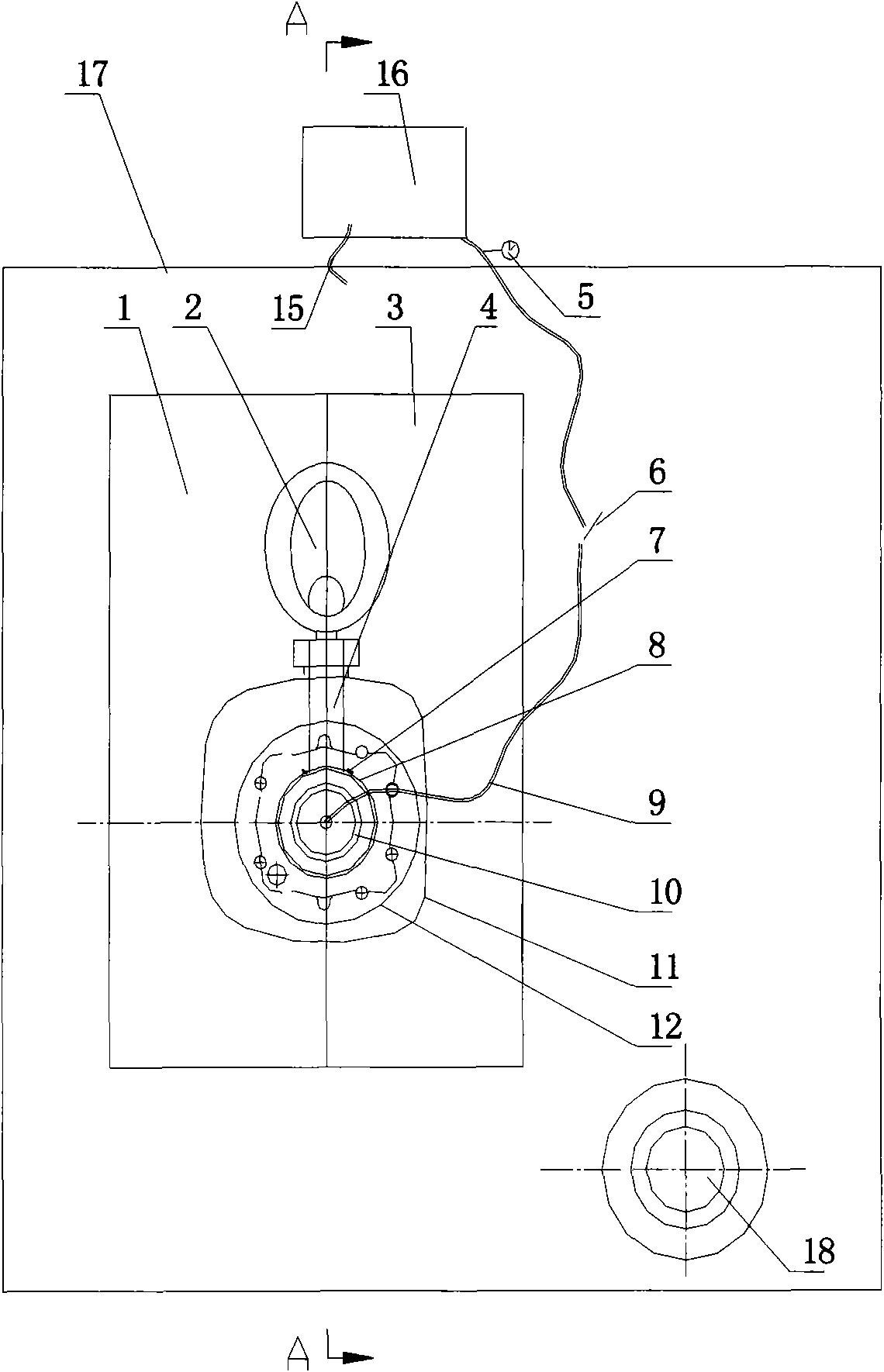

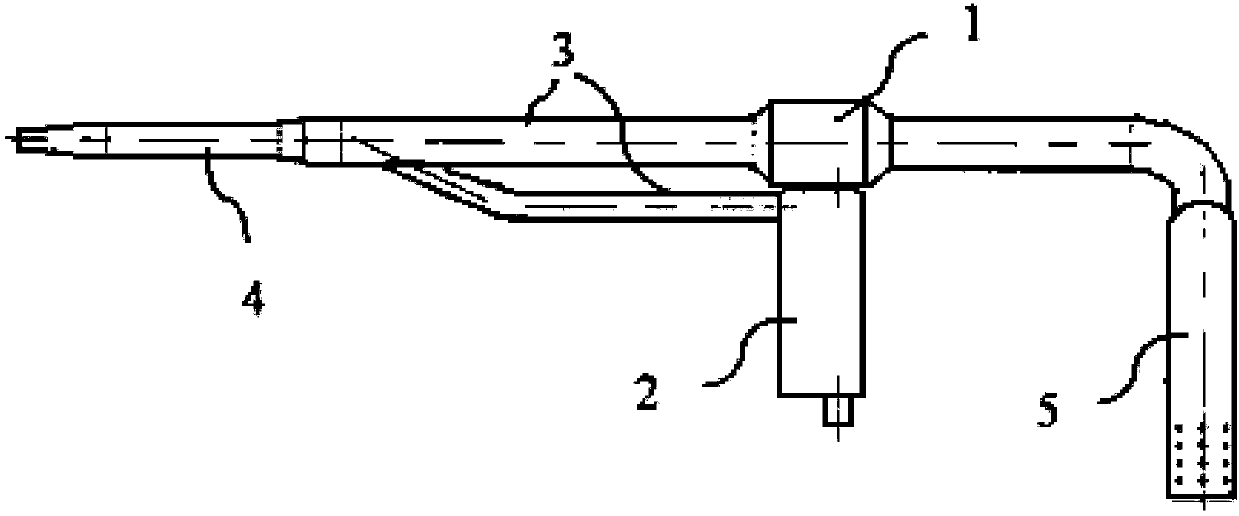

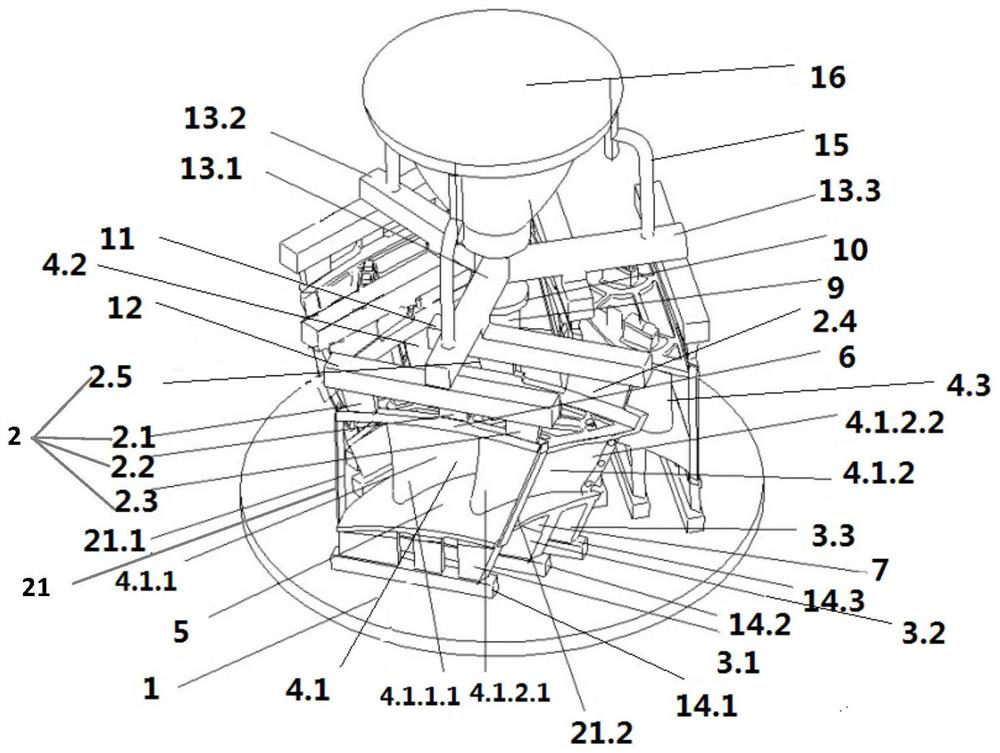

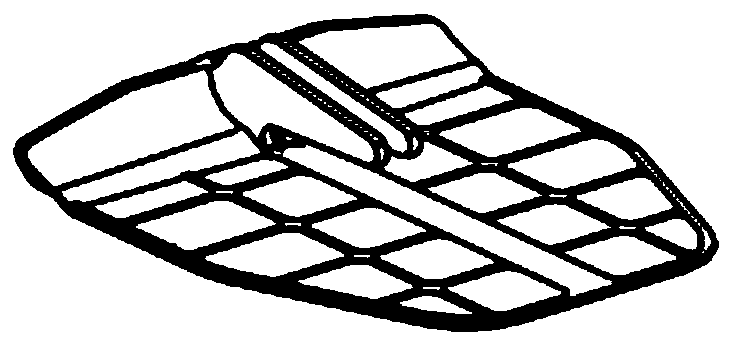

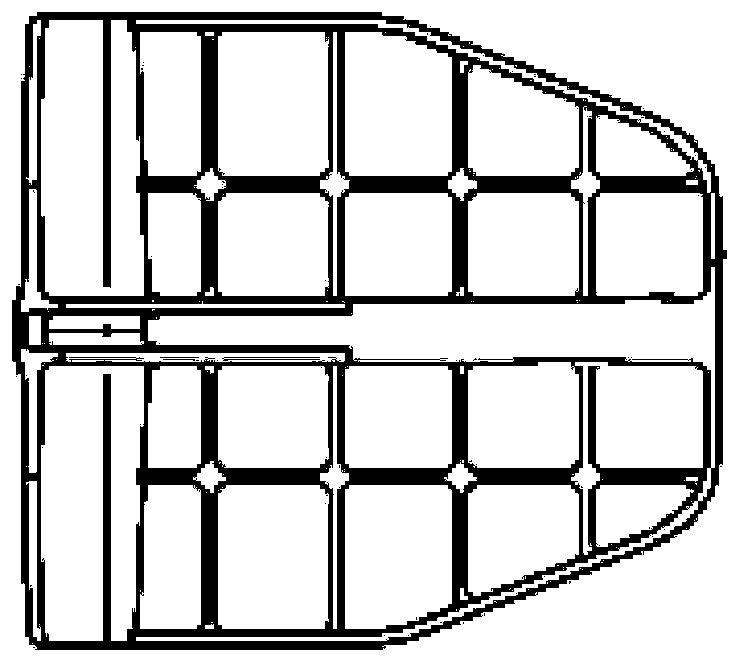

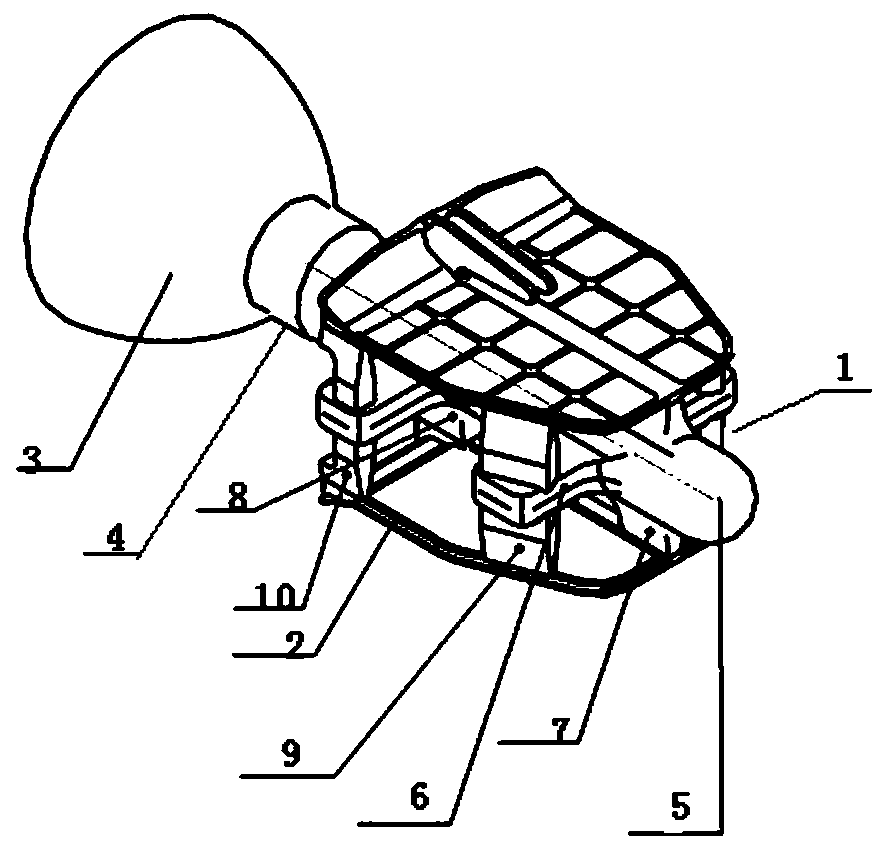

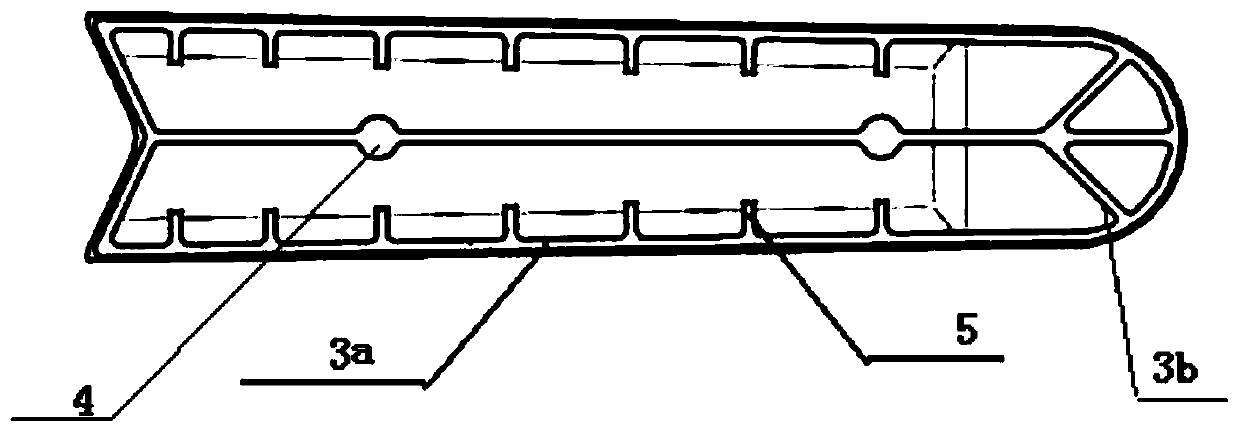

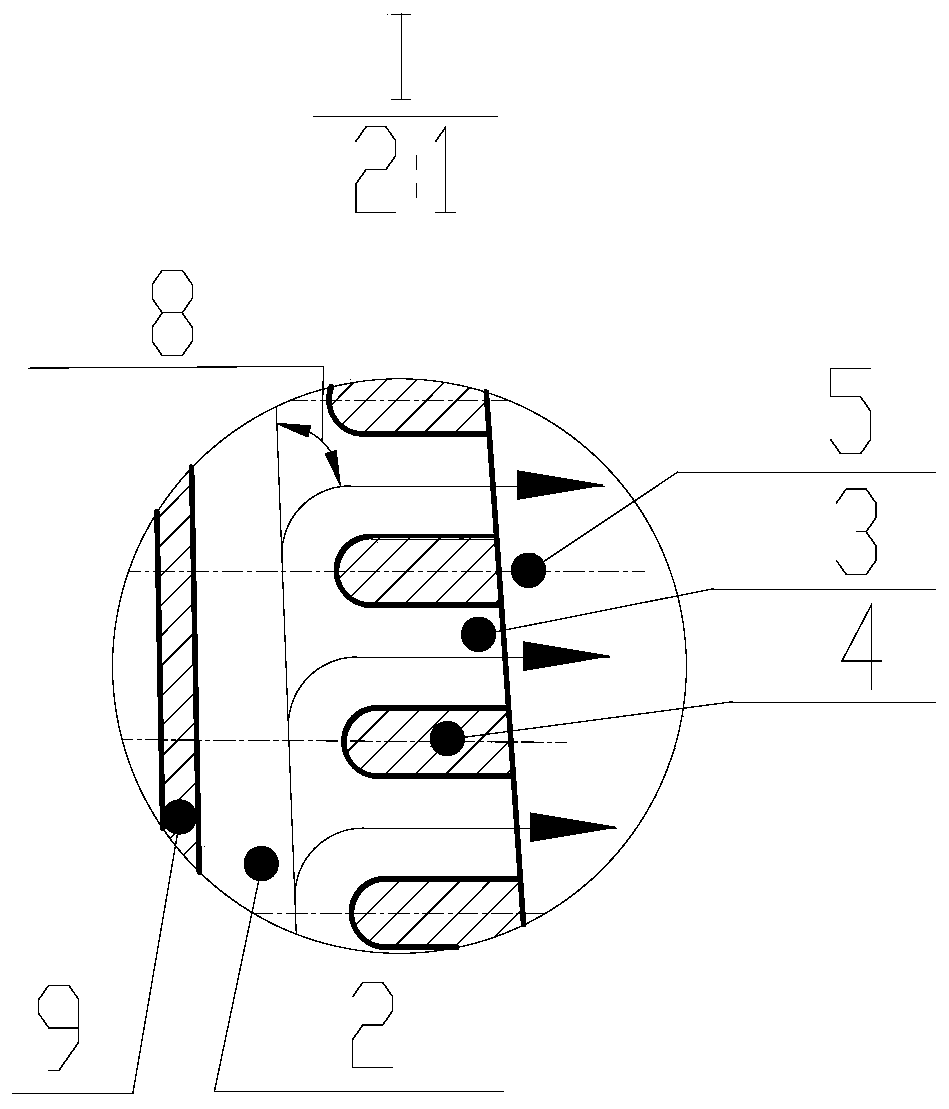

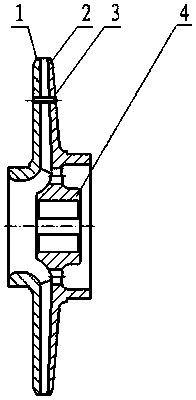

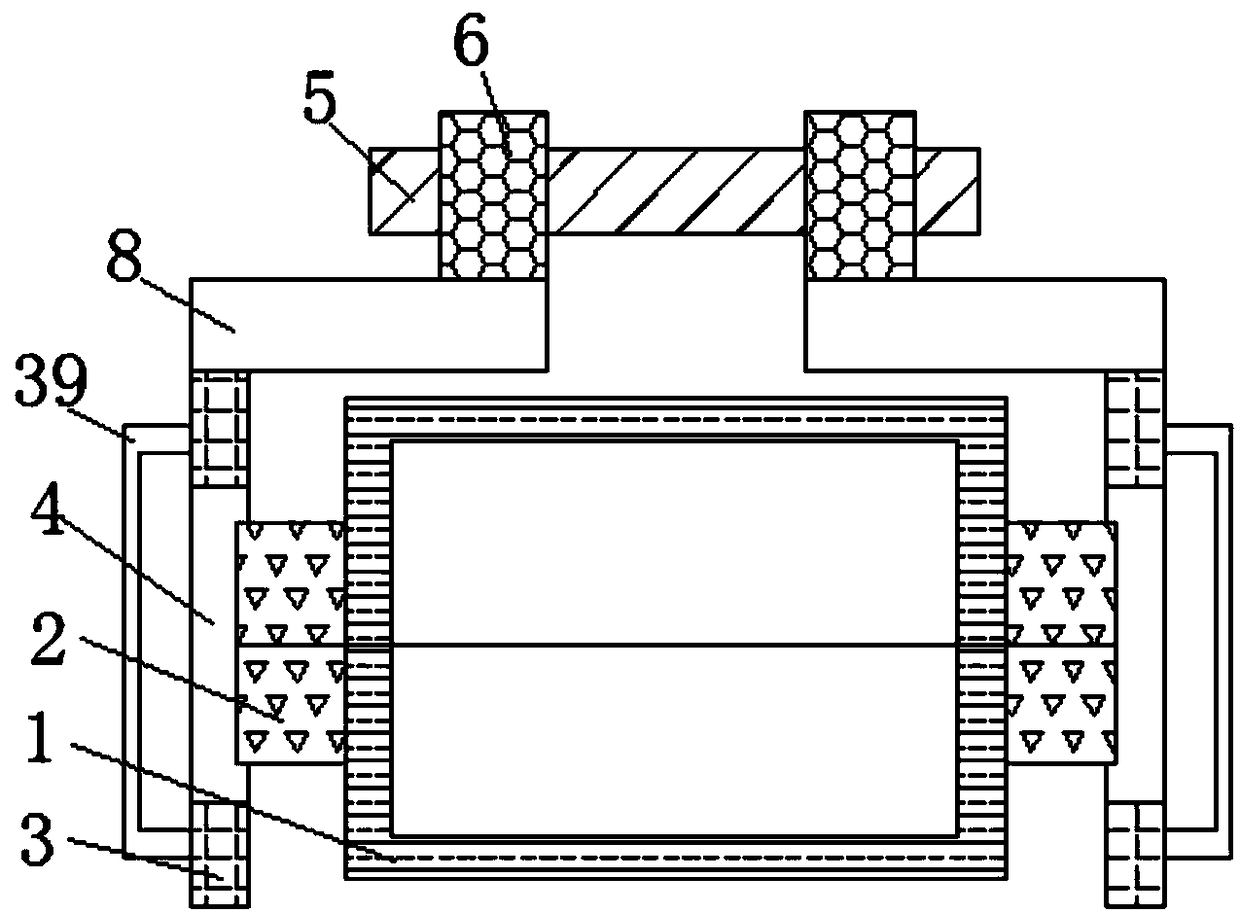

Blowing-suction integrated cleaning device and method for aviation blade and complex component mold shell

InactiveCN109926405AGood effectImprove casting pass rateHollow article cleaningEngineeringLoop control

The invention discloses a blowing-suction integrated cleaning device for an aviation blade and a complex component mold shell. The blowing-suction integrated cleaning device is composed of a vortex inlet mechanism (1), a gas loop control mechanism (2), a blowing-suction head tube (3) and a blowing-suction mouth head (4); the blowing-suction head tube (3) is provided with two parallel gas circuitswhich are the main gas circuit and the branch gas circuit; the blowing-suction mouth head (4), the tubular main gas circuit in the blowing-suction head tube (3) and the vortex inlet mechanism (1) arecoaxially and sequentially connected; and the gas loop control mechanism (2) is simultaneously connected with the branch gas circuit of the blowing-suction head tube (3) and the vortex inlet mechanism(1). The invention further discloses a blowing-suction integrated cleaning method for protecting the aviation blade and the complex component mold shell. According to the blowing-suction integrated cleaning device and method, the percent of pass of casting can be effectively improved, and the blowing-suction integrated cleaning device and method have predictable huge economic value and social value.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Mixing-type pouring device and casting technology for support castings

InactiveCN107096893AGood slag avoidance effectImprove casting pass rateFoundry mouldsFoundry coresSlagMaterials science

The invention relates to the technical field of manufacturing castings and particularly relates to a mixing-type pouring device and a casting technology for support castings. The mixing-type pouring device includes a mould plate, a sprue cup arranged on the upper part of the mould plate and a plurality of support molds arranged on the mould plate, wherein the mould plate is communicated with the support molds through a transversal pouring gate. The transversal pouring gate includes a horizontal transversal pouring gate and a vertical transversal pouring gate. A plurality of risers are externally connected to the support molds and are connected to the support molds through riser necks. The horizontal transversal pouring gate is externally connected to the risers and is communicated with the risers through connecting members. The mixing-type pouring device has good slag avoiding effect and has high casting qualification rate, achieves stable and smooth mold filling, reduces sand blasting defect, and increases the qualification rate of castings.

