Conveying system for industrial production

A transportation system and transportation device technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of high cost, high power consumption, unclear parts classification, etc., and achieve low cost and easy production and the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

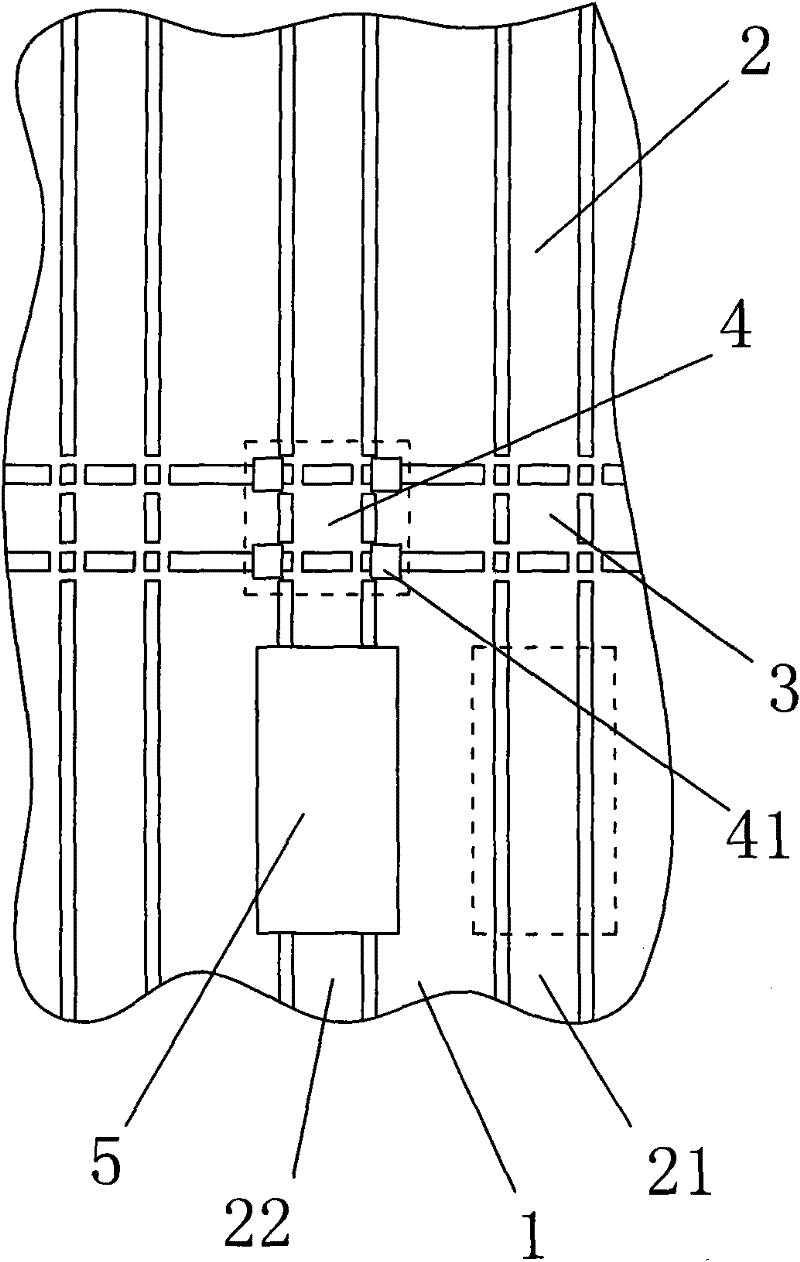

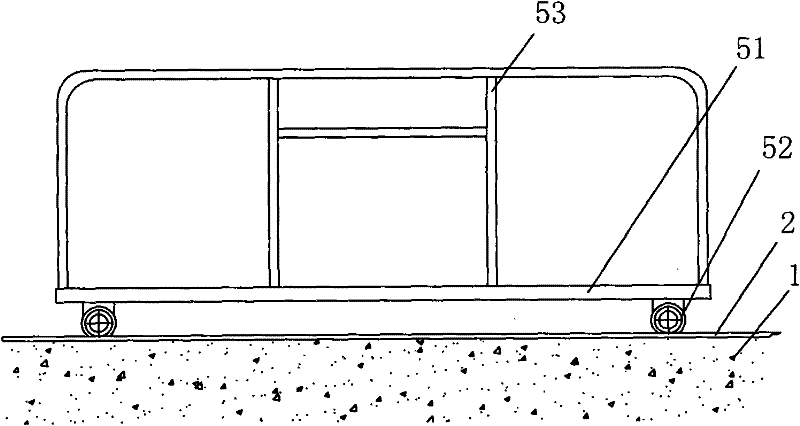

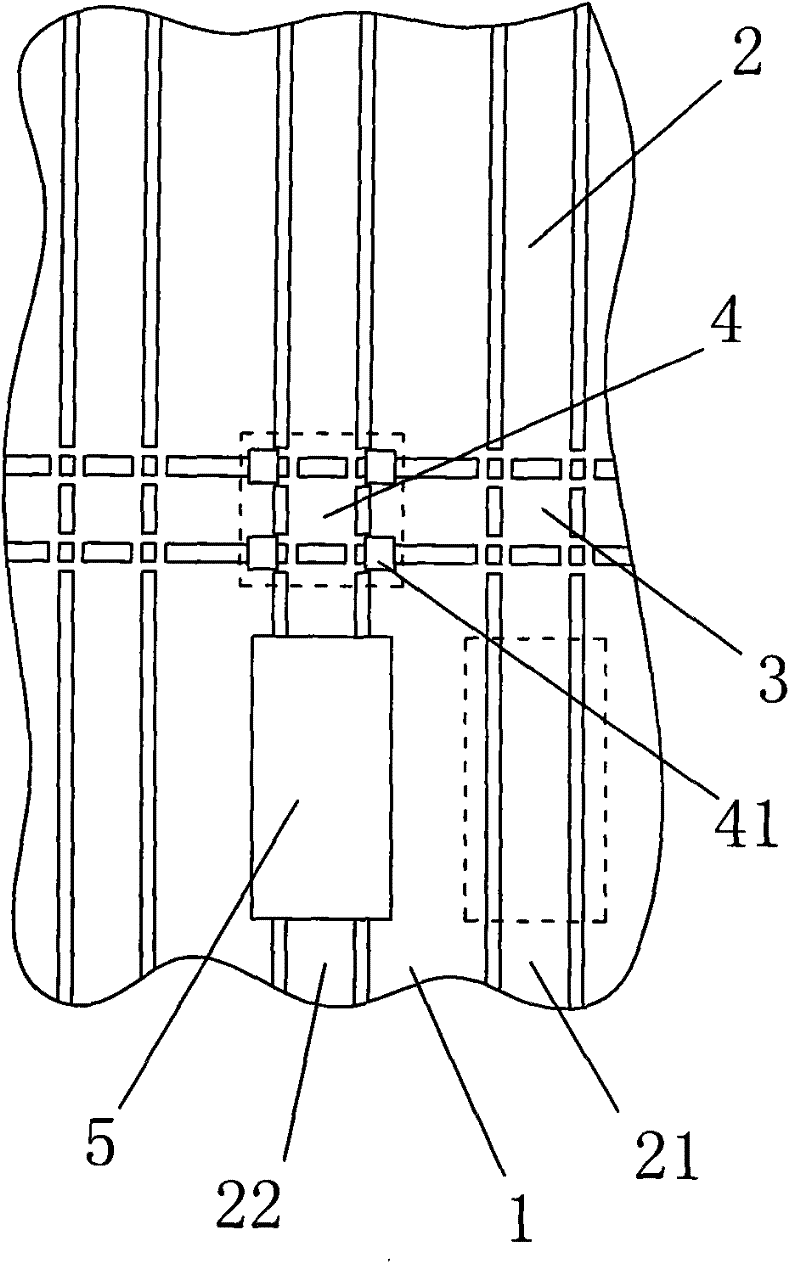

[0024] Such as figure 1 A kind of transportation system for industrialized production shown, comprises the rail device that is fixedly connected with ground 1, transfer device 4 and transportation device 5, and this rail device includes several longitudinal rails 2 and transverse rail 3, and described longitudinal rail 2 and lateral rail 3 are arranged crosswise, the transfer device 4 moves along the transverse track 3, and the transport device 5 moves along the longitudinal track 2, and the transfer device 4 can transfer the transport device 5 from one longitudinal track to another longitudinal track, such as figure 1 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com