Structural wall with a structure exogenous to the longitudinal axis thereof for enabling the inside of the wall to be filled on site

A technology for structural walls and fillers, which is applied to the on-site preparation of building components, infrastructure engineering, walls, etc., can solve the problems of unmentioned construction methods, no column stiffening diagonal bracing, etc., and achieves low cost, labor force Problem solving, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

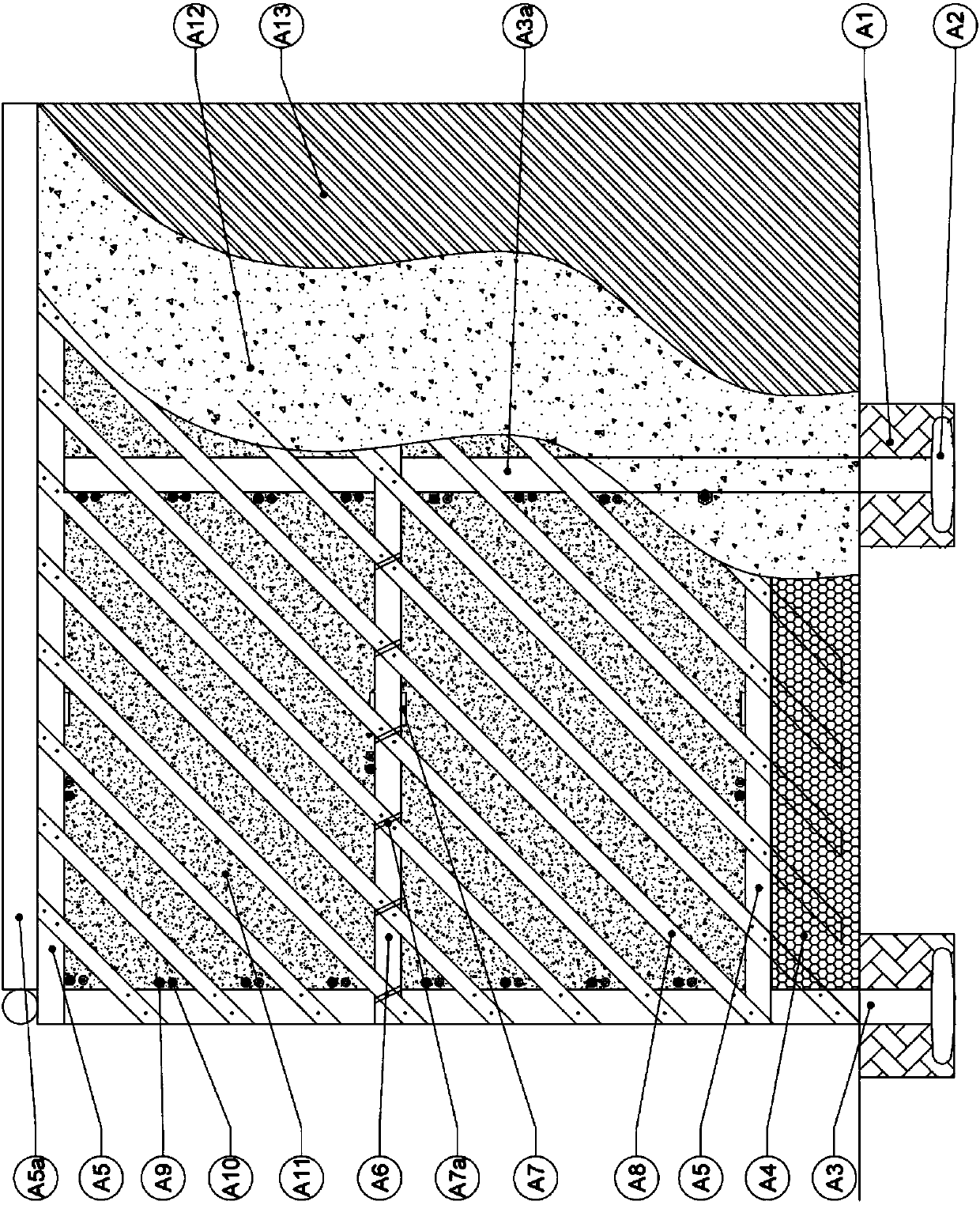

