Patents

Literature

40results about "Mould loosening devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

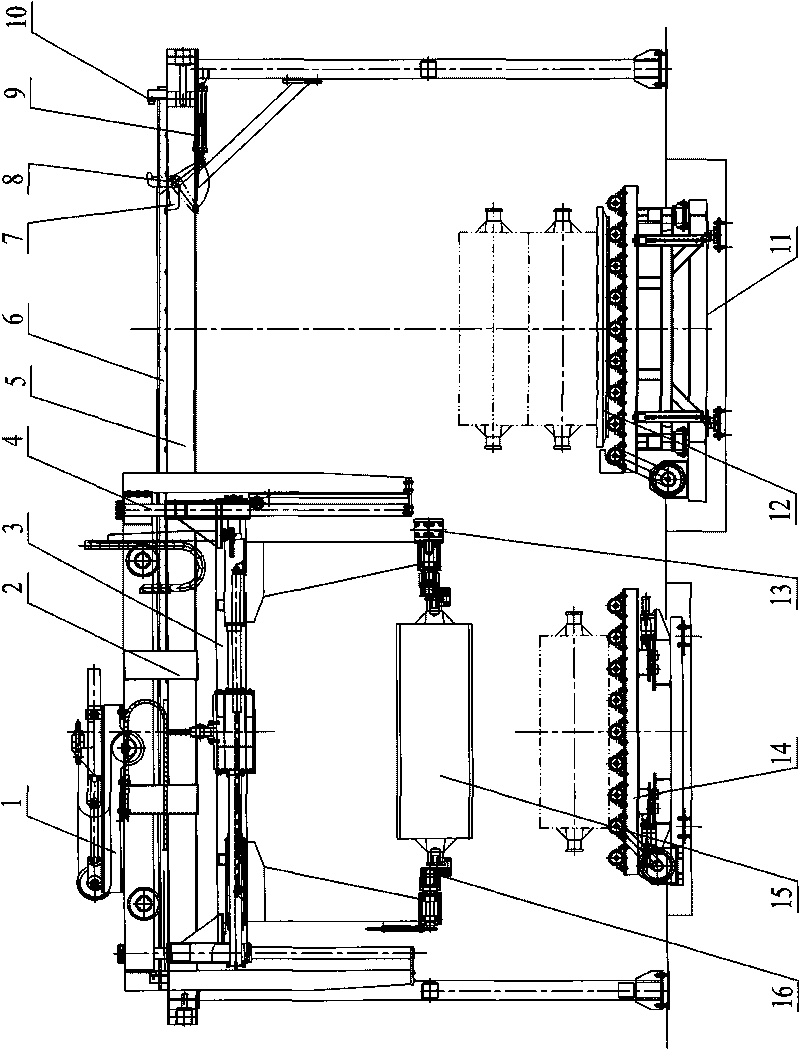

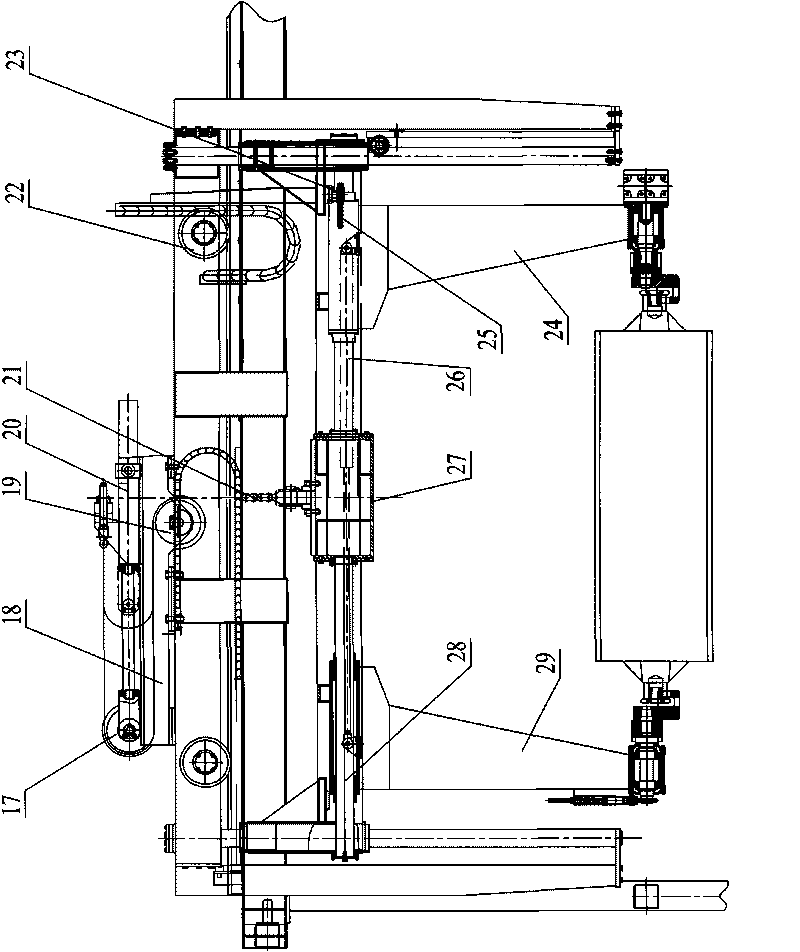

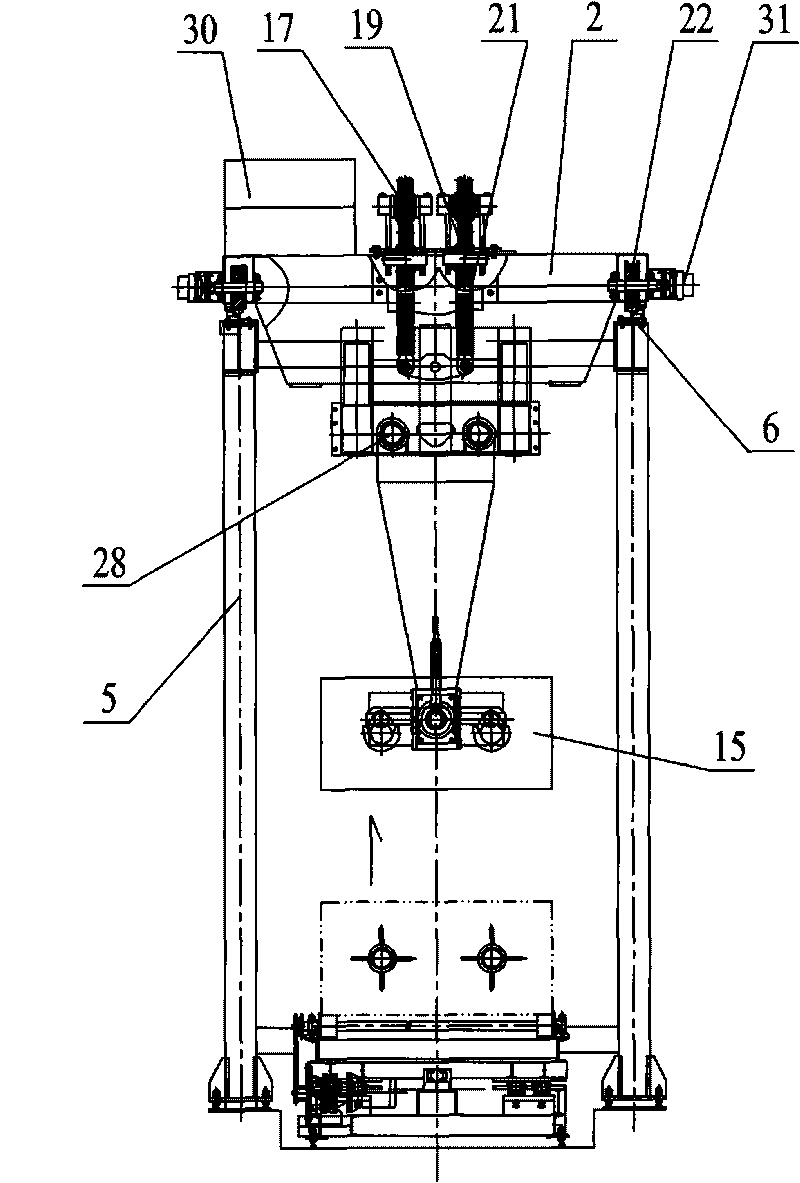

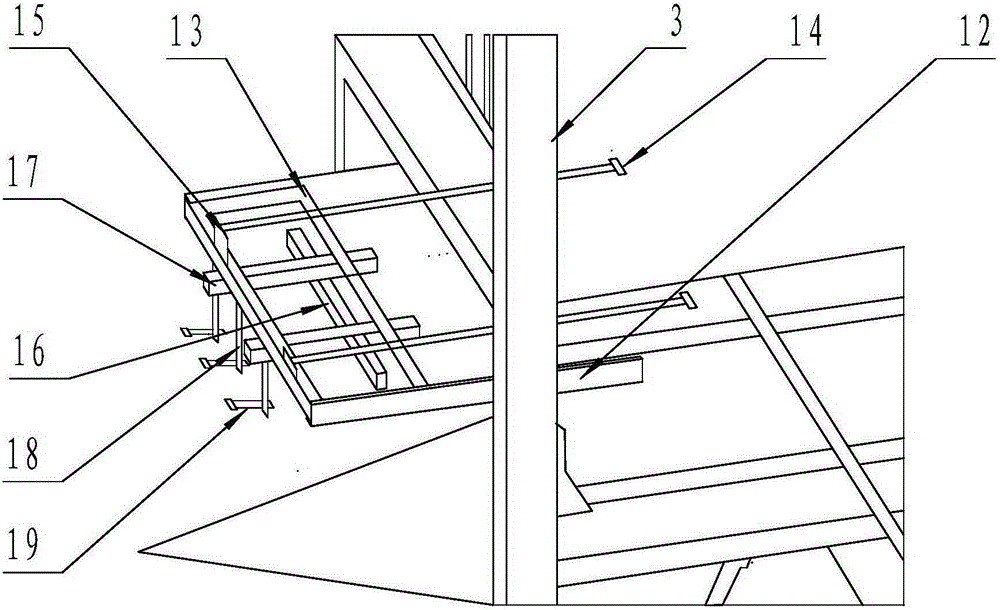

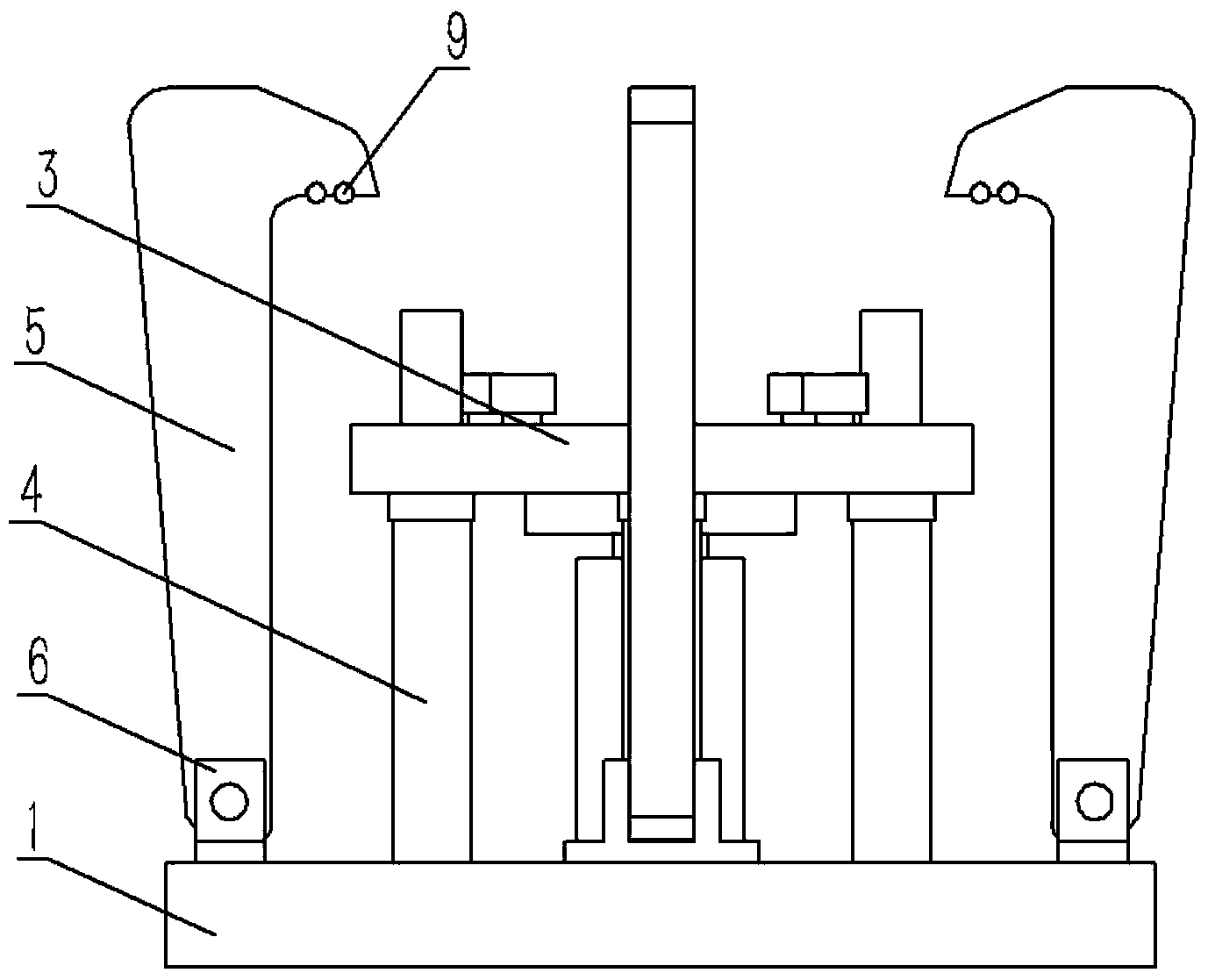

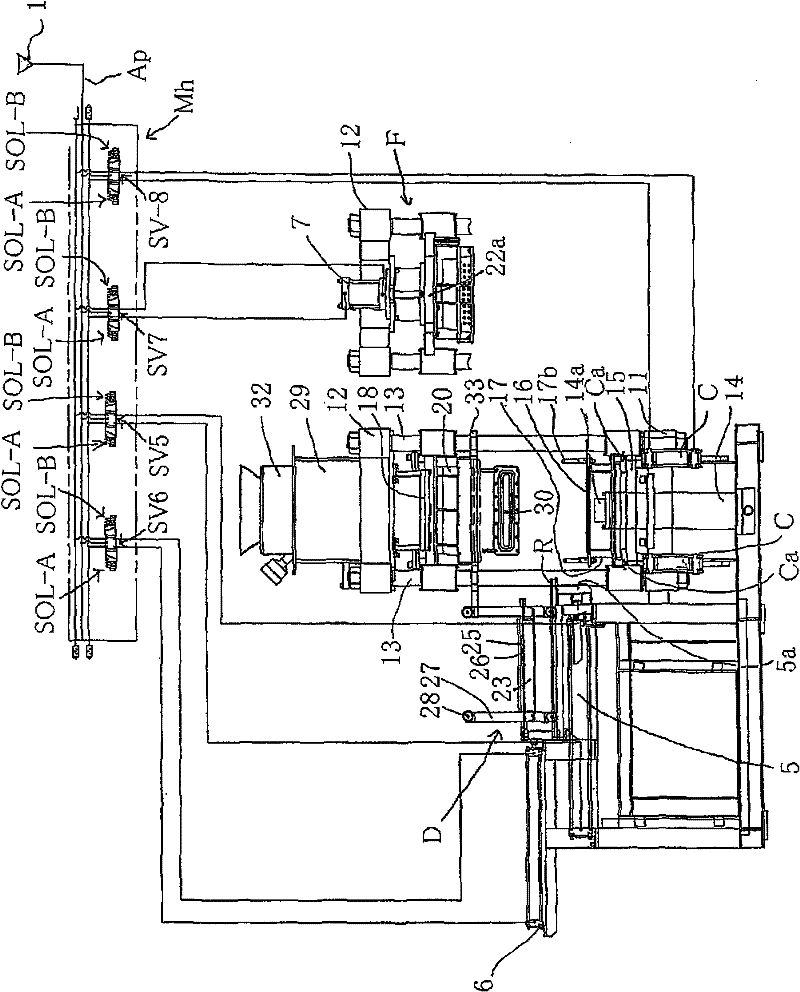

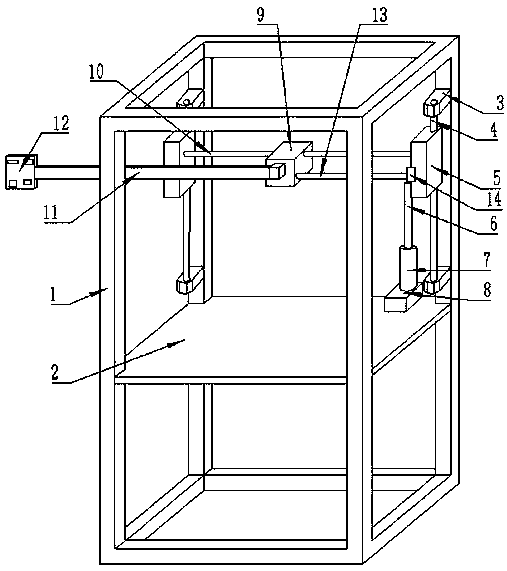

Large drawing and overturning molding box closer

ActiveCN101758166AIncrease production capacityImprove machining accuracyMould loosening devicesProduction lineVehicle frame

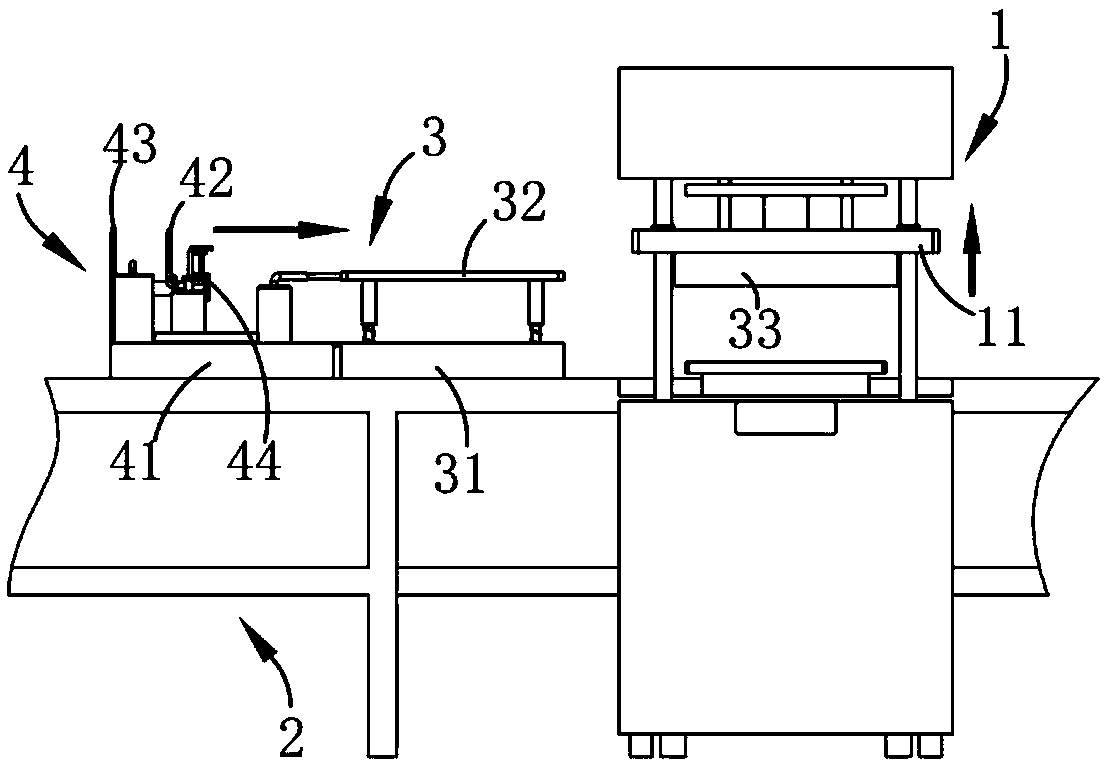

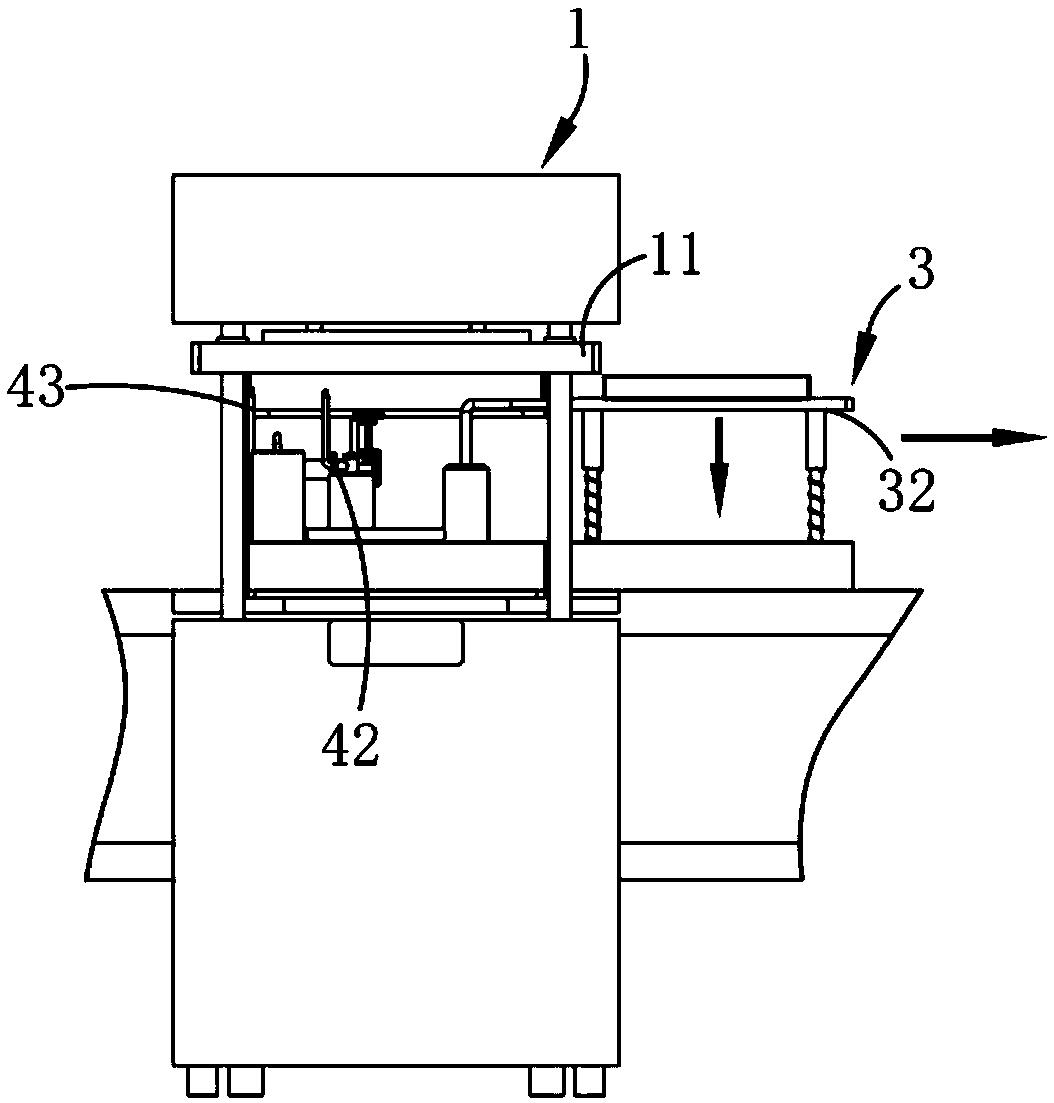

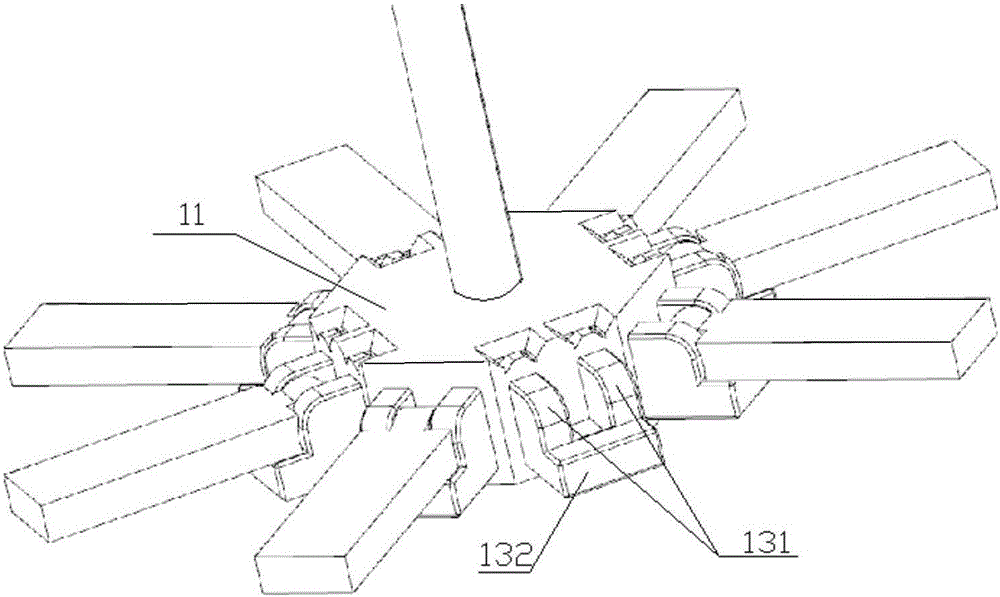

The invention belongs to the technical field of casting, relating to a large drawing and overturning molding box closer. A lead rail is mounted on a fixed framework on which a mobile frame is placed and slides horizontally; a limiting baffle is mounted on the right side of the fixed framework for limiting the sliding position of the mobile frame; a hydraulic lifting mechanism is mounted on the mobile frame and is connected with a hydraulic extensible mechanism and can lift and drop the hydraulic extensible mechanism. A mechanical hand is mounted on the hydraulic extensible mechanism for supporting and releasing the molding flask. A rotary motor is mounted on the mechanical hand to control the rotation of the mechanical hand. The invention is controlled by the all-hydraulic system and has good work coordination, safety and reliability and high precision of functional actions such as drawing, overturning and mould closing. The invention has the advantages of greatly simplified operation sequences and high degree of automation, thereby lightening the labor intensity and enhancing the mechanic production capacity and the machining accuracy of casting production line.