Owner:SHANDONG MEILING CHEM EQUIP

Electrohydraulic valve body casting

InactiveCN104776259ASimple designSimple structureFoundry mouldsFoundry coresAutomatic controlEngineering

The invention relates to the field of valve body castings, in particular to an electrohydraulic valve body casting. The electrohydraulic valve body casting comprises a valve body, a horizontal flow passage, flow passage ports and an auxiliary flow passage, the horizontal flow passage is designed in the valve body, both ends of the horizontal flow passage are provided with the flow passage ports, the middle of the horizontal flow passage is provided with five annular grooves, which are a first annular groove, a second annular groove, a third annular groove, a fourth annular groove and a fifth annular groove, the first annular groove and the fifth annular groove communicate with each other via the auxiliary flow passage, the auxiliary flow passage is located over the horizontal flow passage, and the upper ends of the insides of the flow passage ports at both ends of the horizontal flow passage are provided with inclined flow passages. The electrohydraulic valve body casting has the following advantages: the design is simple and advanced, the electrohydraulic valve body casting is convenient to use, cast and maintain, is ingenious, reasonable, safe, energy-saving and structurally simple, can serve as a key part for an automated control execution system, and has a long service life, the casting percent of pass is increased greatly, and the casting cost is reduced.

Owner:南通华东油压科技有限公司

Ceramic core with high stability and high strength

InactiveCN104446453AImprove high temperature stabilityStrong enoughInvestment castingUltimate tensile strength

A ceramic core with high stability and high strength is provided to mainly overcome the technical problem that the stability and strength of ceramic cores in the prior art is not high enough, which affects the product quality of investment castings. The raw materials of the ceramic core comprise, by weight, 60-85% of zirconia powder, 4-20% of yttria powder, 2-18% of calcium carbonate powder, 0.5-3% of nanometer zirconia powder, 4-8% of paraffin, 0.2-0.6% of beeswax, 0.1-0.3% of polyethylene, and 0.4-0.8% of oleic acid. According to the invention, the ceramic core possesses good high-temperature stability and enough strength, so that the inner cavity quality of investment castings is significantly improved and the core fracture phenomenon resulting from low strength can be avoided during precision casting, which helps substantial increase in the casting qualified rate. By adopting the material system in the invention, the reaction between a fusion metal and a core material, which results in a responsive defect, can be avoided during the high temperature cast. The ceramic core is mainly applied to the field of investment casting.

Owner:LIAONING SILICATE RES INST

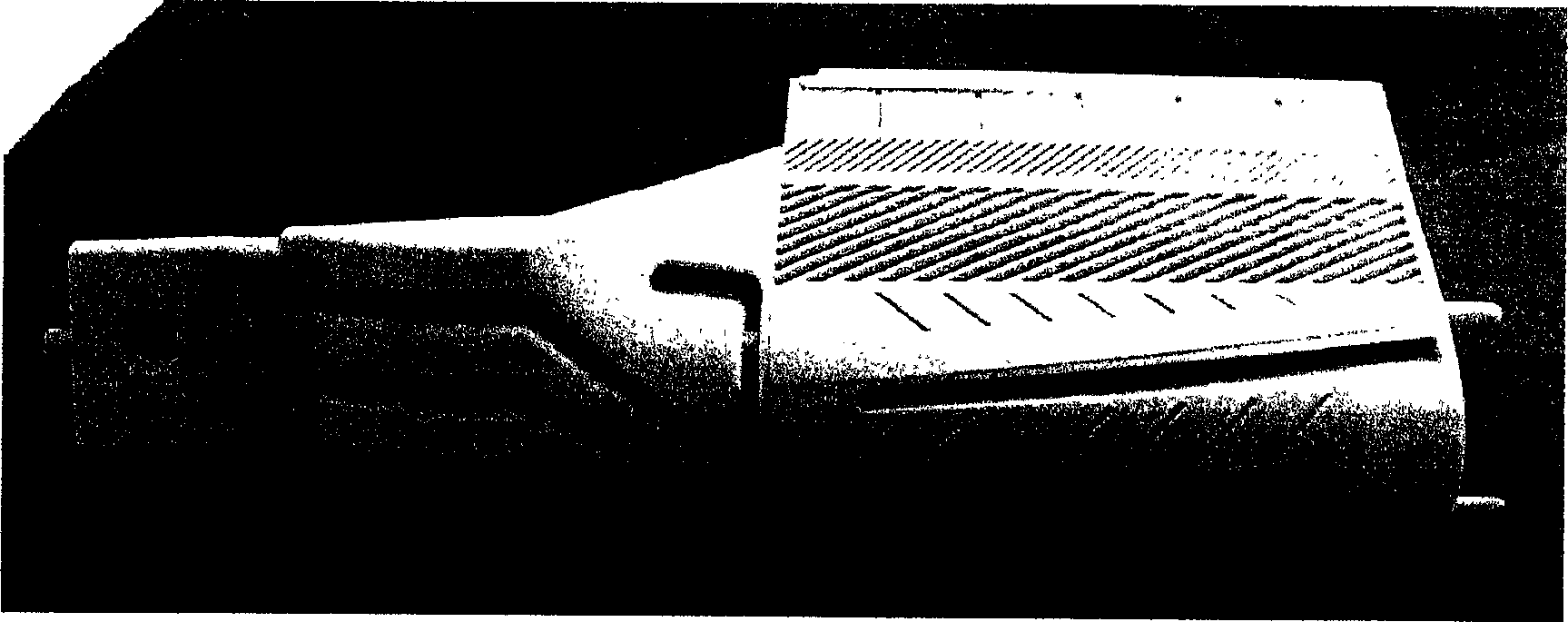

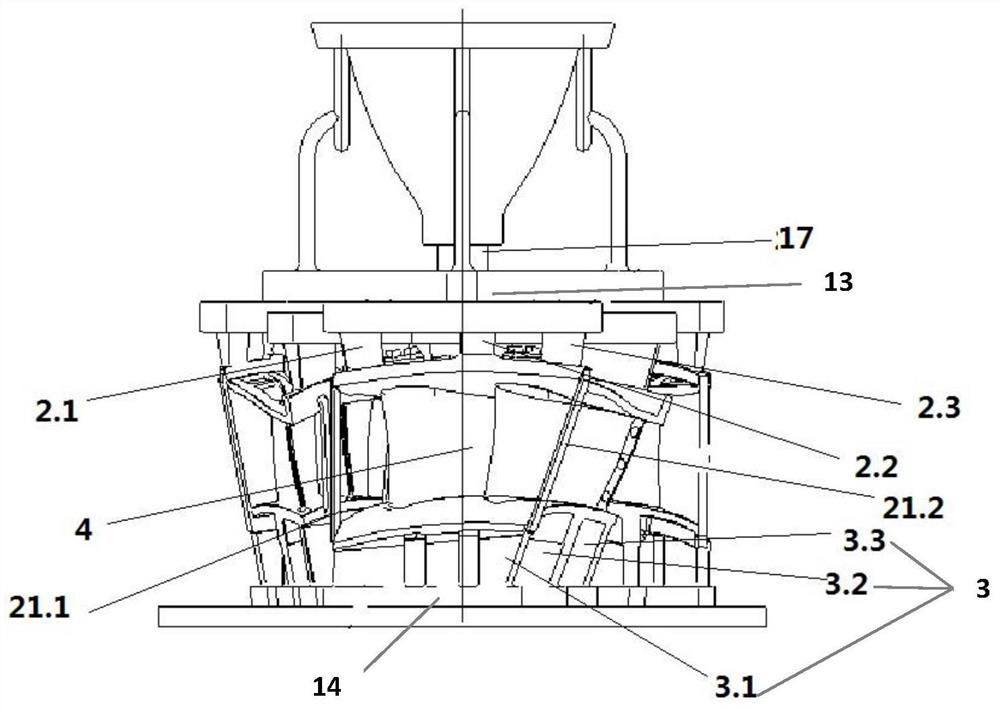

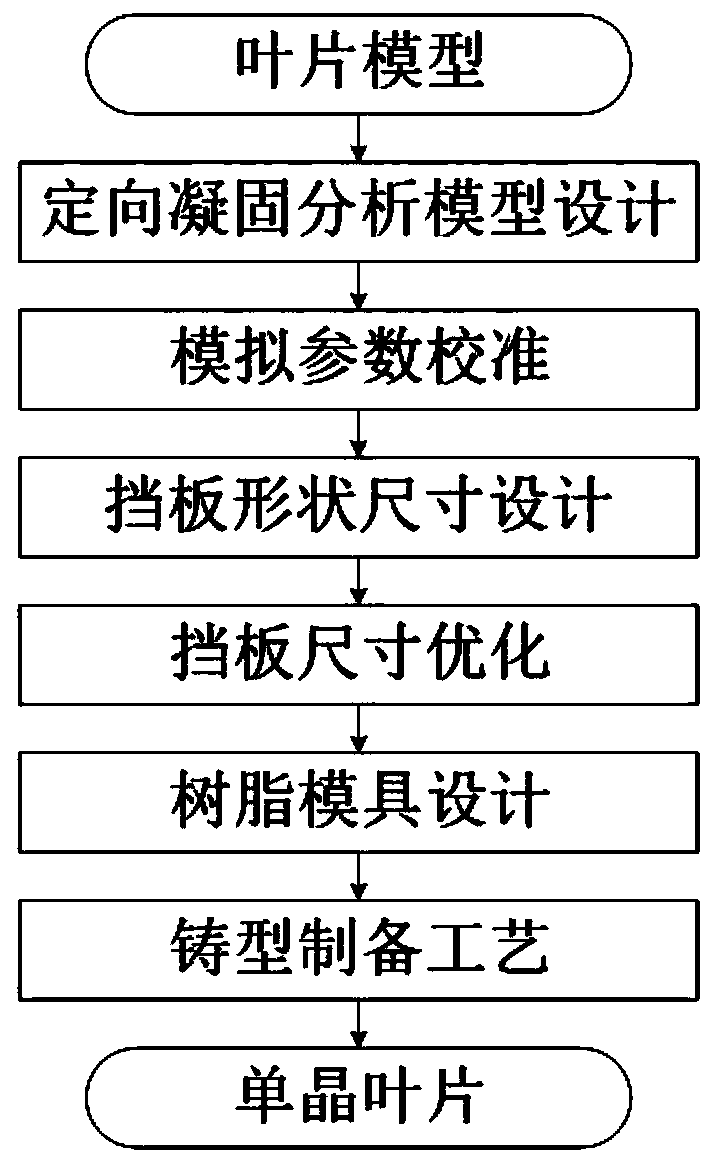

Design method of duplex directional hollow blade casting system

ActiveCN111940679ASolve the problem of orientation deviationImprove casting pass rateFoundry mouldsFoundry coresMold fillingStraight tube

