Patents

Literature

87results about How to "Won't deviate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for coating graphene on surfaces of metal foils

ActiveCN107457141AThe glue layer is thin and uniformStrong adhesionPretreated surfacesCoatingsMetal foilCopper foil

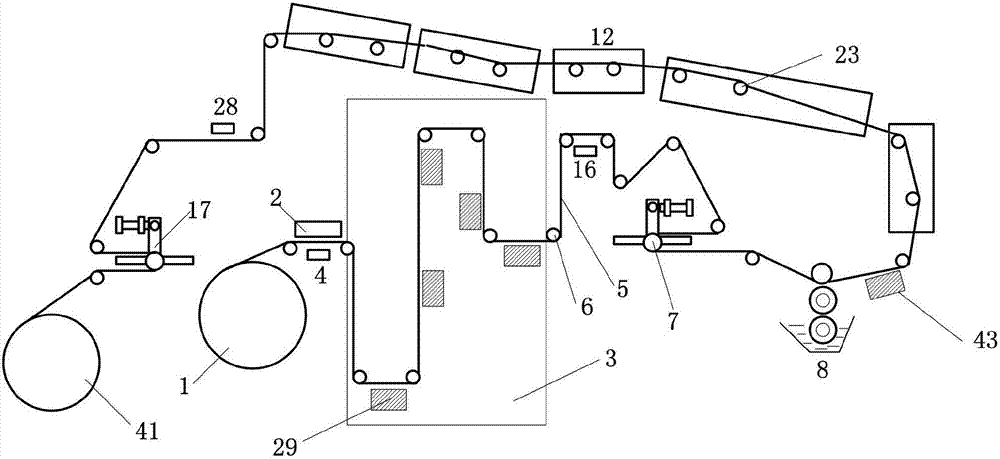

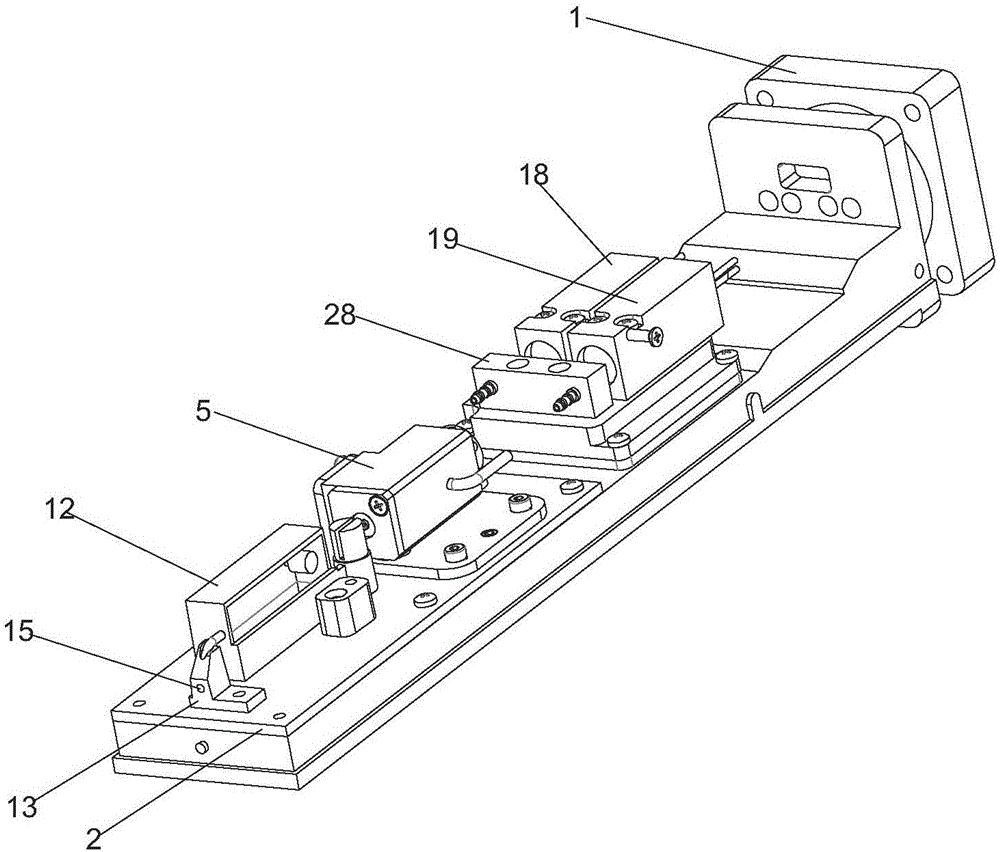

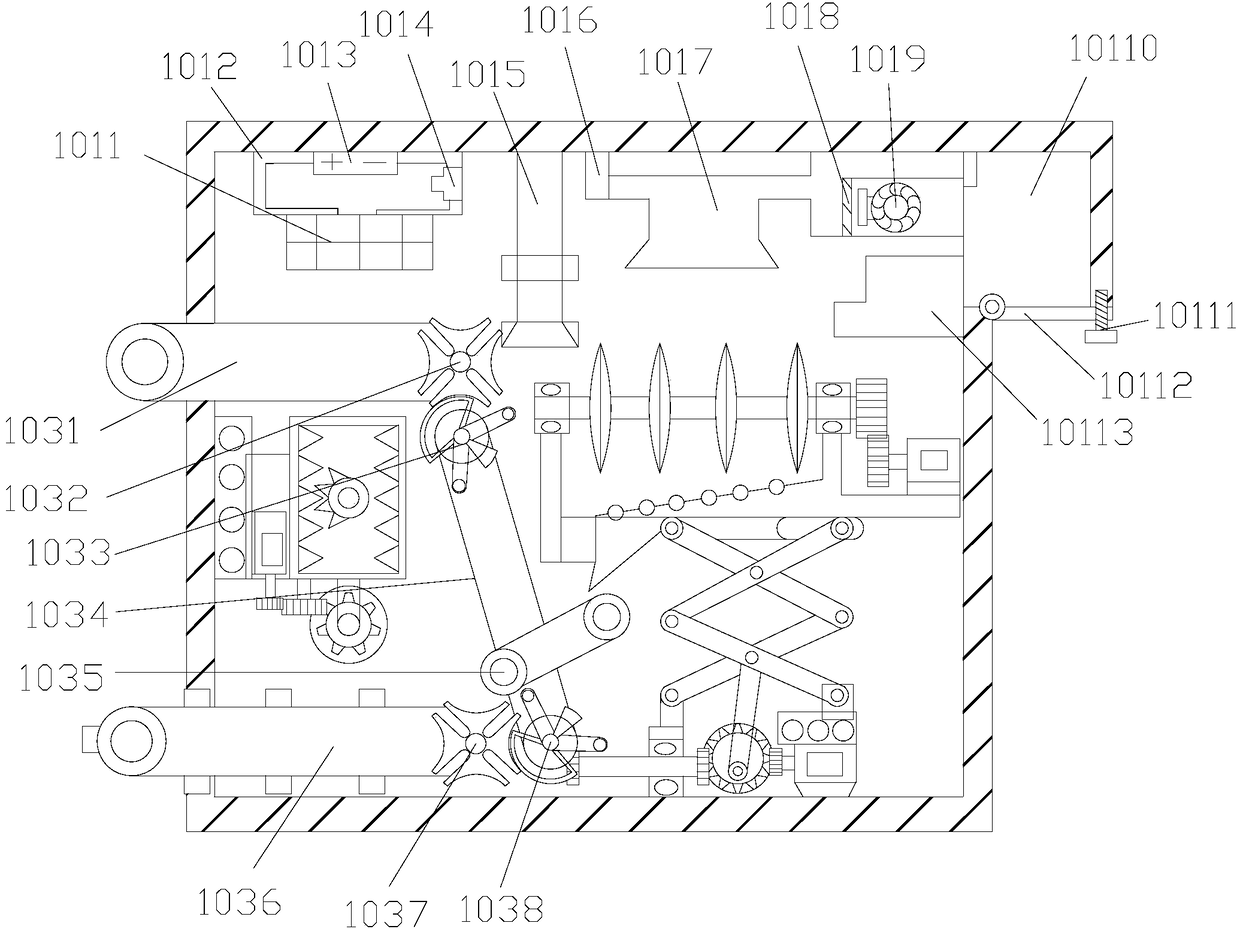

The invention discloses a device for coating graphene on surfaces of metal foils. The device comprises a control unit, and an unwinding unit, a coating printing device, a baking unit and a winding unit arranged in sequence in a moving direction of the metal foils; the metal foils are aluminum foils or copper foils; the coating printing device comprises a pressing roller, a driving silica gel roller and a driving steel roller laminated from top to bottom; the driving silica gel roller and the driving steel roller are rotated in opposite directions by keeping a micron gap; the driving steel roller is dipped in a colloid pool with viscous materials; and a substrate is arranged between the pressing roller and the driving silica gel roller. The device realizes uniform spraying of materials with submicron thicknesses and thinner layers on the surface of the substrate to meet the thickness requirements of the graphene coated on the metal foils, and achieves excellent adhesion to effectively reduce the contact resistance between carbon particles and the metal foils.

Owner:陕西浩合机械有限责任公司

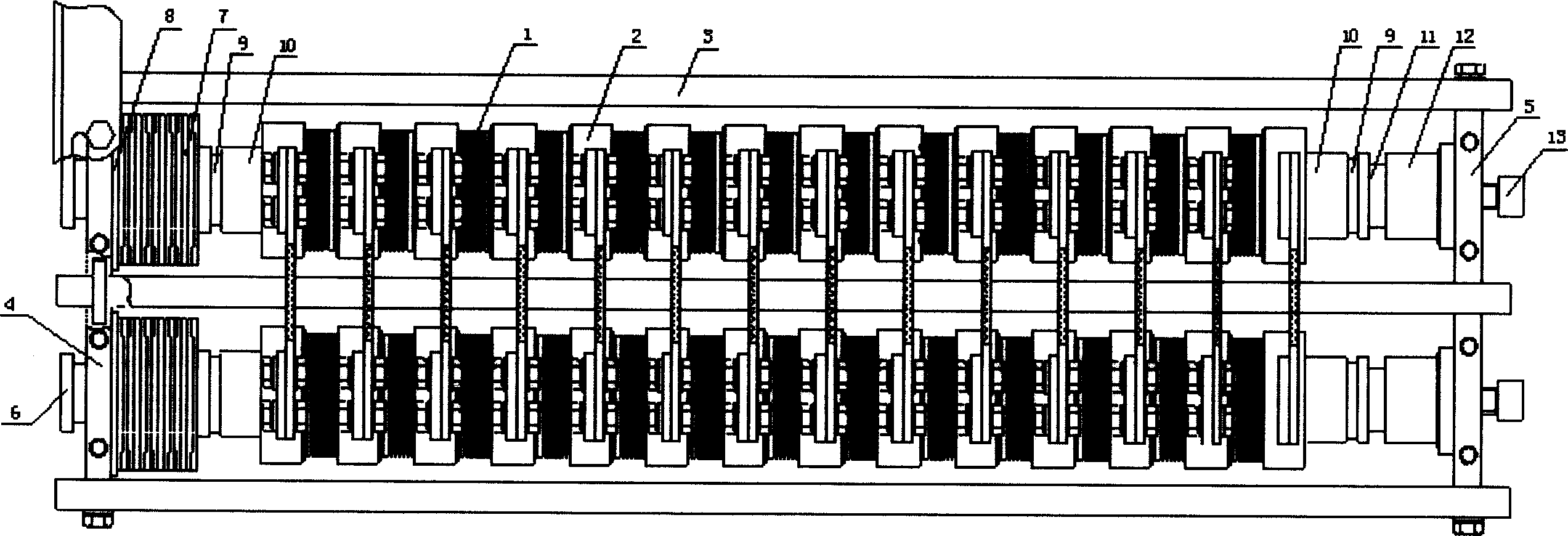

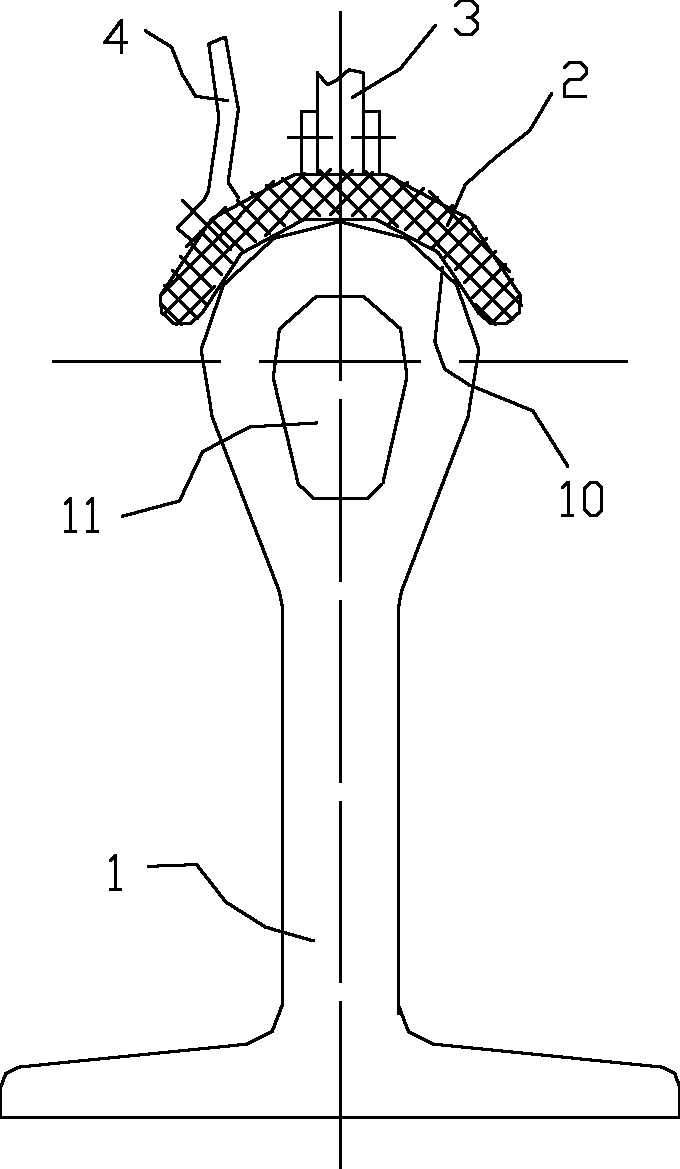

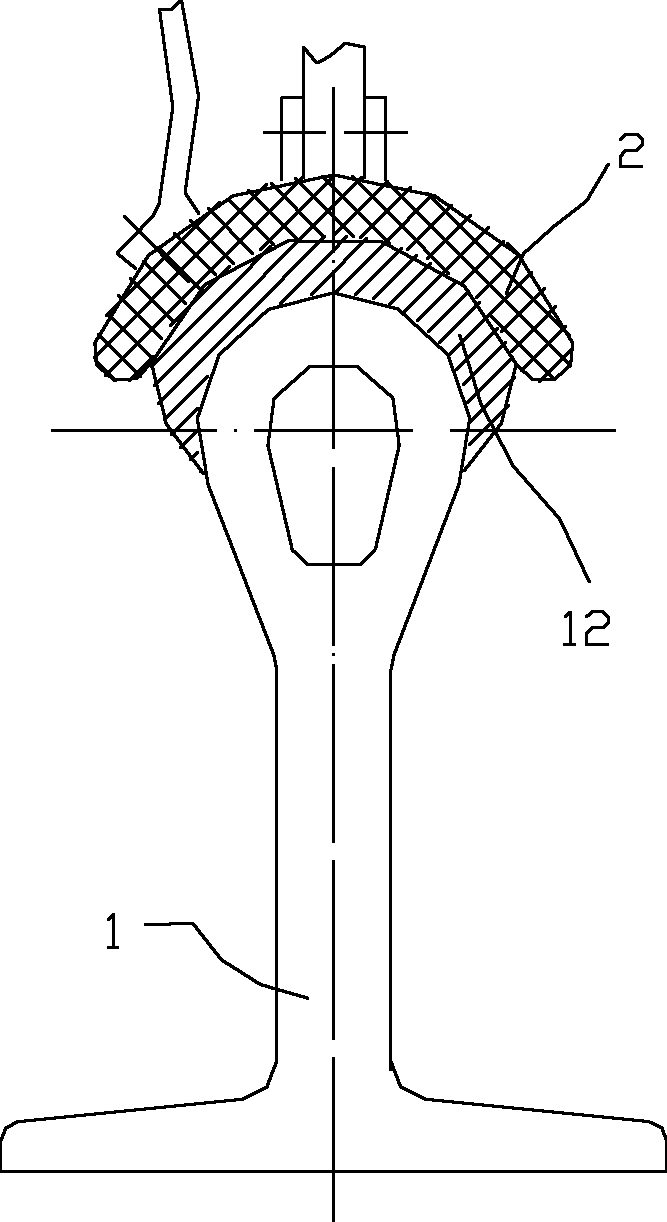

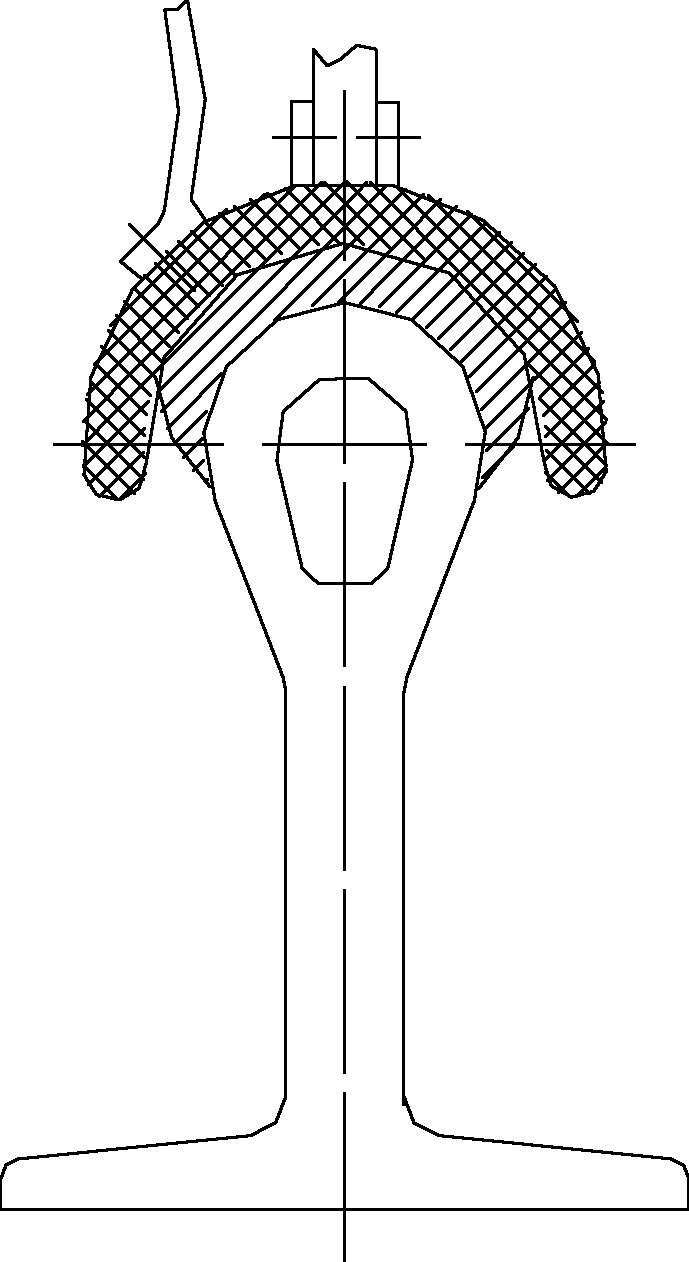

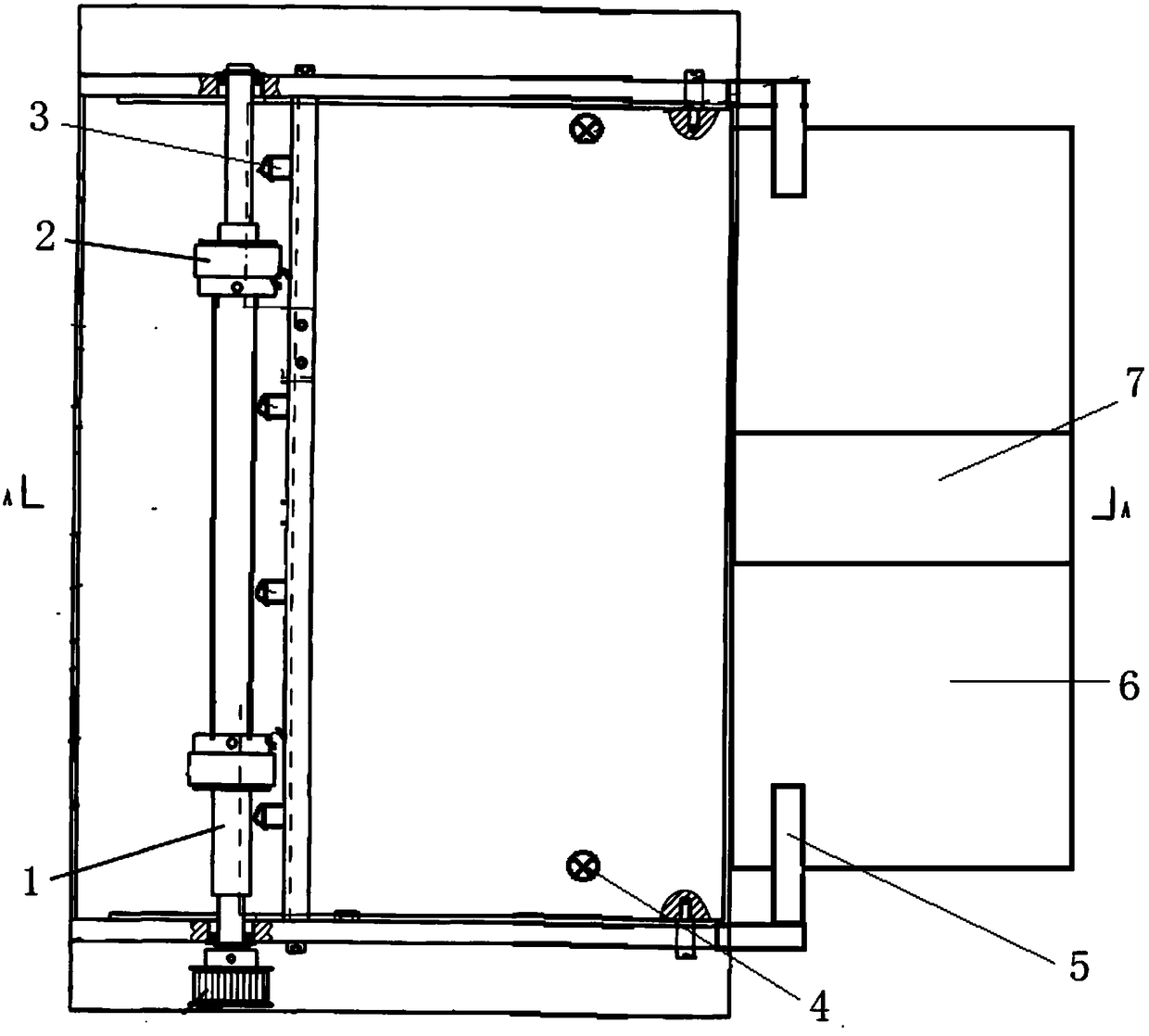

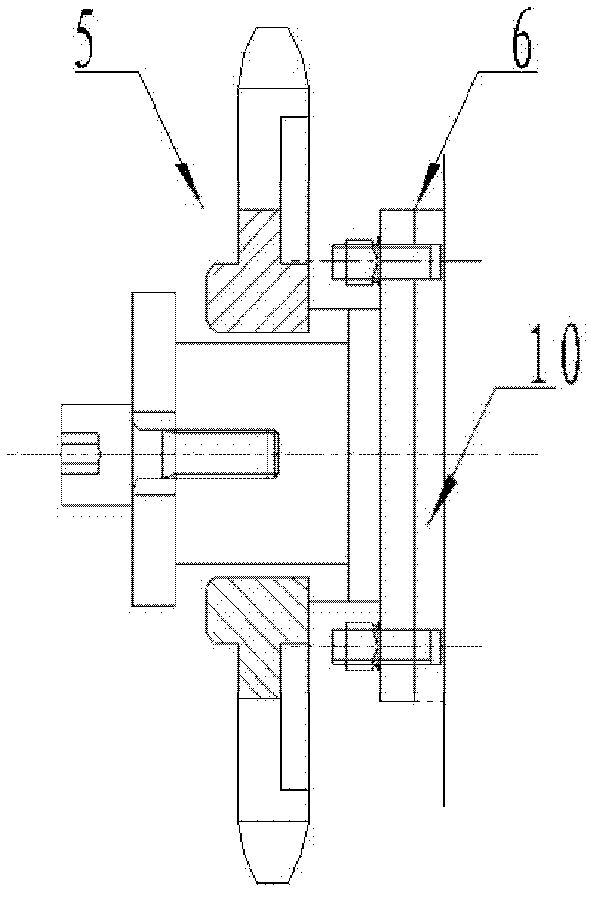

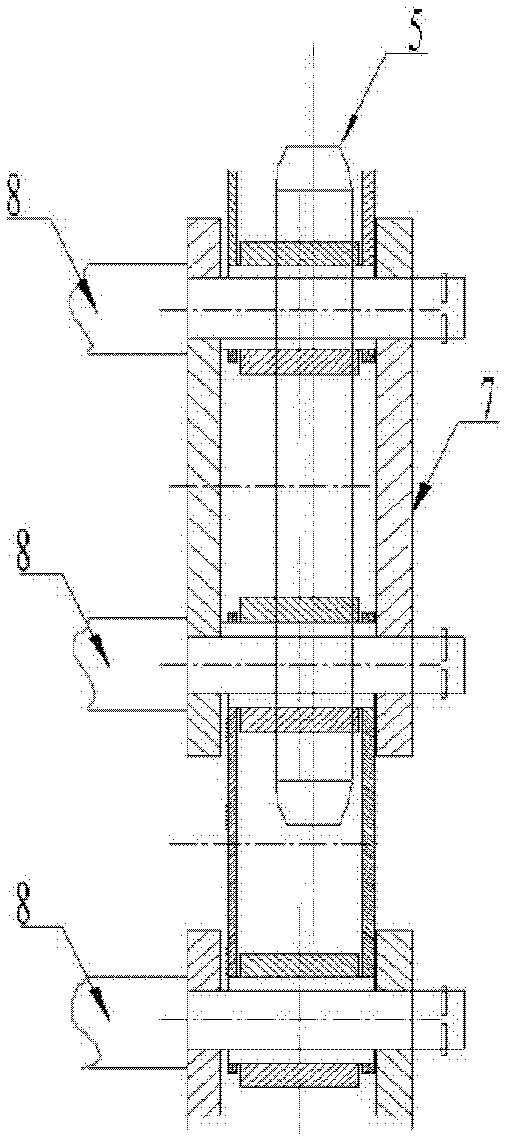

Prossure fixing mechanism of series thyristor valve set

ActiveCN1753181ARealize disassemblyRealize deviation directionSemiconductor/solid-state device detailsSolid-state devicesEpoxyMechanical stability

The invention is a level pressure mechanism for series thyristor valve group, relating to the installing mechanism of thyristor valve, composing an outer frame by three fore bearing epoxy board and head-end flange and rear-end flange; on the side of the head-end flange, a pressure spring guide rod is jacketed with a disc spring; there is a disc spring protection piece arranged at the head end of the disc spring; there is a flow guide copper network and transition regulating circular aluminum arranged at the other end of the disc spring; on the side of the rear-end flange, a guide sleeve is connected with the rear-end flange; the guide sleeve is jacketed in order with transition regulating circular aluminum, the flow guide copper network, and a push guide rod from the head end to the rear end; there is a hexagonal bolt arranged on the outmost side of the rear-end flange; there are groups of water cooling radiators and thyristors alternatively connected in series between the head-end and rear-end transition regulating circular alumina. The invention can assure the force the thyristor valve group bears is uniform and the mechanical stability is excellent.