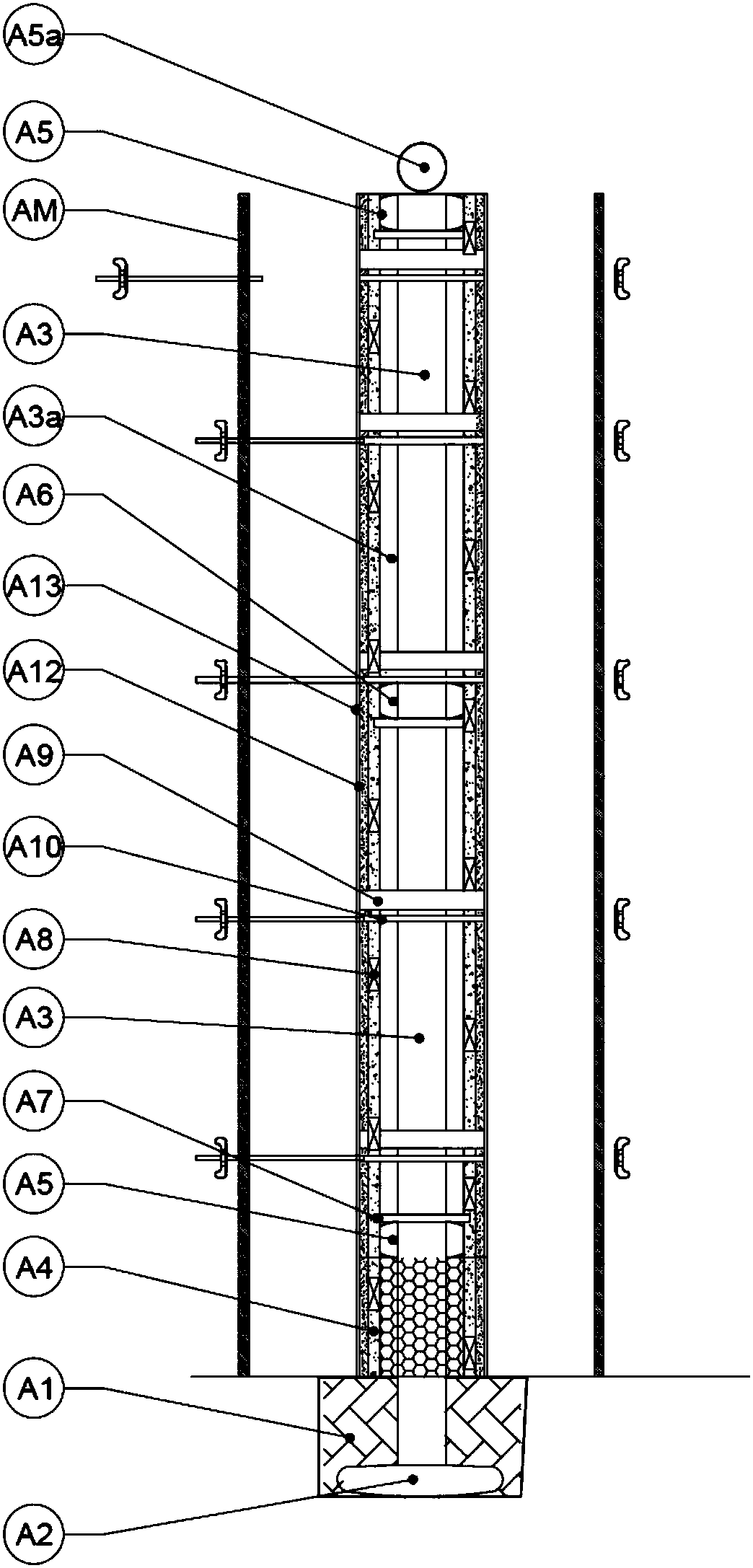

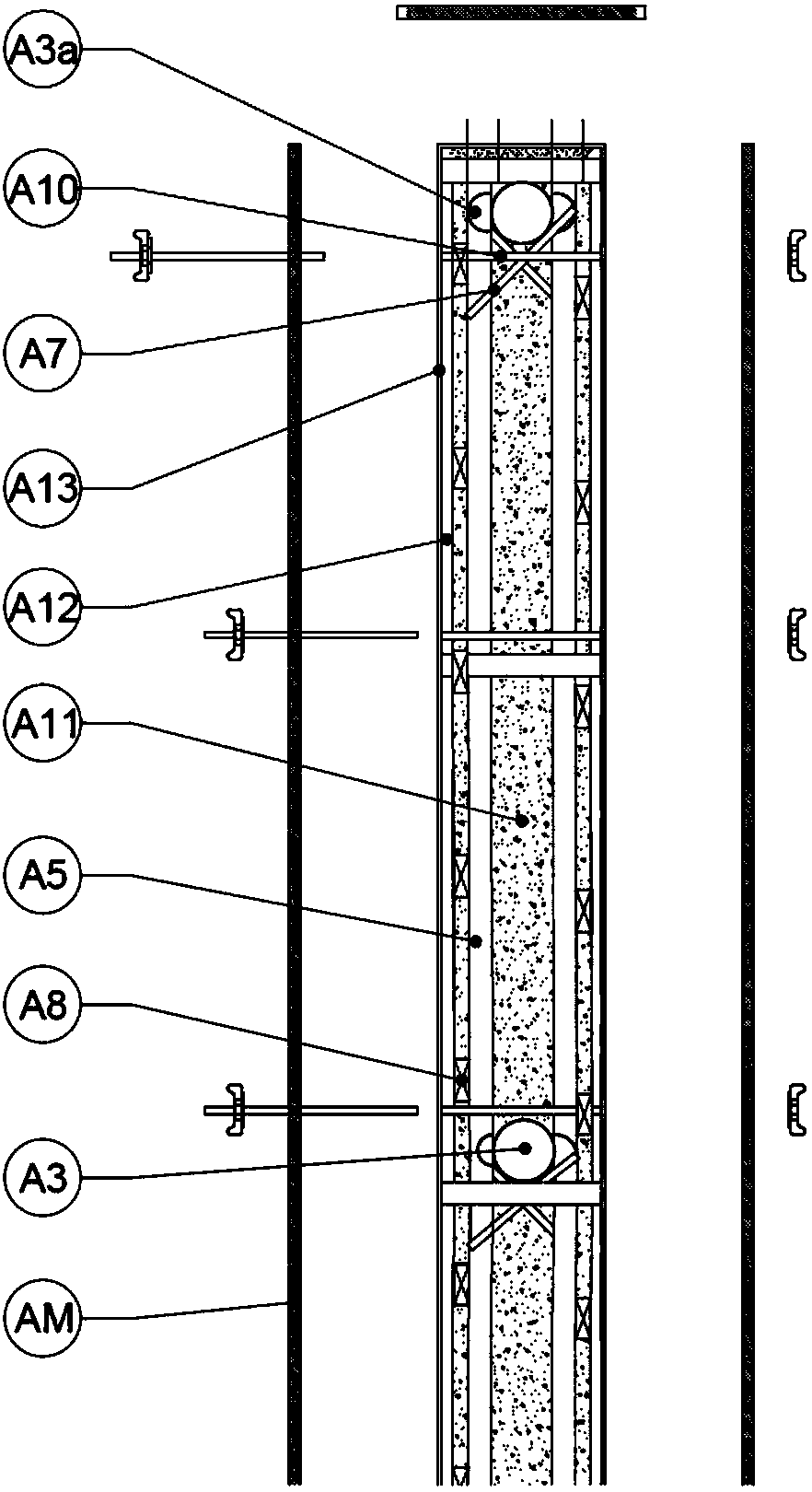

[0134] The invention is a structural wall and includes a replacement for the stiffening elements (pillars, braces and transverse closures) of the wall that are usually located in the longitudinal axis of the wall according to the current state of development and prevent their fillings from being poured in situ, because Reticulated stiffener structural elements form channels for filling from the inside of the wall to its full length and height and can be filled in situ; and / or filled through the structure outside the longitudinal axis of the wall, which turns the wall lining into a stiffener structure, and have the same purpose: to enable the filling or pouring of different types of mixtures inside the walls to achieve high-quality thermal insulation, sound insulation, thermal inertia and fire protection. The above properties can be obtained at minimal cost by using mud with straw; however, the present invention can use materials such as expanded polystyrene-based granular concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com