Closed pneumatic shell vibrating machine

A vibrating shell machine and closed technology, applied in the field of precision casting, can solve the problems of dust easily affecting the environment, unreliable clamping, large vibration and impact, etc., to achieve the effect of protecting physical and mental health, improving the operating environment and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

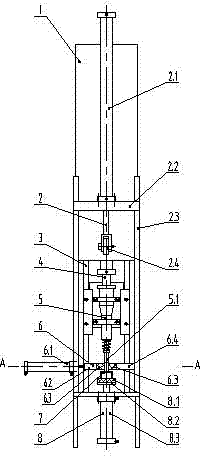

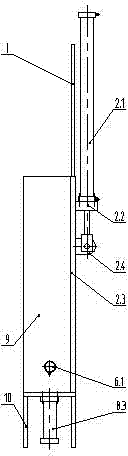

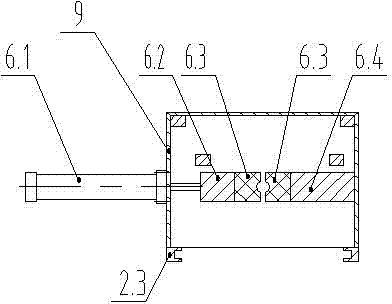

[0015] The enclosed pneumatic shell vibrating machine shown in the accompanying drawings includes a pneumatic pick 5, a frame 3, a cylinder 4, a chassis 9, supporting feet 10, a movable door 1, a pneumatic opening and closing structure 2, a clamping mechanism 6 and an auxiliary supporting mechanism 8. The air pick 5 is fixedly connected to the frame 3, the upper end of the air pick 5 is connected to the cylinder 4, the air pick 5, the frame 3, and the cylinder 4 are arranged in the chassis 9; the chassis 9 is provided with supporting feet 10; the chassis 9 is Only the unclosed box-shaped member at the front is provided with a movable door 1 and a pneumatic opening and closing structure 2 on its unclosed front. The pneumatic opening and closing structure 2 includes a movable door guide rail 2.3, a cylinder support plate 2.2, a movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com