Owner:CHINA ELECTRIC POWER RES INST +1

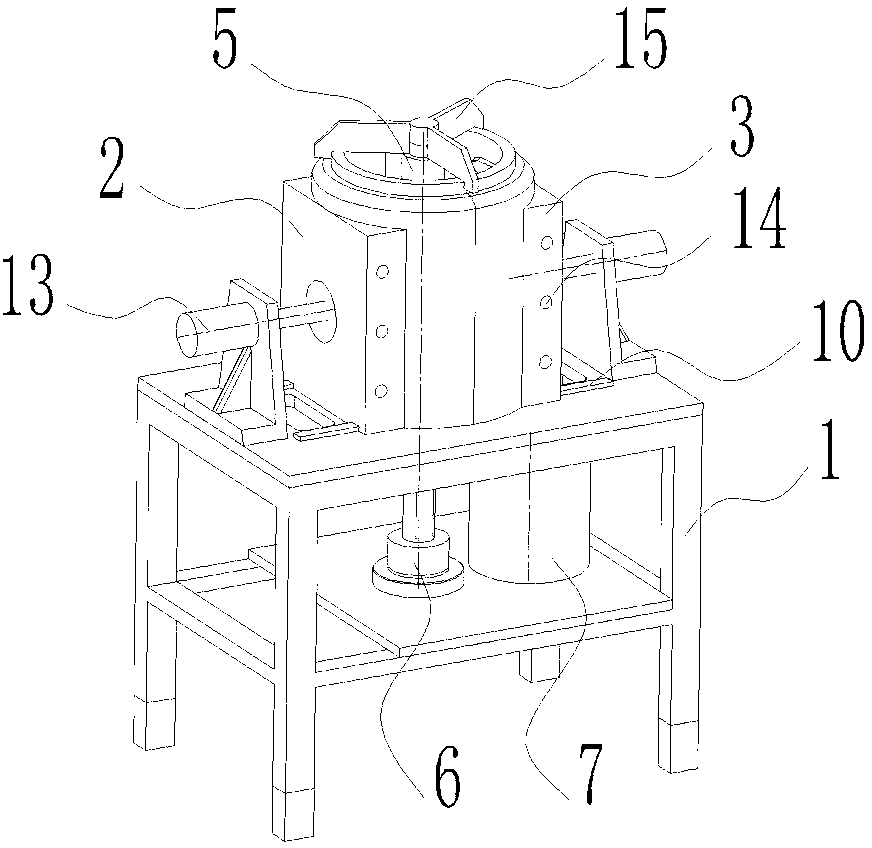

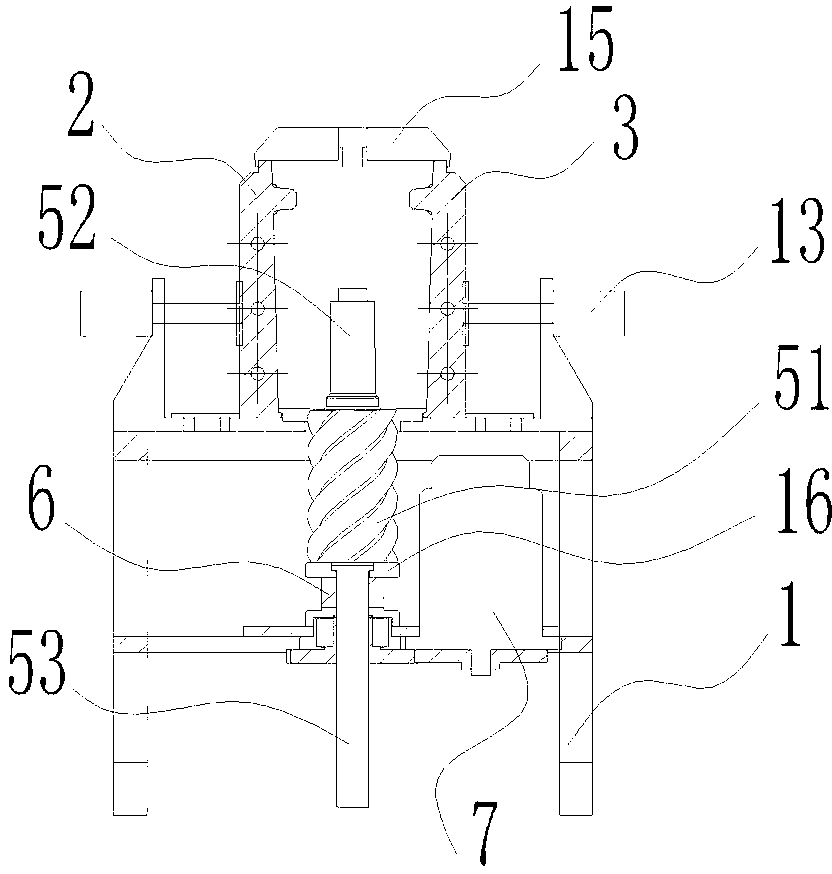

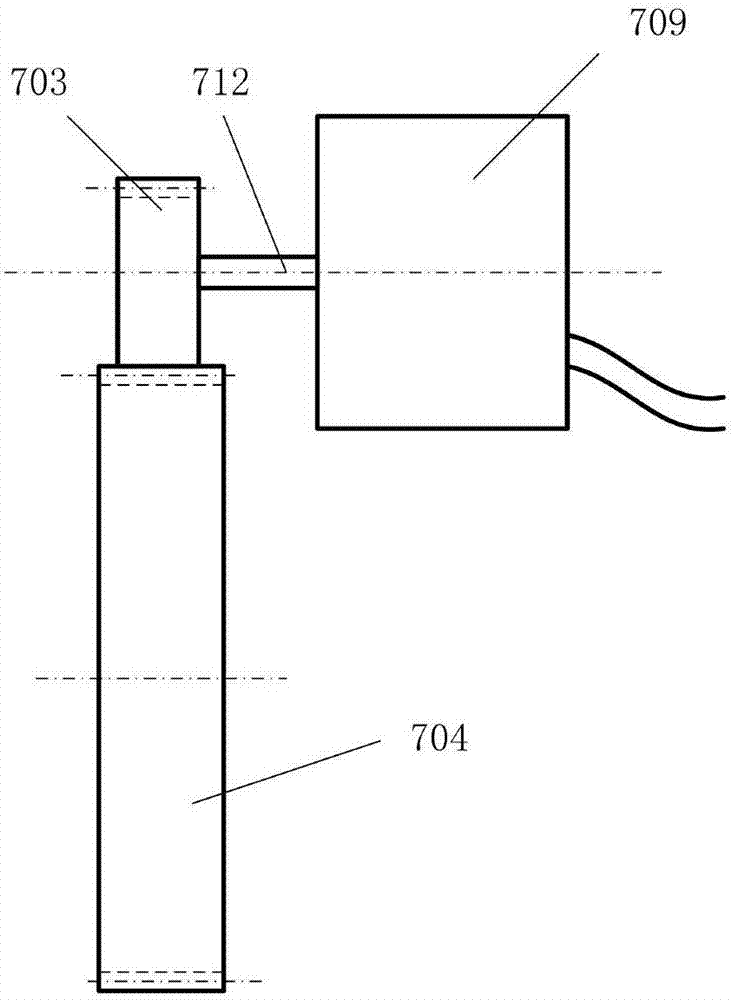

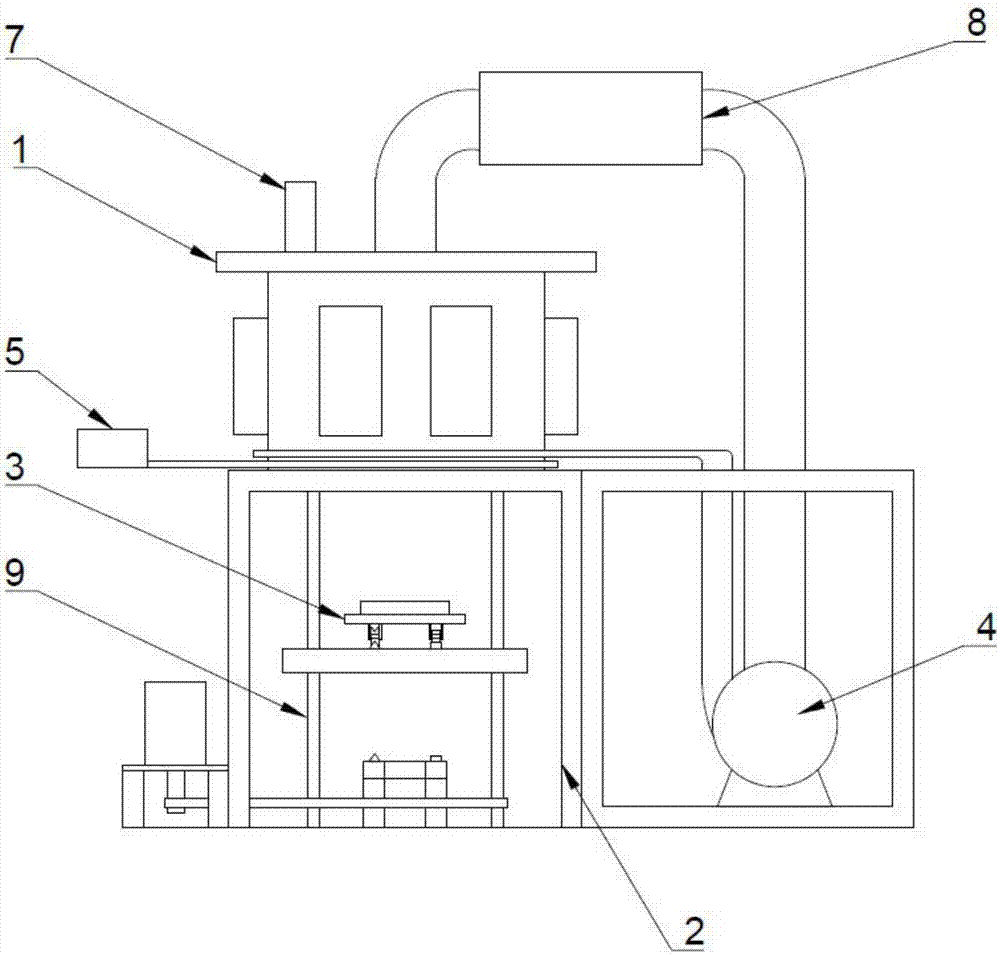

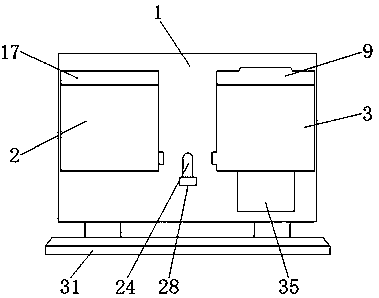

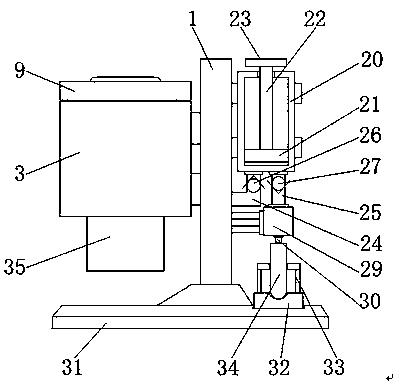

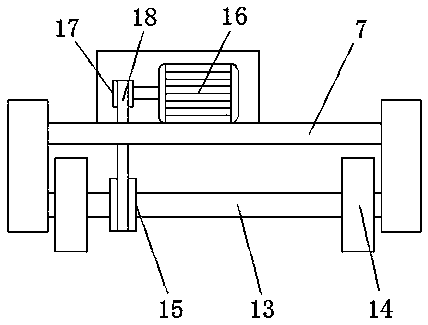

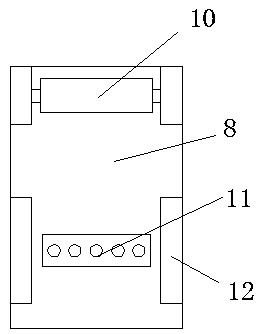

Sand core automatic demoulding mechanism and demoulding method for screw compressor rotor

ActiveCN102909321AQuality assuranceThe speed is stable and easy to controlMould loosening devicesHeater RodEngineering

The invention relates to the field of casting and provides a sand core automatic demoulding mechanism and a demoulding method for a screw compressor rotor, wherein the sand core automatic demoulding mechanism has an ingenious design, sufficiently utilizes the characteristic of a screw thread on the surface of the rotor to carry out demoulding and has a high production efficiency and a high quality. The invention solves the technical problems that in the prior art, the production efficiency is low, the labor intensity of workers is high, a sand core has a poor quality, the quality of the screw compressor rotor cannot be ensured and the like. The sand core automatic demoulding mechanism comprises a bracket, a left die and a right die, wherein the left die and the right die can relatively slide on the bracket along the horizontal direction; after the left and right dies are abutted, a synthetic sand core cavity is surrounded; a screw compressor rotor core rod is arranged at the middle part of the sand core cavity; and the screw compressor rotor core rod is screwed on the bracket and can be driven by a driving mechanism to rotationally enter and exit the synthetic sand core cavity. In the demoulding process, firstly, resin sand is placed into the sand core cavity to be tamped and the upper surface of the resin sand is scraped by a sand scraper; the resin sand is cured by a heating rod; and then the driving mechanism is started to screw out the screw compressor rotor core rod; and finally, the left and right dies are driven by the cylinder to slide outward to be demoulded.

Owner:桐乡合德机械有限公司

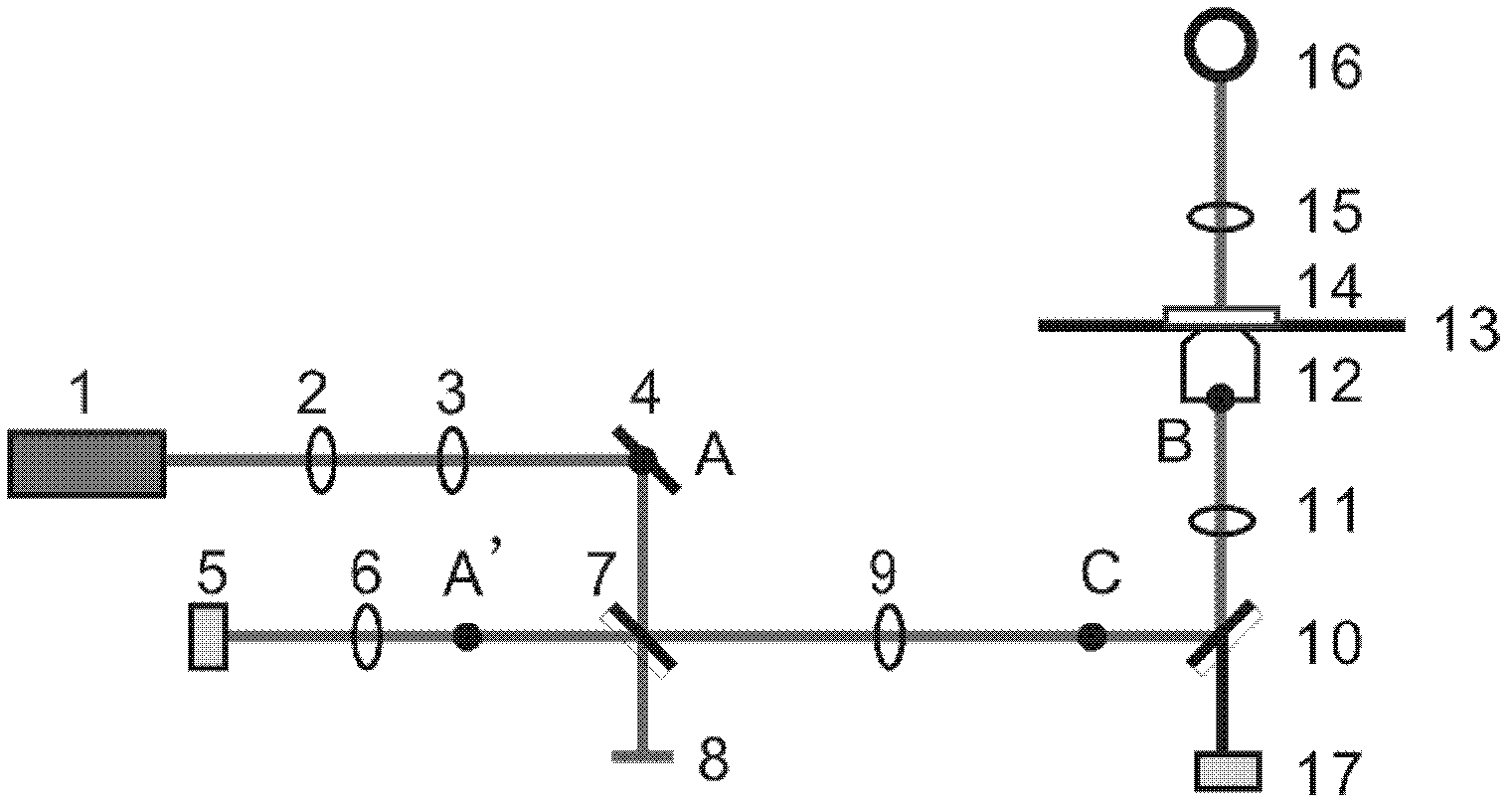

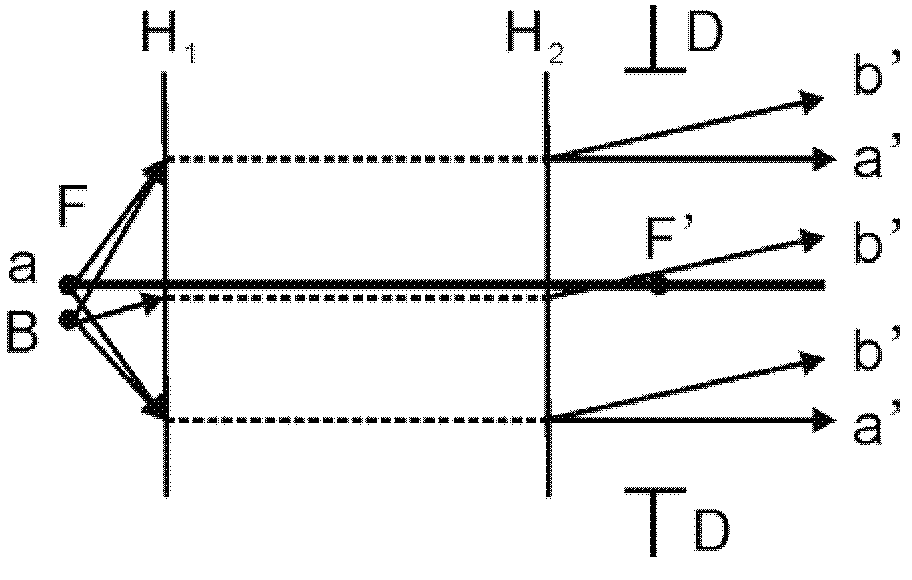

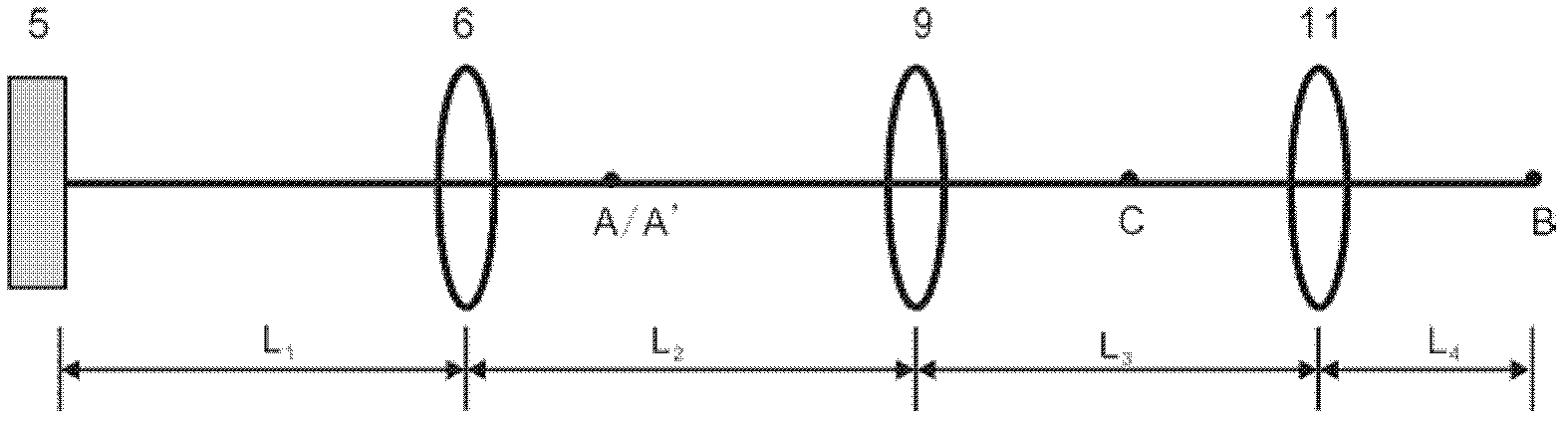

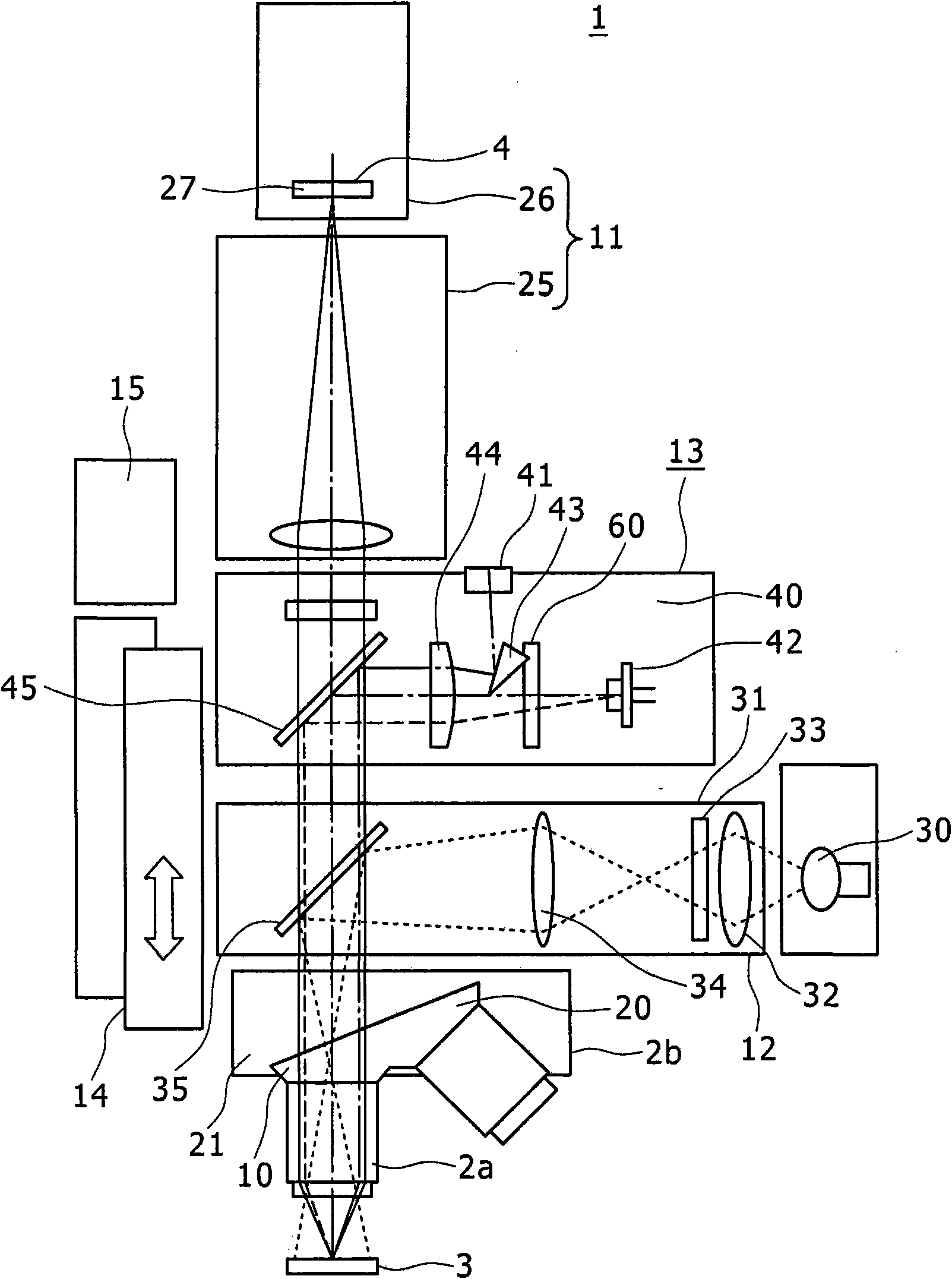

Trapping and detecting multiplexed scanning optical-tweezers system

InactiveCN102540447APerformance unchangedWon't deviateRadiation/particle handlingMaterial analysis by optical meansSystems designTrapping

The invention provides a trapping and detecting multiplexed scanning optical-tweezers system. The trapping and detecting multiplexed scanning optical-tweezers system works by the following steps of: scanning a conjugate surface of a back focal plane of an objective lens to trap light beams to form a pair of scanning optical tweezers; collecting trapped small ball scattering light spots on the back focal plane of the objective lens, and projecting the light spots of the back focal plane of the objective lens onto a four-quadrant detector in a conjugate imaging manner; multiplexing an optical path by a trapping optical path and a detecting optical path through a half-reflecting and half-transparent plane mirror; changing symmetry of light spots when particles deviate the center of a light trap so as to realize high-precision detection on the displacement of the particles; and realizing detection of the light beam on the displacement of the scanning optical tweezers because the conjugate image central position of the light spots of the particles on the back focal plane of the objective lens is still placed on a target surface of a detector when the optical tweezers scan. The trapping and detecting multiplexed scanning optical-tweezers system provided by the invention simplifies a system design of the traditional scanning optical tweezers and also keeps the detection of the optical tweezers at different scanning positions so as to realize requirements on high-precision detection.