The invention provides a design method of a duplex directional hollow blade casting system. The method comprises the steps: combining casting systems; manufacturing a mold shell of a wax mold module;and putting the mold shell into a three-chamber vacuum furnace to complete casting, wherein the casting temperature of a casting piece is 1480 DEG C, and the crystal pulling speed is 4 mm / min. The combination of the casting systems specifically comprises the steps of determining the diameter of a module chassis; determining the process epitaxy of blades; determining the position of the starting section on the module chassis; determining the height of a middle straight pipe of the module; connecting a casting system mold filling path; arranging a cross gate connected with the middle straight pipe and a pouring cup; and connecting the pouring cup to the upper portion of the middle straight pipe. By designing and optimizing the combination mode of the casting system, the problems of metallurgical defects such as broken crystals, oblique crystals and exposed crystals of columnar crystals at the position of an exhaust edge are successfully solved, and deformation of casting pieces in the casting process is effectively controlled.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Fired mold capable of improving mold-filling capacity of complicated thin-walled part of hard-mold-filling-type high temperature alloy

ActiveCN110732633AReduce undercastingReduce crackingFoundry mouldsFoundry coresEngineeringSuperalloy

The invention relates to a fired mold capable of improving the mold-filling capacity of a complicated thin-walled part of hard-mold-filling-type high temperature alloy. Specifically, the fired mold isof a symmetric structure and comprises a pouring gate system and a patch; one side of the patch is opened, the other side of the patch is closed, the bottom of the patch is communicated with a casting bottom plate, the patch comprises a patch a which is designed according to the shape of a casting along the edge of the casting and a patch b which is designed along the symmetry center of the casting, the patch a and the patch b are flush with each other in height, and the patch and a casting wax mold are integrally formed; the pouring gate system is provided with a pouring cup, a main pouringgate is connected to the pouring cup, and comprises a straight pouring gate, a plurality of transverse pouring gates, and a plurality of wedge-shaped dead heads c, and a plurality of wedge-shaped deadheads d, each transverse pouring gate is provided with a wedge-shaped dead head e or a boot-shaped dead head, and the wedge-shaped dead heads c, the wedge-shaped dead heads d, the wedge-shaped dead heads e and the boot-shaped dead heads are all connected to the patch. By means of the fired mold, the occurrence probability of sufficient casting, cracking and loosening of the product is effectivelyreduced, and the casting percent of pass of the product is increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Manufacturing method of super duplex stainless steel single-stage double-suction centrifugal pump case

ActiveCN112387958ASolve crackingImprove casting pass rateFoundry mouldsFurnace typesConventional castingSS - Stainless steel

The invention discloses a manufacturing method of a super duplex stainless steel single-stage double-suction centrifugal pump case in the technical field of casting of fluid conveying equipment. The manufacturing method comprises the steps of box opening and riser gas cutting. During box opening, a box is opened after casting of a cast piece is finished and a riser is solidified, the time when thecast piece is solidified and the body temperature is larger than 1000 DEG C is determined through simulation software, the time is the box opening time, and the box opening time is smaller than 1h. During riser gas cutting, a pouring gate, the riser and molding sand are removed after box opening, the temperature is monitored at the same time, when the temperature is reduced to 700 DEG C, the castpiece must enter a furnace to be heated, it is ensured that the cast piece temperature is larger than 600 DEG C in the sand shakeout and riser gas cutting process, after the pouring gate, the riser and the molding sand are cleaned up, the cast piece is directly put into the furnace for heat treatment, and the heat treatment temperature is 1060 DEG C. Compared with a cast piece manufactured through an existing conventional casting process, the product is free of cracks, and the percent of pass of the product reaches 96%.

Owner:遵义拓特铸锻有限公司

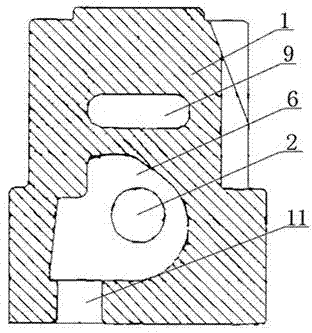

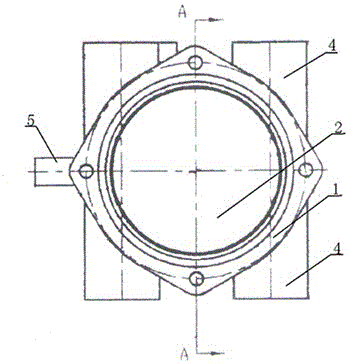

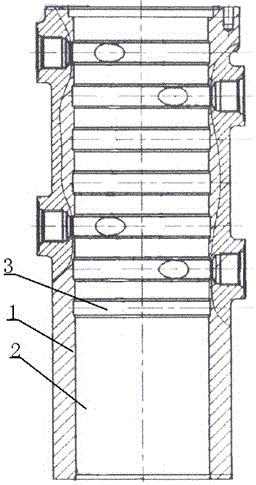

Hydraulic rotation valve casting and die thereof

ActiveCN104972074AImprove scalabilityPromote progressFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention relates to the field of valve castings, in particular to a hydraulic rotation valve casting and a die thereof. The hydraulic rotation valve casting comprises a valve body, a vertical flow channel and annular grooves. The valve body is cylindrical. An opening in the upper end of the valve body is square. Cylindrical protrusions are designed on the outer side of the valve body. A square block is designed on one side of the valve body. The vertical flow channel is formed in the valve body. The annular grooves are formed in the vertical flow channel. The hydraulic rotation valve casting and the die thereof have the advantages that design is simple, use is convenient, ingenuity and reasonability are achieved, casting is convenient, the qualification rate of casting is greatly increased, the casting cost is reduced, the integration degree is high, reliability is high, and the service life is long. Promotion and progress of a current casting technology in China are facilitated, the situation that the precision of casting products of the same kind China is poor, and the technical content is low is changed, and great practical significance is provided for enlarging domestic and foreign market shares in the future.

Owner:南通华东油压科技有限公司

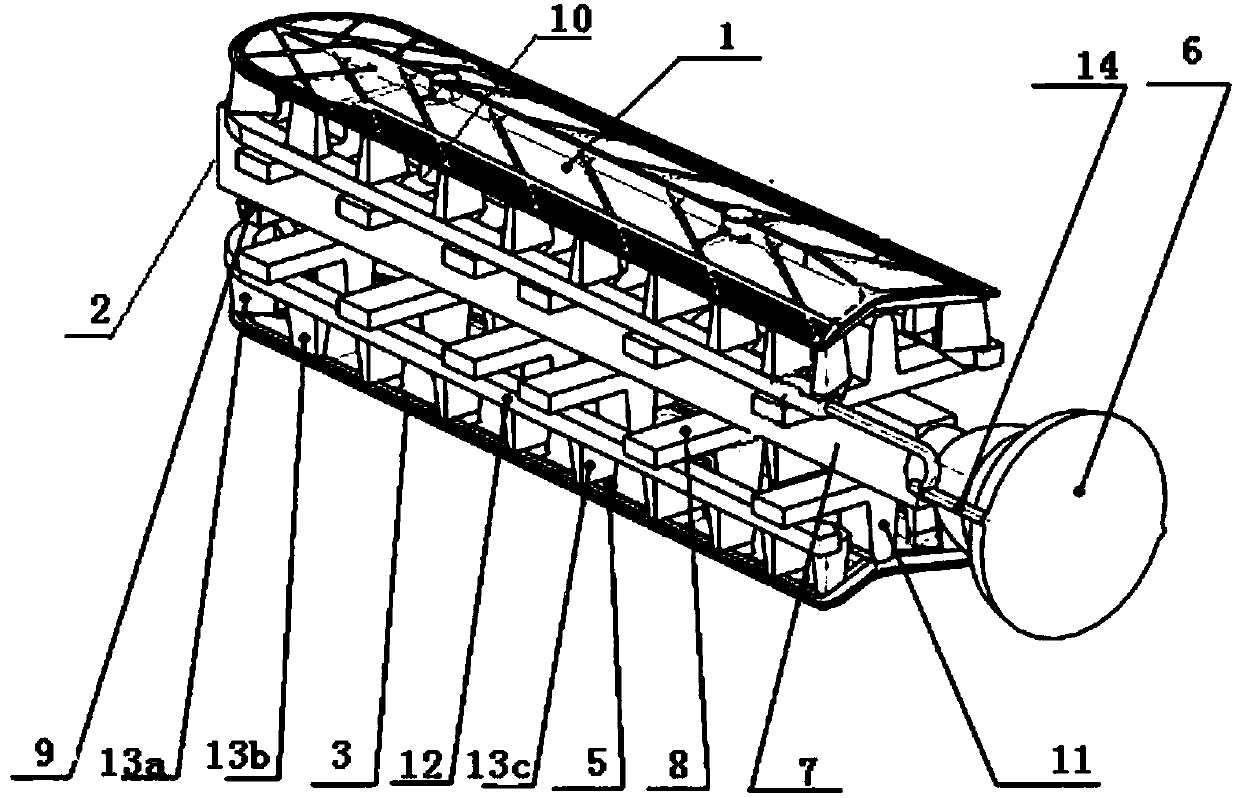

Casting system for large-scale thin-walled high-temperature alloy casting

ActiveCN110773708AAvoid undercastingAvoid looseFoundry mouldsFoundry coresSuperalloyMaterials science

The invention relates to the technical field of precision casting of large-scale thin-walled parts for jet nozzles of aero-engines, in particular to a casting system for a large-scale thin-walled high-temperature alloy casting. According to the specific technical solution, the casting system comprises castings and a pouring gate and is a group of two-piece structures; each casting comprises an ingate formed with the shape, two cylindrical bosses and multiple inner feeder heads; the ingate, the inner feeder heads and the casting are integrally formed; a sprue of the ingate, the cylindrical bosses and the inner feeder heads are flush in the height direction; the pouring gate is provided with a sprue cup, an exhaust passage, a main pouring gate, a transverse pouring gate, a molding pouring gate and two overlap joint wedge-shaped feeder heads; a truncated cone-shaped feeder head or a big wedge-shaped feeder head is arranged at the middle position of the transverse pouring gate; and multiple small wedge-shaped feeder heads are arranged on the molding pouring gate. The casting system effectively reduces the risk of generating metallurgical defects such as incomplete pouring, cracks and looseness, and improves the casting qualification rate of the casting product and the metallurgical quality.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

