Prossure fixing mechanism of series thyristor valve set

A thyristor valve and head-end technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of troublesome installation and disassembly, complex structure, uneven pressure on the contact surface of thyristor and radiator, etc. Uniform force, easy and reliable insulation measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

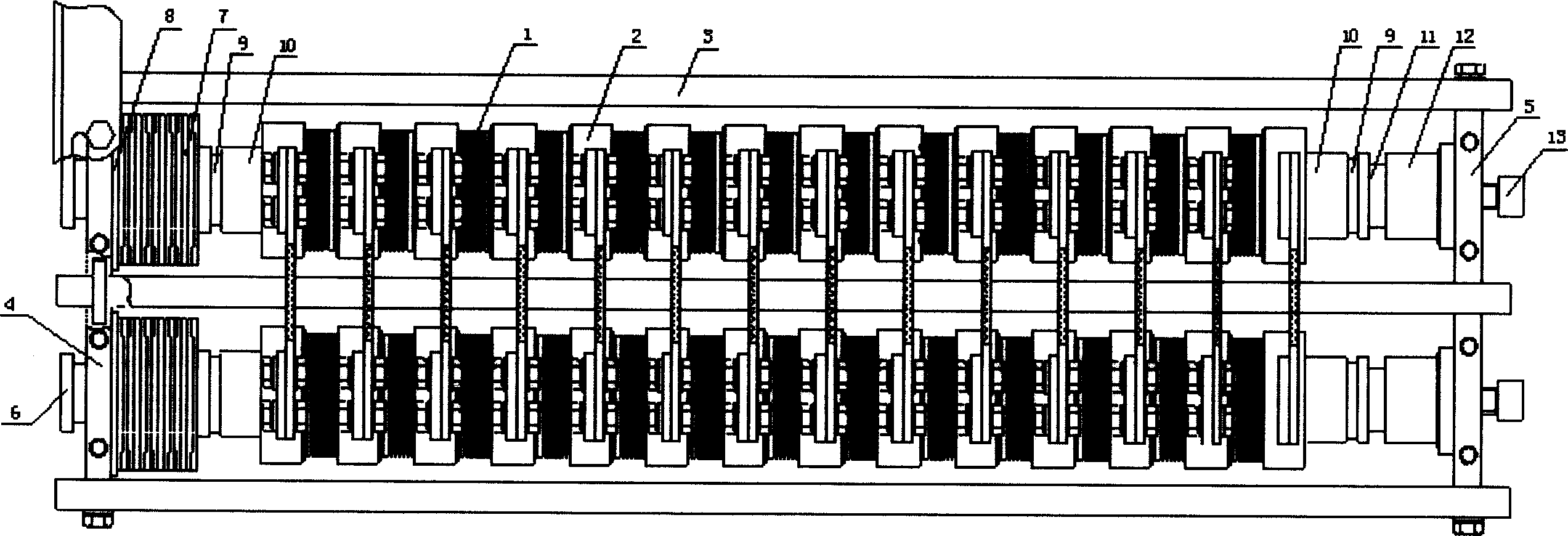

[0022] see figure 1 , is the constant pressure mechanism of the series thyristor valve group of the present invention, which is assembled into an outer frame by three load-bearing epoxy plates 3, a head end flange 4, and a tail end flange 5.

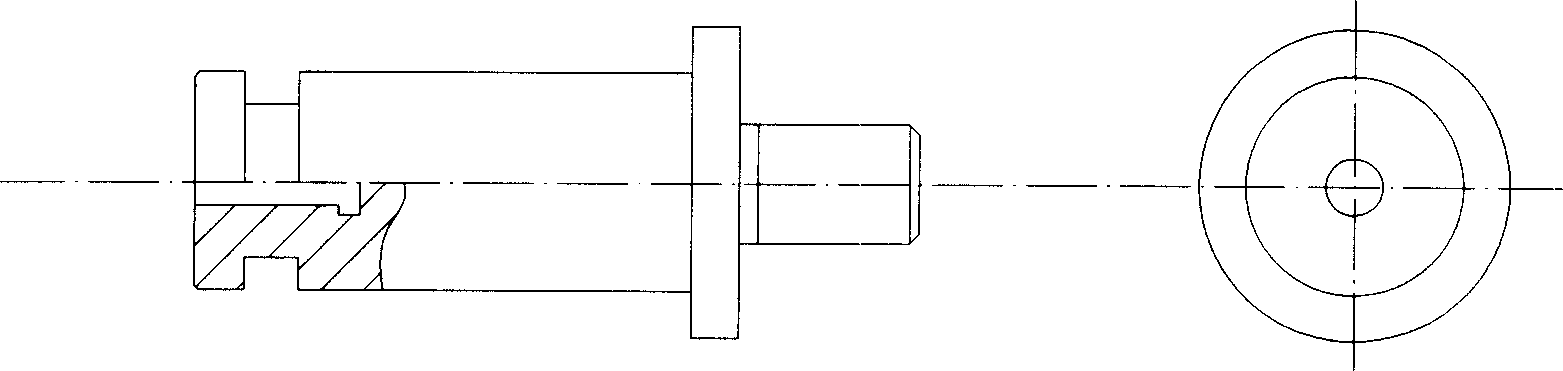

[0023] 1. Put the disc spring 7 into the compression spring guide rod 6;

[0024] 2. Install the disc spring protection sheet 8 on the side of the flange 4 at the head end of the disc spring 7;

[0025] 3. Put the guide copper bar 9 on the side of the flange 4 at the head end and the transition adjustment round aluminum 10 into the compression spring guide rod 6;

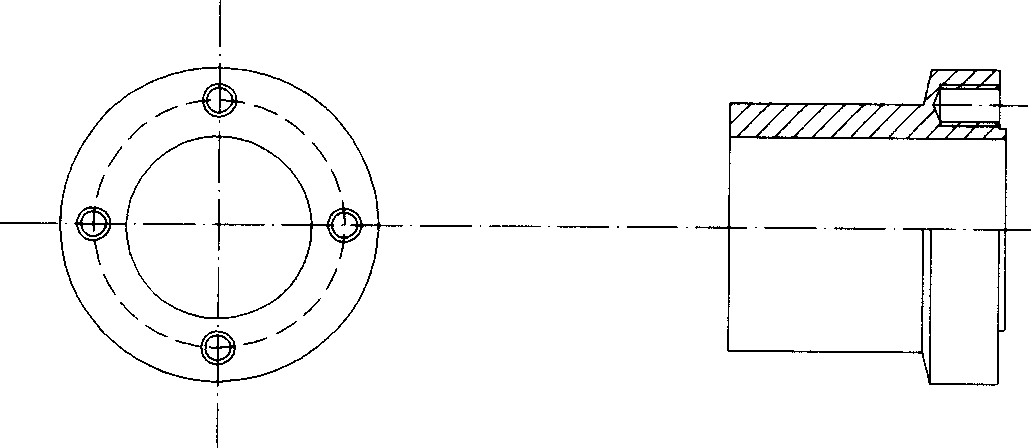

[0026] 4. Connect the guide sleeve 12 to the tail flange 5;

[0027] 5. Connect the transition adjustment round aluminum 10, diversion copper bar 9 and top pressure guide rod 11 on the side of the tail flange 5, and then put them into the guide sleeve 12;

[0028] 6. Install hexagon socket bolts 13 on the outside of the tail flange 5;

[0029] 7. Multiple groups of water-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com