Owner:UNIV OF SCI & TECH OF CHINA

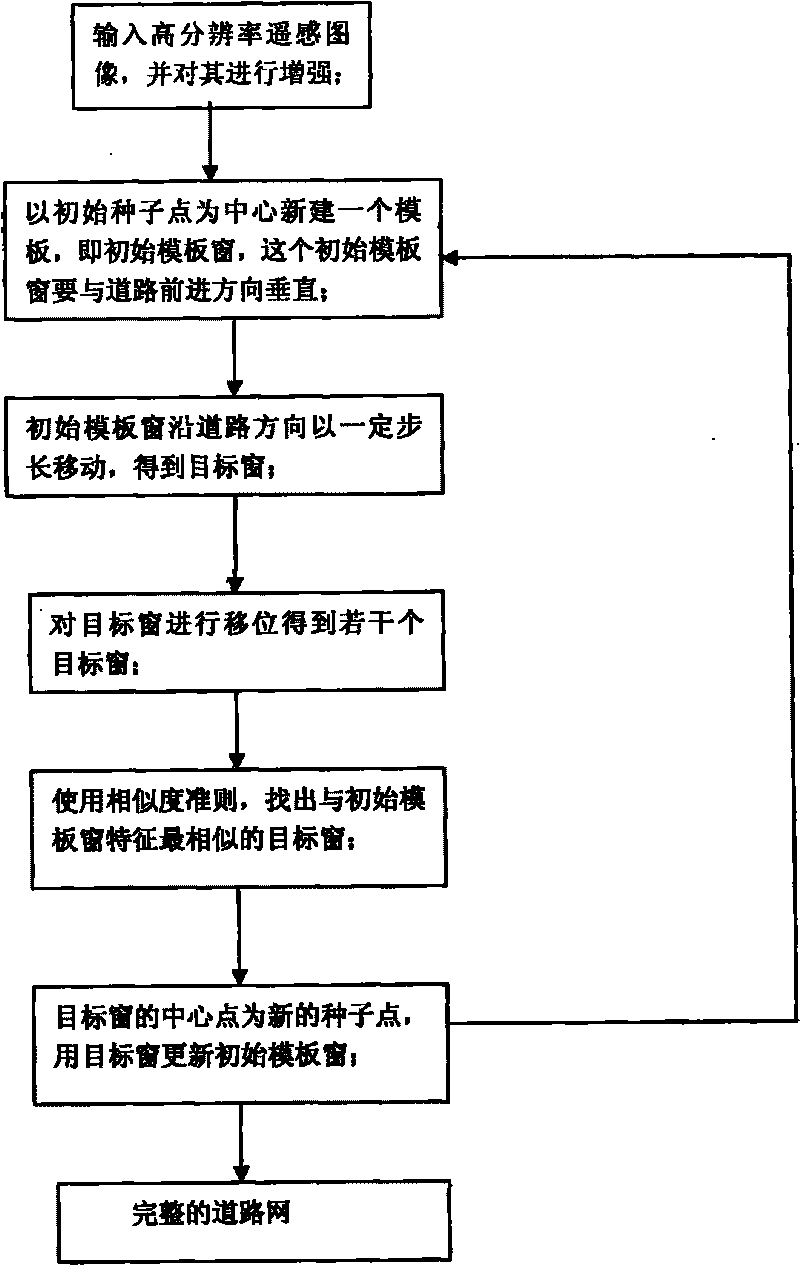

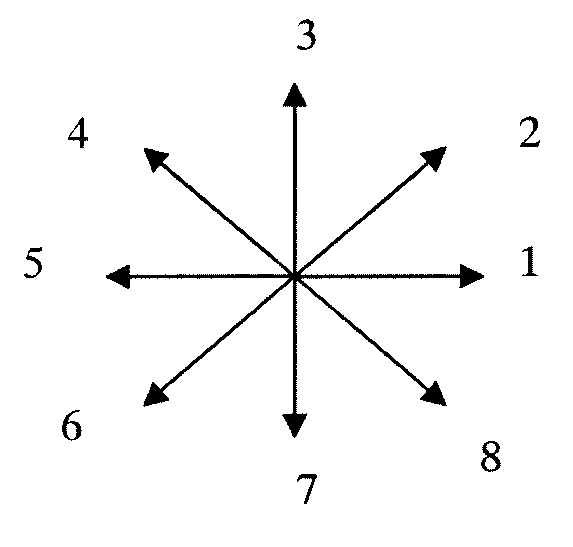

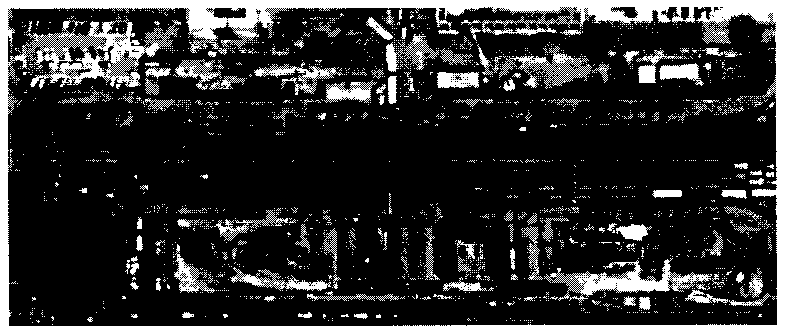

Detection method of high-resolution remote sensing image street center line

InactiveCN101714211AGuaranteed correctnessWon't deviateWave based measurement systemsCharacter and pattern recognitionTemplate matchingTemplate based

The invention discloses a detection method of a high-resolution remote sensing image street center line on the basis of template matching, which mainly solves the problem of low accuracy of the traditional technology for detecting streets. A detecting process comprises the following steps of: (1) inputting a high-resolution remote sensing image and enhancing the image; (2) establishing an initial template window vertical to a street advance direction by using an initial seed point as a center; (3) moving the initial template window along a certain step length to obtain a target window; (4) displacing the target window to obtain a plurality of target windows; (5) using a similarity criterion to find out a target window, characteristics of which are the most similar to the characteristics of the initial template window; and (6) using the central point of the target window as a new seed point, and updating the initial template window by using the target window to carry out a next iteration until the boundary of the image is searched or streets in the image finish being searched so as to obtain a street center line using a circle as a mark. The method is accurate and effective, and can be used for the detection of the high-resolution remote sensing image street center line.

Owner:XIDIAN UNIV

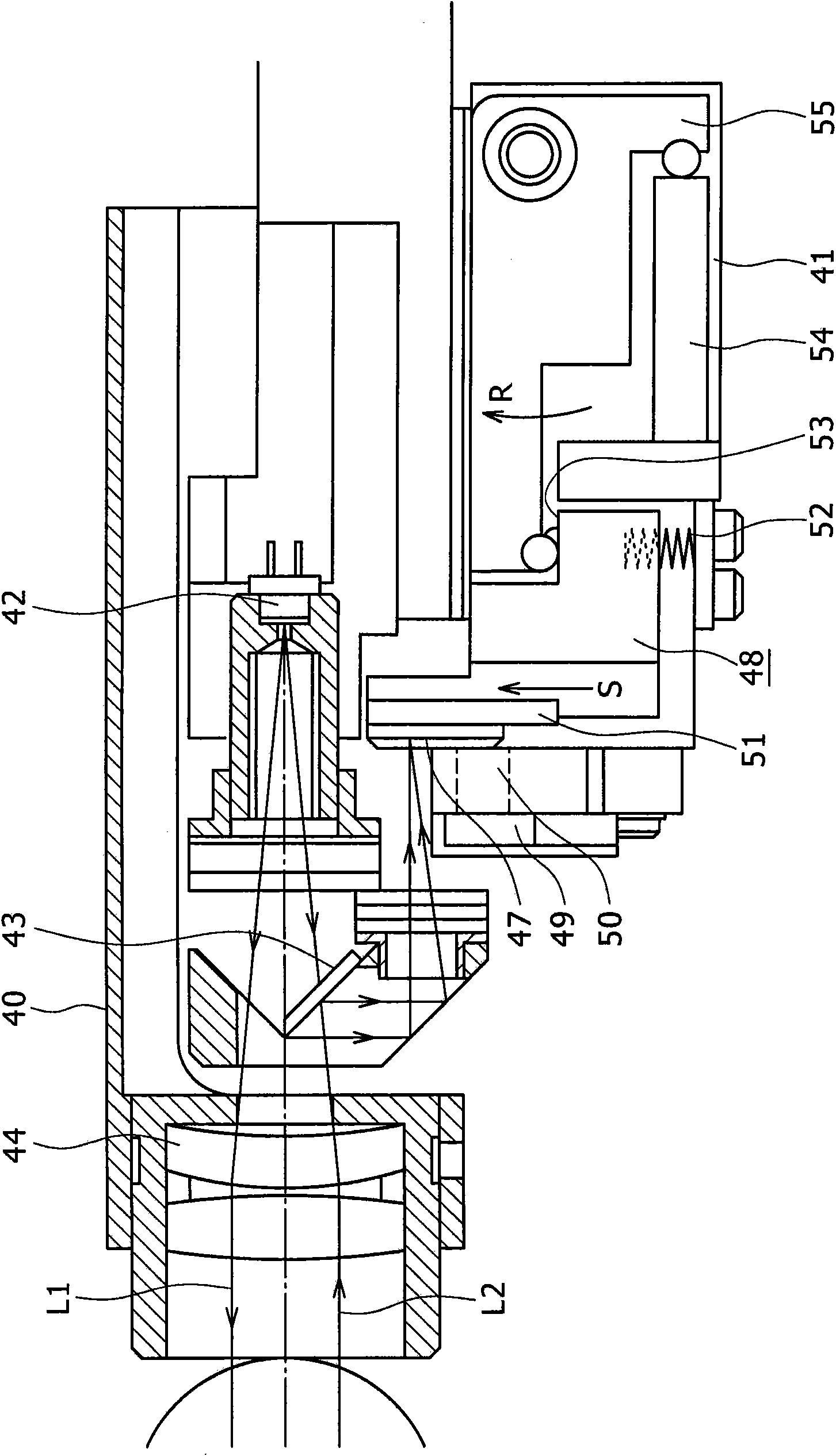

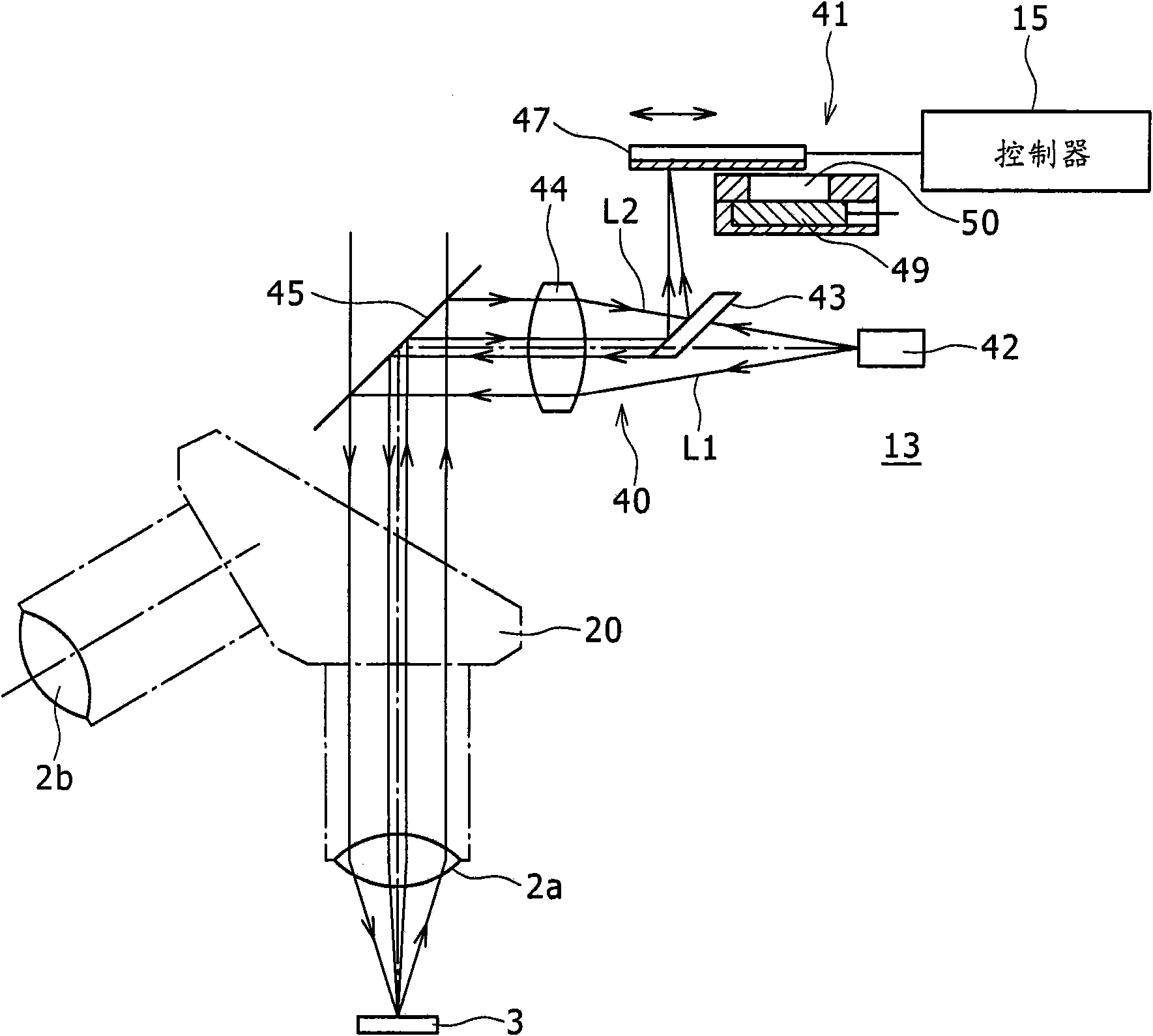

Automatic focus control unit, electronic device and automatic focus control method

The present invention discloses an automatic focus control unit, an electronic device and an automatic focus control method. The automatic focus control unit includes: a first light-emitting element; a line sensor; a second light-emitting element; a slit member; a shifting mechanism; and a controller. The invention may execute rapid focus without generating large deviation of focus point on sample of object lens.

Owner:DEXERIALS CORP

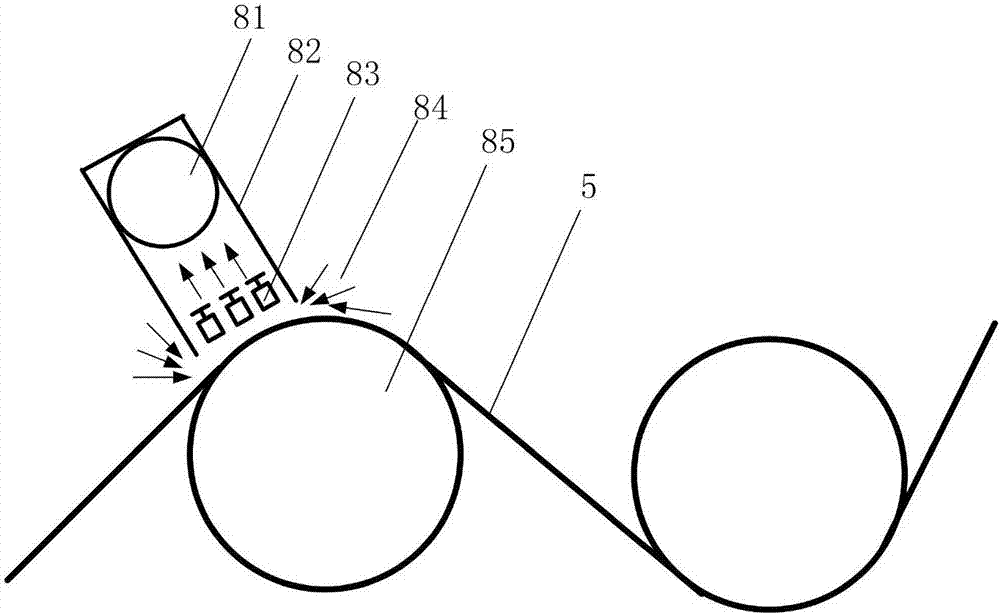

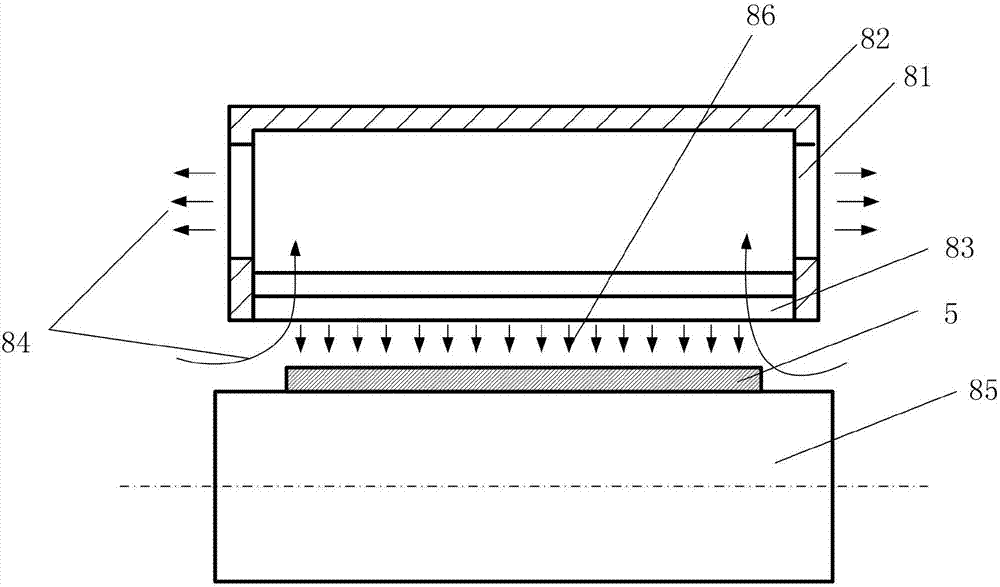

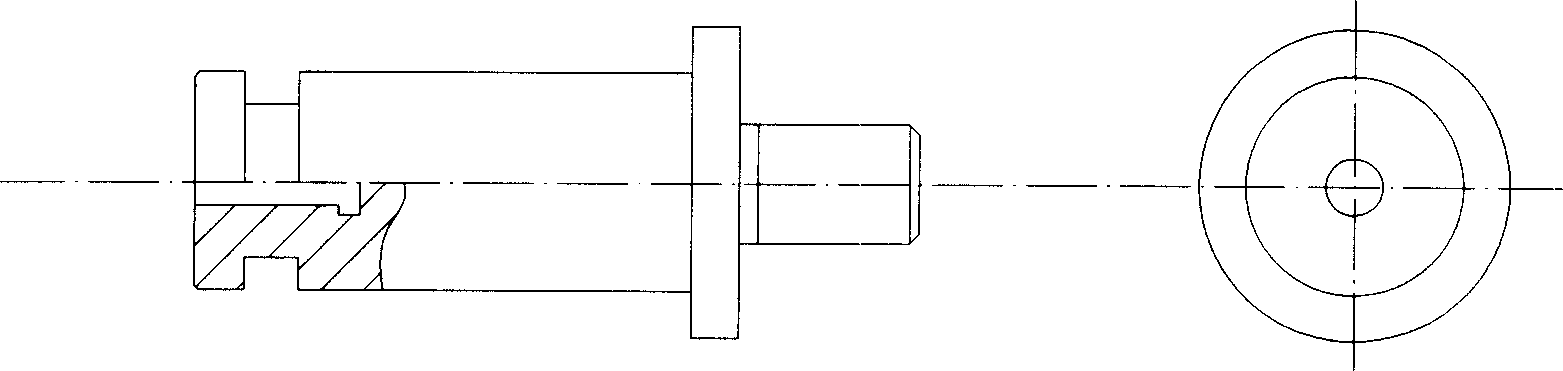

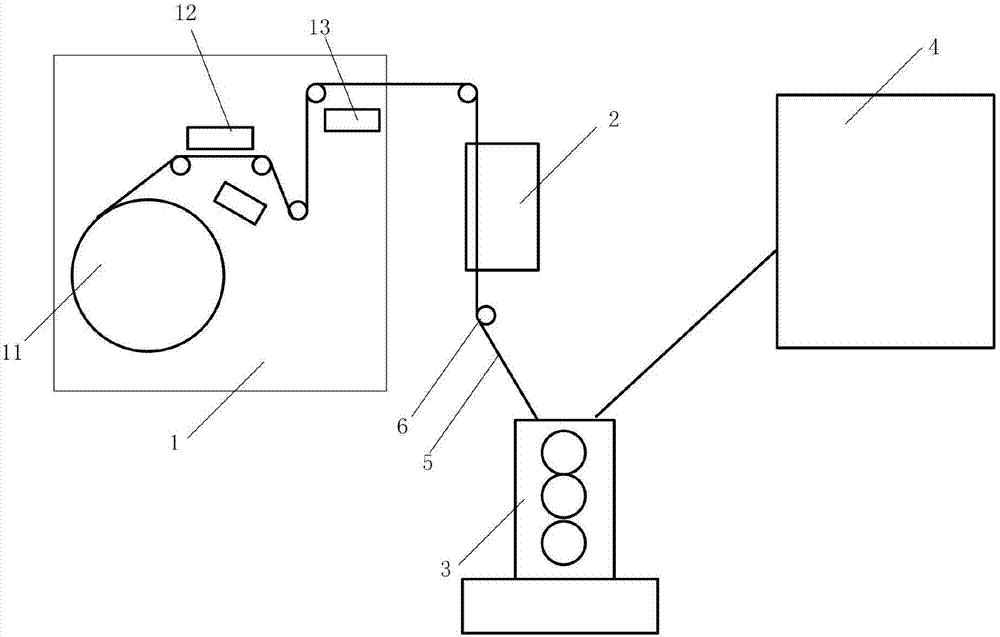

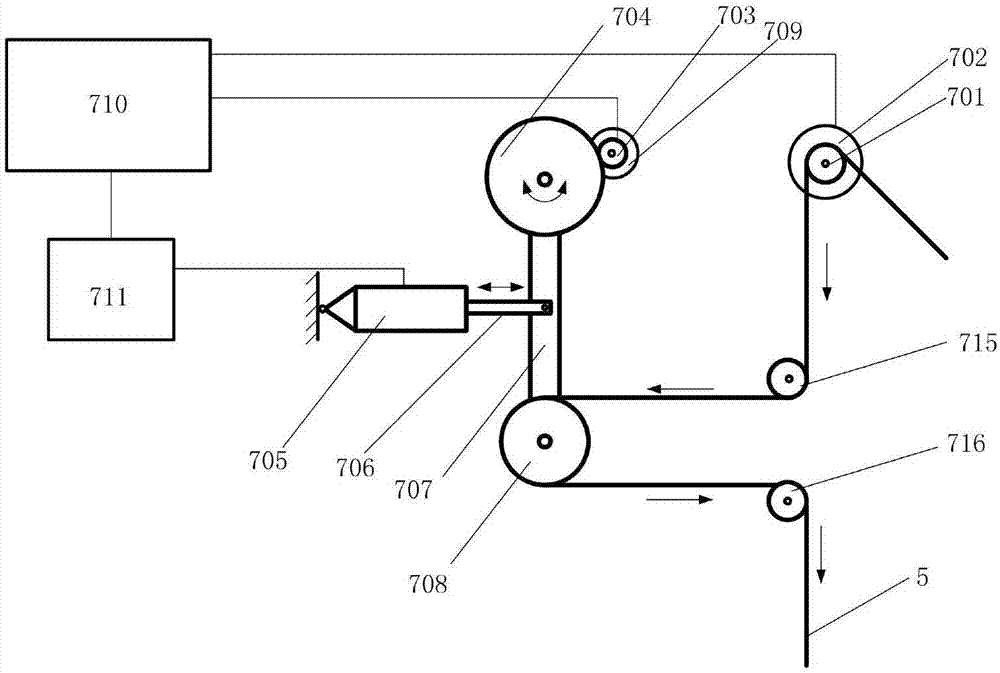

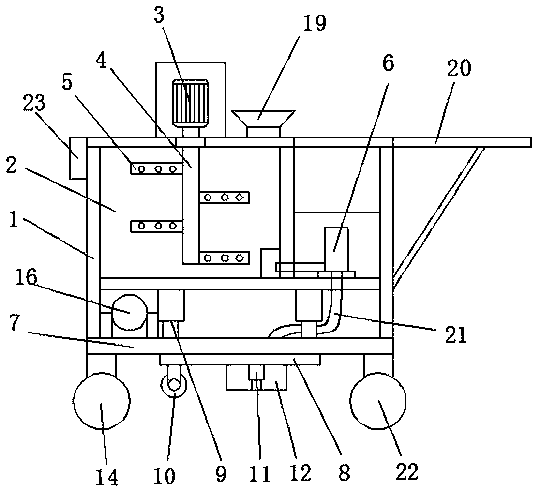

Three-roller coating printing unit for continuously coating surface of base material with viscous material

ActiveCN107350121AThin and uniform glue layerReduce usageLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses a three-roller coating printing unit for continuously coating the surface of a base material with a viscous material. The unit comprises a pressing roller, a driving silica gel roller and a driving steel roller which are stacked from top to bottom. The driving silica gel roller and the driving steel roller rotate in opposite directions, and a micron order gap is kept; the driving steel roller is soaked with a colloid pond containing the viscous material, the base material is arranged between the pressing roller and the driving silica gel roller, and the base material is supported on the supporting roller and moves in the centrifugal force direction of the top vertex of the driving silica gel roller under power traction. Under the effect that the viscous material is extruded, stretched and extended through rotating rollers with the two different rotating speeds and the opposite directions, a rubber layer of the certain thickness is formed on the surface of the rubber covered roller, the material is transferred to the surface of the continuously running base material by means of the pressing roller, the thin and uniform coating is formed, and materials of the micro order and submicron order thickness and thinner materials can be uniformly sprayed to the surface of the base material.