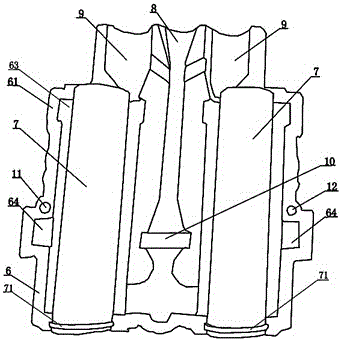

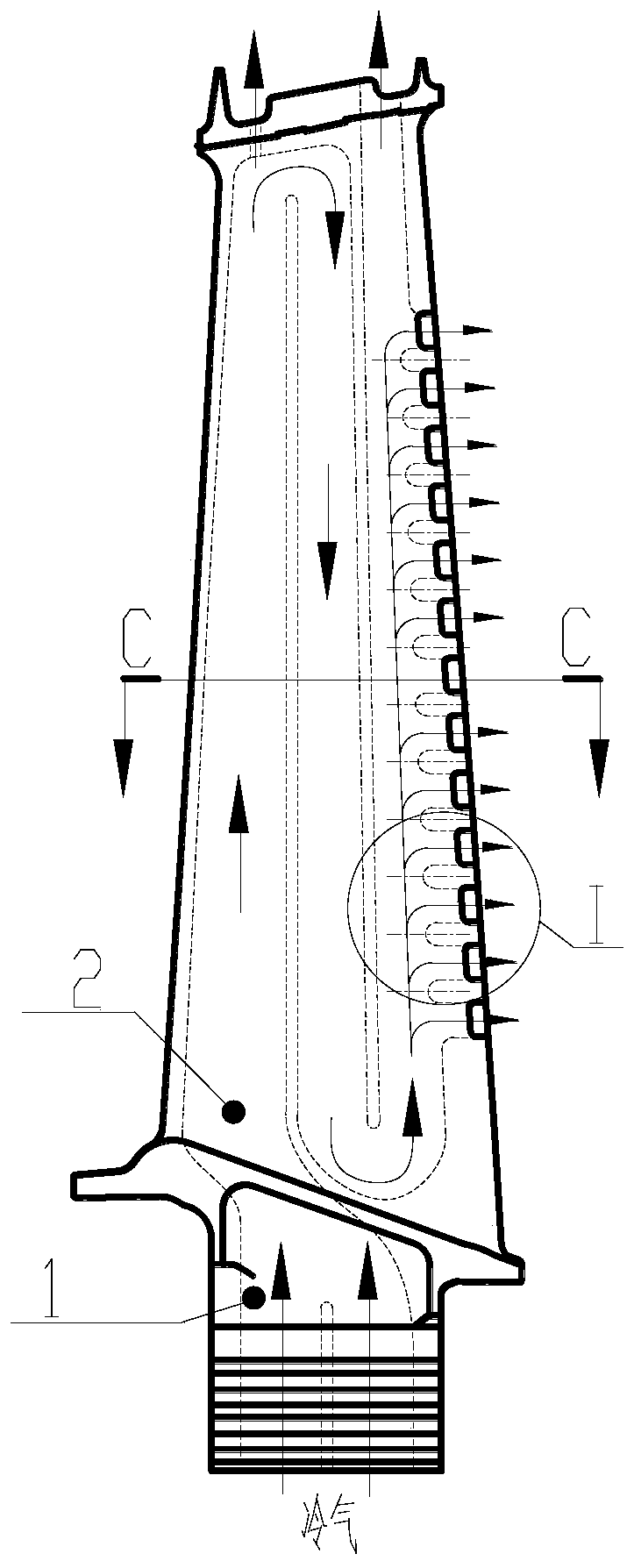

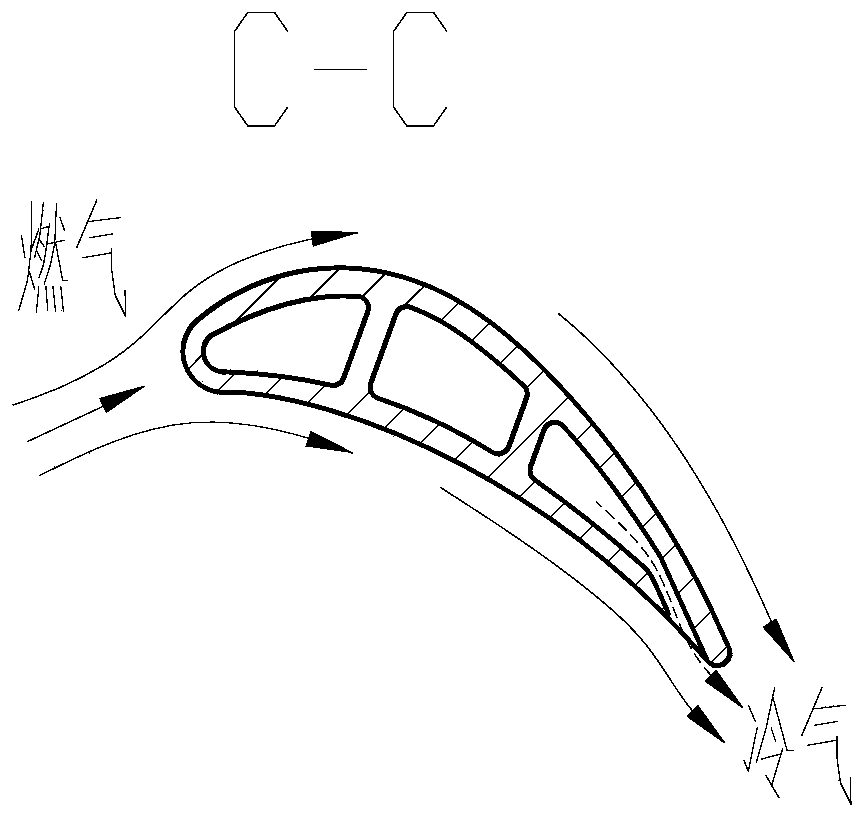

Turbine blade trailing edge fold line type exhaust split seam structure

ActiveCN110748384AIncrease widthLower temperature levelBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a turbine blade trailing edge fold line type exhaust split seam structure. The turbine blade trailing edge fold line type exhaust split seam structure comprises a hollow turbine blade, an inner cavity cold air channel, a trailing edge exhaust split seam channel and trailing edge split seam partition ribs, wherein the inner cavity cold air channel is formed in the hollow turbine blade, and low-temperature cooling gas flows in the blade to cool the blade; the trailing edge split seam partition ribs arranged side by side are arranged on the trailing edge of the hollow turbine blade; and the trailing edge exhaust split seam channel is formed between the trailing edge split seam partition ribs arranged side by side. According to the turbine blade trailing edge fold line type exhaust split seam structure, a trailing edge exhaust split seam is designed into an inclined fold line type exhaust mode, theturning angle of the cooling gas in the split seam is reduced, and cold air is turned twice or multiple times instead of being turned once, so that the flow resistance and loss of the cold air in an inner cavity of the blade are reduced, and the flow resistance can be reduced by about 19%.

Owner:DALIAN UNIV OF TECH

Manufacturing method of narrow-flow-channel closed impeller

InactiveCN110653579AGuaranteed runner size and surface roughnessImprove casting pass ratePump componentsPumpsImpellerRoughcast

The invention discloses a manufacturing method of a narrow-flow-channel closed impeller. The method comprises the steps that the narrow-flow-channel closed impeller is designed into a split-type frontcover plate and an open-type impeller body; a casting mold is used for manufacturing workblanks of the open-type impeller body and the front cover plate respectively, and the cast workblanks are polished and subjected to sand blasting; the processed front cover plate is in butt joint with the face, provided with blades, on the open-type impeller body, a positioning pin is inserted in the butt joint portion for welding fixing, and after welding is completed, the closed impeller is subjected to thermal treatment. According to the manufacturing method, the strength of the impeller and a shaft hole is not influenced, the flow channel size and surface roughness can be guaranteed, the problem that the casting dead corner is difficultly polished and cleaned is solved, so that all flow channels of the impeller completely meet the design demand and achieve impeller performance, and by using the impeller manufactured through the method, the qualification rate of casting the narrow-flow-channelclosed impeller and the working efficiency of an overall pump set can be greatly improved.