Owner:WUXI XINAN FOUNDARY MACHINERY

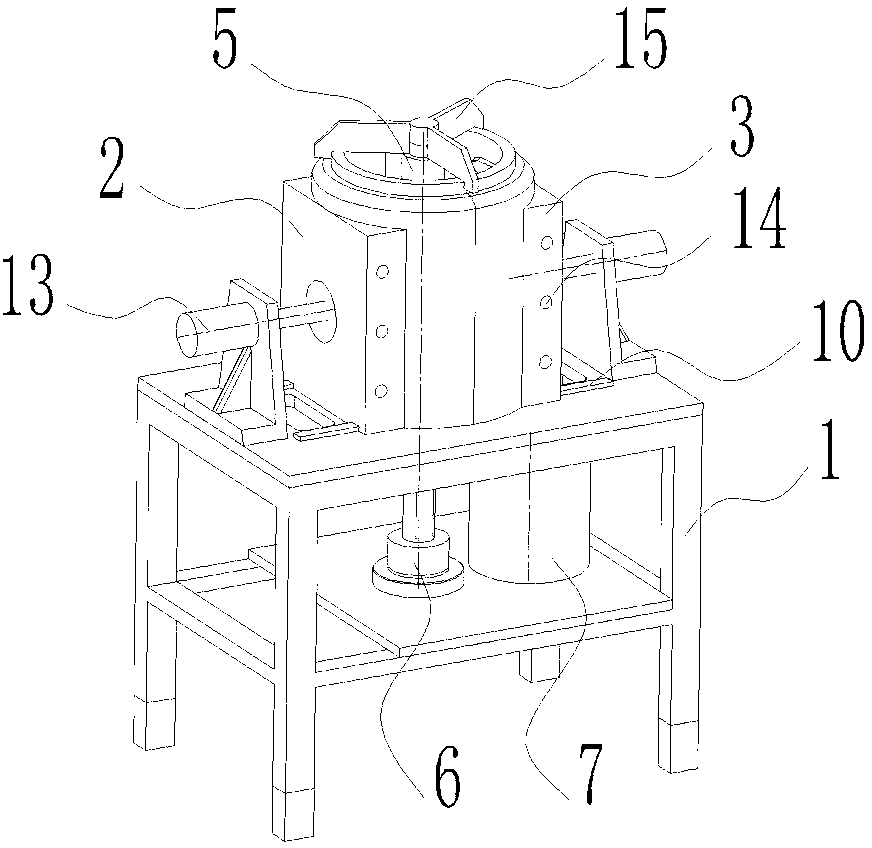

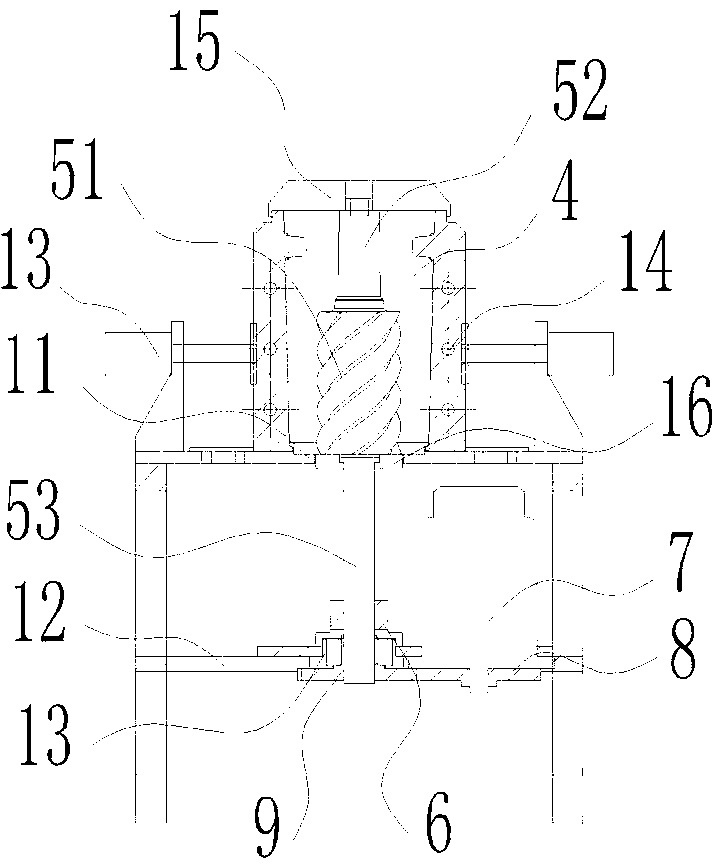

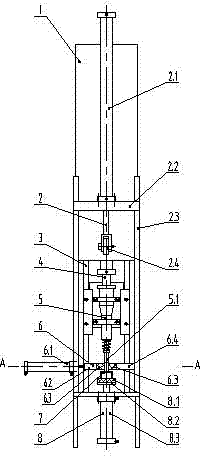

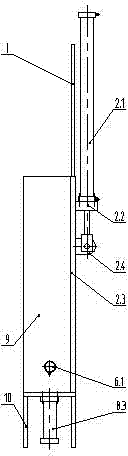

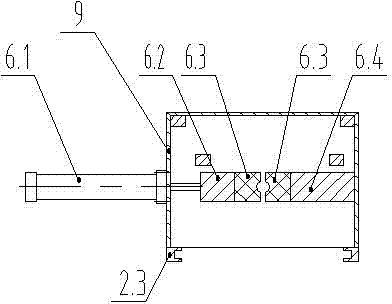

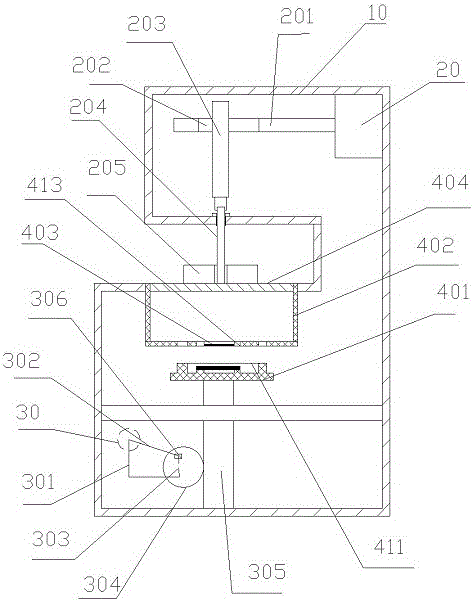

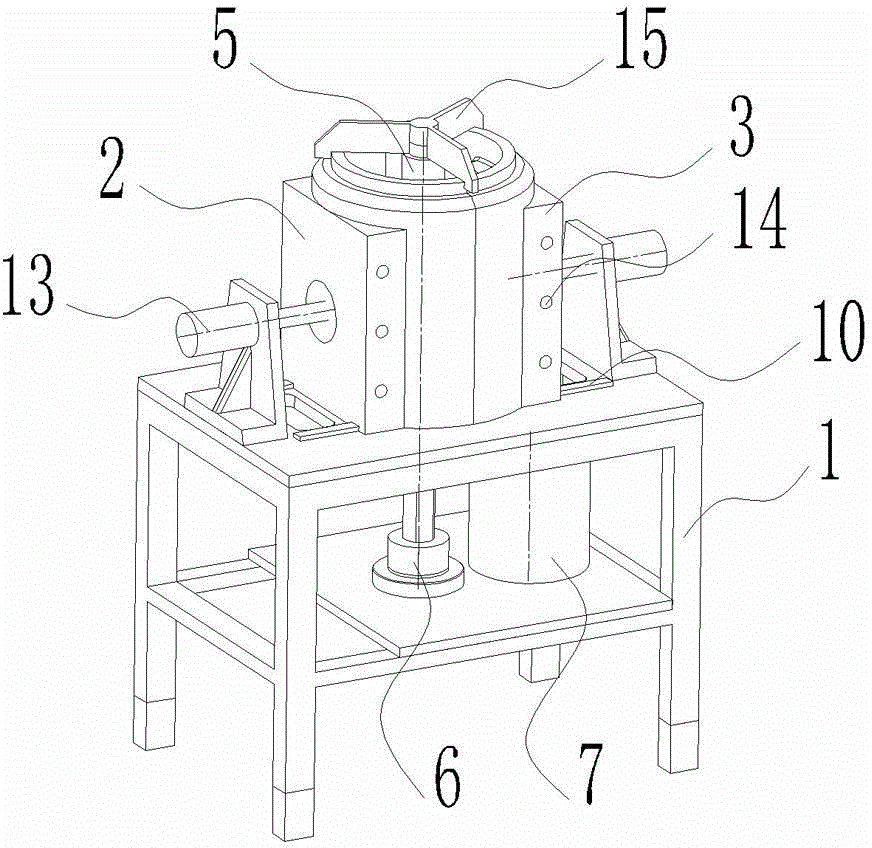

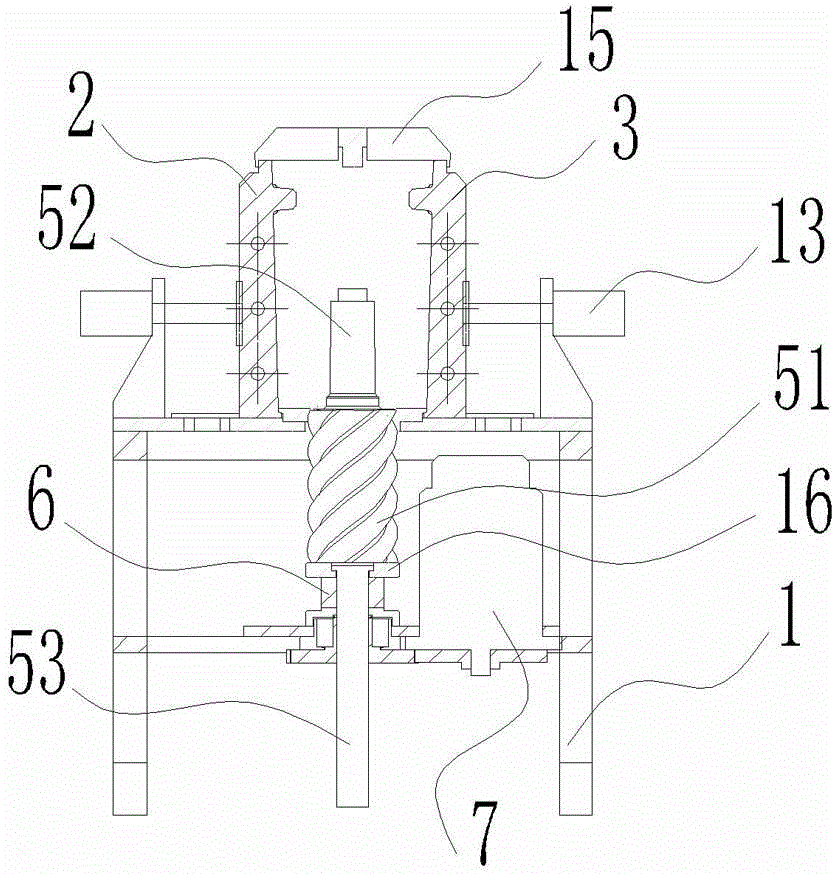

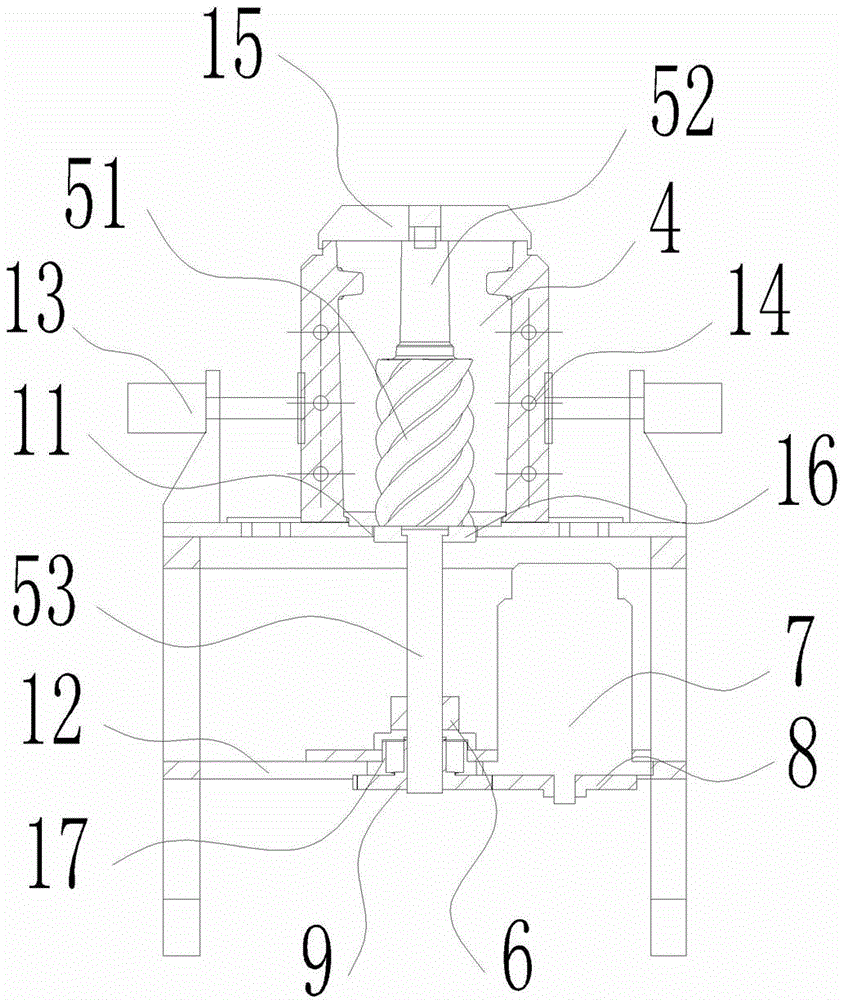

Sand core automatic demoulding mechanism and demoulding method for screw compressor rotor

ActiveCN102909321AQuality assuranceThe speed is stable and easy to controlMould loosening devicesHeater RodEngineering

The invention relates to the field of casting and provides a sand core automatic demoulding mechanism and a demoulding method for a screw compressor rotor, wherein the sand core automatic demoulding mechanism has an ingenious design, sufficiently utilizes the characteristic of a screw thread on the surface of the rotor to carry out demoulding and has a high production efficiency and a high quality. The invention solves the technical problems that in the prior art, the production efficiency is low, the labor intensity of workers is high, a sand core has a poor quality, the quality of the screw compressor rotor cannot be ensured and the like. The sand core automatic demoulding mechanism comprises a bracket, a left die and a right die, wherein the left die and the right die can relatively slide on the bracket along the horizontal direction; after the left and right dies are abutted, a synthetic sand core cavity is surrounded; a screw compressor rotor core rod is arranged at the middle part of the sand core cavity; and the screw compressor rotor core rod is screwed on the bracket and can be driven by a driving mechanism to rotationally enter and exit the synthetic sand core cavity. In the demoulding process, firstly, resin sand is placed into the sand core cavity to be tamped and the upper surface of the resin sand is scraped by a sand scraper; the resin sand is cured by a heating rod; and then the driving mechanism is started to screw out the screw compressor rotor core rod; and finally, the left and right dies are driven by the cylinder to slide outward to be demoulded.