Owner:陕西浩合机械有限责任公司

Sliding contact moving conduction device

InactiveCN102354889APrevent slipping outWon't deviateNon-rotary current collectorProduction lineEngineering

The invention relates to a trolley conductor and a collector applied to unbalance loading and curve places, and provides a sliding contact moving conduction device still capable of keeping normal power supply between an electric brush and the trolley conductor when a balance loading force is generated. The device comprises the trolley conductor, a guide rail and a running part with a collector. By the device, a conventional plane contact designing scheme in the field is changed, the electric brush is improved into a tile shape, and a trolley conductor working surface is changed into an arc shape, so a centrifugal force which is an unbalance loading force for the electric brush and is caused by the automatic generation of a centrifugal force at a curve of a production line can be overcome to a certain extent; and when the unbalance loading force is relatively stronger, an electric brush working surface is preferably arched, so that an 'enveloping' effect can be achieved for the trolley conductor working surface to prevent the electric brush from sliding out of the guide rail. By the device, stable power transmission is ensured, and simultaneously, the electric brush can be ensured not to be deviated and separated from the trolley conductor to further improve the running safety, stability and reliability of equipment.

Owner:江苏江鹤滑线电气有限公司

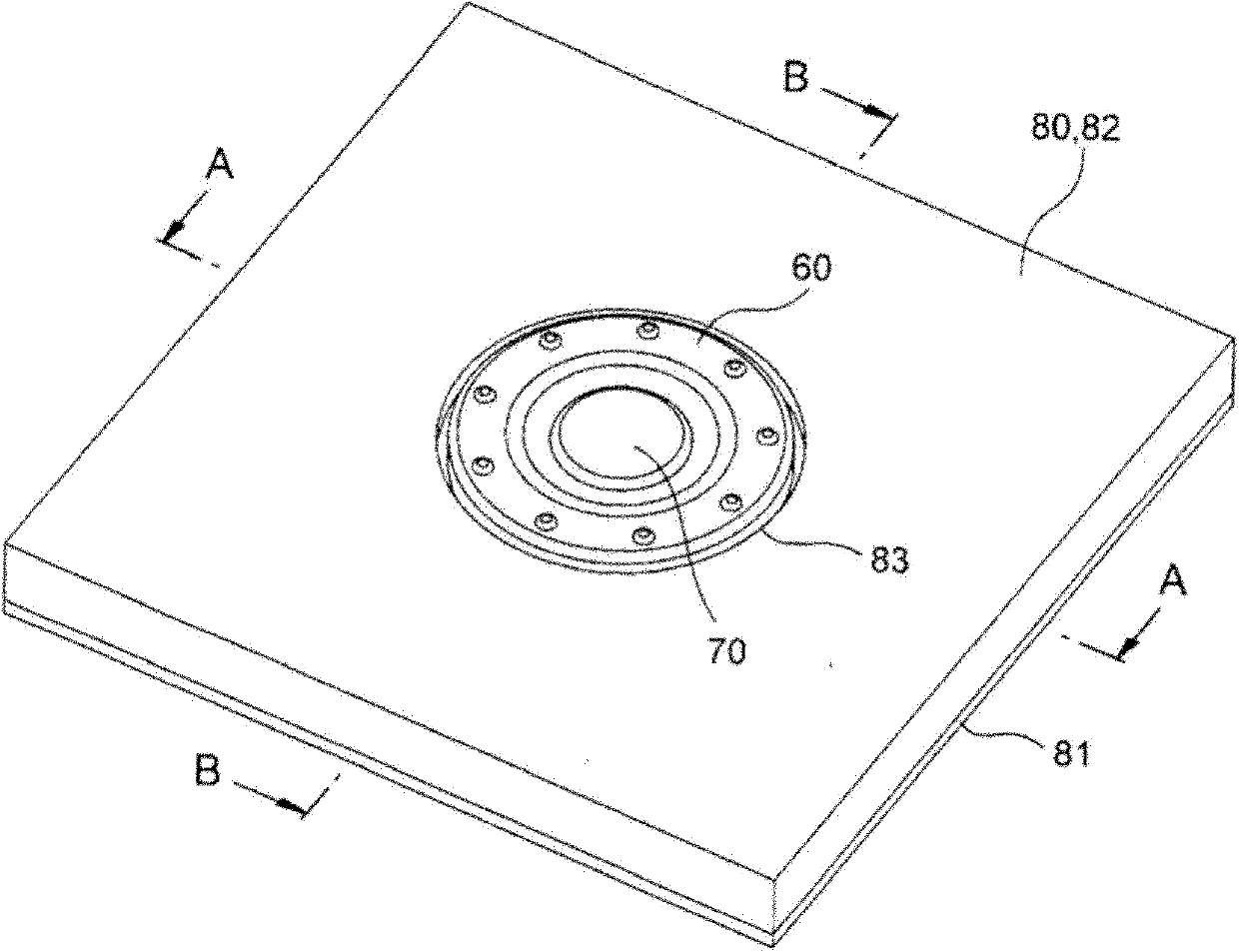

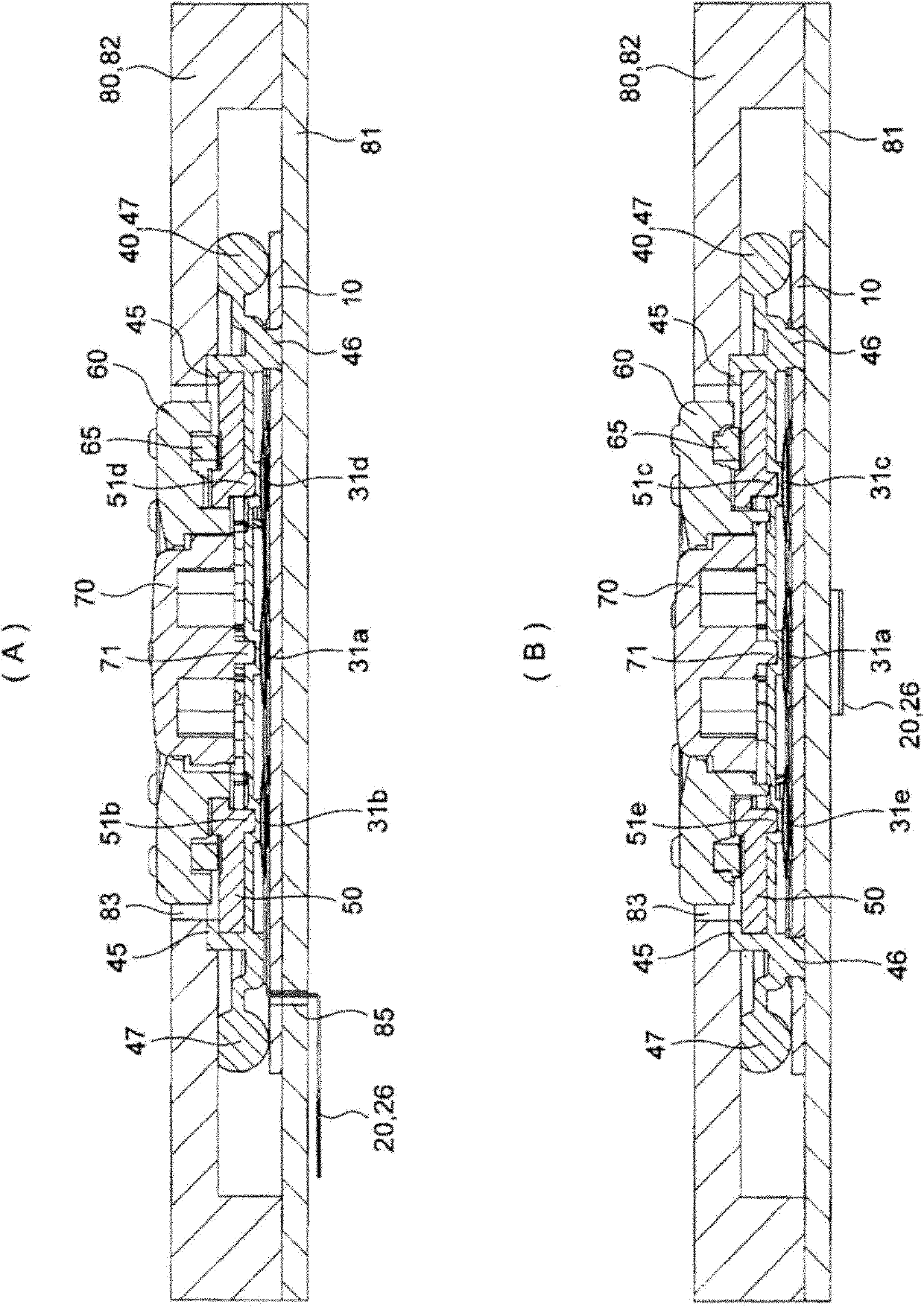

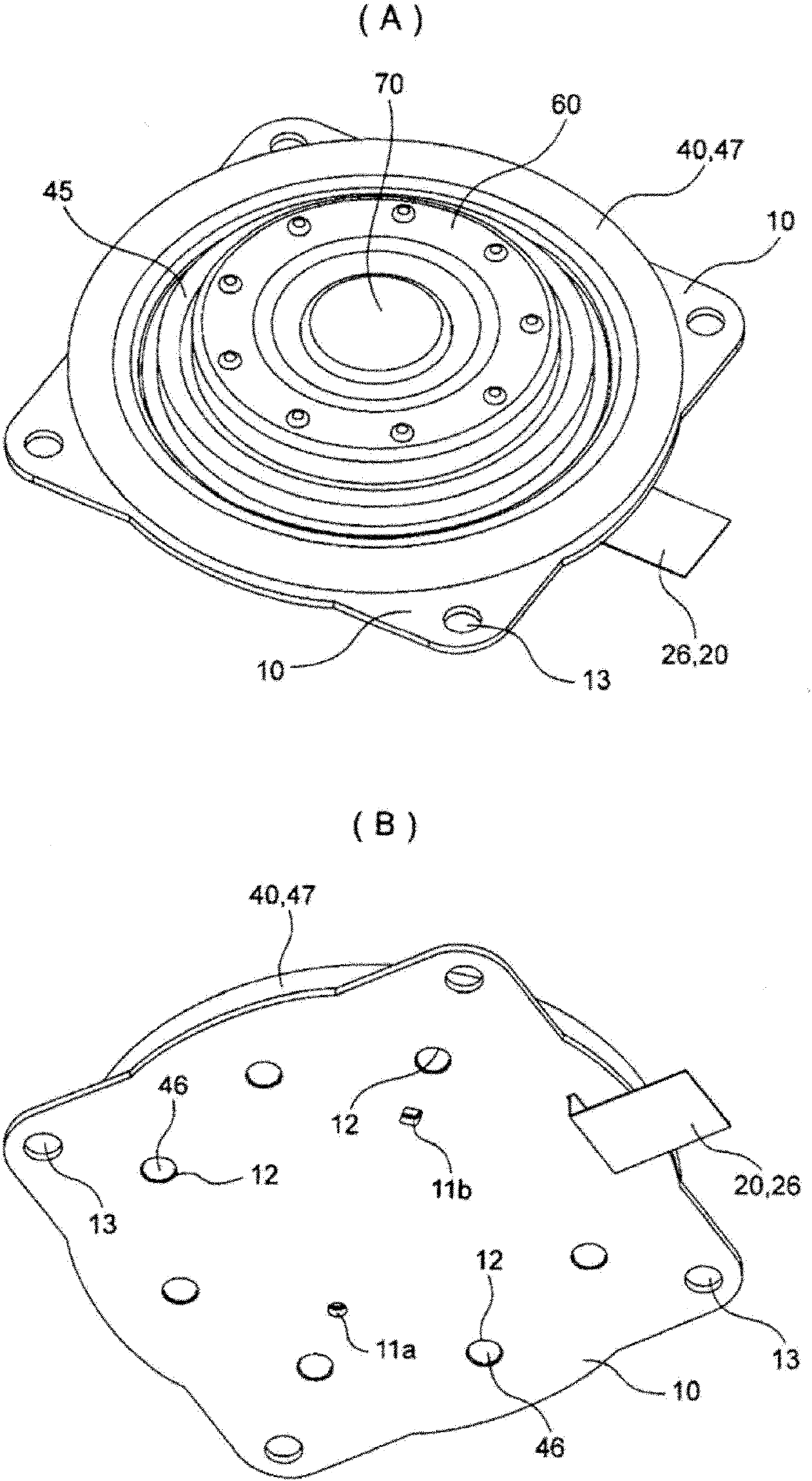

Operation input device and electronic device using the same

InactiveCN102169773ANot easy to bendImprove waterproof performanceElectric switchesRailway traffic control systemsEngineeringThick wall

The invention provides an operation input device which prevents immersion in a housing and an electronic device. An elastic waterproof component (40) is disposed between a printing substrate (20) and an operation ring (50). A thick wall part (47) disposed at the periphery of the elastic waterproof component (40) is clamped by means of the upper surface of a matrix (10) and the top face of a housing (80).