Owner:XIANGYANG WU ER WU PUMP IND

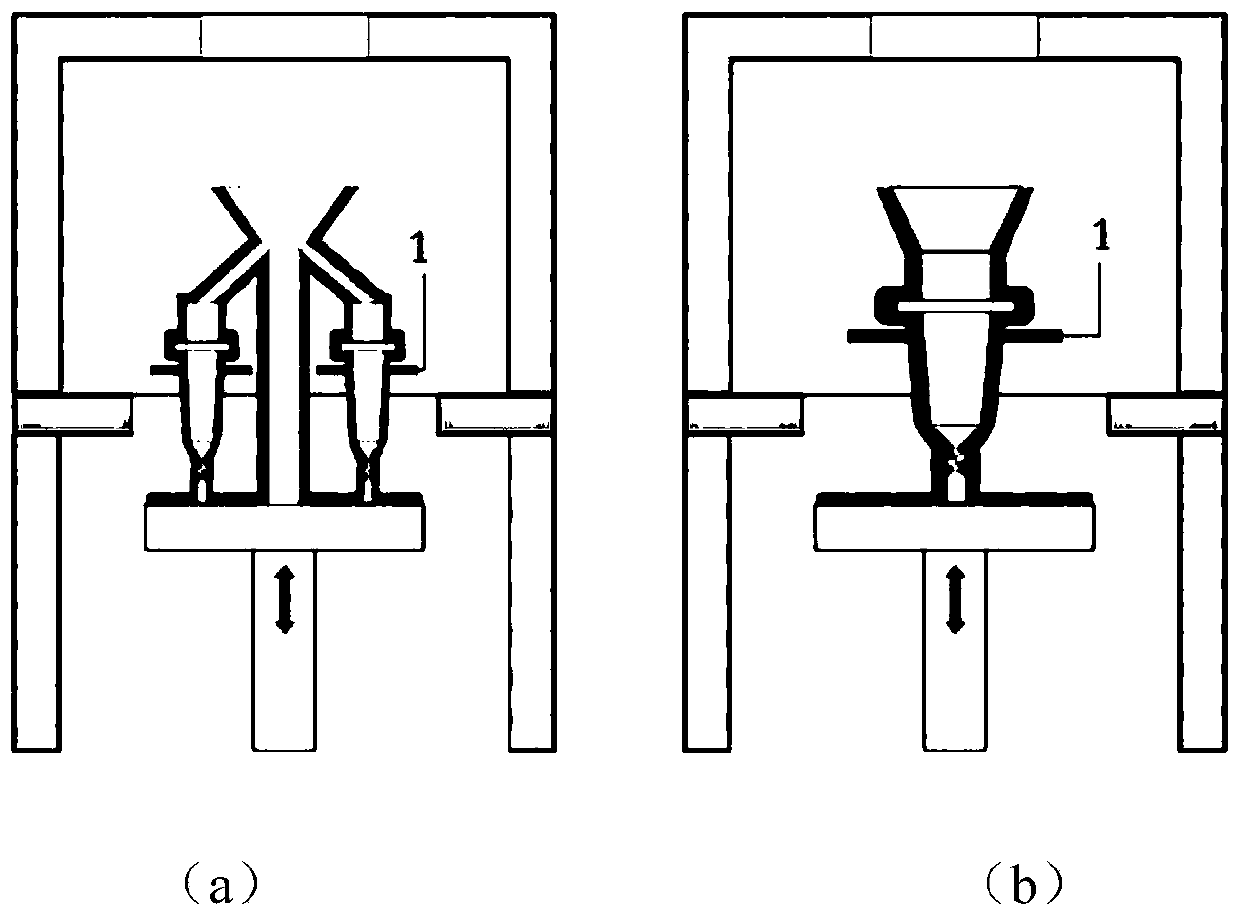

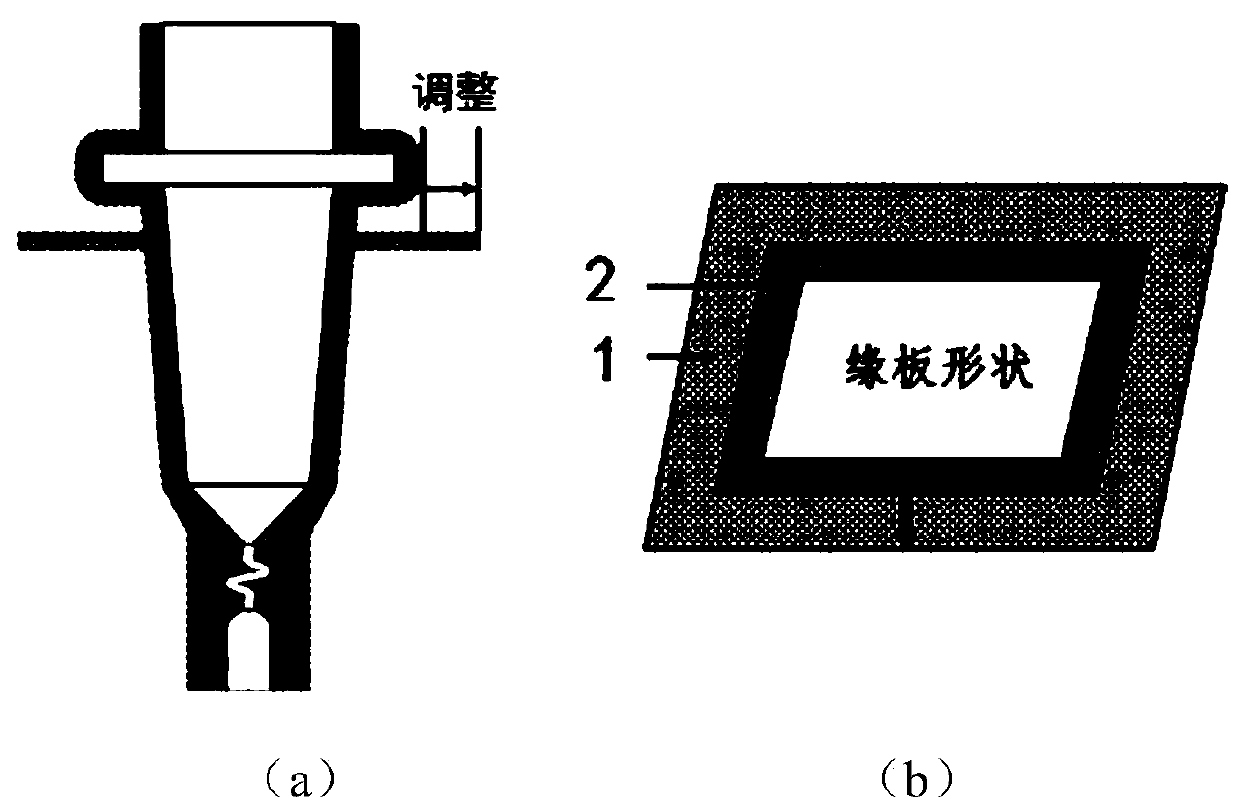

Integrated casting design method for controlling miscellaneous crystals of single crystal blade edge plate

InactiveCN110083927AReduce radiationThe preparation conditions are metGeometric CADFoundry mouldsEngineeringSingle crystal

The invention discloses an integrated casting design and preparation method for controlling miscellaneous crystals of single crystal blade edge plate, and belongs to the technical field of material processing. The technical scheme includes: establishing a computer-experimental analysis model for numerical simulation, analyzing the temperature field distribution of the blade margin plate positionin the orientation process to obtain a local supercooling area of the margin plate position in the solidification process; additionally arranging a baffle plate structure at the blade body to delay the external heat radiation of the protruding position of the edge plate, so as to prevent local supercooling nucleation generated by faster heat radiation at the edge of the edge plate from generatingmiscellaneous crystals; and finally, adopting the mold core / mold shell integrated technology based on the 3D printing technology to perform rapid preparation of the mold, and obtaining the single crystal blade mold with the baffle plate structure for directional solidification pouring. The method is suitable for preparation of single crystal blades of different sizes of gas turbines, can effectively avoid miscellaneous crystal defects at the positions of the blade edge plates, and improves the casting qualification rate of the single crystal blades.

Owner:XI AN JIAOTONG UNIV

Manufacturing method of restrictor of engine

InactiveCN105671437AImprove compactnessLess loose tendencyEngine controllersMachines/enginesMaterials scienceCooling methods

The invention particularly relates to a manufacturing method of a restrictor of an engine. The manufacturing method comprises the following steps: (1) manufacturing a fusible mold according to the size of the restrictor and manufacturing a mold case; (2) roasting the mold case at the temperature of 800-900 DEG C for 2-5 hours; (3) coating the surface of the inner side of the mold case with aluminum, wherein the coating temperature is 800-1,000 DEG C, and a cooling mode is air cooling; (4) configuring molten alloy according to requirements, and injecting the molten alloy into the mold case to obtain a casting; (5) normalizing and tempering the casting, and naturally cooling; (6) oxidizing the surface of the casting by using a discharge oxidation method to obtain a compact aluminum oxide film; (7) grinding the casting in a fine grinding mode to obtain a semi-finished product; and (8) secondarily normalizing and tempering the semi-finished product in a chamber electric furnace to obtain a finished product. The manufacturing method of the restrictor of the engine is simple in technology and low in equipment investment, and meanwhile, an engine valve which is good in wear resistance and large in hardness range can be obtained.

Owner:陈焕道

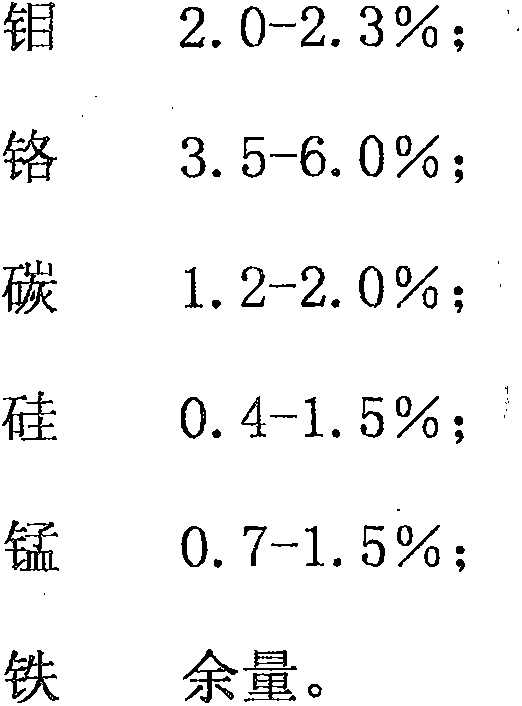

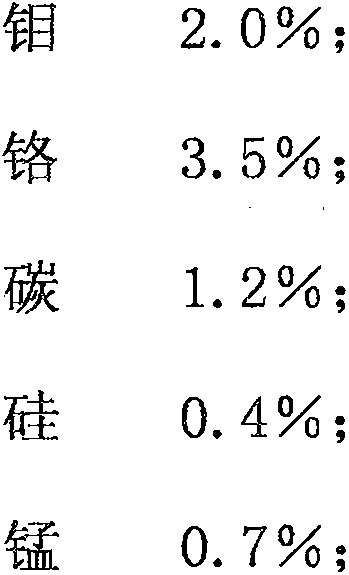

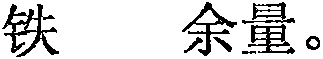

Thin-wall complex cylinder body type iron casting shell mold pouring system and casting process

InactiveCN111774537AQuality improvementReduce leakage scrap rateFoundry mouldsFoundry coresTemperature controlCylinder block

The invention relates to a thin-wall complex cylinder body type iron casting shell mold pouring system. The system involves a pouring outer mold, a sand core and a runner; a pouring cavity is formed in the pouring outer mold; the sand core is arranged in the pouring outer mold, and the sand core is used for forming a cylinder body casting; the runner comprises an ingate, and the ingate is connected to the interior of the sand core; and a cast iron liquid enters the pouring cavity from the ingate in a top pouring type balanced mode, and an oil pan face of the cylinder body casting is formed upwards in a vertical mode. A casting process comprises the steps of top cover core positioning, sand core combining, sand core fixing and bonding, pouring preparation, cylinder body pouring and aftertreatment, a low-temperature pouring scheme is implemented on the casting, and the effective pouring time and the additional pouring time are controlled. According to the system and the process, a molding mode of the pouring system is improved, so that a reasonable pouring temperature is designed, the effective pouring time is controlled, the uniformity of casting materials is good, the compactness of mass structures of a cylinder barrel section is high, the surface quality is good, the percent of pass of castings is high, and the system and the process are suitable for casting cylinder body castings without large equipment investment.

Owner:四川南部宏昊铸造有限公司

Surface layer shell type preparation method capable of effectively improving small-size concave profile rising

ActiveCN111203515ALow viscosityReduce surface tensionFoundry mouldsFoundry coresInvestment castingCoating

The invention relates to the field of shell type preparation of investment casting, in particular to a surface layer shell type preparation method capable of effectively improving a small-size concaveprofile rising. The preparation method comprises the following steps that a coating is prepared, specifically, a first coating is prepared, specifically, 1 part of silica sol, 0.5-1 part of water, 2.5-3.5 parts of an aggregate, 0.001-0.005 parts of a wetting agent in part by weight are prepared, sequentially added into a first batching barrel, and uniformly stirred to form the first coating; a second coating is prepared, specifically, 1 part of the silica sol, and 2.5-3.5 parts of the aggregate in part by weight are prepared, sequentially added into a second batching barrel, and uniformly stirred to form the second coating; a wax mold is pre-coated; and shell manufacturing is carried out. The first coating with low viscosity and low surface tension is used for pre-coating and treating thewax mold, so that a wet pre-coating layer is formed between a surface layer coating and the wax mold, the direct contact between the surface layer coating and the wax mold is avoided, the phenomenonof the bubble accumulation on the small-size concave profile of the wax mold due to the oversized surface tension of the surface layer coating can be avoided, and the rising of a casting is effectively reduced.