Owner:桐乡合德机械有限公司

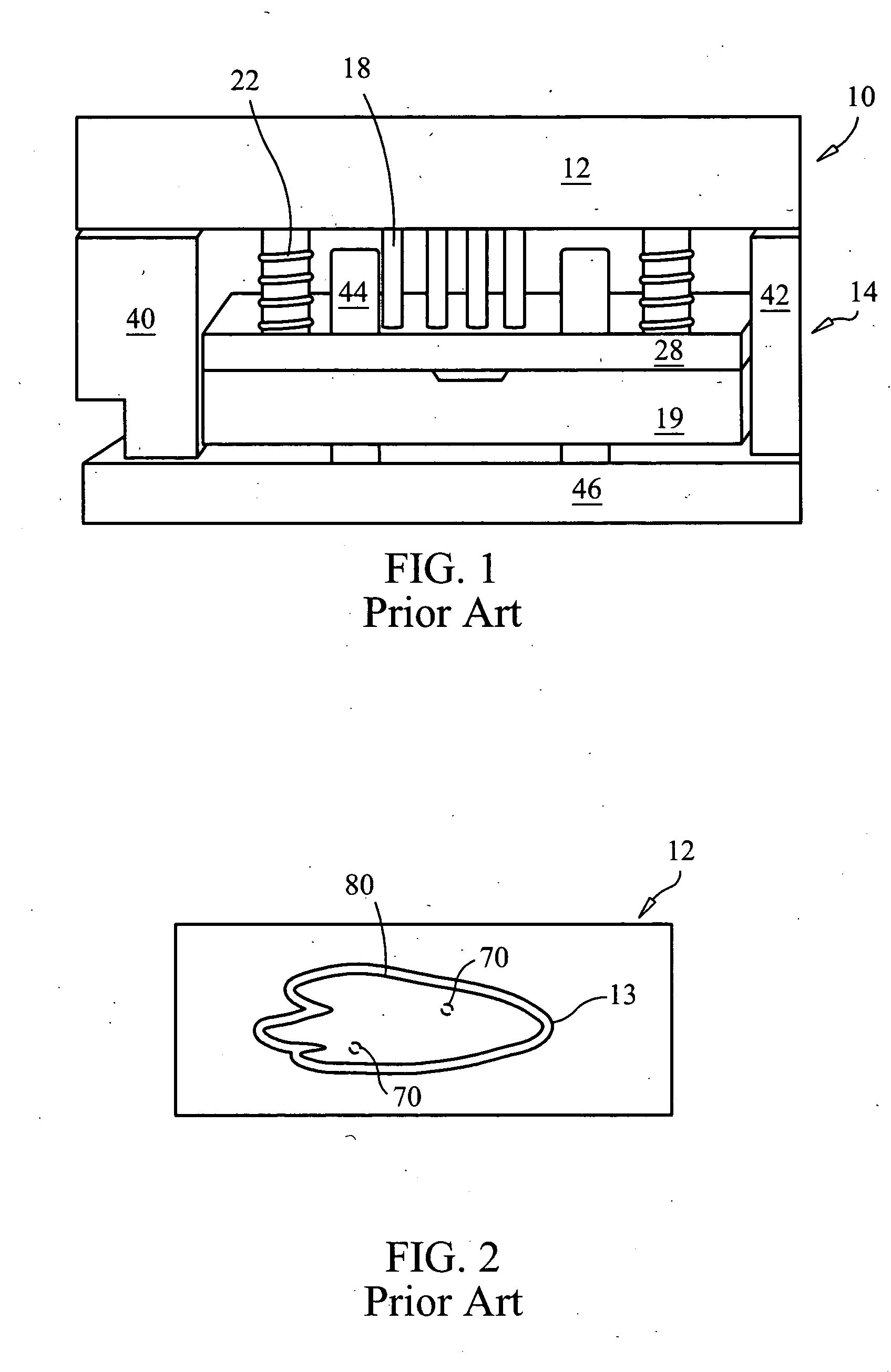

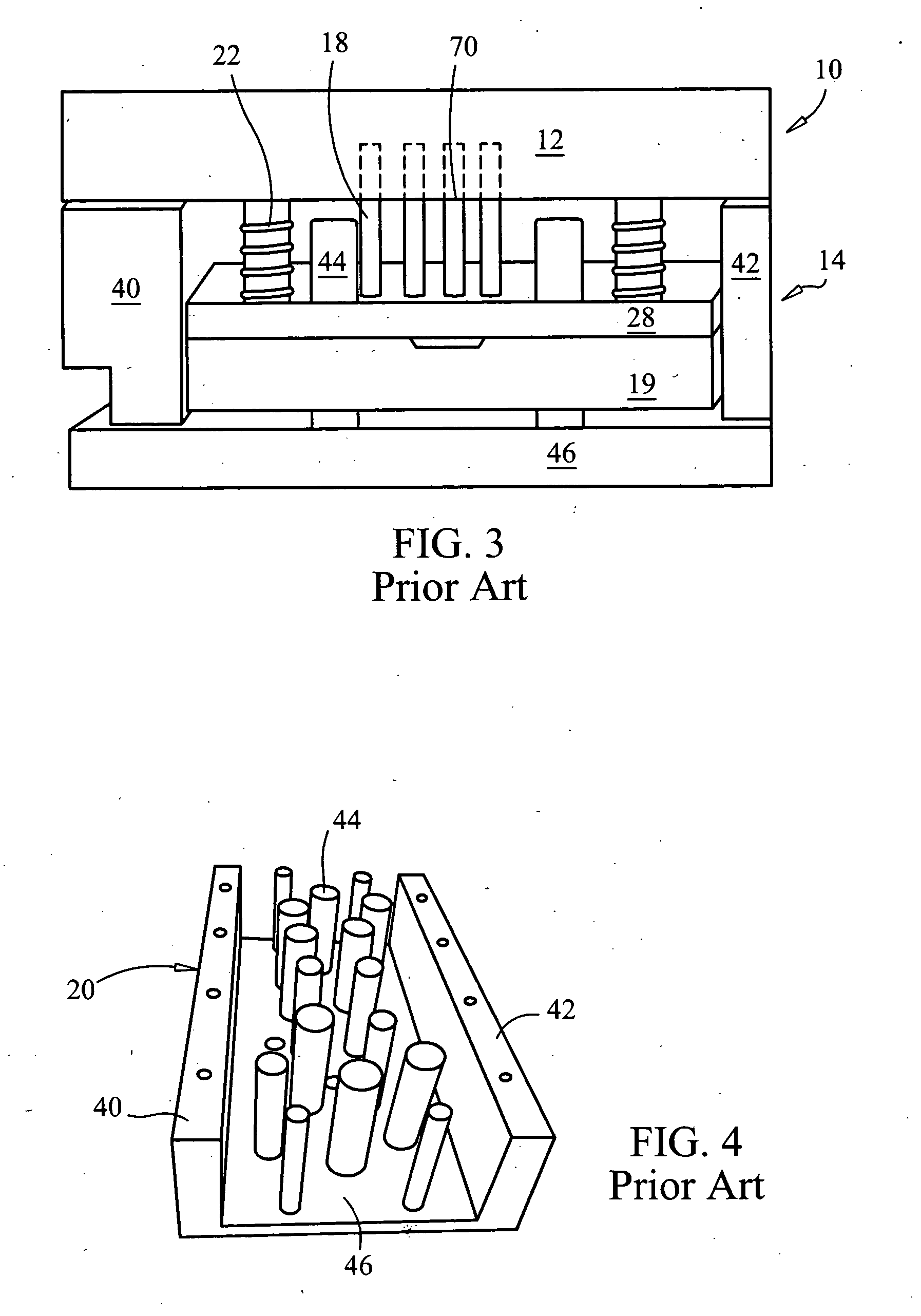

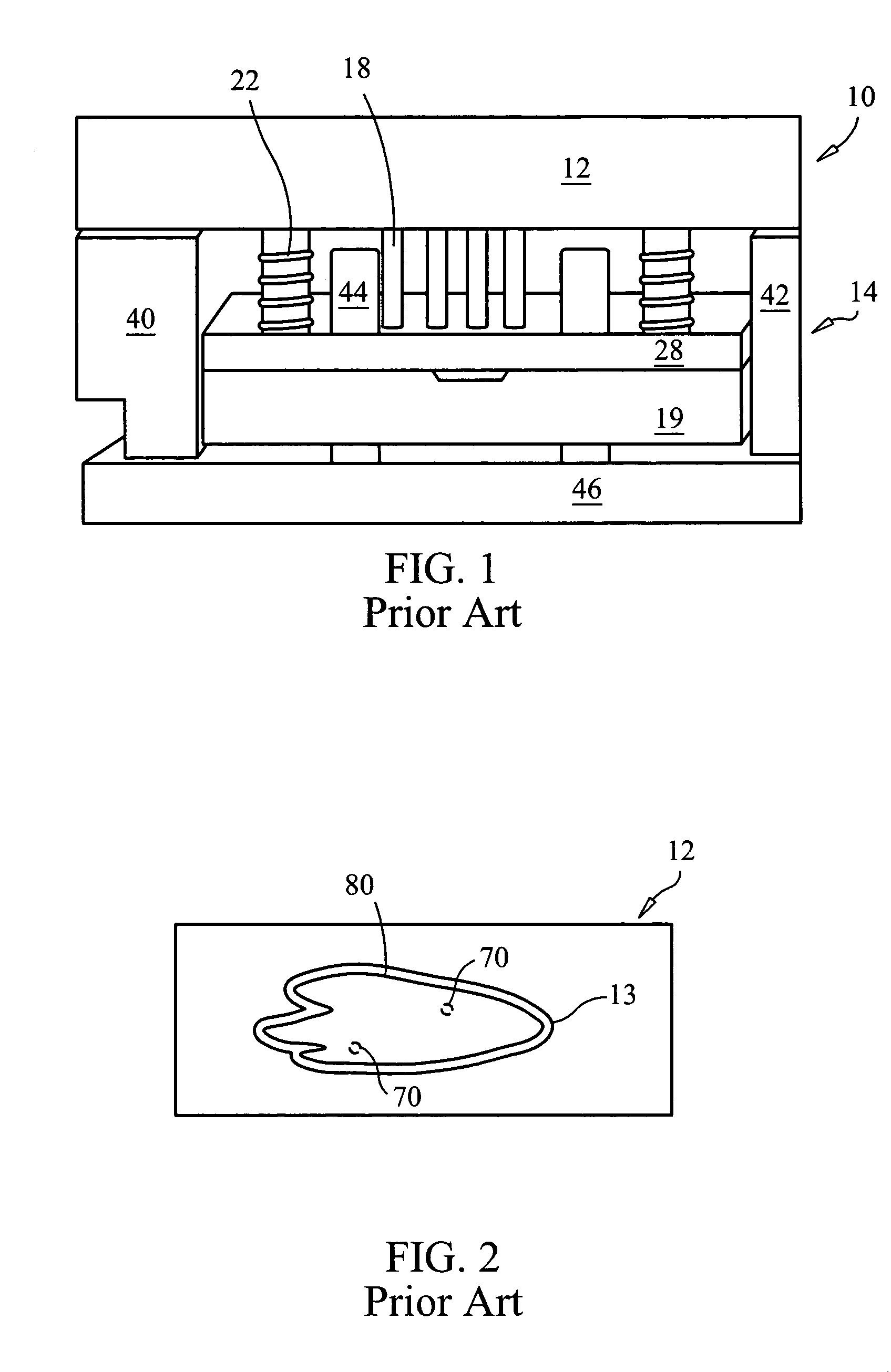

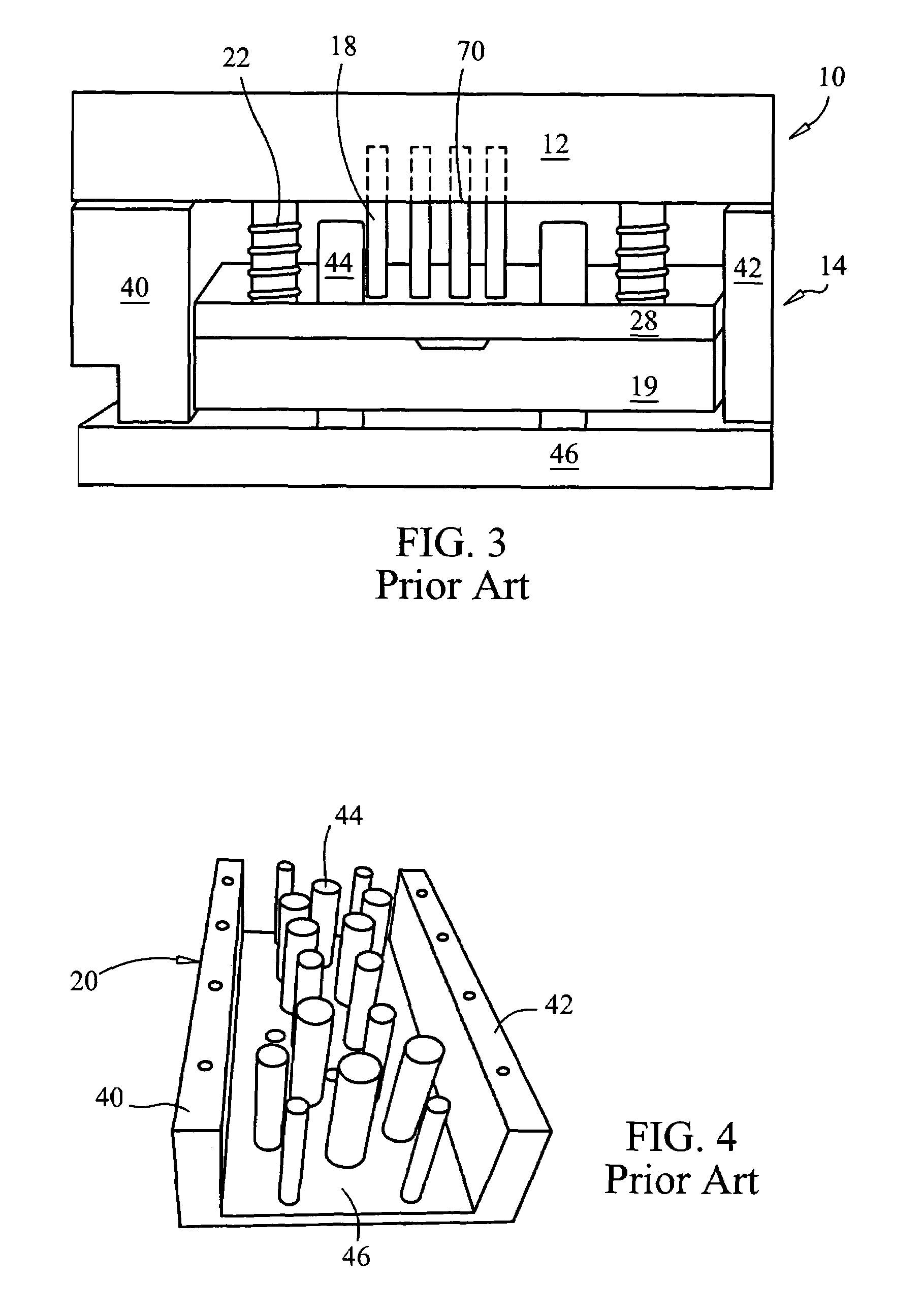

Tool having an ejection assembly, a method for making such a tool, and a method for ejecting a formed object from a tool

Owner:EDMOND DANTES HLDG LLC

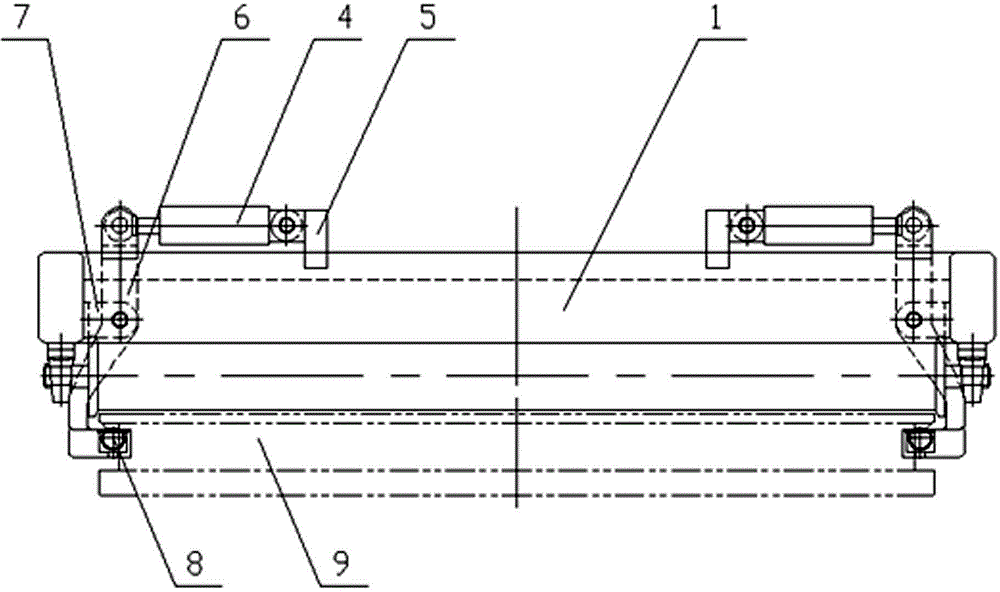

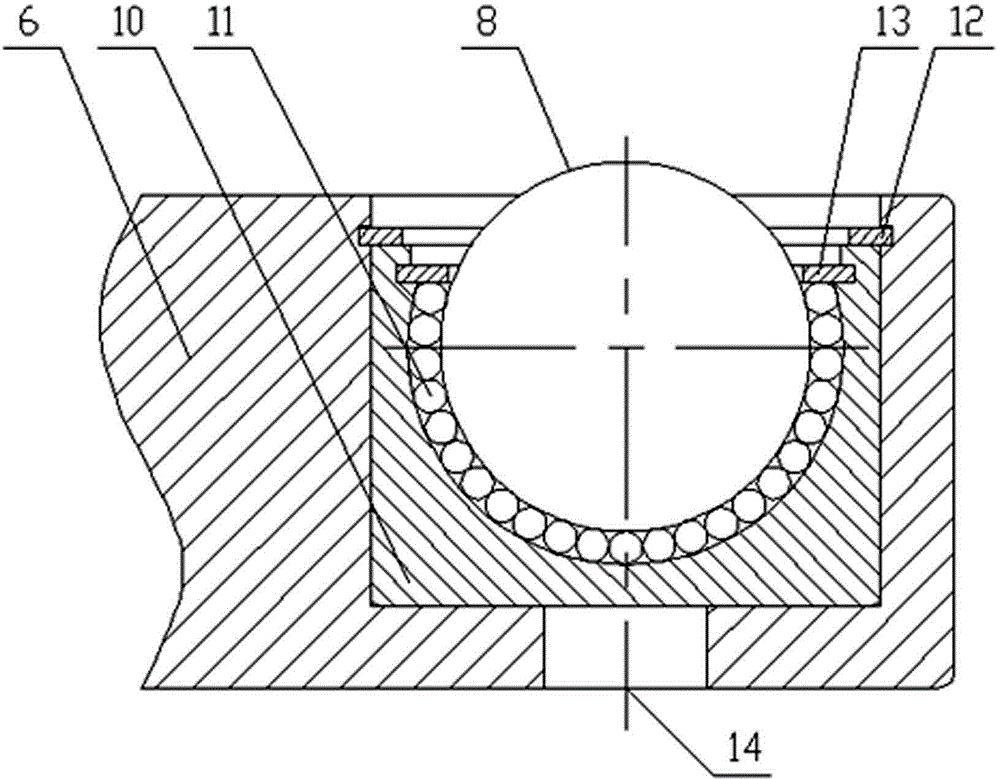

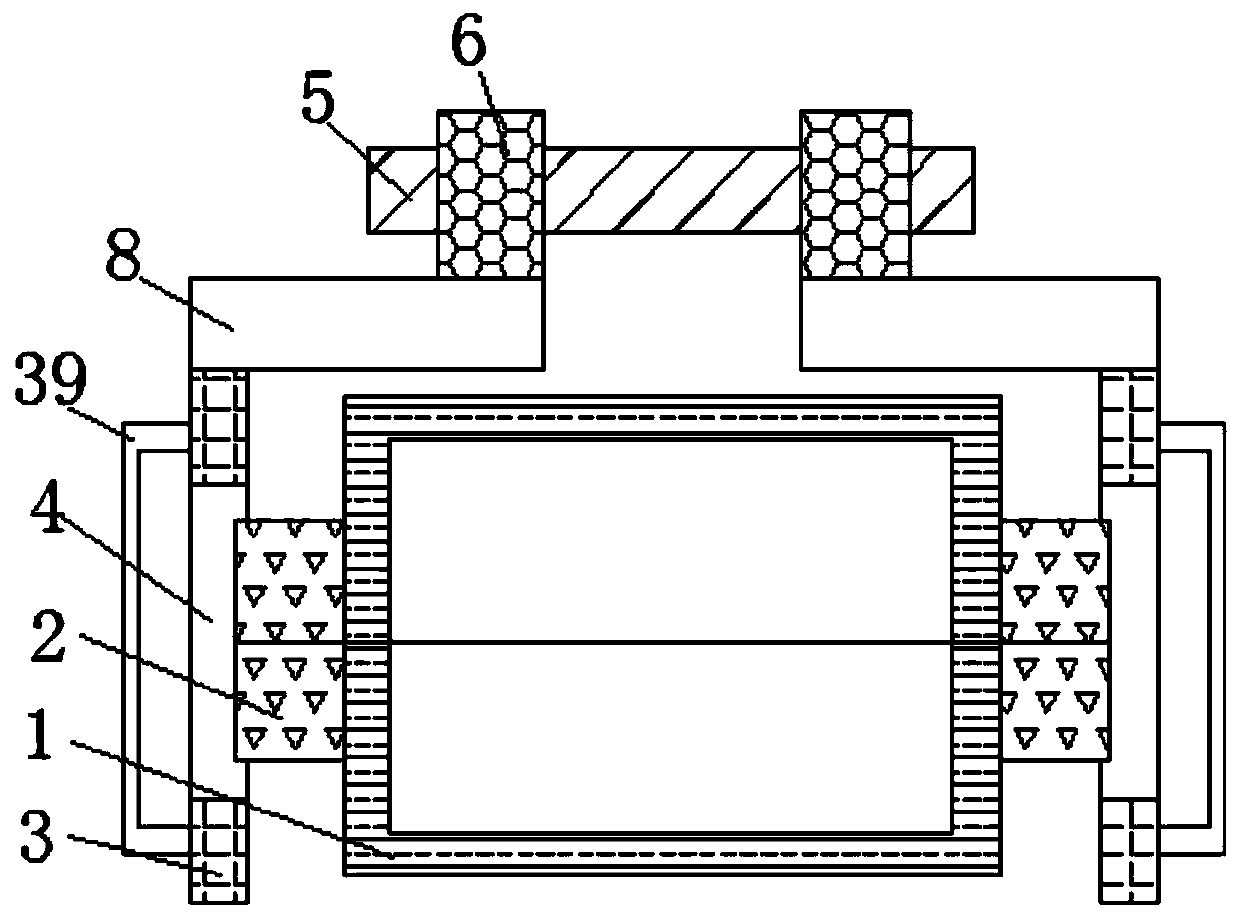

Floating mold clamping device for sand-core accompanying support plate

ActiveCN104942240AWith floating functionImprove accuracyFoundry mouldsFoundry coresLocking mechanismEngineering

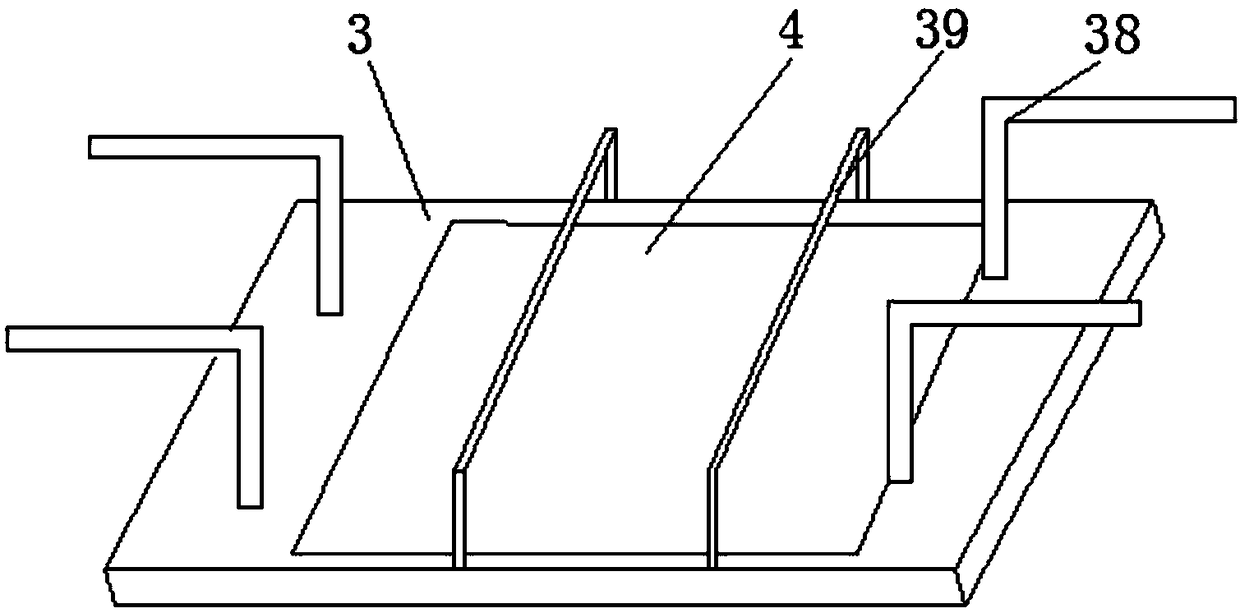

The invention provides a floating mold clamping device for a sand-core accompanying support plate. The floating mold clamping device for the sand-core accompanying support plate is used for overturning a pattern drawing machine. The floating mold clamping device for the sand-core accompanying support plate comprises an upper roller way. Pairs of sand-core accompanying support plate locking mechanisms are symmetrically arranged at the left and the right of the front side and the right side of the upper roller way. Pairs of sand-core accompanying support plate floating mechanisms are symmetrically arranged at the left and right of the front side and the rear side of the upper roller way. The sand-core accompanying support plate floating mechanisms are provided with horizontally-arranged drive oil cylinders. The rear ends of the drive oil cylinders are hinged to backseats of oil cylinders on the upper roller way. The front ends of the drive cylinders are hinged to the upper ends of L-shaped floating clamping jaws. The middle portions of the floating clamping jaws are hinged to the clamping jaw supports fixed on the upper roller way. The lower ends of he floating jaws are provided with moving balls. The moving balls make contact with the lower plane of an upper plate of the sand-core accompanying support plate. The floating mold clamping device for the sand-core accompanying support plate has the advantages that the accuracy of die assembly of the sand-core accompanying plate and the sand core can be improved, the quality of the sand core is improved, and the production efficiency is improved.

Owner:QINHUANGDAO DEV ZONE CHUNGUANG CASTING MACHINERY

Closed pneumatic shell vibrating machine

InactiveCN102950258AProtect physical and mental healthImprove the operating environmentMould loosening devicesStress conditionsEngineering

The invention discloses a closed pneumatic shell vibrating machine which comprises a pneumatic pick, a frame, a cylinder, a case, support legs, a moving door, a pneumatic open-close structure, a clamping mechanism and an auxiliary support mechanism. The pneumatic pick, the frame and the cylinder are disposed in the case. The open front side of the case is provided with the moving door and the pneumatic open-close structure. The clamping mechanism is horizontally disposed below the pneumatic pick. Opposing sides of a moving clamping block and a fixed clamping block are provided with opposing semi-conical openings. The auxiliary support mechanism is vertically disposed below the clamping mechanism and right below the pneumatic pick. When shell vibrating occurs in the closed environment, mass dust produced by shell vibrating is prevented from spreading out, and accordingly operating environment is evidently improved. During shell vibrating, a mould shell is tightly clamped and suspended, so that precision castings are protected from damage caused by rigid extrusion. A flexible support block assists in supporting the mould shell, so that stress condition of the mould shell and the clamping mechanism can be evidently improved during shell vibrating, clamping is reliable and the service life of the clamping mechanism is effectively prolonged.

Owner:TAIZHOU XINYU PRECISION MFG CO LTD

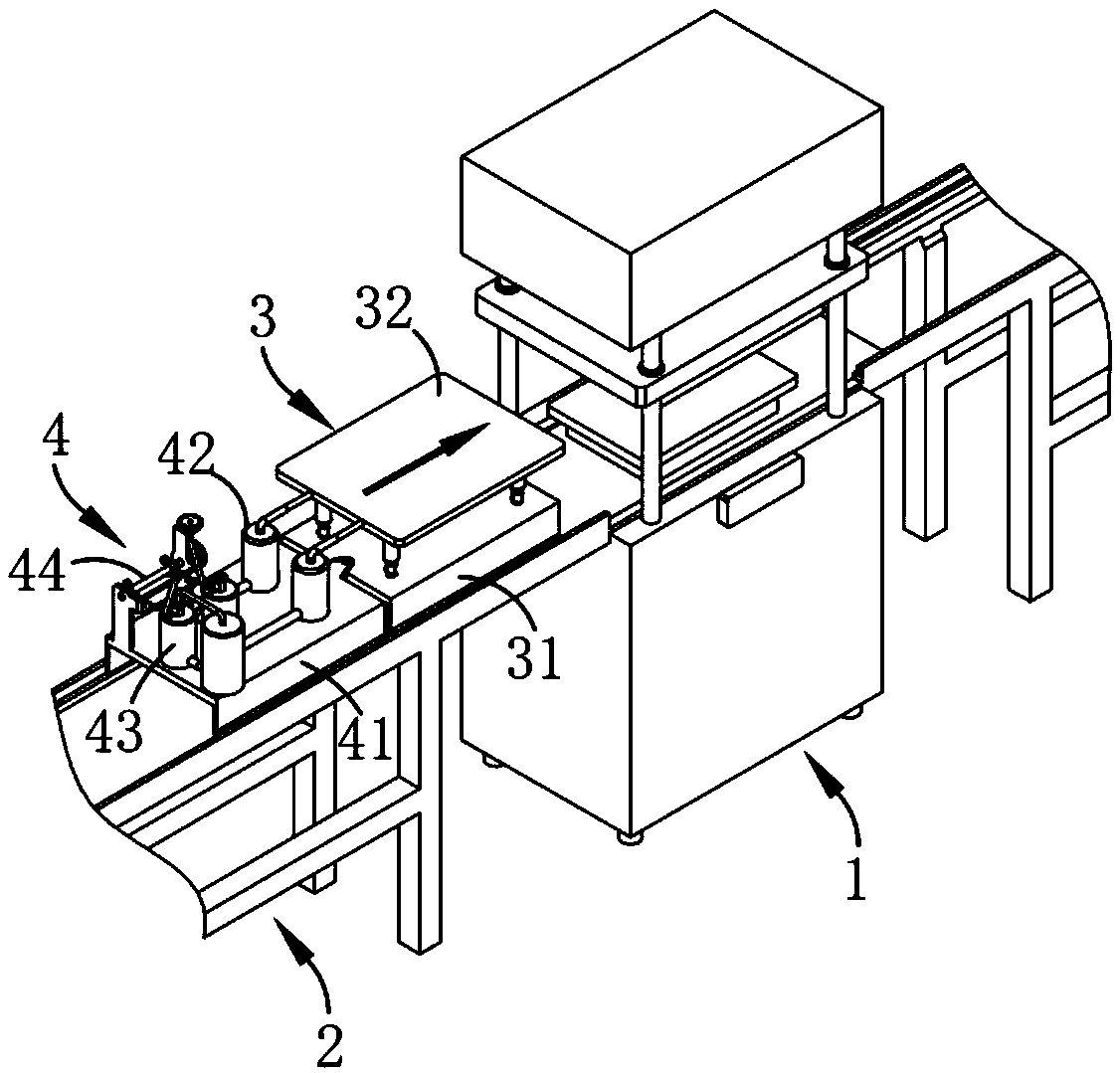

Cast sand core efficient manufacturing equipment

InactiveCN108907113AImprove processing efficiencyShorten the timeMoulding toolsMoulding machinesMechanical engineeringMolding sand

