Full-face rectangular hard rock tunneling and anchoring integrated machine

A full-section, all-in-one machine technology, applied in the direction of safety devices, bolt installation, mining equipment, etc., can solve the problems of large body vibration, low reliability, fast pick wear, etc., to achieve small body vibration and reliability High durability and slow pick wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

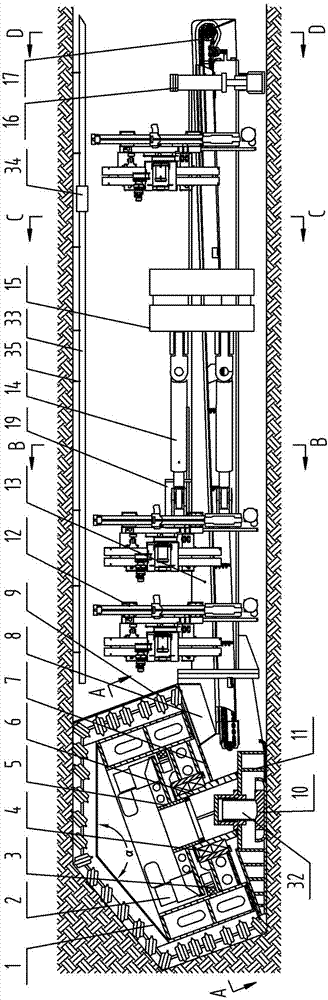

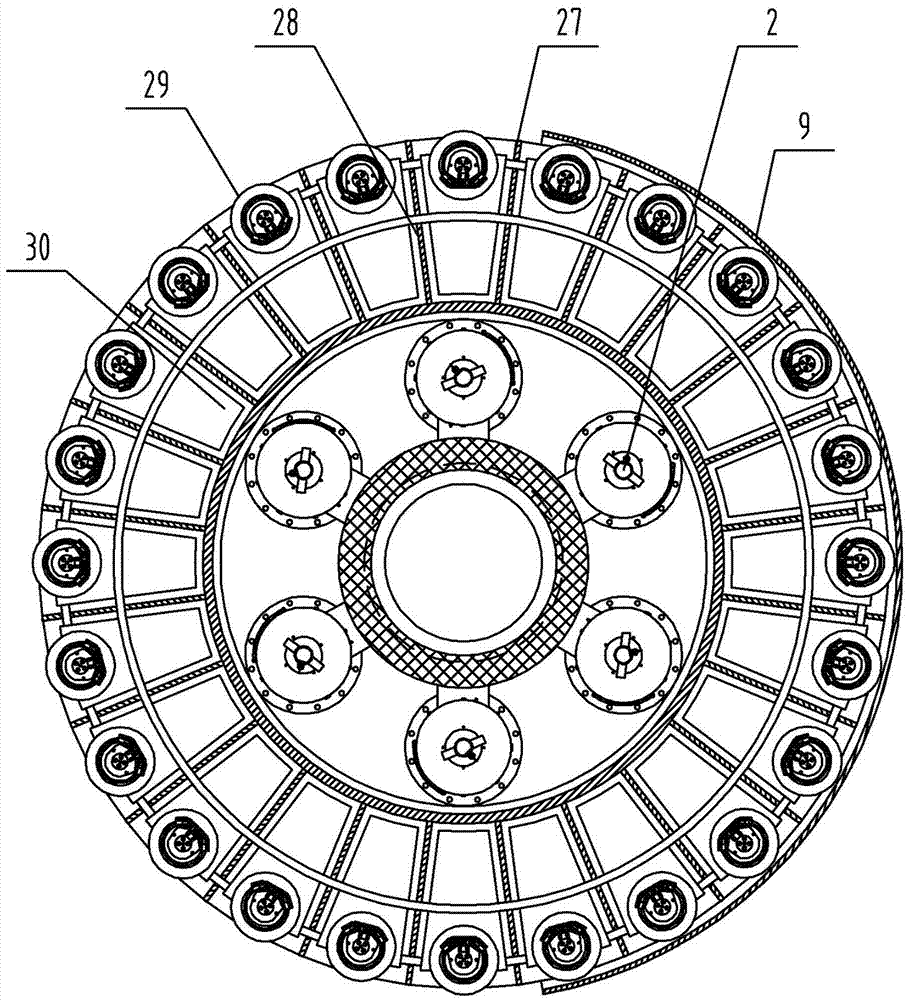

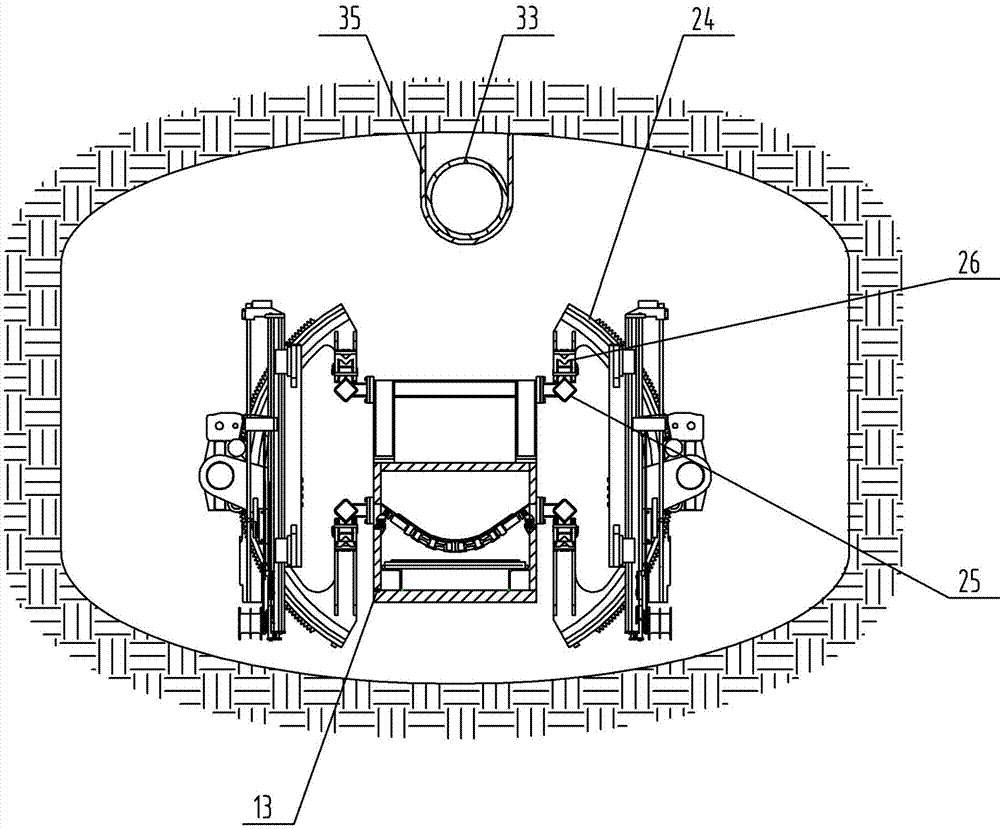

[0035] see Figure 1 to Figure 5, in the figure, the full-section rectangular hard rock bolter digging integrated machine of the present invention includes a frame 13, and the frame 13 is sequentially installed with a cutting device, a supporting device, a propulsion mechanism, a side support mechanism and a rear support mechanism 16 and Ventilation and dust removal device, a slag discharge mechanism is arranged in the horizontal middle part of the frame 13, the front end of the propulsion mechanism is fixed on the frame 13, and the rear end is fixed on the side support mechanism, and the cutting device consists of a cutter head 1, a cutter head The support frame 11 is composed of a cutter head drive mechanism, the cutter head support frame 11 is fixedly connected with the front end of the frame 13, and the cutter head 1 includes a combined disk frame composed of a conical top and a cylindrical bottom. The conical top of the disk frame and the cylindrical A plurality of disc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com