Owner:GUIYANG AVIC POWER PRECISION CASTING

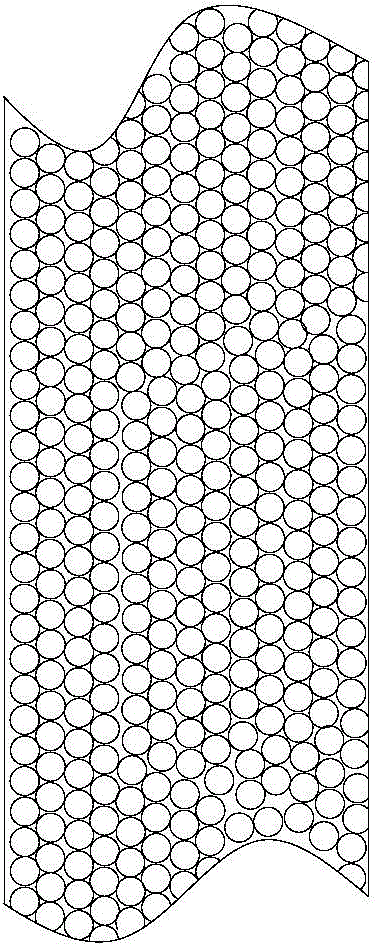

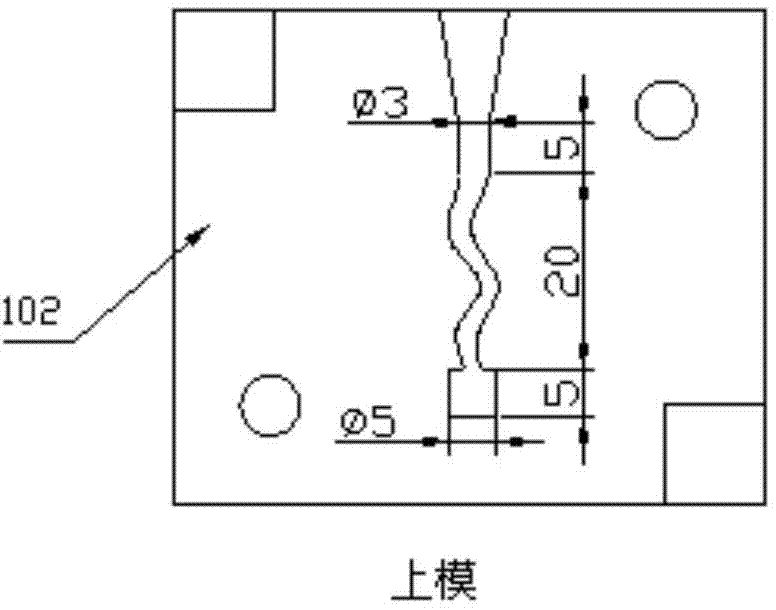

Spiral ceramic crystal selector and fabrication process of selector

The invention relates to a ceramic spiral crystal selector. The spiral ceramic crystal selector is characterized in that the outer part of the ceramic spiral crystal selector is in a column structure, the inner part of the ceramic spiral crystal selector is provided with a spiral through hole, and the diameter of the structural external contour is 8-15mm; the diameter of an initial segment of an internal space is 3-8mm, and the height of the initial segment of the internal space is 4-10mm; a spiral lead angle of a spiral segment of the internal space is 25-60 degrees, and the spiral diameter of the spiral segment of the internal space is 2-5mm; the diameter of an extending segment of the internal space is 2-5mm, and the height of the extending segment of the internal space is 4-10mm. A fabrication process of the spiral ceramic crystal selector comprises the following steps of firstly pressing a model by utilizing an internal shape fabrication mold group including an upper mold and a lower mold, then putting the model into an external contour forming mold group including a left mold, a right mold, an upper positioning block and a lower positioning block, finishing positioning, pouring ceramic slurry into the external contour forming mold group, taking out the slurry from the external contour forming mold group after the slurry is dried, and carrying out high-temperature roasting on the dry slurry to obtain the final spiral ceramic crystal selector. The spiral ceramic crystal selector and the fabrication process of the selector have the advantages that the fabrication is convenient, the use is easy; as a steel leakage problem caused by the position of the crystal selector is thoroughly solved, the cost of wasted alloys is lowered, and the casting yield is increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

