Spring leaf and overrunning clutch mounted with spring leafs

一种超越离合器、弹簧片的技术,应用在离合器、单向离合器、机械设备等方向,能够解决弹簧片移位脱落隐患等问题,达到受力平稳、结构简单、安装方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

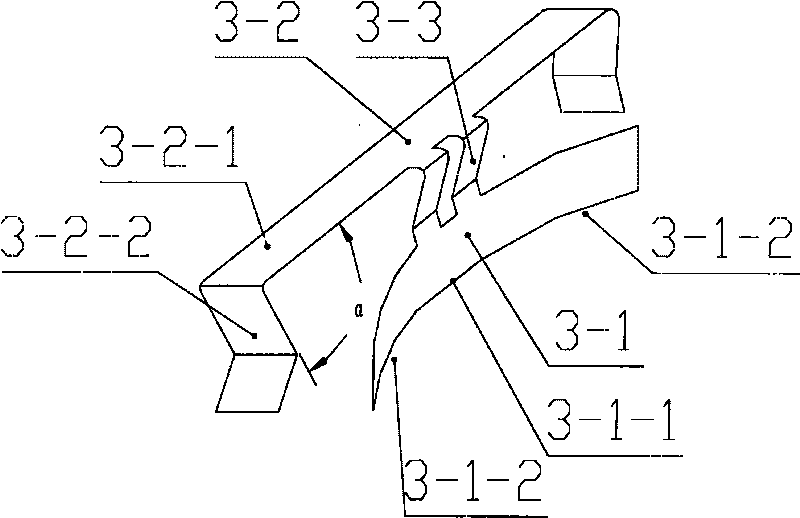

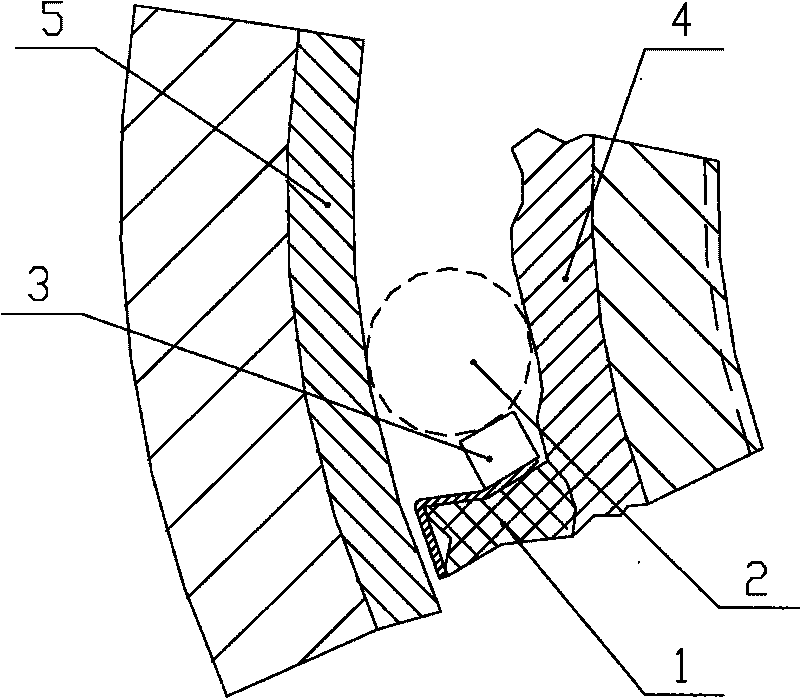

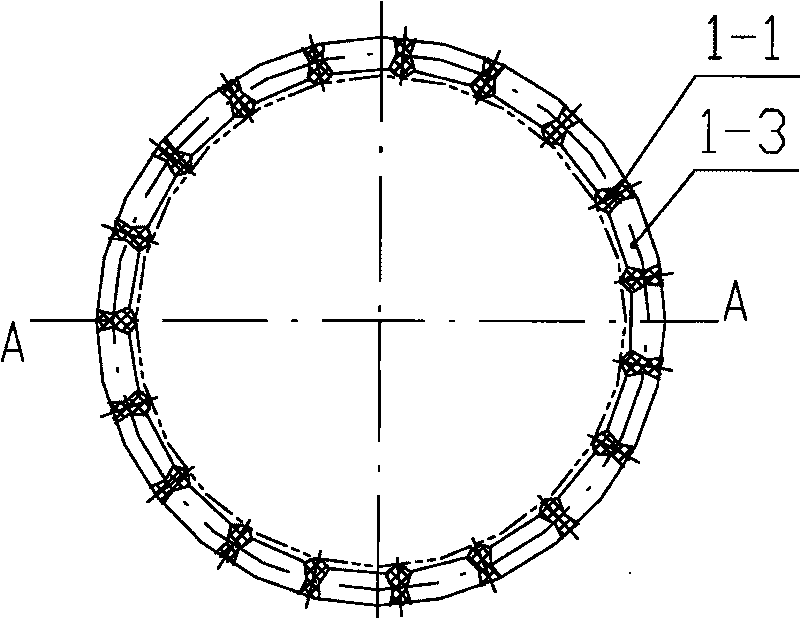

[0017] Such as figure 1 The best embodiment of the spring leaf shown in the present invention, it is by supporting the supporting piece 3-1 of needle roller 2 suspension, clamping piece 3-2 and connecting supporting piece 3-1 and holding piece 3-2 two A connecting beam 3-3 in the shape of a sheet "7" is formed, the main body of the clamping sheet 3-2 is a straight sheet 3-2-1, and the two ends of the straight sheet 3-2-1 are in the shape of a "V". The bending part 3-2-2, the middle part of the support piece 3-1 is a straight section 3-1-1, the two ends are arc sections 3-1-2, the straight section 3-1-1 and the two arc sections 3 -1-2 are tangent to each other, and the end faces of the two arc sections 3-1-2 of the support piece 3-1 support the suspension of the needle roller 2; one end of the connecting beam 3-3 is connected to the straight piece 3-2-1 of the clamping piece The end face of the connecting beam 3-3 is connected to the end face of the straight section 3-1-1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com