Sand core automatic demoulding mechanism and demoulding method for screw compressor rotor

A screw compressor and automatic demoulding technology, applied in the field of casting, can solve the problems such as the inability to guarantee the quality of the screw compressor rotor, high labor intensity of workers, low production efficiency, etc., to achieve stable and easy control of rotational speed, ingenious overall concept, and improved production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

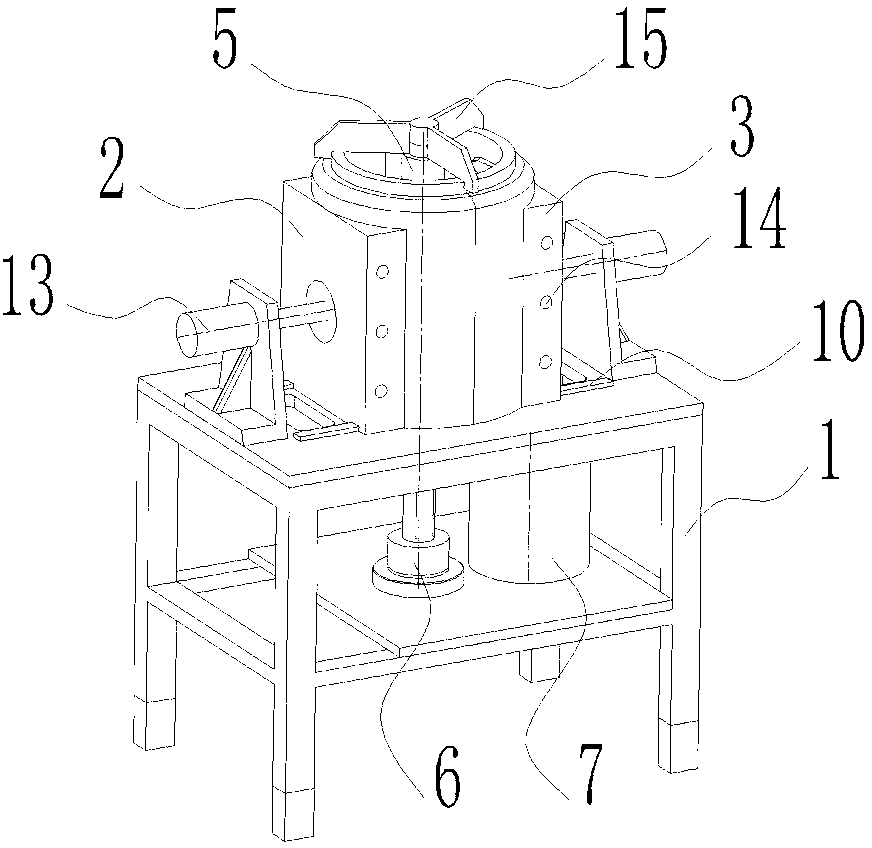

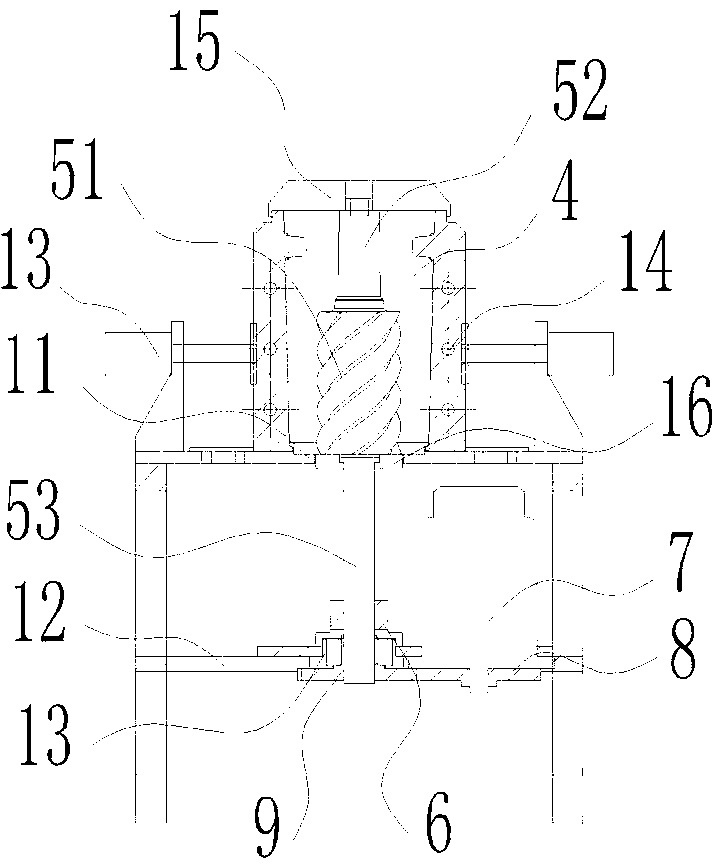

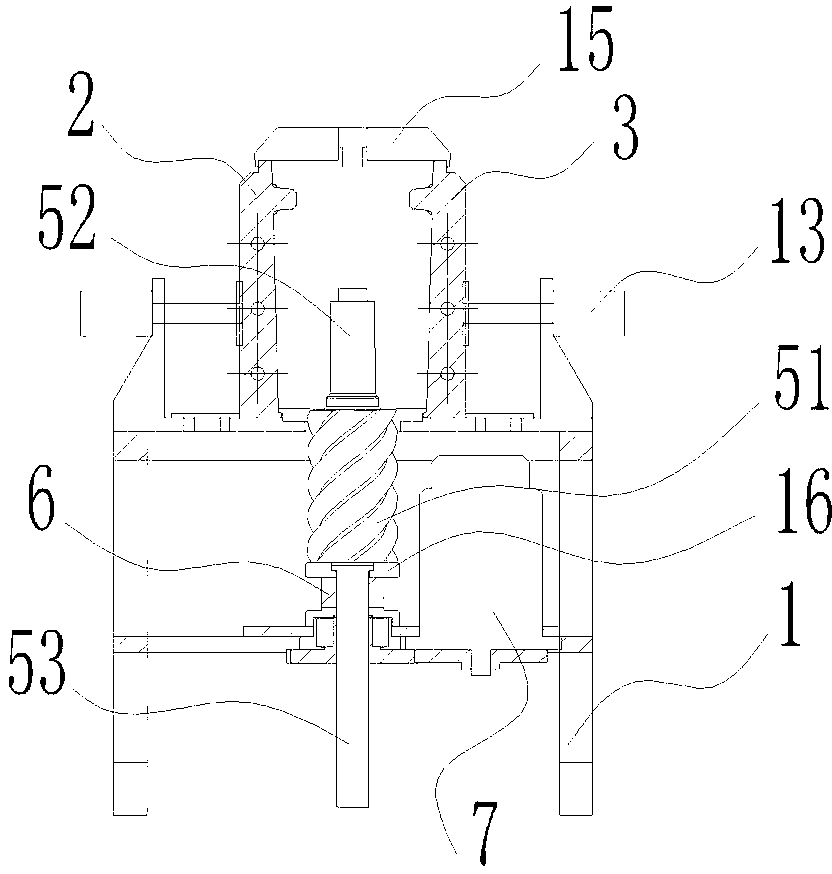

[0028] like figure 1 As shown, a sand core automatic demoulding mechanism for a screw compressor rotor of the present invention includes a bracket 1 of a square frame structure, a horizontal support plate 12 is welded in the middle of the support 1, and a horizontal support plate 12 is fixed by bolts. An air motor 7 with a reducer, the output shaft of the air motor 7 is fixed vertically downward on the horizontal support plate 12, a left mold 2 and a right mold 3 are vertically installed on the upper surface of the bracket 1, the left mold 2 and the The right mold 3 is a symmetrically distributed semicircular structure, and three heating rods 14 connected to an external power supply are installed horizontally in the left mold 2 and the right mold 3 respectively. The mold 3 is symmetrically arranged, and the left mold 2 and the right mold 3 are connected to form a cylindrical sand core cavity 4 together. Rail 10, the outer end of slide rail 10 is equipped with cylinder 13 sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com