Owner:ORMON CORP

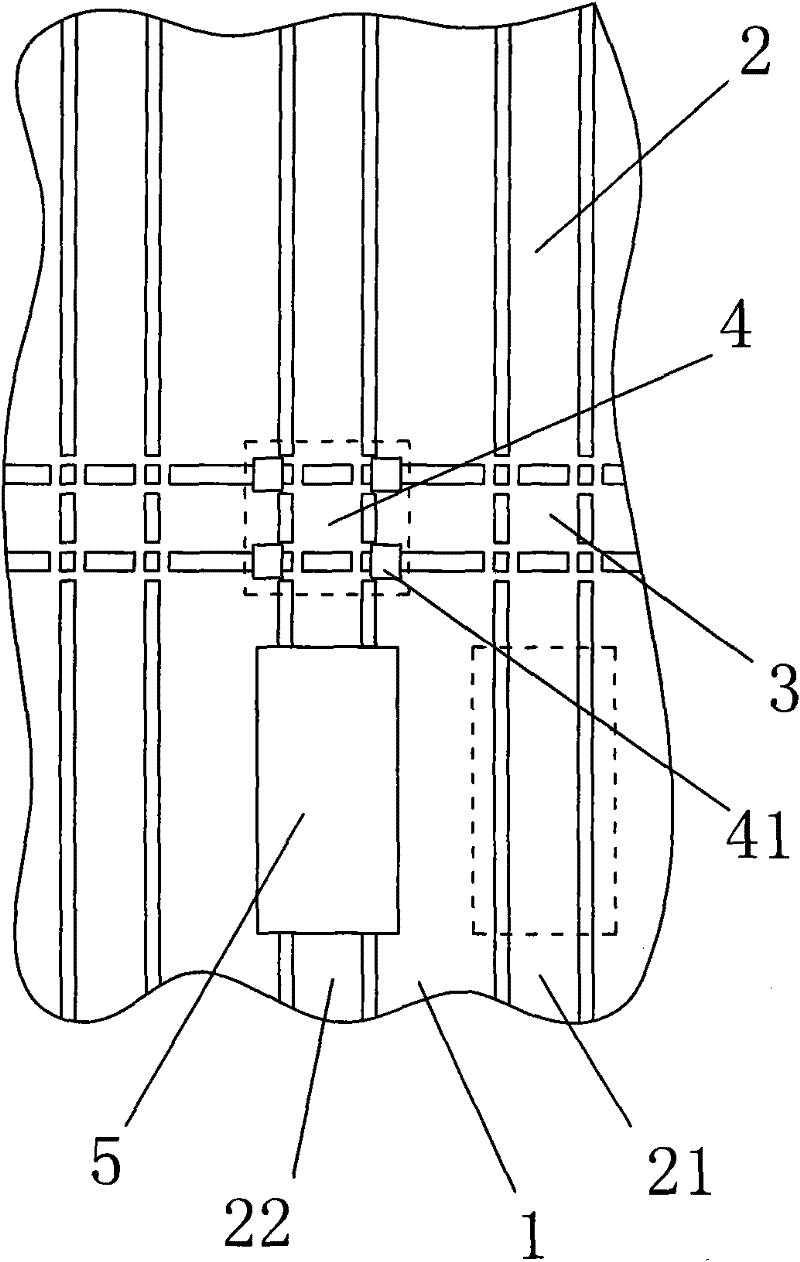

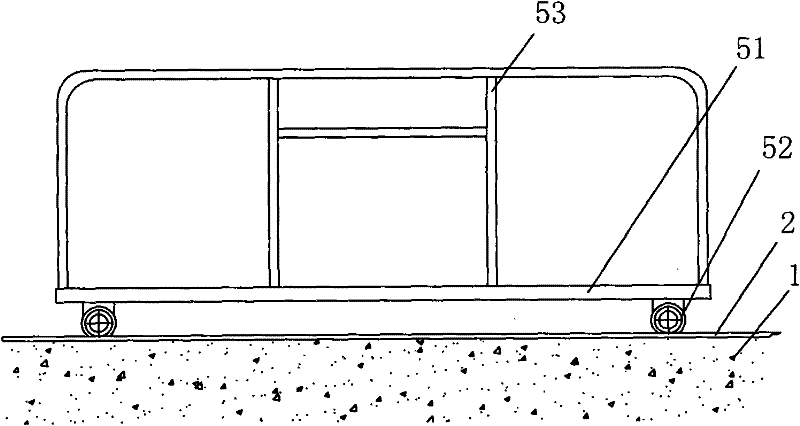

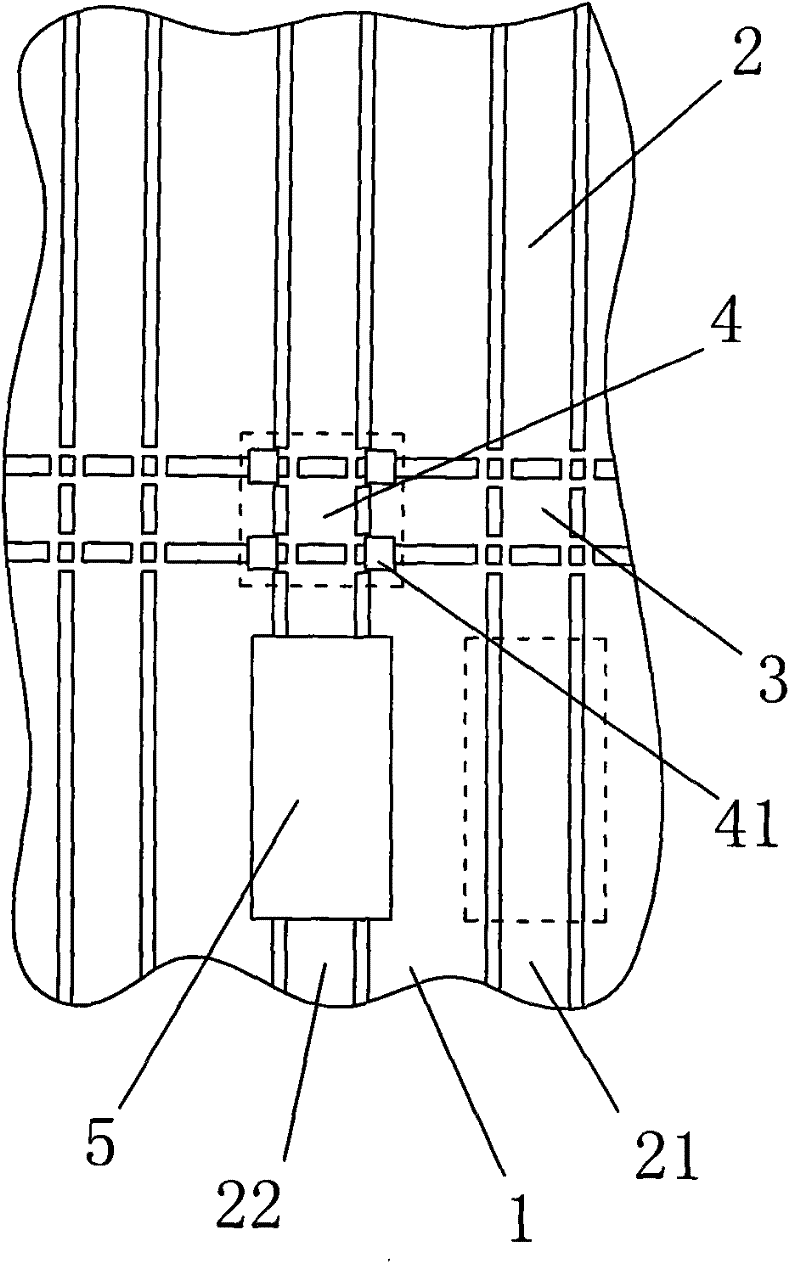

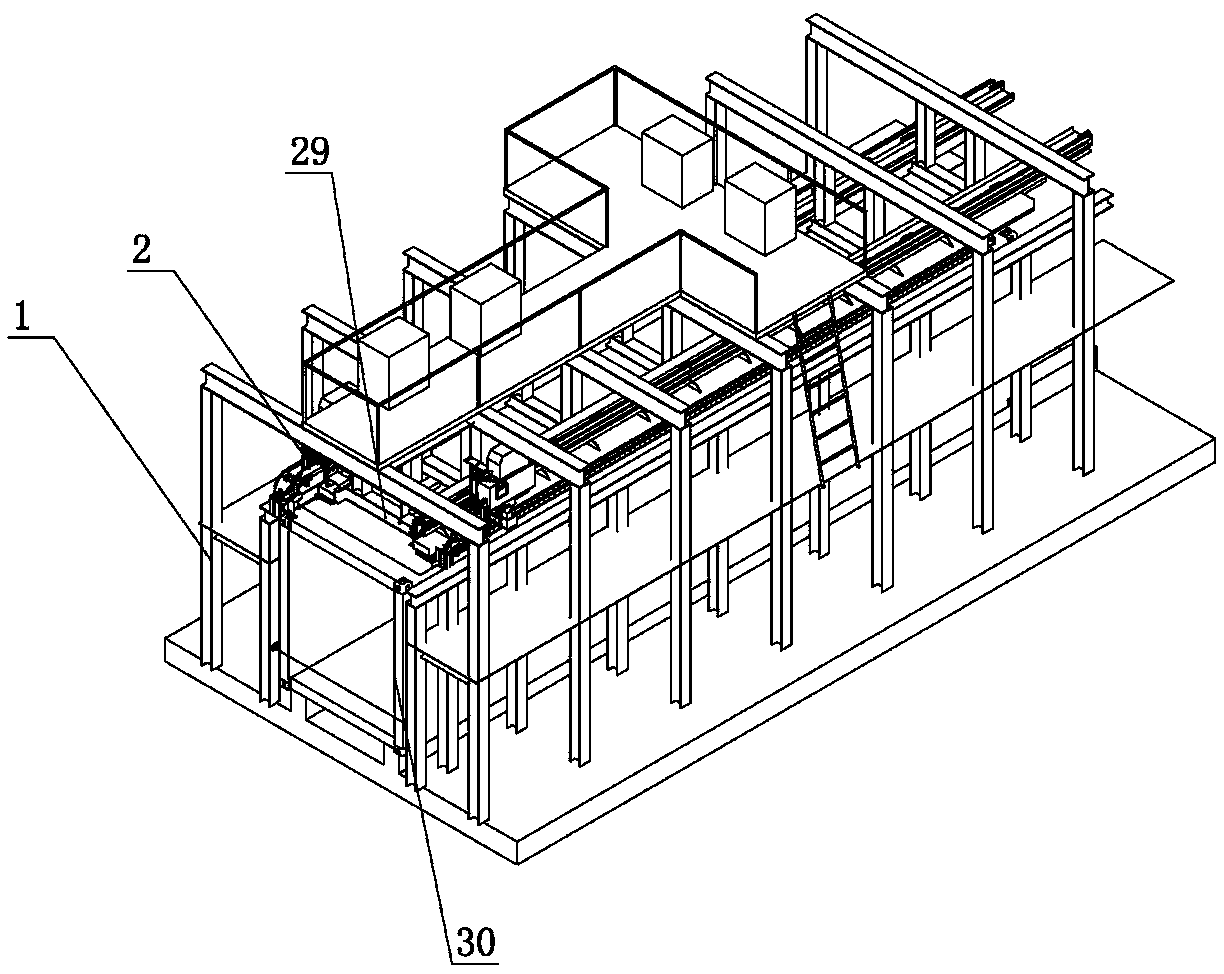

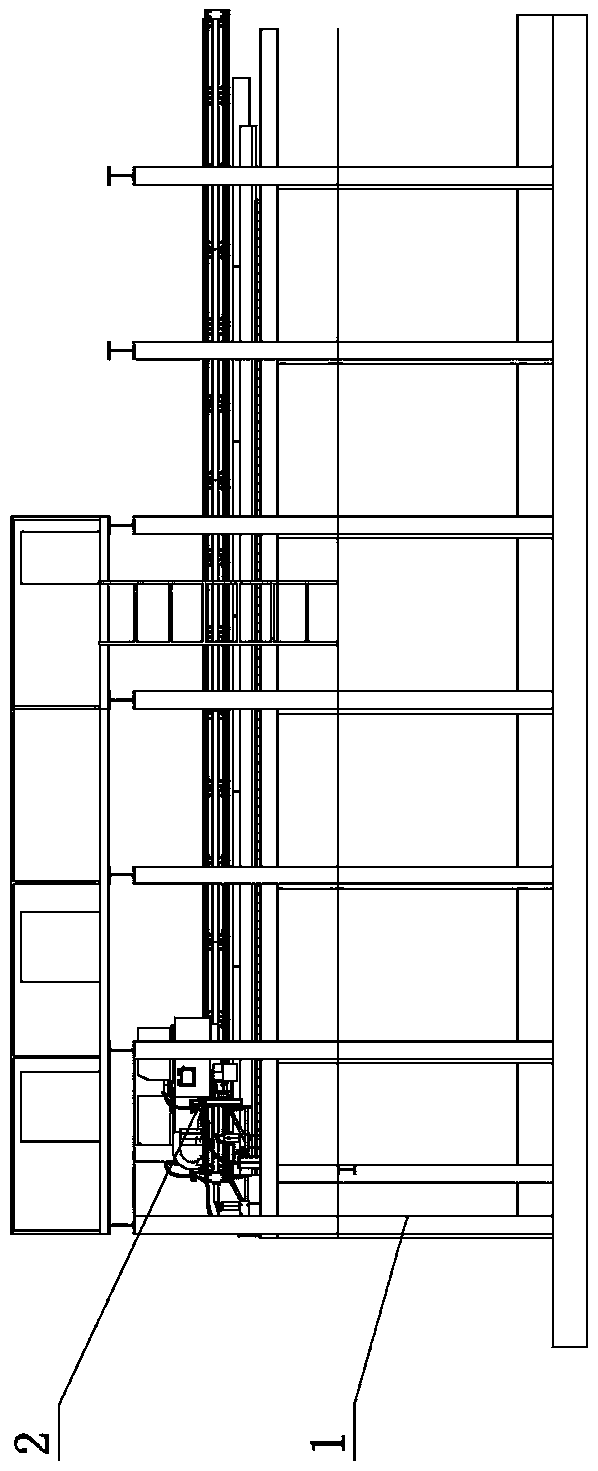

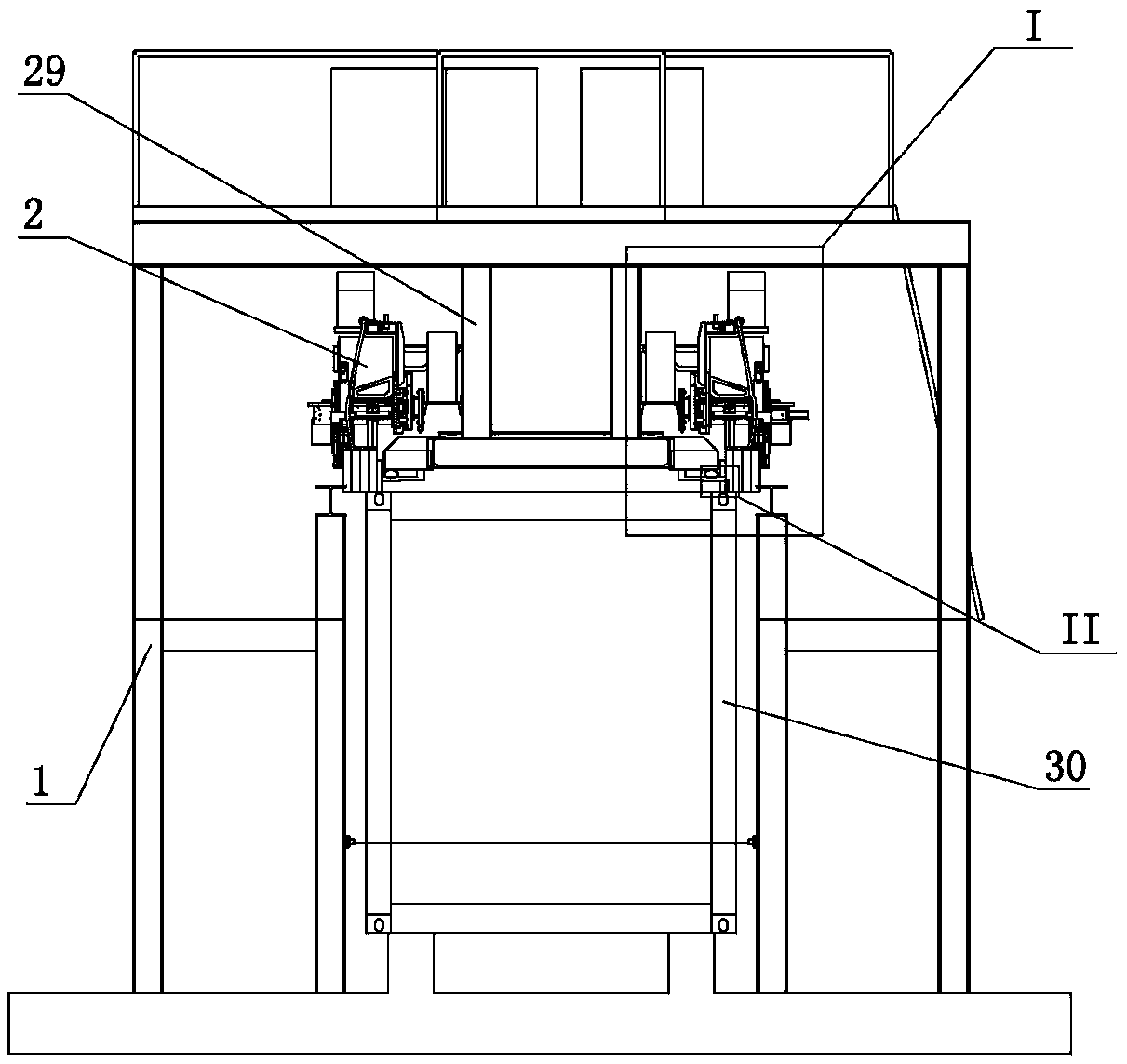

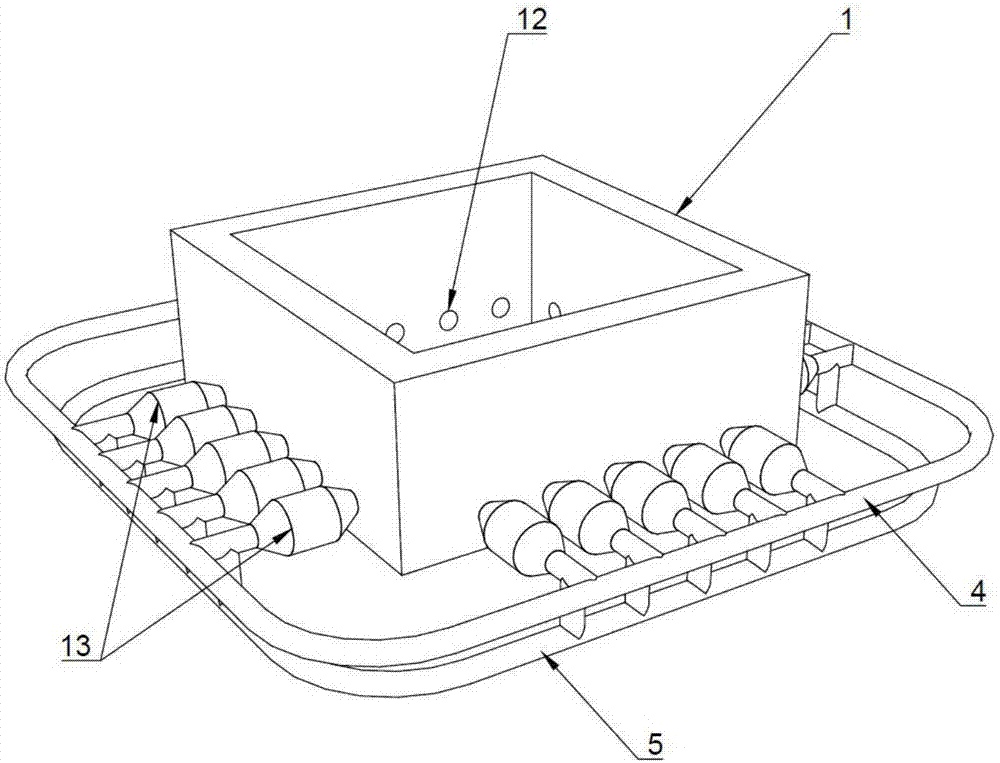

Conveying system for industrial production

InactiveCN102452557ASolve logistics problemsSolve the problem of non-interoperable and non-transferableConveyor partsMechanical conveyorsLogistics managementEngineering

The invention relates to a conveying system for industrial production. The system comprises a rail device fixedly connected with the ground, a transfer device and a conveying device, wherein the rail device comprises a plurality of longitudinal rails and transverse rails which are arranged crosswise; the transfer device moves along the transverse rails; the conveying device moves along the longitudinal rails; and the transfer device can transversely transfer the conveying device from one longitudinal rail to the other longitudinal rail. Compared with the prior art, the conveying system has the characteristics that: cost is low, the logistics problem of small workpiece articles can be solved, parts are clearly classified, the transfer process is clear, the articles can be well classified and flow into the next process to be processed, the system is easy to produce, manufacture and install, is suitable for the fields of various industries, does not need power and avoids energy consumption and pollution, and the like.

Owner:江苏合雅木门有限公司

Device for detecting flatness of electronic component

ActiveCN108286930AWill not shiftPlay the role of positioningMechanical roughness/irregularity measurementsEngineeringElectronic component

The invention relates to the field of electronic detection, in particular to a device for detecting the flatness of an electronic component. The device comprises a walking unit and a detecting unit. The walking unit comprises a first walking frame and a second walking frame. The detecting unit is arranged on the first walking frame and comprises a fixing plate fixed to the first walking frame. Thefixing plate is hinged to a detecting rod. The lower end of the detecting rod is provided with a detecting mechanism. The upper end of the detecting rod is connected with a marking mechanism. A resetting component is connected between the detecting rod and the fixing plate. The detecting mechanism comprises a detecting cylinder. A detecting pen and a marking pen are slidably connected in the detecting cylinder. The end portion of the detecting pen is connected to the detecting rod. One end of the marking pen is opposite to the detecting rod. The marking mechanism comprises a marking cylinderfixed to the fixing plate. The upper end of the marking cylinder is in sealed connection with a piston plate. A piston rod is connected between the piston plate and the detecting rod. A marking hole is arranged at the bottom of the marking cylinder. The device can achieve a purpose of detecting the flatness of the corners of the electronic component.

Owner:日照泰润电子有限公司

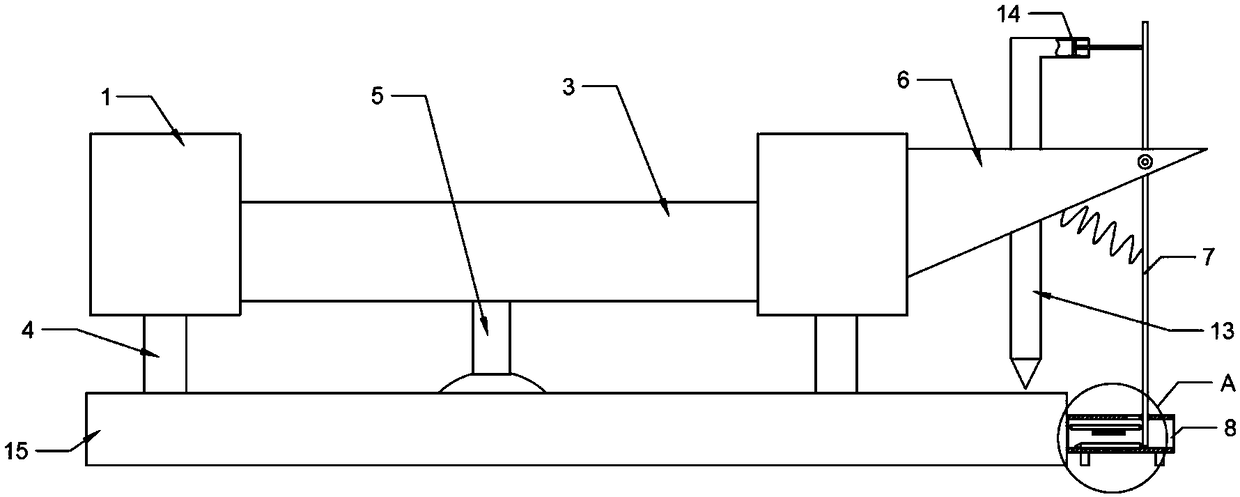

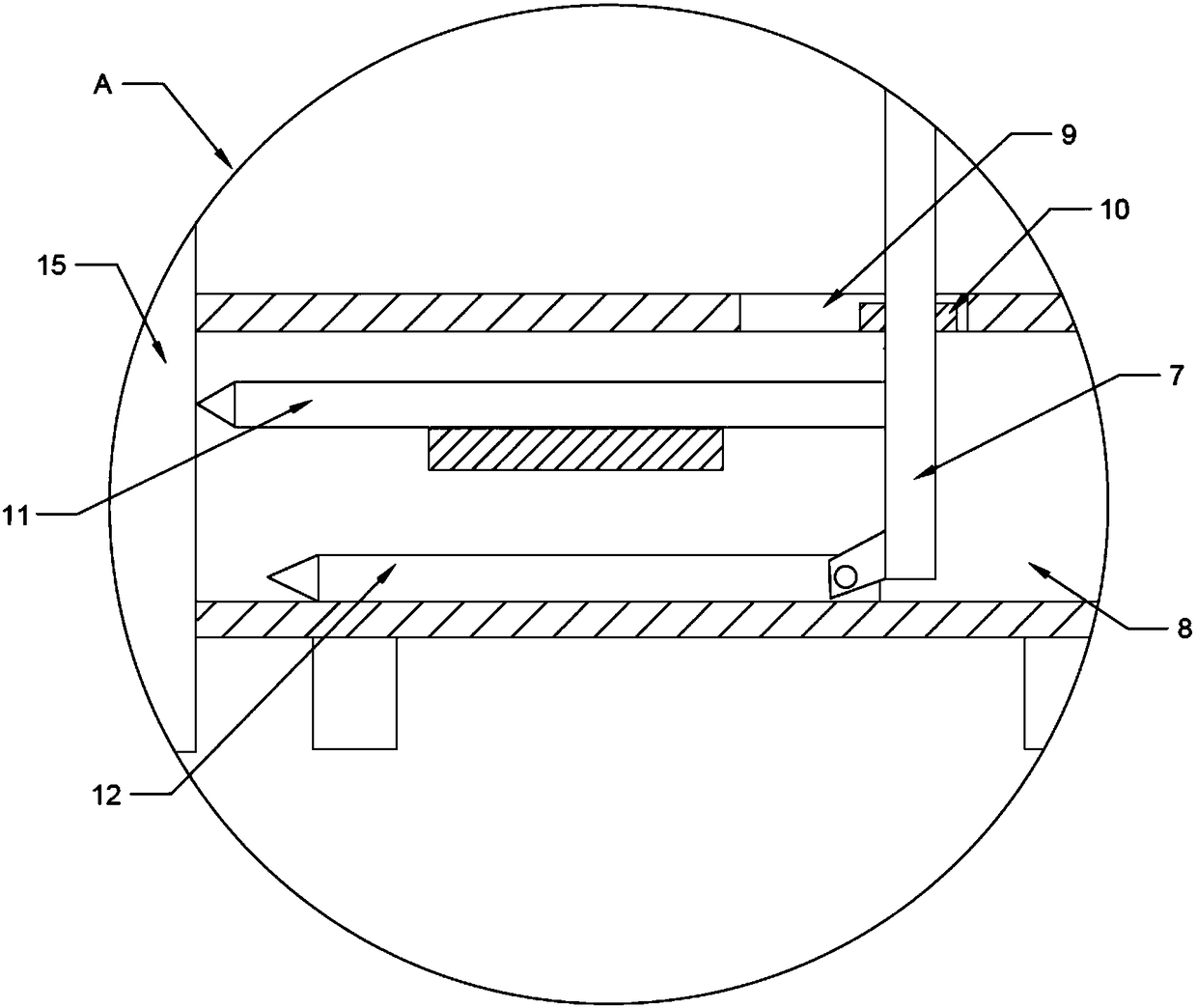

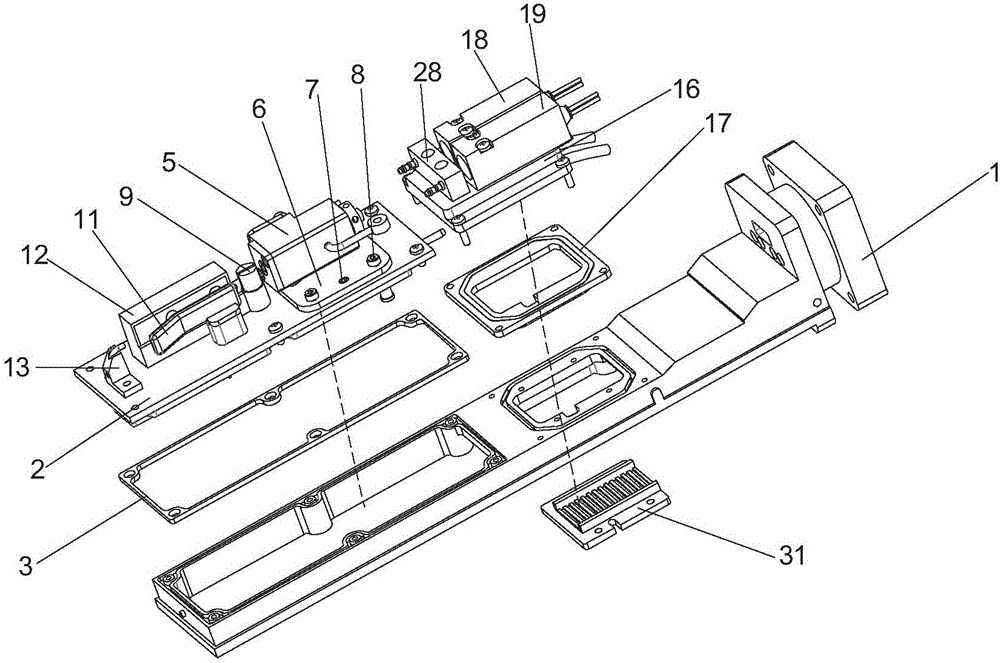

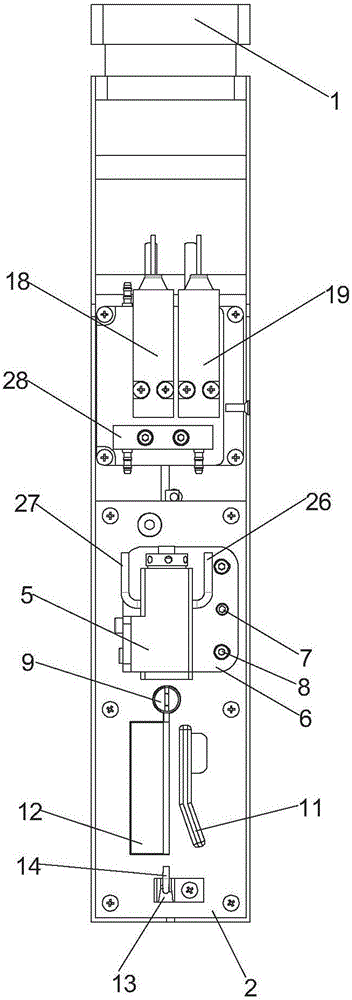

Lap weld laser searching automatic welding machine

PendingCN107900490AWon't deviateCompact structureWelding/cutting auxillary devicesElectrode supporting devicesElectric machineryErbium lasers

The invention discloses a lap weld laser searching automatic welding machine. The lap weld laser searching automatic welding machine comprises a worktable frame; a car guide rail base is longitudinally arranged on the worktable frame; a car guide rail and a rack are longitudinally arranged on the car guide rail base; a welding car is mounted on the car guide rail; the welding car comprises a car base; the car base is provided with a car slide block; the car slide block cooperates with the car guide rail to enable the welding car to longitudinally move along the car guide rail; a walking motoris mounted on the car base; a gear is mounted on the walking motor, and is engaged with the rack; a transverse moving mechanism is mounted on the car base; a vertical moving mechanism is mounted on atransverse moving slide plate of the transverse moving mechanism; a vertical moving slide plate is mounted on the vertical moving mechanism; a welding gun bracket is longitudinally mounted on the vertical moving slide plate; and a welding gun is mounted on the welding gun bracket. The lap weld laser searching automatic welding machine has the advantage of capability of guaranteeing no deviation ofa laser from a welding line. The lap weld laser searching automatic welding machine also has the advantages of simple and compact structure and convenience to install and use.

Owner:刘帅

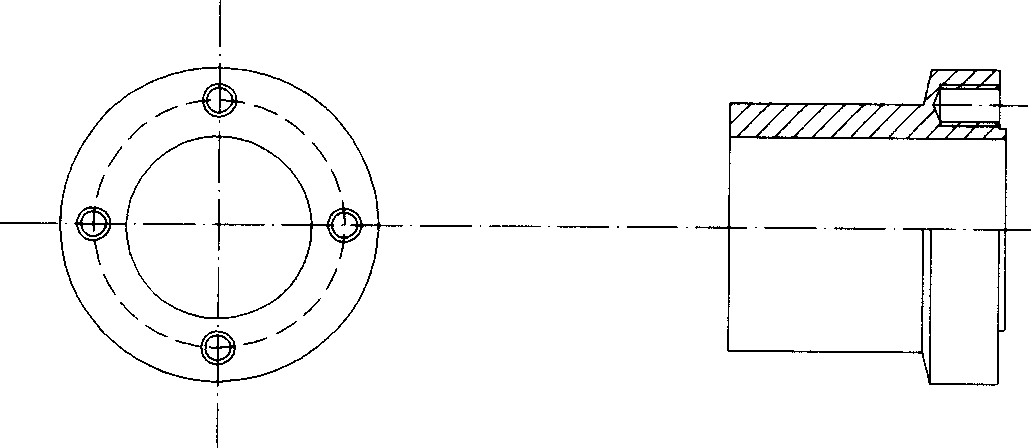

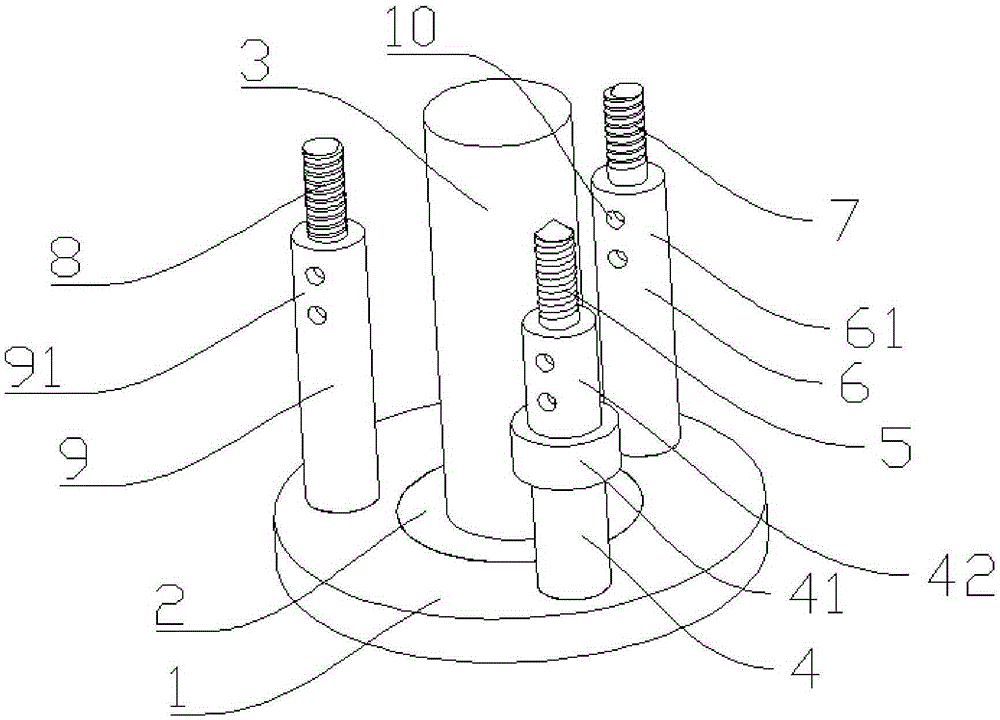

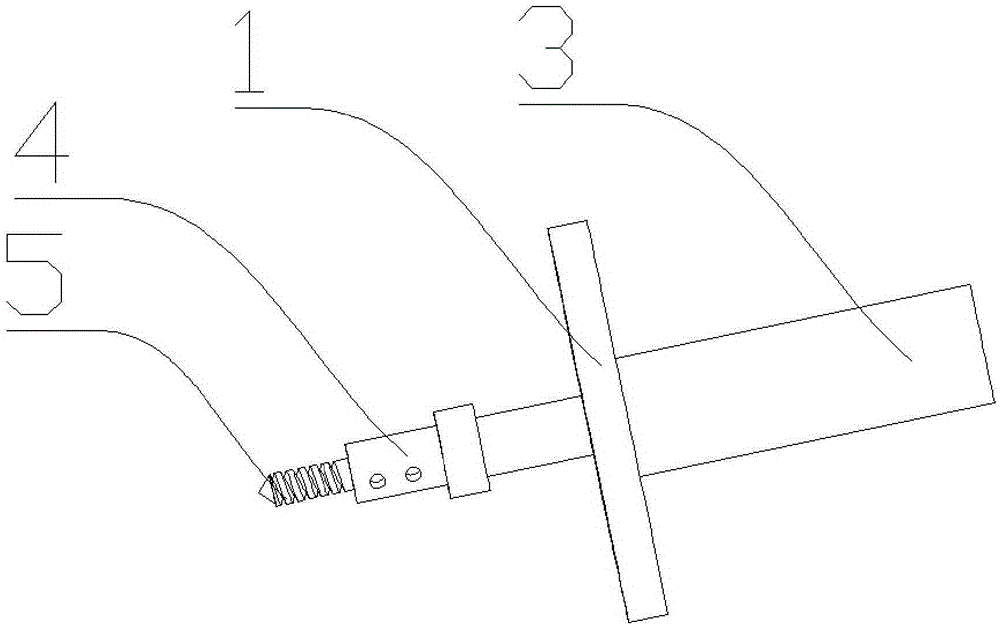

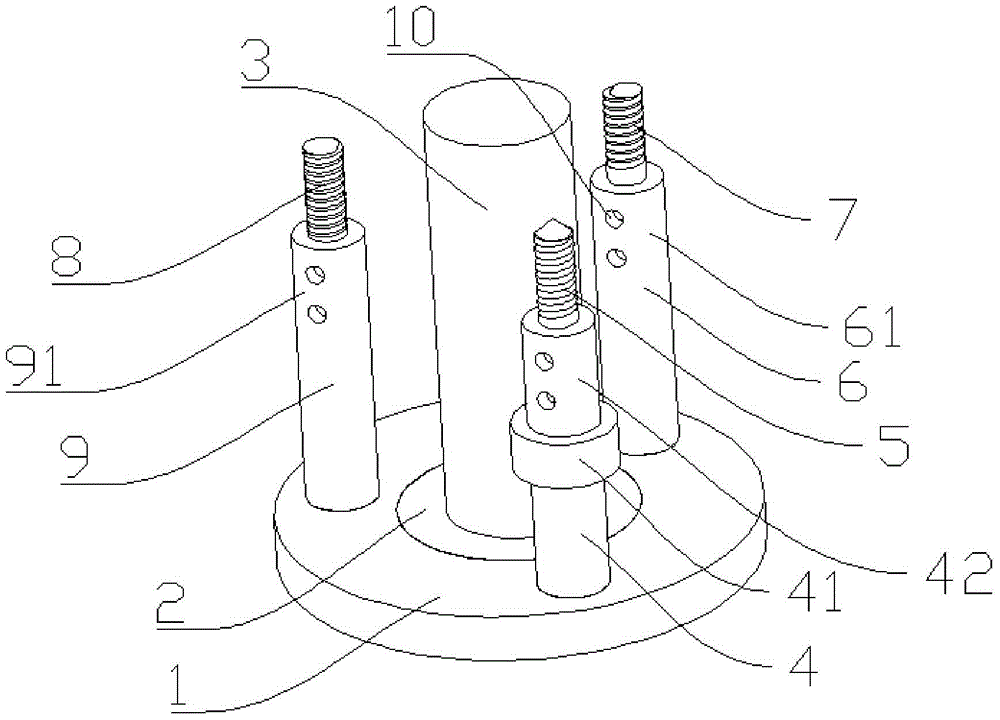

Wind driven generator end cover broken bolt dismounting device and dismounting method thereof

