Operation input device and electronic device using the same

An input device and operation hole technology, applied in transportation and packaging, vehicle route interaction equipment, circuits, etc., can solve problems such as inability to prevent water immersion, and achieve the effects of improving productivity, reducing the number of assembly processes, and high waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Embodiments of the operation input device of the present invention will be described based on the drawings.

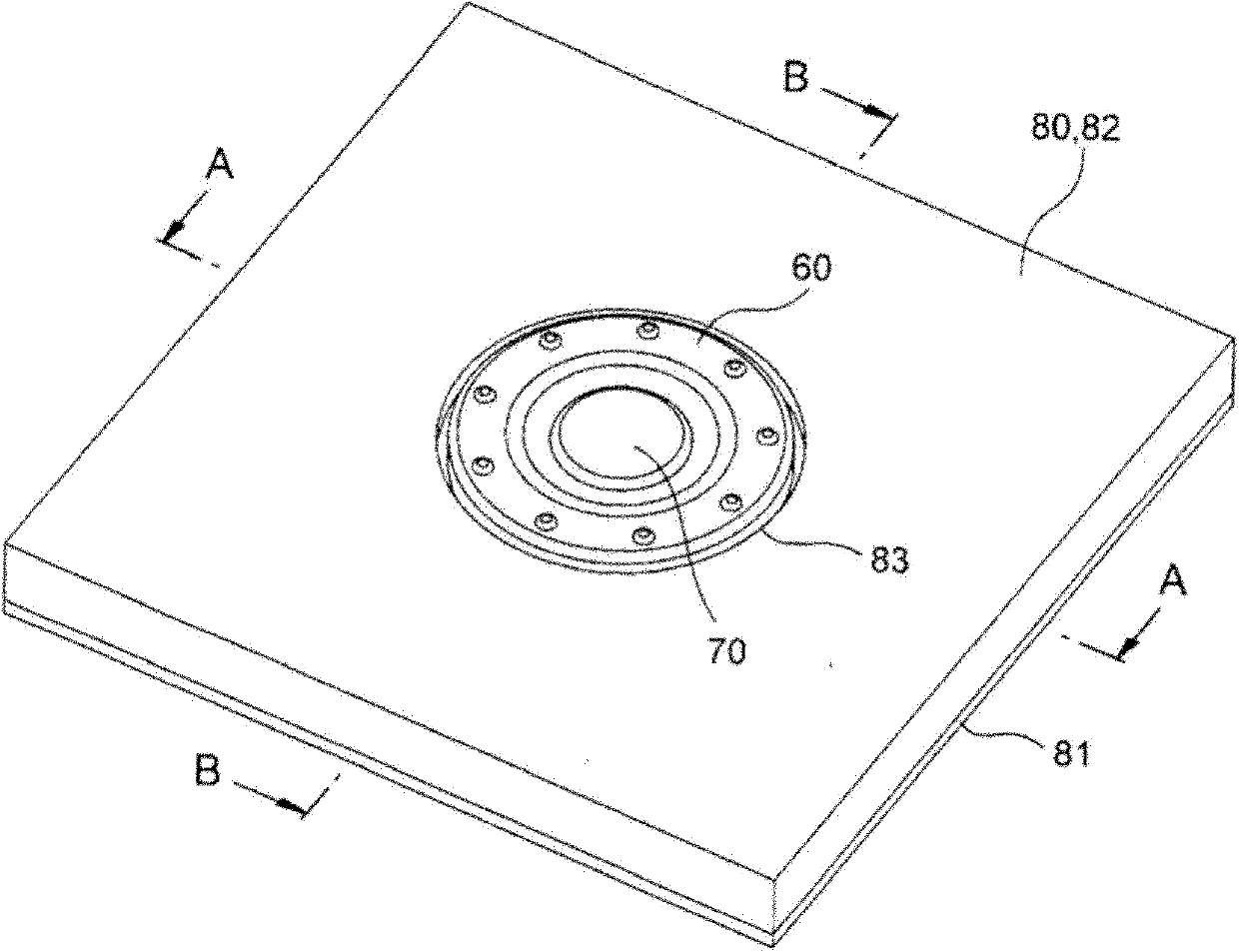

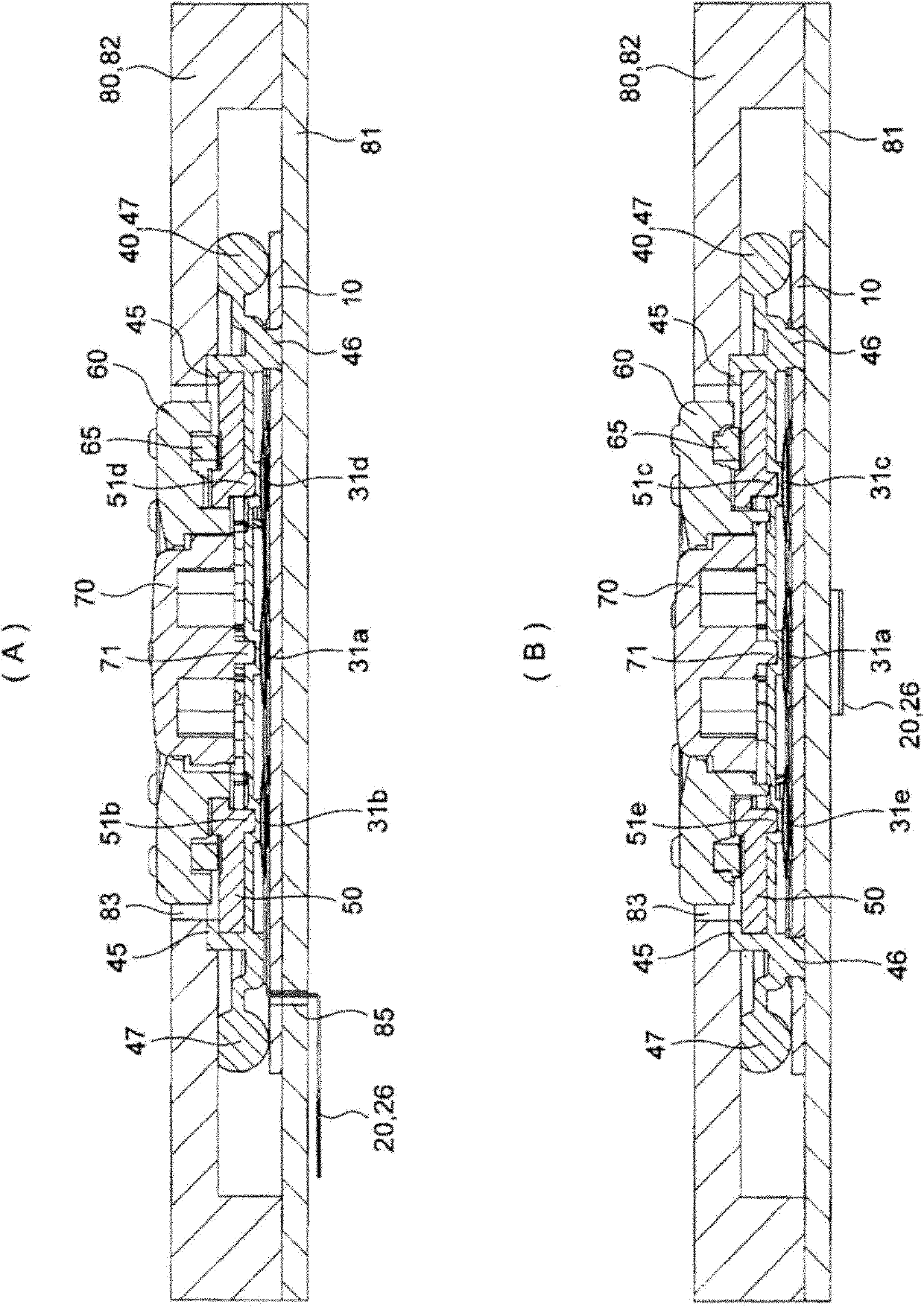

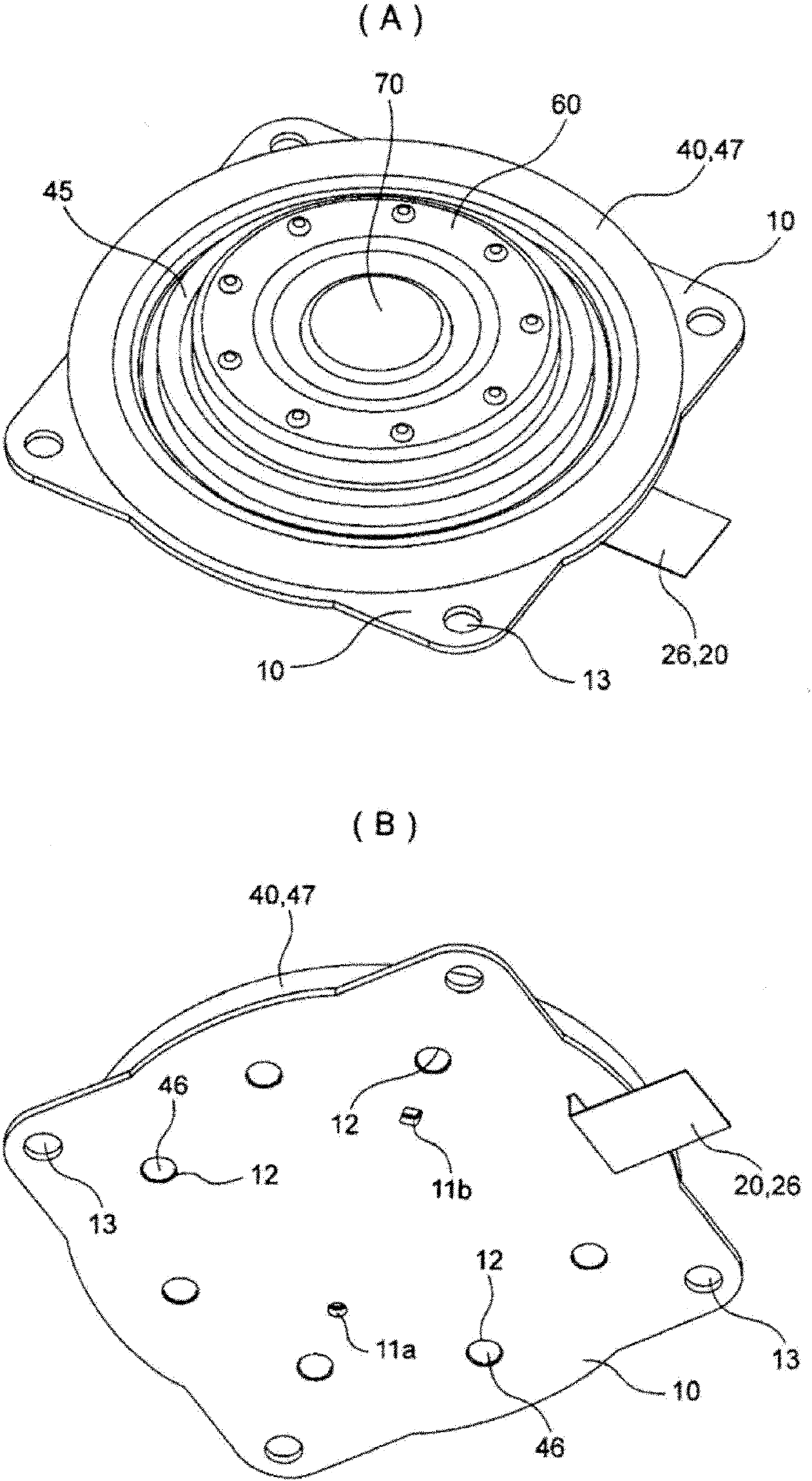

[0074] Such as Figure 1 to Figure 9 ,in particular Figure 4 As shown, the operation input device of the first embodiment roughly includes: a substrate 10; a flexible printed substrate 20; a central button switch 31a composed of a dome-shaped movable contact and four button switches 31b-31e are attached to the lower surface. The resin film cover 30; the elastic waterproof member 40; the operation ring 50 assembled on the elastic waterproof member 40; the operation dial 60 rotatably placed on the operation ring 50 via the sliding sheet 58; The button 70 in the fitting hole 61 of the operation dial 60; the housing 80 ( figure 1 ).

[0075] Such as Figure 4 and Figure 5 As shown, the base body 10 is composed of a substantially square metal thin plate, and a pair of jig holes 11a and 11b are provided on its diagonal, and a fixing hole 12 is provided around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com