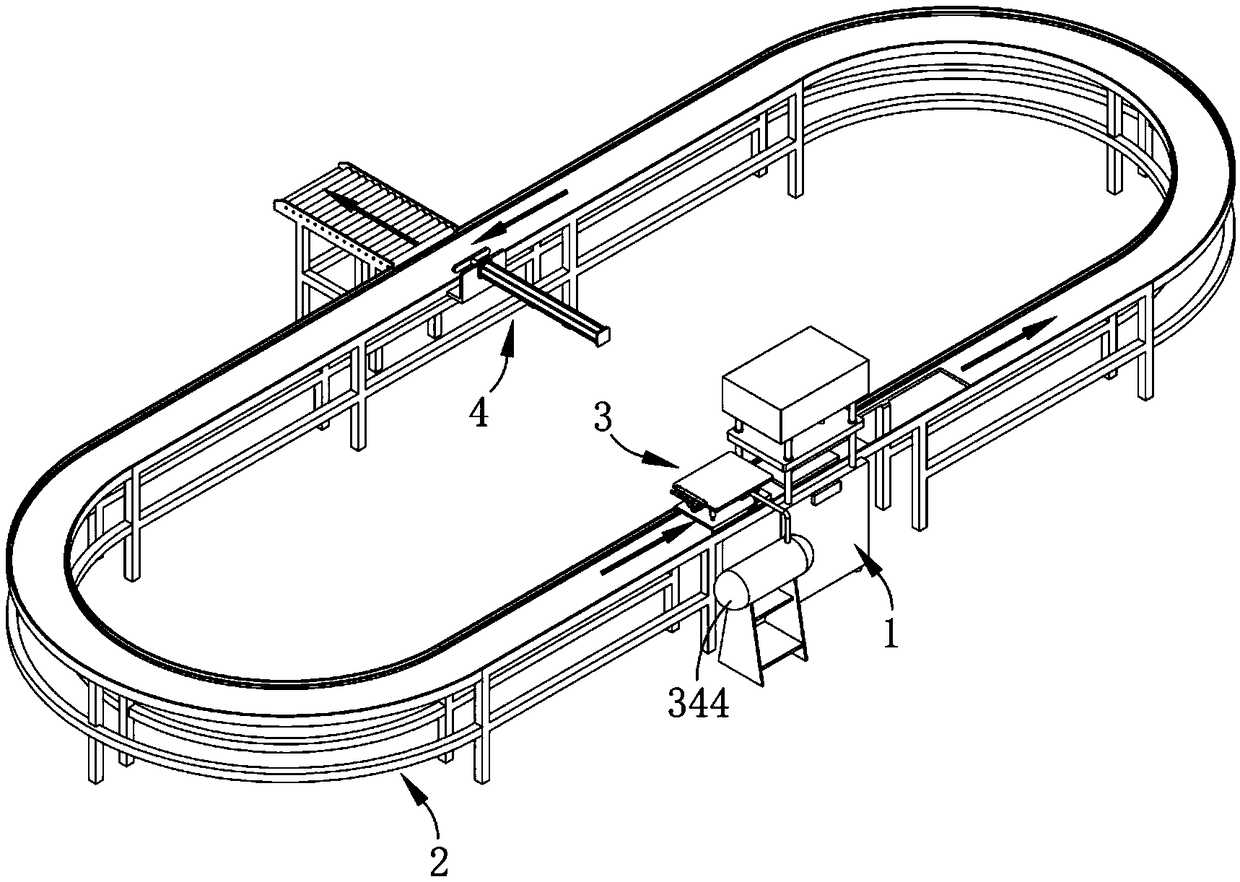

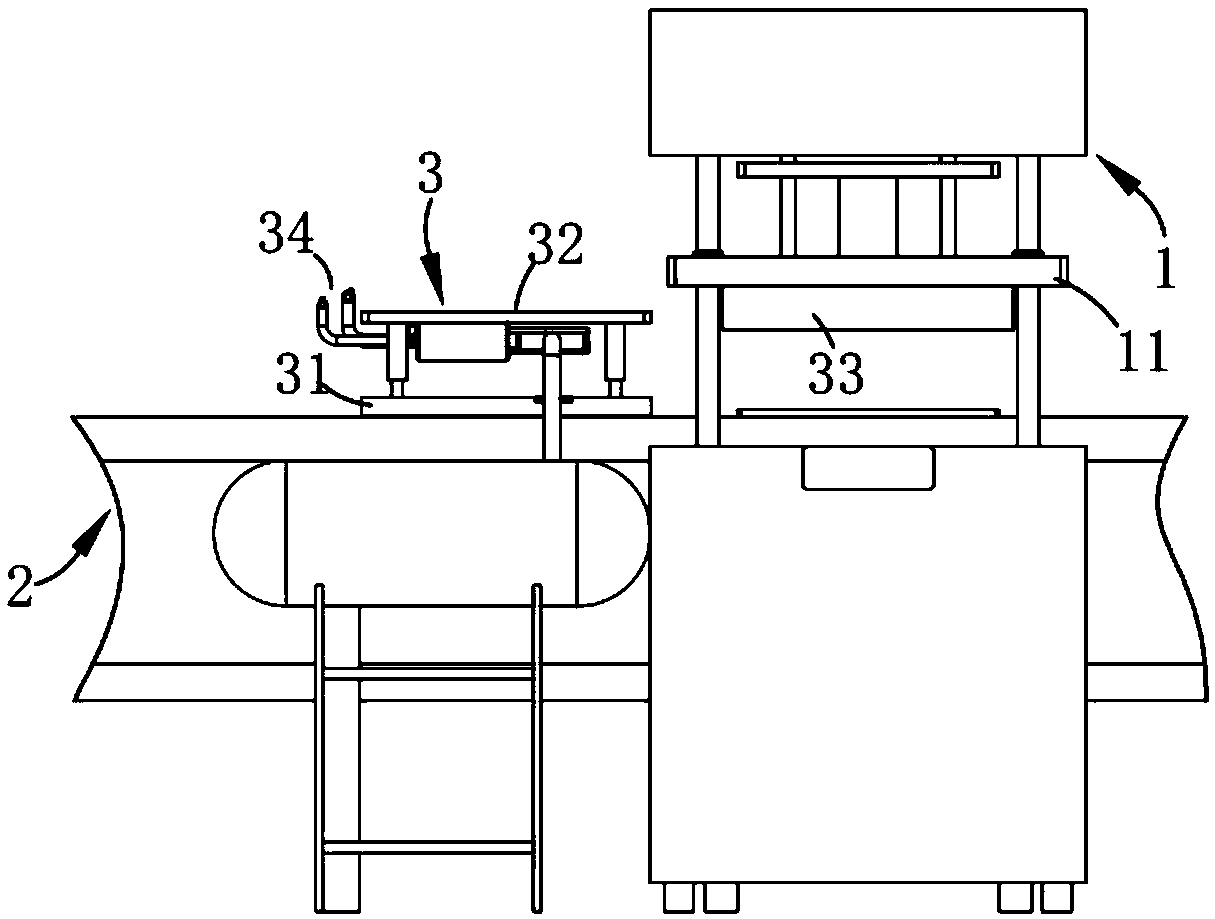

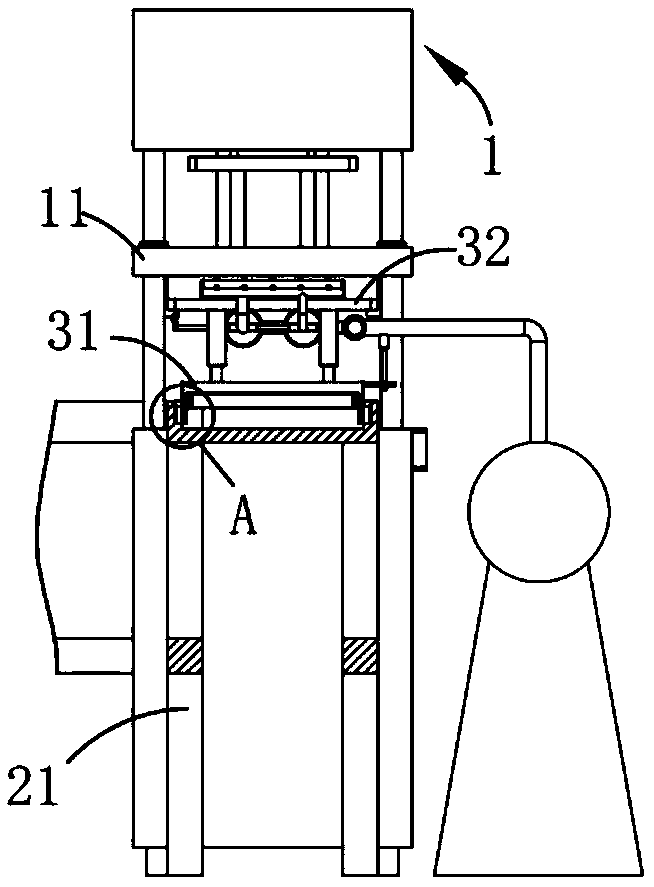

The invention relates to the technical field of automatic production of sand cores, in particular to cast sand core efficient manufacturing equipment. The cast sand core efficient manufacturing equipment comprises a core shooter, a guide mechanism, a receiving mechanism and an arrangement mechanism; the receiving mechanism comprises a driving car, a bearing module, and a connecting module for driving the bearing module to move up; the arrangement mechanism comprises a moving module, a removing module, a spraying module, and a transmission module for driving the removing module and the sprayingmodule to swing; the removing module and the spraying module are driven to operate by the bearing module; in the transmission connection process of the receiving mechanism and an upper mold, the internal inflation of the removing module and the spraying module is realized; and when the bearing module moves down after deviated from the connecting module, the removing module and the spraying moduleare driven to clean the upper mold and to spray a demolding agent, so that the automatic transfer of molding sand and the automatic and efficient treatment of the upper mold are realized, and the technical problem of low production efficiency caused by lower treatment efficiency of the upper mold in the prior art is solved.

Owner:ZHEJIANG ZHENXING CASTING CO LTD

Special stripping machine for motor shell evaporative die

InactiveCN105689645AAvoid deformationAvoid injuryFoundry mouldsFoundry coresControl theoryElectric motor

Owner:TAIZHOU HUANGYAN XUANJIE MOLD CO LTD

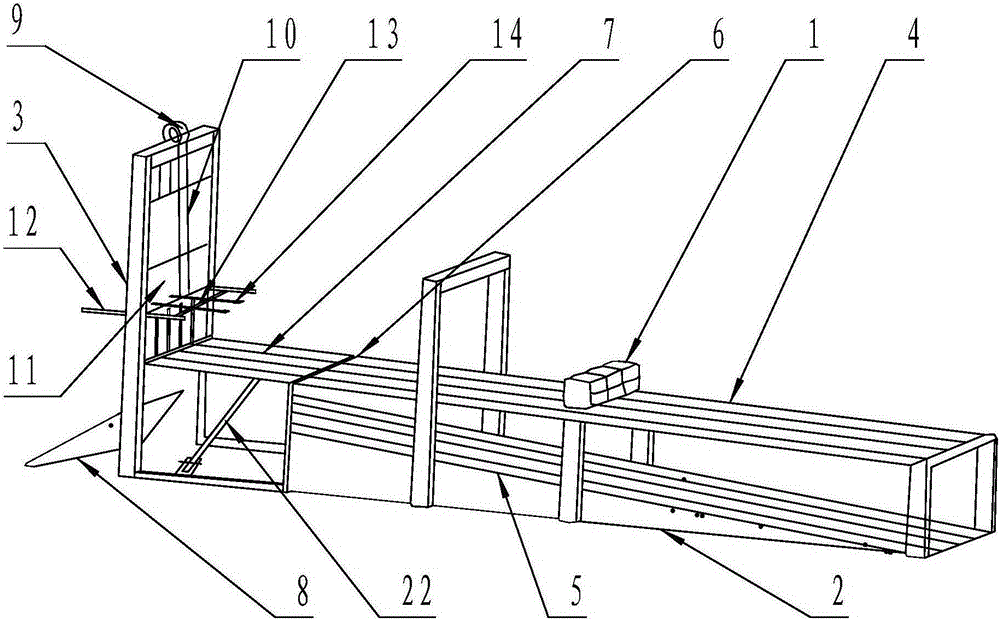

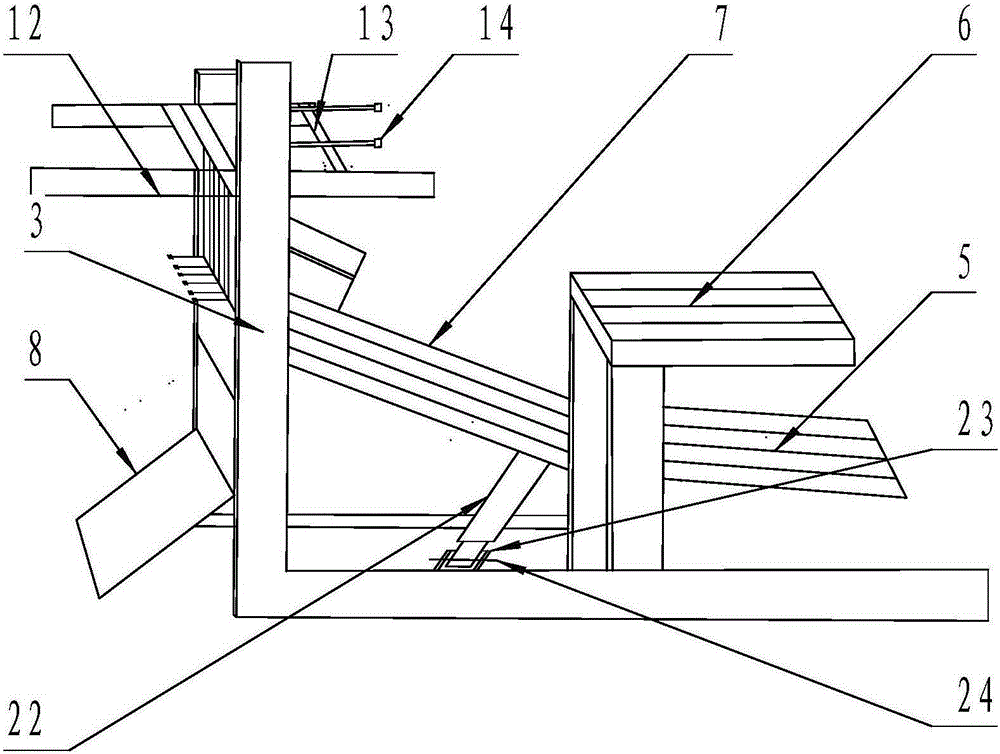

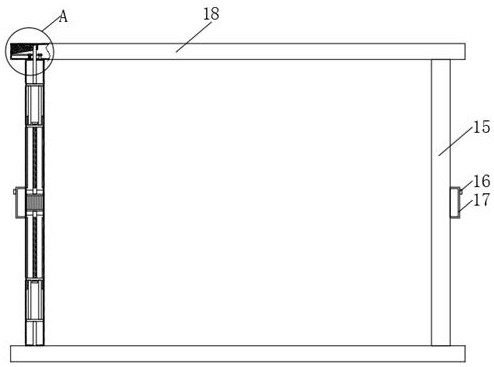

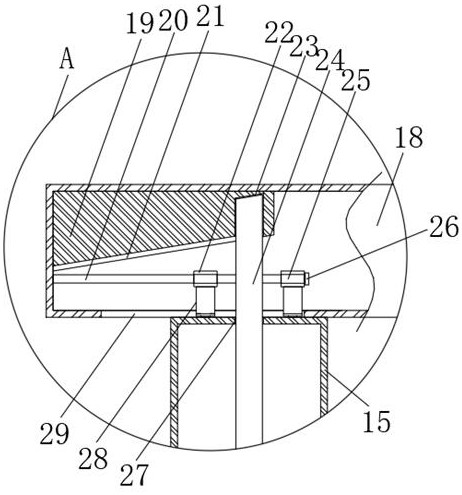

Sand mold frame stripping system

ActiveCN105195687AReduce the labor intensity of unpackingEliminate the safety hazard of injuryMould loosening devicesPush outEngineering

The invention discloses a sand mold frame stripping system. The sand mold frame stripping system comprises a sand box and a rack, wherein a portal frame is mounted at one end of the rack; the portal frame is equipped with a sand box grasping device and a sand mold pushing-out device. The sand mold frame stripping system further comprises a lifting device, which is mounted on the portal frame, of the sand box grasping device, and a movable device for moving the sand box grasping device from front to back along the longitudinal direction of the rack; the rack is further equipped with a horizontal upper rail and a lower rail with an inclined direction; the upper rail comprises a fixed rail and a movable rail; and a movable rail supporting device is mounted on the bottom surface of the movable rail. With the adoption of the sand mold frame stripping system, automatic stripping of a sand box and a sand mold of a casting process is realized, and the stripping labor intensity of workers is alleviated; the stripping working efficiency is improved by 500% and the stripping success rate reaches 100%; and potential safety hazards of causing damages to operators in sand box and sand mold stripping processes are eliminated.

Owner:济南市平阴县玛钢厂

Tool having an ejection assembly, a method for making such a tool, and a method for ejecting a formed object from a tool

Owner:EDMOND DANTES HLDG LLC

Anti-slip denoising device of shell vibration machine

InactiveCN102303099AInhibit sheddingAvoid troubleMould loosening devicesEngineeringMechanical engineering

The invention relates to an anti-slip denoising device of a shell vibration machine. The anti-slip denoising device mainly comprises a rack, a vibration hammer and a base; a rubber gasket with convex or concave decorative patterns is arranged on the base; and an anti-slip steel plate with convex or concave decorative patterns is arranged on the rubber gasket. By the anti-slip denoising device, unnecessary troubles and potential safety hazard caused by the reason that a workpiece falls off from the base during the working of the shell vibration machine can be prevented, and noise pollution can be reduced.

Owner:XINGHUA PRECISION CAST STEEL

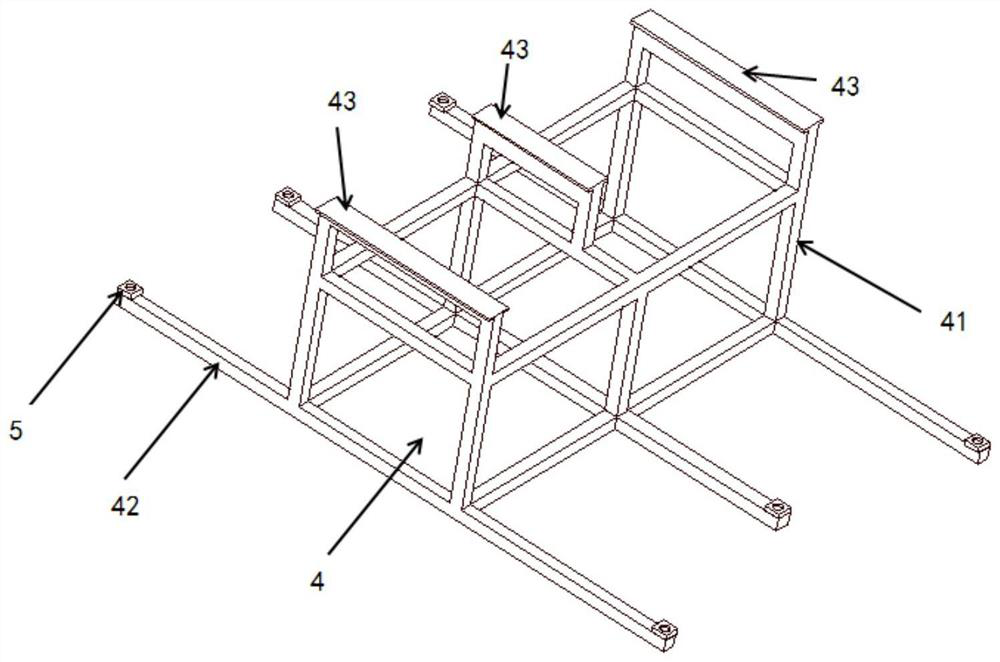

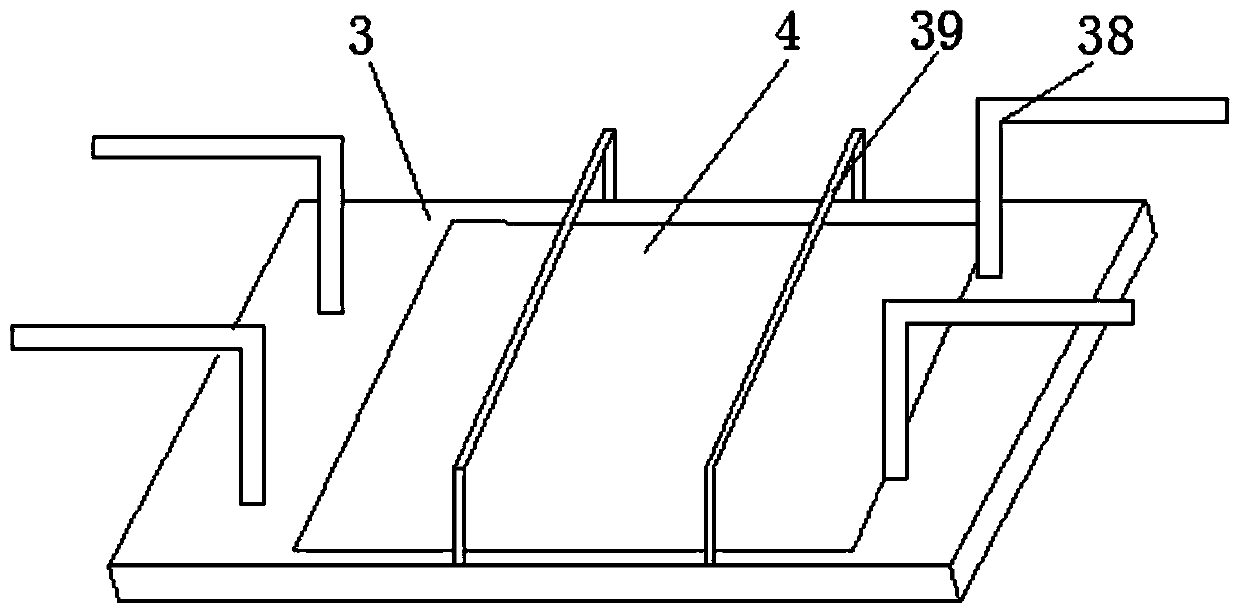

Box separation frame for modeling

The invention discloses a box separation frame for modeling. The box separation frame comprises two sand boxes, wherein one sand box is correspondingly placed on the top side of the other sand box; side lugs are fixedly mounted on two sides of the two sand boxes; hook racks are arranged on two sides of the sand box; hook holes are formed in mutually close sides of the two hook racks; mutually awaysides of the two side lugs respectively extend into the two hook holes; a mounting basket is arranged above the hook racks; two moving blocks are connected to the mounting basket in a sliding manner;a moving hole is formed in one side of each of the two moving blocks. The box separation frame for modeling is simple in design and convenient to operate; after the box separation frame is used, box-staggered rejected products caused by striking the sand boxes with a wooden mallet are reduced, and the casting qualification rate can be increased; manmade box staggering caused by box separation isavoided, so that rejected products caused by the manmade box staggering are reduced; meanwhile, a distance between the two hook racks can be adjusted, and a distance between two push plates can be adjusted; the box separation frame for modeling can adapt to sand boxes of different sizes and side lugs of different sizes, so that the universality of the device is improved, and demands of people aremet.

Owner:济南市平阴县玛钢厂

Fully-automatic molding sand production system and method for precision casting

InactiveCN108907114AAchieve finishingAchieve cleanupMoulding toolsMoulding machinesPositive pressureEngineering

The invention relates to the technical field of casting production, in particular to a fully-automatic molding sand production system and method for precision casting. The fully-automatic molding sandproduction system comprises a core shooting machine, a guide mechanism, a drop mechanism and an output mechanism, wherein the drop mechanism comprises a transfer car, a material receiving assembly arranged on the transfer car, a transmission assembly which is fixedly arranged on an upper mould of the core shooting machine for driving the material receiving assembly to move upwards, and a clear-upassembly which is used for cleaning the surface of the de-molded upper mould; the output mechanism is used for pushing and outputting molding sand on the drop mechanism; in a moving process of the drop mechanism, positive-pressure gas flow guide-in is performed on the clear-up assembly; a bearing part is driven to move upwards to perform molding sand bearing while the upper mould moves upwards toperform molding sand de-molding, and the transmission assembly clears up the de-molded upper mould and sprays a mould release agent, so that fully-automatic treatment for clearing the upper mould andspraying the mould release agent in the molding sand de-molding process is realized, and therefore, the technical problem that automation degree on molding sand transfer or upper mould treatment in the prior art is solved.

