Atmosphere bell-type furnace

An atmosphere bell and bell furnace technology, which is applied in the field of sintering furnaces for electronic products, can solve the problems of gas mixing ratio, unevenness, and low automation of atmosphere bell furnaces, achieve uniform and stable atmosphere, improve cooling efficiency, increase The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The best implementation mode of the present invention will be described below with reference to the accompanying drawings.

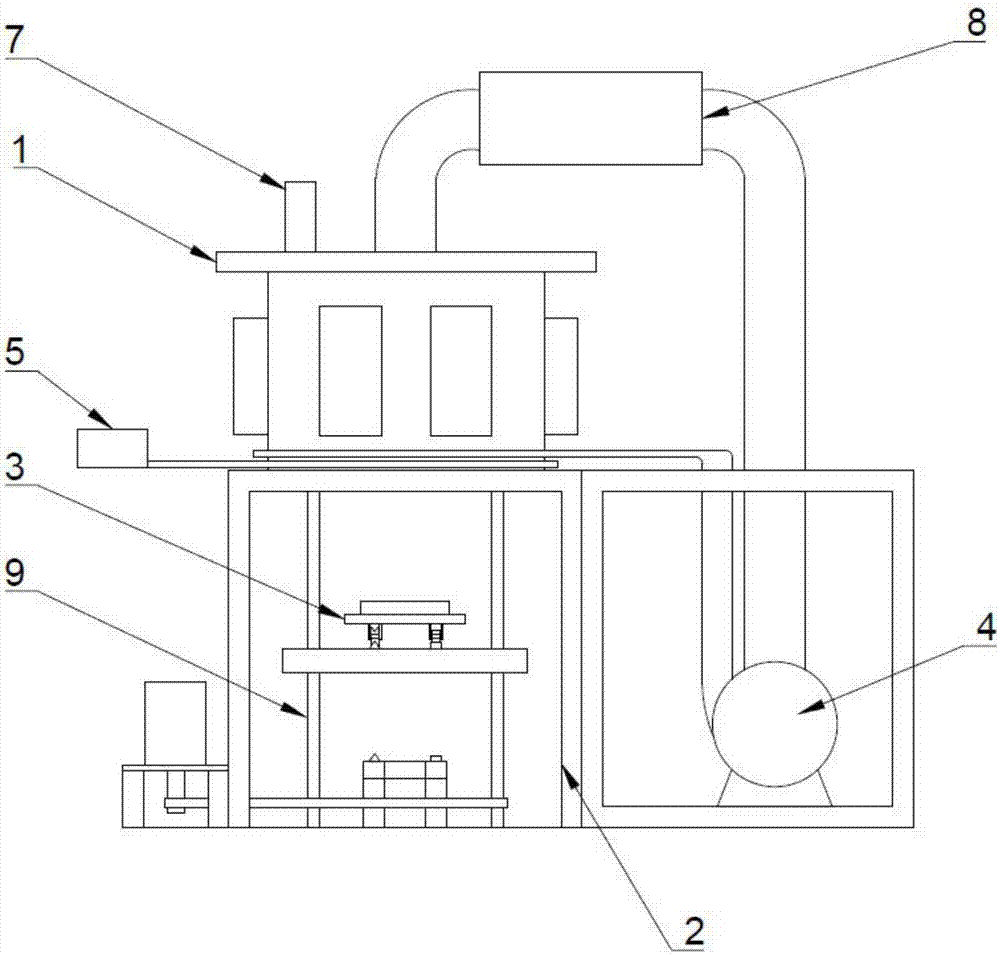

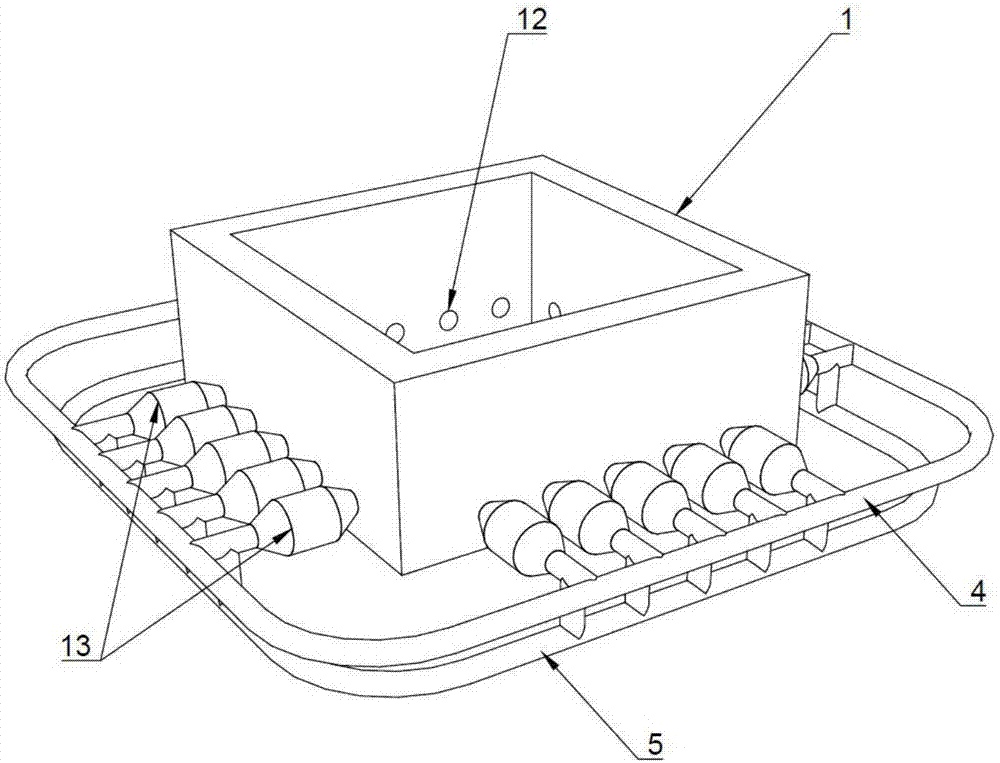

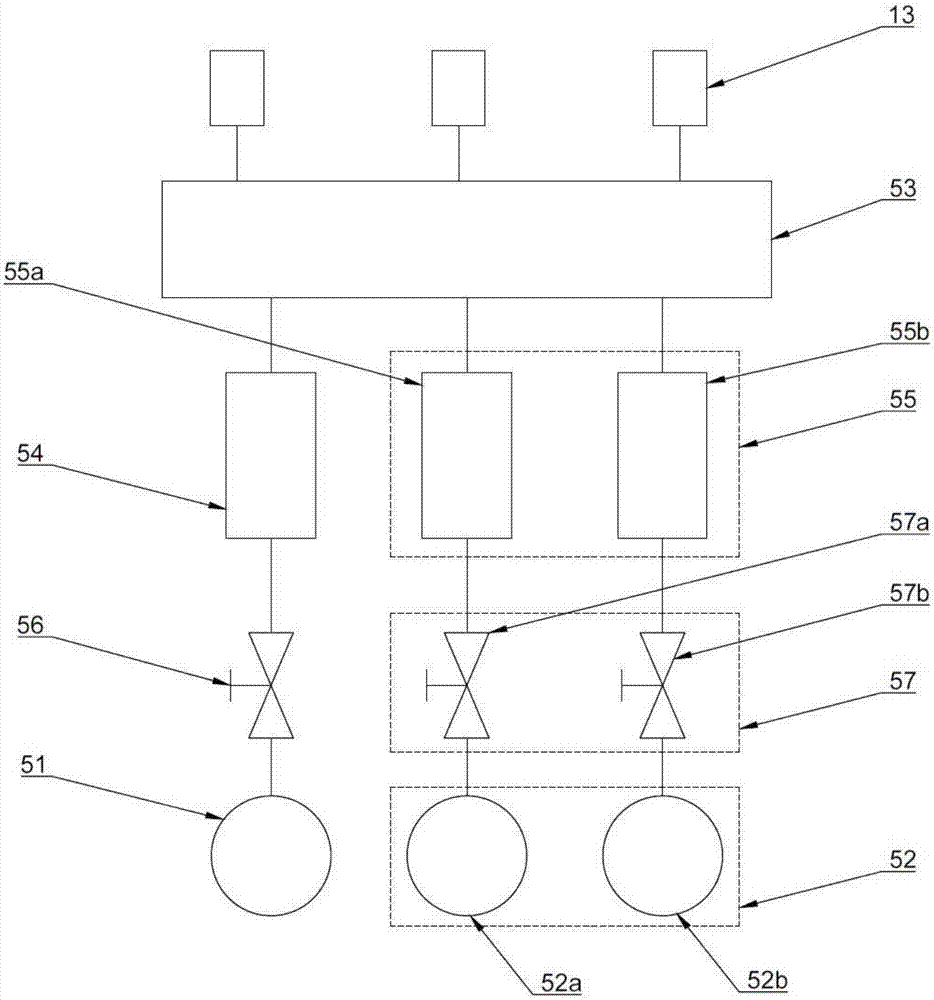

[0033] Such as Figure 1 to Figure 9 As shown, a kind of atmosphere bell jar furnace of the present invention comprises furnace body 1, and furnace body 1 is a hollow structure installed on the furnace frame 2, and the inner cavity is set as furnace, and the bottom of furnace body 1 is provided with as movable The kiln car 3 of the furnace door, and when the kiln car 3 is closed as a movable furnace door, it can form a sealed connection with the furnace body 1. A high-temperature refractory material layer is provided on the top of the furnace and the inner walls around it. A connected gas outlet 11, the bottom side wall of the furnace body 1 is uniformly provided with a gas inlet 12 communicating with the furnace hearth along the circumference of the furnace body 1, and the gas inlet 12 is respectively provided with a mixing chamber communicating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com