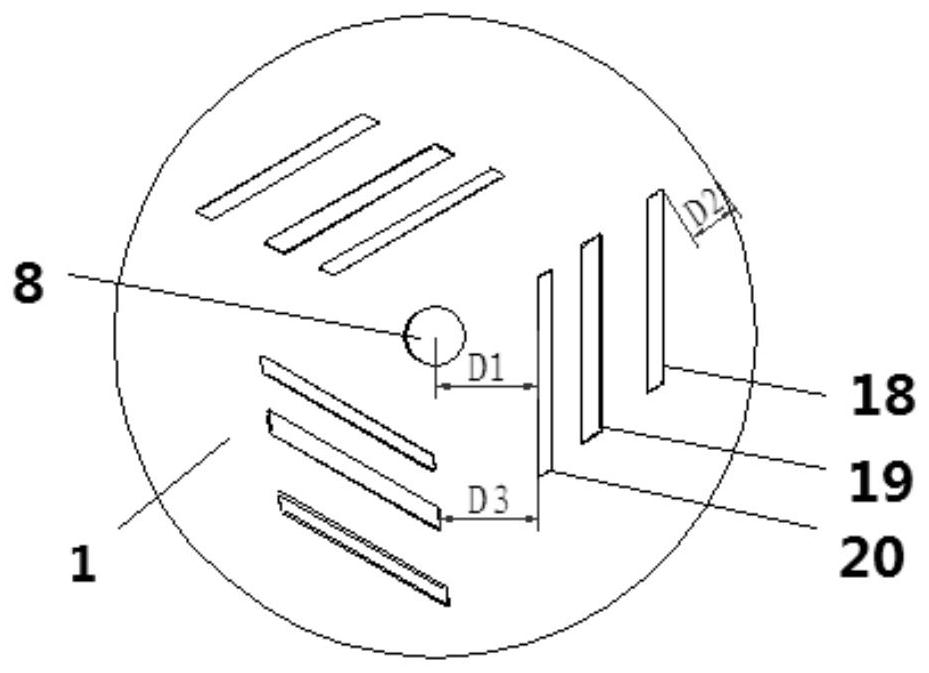

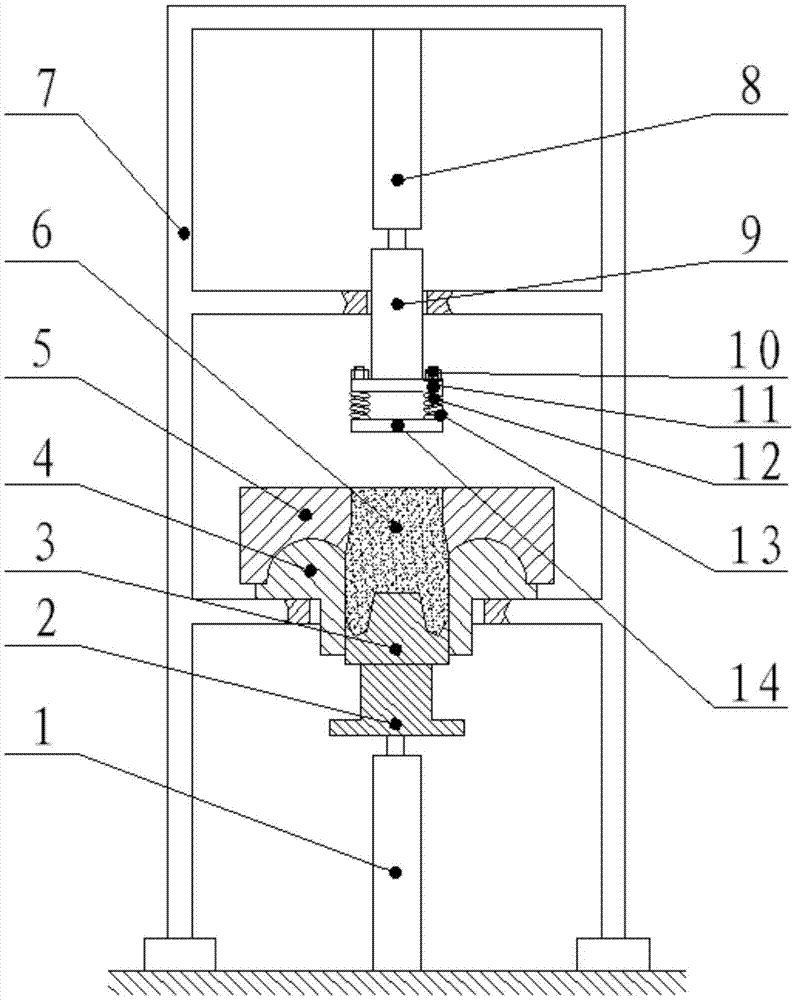

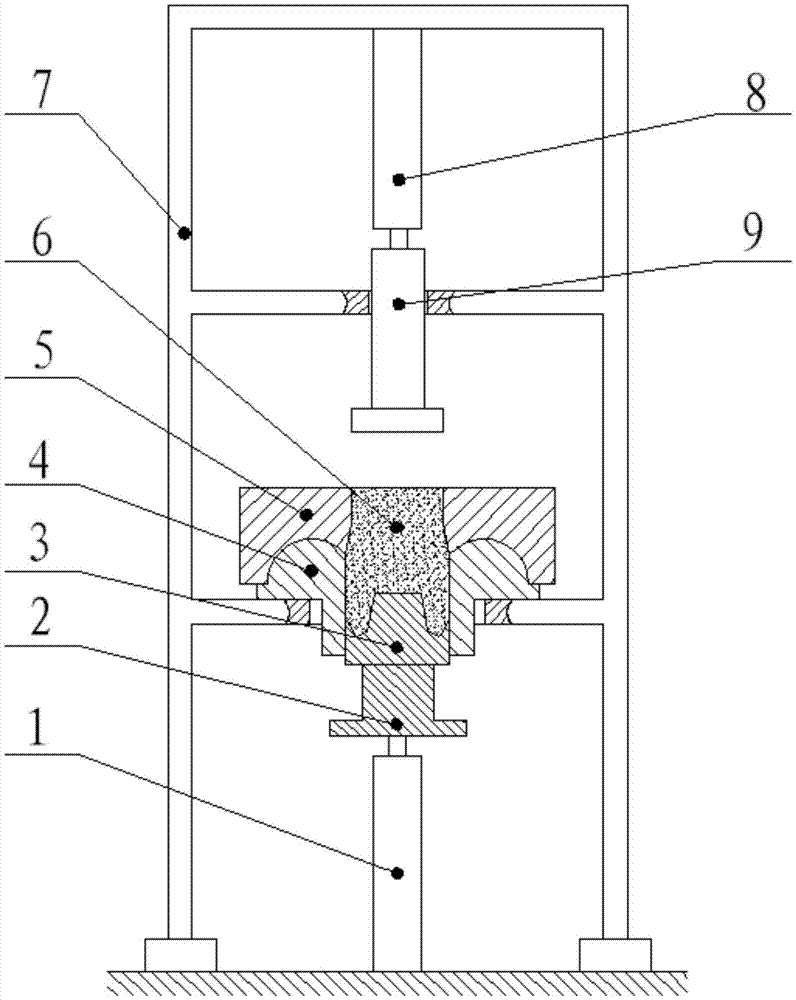

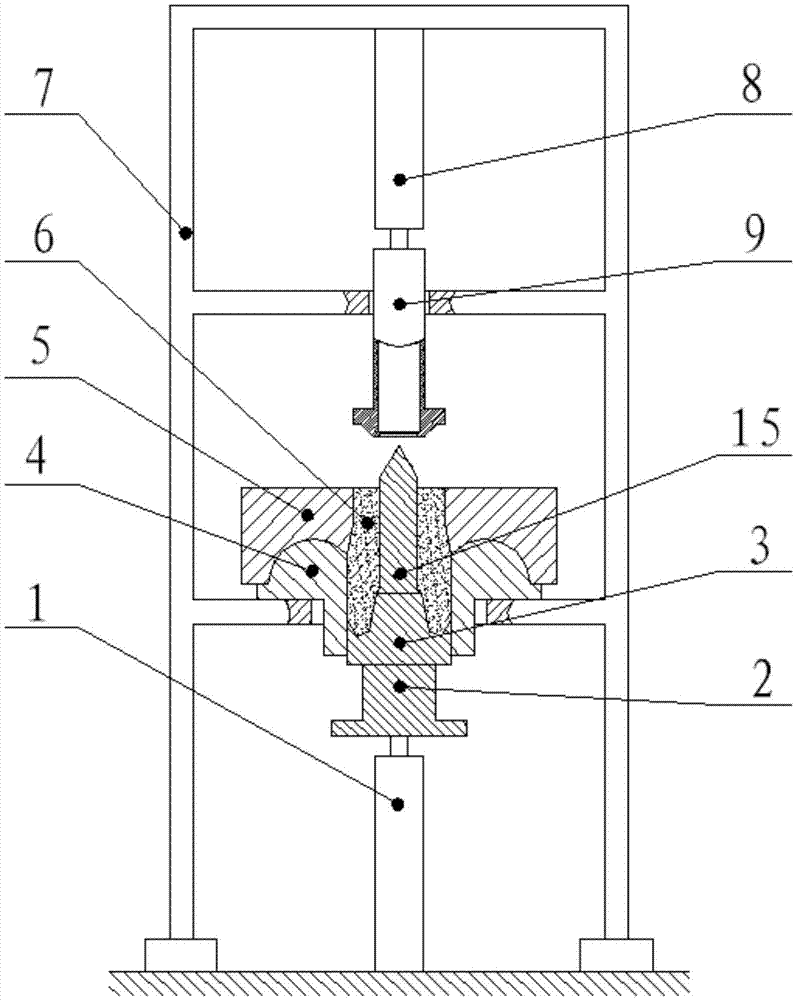

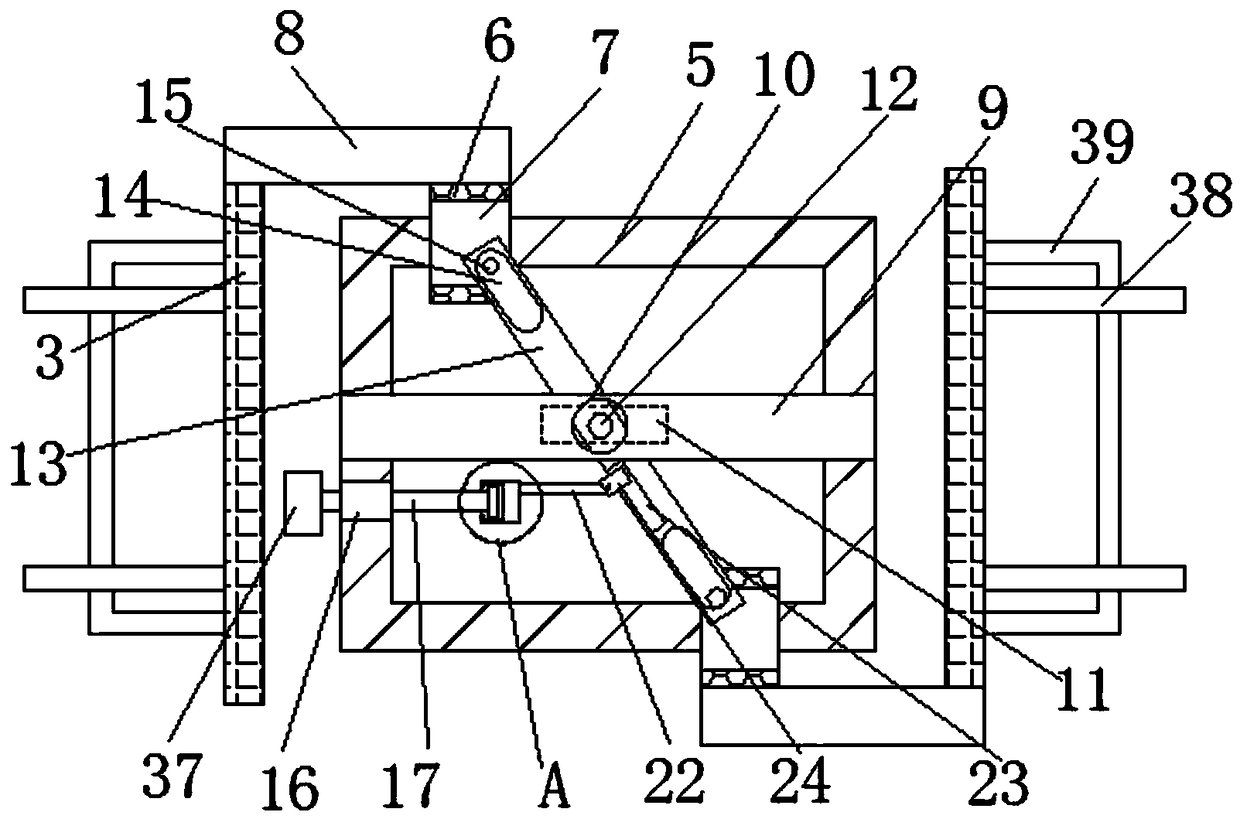

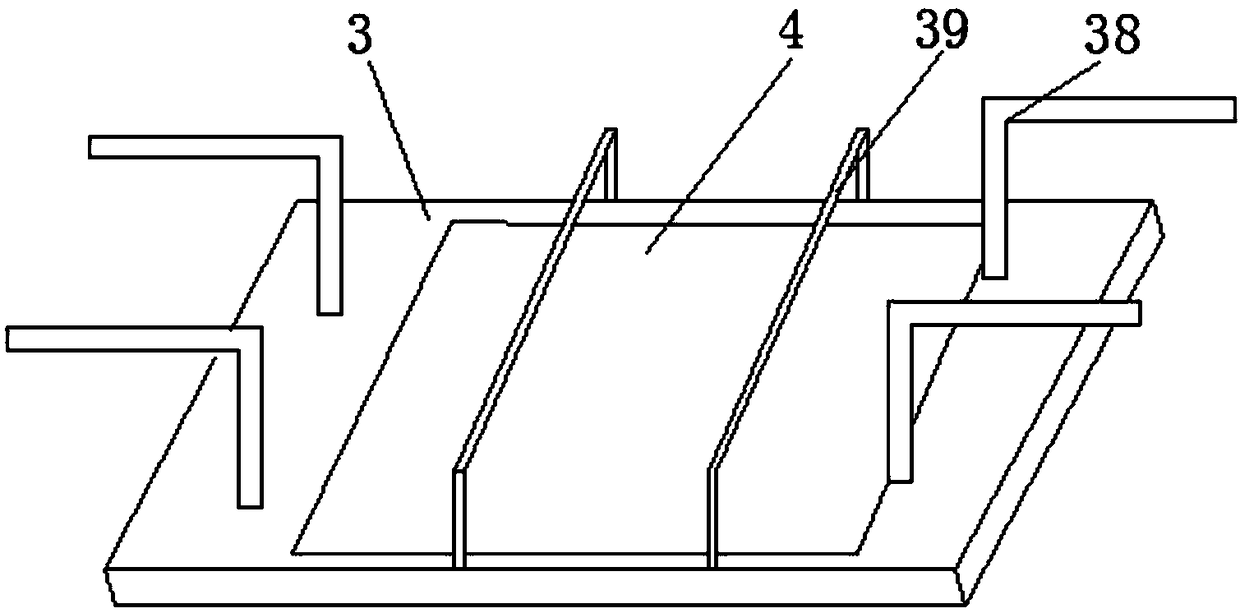

Sand mold molding device and sand mold molding methods

InactiveCN105436425AGood firmness and uniformityControllable firmnessMoulding machinesShape matchingComposite material

The invention relates to a sand mold molding device and sand mold molding methods. The sand mold molding device comprises a mold, a fixed mold plate, a moving mold plate and a compression bar mechanism, wherein the moving mold plate is movably inserted in a second inner cavity of the fixed mold plate from below in a shape matching manner, and is used for applying upward pressure to a parting surface of a sand mold; and the compression bar mechanism is vertically movably arranged above the mold, and is used for applying downward controllable pressure to a non-parting surface of the sand mold. One sand mold molding method comprises the steps of driving the moving mold plate to move upwards to apply upward pressure to the parting surface of the sand mold, and driving the compression bar mechanism to move downwards to apply downward controllable pressure to the non-parting surface of the sand mold at the same time. The other sand mold molding method comprises the steps of applying controllable pressure to the non-parting surface of the sand mold, and applying pressure to the parting surface, arranged opposite to the non-parting surface, of the sand mold at the same time. According to the sand mold molding device and the sand mold molding methods, the compactness and uniformity of the lower part of the sand mold and the air permeability of the upper part of the sand mold are good.

Owner:湖南华民控股集团股份有限公司

Production method of evanescent mold

InactiveCN108907079AMeet needsImprove casting qualityFoundry mouldsFoundry coresAdhesiveMolding machine

The invention discloses a production method of an evanescent mold. The production method comprises the following steps: selecting materials: the particle size of a selected original bead is equal to one eighth of a minimum wall thickness of a casting; pre-foaming: curing, foaming, and sending into a molding machine; producing and stereotyping a mold: introducing steam into the molding machine, secondarily foaming, and molding; assembling the mold: naturally drying the molded mold, transferring into a baking house, bonding the baked mold by virtue of adhesive, and then air drying; paint the mold: preparing the paint; and drying: after the mold is coated with a first coating, sending the mold into the baking house, smearing a second coating, after the second coating is smeared, sending intothe baking house, smearing a third coating, and after the third coating is coated, sending the mold into the baking house. When the evanescent mold prepared in the invention is used for processing thecasting, the casting is good in quality, smooth in surface, fewer in burrs, high in qualification rate, and capable of meeting the requirements of customers.

Owner:JIANGSU CHENLONG VALVE MFG CO LTD

Valve body casting for vehicle-mounted pump

InactiveCN107035679AHighly integratedCompact and reasonable structurePositive displacement pump componentsFoundry mouldsIn vehicleHigh lift

The invention discloses a valve body casting for a vehicle-mounted pump and particularly discloses a large-tonnage and high-lift valve body casting for a concrete vehicle-mounted pump. The casting comprises a main valve body, valve core through holes, a straight runner, an inclined runner, runner ports and a plurality of auxiliary runners; the two valve core through holes are designed in the valve body; the runner ports are located in various surfaces of the valve body and correspond to and communicate with the valve core through holes, a circular oil groove, the straight runner, the inclined runner and the auxiliary runners in the valve body; and the plurality of auxiliary runners are used for connecting the runners in the valve body to enable the runners to communicate with one another. The valve body has the advantages of being reasonable and compact in structure, reliable in action, multiple in function and long in service life.

Owner:南通华东油压科技有限公司

Box separation frame for modeling

The invention discloses a box separation frame for modeling. The box separation frame comprises two sand boxes, wherein one sand box is correspondingly placed on the top side of the other sand box; side lugs are fixedly mounted on two sides of the two sand boxes; hook racks are arranged on two sides of the sand box; hook holes are formed in mutually close sides of the two hook racks; mutually awaysides of the two side lugs respectively extend into the two hook holes; a mounting basket is arranged above the hook racks; two moving blocks are connected to the mounting basket in a sliding manner;a moving hole is formed in one side of each of the two moving blocks. The box separation frame for modeling is simple in design and convenient to operate; after the box separation frame is used, box-staggered rejected products caused by striking the sand boxes with a wooden mallet are reduced, and the casting qualification rate can be increased; manmade box staggering caused by box separation isavoided, so that rejected products caused by the manmade box staggering are reduced; meanwhile, a distance between the two hook racks can be adjusted, and a distance between two push plates can be adjusted; the box separation frame for modeling can adapt to sand boxes of different sizes and side lugs of different sizes, so that the universality of the device is improved, and demands of people aremet.

Owner:济南市平阴县玛钢厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com