Owner:ZHEJIANG ZHENXING CASTING CO LTD

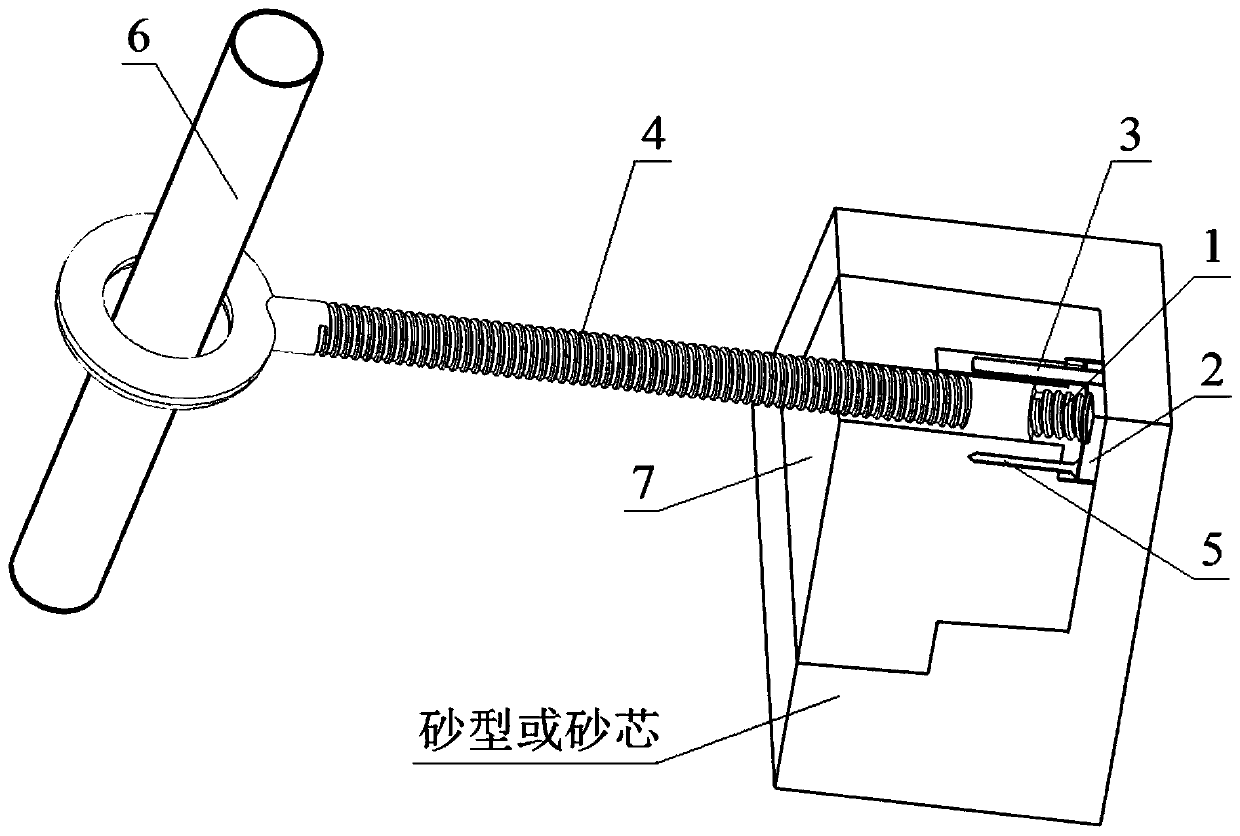

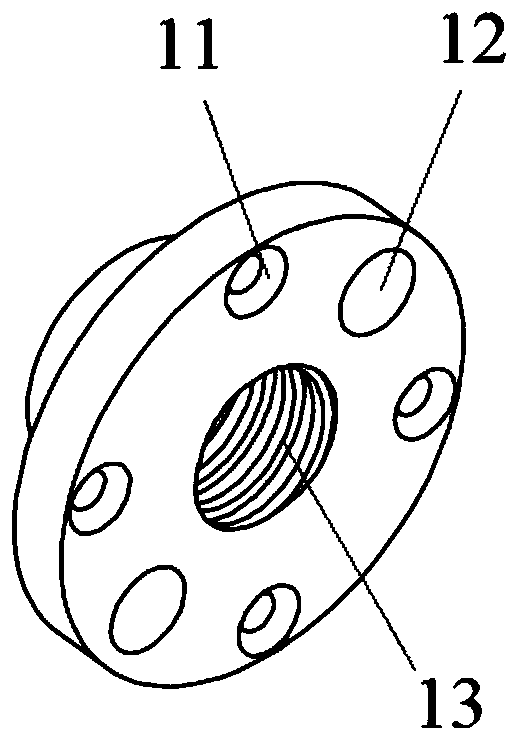

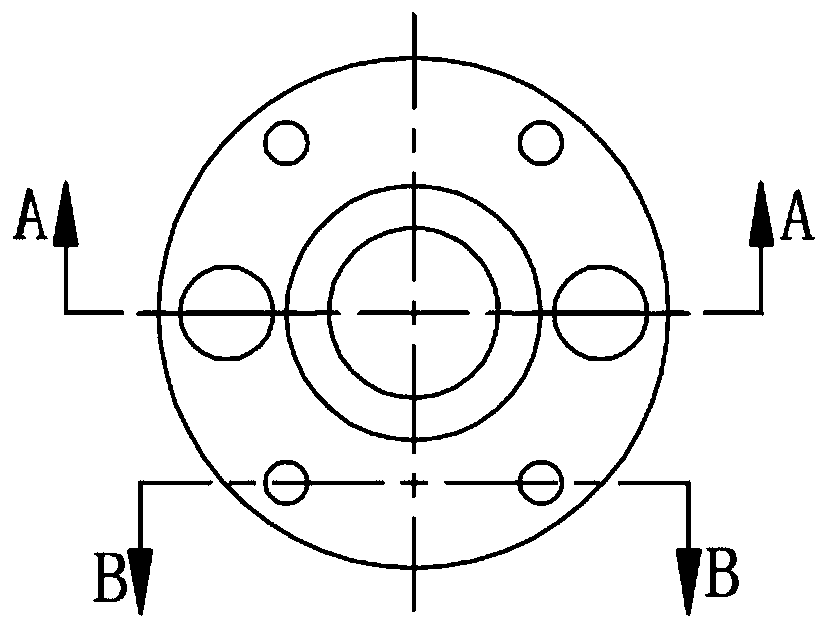

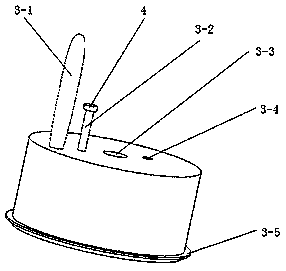

Device for taking out loose piece of sand core of sand mold for large casings and using method of device

The invention provides a device for taking out a loose piece of a sand core of a sand mold for large castings and a using method of the device. The device comprises an embedded jackscrew, a cover plate, positioning screw rods, a screw ejection rod, fastening screws and a torque bar. A long through hole is formed in the bottom of a mounting base. First through holes and second through holes are formed in the bottom of the mounting base. The embedded jackscrew comprises an upper cylinder and a lower cylinder. Through holes I are formed in the lower cylinder in a penetrating mode. The fastening screws are connected into the through holes I in a matched mode. One end of each fastening screw is screwed into the corresponding first through hole. Through holes II are formed in the lower cylinderin a penetrating mode. A through hole III is formed in the middle of the embedded jackscrew in a penetrating mode. An internal thread I of the through hole III is connected with an external thread ofthe screw ejection rod in a matched mode. A circular ring is arranged at one end of the screw ejection rod. The torque bar is arranged in the circular ring. Through holes IV are formed in the cover plate in a penetrating mode. Internal threads II of the through holes IV are connected with external threads of the positioning screw rods in a matched mode. One end of each positioning screw rod stretches into the corresponding second through hole. The device is simple in structure, low in cost, suitable for standard production, high in universality and convenient to operate.

Owner:大连华锐重工铸业有限公司 +1

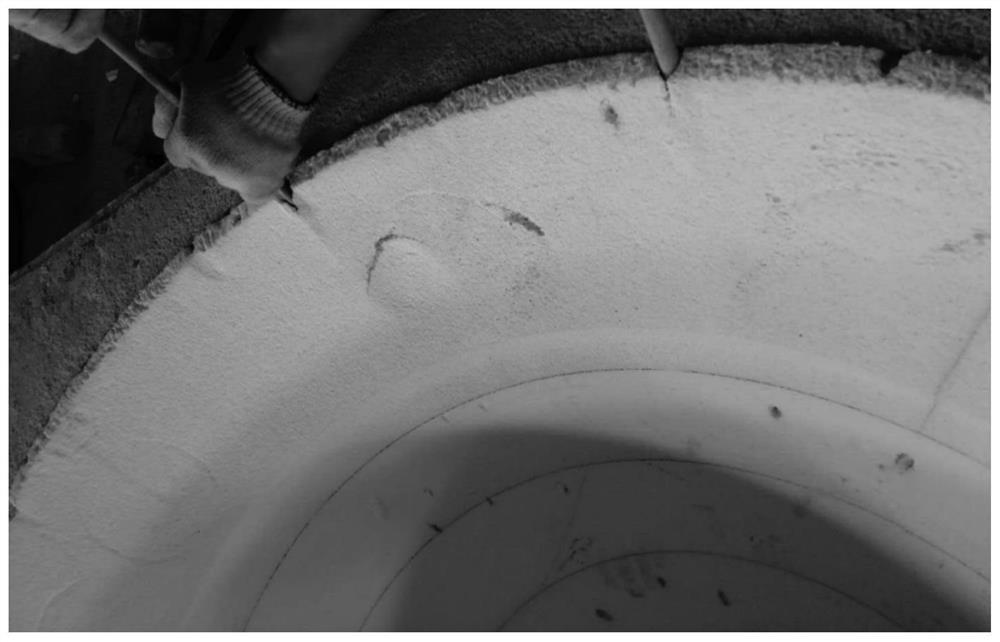

Pattern capable of being lifted and used for large cylinder body

ActiveCN113145794AOvercome the difficulty of formingNot easy to damageMould loosening devicesStructural engineeringCylinder block

The invention relates to a pattern for casting, in particular to a pattern capable of being lifted and used for a large cylinder body. The pattern comprises a pattern main body, a lifting auxiliary component, a movable material and a counterweight piece; the pattern main body comprises a wood component and a steel body component, and the steel body component comprises a component main body and a plurality of lifting parts; the component main body is arranged in an inner cavity of the wood component, the first end of the lifting part is connected with the component main body, and the second end of the lifting part extends out of the inner cavity of the wood component; the movable material is detachably connected to the upper side of the wood component; the second end is connected with a lifting pad; the lifting auxiliary component is connected to the upper part of the lifting pad and is matched with the lifting pad for lifting; the counterweight piece is arranged on the pattern main body. The pattern can efficiently lift a middle ring of the large cylinder block mold, is easy to operate and low in difficulty, cannot damage a sand mold and the mold easily, and effectively improves the dimensional stability of the casting and prolong the service life of the mold.

Owner:KOCEL EQUIP

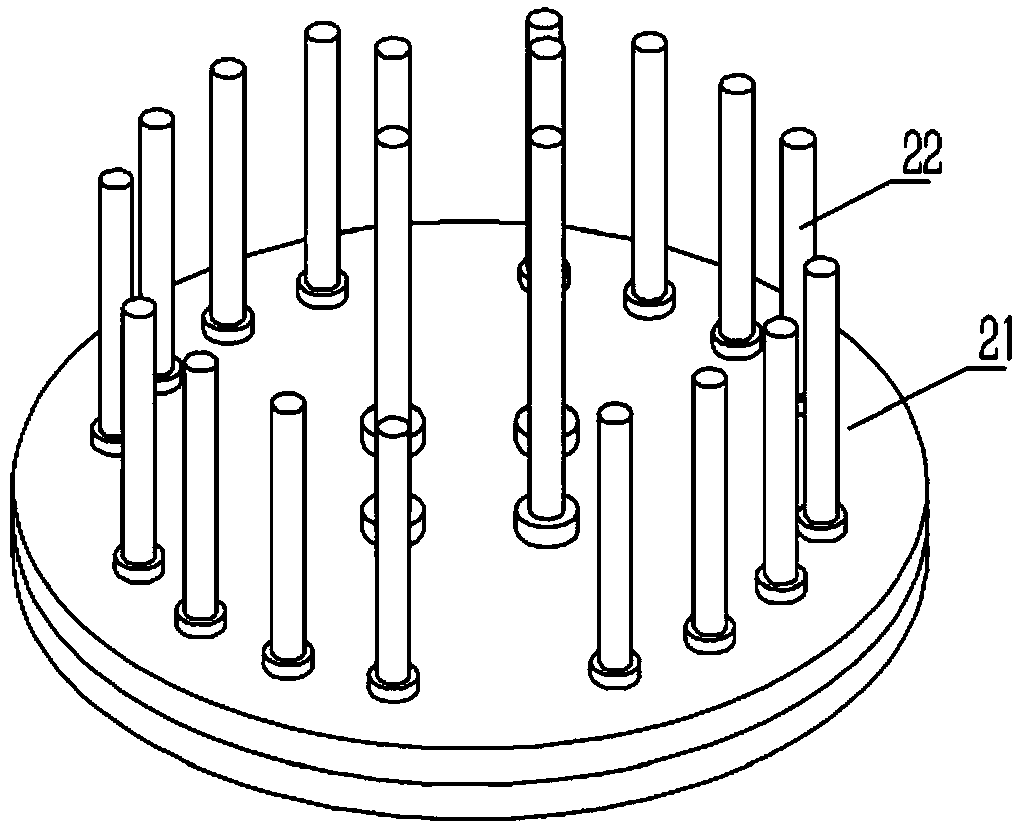

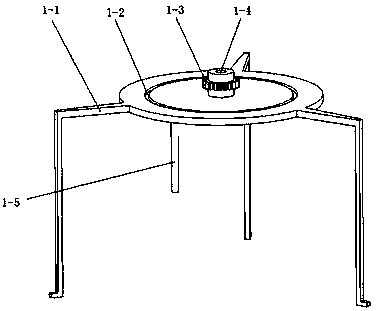

Automatic mold drawing machine for wheel casting mold

ActiveCN104368769AAvoid damageSolve the problem of stuck disassembly troubleMould loosening devicesCasting moldEngineering

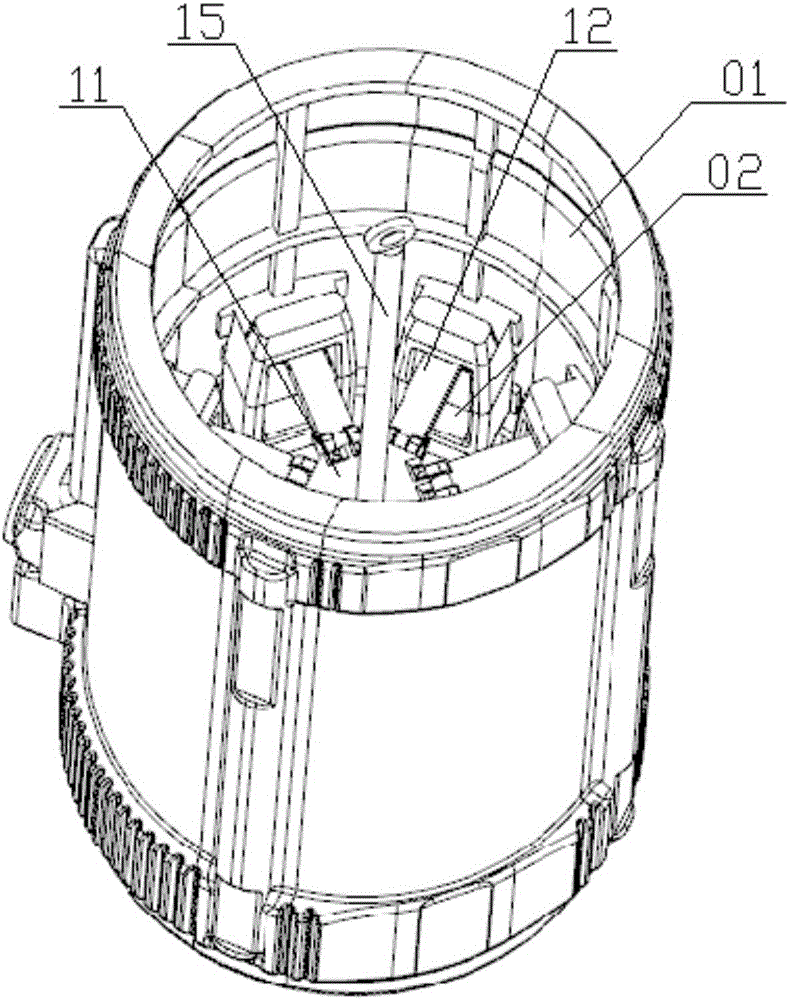

The invention discloses an automatic mold drawing machine for a wheel casting mold. The automatic mold drawing machine comprises a mold drawing mechanism and a mold mounting seat, wherein the mold drawing mechanism comprises a base; an oil cylinder is fixed at the center of the base; a top plate is fixed on a piston rod of the oil cylinder; a plurality of adjustment bolts are fixed on the upper end face of the top plate; a plurality of guide columns are inserted into the top plate and are fixed on the base; a plurality of pull hooks are arranged on the outer side of the top plate and are hinged to the base through hinge seats and hinge shafts; the die mounting seat comprises a base plate; a screw rod is fixed on the base plate; a plurality of guide sleeves are fixed on the base plate, and mandrils are inserted into the guide sleeves and correspond to the adjustment bolts on the drawing mechanism. The automatic mold drawing machine is designed for an upper casting mold of a wheel hub, so that manual demolding by a worker is replaced, and the problems of mandril locking and trouble in detaching are solved; therefore, the demolding speed is increased, injury to the mold is reduced, the labor intensity of the worker is alleviated, and the production efficiency is improved.

Owner:ZHEJIANG WANFENG AUTO WHEEL

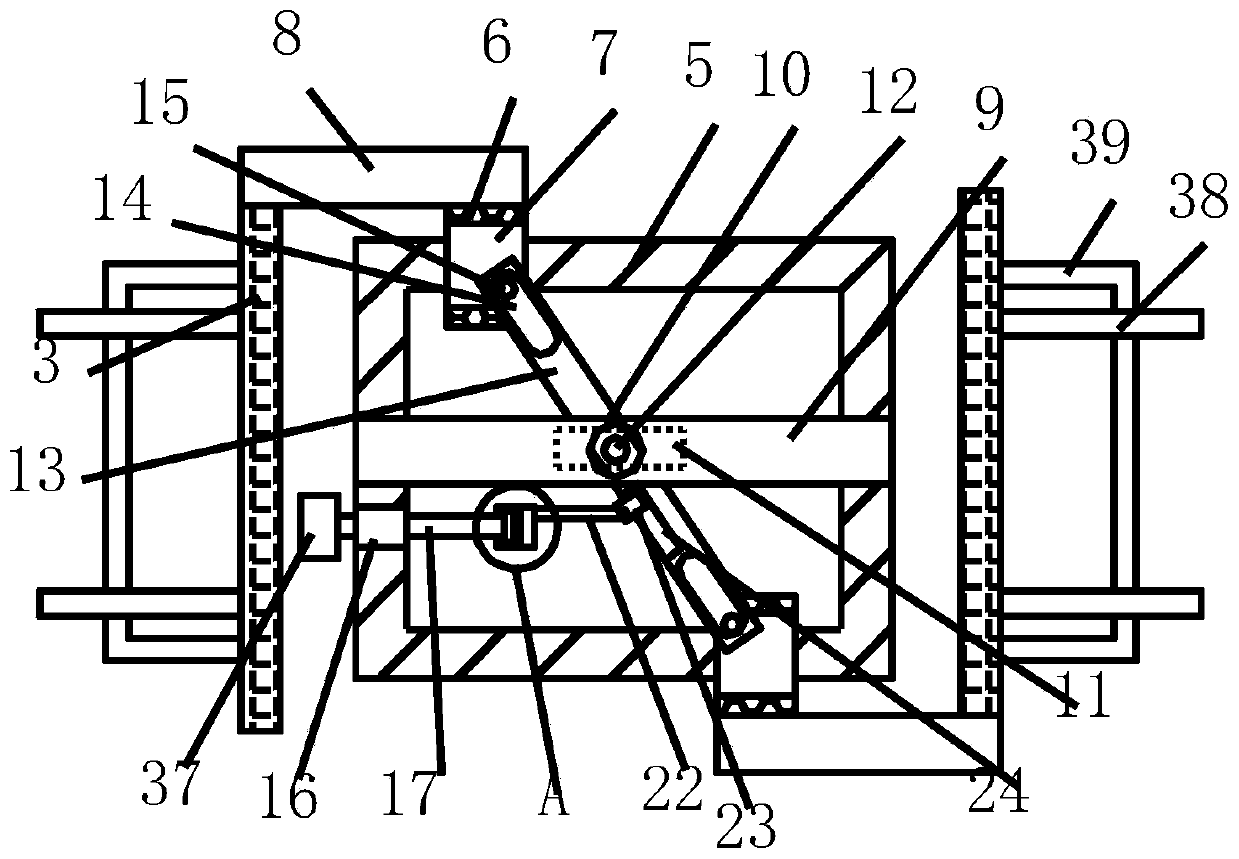

Automatic demolding device

ActiveCN106670400AEasy to take outImprove locking effectMould loosening devicesPressure castingCasting mold

The invention relates to the field of molds and particularly discloses an automatic demolding device. The automatic demolding device comprises a rack, a mold body, a first separation device and a second separation device. The first separation device of the automatic demolding device is fixedly mounted at the bottom of the rack. The second separation device is fixedly mounted at the top of the rack. The first separation device comprises a threaded rod, a first connecting rod mechanism, a handle, a locating block and a gear, wherein the gear is engaged with the threaded rod. The mold body is detachably connected with the upper end of the threaded rod. The locating block is eccentrically arranged on the side face of the gear. One end of the first connecting rod mechanism is connected with the locating block, and the other end of the first connecting rod mechanism is connected with the handle. The second separation device comprises a separation motor, a transmission shaft and a second connecting rod mechanism. The separation motor is connected with one end of the second connecting rod mechanism, and the other end of the second connecting rod mechanism is connected with one end of the transmission shaft. The other end of the transmission shaft is detachably connected with the upper surface of an upper mold. By means of the automatic demolding device, a pressure-casting mold can be manufactured, and a molding mold can be separated from the mold body automatically.

Owner:大冶屹丰机械制造有限公司

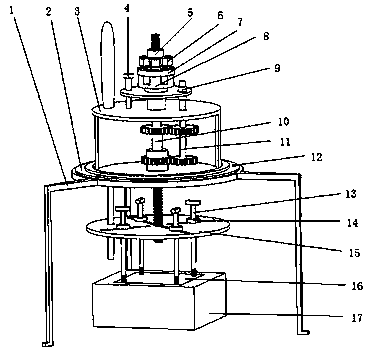

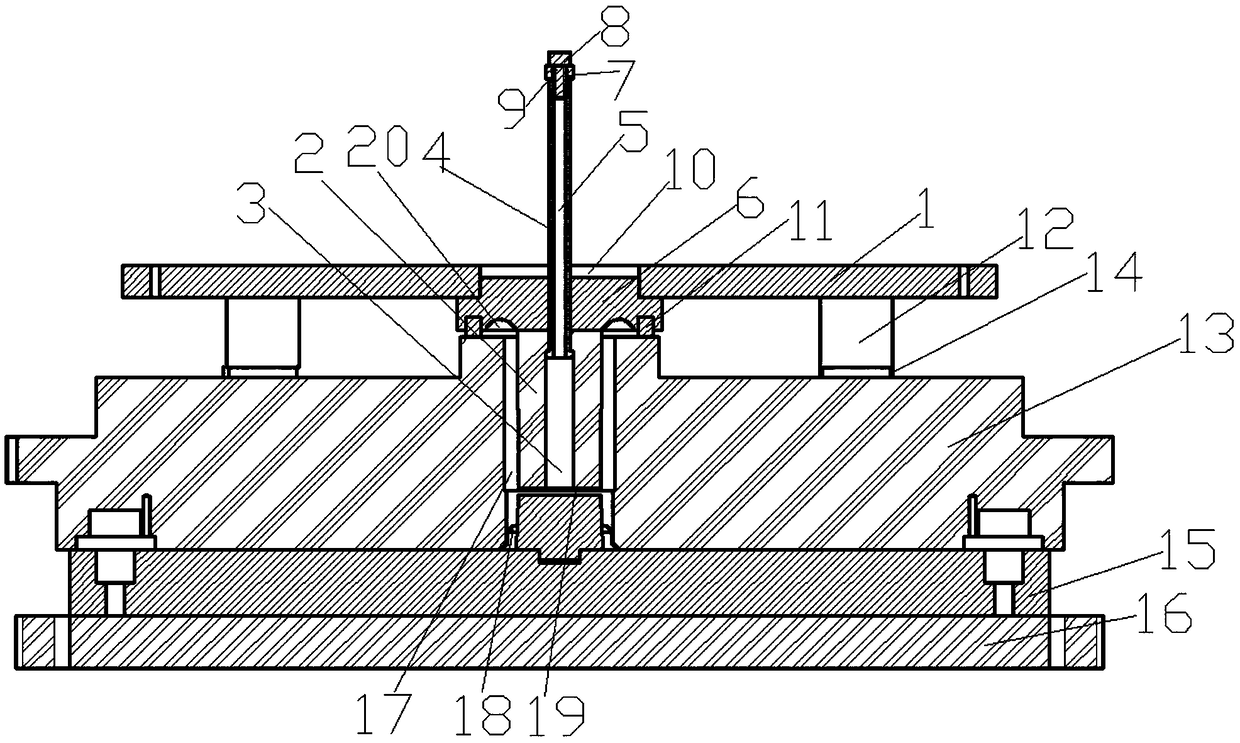

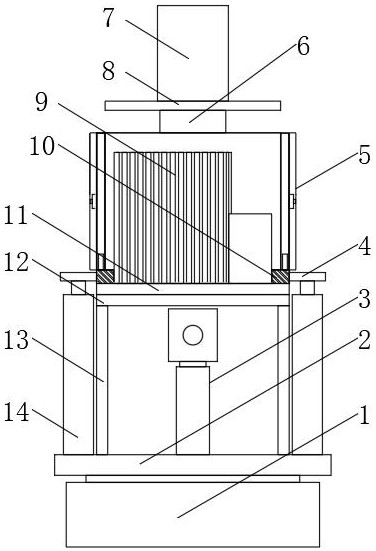

Mold stripping machine with two speeds for casting

ActiveCN111299522AIntegrity guaranteedOvercoming wrapping forceMould loosening devicesGear wheelEngineering

The invention provides a mold stripping machine with two speeds for casting. The mold stripping machine comprises a rack, a gland, a rotary disc, a limiting nut, a locking nut, an upper chuck, a chuckcover, a lower chuck, a fixing nut, a lead screw shaft, a duplex planetary gear, a gland screw, a mold stripping screw, an adjusting nut, a mold stripping disc, a casting mold and a sand box. According to the mold stripping machine, a model can be taken out of the sand box through the mold stripping disc, the lead screw shaft and the like. The mold stripping machine has the advantages that the mold stripping starting speed can be greatly decreased, thus the large coating force of molding sand to the model can be overcome advantageously, and the integrity of the casting mold is effectively maintained; and after mold stripping is conducted by a certain distance, the coating force borne by the model is decreased, the required mold stripping force is also decreased gradually, at the moment, the mold stripping speed of the mold stripping machine can be changed rapidly, the efficiency is improved, thus the mold stripping machine has the characteristics that the mold stripping speed can be decreased firstly and then increased according to the actual situation, and as a result, the mold stripping quality can be ensured, and the mold stripping efficiency can also be improved.

