Hollow cast ceramic core and its preparation method

A technology for ceramic cores and castings, which is applied in the field of hollow casting ceramic cores and their preparation, and achieves the effects of small shrinkage, good high-temperature strength, and improved product life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

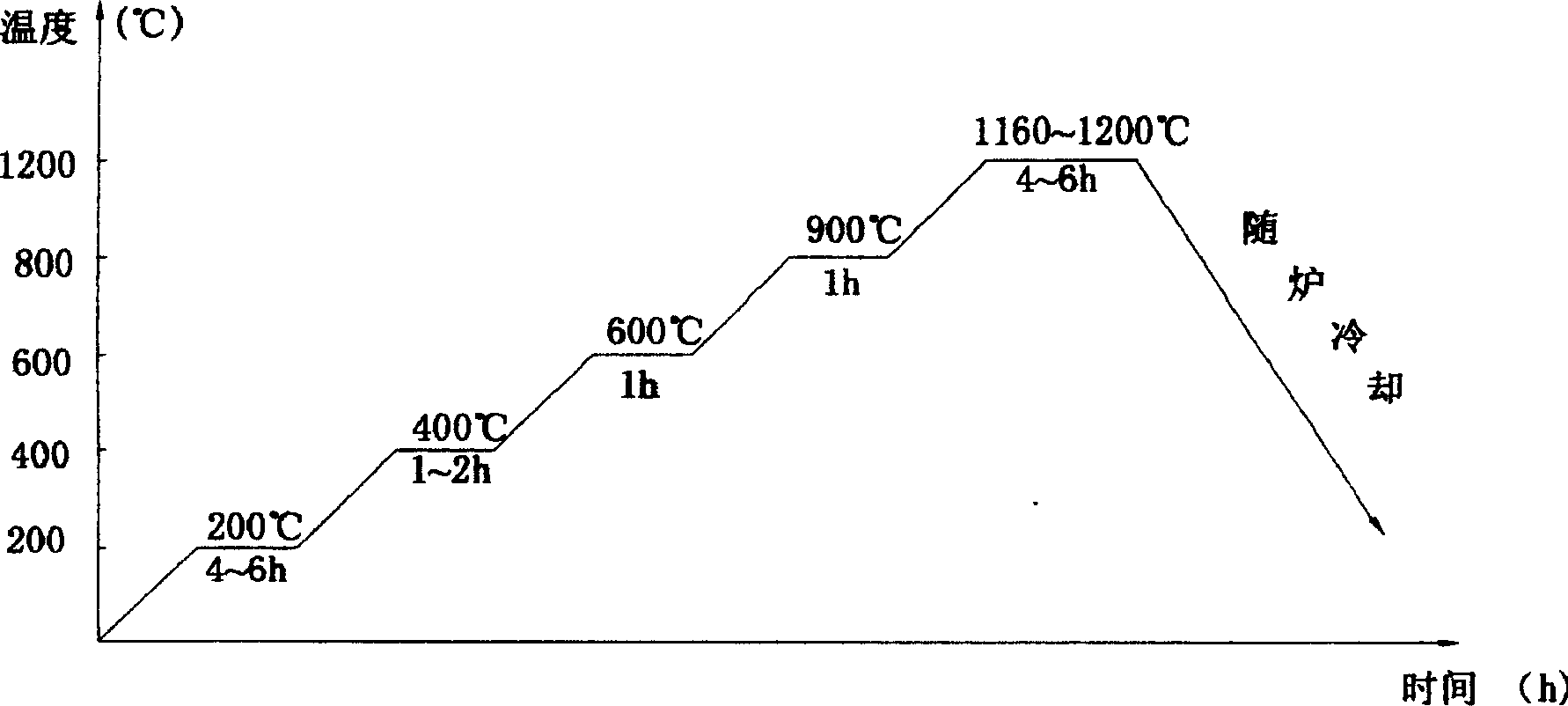

Method used

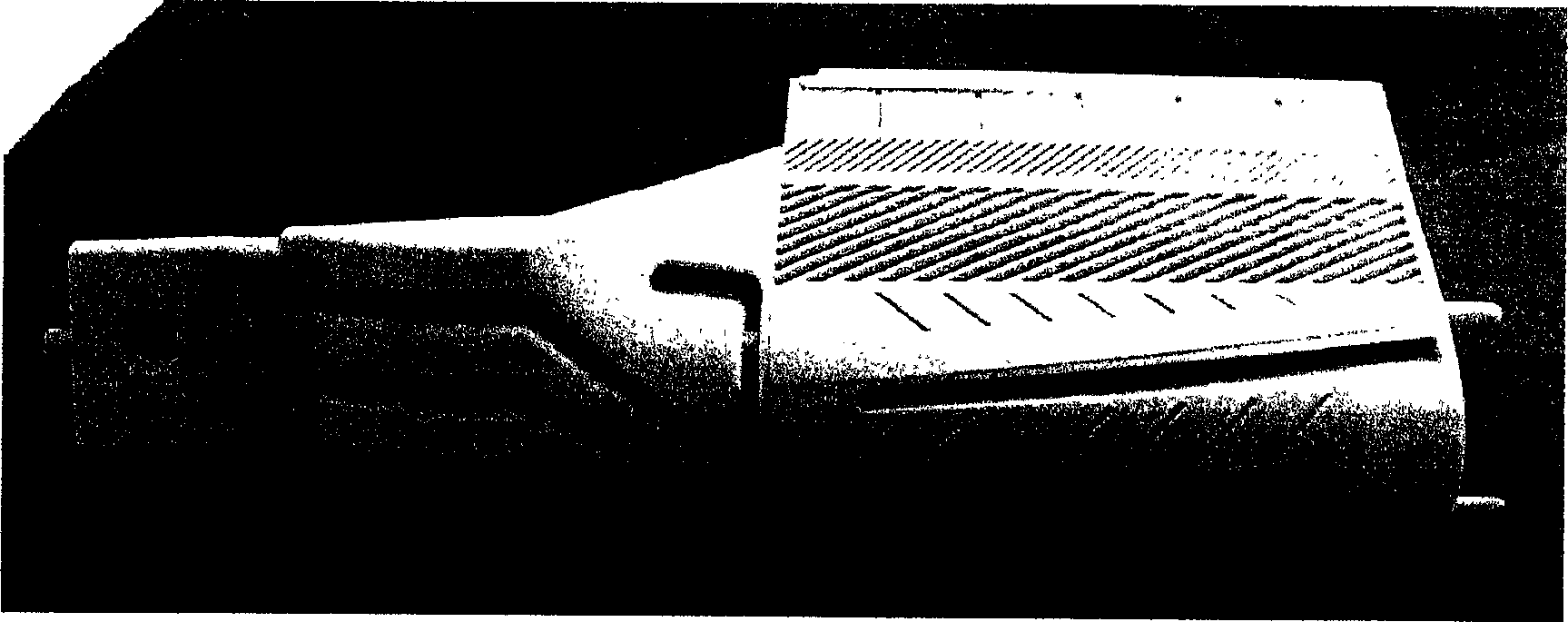

Image

Examples

Embodiment 1

[0030] 1. Ingredients

[0031] The matrix material is a mixture of quartz glass powder and silica porous material, and the quartz glass powder accounts for 60% of the matrix material by weight percentage, and the silica porous material accounts for 40% of the matrix material; the mineralizer material is selected from mullite (3Al 2 o 3 .2 SiO, particle size ≤ 53 μm, GB / T12215-90, produced by Meihekou), the proportion of core material is calculated by weight percentage: 83% of matrix material, 17% of mineralizer material. The plasticizer material is a mixture of 97% white paraffin (GB254-87, 50~60#) and 3% high-pressure polyethylene (HG2-299-65, A grade) by weight percentage, and the plasticizer material accounts for the base material and mineral 16% of the total weight of the agent material.

[0032] Quartz glass powder is made of quartz glass balls (JC177-81, SiO 2 ≥99.97%) made by ball milling. According to the weight ratio of quartz glass: grinding ball: water, the prop...

Embodiment 2

[0050] 1. Ingredients

[0051] The matrix material is a mixture of quartz glass powder and silica porous material. Quartz glass powder accounts for 80% of the matrix material, silica porous material accounts for 20% of the matrix material, and the mineralizer material is mullite (3Al 2 o 