Fired mold capable of improving mold-filling capacity of complicated thin-walled part of hard-mold-filling-type high temperature alloy

A high-temperature alloy and mold filling technology, which is applied in the direction of mold, core, mold composition, etc., can solve problems such as under-casting, cracks, and a large range of alloy mushy areas, so as to reduce under-casting and improve casting pass rate , The effect of saving master alloy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] All directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention are only used to explain the relative positional relationship between the components in a certain posture (as shown in the accompanying drawings) , sports conditions, etc., if the specific posture changes, the directional indication also changes accordingly.

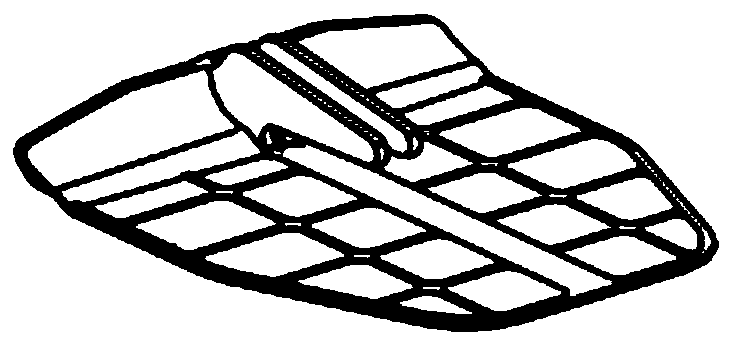

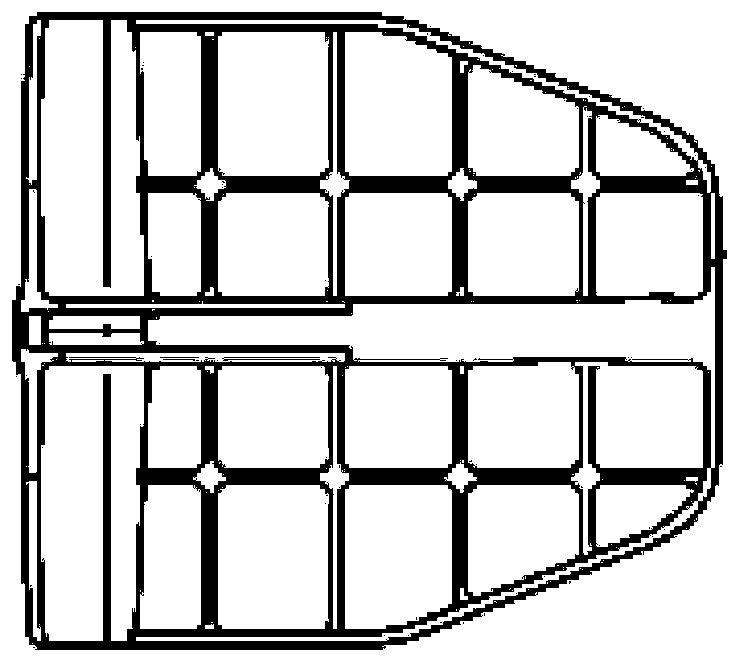

[0027] Such as Figure 1~2 As shown, it is a difficult-to-fill superalloy complex thin-walled part involved in the present invention. The outline size is 200.5mm×100mm. The thickness of the bottom plate is divided into left and right ends. 0.8mm. In the middle is a load-bearing main rib with a thickness of about 0.6mm to 1.0mm, and the overall structure is a criss-cross rib with a thickness of 0.6mm to 1mm. For the complex thin-walled part of the difficult-to-fill superalloy, the following investment model is designed:

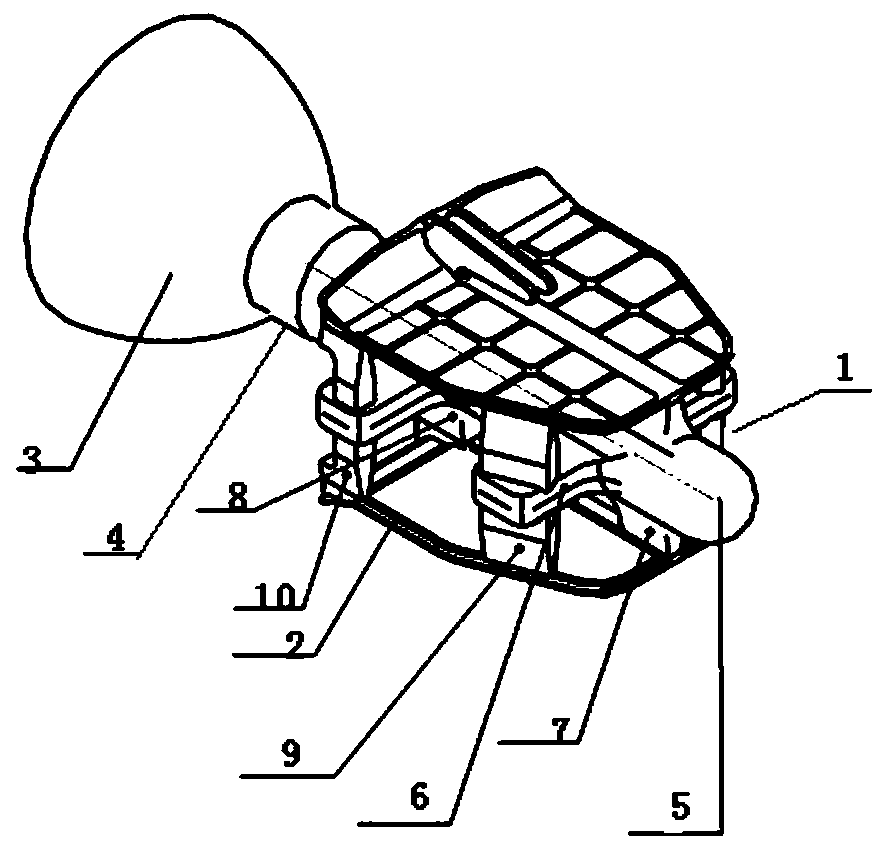

[0028] Such as image 3 As shown, an investment mold to improve the fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com