Owner:宁波三未精实科技有限公司

Sand shooting mechanism and sand shooting method of sand shooting machine

InactiveCN108480571AImprove product qualityIncrease production capacityMoulding machinesMould loosening devicesMaterials scienceCushion

The invention discloses a sand shooting mechanism of a sand shooting machine. The mechanism includes an upper mould, a template and a sand shooting plate. A sand core forming cavity is defined by theupper mould and the template; the central part of the upper mould is provided with up-down through cavities; the sand shooting plate is provided with sand shooting nozzles; the template is provided with pouring riser columns and a filter screen; the central part of the sand shooting plate is provided with a sand shooting curing device; the sand shooting curing device includes a heating curing column, a heat resistant guide rod and a riser column retaining ring; an electric heating tube is disposed inside the heating curing column; the top of the heat resistant guide rod is provided with a limit cushion block and a limit screw; and the limit screw has a hollow structure, and a heating lead wire and a lead wire sealing ring are disposed inside the limit screw. The invention also discloses asand shooting method of the sand shooting machine. Through the utilization of the sand shooting curing device, secondary demoulding heating can be performed on the upper mould, the template and a sandcore, the sand shooting pressure can be reduced, mould loss and mould adhering sand conditions can be reduced, the operator labor intensity is decreased, the operator safety risk is reduced, and thecompany production operation cost is reduced.

Owner:NINGGUO TAISHUN EQUIP MFG CO LTD

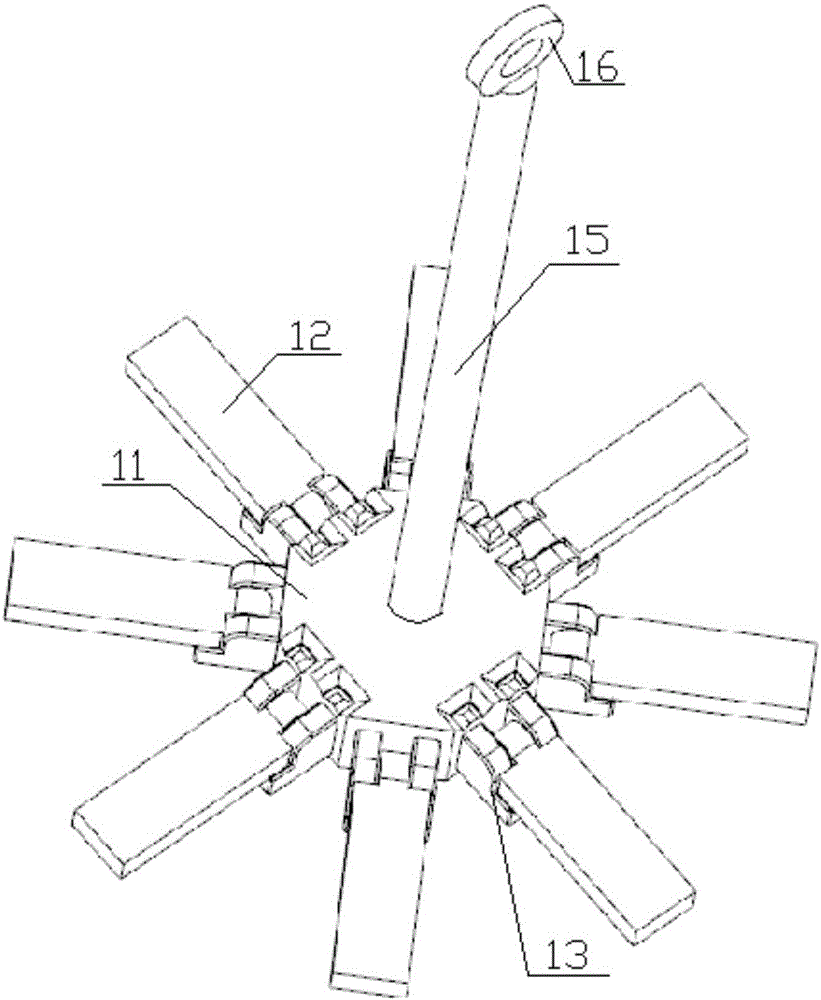

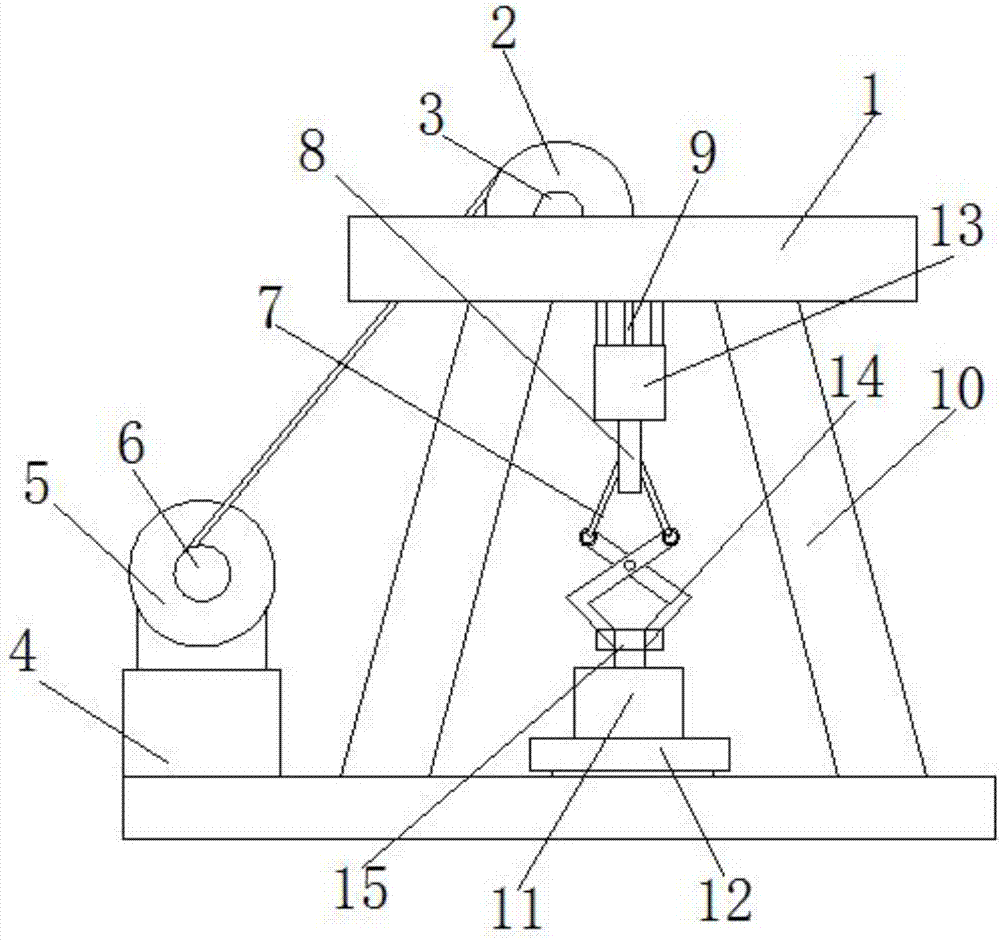

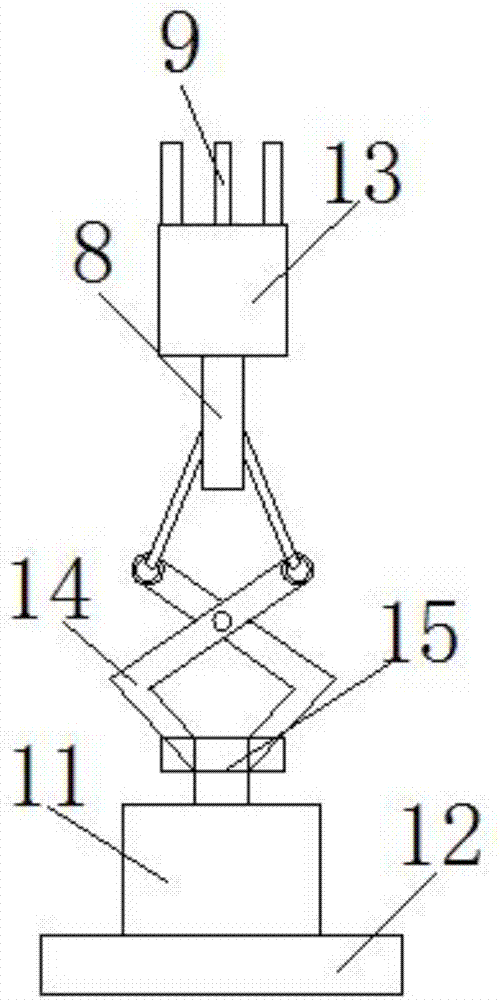

Rotary die sand core withdrawing device of screw air compressor

PendingCN107377897AReduce labor costsChange the direction of forceMoulding machinesMould loosening devicesPhysicsElectric machinery

The invention discloses a rotary die sand core withdrawing device of a screw air compressor. The rotary die sand core withdrawing device comprises a top frame, a pulley, a motor and a support. The pulley is arranged on the upper side of the top frame, the support is fixedly connected with the lower side of the top frame, the motor is arranged on a side of the support, an output shaft is arranged at an end of the motor, a pulling rope is arranged on the lower side of the top frame, a bearing is fixedly connected with the lower side of the pulling rope, an end of the pulling rope is connected with the pulley, a side of the pulley is connected with the output shaft by the pulling rope, a rotary shaft is arranged inside the bearing and is provided with rotary ropes, and a fixture is connected with the lower sides of the rotary ropes. The rotary die sand core withdrawing device has the advantages that the rotary die sand core withdrawing device is simple in structure and novel in design, a die can be driven by the rotary shaft, the bearing and the fixture to rotate, materials can be rotationally discharged from the die under the rotation action of the fixture, the traditional material discharge actions can be replaced, accordingly, the labor cost can be reduced to a great extent, labor and the time can be saved, and the rotary die sand core withdrawing device has an excellent popularization value.

Owner:福建新佳鑫实业有限公司

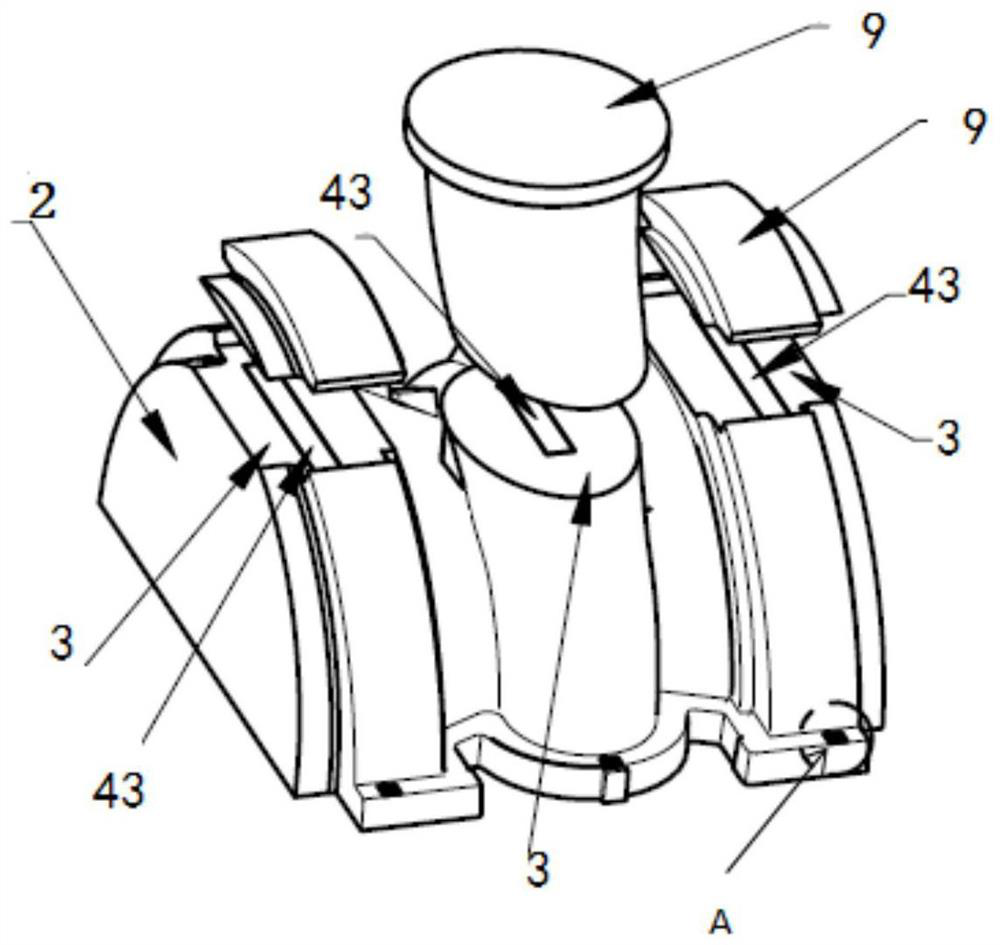

Automatic mold release mechanism for engine casting complex sand core mold

PendingCN108788026AReasonable structureSatisfy automatic demouldingMould loosening devicesInterface designMaterials science

The invention discloses an automatic mold release mechanism for an engine casting complex sand core mold. The automatic mold release mechanism comprises a lower core box and a mold cavity formed in the lower core box and matched with the outer contour of the lower portion of a sand core. The mold cavity of the lower core box is internally and slidably provided with a movable block in an up-down mode, and the movable block and the mold cavity enclose a cavity matched with the outer contour of the lower portion of the sand core. A jacking mold release mechanism capable of jacking the movable block and the sand core upwards is arranged on the lower part of the lower core box, and a sliding guiding structure is arranged between the lower core box and the movable block. According to the automatic mold release mechanism, the structural design is reasonable, the automatic mold release during casting can be met, efficiency is high, core-making precision is high, production cost is low, a moldis convenient to use, and the cumbersome equipment interface design is not required; and since the parts are less, the mold use and maintenance are convenient, automated core-taking production can berealized, and meanwhile, the labor intensity of operators is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

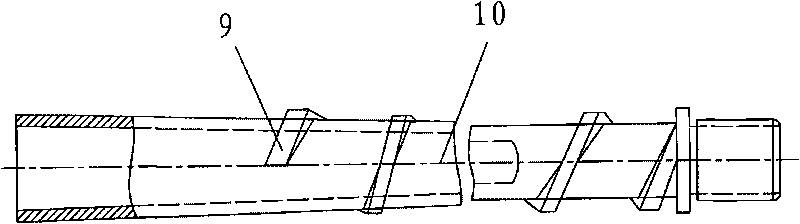

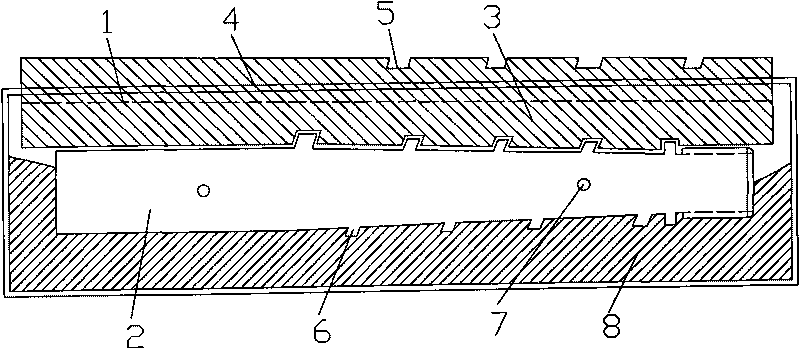

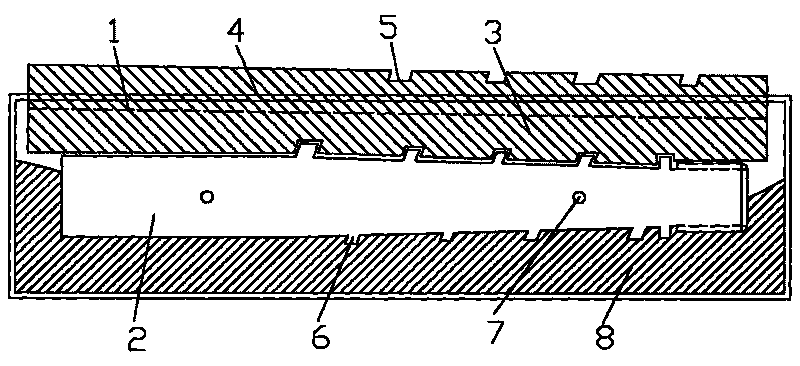

Stirring screw molding process and stripping back plate

InactiveCN101704065AEasy to manufactureAvoid distortionFoundry mouldsFoundry coresEngineeringDistortion

The invention discloses a stirring screw molding process and a stripping back plate. The stripping back plate comprises an upper mold back plate and a lower mold back plate, wherein the tooth-shaped notches of the lower mold back plate and the upper mold back plate are matched with the tooth shapes on two sides of a parting surface of a stirring screw model; the parting surface of the stirring screw model is a plane formed by the tail end of the last tooth shape of the stirring screw model and the axis of the stirring screw; during stripping, the tooth-shaped notch of the upper mold back plate locks the tooth shape of an upper mold model, then pins are inserted in two plug pin holes of the upper mold model respectively, and the upper mold model is screwed out in a screw propelling direction by using the pins to obtain the upper mold of the stirring screw; in the same way, the lower mold of the stirring screw is formed; and finally, the upper and lower molds of the stirring screw are combined to obtain the stirring screw mold. The process avoids the distortion of a sand mold and improves the rate of finished stirring screw sand molds and the rate of finished stirring screw castings, thereby contributing to material conservation, cost reduction and production efficiency improvement.

Owner:HENAN SIDA XIANLONG IND

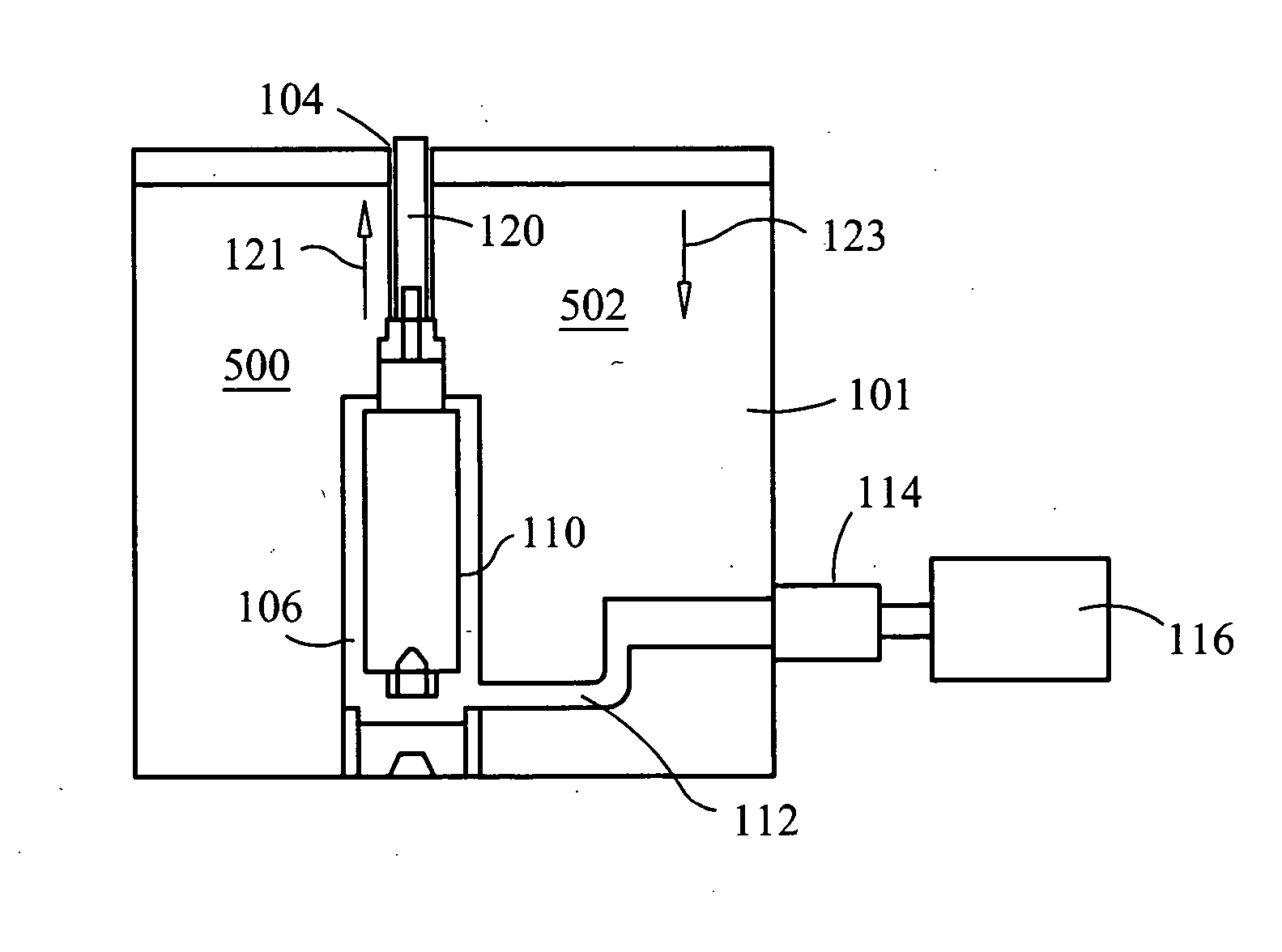

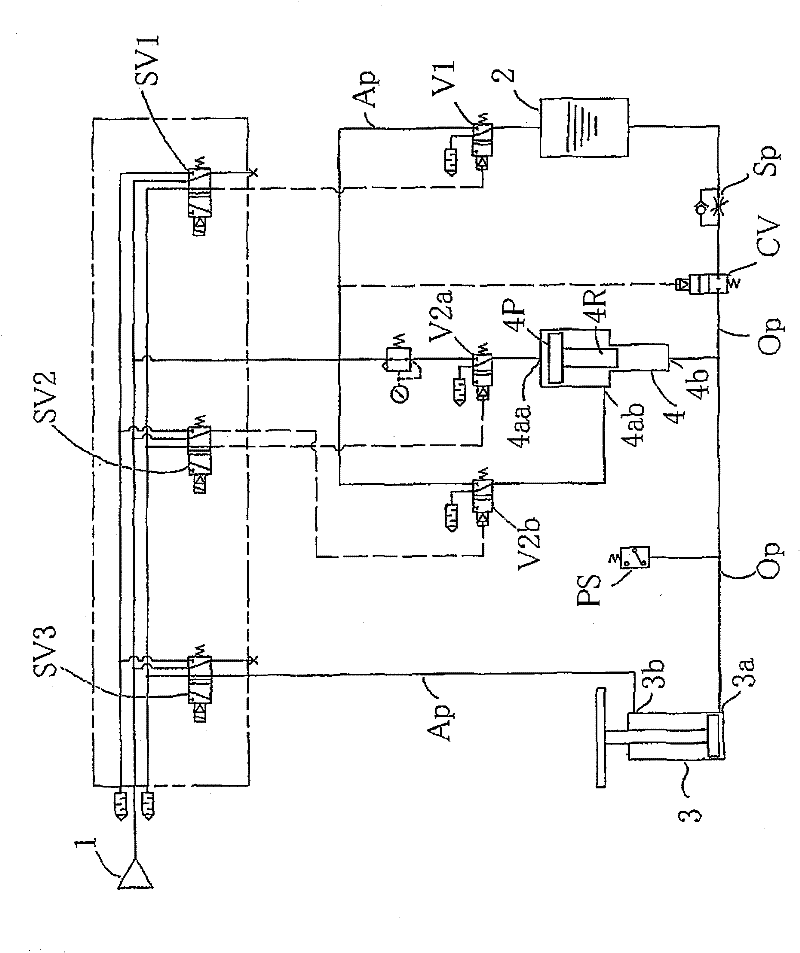

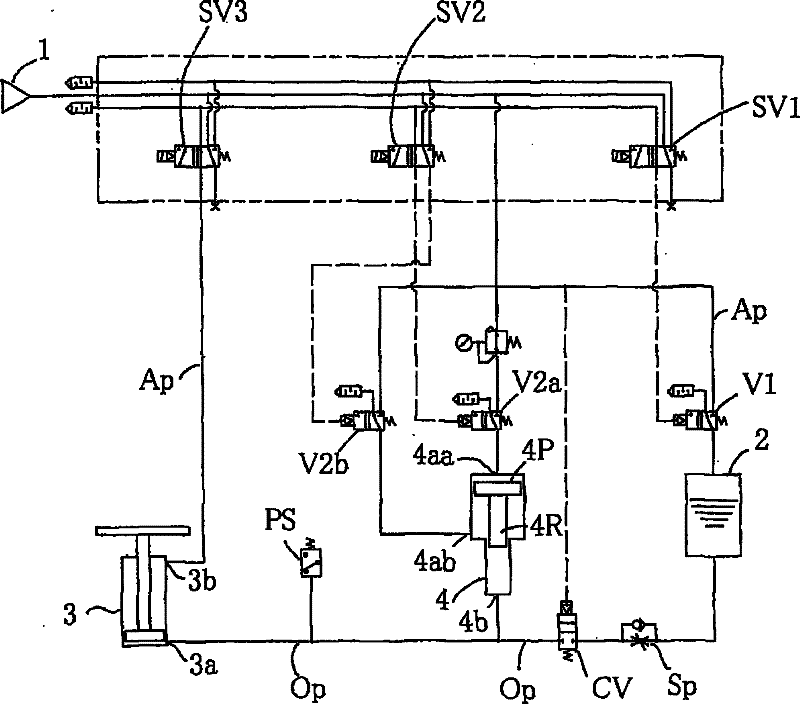

Driving mechanism and slip flask mold molding device in mold molding equipment

ActiveCN101862817BLower replacement costsSuppression of setup costsMoulding machinesMould controlling devicesMiniaturizationPhysics

The present invention provides a driving mechanism with the advantages of capacity for satisfying high-pressure extrusion, easy maintenance and miniaturization in the mold molding equipment, and a slip flask mold molding device with the driving mechanism. The driving mechanism comprises the following components: a compressed air source; an oil tank which has one end that is connected with the compressed air source with a mode that the connection can be switched off; a frame placement extrusion cylinder which has a return hole that is connected with the compressed air source with the mode that the connection can be switched off and has a going hole that is connected with the oil tank with the mode that the connection can be switched off through hydraulic piping; and a pressurizing cylinder. The going hole and the return hole of the pressurizing cylinder can be connected with the compressed air source with a mode that the connection can be switched off and are connected with the oil tank through a mode the communication is allowed. The pressurizing cylinder is connected with the frame placement extrusion cylinder with a normal communication mode through hydraulic piping. The slip flask molding device adopts the mechanism.

