Range hood with purifying and sterilizing functions

A technology of range hood and smoke collecting chamber, which is applied in the directions of disinfection, removal of oil fume, gasification substances, etc. Bacterial growth, convenient operation and maintenance, and the effect of protecting physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

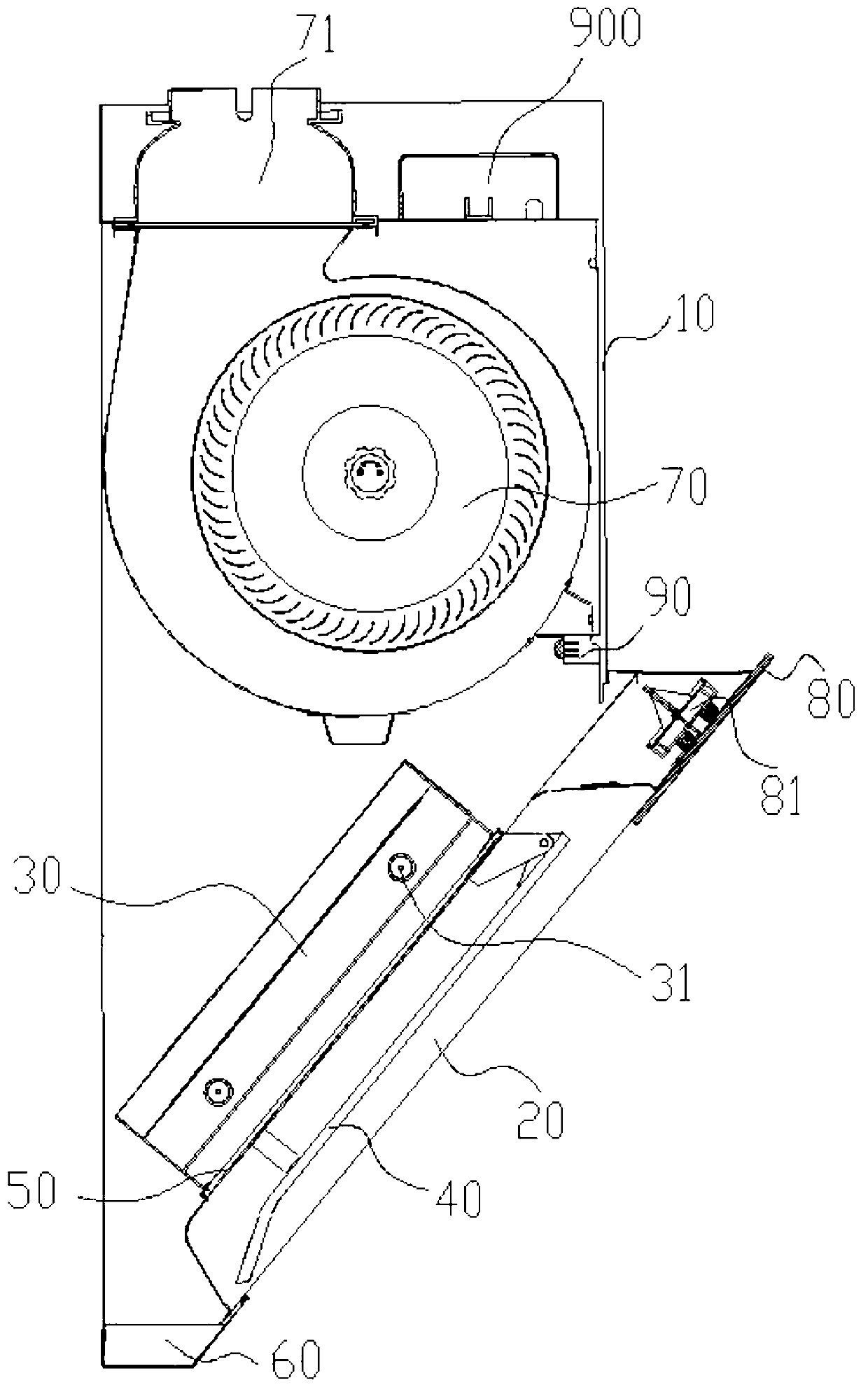

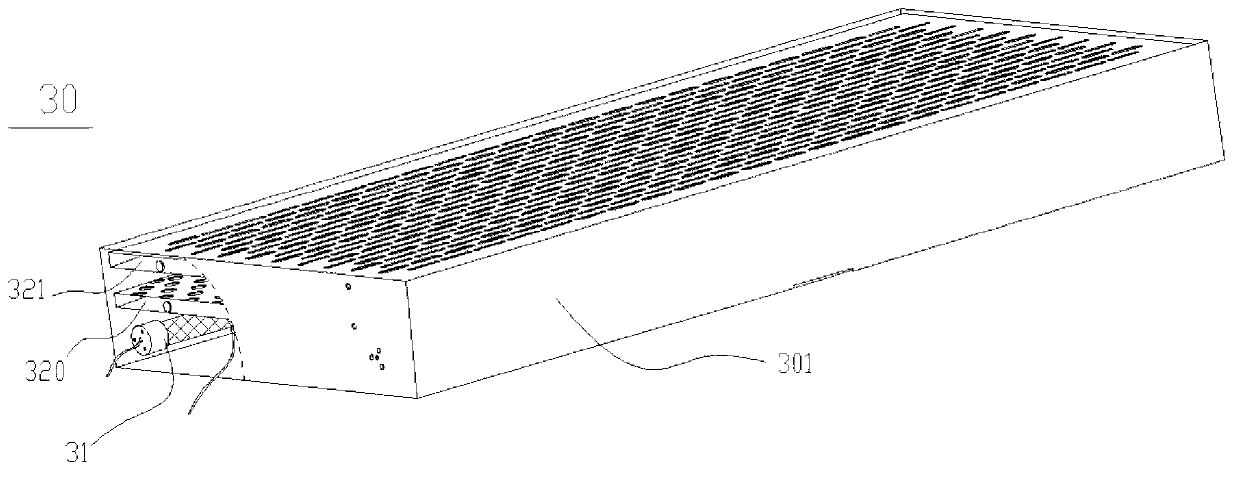

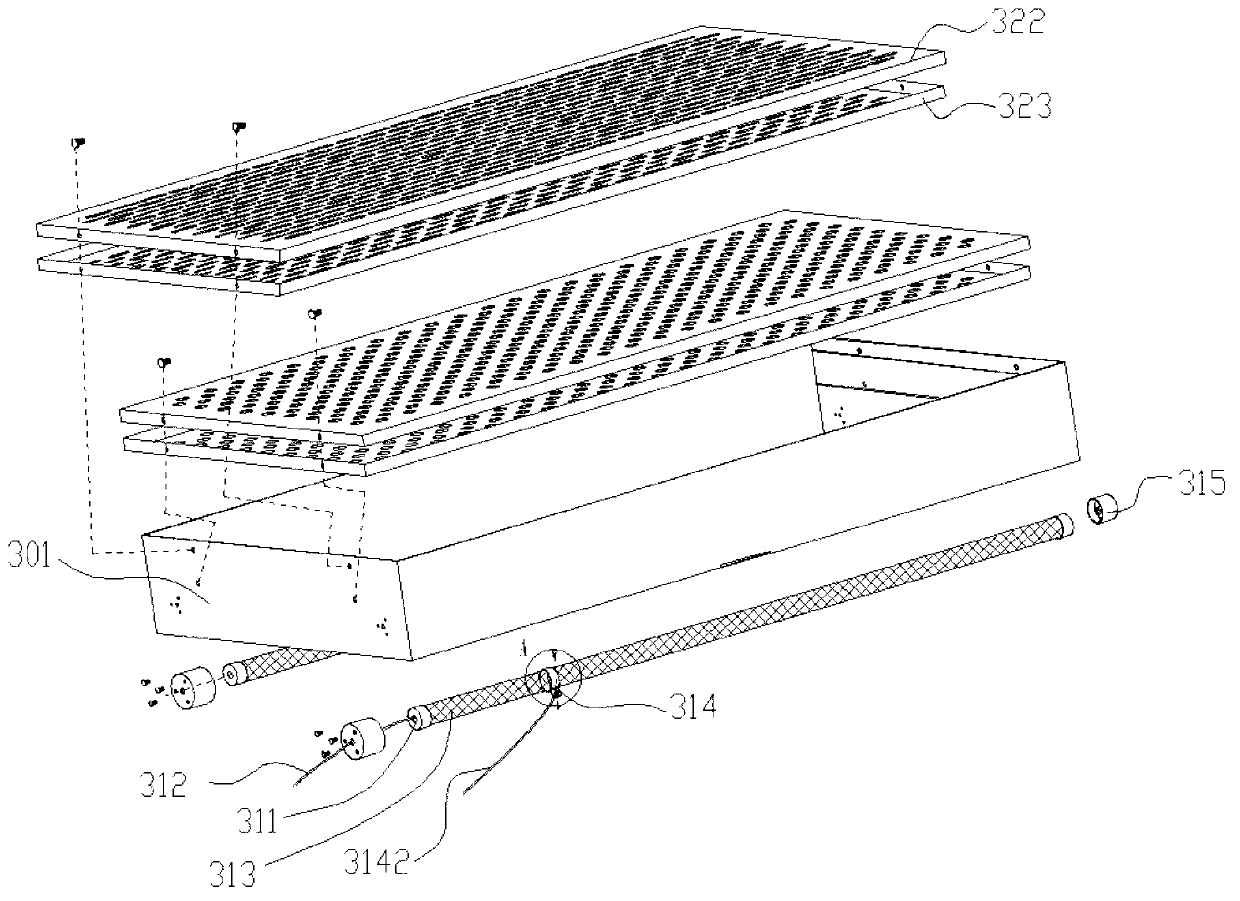

[0027] An embodiment of a purification and disinfection type range hood of the present invention, such as figure 1 , figure 2 As shown, it includes a box body 10, a fan 70 installed in the box body 10, and a smoke collection chamber 20. There is a mixed flow box 30, and the mixed flow box 30 is provided with O 3 with plasma generator 31 and can be used as fume with O 3 And the flow mixing device 32 in the plasma purification reaction zone.

[0028] In the example of the present invention, a mixed flow box 30 is provided behind the smoke collecting chamber 20, and an O 3 With the plasma generator 31 and the mixed flow device 32, after the oil fume enters from the smoke collecting chamber 20, it is purified in the mixed flow box 30 through a series of physical collisions and electrochemical reactions, and the oil fume fluid is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com