Filtering system as well as application thereof

A filter system and filter screen technology, applied in the field of filter systems, can solve the problems of no vacuum melting furnace, shorten the service life of vacuum pumps, and damage to vacuum pump components, so as to reduce maintenance costs, reduce oxygen content, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, further illustrate the present invention.

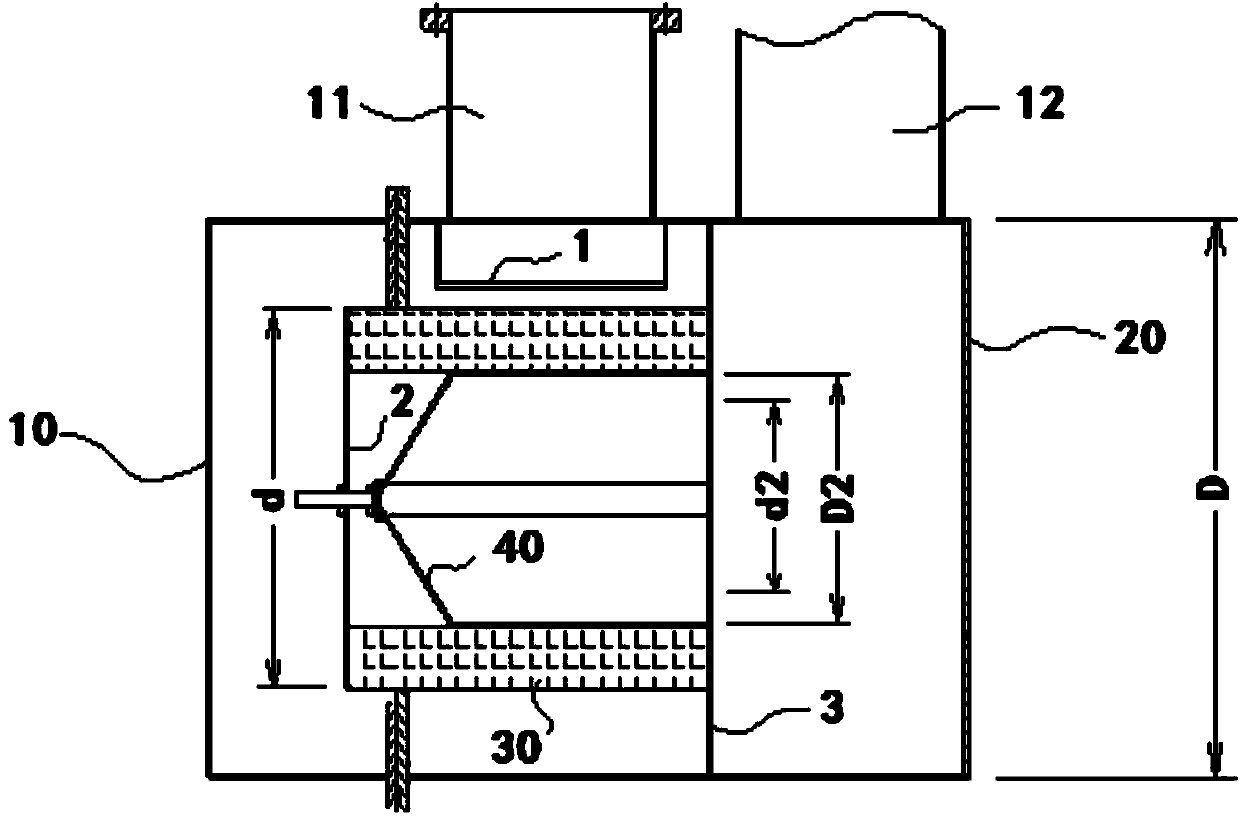

[0022] figure 1 The specific structure of the filtration system of the vacuum melting furnace according to the present invention is shown. figure 1 Among them, the height of the door 10, the box body 20, and the baffle 3 is D, the outer diameter of the hollow filter element 30 and the diameter of the baffle 2 are d, the diameter of the baffle 1 is D1, the diameter of the air inlet 11 is d1, and the hollow The inner diameter of the hollow part of the type filter element 30 and the section height of the support frame 40 are D2, the opening diameter of the baffle plate 3 is d2, d<D, d1≤D1, d2≤D2.

[0023] In one embodiment of the present invention, the hollow filter element 30 is composed of two layers of stainless steel filter screens whose mesh numbers are 50 mesh and 100 mesh respectively, and the support frame is composed of 4 stainless steel bars. 3 Made of stainless steel, d=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com