Owner:SINTOKOGIO LTD

Mechanism for taking movable sand mold block

PendingCN109396362AFully automatedIncrease productivityMould loosening devicesEconomic benefitsIndustrial engineering

The invention discloses a mechanism for taking a movable sand mold block. The mechanism comprises a rack; a vertical driving mechanism is arranged on the rack; a horizontal driving mechanism is arranged on the vertical driving mechanism, and a mechanical claw is arranged on the horizontal driving mechanism. The vertical driving mechanism comprises two groups of sliding guide devices which are arranged on the rack parallelly, the sliding guide devices are provided with vertical sliding blocks, and the vertical sliding blocks are provided with horizontal driving mechanism bodies. The mechanicalclaw can grab the movable block and pull the movable block out of a mold through the horizontal driving mechanism and the vertical driving mechanism; the automated operation of taking the movable block through the mold is achieved. By arranging the mechanism, automation is achieved in the technological procedure of taking the movable block, and the production efficiency is greatly improved; manualoperation is reduced, the production efficiency is greatly improved, the labor cost is reduced, and the economic benefit is increased. The operation precision can be greatly improved, the problem ofmold damage caused by manual errors in the manual operation process can be avoided, and the production quality is improved.

Owner:攀枝花伦奇机器人科技有限公司

Shaped out of the box shelf

ActiveCN109158552BSimple designEasy to operateMoulding flasksMould loosening devicesMalletMarine engineering

The invention discloses a box separation frame for modeling. The box separation frame comprises two sand boxes, wherein one sand box is correspondingly placed on the top side of the other sand box; side lugs are fixedly mounted on two sides of the two sand boxes; hook racks are arranged on two sides of the sand box; hook holes are formed in mutually close sides of the two hook racks; mutually awaysides of the two side lugs respectively extend into the two hook holes; a mounting basket is arranged above the hook racks; two moving blocks are connected to the mounting basket in a sliding manner;a moving hole is formed in one side of each of the two moving blocks. The box separation frame for modeling is simple in design and convenient to operate; after the box separation frame is used, box-staggered rejected products caused by striking the sand boxes with a wooden mallet are reduced, and the casting qualification rate can be increased; manmade box staggering caused by box separation isavoided, so that rejected products caused by the manmade box staggering are reduced; meanwhile, a distance between the two hook racks can be adjusted, and a distance between two push plates can be adjusted; the box separation frame for modeling can adapt to sand boxes of different sizes and side lugs of different sizes, so that the universality of the device is improved, and demands of people aremet.

Owner:济南市平阴县玛钢厂

Mould lifting device with mould lifting disks

Owner:句容市有色金属铸造厂

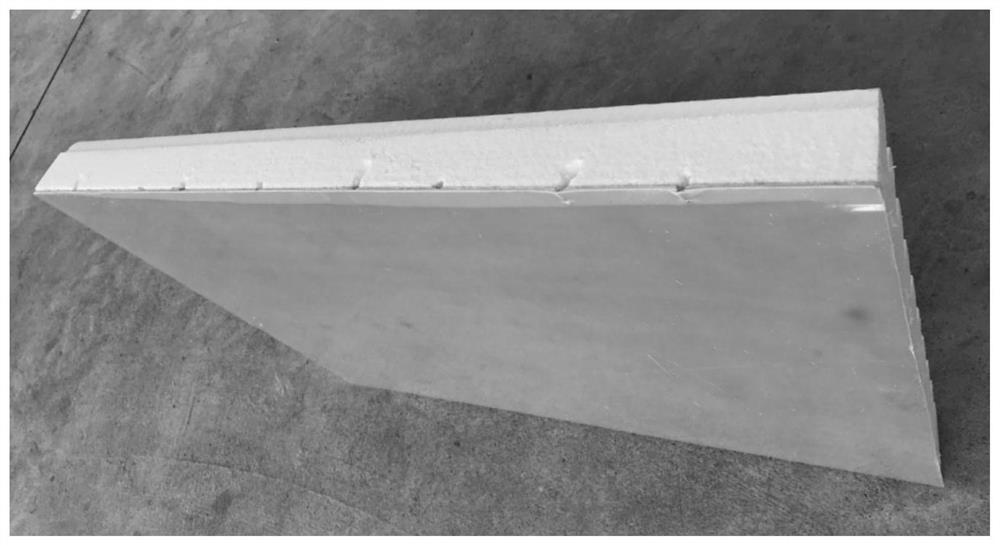

Drawing method of EPS foam-epoxy resin composite die applied to sand casting

PendingCN112111130AHigh strengthSolve the deformation,Non-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive cement

The invention discloses a drawing method of an EPS foam-epoxy resin composite mold applied to sand mold casting. The drawing method comprises the following steps: S1, preparing an epoxy resin plate material with the thickness being 1-5mm; S2, manually splicing EPS foam plates to form a model with the maximum size required by the mold, and integrally feeding the model into an engraving machine forprocessing to obtain a mold sample; S3, cutting, polishing and sanding the epoxy resin plates according to the specific shape and size requirements of the parting surface of the mold sample to obtainepoxy resin reinforcing plates, and attaching the epoxy resin reinforcing plates to the drawing part of the mold by using an adhesive; and S4, during mold drawing, fixing the mold to a molding flat plate through vacuum adsorption equipment, jacking up a sand box and the sand mold through synchronous hydraulic equipment, so as to complete the mold drawing procedure. The epoxy resin reinforcing plate is additionally arranged on the molded surface of the EPS foam mold, mold drawing can be balanced, the stress point can be reinforced, the overall strength of the mold is improved, and the problemsthat the mold is prone to deformation and difficult to draw in the mold process are solved.

Owner:广西长城机械股份有限公司

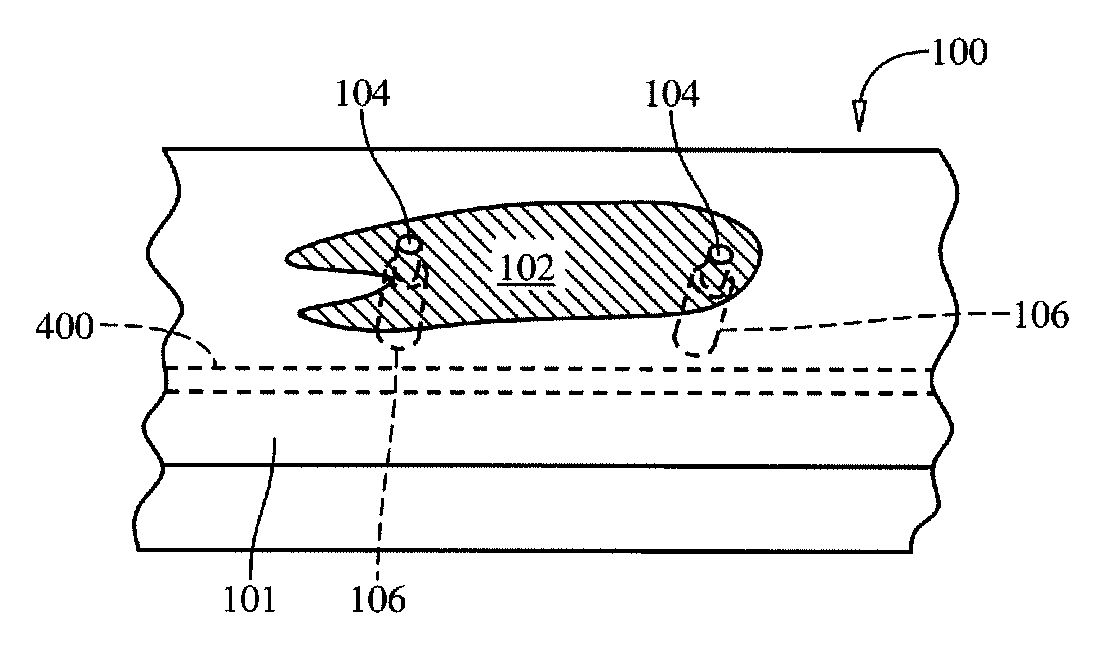

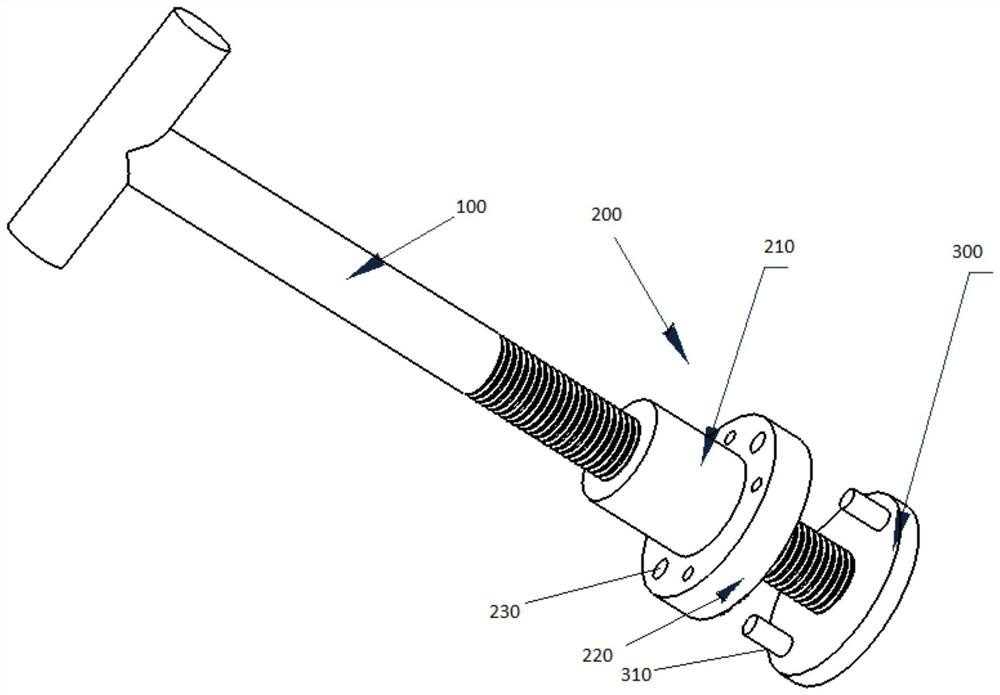

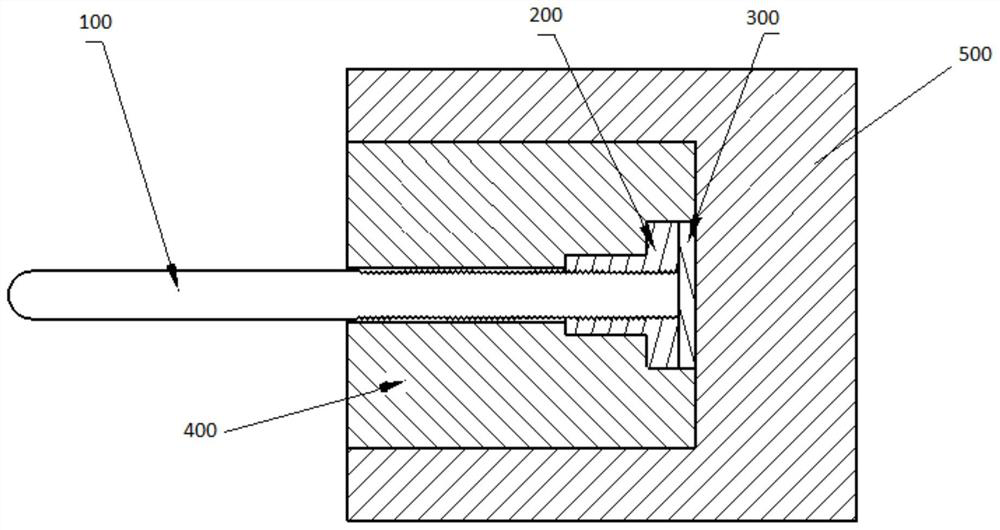

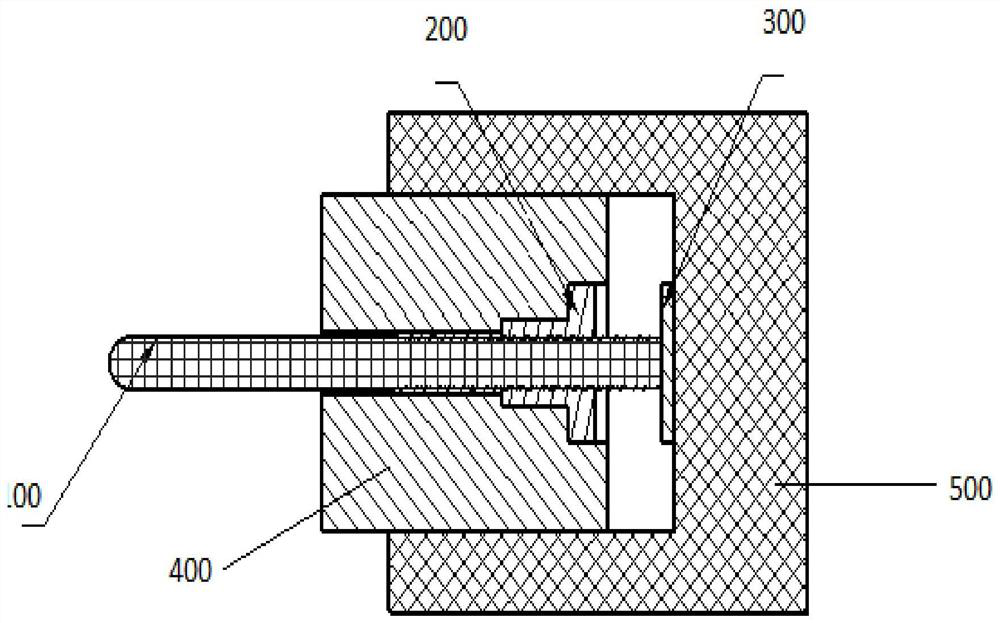

Mold lifting device

PendingCN113732253ASmooth exitProtect completenessMould loosening devicesEngineeringMechanical engineering

The invention relates to a tool for casting a mold, and particularly relates to a mold lifting device. The mold lifting device comprises a rotating structure, an embedding structure and an auxiliary structure, wherein a channel is formed in a mold movable material; the embedding structure is arranged in the channel; the auxiliary structure is positioned between the mold movable material and a sand core; one end of the rotating structure penetrates through the channel and is detachably connected with the auxiliary structure; the rotating structure is connected and matched with the embedding structure; and the rotating structure is rotated to enable the embedding structure to drive the mold to be far away from the sand core. The mold lifting device solves the problems of difficult mold lifting and low casting quality in traditional knocking, reduces the mold lifting difficulty, improves the production efficiency, and is simple in operation and high in adaptability.

Owner:KOCEL EQUIP

Aluminum generator shell mold

PendingCN114178487AQuality assuranceWill not deformMoulding machinesMould loosening devicesCompression moldingHydraulic cylinder

The aluminum generator shell mold comprises a hydraulic cylinder, the movable end of the hydraulic cylinder is fixedly connected with a lifting bottom plate, welding supporting legs are installed at the four corners of the top of the lifting bottom plate in a welded mode, and a workbench is connected to the tops of the welding supporting legs in a welded mode. According to the aluminum generator shell mold, the traditional preparation process is simplified, compression molding can be achieved only by placing the middle mold on the top of the mold bottom plate and guiding green sand into the middle mold, the process is simple and rapid, mechanical hydraulic compaction and manual compaction operation are more convenient, and during demolding, the production efficiency is greatly improved. During demolding, the middle mold directly moves upwards, and the green sand and the shell workpiece are directly separated in a vertical linear manner, so that demolding can be performed quickly and conveniently, a mold core cannot be deformed, and the subsequent casting precision can be ensured.

Owner:曹俊辉

Sand core automatic demoulding mechanism and demoulding method for screw compressor rotor

ActiveCN102909321BQuality assuranceThe speed is stable and easy to controlMould loosening devicesHeater RodEngineering

