Lap weld laser searching automatic welding machine

An automatic welding machine and lap welding seam technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of difficult talent, high labor cost, and high welding technical requirements for workers, and achieve convenient installation and use, simple and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

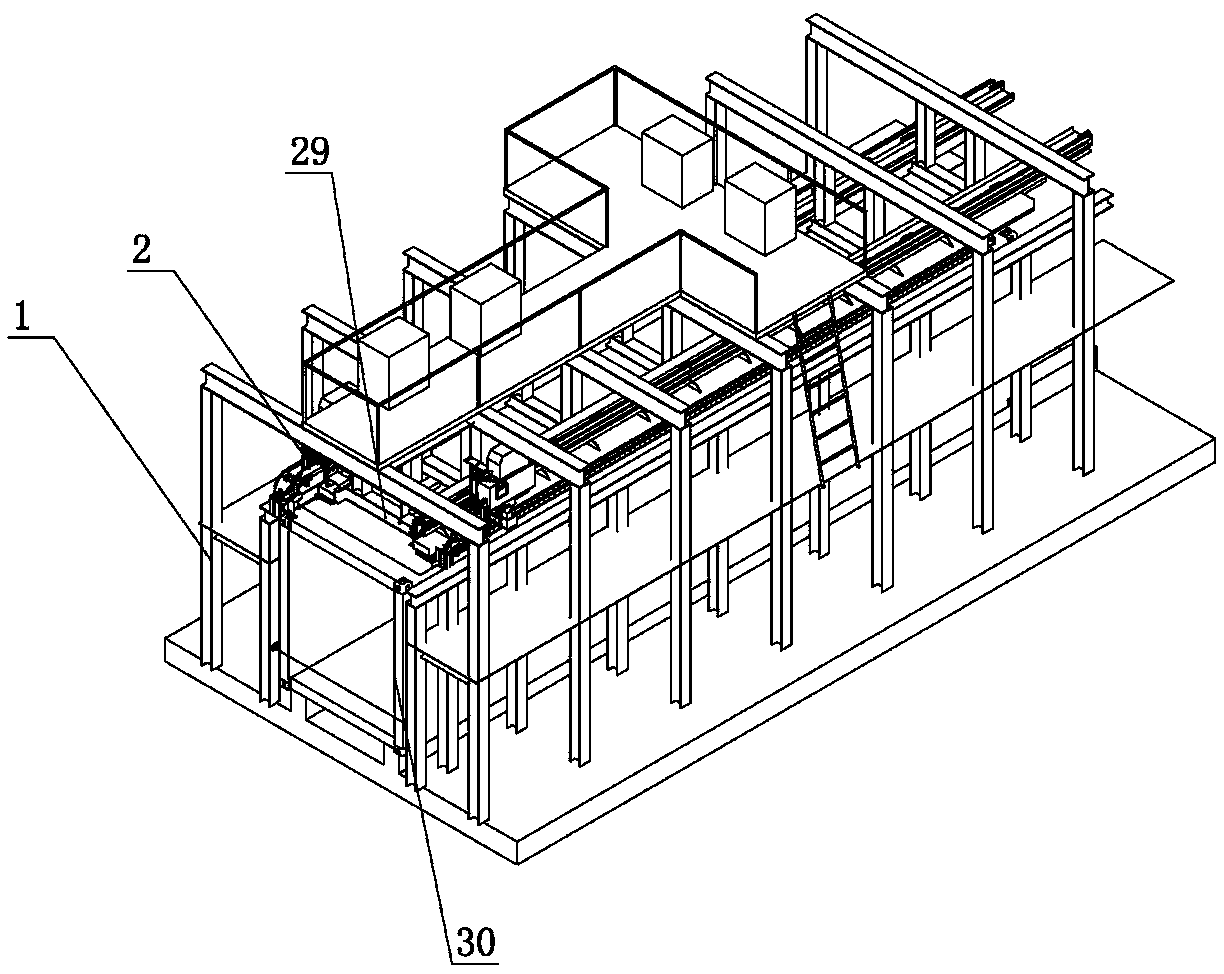

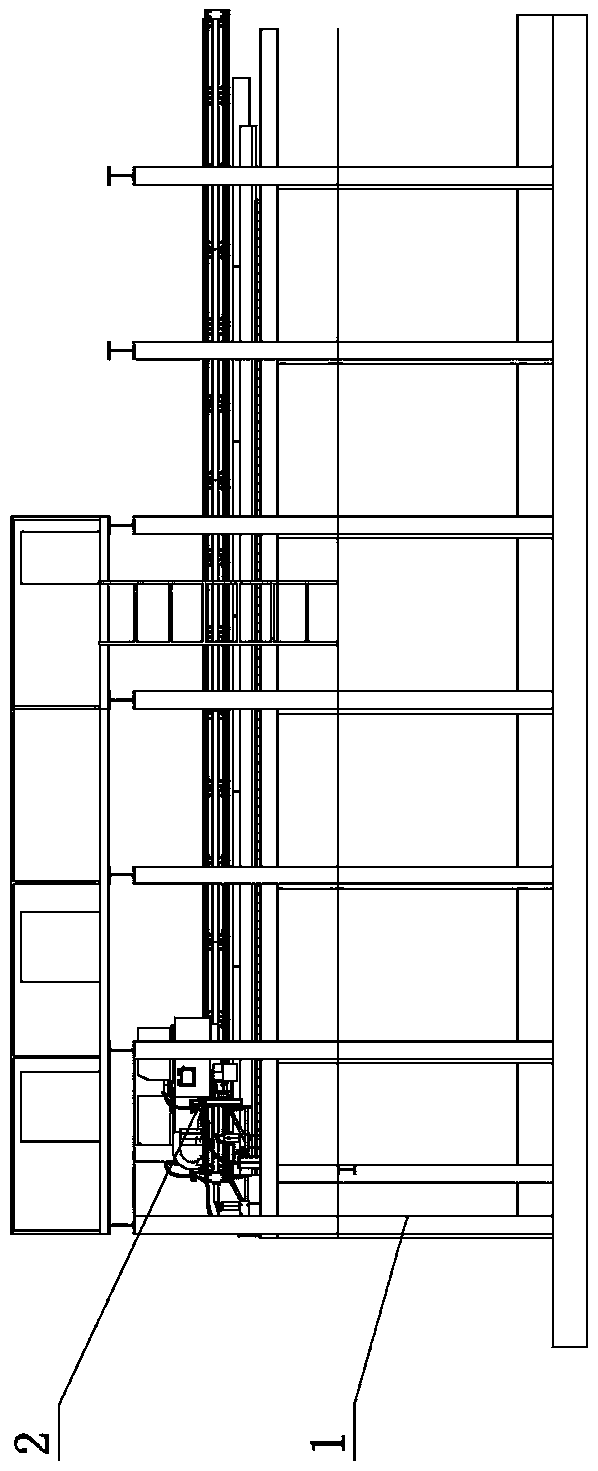

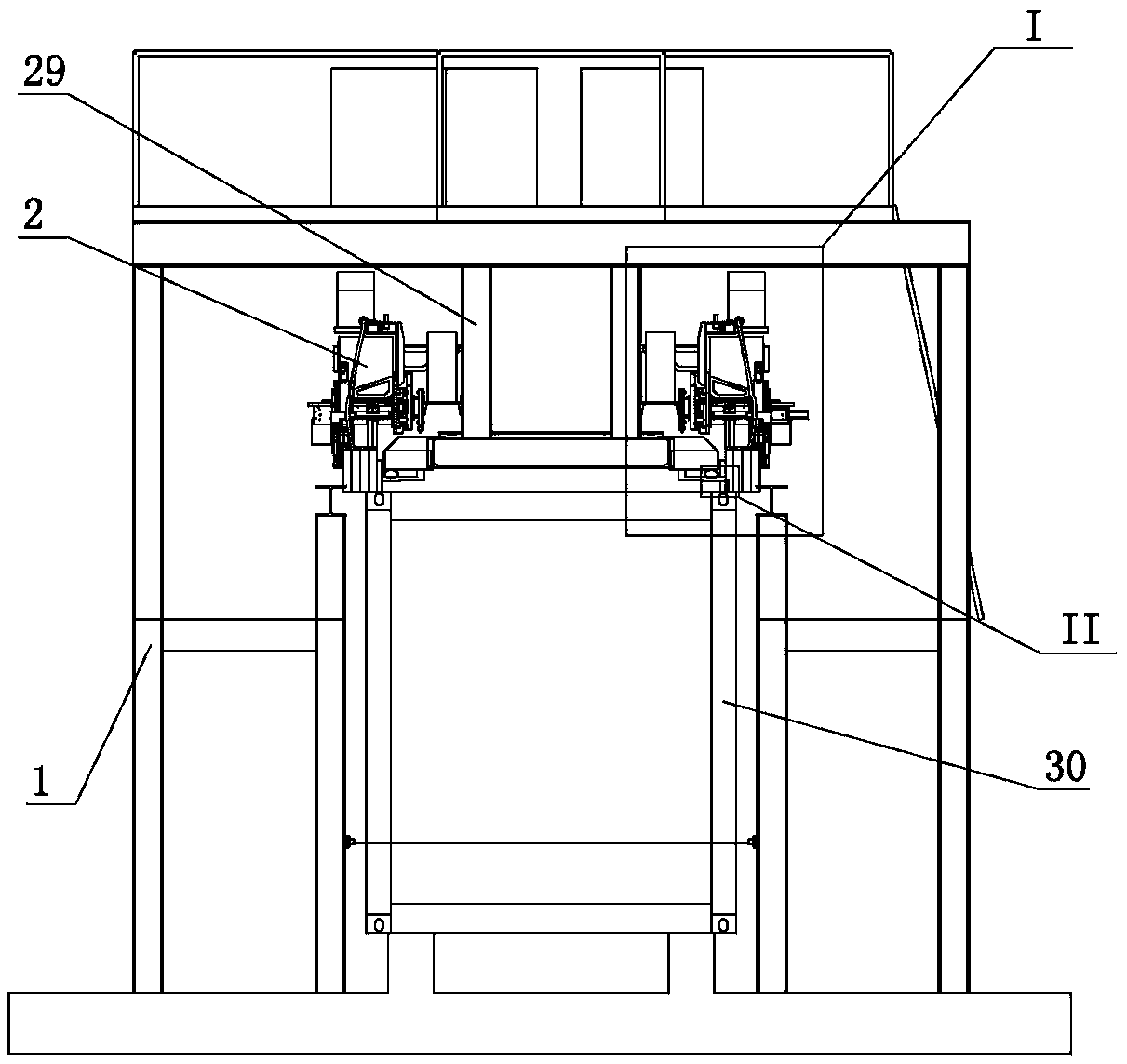

[0009] The laser positioning automatic welding machine for lap welding seam of the present invention, such as Figure 1 to 3 Shown, including workbench frame 1. Such as Figure 4 As shown, a trolley rail seat 3 is longitudinally provided on the workbench frame 1, a trolley rail 4 and a rack 5 are longitudinally provided on the trolley rail seat 3, and a welding trolley 2 is installed on the trolley guide rail 4.

[0010] Such as Picture 8 As shown, the welding carriage 2 includes a carriage base 9. A trolley slider 10 is provided on the trolley base 9. The trolley slider 10 cooperates with the trolley guide rail 4 so that the welding trolley 2 can move longitudinally along the trolley guide rail 4. A walking motor is installed on the trolley base 9 and a gear 11 is installed on the walking motor. The gear 11 meshes with the rack 5 to provide the welding trolley 2 with longitudinal moving force.

[0011] Such as Image 6 with 9 As shown, a horizontal movement mechanism 13 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com