Sand mold frame stripping system

A technology of unboxing and sandboxing, which is applied to the equipment for loosening the model, etc., can solve the problems of low work efficiency, sand loading, wrong boxing, operator injury, etc., so as to improve the work efficiency of unboxing, reduce the labor intensity of unboxing, The effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

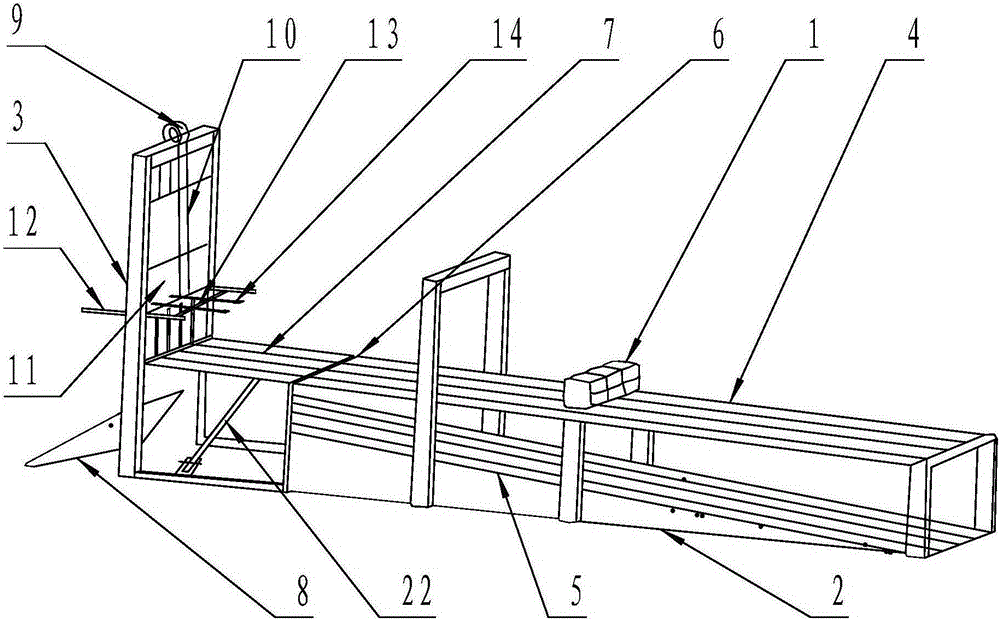

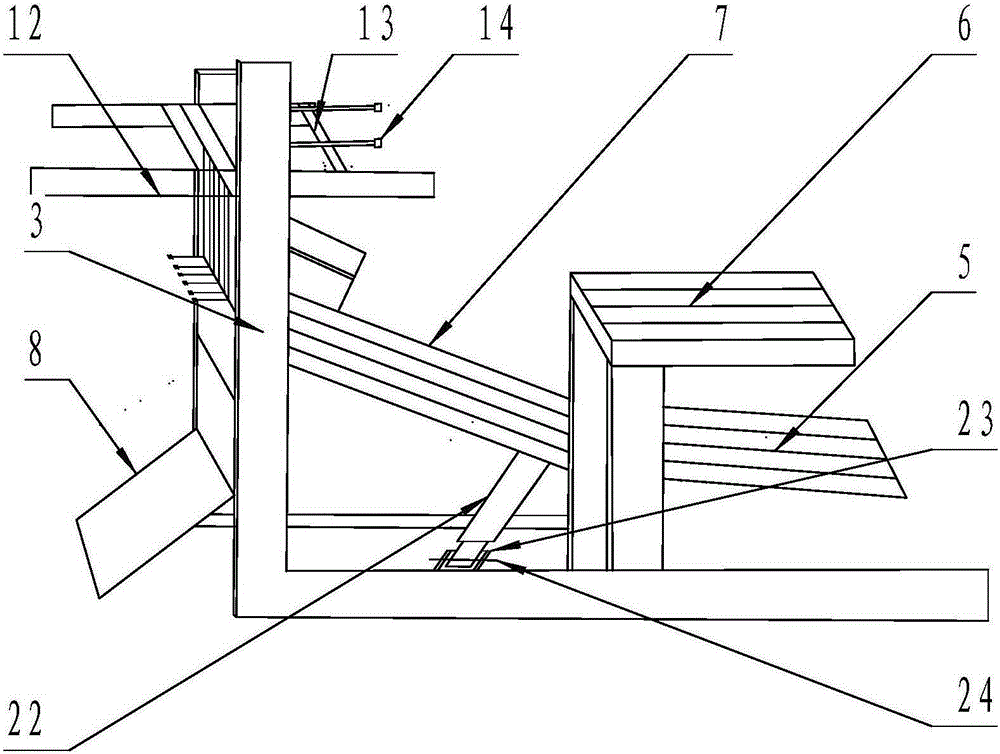

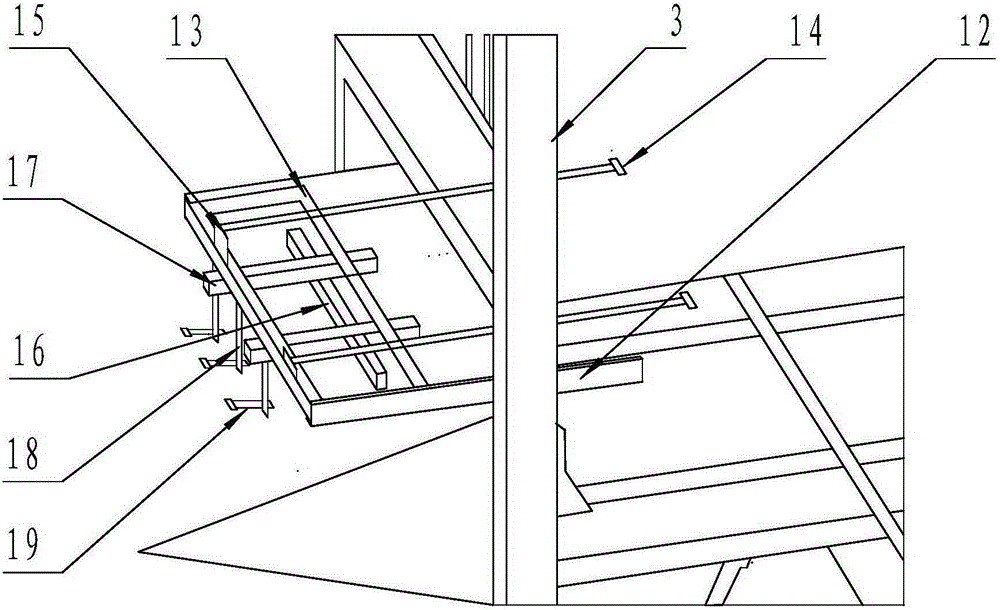

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a sand mold frame unboxing system includes a sand box 1 and a frame 2, and is characterized in that: a portal frame 3 is installed at one end of the frame 1, and a sand box grab is installed on the portal frame 3. The device and the sand mold push-out device also include the lifting device of the sand box grabbing device installed on the portal frame 3, and the moving device for the sand box grabbing device to move back and forth along the longitudinal direction of the frame; the frame 3 is also installed The horizontal upper track 4 and the lower track 5 inclined in one direction, the lower track 5 gradually slopes downward from the end close to the portal frame 3; the upper track 4 includes a fixed track 6 and a movable track 7, and the movable track 7 One end is connected horizontally with the lower part of the portal frame 3, and the other end is a free end, and the movable tr...

Embodiment 2

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a sand mold frame unboxing system includes a sand box 1 and a frame 2, and is characterized in that: a portal frame 3 is installed at one end of the frame 1, and a sand box grab is installed on the portal frame 3. The device and the sand mold push-out device also include the lifting device of the sand box grabbing device installed on the portal frame 3, and the moving device for the sand box grabbing device to move back and forth along the longitudinal direction of the frame; the frame 3 is also installed The horizontal upper track 4 and the lower track 5 inclined in one direction, the lower track 5 gradually slopes downward from the end close to the portal frame 3; the upper track 4 includes a fixed track 6 and a movable track 7, and the movable track 7 One end is connected horizontally with the lower part of the portal frame 3, and the other end is a free end, and the movable tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com