ActiveCN105345743AImprove maintenance efficiencyReduce maintenance costsMetal-working hand toolsWind forceEngineering

The invention discloses a wind driven generator end cover broken bolt dismounting device. A bearing is arranged in the center of a chassis; a rotating shaft rotates around the periphery of the chassis, and fits a bearing; a connecting end fitting a dismounting component is arranged at one end of the rotating shaft; the dismounting component comprises a drilling component for drilling a blind hole in a broken bolt, a tapping component for tapping the blind hole as a thread hole, and a screw rod component fitting the thread hole; the screw rod component comprises a screw rod; and the thread rotating direction of the screw rod is opposite to the thread rotating direction of the broken bolt. The dismounting device has the following beneficial effects: the broken bolt is drilled through the drilling component; then, the drilled hole is tapped; the screw rod component is connected with the tapped thread hole; and as the thread rotating direction of the screw rod is opposite to the thread rotating direction of the broken bolt, the broken bolt can be taken out through reversely rotating the rotating shaft, the operation is convenient and fast, the damage of a traditional thread and the dismounting of an outer end cover are not needed, the repair efficiency is greatly improved, and the repair cost is reduced.

Owner:天赋新能源科技(南通)有限公司

Ink jet printing head device

The invention provides an ink jet printing head device which comprises an electromagnetic valve base and a datum plate, wherein the electromagnetic valve base is fixedly arranged on a spray nozzle shell; an ink supply channel is arranged inside the electromagnetic valve base; an ink supply electromagnetic valve is arranged on the electromagnetic valve base; the ink supply electromagnetic valve communicates with the ink supply channel; the datum plate is fixedly arranged on the spray nozzle shell and is positioned at the back of the electromagnetic valve base; an adjustable nozzle body is arranged on the datum plate; the nozzle body communicates with the ink supply electromagnetic valve; a charging electrode is correspondingly arranged at the back of the nozzle body; an ink droplet deflection mechanism is arranged at the back of the charging electrode; a recoverer corresponding to the nozzle body is arranged at the back of the ink droplet deflection mechanism; and the charging electrode, the ink droplet deflection mechanism and the recoverer are fixed to the datum plate. The ink jet printing head device has the advantages that a nozzle is convenient to adjust, the recoverer deformation is avoided, ink is prevented spilling from the spray nozzle shell, ink is conveniently heated, and the like, and is easy to mount, convenient to use, stable and reliable in operation and long in service life.

Owner:北京赛腾标识系统股份公司

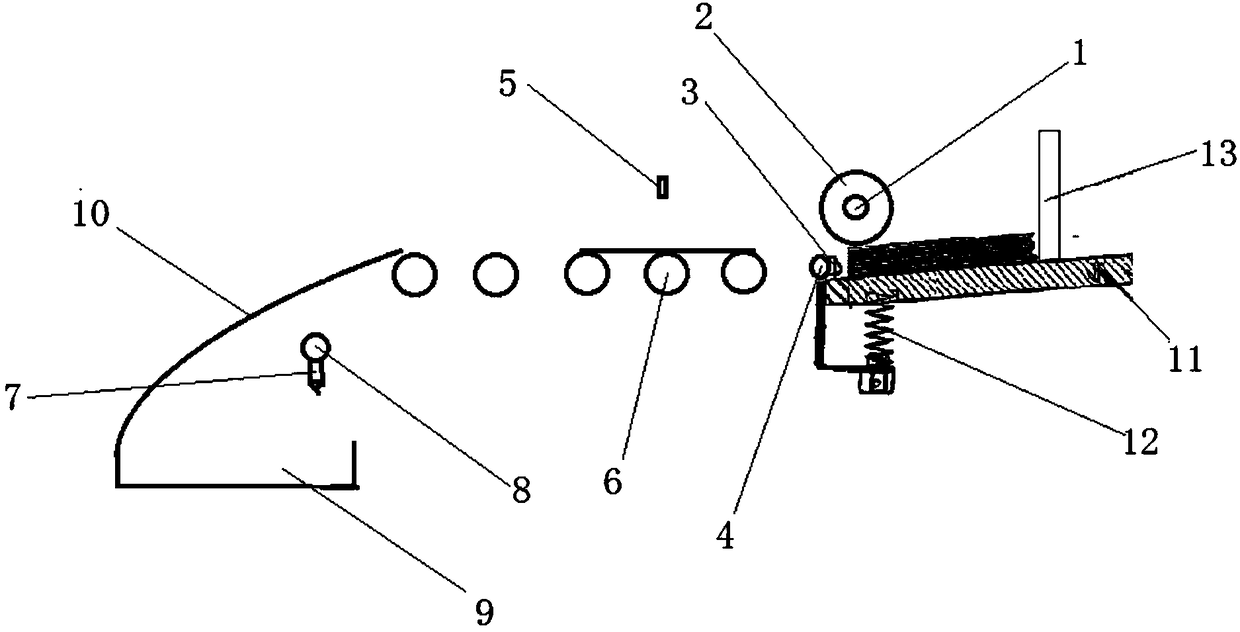

Printing device used for invoice printing

InactiveCN108215470AImprove printing qualityAccurate locationOther printing apparatusPrinting press partsInvoicePulp and paper industry

The invention relates to a printing device used for invoice printing. The device comprises a paper inlet unit, a printing unit, a collecting unit and a blowing unit; the paper inlet unit comprises a supporting plate, a paper inlet shaft and a friction wheel arranged on the paper inlet shaft; the printing unit is arranged at the rear end of the paper inlet unit and comprises a roller used for conveying paper and a checking up subunit used for checking up the paper position; the collecting unit is arranged at the rear end of the printing unit and comprises a guide plate used for stipulating an invoice falling track and a collecting groove used for collecting invoices; the blowing unit comprises a first blowing subunit arranged at the front end of the supporting plate and used for separatingthe paper, a second blowing subunit and an air blower, wherein the second blowing subunit and the air blower are arranged on the two sides of the guide plate and used for blowing the invoices into thecollecting groove in an accelerated manner. Compared with the prior art, the two blowing subunits are arranged, an air film is formed between every two pieces of paper, adjacent pieces of paper are separated, the paper cannot enter in printing operation, printing quality is improved, the tails of the invoices can rapidly enter the collecting groove, and the arranging work of invoices in the laterperiod can be reduced.

Owner:SHANGHAI DONGGANG PRINTING

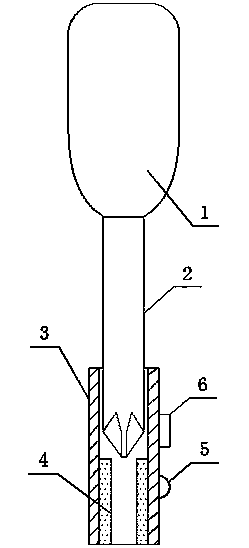

Night-vision anti-slip safety screwdriver

The invention discloses a night-vision anti-slip safety screwdriver which comprises a handle and an operating rod connected at one end of the handle. The operating rod is provided with a screw sleeve coaxial with the operating rod, and one end of the screw sleeve sleeves the operating rod while the other end of the screw sleeve protrudes the end, away from the handle, of the operating rod. An elastic sleeve is arranged on the inner wall of the screw sleeve and positioned, away from the operating rod, on the inner wall of the screw sleeve. An LED (light emitting diode) lamp and a control switch thereof are arranged on the outer wall of the screw sleeve made of transparent plastic. Owing to the screw sleeve arranged on the operating rod, a screw can be conveniently screwed by putting the screw in the screw sleeve and guaranteed against deviating from a preset way, so that stab accidents are avoided effectively. Further, since the operating rod and the screw are both arranged in the screw sleeve, slipping between the screwdriver and the screw is effectively avoided to protect surfaces of parts from being punctured. In addition, the screwdriver is convenient for people to use at night by the aid of the LED lamp arranged on the screw sleeve.

Owner:张素香

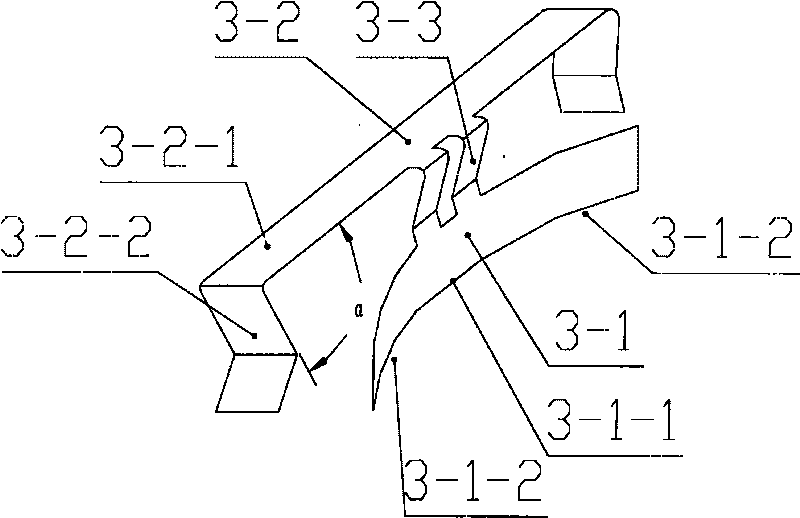

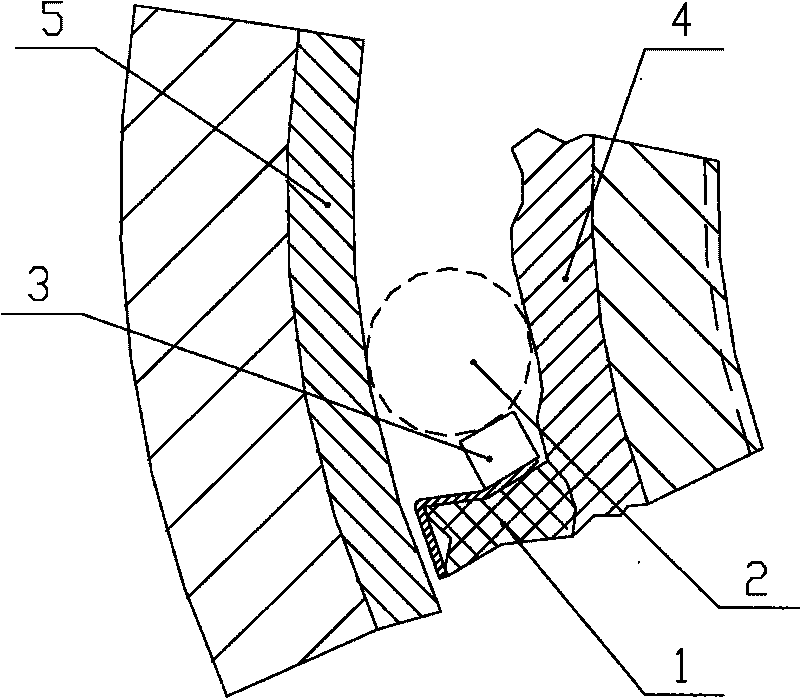

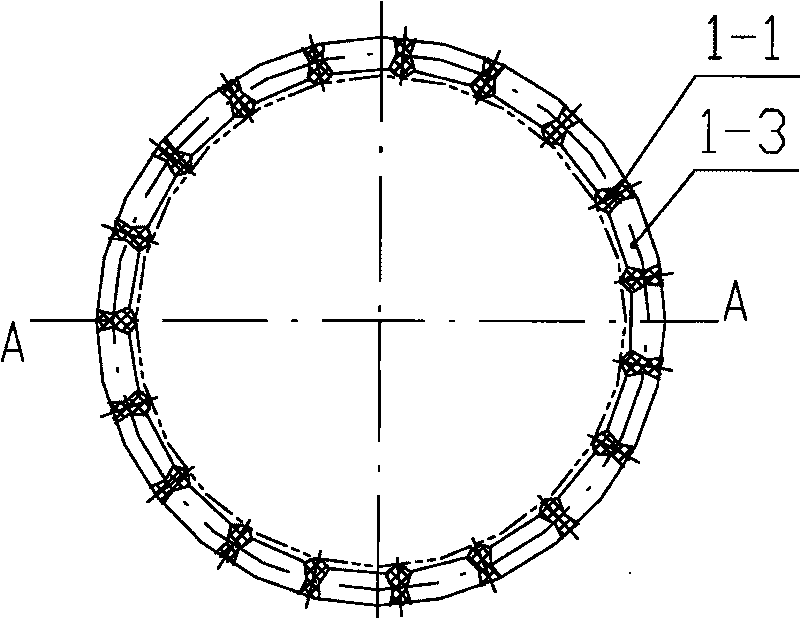

Spring leaf and overrunning clutch mounted with spring leafs

The invention relates to a spring leaf and an overrunning clutch mounted with the spring leafs, the spring leaf is composed of a support piece supporting the suspension of roller pins, a clamping piece and a connection beam connecting the support piece and the clamping piece, wherein the body of the clamping piece is a straight piece with two ends provided with V-shaped bending portions. The overrunning clutch includes a retaining rack, a plurality of roller pins and a plurality of spring leafs, wherein spring leaf installation grooves are respectively arranged at positions, corresponding to the beams, of outer end faces of first and second annular end edges at both ends of an aperture on the retaining rack, the bottoms of the spring leaf installation grooves form into the shape of V by sectioning in the axial direction of the retaining rack; the inner surface of the straight piece of the clamping piece of the spring leaf is adhered to the outer surface of the cross beam, and the inner surfaces of the V-shaped bending portions of the clamping piece are matched with the bottom surfaces of the spring leaf installation grooves. The overrunning clutch mounted with the spring leafs solves the technical problem regarding the hidden danger of displacement and disengagement of the spring during the reciprocating movement of the current overrunning clutch at high rotating speed and high frequency.

Owner:JIANG SU NAN FANG BEARING CO LTD

Smart glasses

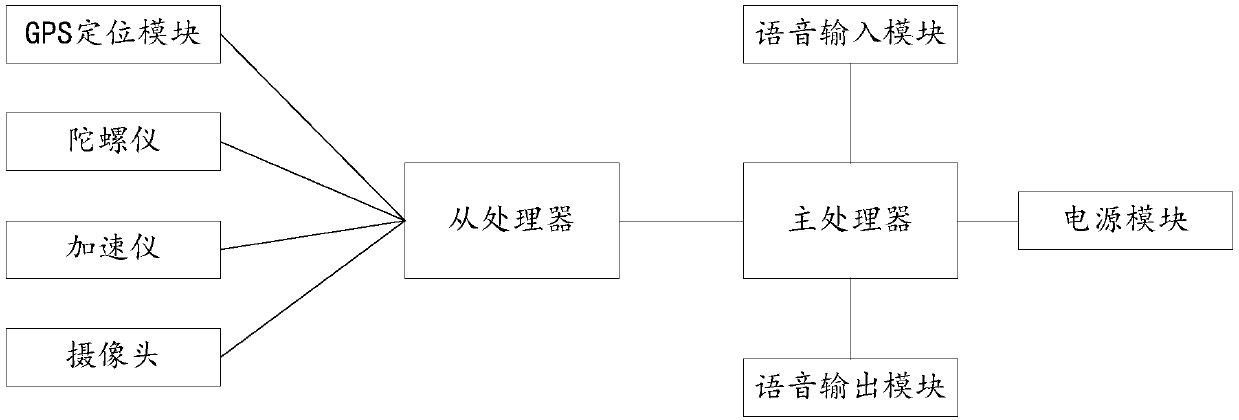

InactiveCN109674628AEasy to useWon't deviateNavigation by speed/acceleration measurementsWalking aidsAccelerometerGyroscope

The invention relates to smart glasses which comprise a camera mounted on a smart glasses body, a main processor, a slave processor, a voice input module, a voice output module, a global positioning system (GPS) positioning module, a gyroscope and an accelerometer. The main processor is connected to the voice input module and the voice output module respectively for performing voice interaction with users. The slave processor is connected to the camera, the GPS positioning module, the gyroscope and the accelerometer respectively for navigation during outdoor and indoor activities for users. The invention can carry out navigation for a special crowd who are having indoor and outdoor activities, and ensure the safety of personnel.

Owner:GUILIN UNIV OF ELECTRONIC TECH

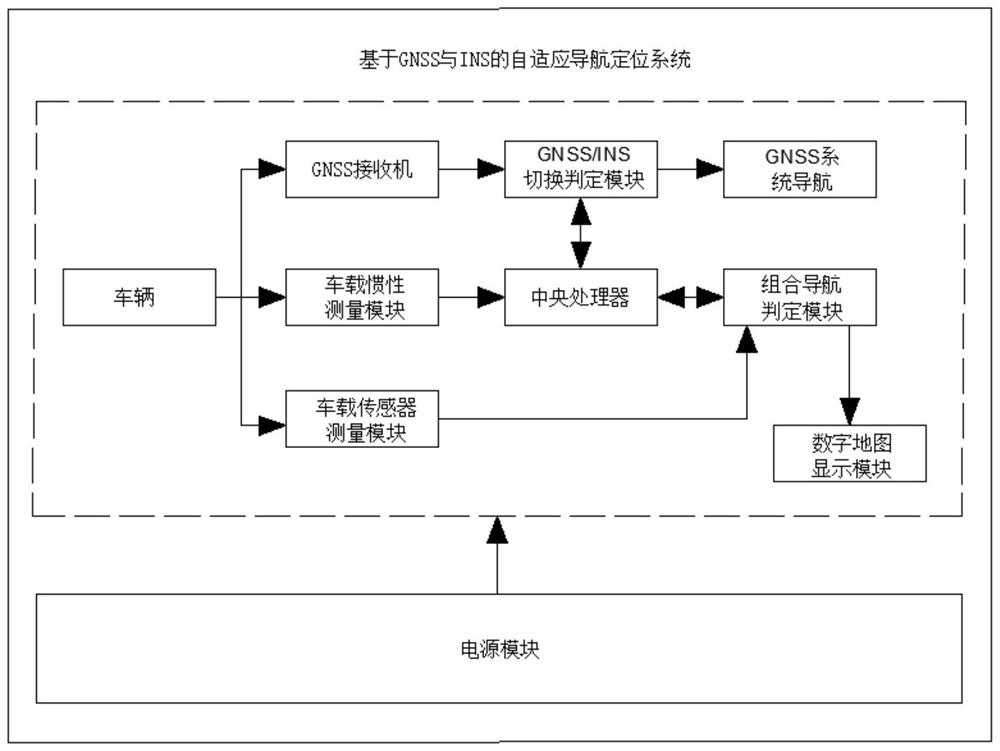

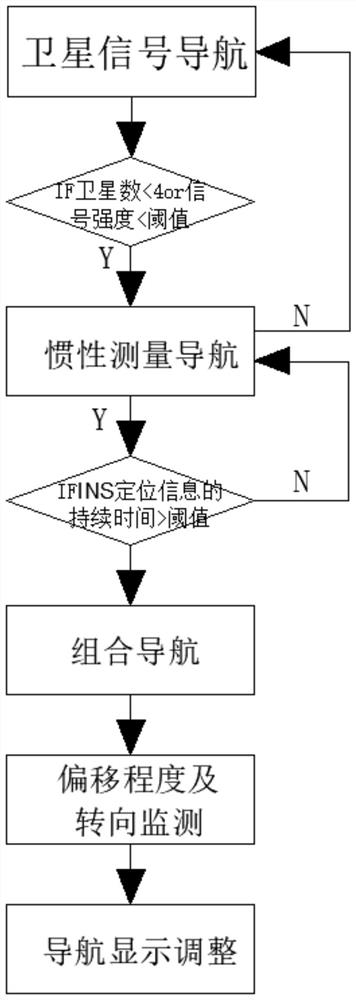

Self-adaptive navigation and positioning system and method based on GNSS and INS

InactiveCN113358115AWon't deviateGuaranteed uptimeNavigation by speed/acceleration measurementsSatellite radio beaconingDriver/operatorIn vehicle

The invention discloses a self-adaptive navigation and positioning system based on GNSS and INS, which belongs to the technical field of navigation and positioning and comprises a vehicle-mounted GNSS receiver, a GNSS / INS switching judgment module, a central processing unit, a vehicle-mounted inertial measurement module, a combined navigation judgment module, a vehicle-mounted sensor measurement module, a digital map display module and a system power supply module. The integrated navigation system composed of the GNSS and the INS is used for navigating and positioning a vehicle, when a satellite signal is normal, the GNSS is used for navigating independently, and when the GNSS / INS switching judgment module monitors that the satellite signal is weak, the GNSS is switched to the INS for navigating the vehicle. Meanwhile, the combined navigation judgment module records and judges the duration time of the INS positioning information by using a timer, and if the duration time exceeds the threshold time, the GNSS and the INS carry out combined navigation; therefore, the vehicle navigation system can continue to operate stably, reliable positioning precision is obtained, and a driver cannot deviate from an original route.

Owner:LIAONING TECHNICAL UNIVERSITY

Vacuum coating equipment for processing metallic films

InactiveCN106435513AHigh degree of automationConvenience for feeding/receivingVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses vacuum coating equipment for processing metallic films. The vacuum coating equipment comprises a vacuum chamber, a feeding mechanism, a coating mechanism and a winding mechanism, wherein the feeding mechanism, the coating mechanism and the winding mechanism are arranged inside the vacuum chamber; the feeding mechanism comprises a first lifting mechanism and a feeding device; a preheating mechanism is arranged between the feeding mechanism and the coating mechanism; a first movable plate assembly adjusting an opening of a first evaporation boat is arranged in the opening area of the top of the first evaporation boat; a second movable plate assembly adjusting an opening of a second first evaporation boat is arranged in the opening area of the top of the second evaporation boat; film limiting devices are arranged between the feeding mechanism and the coating mechanism as well as between the coating mechanism and the winding mechanism; the winding mechanism comprises a fifth lifting mechanism and a winding device; and an extension end of the fifth lifting mechanism is matched with the winding device to drive the winding device to move up and down. The vacuum coating equipment has the advantages that the automation degree is high, supplementing and collecting are convenient and timely, preheating is uniform, the preheating degree can be adjusted, the processing requirements of the films of various models can be met and the coating thickness can be adjusted.

