Manufacturing method of narrow-flow-channel closed impeller

A technology for closed impellers and manufacturing methods, which is applied to non-variable pumps, parts of pumping devices for elastic fluids, machines/engines, etc., and can solve the problems of difficulty in manufacturing narrow channel closed impellers, etc. Achieve the effect of ensuring the size of the runner and surface roughness and improving the casting pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

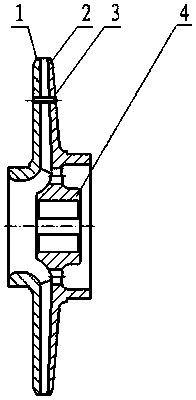

[0017] A method for manufacturing a narrow-channel closed impeller according to the present invention, the narrow-channel closed impeller is designed as a split front cover 1 and an open impeller body, the open impeller body includes a rear cover 2, and the The blades on the front side plate of the rear cover, and the center of the rear cover is provided with a hub 4 for connecting the pump shaft;

[0018] The specific manufacturing steps are as follows:

[0019] Step a, processing of the open impeller body: firstly, the blank of the open impeller body is made by using a casting mold, and the blank of the open impeller body after casting is fully polished. The open-type impeller body exposes the sand inclusions on the inner wall of the impeller flow channel and the dead corner of the casting that could not be processed before, so as to facilitate sand cleaning and grinding and processing; and then process positioning pin holes on each blade of the open-type impeller body;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com