3 .2 SiO, particle size ≤ 53 μm, GB / T12215-90, produced by Meihekou), the core material is composed of matrix material and mineralizer material, and the proportioning is calculated by weight percentage: 85% of matrix material and 15% of mineralizer material. The plasticizer material is a mixture of 97% white paraffin (GB254-87, 50~60#) and 3% high-pressure polyethylene (HG2-299-65, A grade) by weight percentage, and the plasticizer material accounts for the base material and mineral 18% of the total weight of the agent material.

[0052] Quartz glass powder is made of quartz glass balls (JC177-81, SiO 2 ≥99.97%) made by ball milling. According to the weight ratio of quartz glass: grinding ...

Embodiment 3

[0070] 1. Ingredients

[0071] The matrix material is a mixture of quartz glass powder and silica porous material, the quartz glass powder accounts for 70% of the matrix material, the silica porous material accounts for 30% of the matrix material, and the mineralizer material is mullite (3Al 2 o 3 .2 SiO, particle size ≤ 53 μm, GB / T12215-90, produced by Meihekou), the core material is composed of matrix material and mineralizer material, and the proportioning is calculated by weight percentage: 80% of matrix material and 20% of mineralizer material. The plasticizer material is a mixture of 97% white paraffin (GB254-87, 50~60#) and 3% high-pressure polyethylene (HG2-299-65, A grade) by weight percentage, and the plasticizer material accounts for the base material and mineral 15% of the total weight of the agent material.

[0072] Quartz glass powder is made of quartz glass balls (JC177-81, SiO 2 ≥99.97%) made by ball milling. According to the weight ratio of quartz glass: g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com