Owner:铜陵市铜创电子科技有限公司

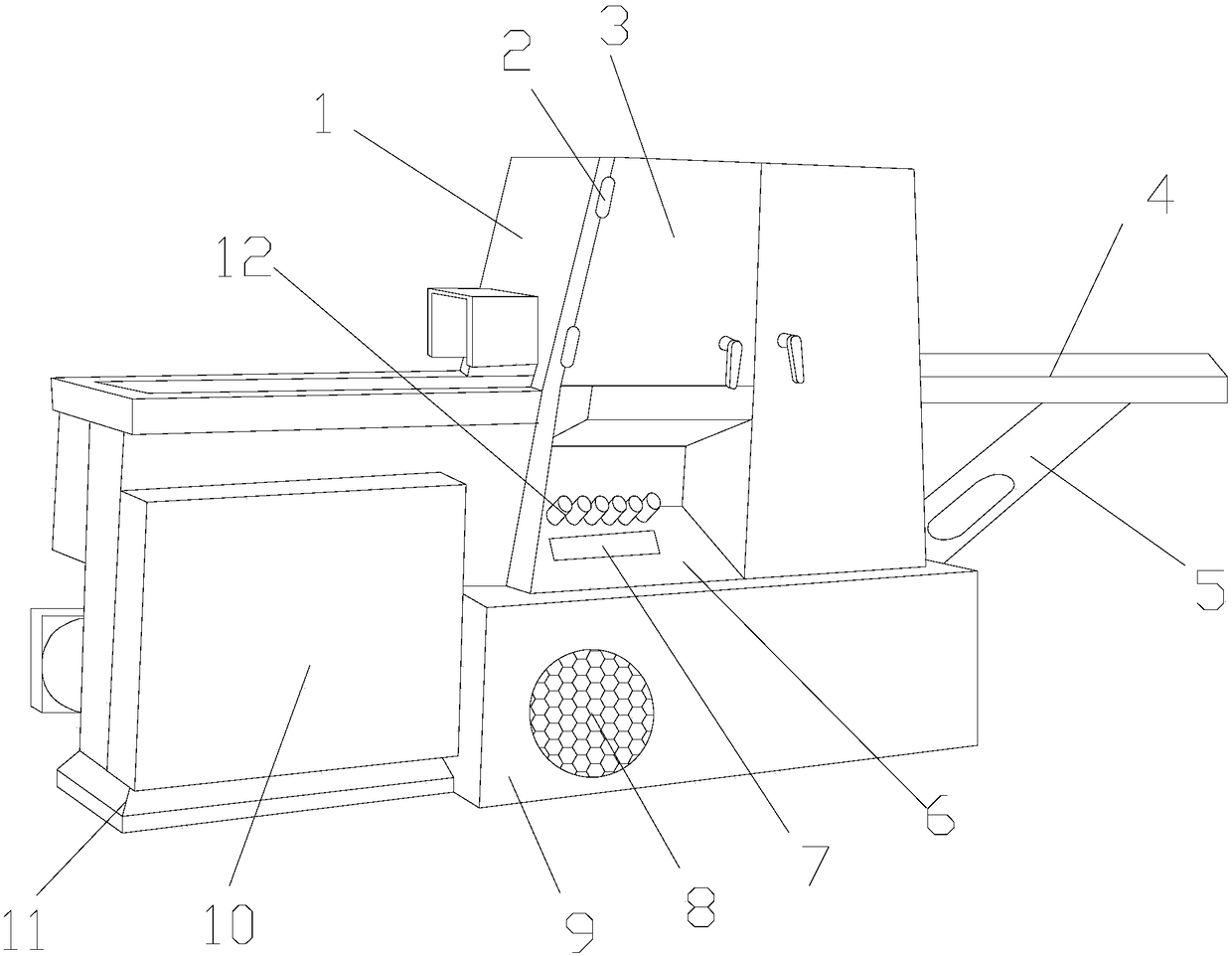

Full-automatic wood-processing machine

InactiveCN108177206AWon't deviateReduce work stressMulti-purpose machinesBark-zones/chip/dust/waste removalEngineeringSurface plate

The invention discloses a full-automatic wood-processing machine structurally comprising a wood processing structure, a hinge, a box door, a tool plate, a bracket, an operation panel, a display screen, a cooling port, a base, a fixed plate, a support seat, and an operation key; the front end of the box door is provided with a handle; the left end of the box door is connected with the left side ofthe front end of the wood processing structure through the hinge; the bottom of the box door is attached with the top portion of the operation panel; the bottom of the operation panel and the top of the base are connected in a welding mode; the outer wall of the cooling port is connected with the front end of the base through a neck connection; the front end of the operation panel and the rear endof the display screen are connected in a neck connection; the bottom of the operation key is in clearance fit with the front end of the operation panel. The full-automatic wood-processing machine structurally comprises a wood processing structure, the device integrates drying, cutting and grinding, separate rework treatment is not required, full automatic operation is achieved, the manual operation is saved, the work efficiency is improved, the work stress of a worker is reduced, compared with manual operation, and the product precision is improved.

Owner:惠安闽神石材加工设备开发有限公司

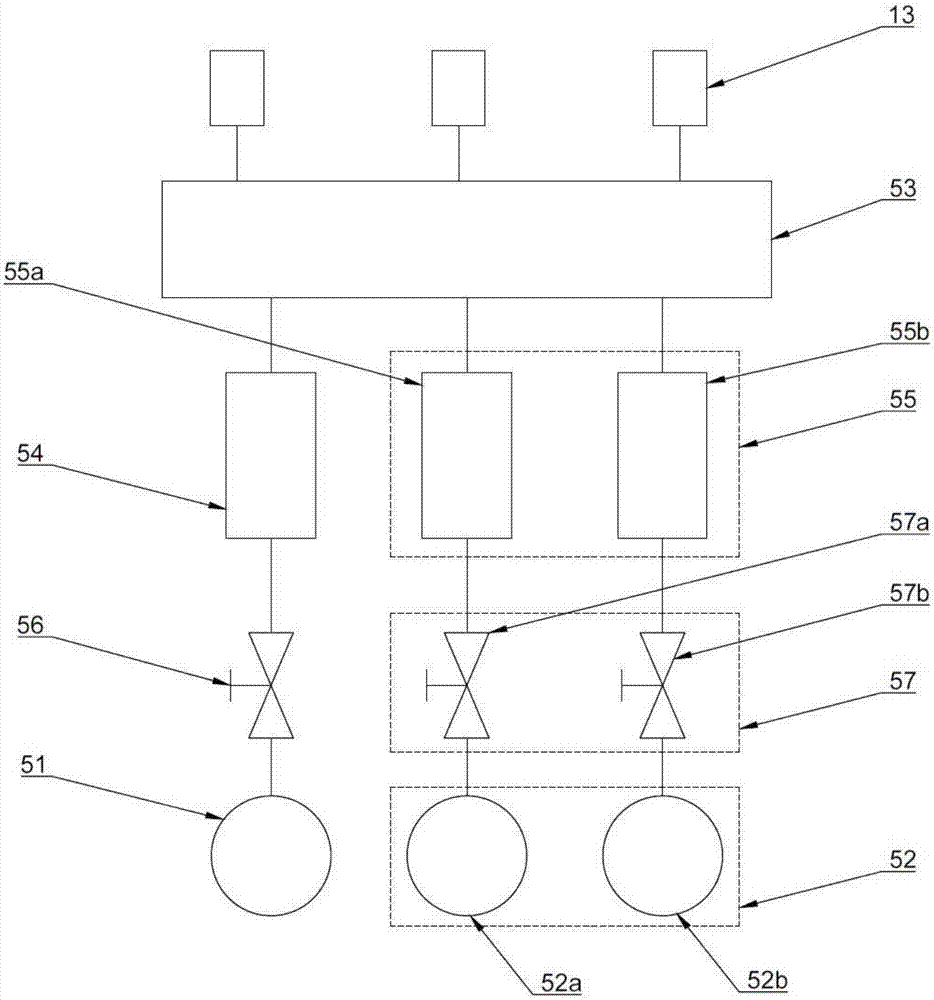

Atmosphere bell-type furnace

PendingCN106949734AWell mixedProportional balanceBell type furnacesControl devices for furnacesMetallurgyEngineering

The invention provides an atmosphere bell-type furnace, and relates to the technical field of sintering furnaces of electronic products. The atmosphere bell-type furnace comprises a furnace body, wherein a gas outlet communicated with the hearth is formed in the top of the furnace body; gas inlets communicated with the hearth are uniformly formed in the side wall at the bottom of the furnace body in the circumferential direction; a mixing chamber communicated with the gas inlets is arranged at each of the gas inlets; a gas circulating system is further arranged on the furnace body; one end of the gas circulating system is connected with the gas outlet; the other end of the gas circulating system is connected with the each of the mixing chambers; a mixed gas regulating system is also arranged on the furnace body; the mixed gas regulating system is connected with each of the mixing chambers; an oxygen content analysis system is arranged in the furnace body; the oxygen content analysis system is connected with the mixed gas regulating system. According to the atmosphere bell-type furnace, before a mixed gas enters the furnace body, the mixing volume of a nitrogen flow and an air flow is regulated, so that gases entering the furnace body can be mixed uniformly in proportion, and the product can achieve a better sintering effect.

Owner:SUZHOU KILN-PARTNER MASCH TECH CO LTD

Solid-liquid universal food detection apparatus

InactiveCN108645650AWon't deviateEasy extractionWithdrawing sample devicesTesting foodSolid massSolid food

The invention discloses a solid-liquid universal food detection apparatus. The solid-liquid universal food detection apparatus comprises a support plate, a liquid sampling cylinder and a solid sampling cylinder are fixedly connected with the right side of the support plate in order from left to right, a motor box is fixedly connected with the bottom of the solid sampling cylinder, a motor is fixedly connected with an inner part of the motor box, the top of a motor output shaft penetrates the solid sampling cylinder and is extended into the solid sampling cylinder, and a rotation block is fixedly connected with the top of the motor output shaft. The food detection apparatus relates to the technical field of food detection. The food detection apparatus is simultaneously equipped with the liquid sampling cylinder and the solid sampling cylinder for sampling different food, a blade is used for crushing the solid food in the solid sampling cylinder and is convenient for extracting the sample, the rotating shaft can be dismounted and is convenient for cleaning, the liquid sampling cylinder is used for liquid sampling and is convenient for cleaning, a groove at the bottom of a first casecover is used, the rotating shaft cannot be deviated while being rotated, and the usage safety can be guaranteed.

Owner:雷磊

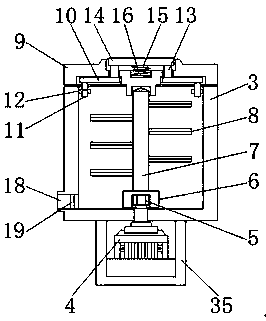

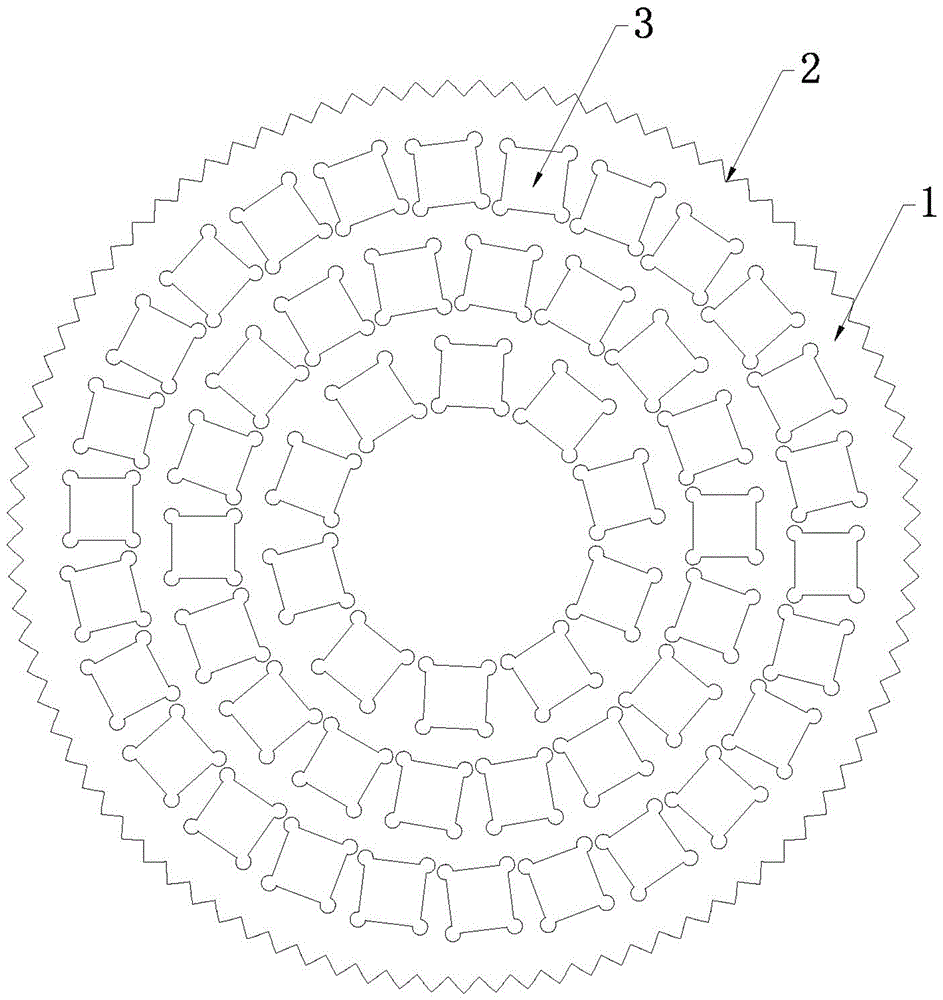

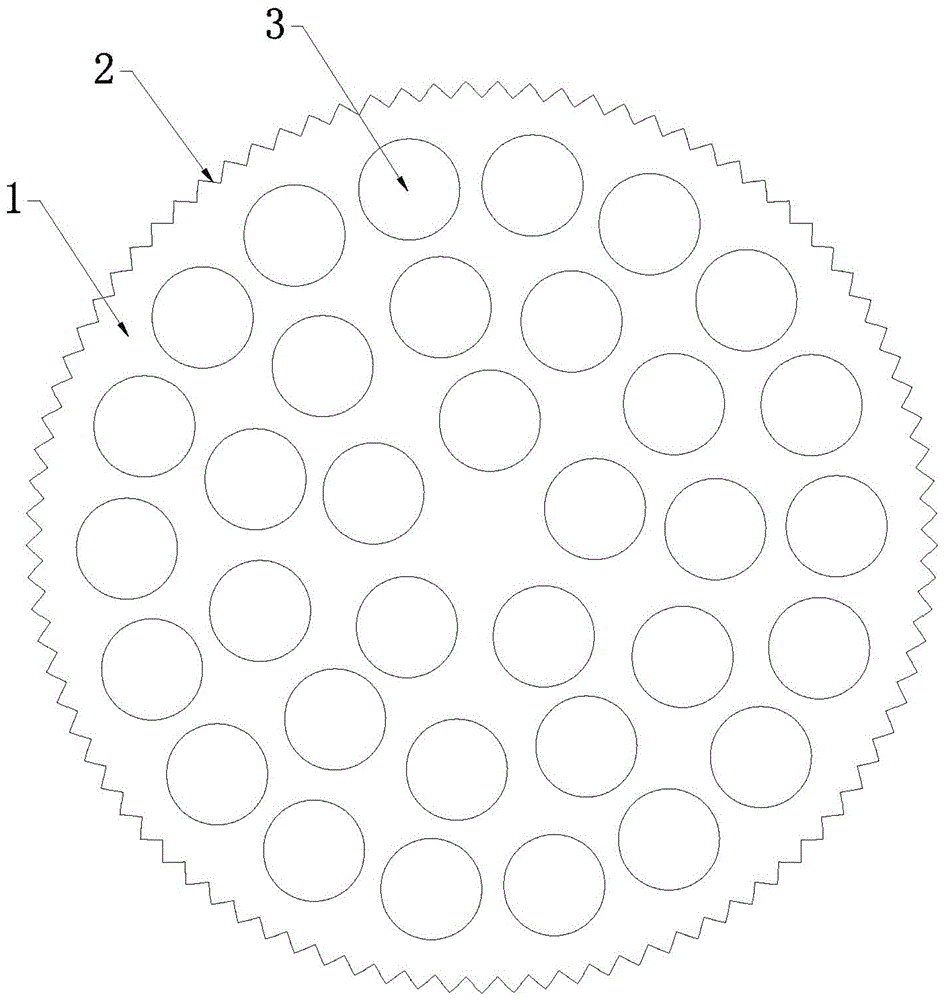

Work fixture for double-side grinding and polishing machine

InactiveCN106363529AProcessing quality meetsLow movement resistanceWork carriersEngineeringMachining process

The invention discloses a work fixture for a double-side grinding and polishing machine. The work fixture for the double-side grinding and polishing machine comprises a fixture body (1), wherein the fixture body (1) is disc-shaped; gear slots (2) which are uniformly distributed are formed in the outer edge of the periphery of the fixture body (1) and can be simultaneously engaged with a sun gear and an internal gear ring of the double-side grinding and polishing machine; and hollowed-out workpiece grooves (3) are formed in the fixture body (1), so that the upper surfaces and the lower surfaces of to-be-machined workpieces placed in the workpiece grooves (3) can be ground and polished, and the to-be-machined workpieces can rotate. The shape of the work fixture of the grinding and polishing machine is designed according to the shape of the grinding and polishing machine, and the work fixture can be engaged with the gear of the grinding and polishing machine well during running; and by the work fixture, the to-be-machined workpieces can be mounted rapidly and accurately, the workpiece grooves correspond to the to-be-machined workpieces to ensure that the to-be-machined workpieces cannot move or deviate in a machining process, and therefore, the machining quality of the to-be-machined workpieces meets requirements.