Owner:桐乡合德机械有限公司

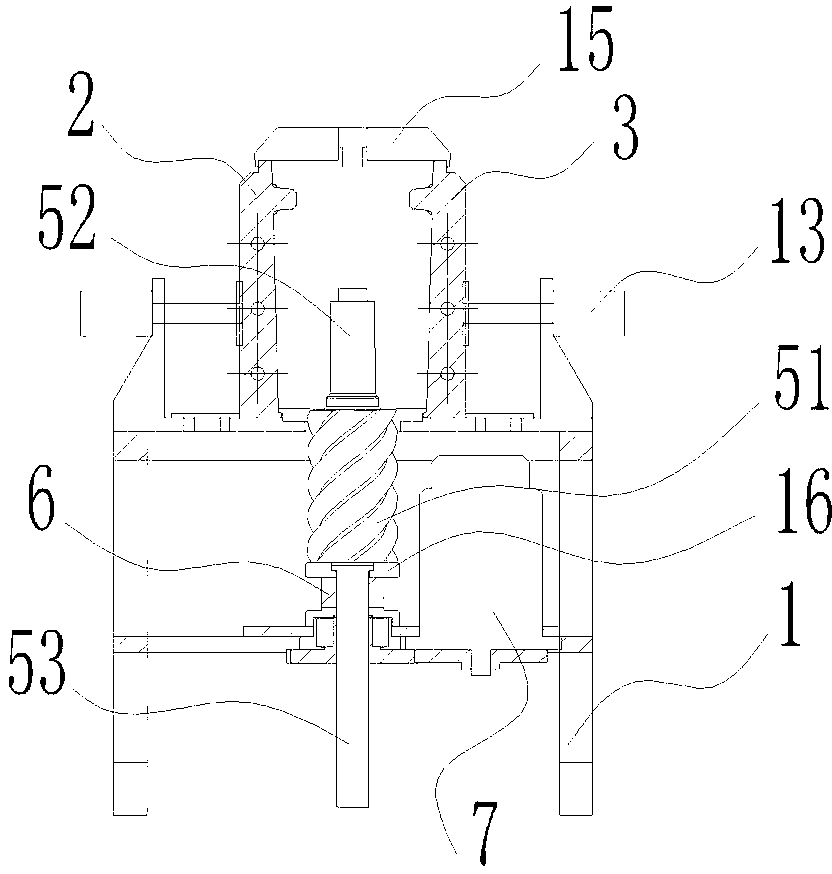

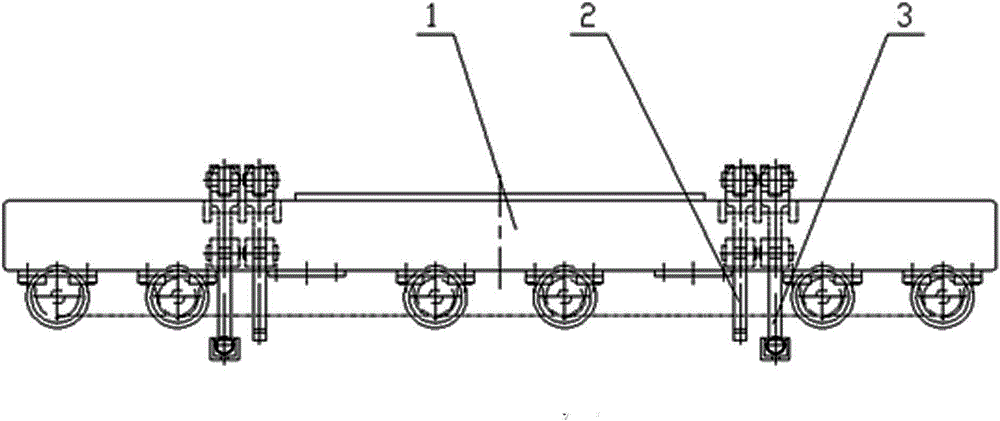

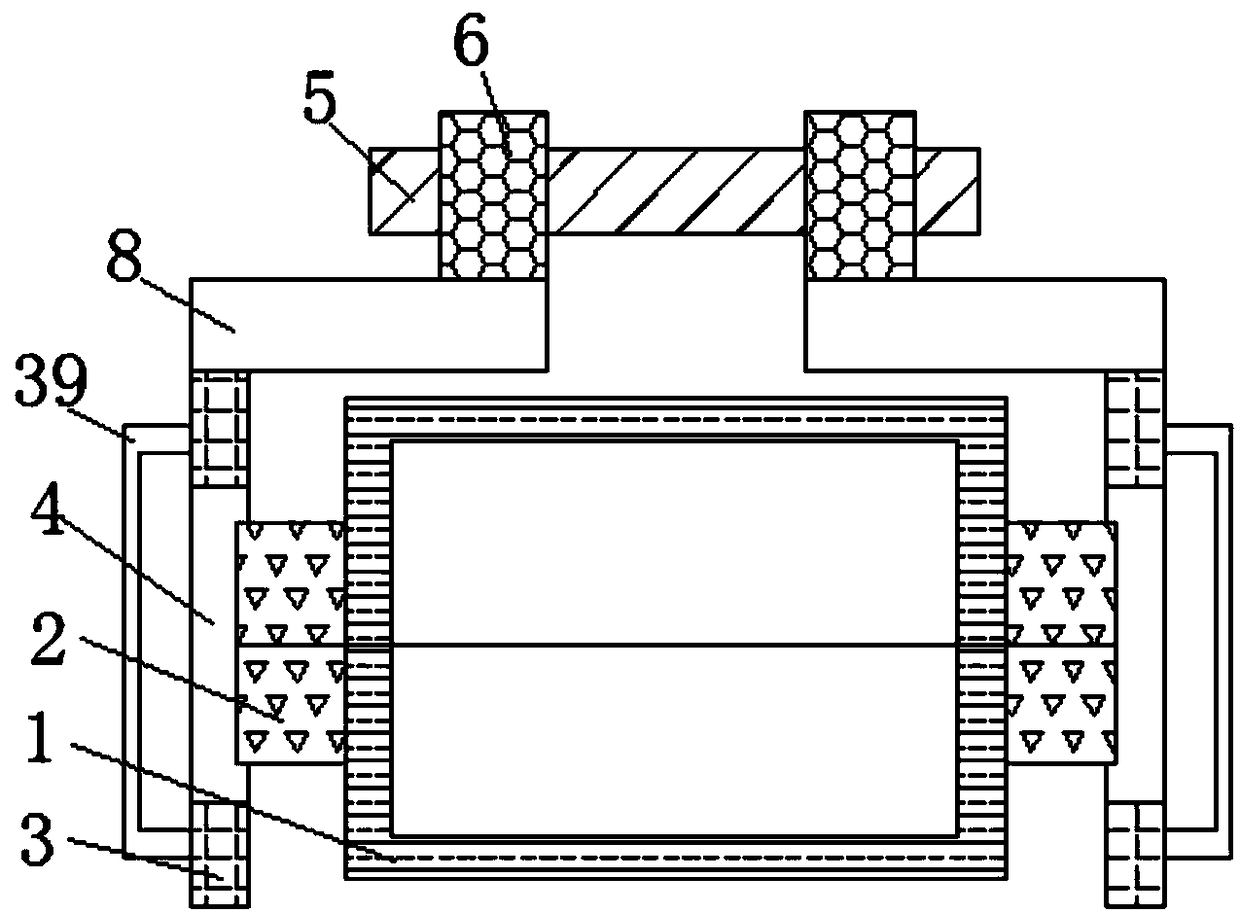

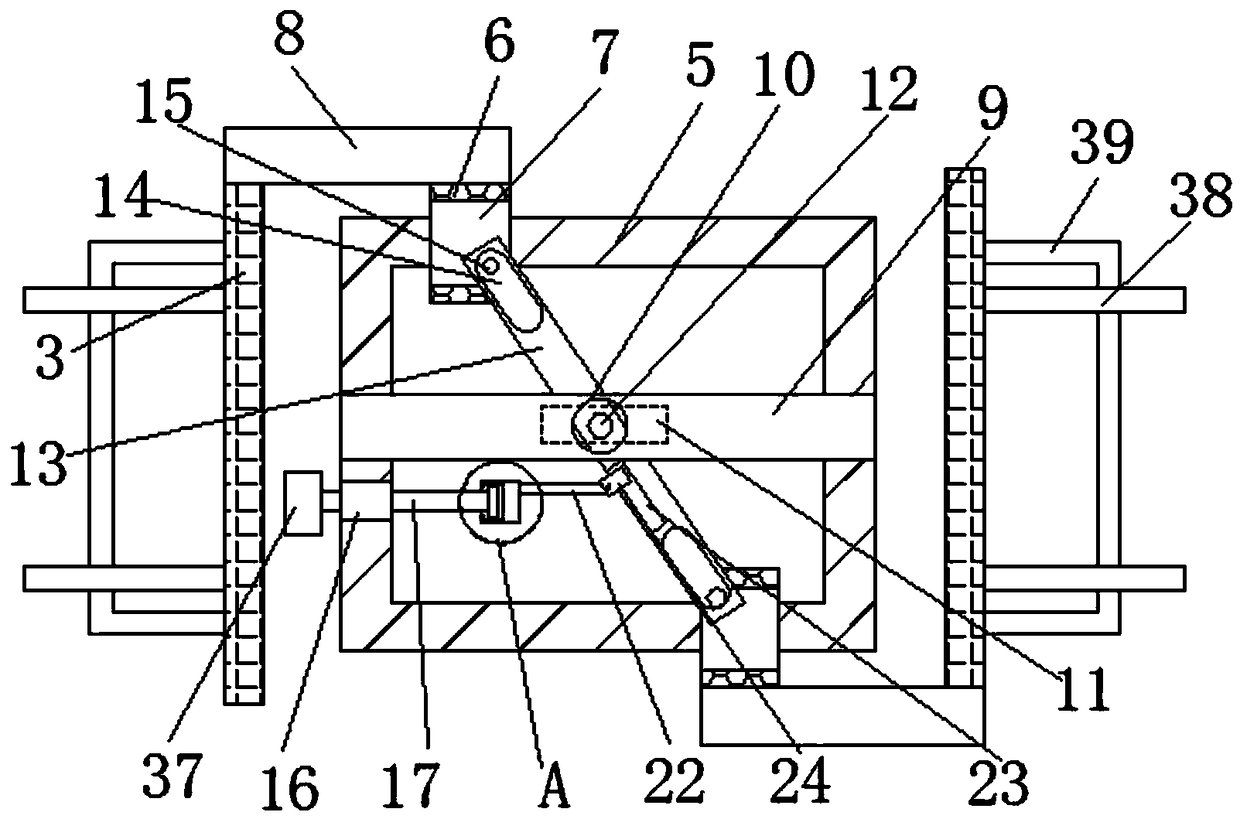

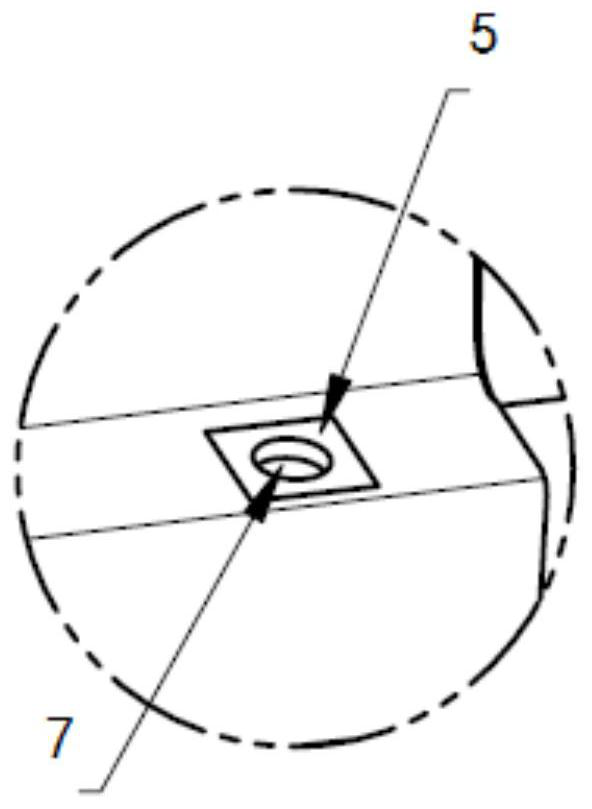

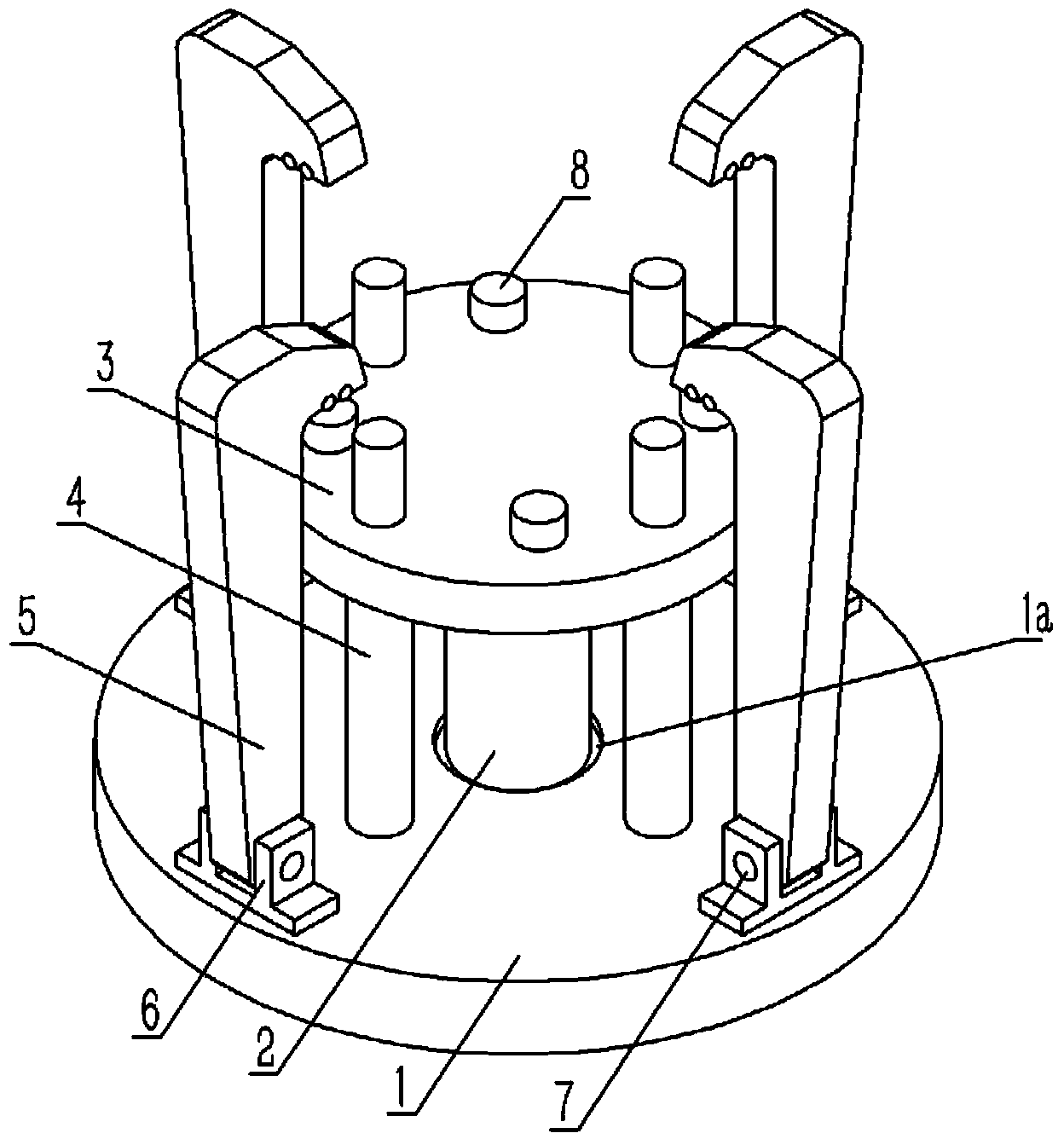

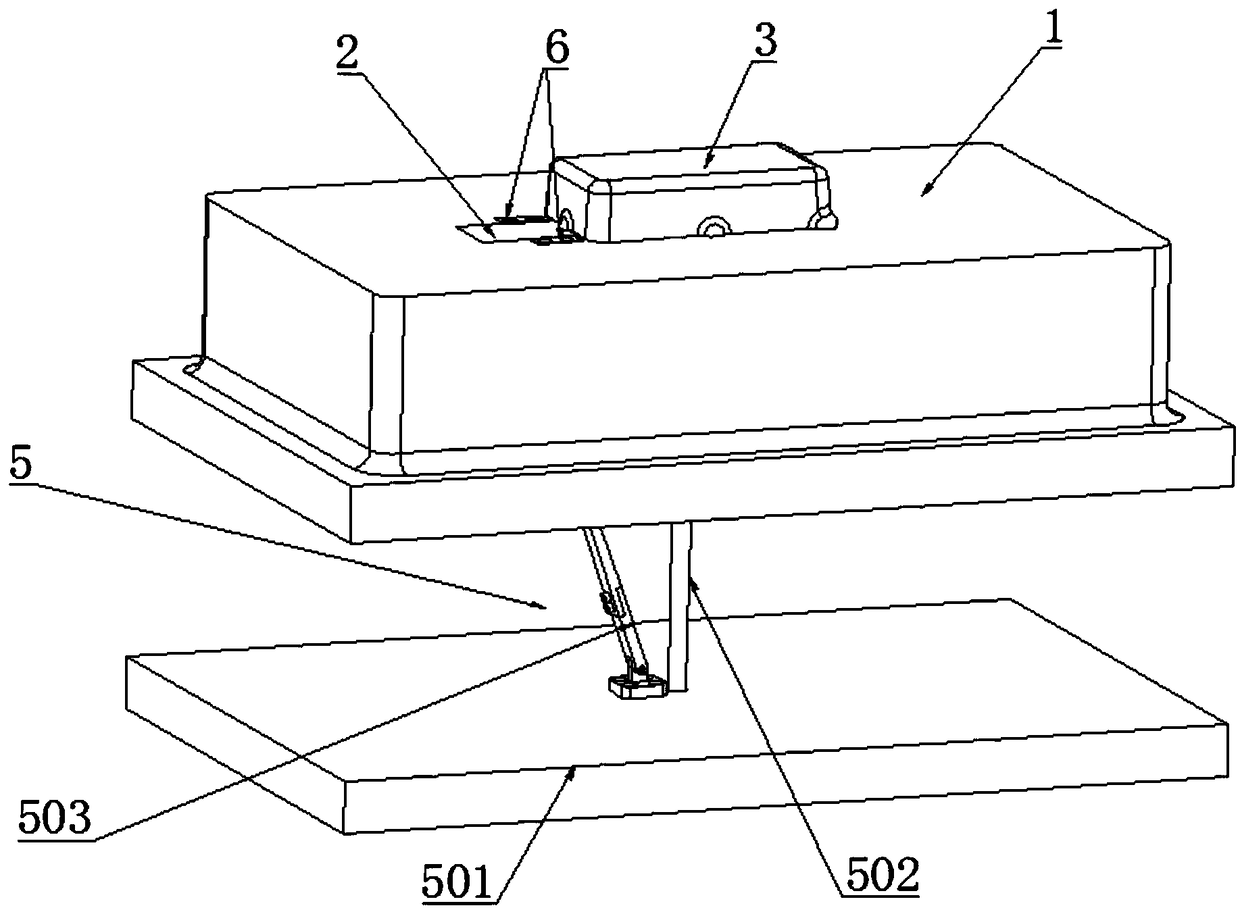

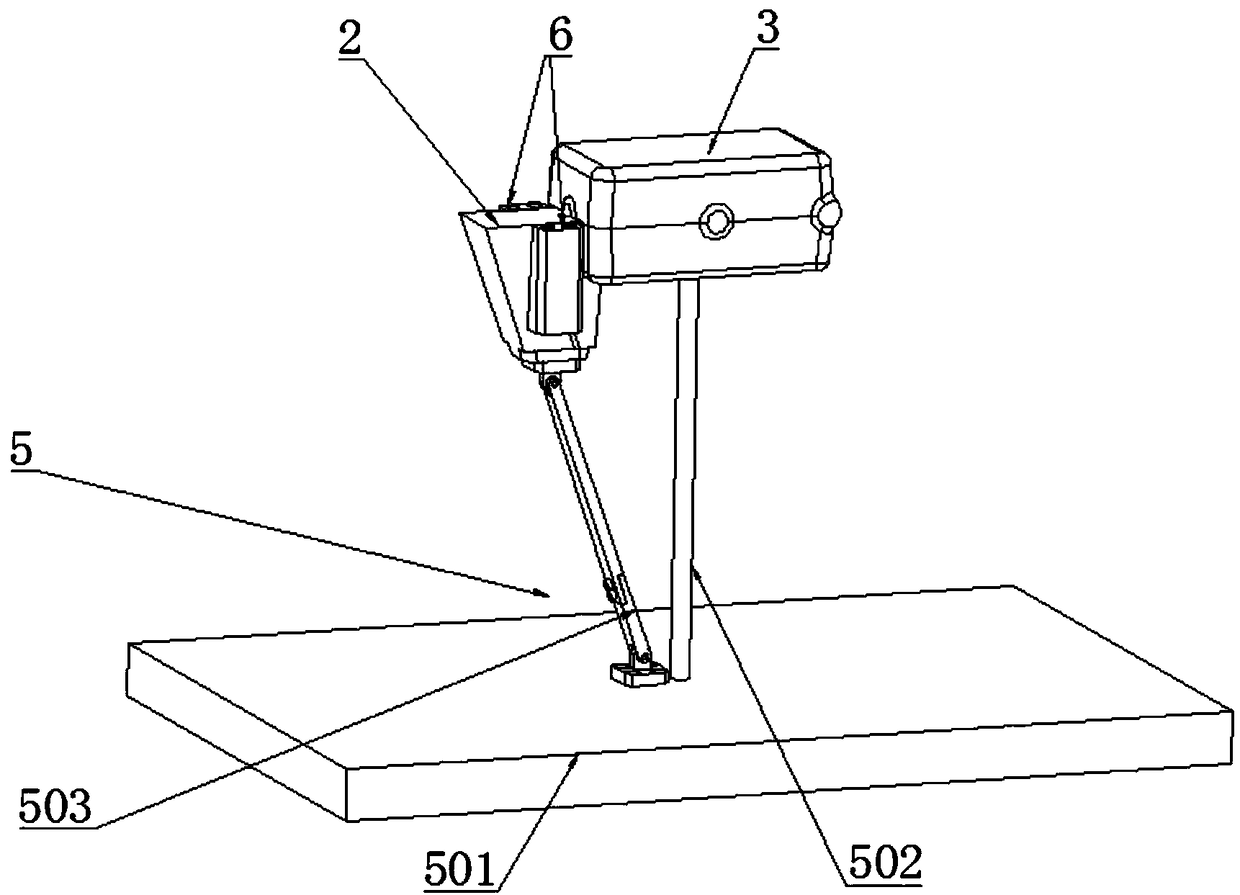

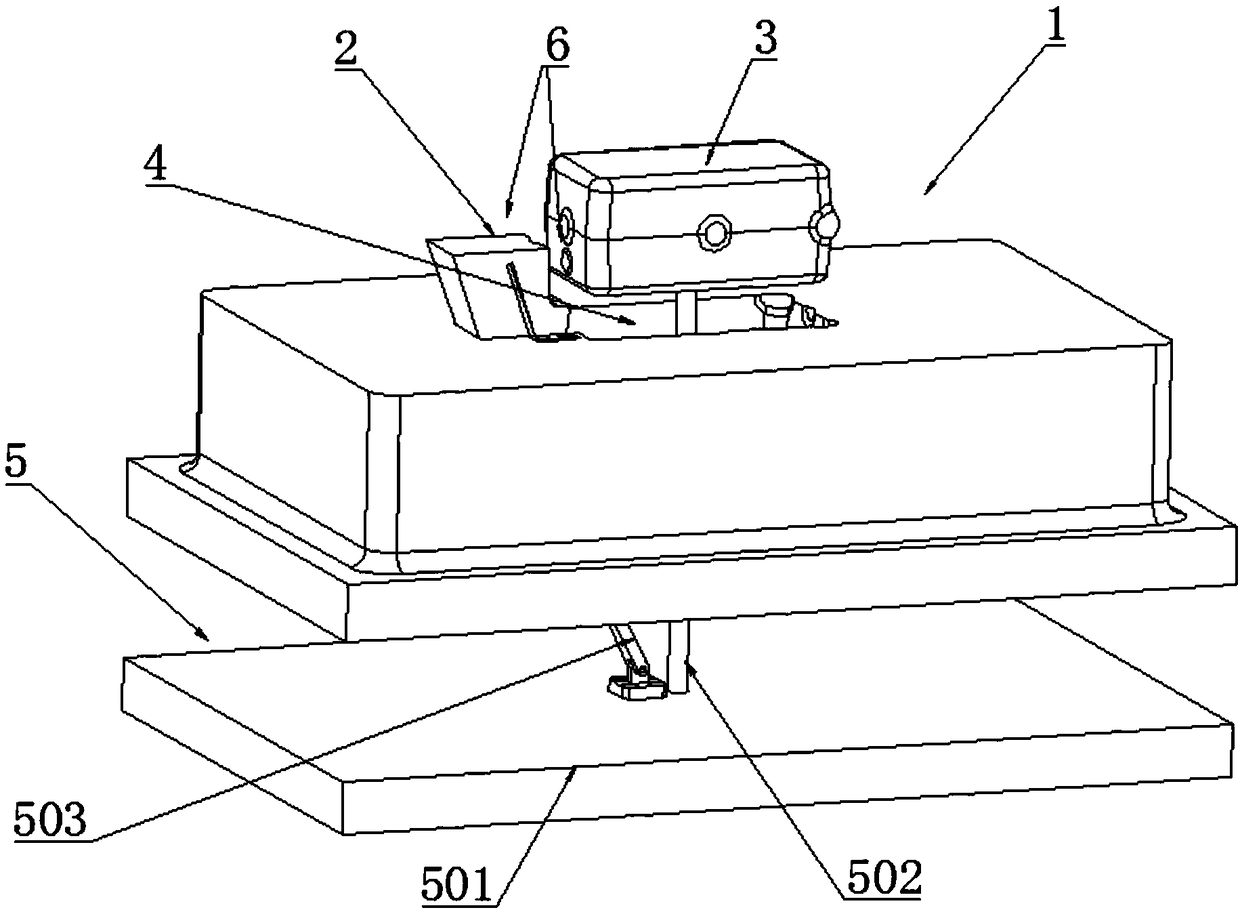

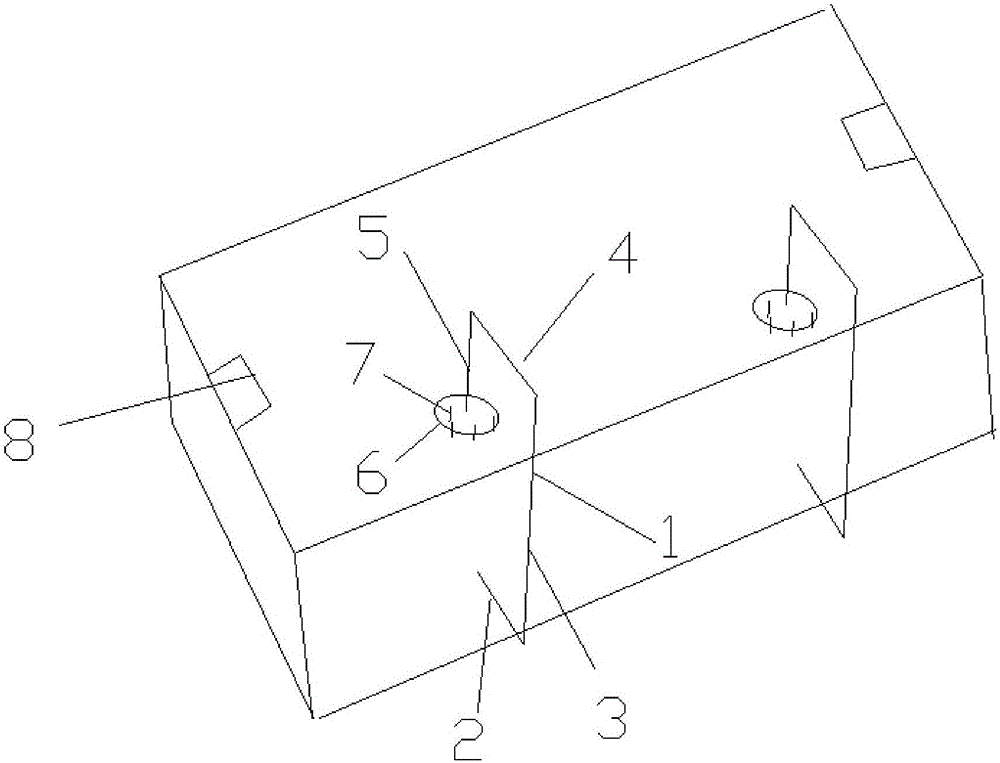

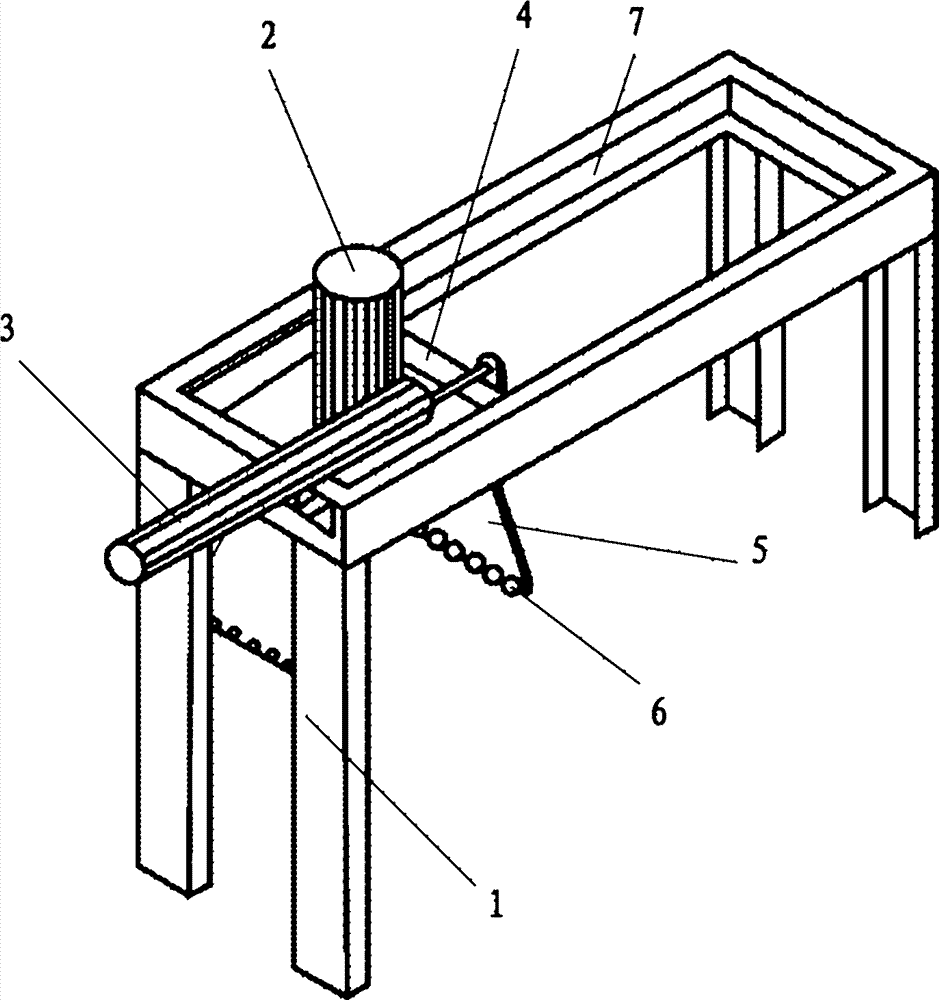

A mold opening and closing machine

ActiveCN102601321BSimple structureReduce manufacturing costMoulding machinesMould loosening devicesControl engineeringPiston rod

The invention discloses a mold opening and closing machine, which comprises a fixed rack (1), a lifting cylinder (2), a stretching cylinder (3), a fixed flat car (4), a mold grasping rack (5) and rollers (6), wherein a guide rail (7) is arranged on the fixed rack (1), and the fixed flat car (4) is arranged in the guide rail (7); a barrel of the stretching cylinder (3) is fixedly arranged on the fixed rack (1), and a piston rod of the stretching cylinder (3) is fixedly arranged on the flat car (4), and makes stretching movement to drive the fixed flat car (4) to slide in the guide rail (7); a barrel of the lifting cylinder (2) is fixedly arranged on the fixed flat car (4), and a piston rod of the lifting cylinder (2) is fixedly arranged on the mold grasping rack (5), and makes stretching movement to drive the mold grasping rack (5) to make vertical lifting movement so as to open and close a mold; and a plurality of rollers (6) are arranged on the mold grasping rack (5). The mold opening and closing machine disclosed by the invention has the advantages that: the power mechanism is simple in structure, and the manufacturing cost is reduced.

Owner:安徽新高新钢球集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com