Owner:YIXING JINGKE OPTICAL INSTR

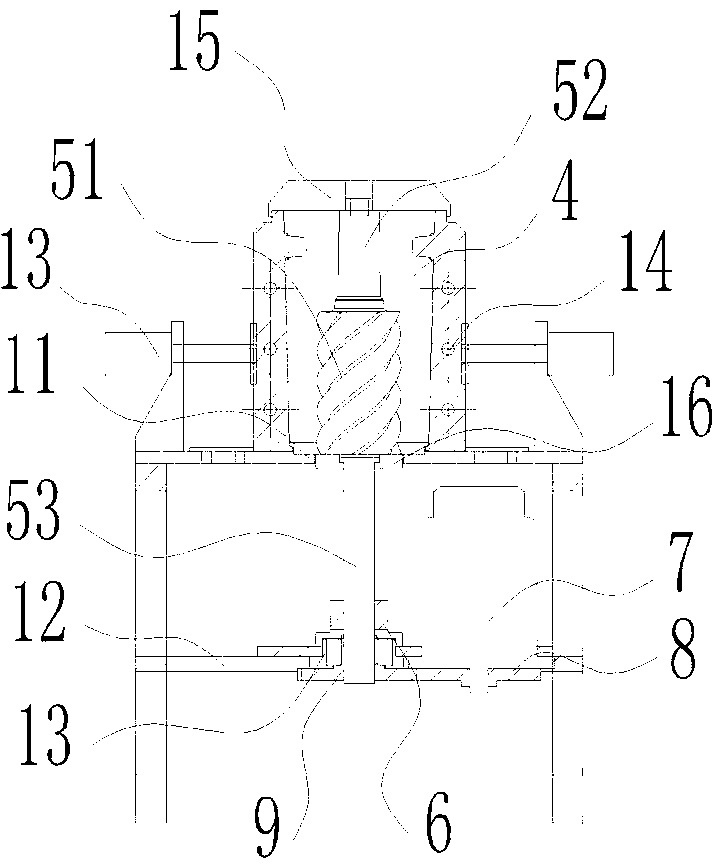

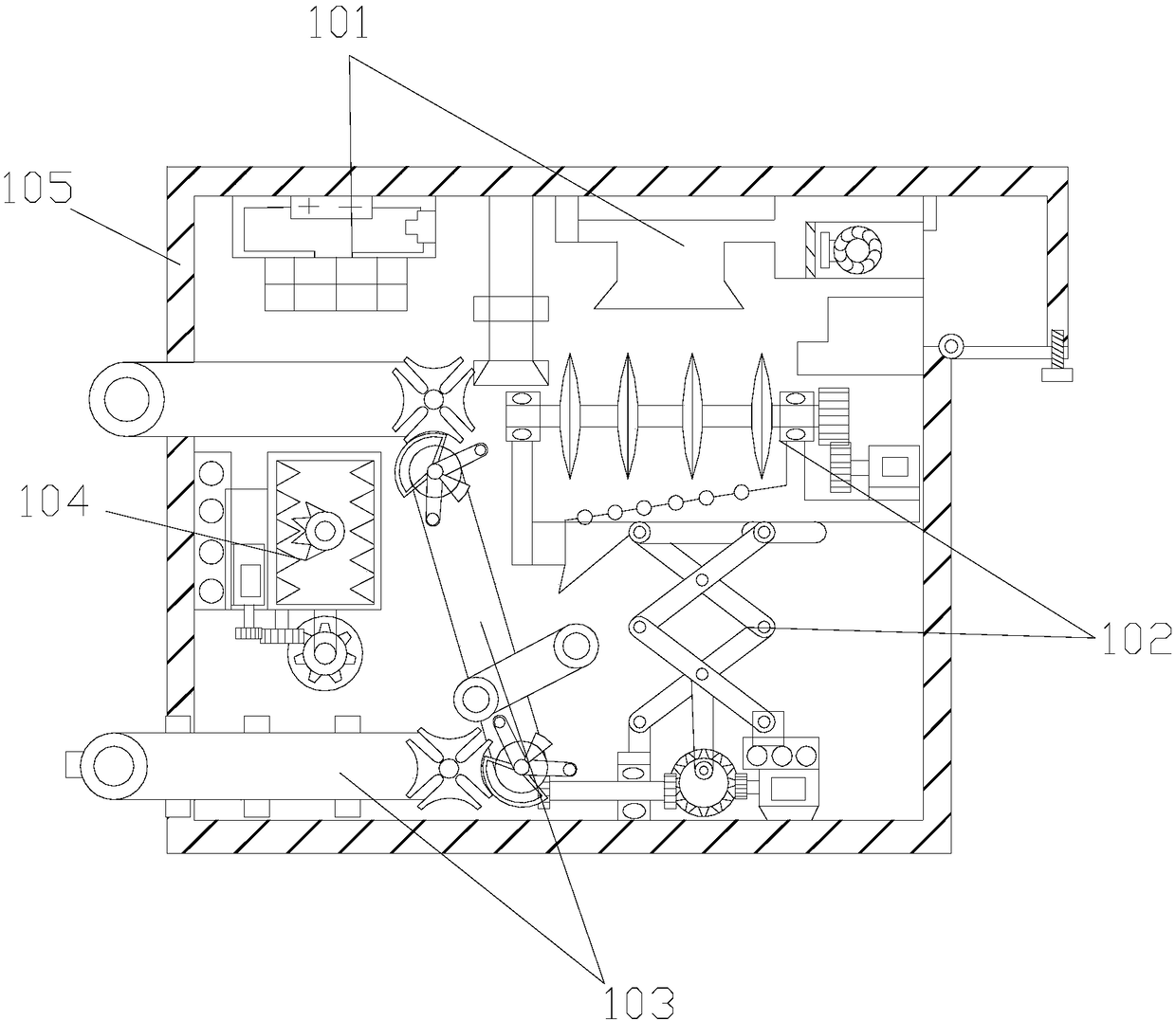

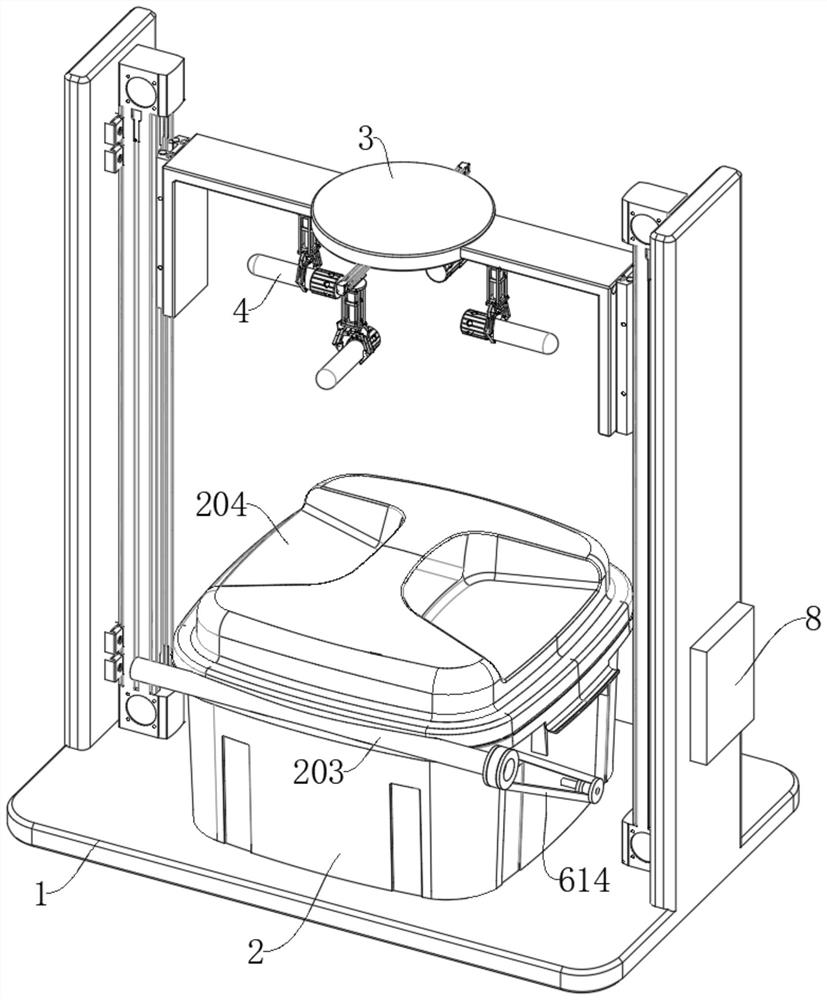

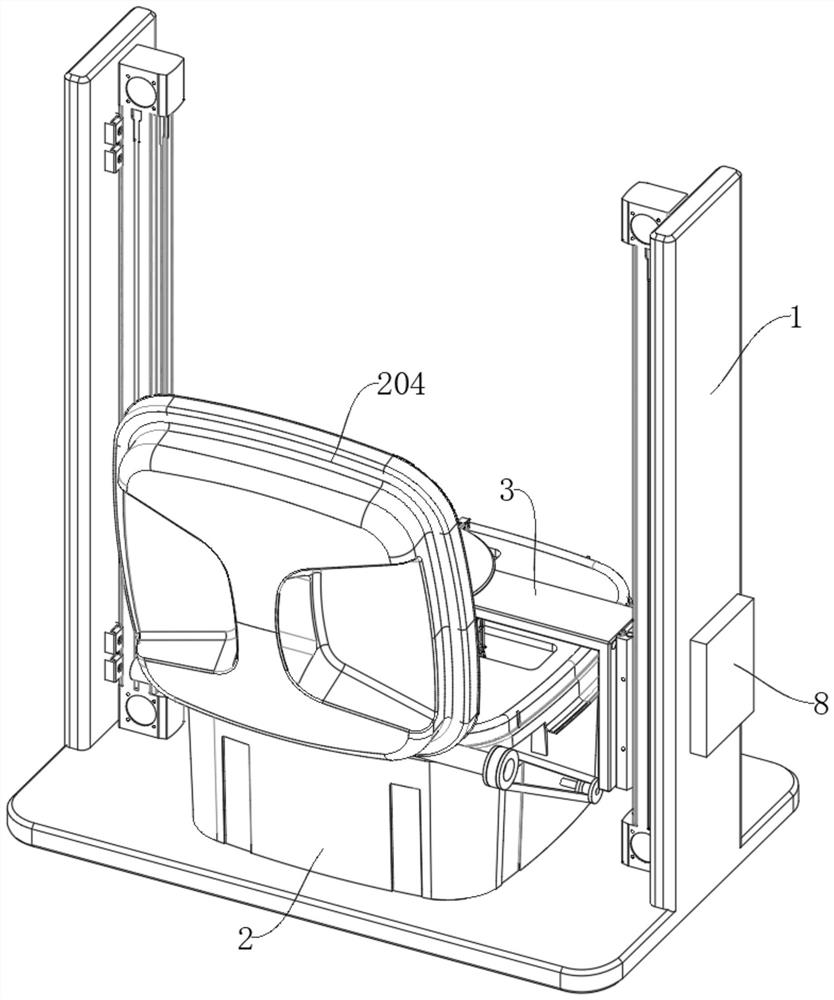

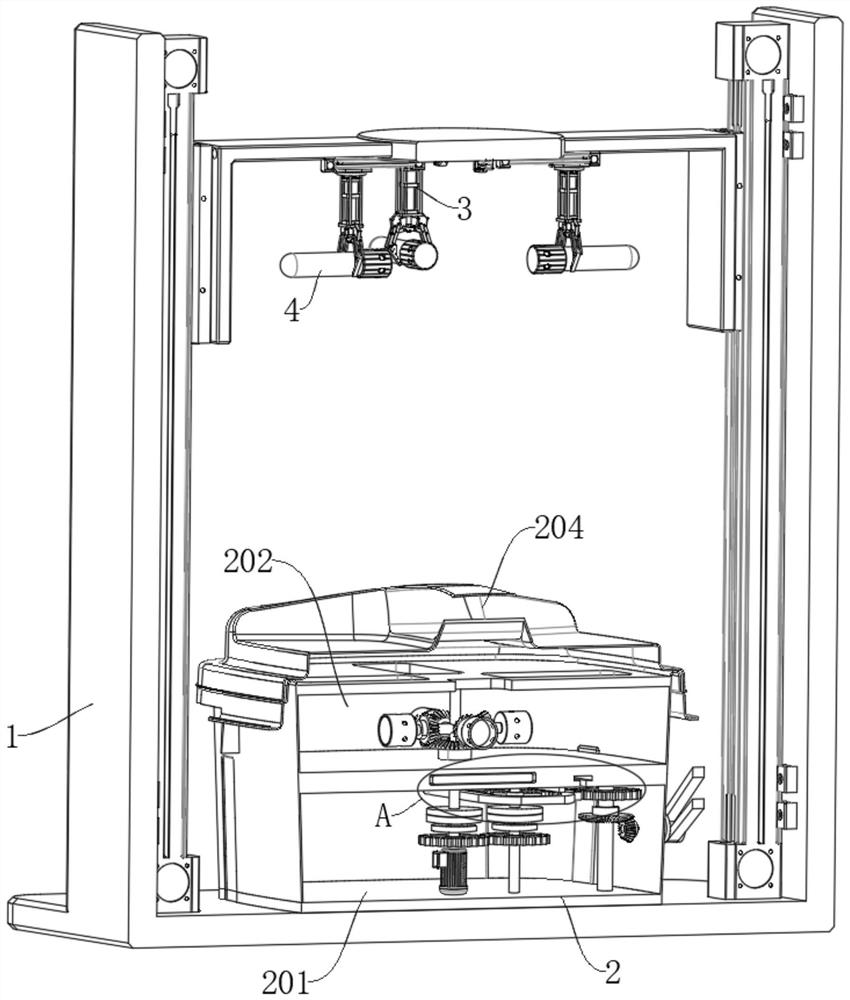

Integrated centrifugal system and method for full-automatic pelleter

The invention provides an integrated centrifugal system and method for a full-automatic pelleter, and belongs to the technical field of pelleters. The integrated centrifugal system for the full-automatic pelleter comprises a base; a shell is fixedly connected to the upper end of the base; and when the device is used for performing centrifugal treatment on multiple test tubes, the multiple test tubes rotate while performing circumferential centrifugal motion based on the midpoint of the shell, and the multiple test tubes can be subjected to excellent centrifugal treatment by applying a two-phase mixed centrifugal treatment mode, so that cells and impurities in samples are separated more thoroughly, thus improving accuracy of subsequent section production and pathological detection. In addition, according to the device, the multiple test tubes are automatically installed through a three-axis moving mechanical arm, the test tubes and the shell are integrated, and therefore the operation efficiency of centrifugal treatment is higher. By means of the ingenious design of the structure, a door opening and closing mechanism and a centrifugal mechanism can alternately operate by only arranging one servo motor as a power source.

Owner:深圳市森盈生物科技有限公司

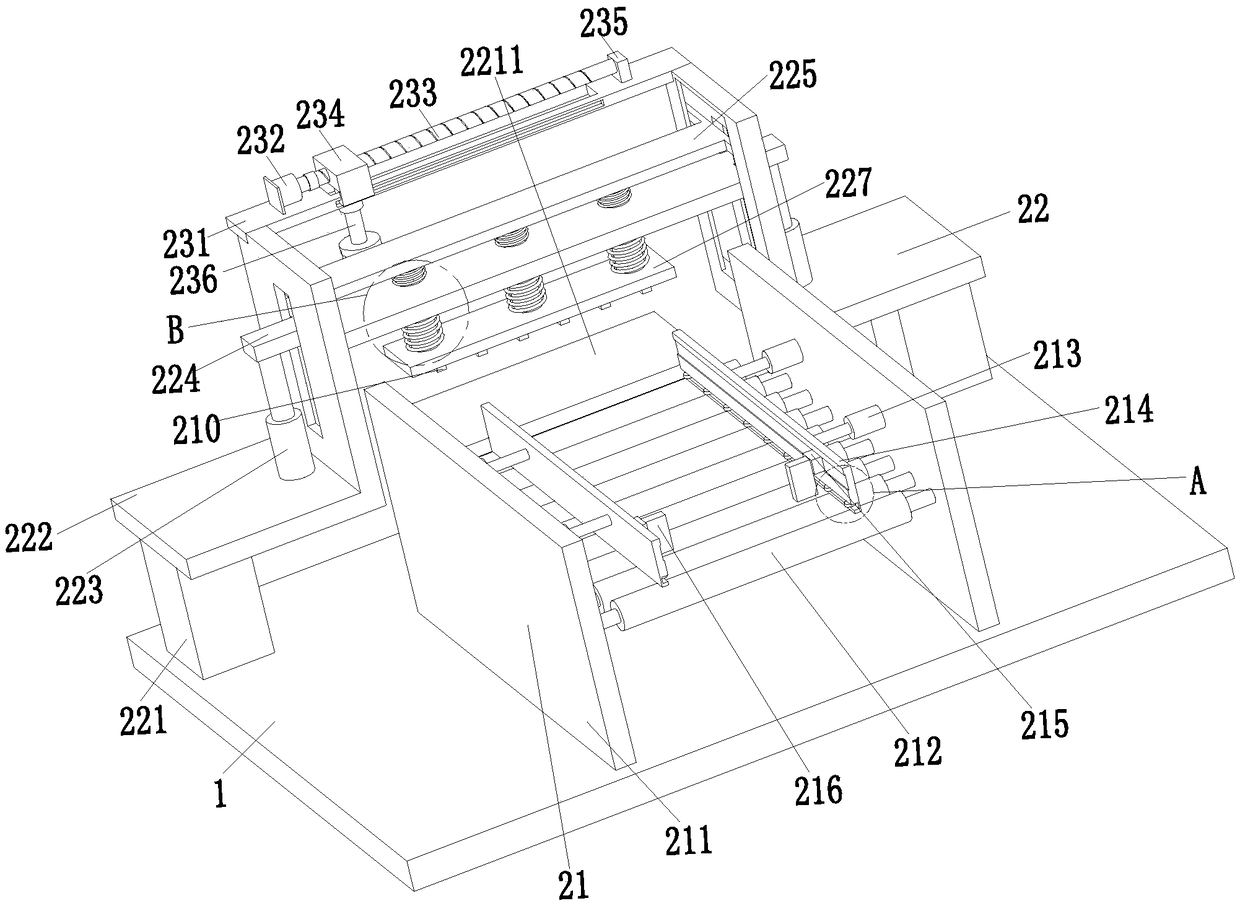

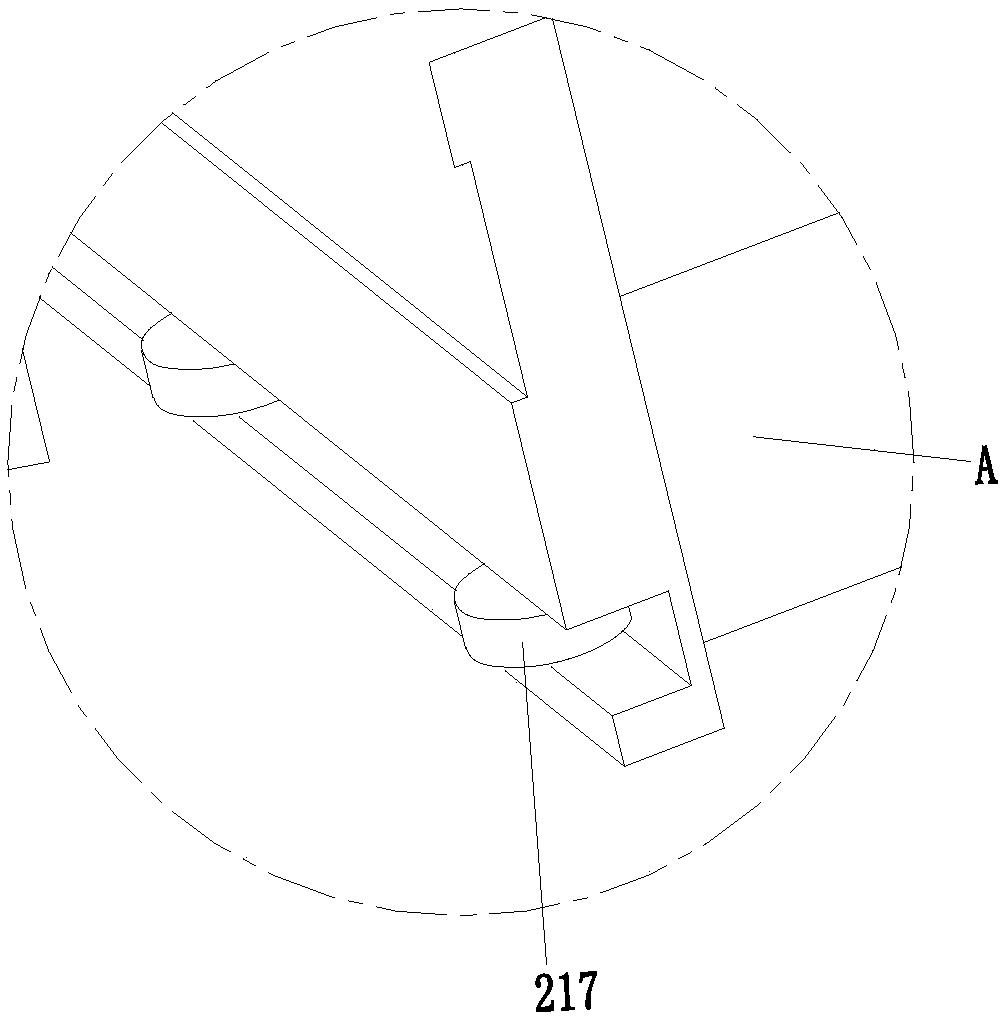

Aluminum base plate automatic cutting system

The invention relates to an aluminum base plate automatic cutting system. The aluminum base plate automatic cutting system comprises a bottom plate and a plate shearing device, wherein the upper end of the bottom plate is provided with the plate shearing device. By means of the aluminum base plate automatic cutting system, the problems in existing equipment that twist deformation of aluminum baseplates is prone to being caused due to unilateral force bearing is too large in cutting the aluminum base plates, meanwhile, in the cutting process, the aluminum base plates are prone to being cut baddue to the instability of the equipment, and in the conveying process, the mechanical equipment often hurts surfaces of the aluminum base plates to cause the surfaces of the aluminum base plates to be scratched and the like can be solved; a function of cutting the aluminum base plates automatically can be realized, the fact that the aluminum base plates will not deviate in the cutting process canbe guaranteed, and the condition that the aluminum base plates are cut bad due to the force bearing is too large will not be generated; and the aluminum base plate automatic cutting system has the advantages of being easy to operate, good in stability, low in labor intensity and high in work efficiency.

Owner:山西奕华富彩建材科技有限公司

Zebra crossing marking device for road engineering construction

InactiveCN109183597AGuaranteed cleanlinessAvoid affecting the construction processRoads maintainenceRoad engineeringElectric machinery

The invention relates to a zebra crossing marking device for road engineering construction, including a bracket, wherein a paint storage tank is arranged on the left side of the inner cavity of the bracket, a stirring motor is arranged on the top of the paint storage tank, a stirring shaft is fixedly connected with the stirring motor through the paint storage tank, a stirring blade is fixedly connected to the outside of the stirring shaft, a water pump is arranged on the right side of the paint storage tank, a chassis is arranged at the bottom of the bracket, a lifting plate is arranged in thechassis, a lifting plate is fixedly connected with that bottom of the bracket through an electric telescopic rod, a clean roller is rotatably connected with the bottom of the lifting plate through aconnecting rod, a spray head is arranged on the right side of the cleaning roller, a protective plate is arranged on both sides of the spray head and a rotating shaft is arranged on the left side of the bottom of the chassis, which can be used after the paint stored in the paint storage tank is uniformly mixed. At the same time, in the construction process, the influence of human factors and external factors on the spraying effect is effectively avoided, the labor of the construction personnel is lightened, and the marking efficiency is increased.

Owner:潍坊市工业学校

Device for dismantling broken bolts of end cover of wind power generator

ActiveCN105345743BFree from destructionImprove maintenance efficiencyMetal-working hand toolsEngineeringTurbine

The invention discloses a wind driven generator end cover broken bolt dismounting device. A bearing is arranged in the center of a chassis; a rotating shaft rotates around the periphery of the chassis, and fits a bearing; a connecting end fitting a dismounting component is arranged at one end of the rotating shaft; the dismounting component comprises a drilling component for drilling a blind hole in a broken bolt, a tapping component for tapping the blind hole as a thread hole, and a screw rod component fitting the thread hole; the screw rod component comprises a screw rod; and the thread rotating direction of the screw rod is opposite to the thread rotating direction of the broken bolt. The dismounting device has the following beneficial effects: the broken bolt is drilled through the drilling component; then, the drilled hole is tapped; the screw rod component is connected with the tapped thread hole; and as the thread rotating direction of the screw rod is opposite to the thread rotating direction of the broken bolt, the broken bolt can be taken out through reversely rotating the rotating shaft, the operation is convenient and fast, the damage of a traditional thread and the dismounting of an outer end cover are not needed, the repair efficiency is greatly improved, and the repair cost is reduced.

Owner:天赋新能源科技(南通)有限公司

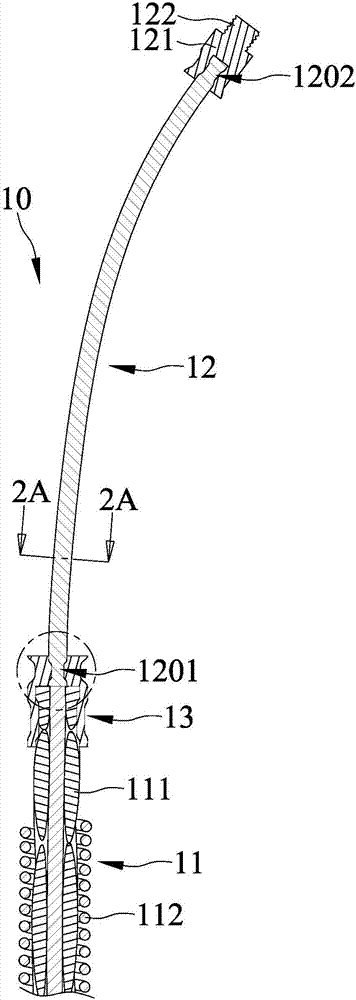

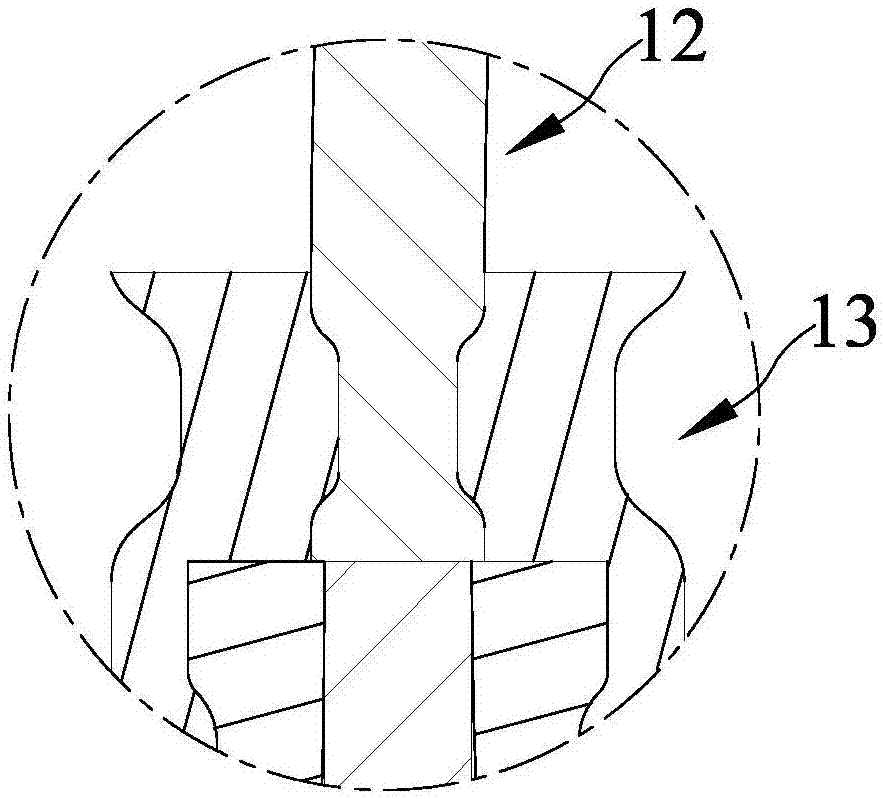

Delivery device of medical device

The invention provides a delivery device of a medical device. The delivery device can deliver the medical device to the heart defect part through a catheter, and comprises a first line segment and a second line segment, wherein the first line segment is provided with a near end and a far range part, the second line segment is provided with a first end and a second end, the first end of the second line segment is fixedly connected to the far range part of the first line segment, the second end of the second line segment is provided with a connector for connecting with the medical device, the cross sectional area of the second line segment is smaller than the cross sectional area of the first line segment, so that the second line segment is configured in a manner that when the medical device is delivered to the heart defect part through the delivery device and the heart defect part is closed through withdrawal of the catheter, the second line segment with the flexibility can be connected with the medical device and the disturbing vibration coming from the heart beat can be received, and meanwhile, the medical device can not deviate from the placing position.

Owner:胡厚飞

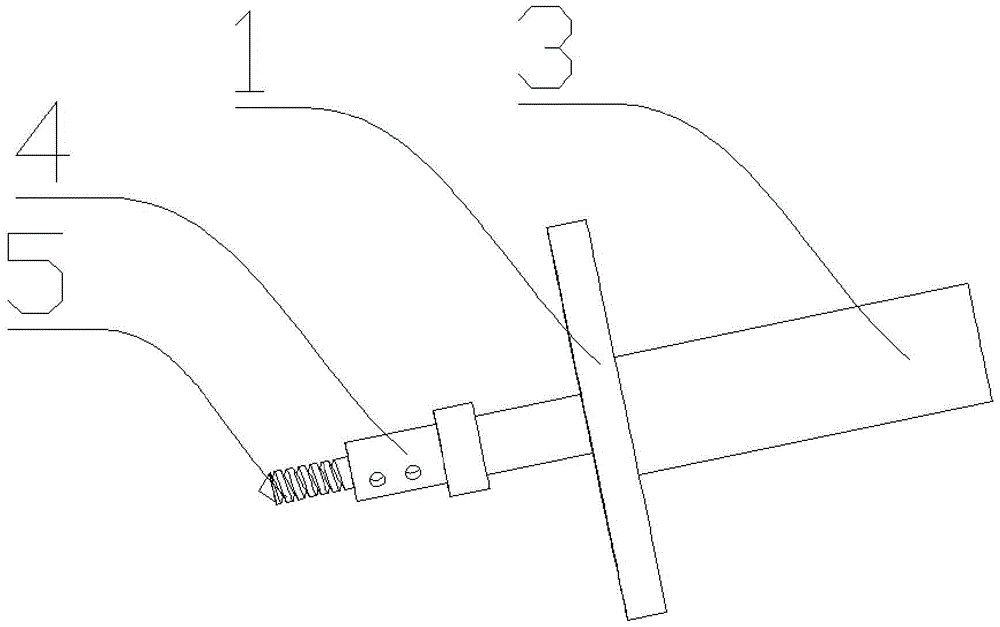

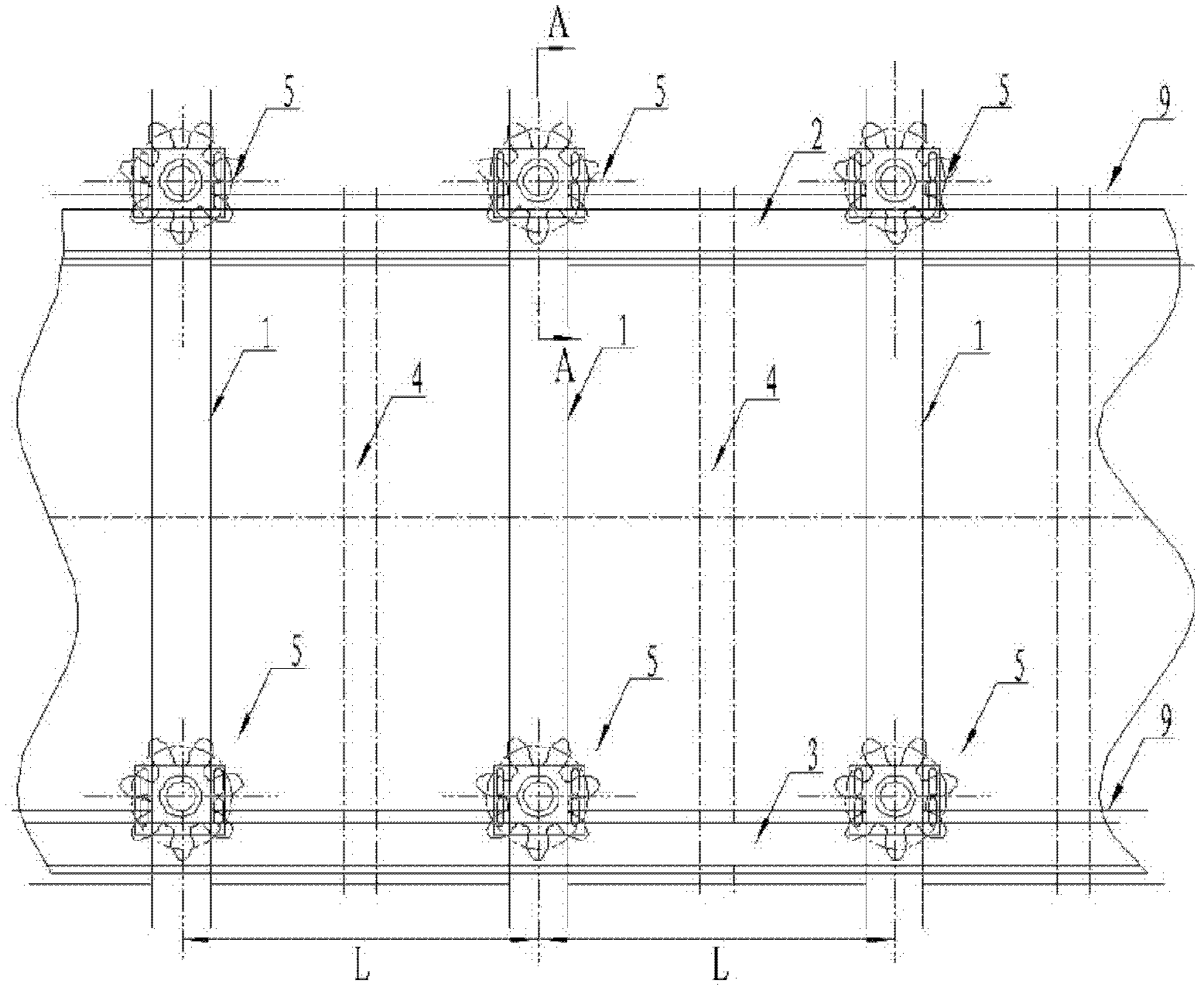

Method for preventing net belt of belt type drying machine from deviating and belt type drying machine

The invention discloses a method for preventing the net belt of a belt type drying machine from deviating. The belt type drying machine comprises a framework (1), a pair of tracks, two chains (7), a net belt support rod (8) and a net belt, wherein the tracks are fixed on the framework (1); the net belt support rod (8) is connected between two chains (7) and is paved on the track together with the chains (7); and the net belt is paved on the net belt support rod (8) and supported by the net belt support rod (8). The method comprises the step that the positioning wheels (5) meshed with the chains (7) are arranged along the tracks. The invention further provides the belt type drying machine for preventing the net belt from deviating. According to the technical scheme, when the belt type drying machine runs, the positioning wheels arranged along the tracks can be meshed with the chains, and thus the chains can be guided to operate along the tracks. Therefore, the chains are prevented from deviating from the tracks due to the expansion of the net belt support rod, and thus the deviation of the net belt is avoided.

Owner:PANZHIHUA IRON AND STEEL +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com